Preparation of KI/Hydroxyapatite Catalyst from Phosphate Rocks and Its Application for Improvement of Biodiesel Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. HAP Catalyst Synthesis

2.3. Catalyst Characterization

2.4. Biodiesel Synthesis

2.5. Biodiesel Characterization

3. Result and Discussion

3.1. Functional Group Analysis

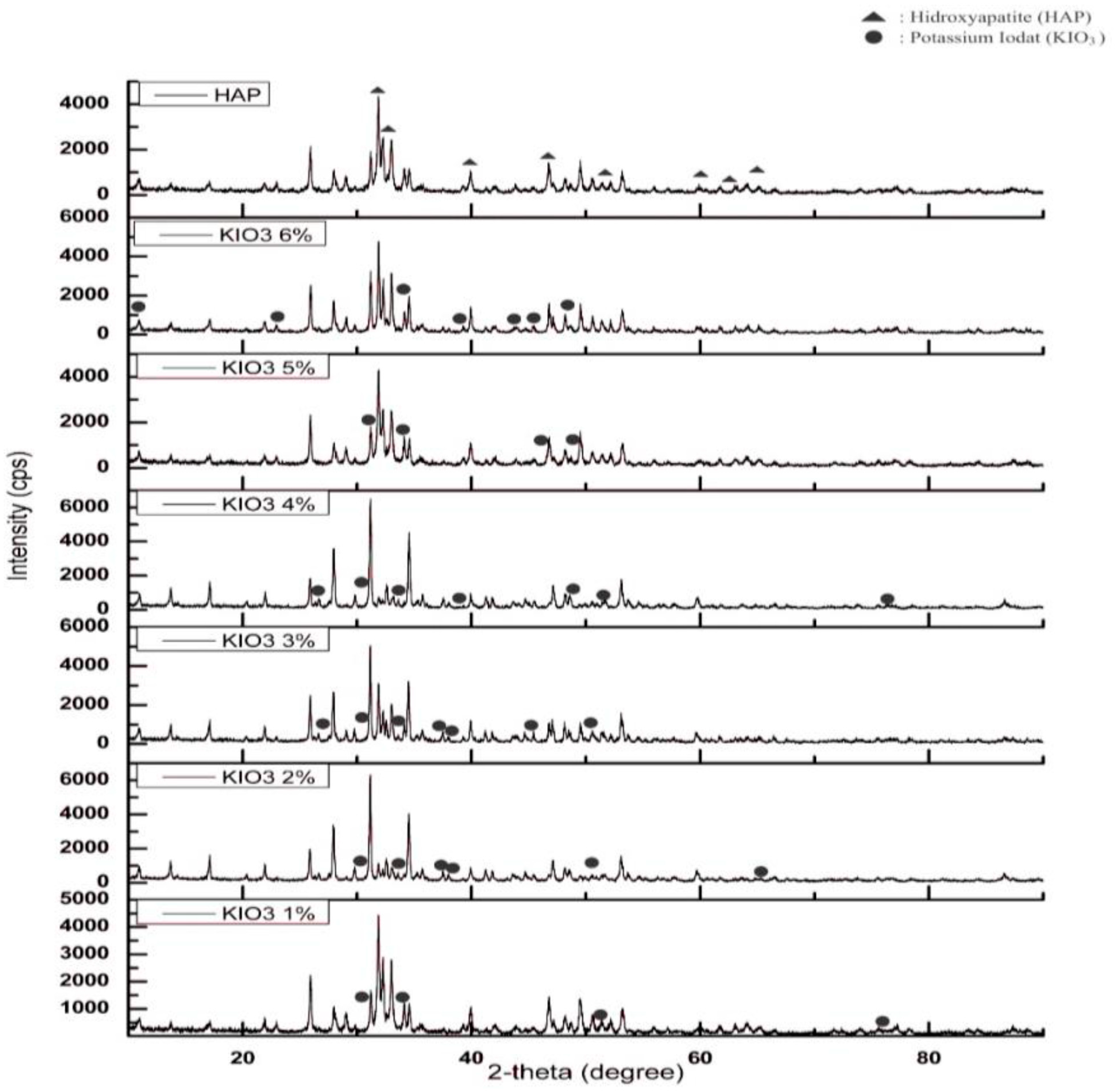

3.2. XRD Analysis

3.3. Catalyst Surface Area and Pore Volume Analysis

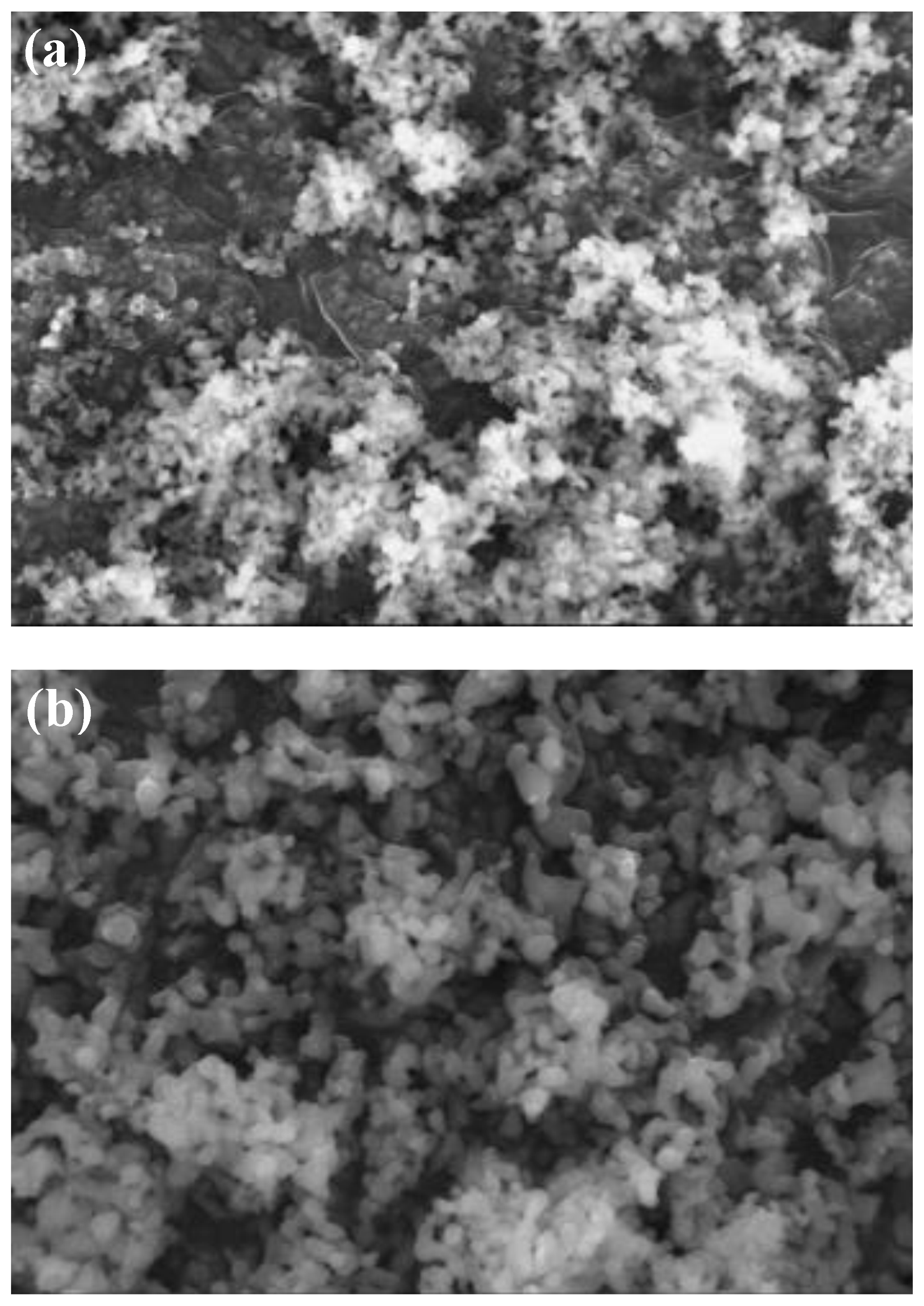

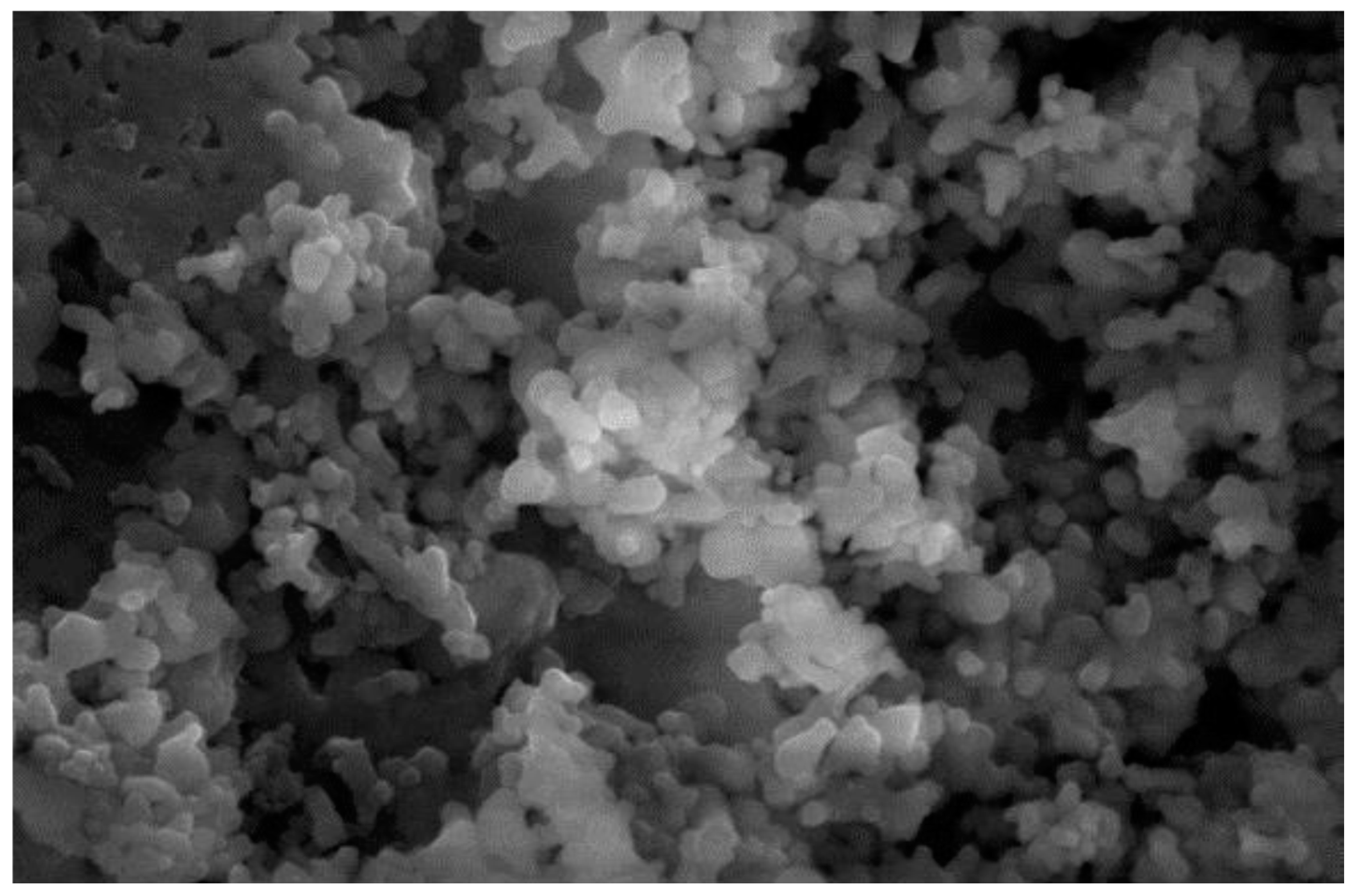

3.4. Catalyst Surface Morphology Analysis

3.5. WCO Characterization

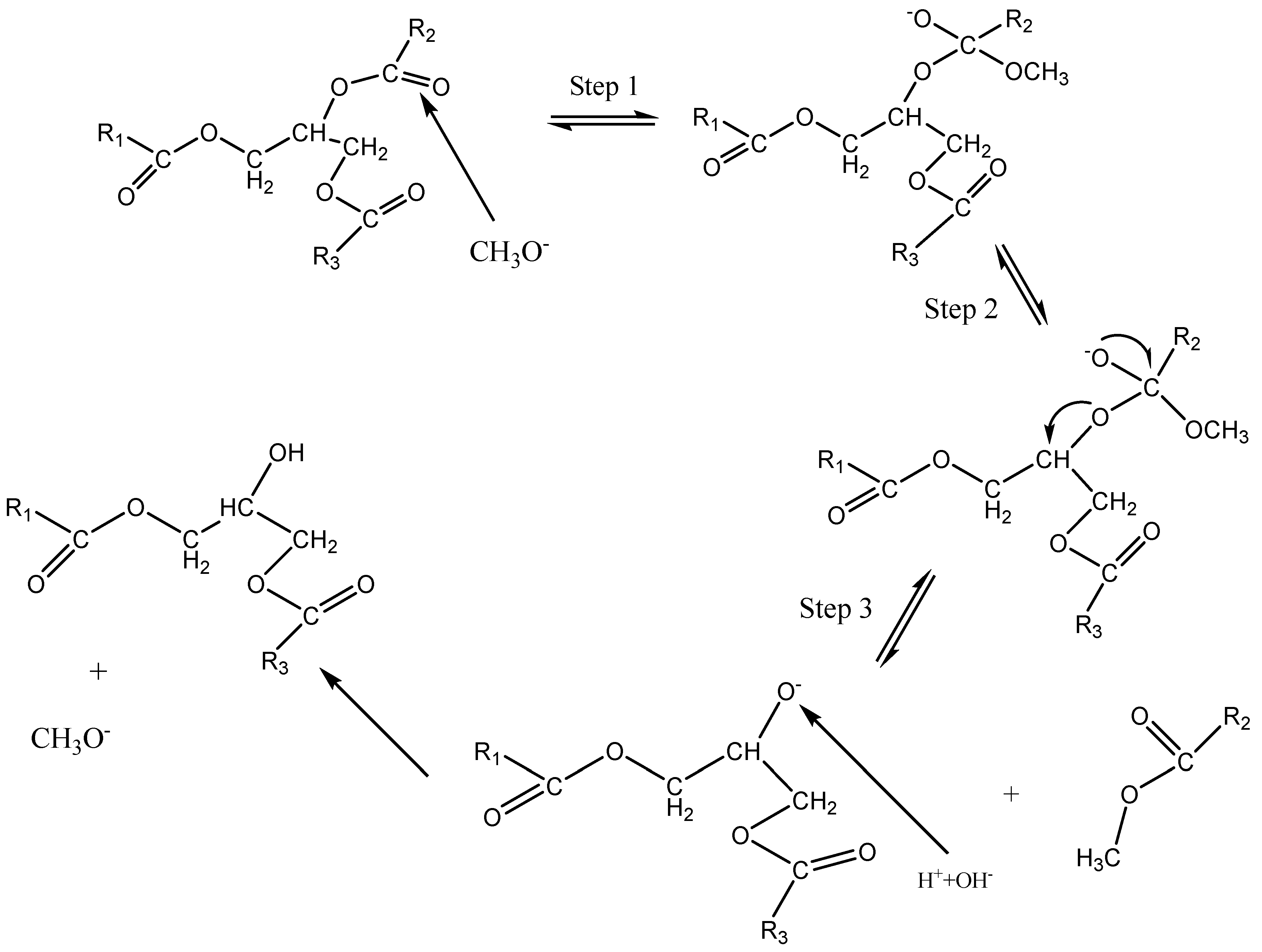

3.6. Heterogeneous Catalyst Reaction Mechanism

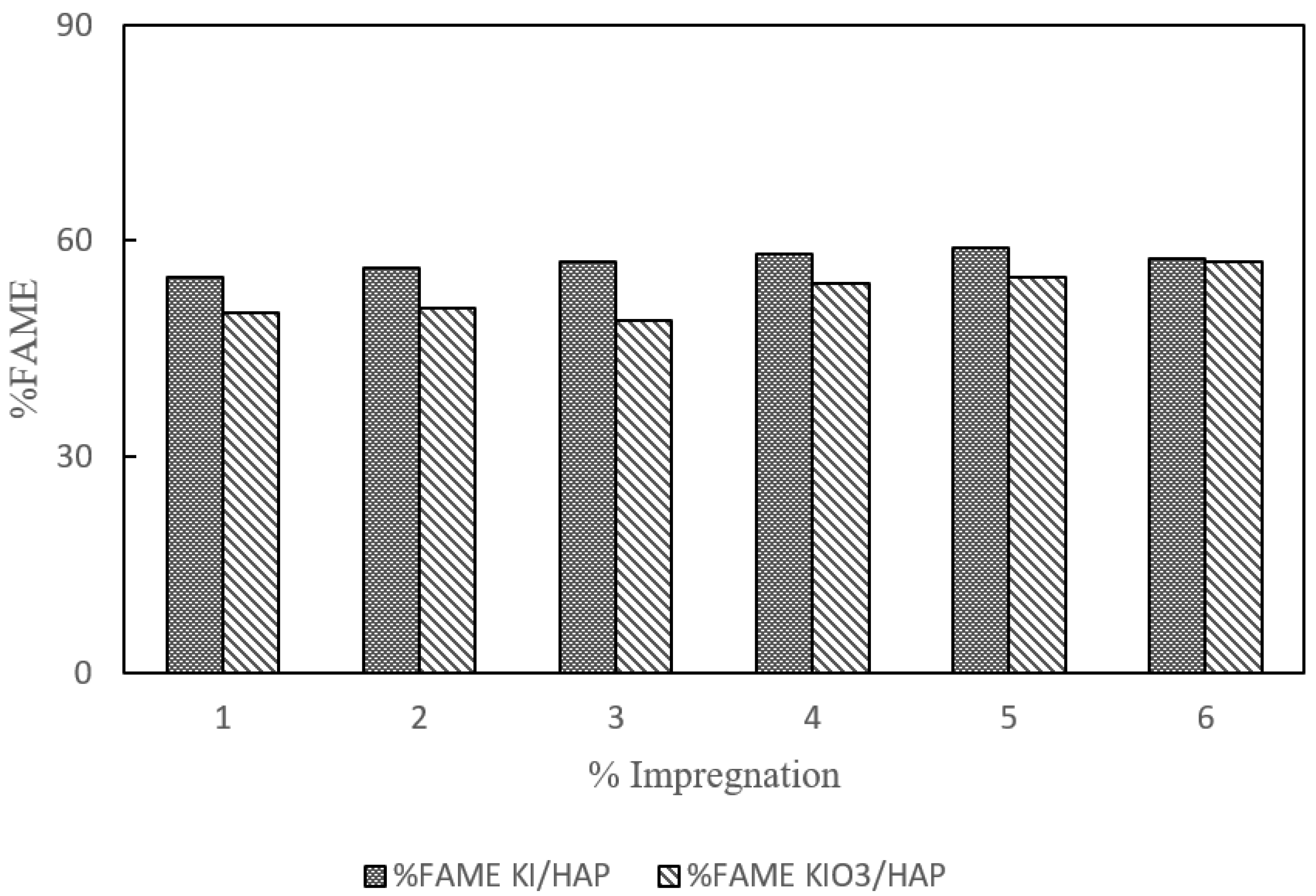

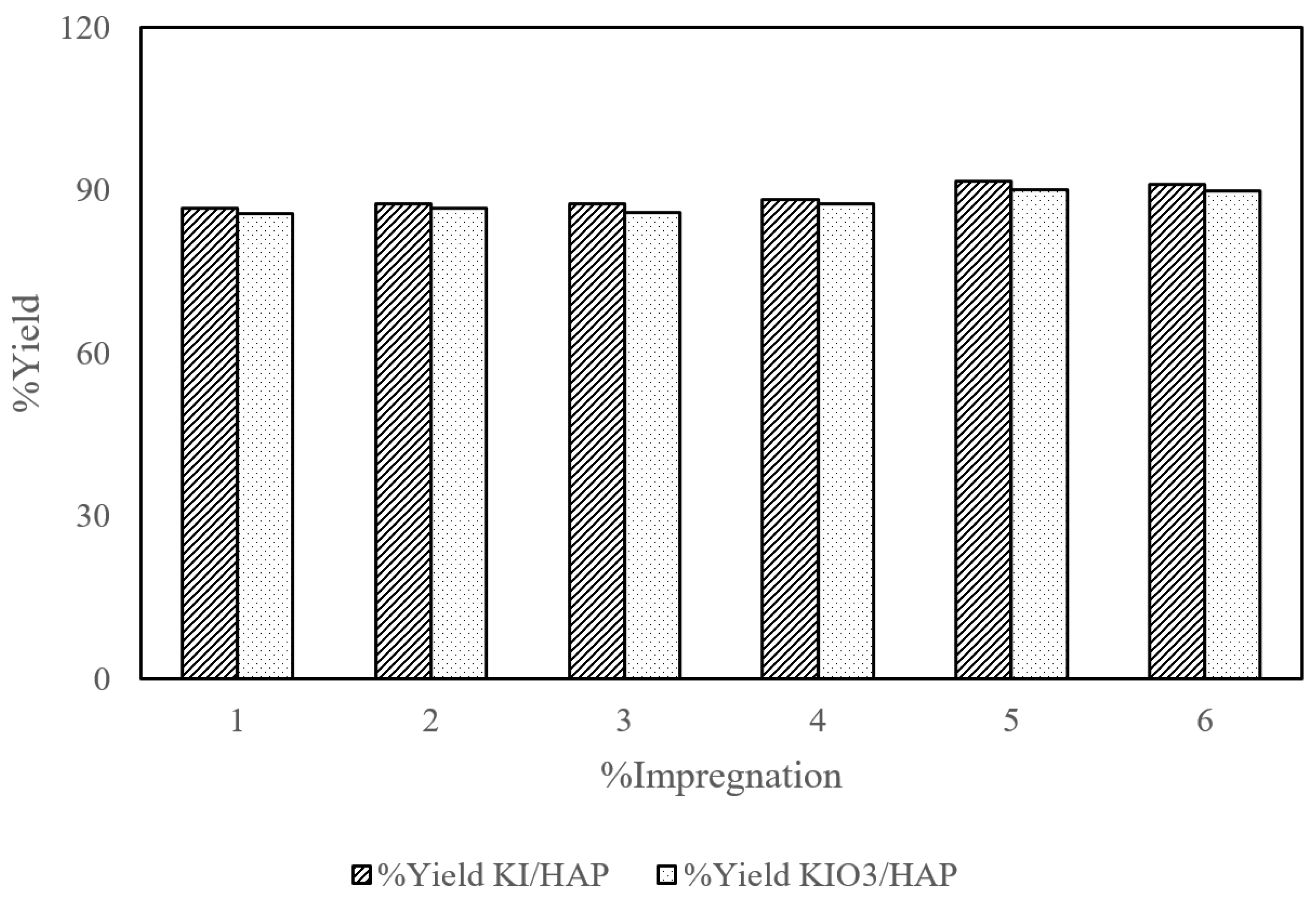

3.7. Effect of Catalyst Type to Yield

3.8. Biodiesel Product Characterization

3.9. Biodiesel Product Chemical Composition

3.10. Catalyst Reusability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Knothe, G.; Razon, L.F. Biodiesel Fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Konwar, L.J.; Warna, J.; Arvela, P.M.; Kumar, N.; Mikkola, J.P. Reaction Kinetics with Catalyst Deactivation in Simultaneous Esterification and Transesterification of Acid Oils to Biodiesel (FAME) Over A Mesoporous Sulphonated Carbon Catalyst. Fuel J. 2016, 166, 1–11. [Google Scholar] [CrossRef]

- Mohandass, R.; Ashok, K.; Selvaraju, A. Homogeneous Catalysts Used in Biodiesel Production: A Review. Int. J. Eng. Res. Technol. 2016, 5, 264–268. [Google Scholar] [CrossRef]

- Ferreira, R.S.B.; dos Passos, R.M.; Sampaio, K.A.; Batista, E.A. Heterogeneous Catalysts for Biodiesel Production: A Review. Food Public Health 2019, 9, 125–137. [Google Scholar]

- Encinar, J.M.; Gonzalez, J.F.; Sanchez, N.; Nogales-Delgado, S. Sunflower Oil Transesterification with Methanol Using Immobilized Lipase Enzymes. Bioprocess Biosyst. Eng. 2018, 42, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, S.; Khairudin, N.; Jamal, P.; Alam, M.Z.; Zainudin, Z.; Azmi, S. Characterization of Fish Bone Catalyst for Biodiesel Production. Int. J. Chem. Mol. Eng. 2014, 8, 464–466. [Google Scholar]

- Xie, W.; Huang, M. Enzymatic Production of Biodiesel Using Immobilized Lipase on Core-Shell Structure Fe3O4@MIL-100(Fe) Composites. Catalysts 2019, 9, 850. [Google Scholar] [CrossRef]

- Romero, R.; Martinez, S.L.; Natividad, R. Biodiesel Production by Using Heterogeneous Catalysts. In Alternative Fuel; Manzanera, M., Ed.; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar] [CrossRef]

- Kasno, A.; Rochayati, S.; Prasetyo, B.H. Deposit, Penyebaran dan Karakteristik Fosfat Alam; Balai Penelitian Tanah Kementrian Pertanian: Kota Bogor, Indonesia, 2009. [Google Scholar]

- Khan, H.M.; Iqbal, T.; Ali, C.H.; Yasin, S.; Jamil, F. Waste quail beaks as renewable source for synthesizing novel catalysts for biodiesel production. Renew. Energy 2020, 154, 1035–1043. [Google Scholar] [CrossRef]

- Essamlali, Y.; Amadine, O.; Larzek, M.; Len, C.; Zahouily, M. Sodium Modified Hydroxyapatite: Highly Efficient and Stable Solid-Base Catalyst for Biodiesel Production. Energy Convers. Manag. 2017, 149, 355–367. [Google Scholar] [CrossRef]

- Chen, G.; Shan, R.; Shi, J.; Liu, C.; Yan, B. Biodiesel Production from Palm Oil Using Active and Stable K Doped Hydroxyapatite Catalyst. Energy Convers. Manag. J. 2015, 98, 463–469. [Google Scholar] [CrossRef]

- Islam, A.; Taufiq-Yap, Y.H.; Ravindra, P.; Teo, S.H.; Sivasangar, S.; Chan, E.S. Biodiesel Synthesis over Millimetric γ-Al2O3/KI catalyst. Energy 2015, 89, 965–973. [Google Scholar] [CrossRef]

- Malani, R.S.; Shinde, V.; Ayachit, S.; Goyal, A.; Moholkar, V.S. Ultrasound-assisted Biodiesel Production Using Heterogeneous Base Catalyst and Mixed Non-edible Oils. Ultrason. Sonochem. 2019, 52, 232–243. [Google Scholar] [CrossRef] [PubMed]

- Tantirungrotechai, J.; Chotmongkolsap, P.; Pohmakotr, M. Synthesis, Characterization and Activity in Transesterification of Mesoporous Mg-Al Mixed-Metal Oxides. Microporous Mesoporous Mater. 2010, 128, 41–47. [Google Scholar] [CrossRef]

- Jairam, S.; Kolar, P.; Sharma-Shivappa, R.; Osborne, J.A.; Davis, J.P. KI-impregnated Oyster Shell as a Solid Catalyst for Soybean Oil Transesterification. Bioresour. Technol. 2012, 104, 329–335. [Google Scholar] [CrossRef]

- Rivera, E.M.; Araiza, M.; Brostow, W.; Castano, V.M.; Diaz-Estrada, J.R.; Hernandez, R.; Rodriguez, J.R. Synthesis of Hydroxyapatite from Eggshells. Mater. Lett. 1999, 41, 128–134. [Google Scholar] [CrossRef]

- Yielmaz, A.; Yilmaz, S. Wet Chemical Precipitation Synthesis of Hydroxyapatite (HA) Powders. Ceram. Int. 2018, 44, 9703–9710. [Google Scholar] [CrossRef]

- Darwis, D.; Warastuti, Y.; Sugiyono, K. Sintesis dan Karakterisasi Komposit Hidroksiapatite (HA) Sebagai Graft Tulang Sintetik. J. Ilm. Apl. Isot. Dan Radiasi 2008, 4, 143–153. [Google Scholar]

- Kytin, V.V.K.; Dyulgerova, E.; Ilievac, R.; Petkova, V. Powder X-ray Diffraction Studies of Hydroxyapatite and ꞵ-TCP Mixtures Processed by High Energy Dry Milling. Ceram. Int. 2018, 44, 8664–8671. [Google Scholar] [CrossRef]

- Uota, M.; Arakawa, H.; Kitamura, N.; Yoshimura, T.; Tanaka, J.; Kijima, T. Synthesis of High Surface Area Hydroxyapatite Nanoparticles by Mixed Surfactant-Mediated Approach. Langmuir 2005, 21, 4724–4728. [Google Scholar] [CrossRef]

- Kamieniak, J.; Bernalte, E.; Foster, C.W.; Doyle, A.M.; Kelly, P.J.; Banks, C.E. High Yield Synthesis of Hydroxyapatite (HAP) and Palladium Doped HAP via Wet Chemical Synthetic Route. J. Catal. 2016, 6, 119. [Google Scholar] [CrossRef]

- Gupta, J.; Agarwal, M.; Dalai, A.K. Marble Slurry Derived Hydroxyapatite as Heterogeneous Catalyst for Biodiesel Production from Soy Bean Oil. Can. J. Chem. Eng. 2018, 96, 1871–1876. [Google Scholar] [CrossRef]

- Abidin, S.Z.; Patel, D.; Saha, B. Quantitative Analysis of Fatty Acids Composition in the Used Cooking Oil (UCO) by Gas Chromatography Mass Spectrometry. Can. J. Chem. Eng. 2013, 91, 1896–1903. [Google Scholar] [CrossRef]

- Banani, R.; Youssef, S.; Bezzarga, M.; Abderrabba, M. Waste frying oil with 412 high levels of free fatty acids as one of the prominent sources of biodiesel production. J. Mater. Environ. Sci. 2015, 6, 1178–1185. [Google Scholar]

- Garcia, S.D.; Osman, M.B.; Krafft, J.M.; Cassale, S.; Thomas, C.; Kubo, J.; Costentin, G. Identification of Surface Basic Sites and Acid-Base Pairs of Hydroxyapatite. J. Phys. Chem. 2016, 118, 12744–12757. [Google Scholar]

- Guo, F.; Wei, N.N.; Xiu, Z.L.; Fang, Z. Transesterification mechanism of soybean oil to biodiesel catalyzed by calcined sodium silicate. Fuel 2012, 93. [Google Scholar] [CrossRef]

- Razak, Z.K.A.; Kamarullah, S.H.; Khazaai, S.N.M.; Maniam, G.P. Synthesis of Alumina-CaO-KI Catalyst for the Production of Biodiesel from Rubber Seed Oil. Malays. J. Anal. Sci. 2018, 22, 279–285. [Google Scholar]

- Widayat, W.; Wicaksono, A.R.; Firdaus, L.H.; Okvitarini, N. Synthesis H-Zeolite Catalyst by Impregnation KI/KIO3 and Performance Test Catalyst for Biodiesel Production. Mater. Sci. Eng. 2016, 107. [Google Scholar] [CrossRef]

- Cakraborty, R.; Roychowdhury, D. Fish Bone Derived Natural Hydroxyapatite-Supported Copper Acid Catalyst: Taguchi Optimization of Semi-batch Oleic Acid Esterification. Chem. Eng. J. 2012, 215–216, 491–499. [Google Scholar]

- Istadi, I.; Mabruro, U.; Kalimantini, B.A.; Buchori, L.; Anggoro, D.D. Reusability and Stability Tests of Calcium Oxide Based Catalyst (K2O/CaO-ZnO) for Transesterification of Soybean Oil to Biodiesel. Bull. Chem. React. Eng. Catal. 2016, 11, 34–39. [Google Scholar]

- Yan, B.; Zhang, Y.; Chen, G.; Shan, R.; Ma, W.; Liu, C. The Utilization of Hydroxyapatite-Supported CaO-CeO2 Catalyst for Biodiesel Production. Energy Convers. Manag. 2016, 130, 156–164. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R.; Muniyandi, B. Catalysis in Biodiesel Production—A Review. Clean Energy 2019, 3, 2–23. [Google Scholar] [CrossRef]

- Su, C.H. Recoverable and Reusable Hydrochloric Acid Used as a Homogeneous Catalyst for Biodiesel Production. Appl. Energy 2013, 104, 503–509. [Google Scholar] [CrossRef]

- Karmee, S.K.; Patria, R.D.; Lin, C.Z.K. Techno-Economic Evaluation of Biodiesel Production from Waste Cooking Oil—A Case Study of Hong Kong. Int. J. Mol. Sci. 2015, 16, 4362–4371. [Google Scholar] [CrossRef] [PubMed]

| Test Parameter | Unit | Catalyst | ||

|---|---|---|---|---|

| HAP | KI/HAP (5%) * | KIO3/HAP (6%) * | ||

| Surface Area | m2/g | 21.631 | 13.513 | 10.651 |

| Pore Volume | cc/g | 0.0330 | 0.0083 | 0.0065 |

| Pore Radius | Å | 16.330 | 7.380 | 6.830 |

| Component | Composition (% w/w) | |

|---|---|---|

| This Research | Abidin et al. [24] | |

| Octadecanoic acid (stearic acid) | 4.000 | 4.650 |

| 9-Octadecenoic acid (oleic acid) | 2.100 | 33.750 |

| Hexadecenoic acid (palmitic acid) | 93.650 | 13.620 |

| Linoleic acid | 43.850 | |

| Linolenic acid | 4.650 | |

| Total | 100 | 100 |

| Test Parameter | KI impregnation (% w/w) | Indonesian Standard | European Standard | |||||

|---|---|---|---|---|---|---|---|---|

| 1% | 2% | 3% | 4% | 5% | 6% | |||

| Density (g/cm3) | 0.873 | 0.868 | 0.864 | 0.861 | 0.859 | 0.861 | 0.850–0.900 | 0.860–0.900 |

| Viscosity (cSt) | 7.803 | 6.465 | 6.242 | 6.688 | 5.574 | 5.797 | Max. 6 at 40 °C | 3.5–5.0 at 40 °C |

| % FFA | 1.876 | 1.721 | 1.753 | 1.817 | 1.787 | 1.726 | <1 | <1 |

| Test Parameter | KI Impregnation (% w/w) | Indonesian Standard | European Standard | |||||

|---|---|---|---|---|---|---|---|---|

| 1% | 2% | 3% | 4% | 5% | 6% | |||

| Density (g/cm3) | 0.875 | 0.871 | 0.868 | 0.861 | 0.863 | 0.854 | 0.850–0.900 | 0.860–0.900 |

| Viscosity (cSt) | 8.249 | 6.242 | 6.020 | 6.911 | 6.020 | 5.797 | Max. 6 at 40 °C | 3.5–5.0 at 40 °C |

| % FFA | 1.815 | 1.879 | 1.848 | 1.819 | 1.789 | 1.759 | <1 | <1 |

| Compounds | Molecular Formulas | Chemical Structure |

|---|---|---|

| Hexadecanoic acid, methyl ester (CAS) | C17H34O2 |  |

| 9-Octadecenoic acid, methyl ester (CAS) | C19H36O2 |  |

| Hexadecanoic acid, 2-hydroxy-1,3-propannediyl ester (CAS) | C35H68O5 |  |

| Octadecanoic acid, 2-hydroxy-1,3-propanediyl ester | C39H76O5 |  |

| Di-(9-octadecenoyl)-glycerol | C57H102O6 |  |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Widayat, W.; Hadiyanto, H.; Wardani, P.W.A.; Az Zuhra, U.; Prameswari, J. Preparation of KI/Hydroxyapatite Catalyst from Phosphate Rocks and Its Application for Improvement of Biodiesel Production. Molecules 2020, 25, 2565. https://doi.org/10.3390/molecules25112565

Widayat W, Hadiyanto H, Wardani PWA, Az Zuhra U, Prameswari J. Preparation of KI/Hydroxyapatite Catalyst from Phosphate Rocks and Its Application for Improvement of Biodiesel Production. Molecules. 2020; 25(11):2565. https://doi.org/10.3390/molecules25112565

Chicago/Turabian StyleWidayat, Widayat, Hadiyanto Hadiyanto, Permadi Wisnu Aji Wardani, Ummi Az Zuhra, and Jedy Prameswari. 2020. "Preparation of KI/Hydroxyapatite Catalyst from Phosphate Rocks and Its Application for Improvement of Biodiesel Production" Molecules 25, no. 11: 2565. https://doi.org/10.3390/molecules25112565

APA StyleWidayat, W., Hadiyanto, H., Wardani, P. W. A., Az Zuhra, U., & Prameswari, J. (2020). Preparation of KI/Hydroxyapatite Catalyst from Phosphate Rocks and Its Application for Improvement of Biodiesel Production. Molecules, 25(11), 2565. https://doi.org/10.3390/molecules25112565