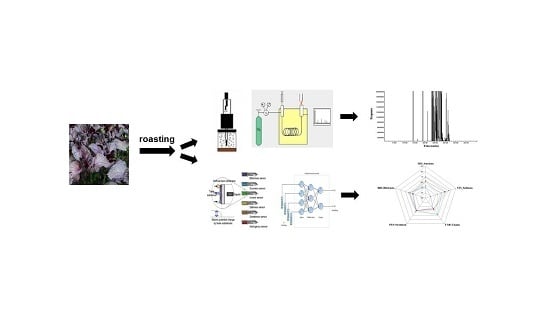

Perilla frutescens Britton: A Comprehensive Study on Flavor/Taste and Chemical Properties During the Roasting Process

Abstract

:1. Introduction

2. Results and Discussion

2.1. Votile Compounds and Sensory Desciption by GC-Olfactometry

2.1.1. Volatile Compounds Analyzed by GC-MS

2.1.2. Sensory Description by GC-Olfactometry Installed in GC-MS

2.2. Constituent and Free Amino Acids Analyses and E-Tongue Analysis

2.2.1. Constituent Amino Acids Analysis

2.2.2. Free Amino Acids Analysis

2.2.3. E-Tongue Analysis

2.3. Chemical Characteristics

2.3.1. Total Phenolic Content (TPC)

2.3.2. Antioxidant Capacity

2.3.3. Browning Intensity

3. Materials and Methods

3.1. Materials and Sample Treatment

3.2. Volatile Compound Identification and Sniffing Test Using Gas Chromatography-Olfactometry (GC-Olfactometry)

3.2.1. SPME and GC-MS

3.2.2. Sniffing Test Using GC-Olfactometry Installed in GC-MS

3.3. Electronic Tongue and Amino Acids Analyses

3.3.1. Constituent Amino Acid Composition

3.3.2. Free Amino Acid Composition

3.3.3. E-tongue Analysis

3.4. Chemical Characteristics

3.4.1. Total Phenolic Content (TPC)

3.4.2. Antioxidant Capacity

3.4.3. Browning Intensity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- He, Y.K.; Yao, Y.Y.; Chang, Y.N. Characterization of anthocyanins in Perilla frutescens var. acuta extract by advanced UPLC-ESI-IT-TOF-MSn method and their anticancer bioactivity. Molecules 2015, 20, 9155–9169. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, A.Y.; Jo, A.; Choi, H.; Cho, S.S.; Choi, C. Development of user-friendly method to distinguish subspecies of the Korean medicinal herb Perilla frutescens using multiplex-PCR. Molecules 2017, 22, 665. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Lozano, Y.F.; Gaydou, E.M.; Li, B. Antioxidant activities of polyphenols extracted from Perilla frutescens varieties. Molecules 2009, 14, 133–140. [Google Scholar] [CrossRef]

- Park, J.H.; Yang, C.B. Studies on the removal of phytate from Korean Perilla protein. Korean J. Food Sci. Technol. 1990, 22, 343–349. [Google Scholar]

- Kim, J.; Kang, H.; Choi, H.; Jo, A.; Oh, D.R.; Kim, Y.; Im, S.; Lee, S.G.; Jeong, K.I.; Ryu, G.C.; et al. Aqueous extract of Perilla frutescens var. acuta relaxes the ciliary smooth muscle by increasing NO/cGMP content in vitro and in vivo. Molecules 2018, 23, 1777. [Google Scholar] [CrossRef] [PubMed]

- Jun, H.I.; Kim, B.T.; Songm, G.S.; Kim, Y.S. Structural characterization of phenolic antioxidants from purple perilla (Perilla frutescens var. acuta) leaves. Food Chem. 2014, 148, 367–372. [Google Scholar] [CrossRef]

- Zhou, X.J.; Yan, L.L.; Yin, P.P.; Shi, L.L.; Zhang, J.H.; Liu, Y.J.; Ma, C. Structural characterization and antioxidant activity evaluation of phenolic compounds from cold-pressed Perilla frutescens var. arguta seed flour. Food Chem. 2014, 164, 150–157. [Google Scholar] [CrossRef]

- Jeon, I.H.; Kim, H.S.; Kang, H.J.; Lee, H.S.; Jeong, S.I.; Kim, S.J.; Jang, S.I. Anti-inflammatory and antipruritic effects of luteolin from Perilla (P. frutescens L.) leaves. Molecules 2014, 19, 6941–6951. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Kim, Y.C.; Choi, U.K. Optimization of antibacterial activity of Perilla frutescens var. acuta leaf against staphylococcus aureus using evolutionary operation factorial design technique. Int. J. Mol. Sci. 2011, 12, 2395–2407. [Google Scholar] [CrossRef]

- Han, H.S.; Park, J.H.; Choi, H.J.; Sung, T.S.; Woo, H.S.; Choi, J. Optimization of roasted perilla leaf tea using response surface methodology. Appl. Biol. Chem. 2004, 47, 96–106. [Google Scholar]

- Yun, U.J.; Yang, S.Y.; Lee, H.S.; Hong, C.O.; Lee, K.W. Optimum roasting conditions for maximizing the quality of tea leached from high functional Perilla frutescens leaves. Korean J. Food Sci. Technol. 2012, 44, 34–40. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, H.R.; Nam, S.M. Optimization for preparation of perilla jangachi according to steaming time and onion contents. Korean J. Food Culture 2002, 17, 653–662. [Google Scholar]

- Jang, I.C.; Kang, S.J.; Kim, J.K.; Hyon, J.S.; Kim, M.S.; Moon, Y.H. Effects of addition of perilla leaf powder and carcass grade on the quality and palatability of pork sausage. J. Korean Soc. Food Sci. Nutr. 2003, 32, 350–355. [Google Scholar]

- Song, J.; Bi, J.; Chen, Q.; Wu, X.; Lyu, Y.; Meng, X. Assessment of sugar content, fatty acids, free amino acids, and volatile profiles in jujube fruits at different ripening stages. Food Chem. 2019, 270, 344–352. [Google Scholar] [CrossRef]

- Centonze, V.; Lippolis, V.; Cervellieri, S.; Damascelli, A.; Casiello, G.; Pascale, M.; Logrieco, A.; Longobardi, F. Discrimination of geographical origin of oranges (Citrus sinensis L. Osbeck) by mass spectrometry-based electronic nose and characterization of volatile compounds. Food Chem. 2019, 277, 25–30. [Google Scholar] [CrossRef]

- Castro, A.; Sanchez, A.; Cortez-Delgado, A.; Lopez-Lopez, A.; Montano, A. Effect of Spanish-style processing steps and inoculation with Lactobacillus pentosus starter culture on the volatile composition of cv. Manzanilla green olives. Food Chem. 2019, 271, 543–549. [Google Scholar] [CrossRef]

- Guo, X.; Ho, C.; Schwab, W.; Song, C.; Wan, X. Aroma compositions of large-leaf yellow tea and potential effect of theanine on volatile formation in tea. Food Chem. 2019, 280, 73–82. [Google Scholar] [CrossRef]

- Kim, J.H.; Oh, S.H.; Park, K.Y. Inhibitory effects of d-Limonene on the mutagenicity and growth of human cancer cells. J. Nat. Sci. 2005, 17, 145–155. [Google Scholar]

- Emberger, M.; Lin, J.; Pika, J.; Christ, I.; Eigenbrodt, B. Automated solid-phase microextraction GC-MS/MS method for quantification of volatile limonene oxidation products in encapsulated orange oil. Flav. Fragr. J. 2019, 34, 52–62. [Google Scholar] [CrossRef]

- Meng, J.; Liu, Z.; Gou, C.; Rogers, K.; Yu, W.; Zhang, S.; Yuan, Y.; Zhang, L. Geographical origin of Chinese wolfberry (goji) determined by carbon isotope analysis of specific volatile compounds. J. Chromatogr. B. 2019, 1105, 104–112. [Google Scholar] [CrossRef]

- Ledesma-Escobar, C.; Proego-Capote, F.; Robles-Olvera, V.; Garcia-Torres, R.; Corcuera, J.; Castro, M. GC-MS study of changes in polar/mid-polar and volatile compounds in Persian lime (Citrus latifolia) during fruit growth. J. Sci. Food Agric. 2018, 99, 1020–1028. [Google Scholar] [CrossRef]

- Burdock, G. Fenaroli’s Handbook of Flavor Ingredients, 6th ed.; CRC press Taylor & Francis Group: Boca Raton, FL, USA, 2010; pp. 1090–1216. [Google Scholar]

- Ahmed, H.M.; Tavaszi-Sarosi, S. Identification and quantification of essential oil content and composition, total polyphenols and antioxidant capacity of Perilla frutescens (L.) Britt. Food Chem. 2019, 275, 730–738. [Google Scholar] [CrossRef]

- Seo, W.H.; Baek, H.H. Characteristic aroma-active compounds of Korean Perilla (Perilla frutescens Britton) leaf. J. Agric. Food Chem. 2009, 57, 11537–11542. [Google Scholar] [CrossRef]

- Reineccius, G. Changes in food flavor due to processing. In Flavor Chemistry and Technology, 2nd ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2006; pp. 103–137. [Google Scholar]

- Kim, D.S.; Kim, H.S.; Hong, S.J.; Cho, J.J.; Shin, E.C. Change in physicochemical and antioxidative properties of Cynanchi wilfordii Radix after a roasting treatment. J. Korean Soc. Food Sci. Nutr. 2018, 47, 363–372. [Google Scholar] [CrossRef]

- Kato, H.; Rhue, M.R.; Nishimura, T. Role of free amino acids and peptides in food taste. In Flavor Chemistry: Trends and Developments. J. Am. Chem. Soc. 1989, 388, 158–174. [Google Scholar]

- Kim, D.S.; Kim, H.S.; Seo, W.T.; Shin, E.C. Flavor and taste properties of fermented soybeans with mycelia of Tricholoma matsutake and Bacillus sp. J. Korean Soc. Food Sci. Nutr. 2018, 47, 107–115. [Google Scholar] [CrossRef]

- Seifikalhor, M.; Aliniaeifard, S.; Hassani, B.; Niknam, V.; Lastochkina, O. Diverse role of γ-aminobutyric acid in dynamic plant cell responses. Plant Cell Rep. 2019, ePub, 1–21. [Google Scholar] [CrossRef]

- Kim, D.S.; Kim, H.S.; Lee, J.; Pan, J.H.; Kim, Y.J.; Kim, J.K.; Woo, S.; Shin, E.C. Wasabi koreana Nakai: A preliminary study on nutrients and chemical compounds that may impact sensory properties. Molecules 2018, 23, 2512. [Google Scholar] [CrossRef]

- Dong, H.; Moon, J.Y.; Lee, S.H. Discrimination of geographical origins of raw ginseng using the electronic tongue. Korean J. Food Sci. Technol. 2017, 49, 349–354. [Google Scholar]

- Jeon, S.Y.; Kim, J.S.; Kim, G.C.; Choi, S.Y.; Kim, S.B.; Kim, K.M. Analysis of electronic nose and electronic tongue and sensory characteristics of commercial seasonings. Korean J. Food Cook Sci. 2017, 33, 538–550. [Google Scholar] [CrossRef]

- Yoon, S.R.; Lee, M.H.; Park, J.H.; Lee, I.S.; Kwon, J.H.; Lee, G.D. Changes in physicochemical compounds with heating treatment of ginseng. J. Korean Soc. Food Sci. Nutr. 2005, 34, 1572–1578. [Google Scholar]

- Jang, G.Y.; Kim, H.Y.; Lee, S.H.; Kang, Y.; Hwang, I.G.; Woo, K.S.; Kang, T.S.; Lee, J.; Jeong, H.S. Effects of heat treatment and extraction method on antioxidant activity of several medicinal plants. J. Korean Soc. Food Sci. Nutr. 2012, 47, 914–920. [Google Scholar] [CrossRef]

- Kwon, J.H.; Ryu, K.C.; Lee, G.D. Dynamic changes in browning reaction substrates of Polygonatum odoratum roots during roasting. J. Korean Soc. Food Sci. Nutr. 1997, 26, 654–661. [Google Scholar]

- Kim, E.K.; Lee, S.J.; Lim, B.O.; Jeon, Y.J.; Song, M.D.; Park, T.K.; Lee, K.H.; Kim, B.; Lee, S.R.; Moon, S.H.; et al. Antioxidative and neuroprotective effects of enzymatic extracts from leaves of Perilla frutescens var.japonica. Food Sci. Biotech. 2008, 17, 279–286. [Google Scholar]

- McLafferty, F.W.; Turecek, F. Interpretation of Mass Spectra; University Science Books: Sausalito, CA, USA, 1993; pp. 225–282. [Google Scholar]

- Kim, D.S.; Kim, H.S.; Lee, K.T.; Hong, D.L.; Cho, S.R.; Pan, J.H.; Park, Y.B.; Lee, Y.B.; Kim, J.K.; Shin, E.C. Chemical characterization and oxidative stability of medium- and long-chain fatty acid profiles in tree-borne seed oils. J. Anal. Methods Chem. 2018, 2018, 2178684. [Google Scholar] [CrossRef]

- Lim, H.J.; Kim, D.S.; Pan, J.H.; Pae, S.B.; Kim, H.S.; Shin, E.C.; Kim, J.K. Characterization of physicochemical and sensory attributes of a novel high-oleic peanut oil cultivar (Arachi hypogaea ssp. Fastigiata L.). Appl. Biol. Chem. 2017, 60, 653–657. [Google Scholar] [CrossRef]

- Folin, O.; Denis, W. On phosphotungstic-phosphomolybdic compounds as color reagents. J. Biol. Chem. 1912, 12, 239–243. [Google Scholar]

- Blois, M.S. Antioxidant determinations by the use of a stable free radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Van den Berg, R.; Haenen, G.R.; Van den Berg, H.; Bast, A. Applicability of an improved trolox equivalent antioxidant capacity (TEAC) assay for evaluation of antioxidant capacity measurements of mixtures. Food Chem. 1999, 66, 511–517. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Compounds 1) | Retention Time (min) | Retention Index | Roasting Time (min) | ||||

|---|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | |||

| Relative Concentration (μg/100 g) | |||||||

| Alcohols (16) | |||||||

| Isooctanol | 17.71 | 1088 | 0.07 | ND 2) | ND | ND | ND |

| 3,7-Dimethyl-1,6-octadien-3-ol | 18.29 | 1102 | ND | 2.70 | ND | ND | ND |

| Linalool | 18.31 | 1103 | 1.64 | ND | 4.15 | 3.52 | 0.50 |

| 2-Ethyl-1-decanol | 18.41 | 1107 | 0.46 | ND | ND | ND | ND |

| 3,4-Dimethyl cyclohexanol | 18.62 | 1114 | ND | 0.36 | ND | ND | ND |

| 3,5-Dimethyl cyclohexanol | 18.64 | 1115 | 0.29 | ND | 0.31 | ND | 0.26 |

| 2-Ethyl-1-dodecanol | 18.73 | 1118 | 0.20 | ND | ND | ND | ND |

| 3,7,11-Trimethyl-1-dodecanol | 18.83 | 1122 | 0.13 | ND | ND | ND | ND |

| 8-Methylene-2-exo-noradamantanol | 21.81 | 1226 | ND | ND | 1.35 | ND | ND |

| 2-Methylene cycloheptanol | 22.25 | 1242 | ND | ND | ND | 0.30 | ND |

| 1-Tridecanol | 22.32 | 1245 | ND | ND | ND | ND | 0.12 |

| 4-1-Methyl ethenyl-1-cyclohexene-1-methanol | 24.02 | 1306 | ND | 1.48 | ND | ND | ND |

| Perilla alcohol | 24.02 | 1306 | ND | ND | 1.93 | ND | ND |

| 1-Eicosanol | 27.62 | 1464 | ND | 0.66 | ND | ND | ND |

| Isopulegol | 28.34 | 1501 | ND | ND | ND | 0.22 | ND |

| 1-Ethynyl-2-methyl cyclohexanol | 29.35 | 1544 | 0.34 | ND | ND | ND | ND |

| Aldehydes (5) | |||||||

| 6-Oxononanal 2-Undecenal Citral | 18.64 21.98 23.19 | 1232 1115 1277 | ND 0.31 ND | ND ND ND | ND ND 0.17 | 0.30 ND 0.36 | ND ND ND |

| 2-Eehoxybenzaldehyde | 23.60 | 1291 | ND | ND | ND | ND | 0.48 |

| Caryophyll-5-en-12-al | 30.58 | 1596 | ND | 0.65 | ND | ND | ND |

| Esters (2) | |||||||

| Phosphonic acid, dioctadecyl ester | 26.20 | 1393 | ND | 0.28 | ND | 0.21 | ND |

| 2-Ethyl hexyl ester | 29.00 | 1529 | 1.42 | 0.92 | ND | ND | 0.78 |

| Hydrocarbons (110) | |||||||

| 5-Methyl styrene-1,6-heptadien-3-yne | 11.74 | 921 | 0.13 | ND | ND | ND | ND |

| 1,5-Cyclooctadiyne | 11.72 | 921 | ND | 0.24 | ND | ND | ND |

| δ-3-Carene | 12.87 | 956 | ND | ND | 0.10 | ND | 0.10 |

| α-Phellandrene | 12.87 | 956 | ND | ND | ND | 0.06 | ND |

| 2,6,6-Trimethyl bicyclo hept-2-ene | 13.06 | 962 | ND | 3.26 | ND | ND | ND |

| α-Pinene | 13.08 | 963 | 2.65 | ND | 6.42 | 4.26 | 0.10 |

| 3,7-Dimethyl-1,3,6-octatriene | 13.10 | 963 | ND | ND | ND | ND | 0.76 |

| 6-Methylene bicyclo-3,2,0-heptane | 13.35 | 970 | ND | ND | ND | 0.13 | ND |

| 4-Methyl bicyclo-3,2,1-octan-3-ene | 13.36 | 971 | ND | ND | 0.11 | ND | ND |

| Sabinene | 14.38 | 998 | ND | ND | 2.05 | 0.62 | 0.56 |

| 2-β-Pinene | 14.50 | 1002 | 3.02 | 3.91 | 5.65 | 3.59 | ND |

| β-Myrcene | 14.90 | 1014 | ND | 0.44 | 1.31 | 0.57 | ND |

| Cyclofenchene | 14.93 | 1014 | 0.32 | ND | 0.85 | ND | ND |

| 2,6,6-Trimethylbicyclo-3,1,1-hept-2-ene | 14.93 | 1014 | ND | ND | ND | ND | 0.17 |

| α-Fenchene | 15.35 | 1026 | ND | ND | ND | 0.54 | ND |

| 6,6-Dimethyl-2-methylene bicyclo-3,1,1-heptane | 15.35 | 1026 | 0.45 | ND | ND | ND | ND |

| 1-Methyl-5-1-methyl ethenyl cyclohexene | 15.36 | 1027 | ND | ND | ND | ND | 0.09 |

| 2,4-Dimethyl-1-decene | 15.93 | 1042 | ND | ND | ND | ND | 0.04 |

| 4-Ethyl-1,2-dimethyl benzene | 16.00 | 1044 | ND | 0.13 | ND | ND | ND |

| Limonene | 16.15 | 1048 | 54.66 | 58.18 | 137.24 | 60.92 | 12.56 |

| 2,6,7-Trimethyl decane | 16.85 | 1066 | ND | 0.17 | ND | ND | ND |

| 2,6-dimethyl octane | 16.88 | 1067 | ND | ND | ND | 0.35 | 0.29 |

| 1-ethenyloxy octadecane | 16.95 | 1069 | ND | 0.14 | ND | ND | ND |

| 2,4-dimethyl heptane | 16.97 | 1069 | ND | ND | ND | 0.12 | 0.35 |

| 2,4-Dimethyl hexane | 16.97 | 1069 | ND | ND | ND | ND | 0.08 |

| β-Phellandrene | 17.06 | 1072 | ND | ND | 0.18 | ND | ND |

| l-Phellandrene | 17.07 | 1072 | ND | ND | ND | 0.16 | ND |

| γ-Terpinene | 17.07 | 1072 | 0.14 | 0.17 | ND | ND | ND |

| 3,5-Dimethyl undecane | 17.13 | 1073 | ND | 0.24 | ND | 0.24 | 0.13 |

| 2-Methyl decane | 17.16 | 1073 | ND | ND | ND | ND | 0.15 |

| 2,8-Dimethyl undecane | 17.52 | 1083 | ND | 0.57 | 0.38 | ND | ND |

| 11-1-Ethylpropyl heneicosane | 17.54 | 1083 | ND | ND | ND | 0.42 | ND |

| 3,7-Dimethyl decane | 17.54 | 1084 | ND | ND | ND | ND | 0.27 |

| α-Terpinolene | 17.97 | 1094 | ND | 0.78 | 1.02 | 0.67 | ND |

| α-Terpinene | 17.98 | 1095 | 0.63 | ND | 0.88 | ND | ND |

| Undecane | 18.23 | 1100 | 0.37 | ND | ND | ND | 0.35 |

| 5-(1-Methyl propyl)-Nonane | 18.72 | 1118 | ND | ND | 0.18 | ND | ND |

| Dodecane | 18.74 | 1200 | ND | ND | ND | ND | 0.14 |

| 1,1′-Oxybis decane | 18.83 | 1122 | ND | 0.15 | 0.14 | 0.06 | ND |

| Dodecyloxy methyl oxirane | 18.94 | 1126 | ND | 0.27 | ND | ND | ND |

| 3-Methyl tridecane | 18.96 | 1127 | 0.20 | ND | ND | ND | ND |

| 2,3,6,7-Tetramethyl octane | 19.03 | 1129 | ND | 0.16 | ND | ND | ND |

| 1-Fluoro dodecane | 19.04 | 1130 | ND | ND | ND | ND | 0.12 |

| 3,7-Dimethyl nonane | 19.04 | 1130 | 0.14 | ND | ND | 0.15 | ND |

| 3-Ethyl-3-methyl heptane | 19.20 | 1135 | ND | ND | 0.09 | ND | ND |

| 1,1,1,2-Tetrafluoro-2-tridecene | 19.21 | 1136 | ND | ND | ND | ND | 0.12 |

| 4-Methyl undecane | 19.96 | 1162 | ND | 0.37 | ND | 0.34 | ND |

| 3-Methyl decane | 19.97 | 1162 | ND | ND | 0.32 | 0.18 | ND |

| 1-Chloro hexadecane | 19.97 | 1162 | ND | ND | ND | ND | 0.17 |

| 2,6,10-Trimethyl dodecane | 19.97 | 1162 | 0.28 | ND | ND | ND | ND |

| 2-Methyl undecane | 20.10 | 1166 | 0.16 | ND | ND | ND | ND |

| 3-Ethyl octane | 20.14 | 1168 | ND | 0.53 | ND | ND | ND |

| 2,6,10,14-Tetramethyl hexadecane | 20.15 | 1168 | ND | ND | 0.25 | ND | ND |

| 2,6,11-Trimethyl dodecane | 20.16 | 1168 | 0.25 | ND | 0.24 | ND | ND |

| 3,6-Dimethyl undecane | 20.16 | 1168 | ND | ND | ND | ND | 0.19 |

| 3,5,24-Trimethyl tetracontane | 20.28 | 1172 | ND | ND | ND | 0.53 | ND |

| 1-Methoxymethoxy dodecane | 20.65 | 1185 | 0.17 | ND | ND | ND | ND |

| 1,1,4,4,7,7,-Hexamethyl cyclononane | 20.73 | 1187 | 0.13 | ND | ND | ND | ND |

| 2,3,5,8-Tetramethyl decane | 20.74 | 1187 | ND | ND | ND | 0.19 | ND |

| Azulene | 20.86 | 1192 | 1.41 | 1.80 | 1.45 | 1.33 | ND |

| Naphthalene | 20.87 | 1192 | ND | ND | ND | ND | 0.84 |

| Camphene | 21.02 | 1197 | ND | 0.53 | 0.17 | 0.10 | ND |

| 1-Methyl-4-1-methyl ethylidene cyclohexene | 21.03 | 1197 | ND | ND | ND | 0.62 | ND |

| Dodecane | 21.12 | 1200 | 1.97 | 2.41 | 2.37 | 2.44 | 1.79 |

| 7-Butyl bicyclo-4,1,0-heptane | 21.26 | 1205 | ND | ND | ND | 0.25 | ND |

| Pulegone | 21.35 | 1209 | ND | 0.62 | ND | ND | ND |

| Decahydro naphthoxirene | 21.36 | 1209 | 0.40 | ND | ND | ND | ND |

| 2,5-Dimethyl undecane | 21.49 | 1214 | ND | 0.47 | ND | ND | ND |

| 2,6-Dimethyl undecane | 21.51 | 1215 | 0.37 | ND | 0.39 | 0.42 | 0.15 |

| 4,6-Dimethyl undecane | 21.51 | 1215 | ND | ND | ND | ND | 0.27 |

| cis-Ocimene | 21.81 | 1226 | ND | 0.94 | ND | ND | ND |

| 1,3-Dimethyl butyl cyclohexane | 22.25 | 1242 | ND | ND | ND | ND | 0.16 |

| Methoxy methoxy cyclooctane | 22.56 | 1254 | ND | ND | ND | 0.28 | ND |

| 2-2-Tetrafuryl methyl tetrahy dropyran | 22.73 | 1260 | ND | 0.43 | ND | ND | ND |

| 4,4-Dipropylheptane | 22.74 | 1260 | 0.30 | ND | ND | ND | ND |

| 2,3,6-Trimethyl decane | 22.86 | 1265 | ND | 0.60 | ND | ND | ND |

| 2,3-Dimethyl undecane | 22.87 | 1265 | 0.49 | ND | ND | ND | ND |

| 2,3,5-Trimethyl decane | 22.87 | 1265 | ND | ND | 0.44 | ND | ND |

| 3-Methyl undecane | 22.87 | 1265 | ND | ND | ND | 0.51 | ND |

| 3-Methyl dodecane | 23.07 | 1272 | ND | ND | 0.32 | ND | ND |

| 2,6-Dimethyl heptadecane | 23.11 | 1273 | 0.73 | ND | ND | ND | 0.23 |

| 3-Methyl nonane | 23.11 | 1274 | ND | ND | ND | 0.67 | ND |

| 2,5,6-Trimethyl-1,3,6-heptatriene | 23.25 | 1279 | 1.78 | ND | ND | ND | ND |

| Tricyclodecane | 23.26 | 1279 | ND | 3.46 | ND | ND | ND |

| Tridecane | 23.83 | 1300 | 4.50 | 5.36 | 5.09 | 5.15 | 3.33 |

| 2-Methyl-1,3-cyclononadiene | 24.81 | 1338 | ND | 0.52 | ND | ND | ND |

| 6-Isopropylidene-1-methyl Bicyclo-3,1,0-hexane | 24.82 | 1339 | ND | ND | 0.81 | ND | ND |

| 4,4-Dipropyl heptane | 25.21 | 1354 | ND | 0.38 | ND | ND | 0.09 |

| 5-Methyl tetradecane | 25.21 | 1355 | 0.28 | ND | ND | ND | ND |

| 2,7-Dimethyl undecane | 25.22 | 1355 | ND | ND | ND | ND | 0.19 |

| 3-Methyl tridecane | 25.64 | 1371 | ND | 0.58 | ND | ND | ND |

| α-Cubebene | 26.01 | 1386 | 0.73 | 1.13 | ND | 0.98 | ND |

| Copaene | 26.01 | 1386 | ND | ND | 1.12 | ND | 0.41 |

| Methyl cyclooctane | 26.19 | 1392 | 0.27 | ND | ND | ND | ND |

| β-Bourbonene | 26.27 | 1395 | ND | ND | 0.56 | 0.35 | ND |

| Tetradecane | 26.39 | 1400 | 2.81 | 3.12 | 3.15 | 2.90 | 1.84 |

| Decyl oxirane | 26.67 | 1415 | ND | ND | ND | ND | 0.27 |

| α-Longipinene | 27.01 | 1433 | ND | ND | ND | 0.36 | ND |

| Caryophyllene | 27.16 | 1441 | ND | 24.84 | 52.34 | 32.33 | 5.49 |

| trans-Caryophyllene | 27.16 | 1441 | 26.04 | ND | ND | ND | ND |

| Sinularene | 27.35 | 1451 | ND | 1.13 | ND | ND | ND |

| Aromadendrene | 27.36 | 1451 | ND | ND | ND | 1.05 | ND |

| 1-Hexyl-1-nitrocyclohexane | 27.63 | 1465 | ND | ND | ND | ND | 0.30 |

| α-Humulene | 27.99 | 1483 | 1.97 | ND | ND | ND | 0.45 |

| α-Caryophyllene | 28.00 | 1483 | ND | ND | ND | 1.99 | ND |

| Germacrene D | 28.65 | 1514 | 1.36 | 3.78 | 5.15 | 1.73 | ND |

| α-Farnesene | 28.76 | 1519 | 5.02 | ND | 1.72 | 0.59 | ND |

| 3,7,11-Trimethyl-1,3,6,10-dodecatetraene | 28.77 | 1519 | ND | ND | ND | 6.88 | ND |

| Bicyclogermacrene | 29.01 | 1530 | ND | ND | ND | 1.35 | ND |

| Dispiro-4,2,4,2-tetradecane | 29.23 | 1539 | ND | ND | ND | 0.35 | ND |

| Ketons (1) | |||||||

| 5,6-Methylidene-2-norbornen-7-one | 11.71 | 921 | ND | ND | 0.24 | ND | ND |

| Heterocyclic (3) | |||||||

| 4-Ethyl-2,6-dimethyl pyridine | 29.55 | 1045 | 0.56 | ND | ND | ND | ND |

| 3-Methyl-2,3-dihydro benzofuran | 16.02 | 1553 | ND | ND | ND | 0.09 | ND |

| 4-Ethyl-2,6-dimethyl pyridine | 30.70 | 1601 | ND | 0.60 | ND | ND | ND |

| Miscellaneous (5) | |||||||

| α-Terpinenyl acetate | 21.03 | 1118 | 0.45 | ND | ND | ND | ND |

| Dihexyl sulfide | 18.72 | 1197 | ND | ND | ND | 0.26 | ND |

| O-Decyl hydroxylamine | 22.74 | 1260 | ND | ND | ND | ND | 0.21 |

| Methyl benzoate | 23.39 | 1284 | 88.08 | 112.46 | 203.10 | 122.67 | 21.31 |

| Calarene epoxide | 28.22 | 1494 | ND | 0.27 | ND | ND | ND |

| Major Volatile Compounds 1) | Odor Description | Odor Intensity | ||||

|---|---|---|---|---|---|---|

| Roasting Time (min) | ||||||

| 0 | 2 | 4 | 6 | 8 | ||

| Limonene | Mint | 1 | 1 | 1 | - | - |

| α-Terpinene | Bitter | 4 | - | - | - | - |

| Linalool | Sweet | 1 | - | - | 2 | 1 |

| Azulene | Spicy, Medicinal herb, Garlic | 4 | 4 | - | 3 | - |

| 2,6-Dimethylundecane | Oil | 2 | - | - | 2 | - |

| Methyl benzoate | Perilla | 4 | 4 | 4 | 4 | 4 |

| γ-Terpinene | Bitter | 3 | - | - | - | - |

| 3,7-Dimethyl-1,6-octadien-3-ol | Sweet | 2 | - | - | - | - |

| 2,5-Dimethylundecane | Oil | - | 3 | - | - | - |

| β-Phellandrene | Spicy, Grass | - | - | 2 | 2 | - |

| α-Terpinolene | Spicy, Green onion | - | 3 | 1 | 1 | - |

| α-Pinene | Spicy, Pepper | - | - | - | - | 2 |

| 4,4-Dipropylheptane | Roasted | - | - | - | - | 1 |

| Constituent Amino Acid (% Perilla) | Roasting Time (min) | Inc. Dec. Ratio 2) (% Perilla) | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| Aspartic acid | 12.45 ± 0.52 a,1) | 11.99 ± 0.13 a | 12.43 ± 0.04 a | 12.00 ± 0.13 a | 12.65 ± 0.32 a | 1.01 |

| Threonine | 5.27 ± 0.20 a | 5.03 ± 0.06 ab | 4.90 ± 0.02 b | 5.04 ± 0.05 ab | 5.17 ± 0.13 ab | 0.98 |

| Serine | 6.91 ± 0.24 ab | 6.49 ± 0.07 b | 6.68 ± 0.01 ab | 6.51 ± 0.07 b | 7.05 ± 0.18 a | 1.02 |

| Glutamic acid | 14.68 ± 0.46 ab | 14.33 ± 0.13 a | 14.60 ± 0.02 ab | 14.35 ± 0.14 b | 15.30 ± 0.38 a | 1.04 |

| Glycine | 8.03 ± 0.21 a | 7.40 ± 0.12 b | 7.49 ± 0.03 b | 7.18 ± 0.06 b | 7.60 ± 0.19 b | 0.94 |

| Alanine | 8.72 ± 0.22 a | 8.31 ± 0.12 ab | 8.49 ± 0.04 ab | 8.12 ± 0.08 b | 8.64 ± 0.21 a | 0.99 |

| Cysteine | 3.23 ± 0.16 a | 2.57 ± 0.10 b | 3.19 ± 0.04 a | 2.73 ± 0.01 b | 3.44 ± 0.08 a | 1.06 |

| Valine | 4.21 ± 0.13 ab | 3.93 ± 0.05 c | 3.95 ± 0.01 c | 4.03 ± 0.04 bc | 4.29 ± 0.12 a | 1.02 |

| Methionine | 2.44 ± 0.12 a | 1.79 ± 0.34 b | 1.21 ± 0.03 c | 1.56 ± 0.02 bc | 1.14 ± 0.02 c | 0.47 |

| Isoleucine | 1.84 ± 0.02 bc | 2.02 ± 0.01 a | 1.80 ± 0.01 c | 2.03 ± 0.01 a | 1.90 ± 0.03 b | 1.03 |

| Leucine | 8.01 ± 0.08 b | 8.65 ± 0.07 a | 8.04 ± 0.02 b | 8.47 ± 0.05 a | 8.15 ± 0.11 b | 1.02 |

| Tyrosine | 3.95 ± 0.28 b | 4.28 ± 0.02 ab | 4.33 ± 0.03 a | 4.32 ± 0.03 a | 4.15 ± 0.12 ab | 1.05 |

| Phenylalanine | 7.47 ± 0.96 b | 8.52 ± 0.10 ab | 9.02 ± 0.04 a | 8.60 ± 0.05 ab | 8.10 ± 0.73 ab | 1.08 |

| Lysine | 5.32 ± 0.62 ab | 6.03 ± 0.01 a | 5.99 ± 0.04 ab | 6.00 ± 0.04 a | 4.96 ± 0.57 b | 0.93 |

| Histidine | 2.41 ± 0.26 b | 3.00 ± 0.19 a | 2.92 ± 0.06 ab | 3.03 ± 0.08 a | 2.43 ± 0.35 b | 1.01 |

| Arginine | 5.05 ± 0.08 a | 5.65 ± 0.76 a | 4.97 ± 0.01 a | 6.02 ± 0.67 a | 5.04 ± 0.12 a | 0.99 |

| Free Amino Acid (% Perilla) | Roasting Time (min) | Inc. Dec. Ratio 2) | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | (% Perilla) | |

| Serine | 1.76 ± 0.17 b,1) | 1.79 ± 0.14 b | 2.55 ± 0.09 a | 2.00 ± 0.18 b | ND c | 0 |

| Glycine | 7.42 ± 0.59 a | 7.82 ± 0.30 a | 8.46 ± 0.24 a | 8.11 ± 0.76 a | 8.97 ± 1.03 a | 1.07 |

| Alanine | 37.33 ± 2.79 a | 29.90 ± 5.99 a,b | 28.96 ± 0.66 b | 26.98 ± 1.66 b | 22.73 ± 1.60 b | 0.54 |

| Valine | 20.24 ± 0.92 b | 22.76 ± 2.53 a,b | 21.79 ± 0.55 b | 24.54 ± 1.51 ab | 28.59 ± 0.36 b | 1.25 |

| Isoleucine | 1.51 ± 0.06 | ND 3) | ND | ND | ND | 0 |

| GABA | 13.61 ± 0.01 a,b | 15.00 ± 0.11 a | 13.86 ± 0.15 b | 12.68 ± 0.17 c | 8.96 ± 0.47 d | 0.58 |

| Hydroxylysine | 18.13 ± 0.28 c | 22.72 ± 2.19 bc | 24.38 ± 0.35 b | 25.67 ± 0.46 ab | 30.73 ± 1.11 a | 1.50 |

| Roasting Time (min) | |||||

|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | |

| TPC (mg/mL) 1) | 0.04 ± 0.01 d,2) | 0.11 ± 0.01 a | 0.08 ± 0.01 b | 0.11 ± 0.01 a | 0.04 ± 0.01 c |

| DPPH(IC50) (mg) | 123 | 84 | 86 | 90 | 138 |

| ABTS(IC50) (mg) | 4 | 3 | 3 | 3 | 7 |

| Browning intensity (420 nm) | 0.15 ± 0.01 e | 0.29 ± 0.01 b | 0.25 ± 0.01 c | 0.33 ± 0.01 a | 0.23 ± 0.01 d |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, D.-S.; Cho, J.; Hong, S.J.; Pan, J.H.; Kim, J.K.; Shin, E.-C. Perilla frutescens Britton: A Comprehensive Study on Flavor/Taste and Chemical Properties During the Roasting Process. Molecules 2019, 24, 1374. https://doi.org/10.3390/molecules24071374

Lee J, Kim D-S, Cho J, Hong SJ, Pan JH, Kim JK, Shin E-C. Perilla frutescens Britton: A Comprehensive Study on Flavor/Taste and Chemical Properties During the Roasting Process. Molecules. 2019; 24(7):1374. https://doi.org/10.3390/molecules24071374

Chicago/Turabian StyleLee, Jookyeong, Da-Som Kim, Jinju Cho, Seong Jun Hong, Jeong Hoon Pan, Jae Kyeom Kim, and Eui-Cheol Shin. 2019. "Perilla frutescens Britton: A Comprehensive Study on Flavor/Taste and Chemical Properties During the Roasting Process" Molecules 24, no. 7: 1374. https://doi.org/10.3390/molecules24071374