Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges

Abstract

:1. Introduction

2. Shape-Memory Polymeric Artificial Muscles

2.1. Shape-Memory Effects

2.2. Programmable Shape-Memory Polymeric Artificial Muscles

3. Applications of Shape-Memory Polymeric Artificial Muscles

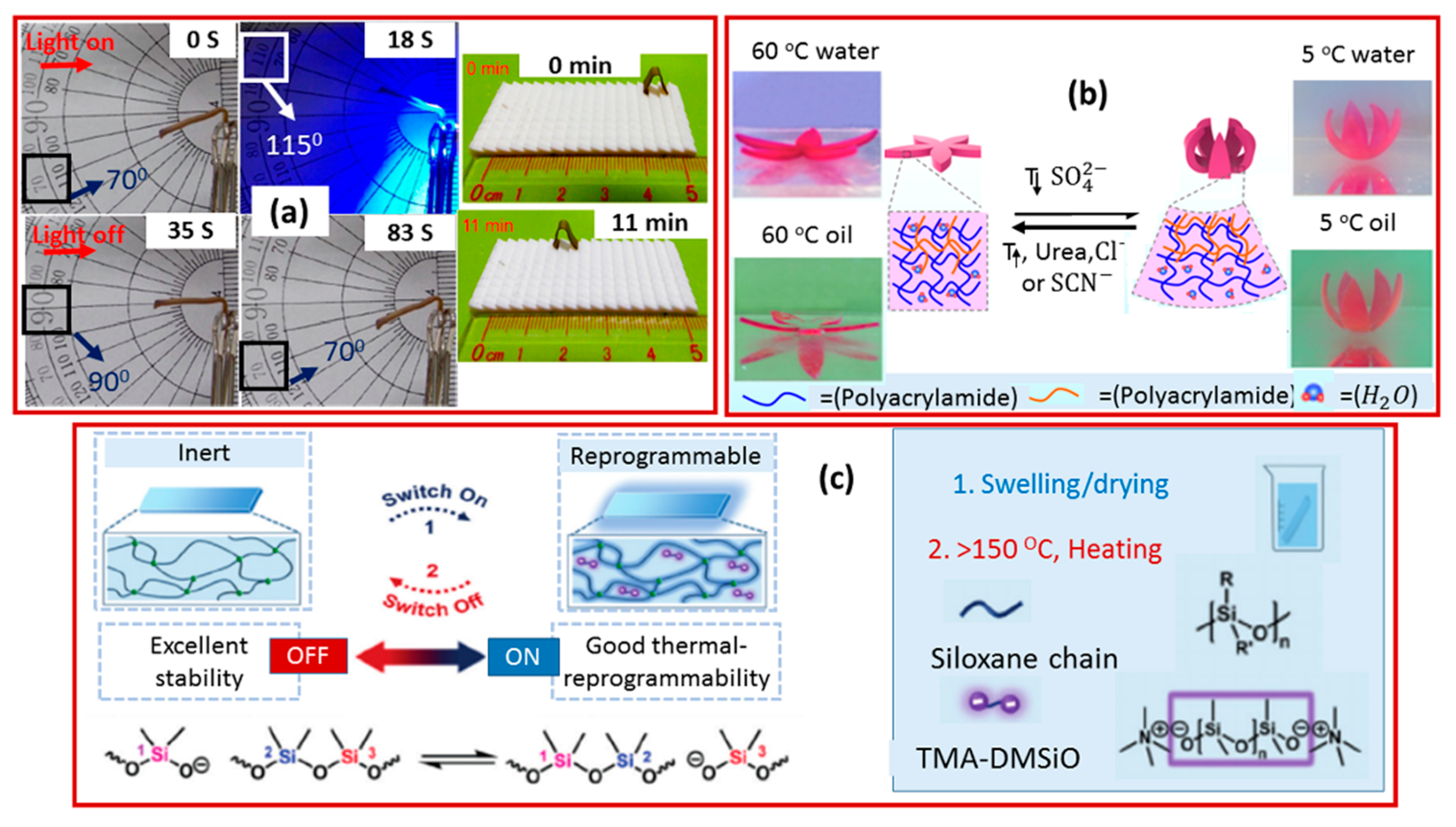

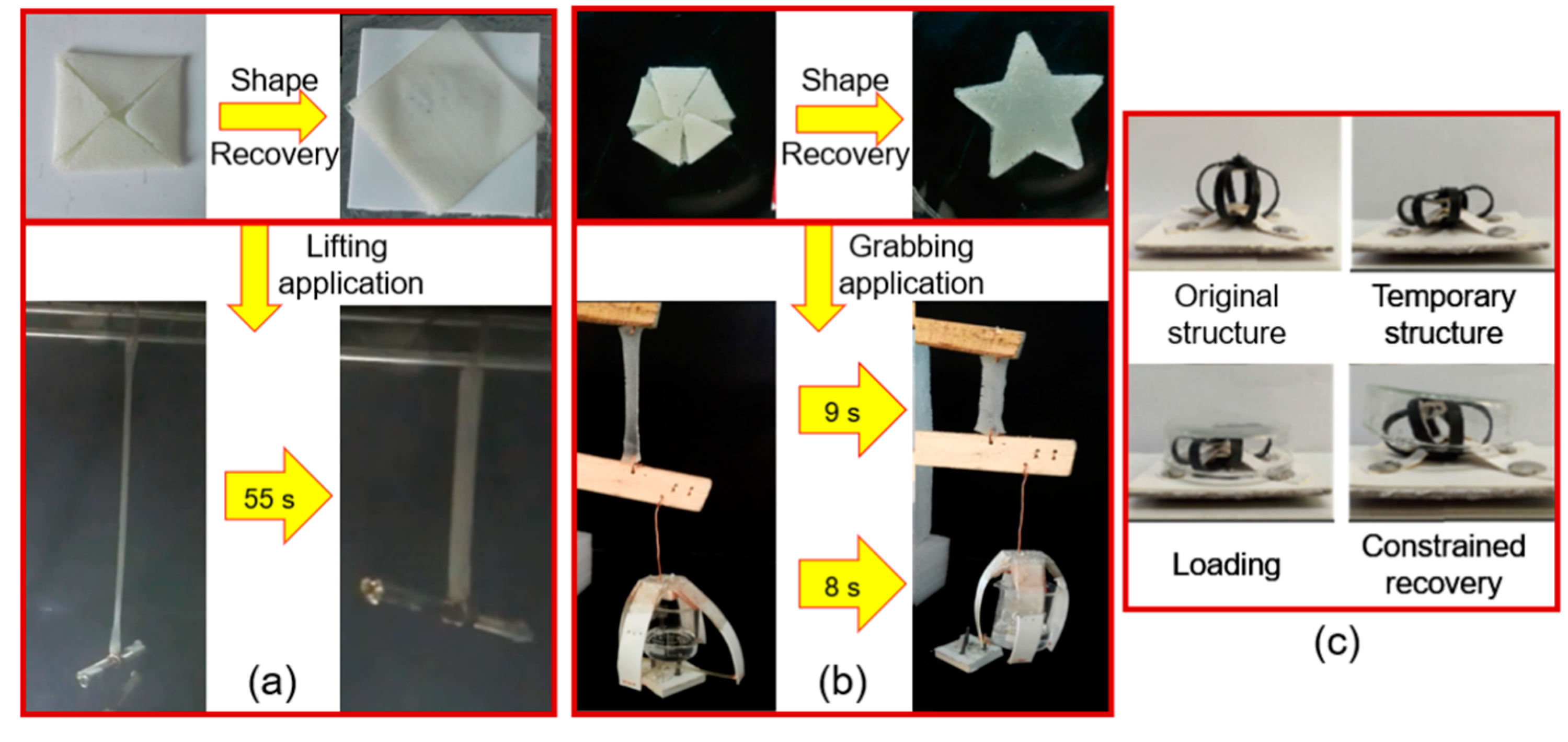

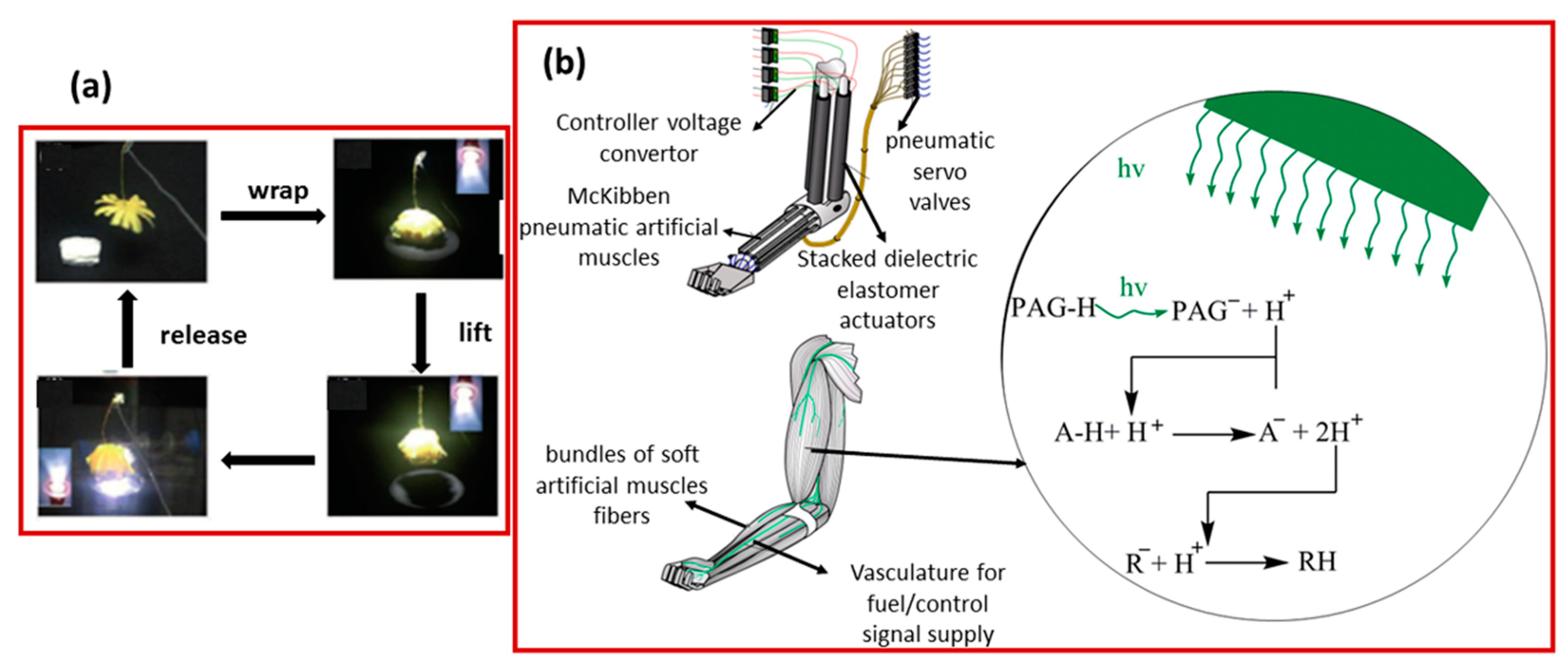

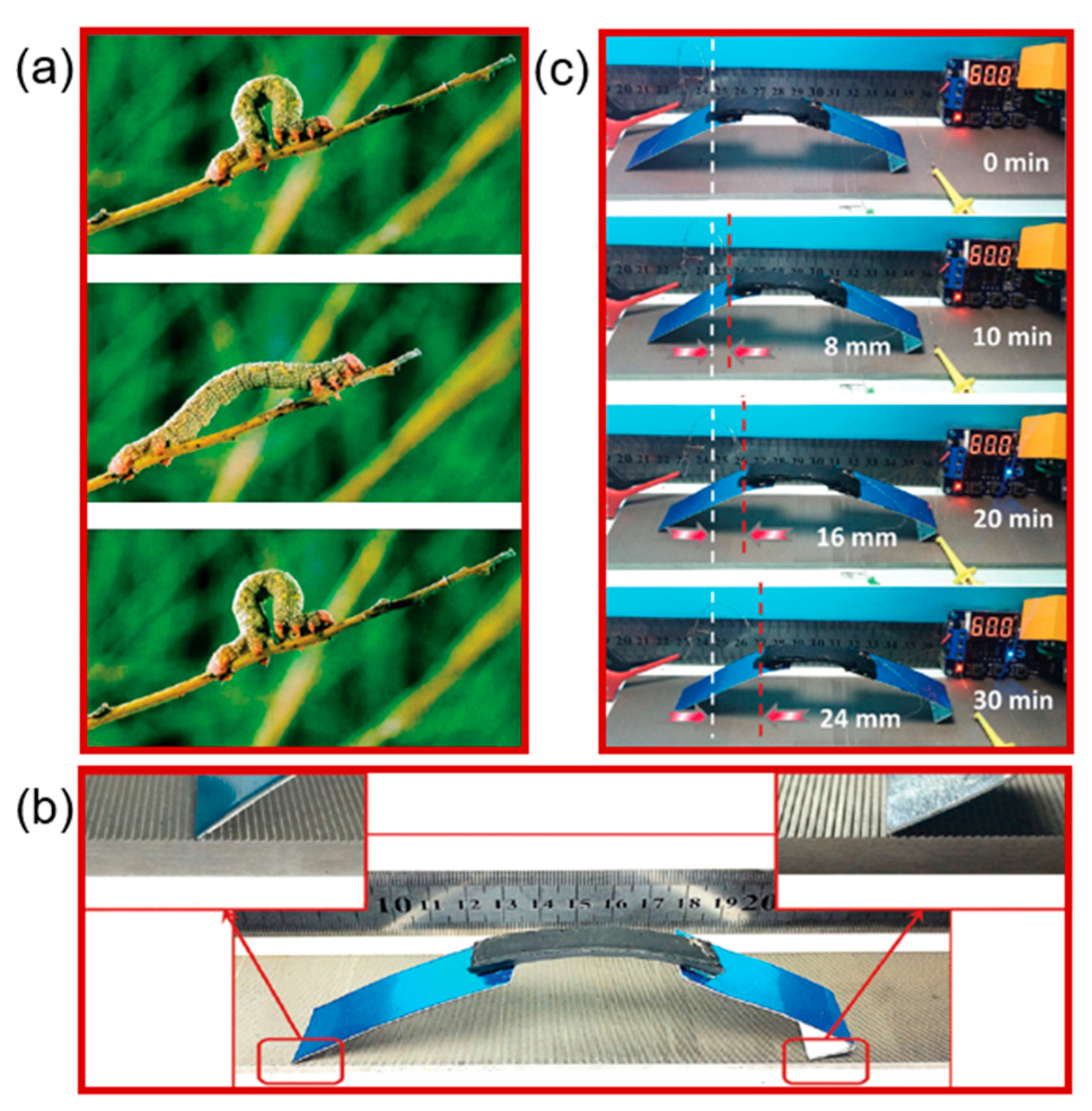

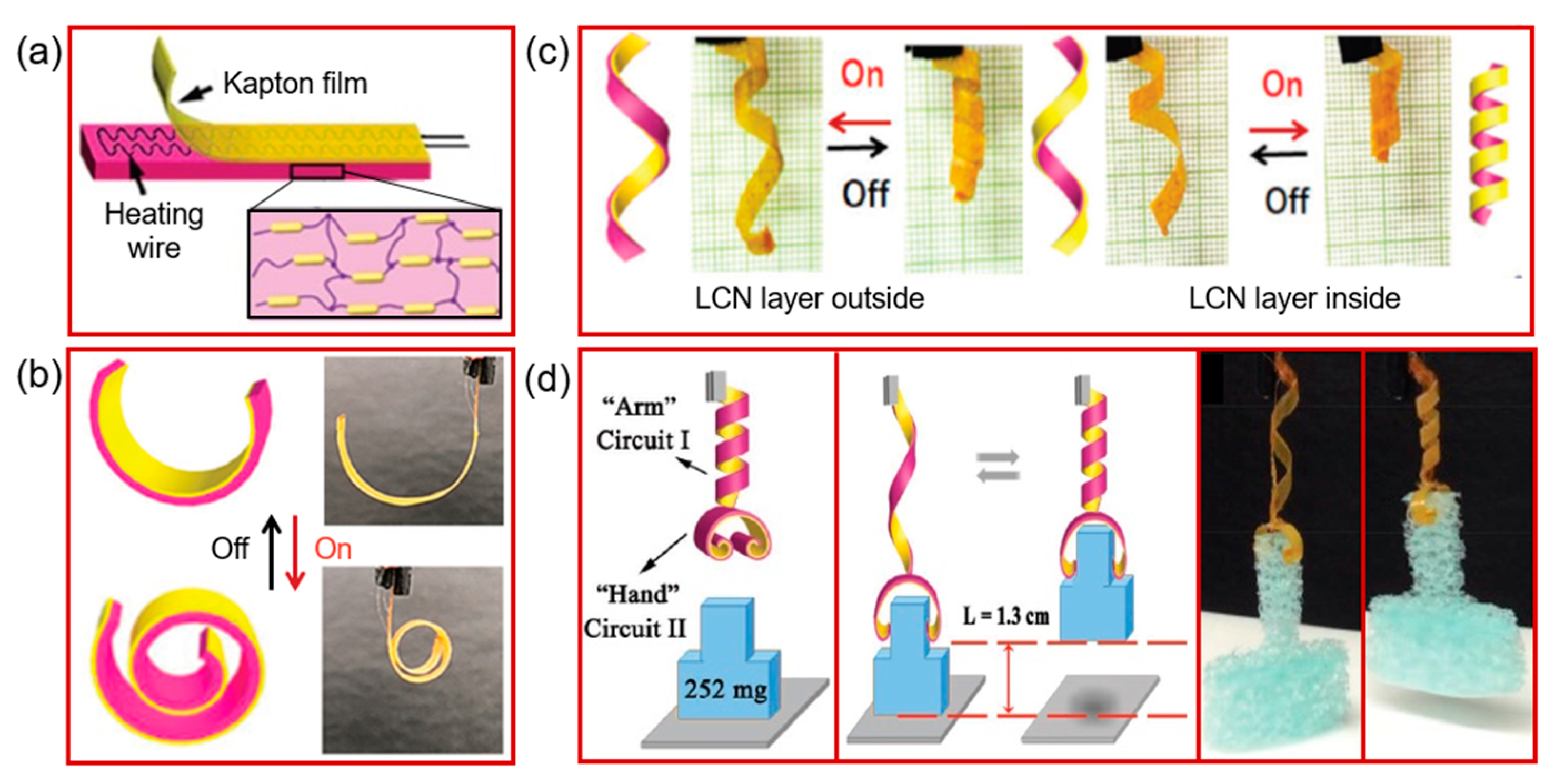

3.1. Thermo-Induced Shape-Memory Polymeric Artificial Muscles

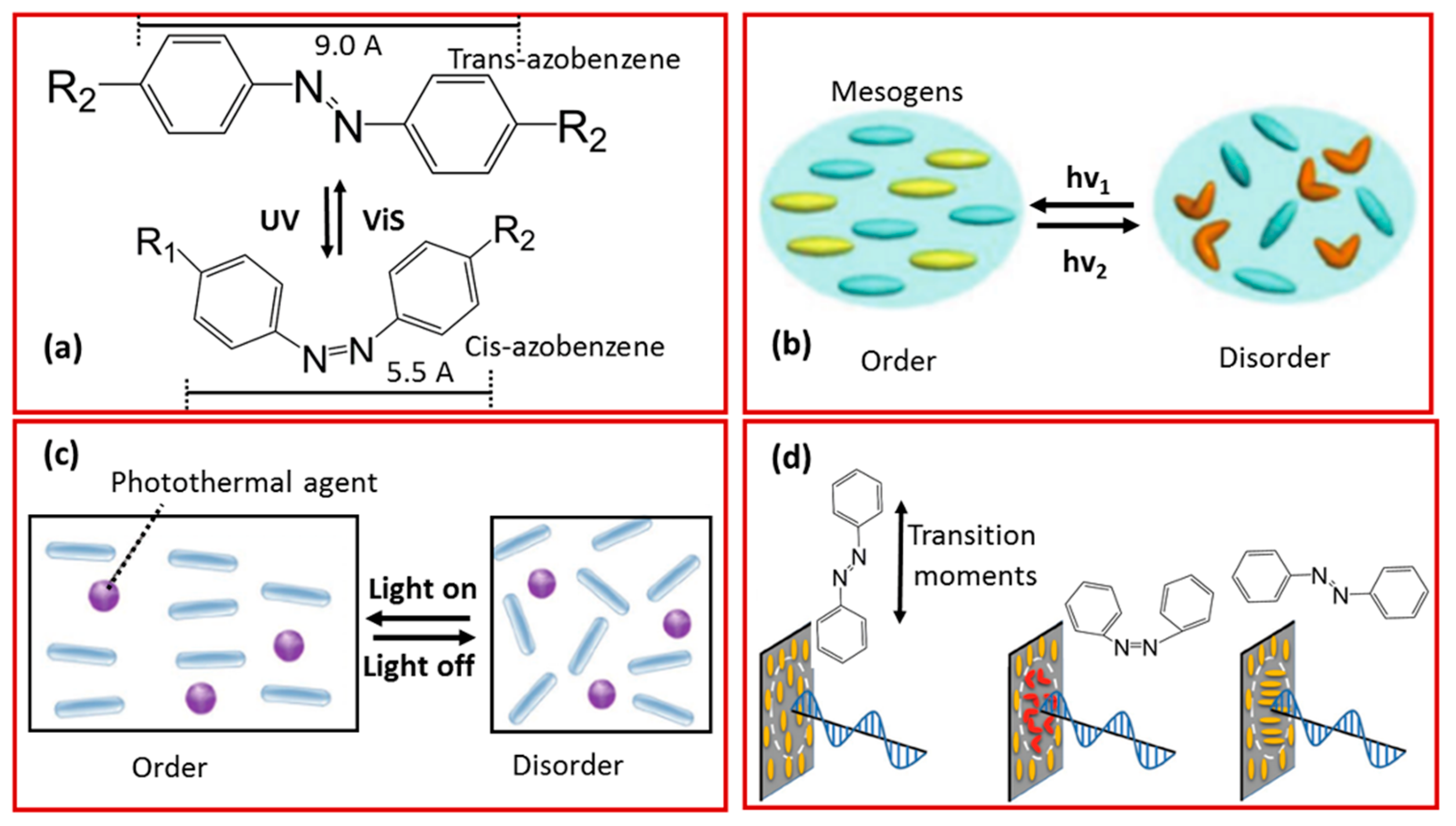

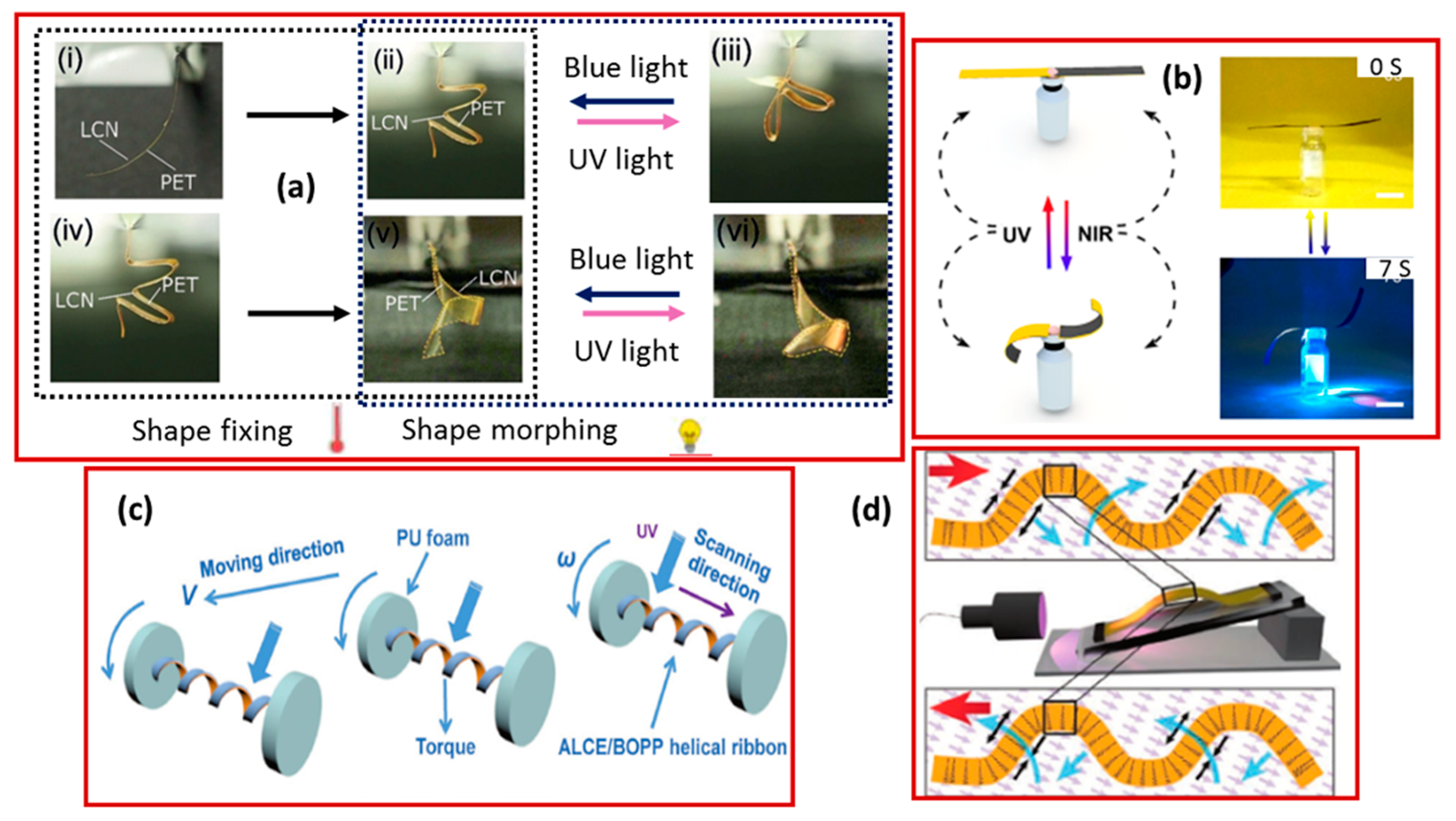

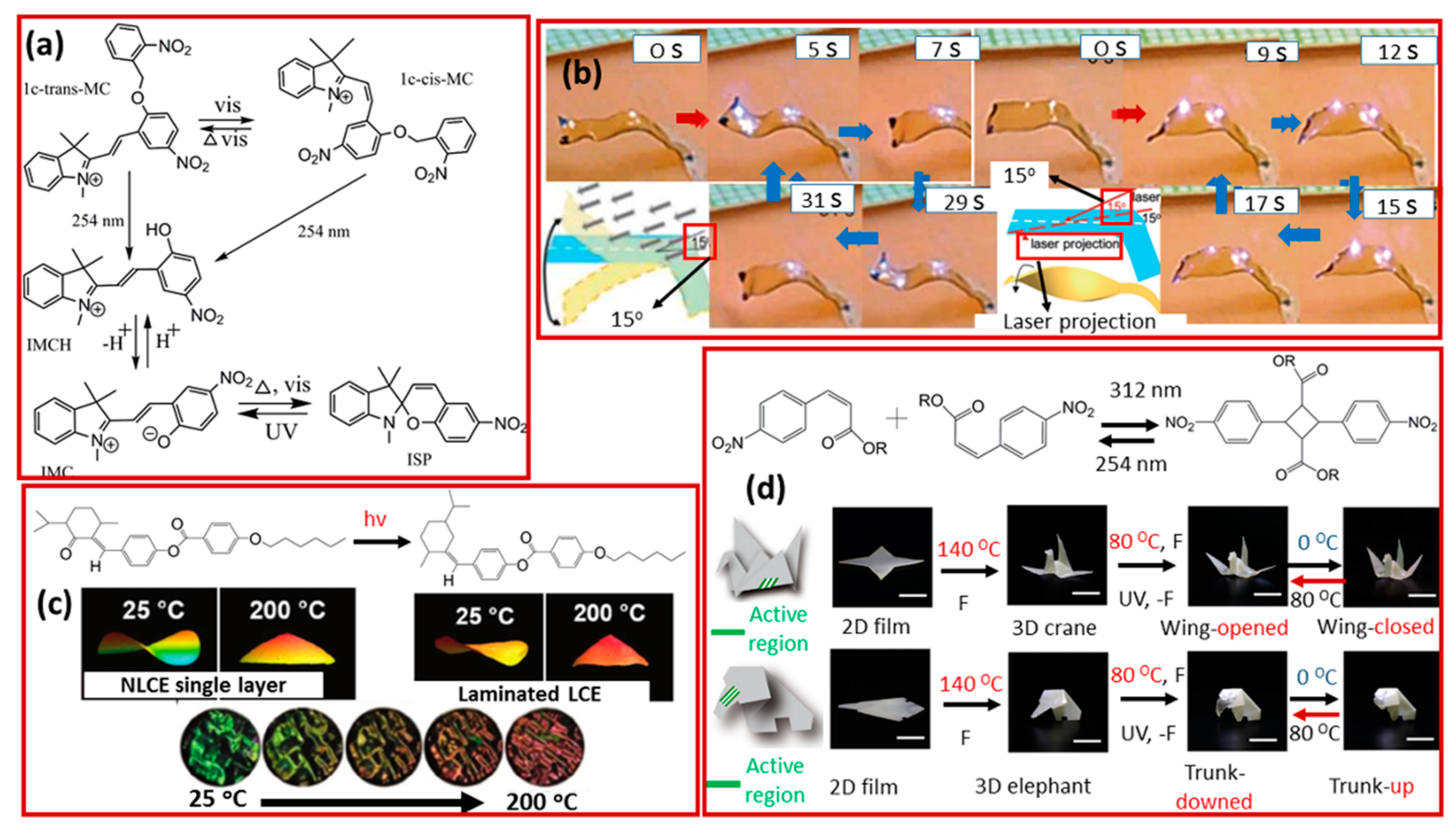

3.2. Photo-Induced Shape-Memory Polymeric Artificial Muscles

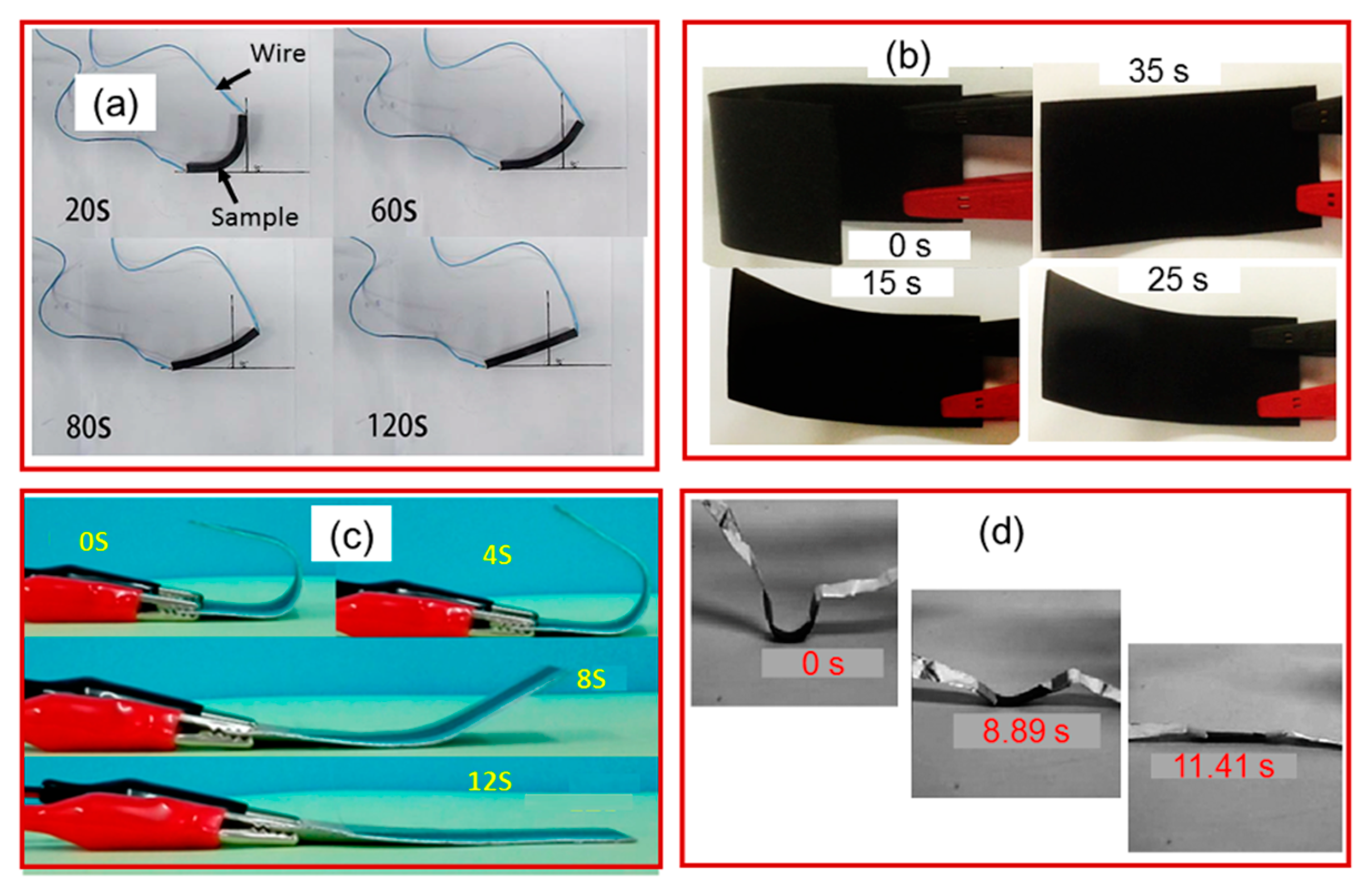

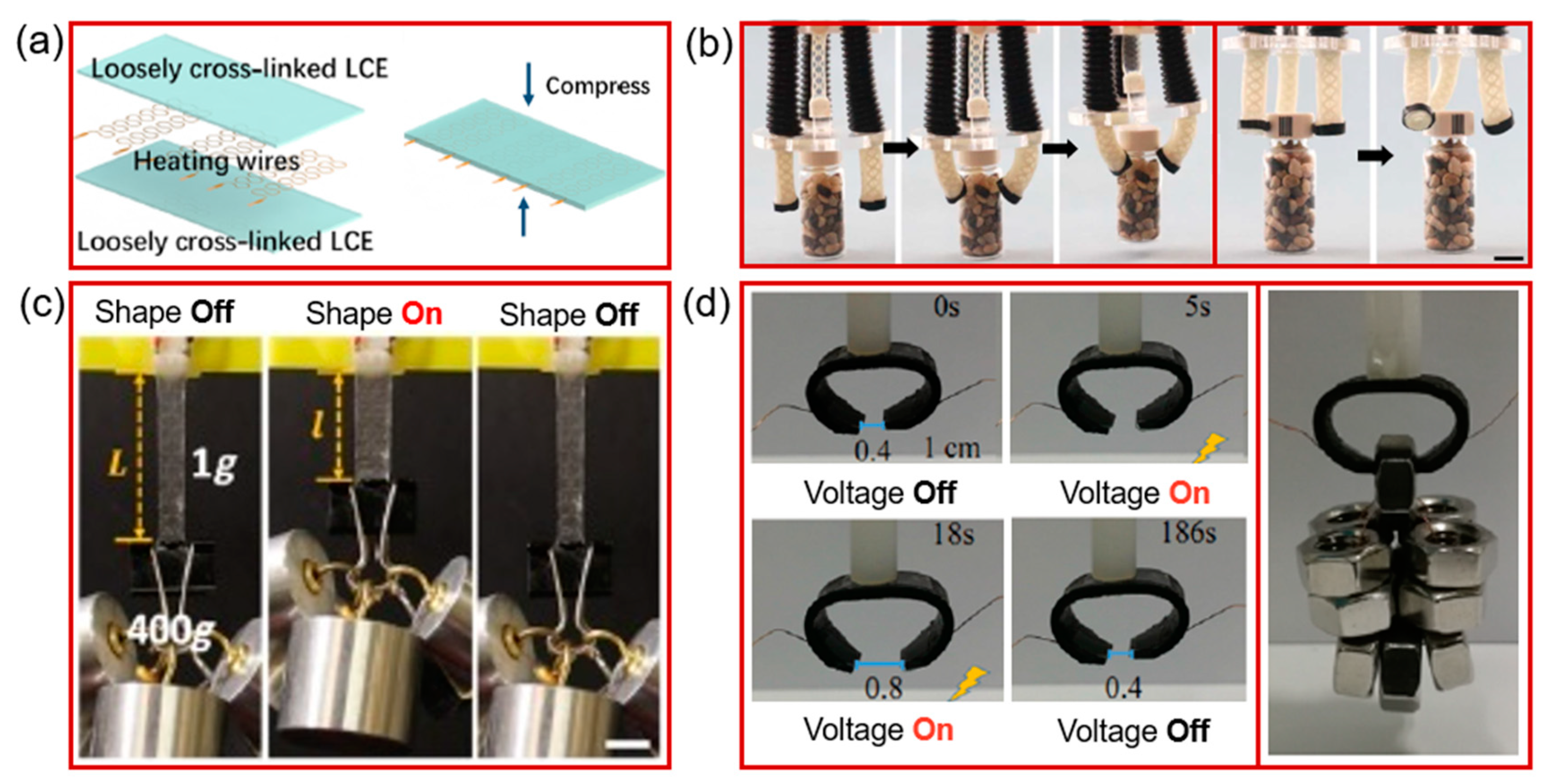

3.3. Electro-Induced Shape-Memory Polymeric Artificial Muscles

4. Concluding Remarks with Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Feinberg, A.W.; Feigel, A.; Shevkoplyas, S.S.; Sheehy, S.; Whitesides, G.M.; Parker, K.K. Muscular Thin Films for Building Actuators and Powering Devices. Science 2007, 317, 1366–1370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Madden, J.D.W. Mobile Robots: Motor Challenges and Materials Solutions. Science 2007, 318, 1094–1097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R. Polymer artificial muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Rehman, H.U.; Chen, Y.; Hedenqvist, M.S.; Li, H.; Xue, W.; Guo, Y.; Guo, Y.; Duan, H.; Liu, H. Self-Healing Shape Memory PUPCL Copolymer with High Cycle Life. Adv. Funct. Mater. 2017, 28, 1704109. [Google Scholar] [CrossRef]

- Lima, M.D.; Li, N.; De Andrade, M.J.; Fang, S.; Oh, J.; Spinks, G.M.; Kozlov, M.G.; Haines, C.S.; Suh, D.; Foroughi, J.; et al. Electrically, Chemically, and Photonically Powered Torsional and Tensile Actuation of Hybrid Carbon Nanotube Yarn Muscles. Science 2012, 338, 928–932. [Google Scholar] [CrossRef]

- Park, S.-J.; Gazzola, M.; Park, K.S.; Di Santo, V.; Blevins, E.L.; Lind, J.U.; Campbell, P.H.; Dauth, S.; Capulli, A.K.; Pasqualini, F.S.; et al. Phototactic guidance of a tissue-engineered soft-robotic ray. Science 2016, 353, 158–162. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Sim, K.; Chen, J.; Kim, H.; Rao, Z.; Li, Y.; Chen, W.; Song, J.; Verduzco, R.; Yu, C. Soft Ultrathin Electronics Innervated Adaptive Fully Soft Robots. Adv. Mater. 2018, 30, 1706695. [Google Scholar] [CrossRef] [Green Version]

- Ratna, D.; Karger-Kocsis, J. Recent advances in shape memory polymers and composites: A review. J. Mater. Sci. 2007, 43, 254–269. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Jung, Y.C.; Goo, N.S.; Cho, J.W. Conducting Shape Memory Polyurethane-Polypyrrole Composites for an Electroactive Actuator. Macromol. Mater. Eng. 2005, 290, 1049–1055. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Jung, Y.C.; Yoo, H.J.; Cho, J.W. Influence of carbon nanotubes and polypyrrole on the thermal, mechanical and electroactive shape-memory properties of polyurethane nanocomposites. Compos. Sci. Technol. 2007, 67, 1920–1929. [Google Scholar] [CrossRef]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef] [Green Version]

- Mirvakili, S.M.; Hunter, I.W. Multidirectional Artificial Muscles from Nylon. Adv. Mater. 2016, 29, 1604734. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Arazoe, H.; Miyajima, D.; Akaike, K.; Araoka, F.; Sato, E.; Hansen, J.C.; Kawamoto, M.; Aida, T. An autonomous actuator driven by fluctuations in ambient humidity. Nat. Mater. 2016, 15, 1084–1089. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Huang, R.; Liu, Z. A Periodic Deformation Mechanism of a Soft Actuator for Crawling and Grasping. Adv. Mater. Technol. 2019, 4, 1900653. [Google Scholar] [CrossRef]

- Thakur, V.; Ding, G.; Ma, J.; Lee, P.S.; Lu, X. Hybrid Materials and Polymer Electrolytes for Electrochromic Device Applications. Adv. Mater. 2012, 24, 4071–4096. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Santaniello, T.; Bettini, L.G.; Minnai, C.; Bellacicca, A.; Porotti, R.; Denti, I.; Faraone, G.; Merlini, M.; Lenardi, C.; et al. Electroactive Ionic Soft Actuators with Monolithically Integrated Gold Nanocomposite Electrodes. Adv. Mater. 2017, 29, 1606109. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef]

- Chen, T.; Bilal, O.R.; Shea, K.; Daraio, C. Harnessing bistability for directional propulsion of soft, untethered robots. Proc. Natl. Acad. Sci. USA 2018, 115, 5698–5702. [Google Scholar] [CrossRef] [Green Version]

- Mao, Y.; Yu, K.; Isakov, M.S.; Wu, J.; Dunn, A.P.M.L.; Qi, H.J. Sequential Self-Folding Structures by 3D Printed Digital Shape Memory Polymers. Sci. Rep. 2015, 5, 13616. [Google Scholar] [CrossRef]

- Lan, X.; Liu, Y.; Lv, H.; Wang, X.; Leng, J.; Du, S. Fiber reinforced shape-memory polymer composite and its application in a deployable hinge. Smart Mater. Struct. 2009, 18, 24002. [Google Scholar] [CrossRef] [Green Version]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Lin, J.; Knoll, C.; Willey, C. Shape Memory Rigidizable Inflatable (RI) Structures for Large Space Systems Applications. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006. [Google Scholar]

- Fan, J.; Li, G. High performance and tunable artificial muscle based on two-way shape memory polymer. RSC Adv. 2017, 7, 1127–1136. [Google Scholar] [CrossRef] [Green Version]

- Mirvakili, S.M.; Hunter, I.W. Artificial Muscles: Mechanisms, Applications, and Challenges. Adv. Mater. 2017, 30, 1704407. [Google Scholar] [CrossRef]

- Schulz, M. Speeding Up Artificial Muscles. Science 2012, 338, 893–894. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Wei, X.; Yang, J.-H.; Zhang, N.; Huang, T.; Wang, Y.; Gao, X.-L. Triple-Shape Memory Materials Based on Cross-Linked Poly(ethylene vinyl acetate) and Poly(ε-caprolactone). Ind. Eng. Chem. Res. 2016, 55, 12232–12241. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49, 79–120. [Google Scholar] [CrossRef] [Green Version]

- Fan, L.F.; Rong, M.Z.; Zhang, M.Q.; Chen, X.D.; Longfei, F. Dynamic reversible bonds enable external stress-free two-way shape memory effect of a polymer network and the interrelated intrinsic self-healability of wider crack and recyclability. J. Mater. Chem. A 2018, 6, 16053–16063. [Google Scholar] [CrossRef]

- Zare, M.; Prabhakaran, M.P.; Parvin, N.; Seeram, R. Thermally-induced two-way shape memory polymers: Mechanisms, structures, and applications. Chem. Eng. J. 2019, 374, 706–720. [Google Scholar] [CrossRef]

- Li, Y.; Pruitt, C.; Rios, O.; Wei, L.; Rock, M.; Keum, J.; McDonald, A.G.; Kessler, M. Controlled Shape Memory Behavior of a Smectic Main-Chain Liquid Crystalline Elastomer. Macromolecules 2015, 48, 2864–2874. [Google Scholar] [CrossRef]

- Turner, S.A.; Zhou, J.; Sheiko, S.S.; Ashby, V.S. Switchable Micropatterned Surface Topographies Mediated by Reversible Shape Memory. ACS Appl. Mater. Interfaces 2014, 6, 8017–8021. [Google Scholar] [CrossRef] [PubMed]

- Behl, M.; Kratz, K.; Zotzmann, J.; Nöchel, U.; Lendlein, A. Reversible Bidirectional Shape-Memory Polymers. Adv. Mater. 2013, 25, 4466–4469. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Hu, J.; Zhuo, H.; Zhu, Y. Two-way shape memory effect in polymer laminates. Mater. Lett. 2008, 62, 4088–4090. [Google Scholar] [CrossRef]

- Ke, H.; Chen, Z.; Momo, Z.Y.; Jiani, W.; Xuan, C.; Xiao, X.; Xueliang, X.; Dong, K.; Zhao, C.; Yan, M.Z.; et al. Recent advances of two-way shape memory polymers and four-dimensional printing under stress-free conditions. Smart Mater. Struct. 2020, 29, 023001. [Google Scholar] [CrossRef]

- Yan, C.; Yang, Q.; Li, G. A phenomenological constitutive model for semicrystalline two-way shape memory polymers. Int. J. Mech. Sci. 2020, 177, 105552. [Google Scholar] [CrossRef]

- Fan, L.F.; Rong, M.Z.; Zhang, M.Q.; Chen, X.D. A Facile Approach Toward Scalable Fabrication of Reversible Shape-Memory Polymers with Bonded Elastomer Microphases as Internal Stress Provider. Macromol. Rapid Commun. 2017, 38, 1700124. [Google Scholar] [CrossRef]

- Fan, L.F.; Rong, M.Z.; Zhang, M.Q.; Chen, X. Repeated Intrinsic Self-Healing of Wider Cracks in Polymer via Dynamic Reversible Covalent Bonding Molecularly Combined with a Two-Way Shape Memory Effect. ACS Appl. Mater. Interfaces 2018, 10, 38538–38546. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Jia, Y.-G.; Zhu, X. Two-Way Reversible Shape Memory Polymers Made of Cross-Linked Cocrystallizable Random Copolymers with Tunable Actuation Temperatures. Macromolecules 2017, 50, 8570–8579. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, X. Two-Way Reversible Shape Memory Polymers Containing Polydopamine Nanospheres: Light Actuation, Robotic Locomotion, and Artificial Muscles. ACS Biomater. Sci. Eng. 2018, 4, 3099–3106. [Google Scholar] [CrossRef]

- Chung, T.; Romo-Uribe, A.; Mather, P.T. Two-Way Reversible Shape Memory in a Semicrystalline Network. Macromolecules 2008, 41, 184–192. [Google Scholar] [CrossRef]

- Pilate, F.; Stoclet, G.; Mincheva, R.; Dubois, P.; Raquez, J.-M. Poly(ε-caprolactone) and Poly(ω-pentadecalactone)-Based Networks with Two-Way Shape-Memory Effect through [2 + 2] Cycloaddition Reactions. Macromol. Chem. Phys. 2018, 219, 1700345. [Google Scholar] [CrossRef]

- Yang, G.; Liu, X.; Tok, A.I.Y.; Lipik, V. Body temperature-responsive two-way and moisture-responsive one-way shape memory behaviors of poly(ethylene glycol)-based networks. Polym. Chem. 2017, 8, 3833–3840. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, W.; Zhu, S. Reversible Shape Memory Polymer from Semicrystalline Poly(ethylene-co-vinyl acetate) with Dynamic Covalent Polymer Networks. Macromolecules 2018, 51, 8956–8963. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, W.; Zhu, S. Polyolefin Thermoplastics for Multiple Shape and Reversible Shape Memory. ACS Appl. Mater. Interfaces 2017, 9, 4882–4889. [Google Scholar] [CrossRef]

- Lu, L.; Cao, J.; Li, G. A polycaprolactone-based syntactic foam with bidirectional reversible actuation. J. Appl. Polym. Sci. 2017, 134, 45225. [Google Scholar] [CrossRef]

- Pandini, S.; Dioni, D.; Paderni, K.; Messori, M.; Toselli, M.; Bontempi, E.; Riccò, T. The two-way shape memory behaviour of crosslinked poly(ε-caprolactone) systems with largely varied network density. J. Intell. Mater. Syst. Struct. 2015, 27, 1388–1403. [Google Scholar] [CrossRef]

- Pandini, S.; Passera, S.; Messori, M.; Paderni, K.; Toselli, M.; Gianoncelli, A.; Bontempi, E.; Riccò, T. Two-way reversible shape memory behaviour of crosslinked poly(ε-caprolactone). Polymer 2012, 53, 1915–1924. [Google Scholar] [CrossRef]

- Hui, J.; Xia, H.; Chen, H.; Qiu, Y.; Fu, Y.; Ni, Q.-Q.; Fu, Y. Two-way reversible shape memory polymer: Synthesis and characterization of benzoyl peroxide-crosslinked poly(ethylene-co-vinyl acetate). Mater. Lett. 2020, 258, 126762. [Google Scholar] [CrossRef]

- Stroganov, V.; Al-Hussein, M.; Sommer, J.-U.; Janke, A.; Zakharchenko, S.; Ionov, L. Reversible Thermosensitive Biodegradable Polymeric Actuators Based on Confined Crystallization. Nano Lett. 2015, 15, 1786–1790. [Google Scholar] [CrossRef]

- Ge, Q.; Westbrook, K.K.; Mather, P.T.; Dunn, A.P.M.L.; Qi, H.J. Thermomechanical behavior of a two-way shape memory composite actuator. Smart Mater. Struct. 2013, 22, 55009. [Google Scholar] [CrossRef]

- Westbrook, K.K.; Mather, P.T.; Parakh, V.; Dunn, A.P.M.L.; Ge, Q.; Lee, B.M.; Qi, H.J. Two-way reversible shape memory effects in a free-standing polymer composite. Smart Mater. Struct. 2011, 20, 65010. [Google Scholar] [CrossRef]

- Biswas, A.; Aswal, V.K.; Sastry, P.U.; Rana, D.; Maiti, P. Reversible Bidirectional Shape Memory Effect in Polyurethanes through Molecular Flipping. Macromolecules 2016, 49, 4889–4897. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, J.; Vatankhah-Varnoosfaderani, M.; Nykypanchuk, D.; Gang, O.; Sheiko, S.S. Advancing Reversible Shape Memory by Tuning the Polymer Network Architecture. Macromolecules 2016, 49, 1383–1391. [Google Scholar] [CrossRef]

- Meng, Y.; Jiang, J.; Anthamatten, M. Shape Actuation via Internal Stress-Induced Crystallization of Dual-Cure Networks. ACS Macro Lett. 2015, 4, 115–118. [Google Scholar] [CrossRef]

- Belmonte, A.F.; Lama, G.C.; Cerruti, P.; Ambrogi, V.; Fernández-Francos, X.; De La Flor, S. Motion control in free-standing shape-memory actuators. Smart Mater. Struct. 2018, 27, 075013. [Google Scholar] [CrossRef] [Green Version]

- Belmonte, A.; Lama, G.C.; Gentile, G.; Fernández-Francos, X.; De La Flor, S.; Cerruti, P.; Ambrogi, V. Synthesis and Characterization of Liquid-Crystalline Networks: Toward Autonomous Shape-Memory Actuation. J. Phys. Chem. C 2017, 121, 22403–22414. [Google Scholar] [CrossRef]

- Lama, G.C.; Cerruti, P.; Lavorgna, M.; Carfagna, C.; Ambrogi, V.; Gentile, G. Controlled Actuation of a Carbon Nanotube/Epoxy Shape-Memory Liquid Crystalline Elastomer. J. Phys. Chem. C 2016, 120, 24417–24426. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D Printing: 3D Printing of Shape Memory Polymers for Flexible Electronic Devices (Adv. Mater. 22/2016). Adv. Mater. 2016, 28, 4166. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef]

- Davidson, E.C.; Kotikian, A.; Li, S.; Aizenberg, J.; Lewis, J.A. 3D Printable and Reconfigurable Liquid Crystal Elastomers with Light-Induced Shape Memory via Dynamic Bond Exchange. Adv. Mater. 2019, 32, 1905682. [Google Scholar] [CrossRef]

- Yuan, C.; Roach, D.J.; Dunn, C.K.; Mu, Q.; Kuang, X.; Yakacki, C.M.; Wang, T.J.; Yu, K.; Qi, H.J. 3D printed reversible shape changing soft actuators assisted by liquid crystal elastomers. Soft Matter 2017, 13, 5558–5568. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Yang, Y.; Gu, K.; Amis, E.J.; Cavicchi, K.A. Digital Light Processing 3D Printing of Triple Shape Memory Polymer for Sequential Shape Shifting. ACS Mater. Lett. 2019, 1, 410–417. [Google Scholar] [CrossRef]

- Roach, D.J.; Kuang, X.; Yuan, C.; Chen, K.; Qi, H.J.; Qi, J. Novel ink for ambient condition printing of liquid crystal elastomers for 4D printing. Smart Mater. Struct. 2018, 27, 125011. [Google Scholar] [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2018, 29, 1806412. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Wang, M.; Liang, Y.; Ren, L.; Ren, L. Recent progress in 4D printing of stimuli-responsive polymeric materials. Sci. China Technol. Sci. 2019, 63, 532–544. [Google Scholar] [CrossRef]

- Yu, L.; Shahsavan, H.; Rivers, G.; Zhang, C.; Si, P.; Zhao, B. Programmable 3D Shape Changes in Liquid Crystal Polymer Networks of Uniaxial Orientation. Adv. Funct. Mater. 2018, 28, 1802809. [Google Scholar] [CrossRef]

- Hua, L.; Xie, M.; Jian, Y.; Wu, B.; Chen, C.; Zhao, C. Multiple-Responsive and Amphibious Hydrogel Actuator Based on Asymmetric UCST-Type Volume Phase Transition. ACS Appl. Mater. Interfaces 2019, 11, 43641–43648. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, Y.; Qian, X.; Chen, Q.; Wei, Y.; Ji, Y. Liquid-Crystalline Soft Actuators with Switchable Thermal Reprogrammability. Angew. Chem. 2020, 132, 4808–4814. [Google Scholar] [CrossRef]

- Cherubini, A.; Moretti, G.; Vertechy, R.; Fontana, M. Experimental characterization of thermally-activated artificial muscles based on coiled nylon fishing lines. AIP Adv. 2015, 5, 067158. [Google Scholar] [CrossRef]

- Inomata, K.; Nakagawa, K.; Fukuda, C.; Nakada, Y.; Sugimoto, H.; Nakanishi, E. Shape memory behavior of poly(methyl methacrylate)-graft-poly(ethylene glycol) copolymers. Polymer 2010, 51, 793–798. [Google Scholar] [CrossRef]

- Zhuohong, Y.; Jinlian, H.; Yeqiu, L.; Lapyan, Y. The study of crosslinked shape memory polyurethanes. Mater. Chem. Phys. 2006, 98, 368–372. [Google Scholar] [CrossRef]

- Heo, Y.; Sodano, H.A. Self-Healing Polyurethanes with Shape Recovery. Adv. Funct. Mater. 2014, 24, 5261–5268. [Google Scholar] [CrossRef]

- Kong, D.; Xiao, X. High Cycle-life Shape Memory Polymer at High Temperature. Sci. Rep. 2016, 6, 33610. [Google Scholar] [CrossRef]

- Zhao, Q.; Zou, W.; Luo, Y.; Xie, T. Shape memory polymer network with thermally distinct elasticity and plasticity. Sci. Adv. 2016, 2, e1501297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, H.; Yao, Y.; Liu, Y.; Leng, J. A dual-functional polymeric system combining shape memory with self-healing properties. Compos. Part B 2015, 83, 7–13. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, J.; Lu, H.; Bin Xu, B.; Fu, Y.; Liu, Y.; Leng, J. Thermosetting epoxy resin/thermoplastic system with combined shape memory and self-healing properties. Smart Mater. Struct. 2015, 25, 015021. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, Y.; Wang, Q.; Wang, T. Poly(vinyl butyral) based polymer networks with dual-responsive shape memory and self-healing properties. J. Mater. Chem. A 2014, 2, 9169. [Google Scholar] [CrossRef]

- Peponi, L.; Navarro-Baena, I.; Sonseca, A.; Giménez, E.; Marcos-Fernández, A.; Kenny, J.M. Synthesis and characterization of PCL–PLLA polyurethane with shape memory behavior. Eur. Polym. J. 2013, 49, 893–903. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Liu, L.-B.; Fang, W.; Qiao, C.; Li, T. Effect of hard segment architecture on shape memory properties of polycaprolactone-based polyurethane containing azobenzene. J. Mater. Sci. 2015, 51, 2727–2738. [Google Scholar] [CrossRef]

- Li, W.; Jiang, X.; Wu, R.; Wang, W. Fast shape recovery by changing the grafting ratio in polyurethane/montmorillonite–poly(methyl methacrylate) composites. Polym. J. 2016, 49, 263–271. [Google Scholar] [CrossRef]

- Ban, J.; Zhu, L.; Chen, S.; Wang, Y. The Effect of 4-Octyldecyloxybenzoic Acid on Liquid-Crystalline Polyurethane Composites with Triple-Shape Memory and Self-Healing Properties. Materials 2016, 9, 792. [Google Scholar] [CrossRef]

- Liu, C.; Chun, S.B.; Mather, P.T.; Zheng, L.; Haley, E.H.; Coughlin, E.B. Chemically Cross-Linked Polycyclooctene: Synthesis, Characterization, and Shape Memory Behavior. Macromolecules 2002, 35, 9868–9874. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, X.; Wang, M.; Ma, D.; Xu, M.; Li, F. Thermally stimulated shape-memory behavior of ethylene oxide-ethylene terephthalate segmented copolymer. J. Appl. Polym. Sci. 1997, 64, 2433–2440. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.W.; Kim, S.H.; Fang, S.; De Andrade, M.J.; Göktepe, F.; et al. Artificial Muscles from Fishing Line and Sewing Thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.H.; Song, M.G.; Jung, H.; Park, J.; Moon, H.; Koo, J.C.; Nam, J.-D.; Choi, H.R. A robotic finger driven by twisted and coiled polymer actuator. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD), Las Vegas, NV, USA, 21–24 March 2016; p. 97981J. [Google Scholar]

- Wu, L.; De Andrade, M.J.; Rome, R.S.; Haines, C.; Lima, M.D.; Baughman, R.; Tadesse, Y. Nylon-muscle-actuated robotic finger. Act. Passiv. Smart Struct. Integr. Syst. 2015, 9431, 94310. [Google Scholar] [CrossRef]

- Rehman, H.U.; Chen, Y.; Hedenqvist, M.S.; Pathan, R.; Liu, H.; Wang, H.; Chen, T.; Zhang, X.; Li, H. High-cycle-life and high-loading copolymer network with potential application as a soft actuator. Mater. Des. 2019, 182, 108010. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Deng, X.-Y.; Cheng, C.-Y.; Yang, K.-K.; Wang, Y.-Z. Reinforcement of shape-memory poly(ethylene-co-vinyl acetate) by carbon fibre to access robust recovery capability under resistant condition. Compos. Sci. Technol. 2018, 157, 202–208. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Cheng, C.-Y.; Yang, K.-K.; Wang, Y.-Z. Poly (ethylene-co-vinyl acetate)/graphene shape-memory actuator with a cyclic thermal/light dual-sensitive capacity. Compos. Sci. Technol 2019, 173, 41–46. [Google Scholar] [CrossRef]

- Gelebart, A.H.; Mulder, D.J.; Varga, M.; Konya, A.; Vantomme, G.; Meijer, E.W.; Selinger, R.L.B.; Broer, D.J.; Varga, M. Making waves in a photoactive polymer film. Nature 2017, 546, 632–636. [Google Scholar] [CrossRef] [Green Version]

- Kortekaas, L.; Browne, W.R. The evolution of spiropyran: Fundamentals and progress of an extraordinarily versatile photochrome. Chem. Soc. Rev. 2019, 48, 3406–3424. [Google Scholar] [CrossRef] [Green Version]

- Han, B.; Zhang, Y.; Zhu, L.; Li, Y.; Ma, Z.; Liu, Y.; Zhang, X.; Cao, X.; Chen, Q.-D.; Qiu, C.-W.; et al. Plasmonic-Assisted Graphene Oxide Artificial Muscles. Adv. Mater. 2018, 31, 1806386. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Sun, R.; Yin, L.; Chai, Z.; Shi, H.; Gao, M. Light-Triggered Assembly of Gold Nanoparticles for Photothermal Therapy and Photoacoustic Imaging of Tumors In Vivo. Adv. Mater. 2016, 29, 1604894. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Y.; Luo, H.; Zhu, A.; Ke, H.; Yang, H.; Chen, H. Light-Responsive Nanoparticles for Highly Efficient Cytoplasmic Delivery of Anticancer Agents. ACS Nano 2017, 11, 12134–12144. [Google Scholar] [CrossRef] [PubMed]

- Pang, X.; Lv, J.; Zhu, C.; Qin, L.; Yu, Y. Photodeformable Azobenzene-Containing Liquid Crystal Polymers and Soft Actuators. Adv. Mater. 2019, 31, e1904224. [Google Scholar] [CrossRef]

- Matějka, L.; Ilavský, M.; Dušek, K.; Wichterle, O. Photomechanical effects in crosslinked photochromic polymers. Polymer 1981, 22, 1511–1515. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Li, Q. Light-Driven Liquid Crystalline Materials: From Photo-Induced Phase Transitions and Property Modulations to Applications. Chem. Rev. 2016, 116, 15089–15166. [Google Scholar] [CrossRef]

- Rešetič, A.; Milavec, J.; Zupančič, B.; Domenici, V.; Zalar, B. Polymer-dispersed liquid crystal elastomers. Nat. Commun. 2016, 7, 13140. [Google Scholar] [CrossRef]

- Bléger, D.; Hecht, S. Visible-Light-Activated Molecular Switches. Angew. Chem. Int. Ed. 2015, 54, 11338–11349. [Google Scholar] [CrossRef]

- Ube, T.; Ikeda, T. Photomobile Polymer Materials with Complex 3D Deformation, Continuous Motions, Self-Regulation, and Enhanced Processability. Adv. Opt. Mater. 2019, 7. [Google Scholar] [CrossRef]

- Zhao, J.; Cheng, F.; Yu, Y. Light-responsive actuation materials based on the photodeformable liquid crystal polymers. In Proceedings of the SPIE Nanoscience and Engineering Conference, San Diego, CA, USA, 21–25 August 2011; p. 810705. [Google Scholar] [CrossRef]

- Dong, L.; Zhao, Y. Photothermally driven liquid crystal polymer actuators. Mater. Chem. Front. 2018, 2, 1932–1943. [Google Scholar] [CrossRef]

- Verpaalen, R.C.; Pilz da Cunha, M.; Engels, T.A.; Debije, M.G.; Schenning, A.P. Liquid crystal networks on thermoplastics; reprogrammable photo-responsive actuators. Angew. Chem. Int. Ed. 2020, 59, 4532–4536. [Google Scholar] [CrossRef] [PubMed]

- Brans, C.H. What exactly is “Mach’s Principle?”. Ann. Phys. 2012, 524, A15–A16. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Wang, W.-Y.; Yang, J.-H.; Zhang, N.; Huang, T.; Wang, Y. Excellent Electroactive Shape Memory Performance of EVA/PCL/CNT Blend Composites with Selectively Localized CNTs. J. Phys. Chem. C 2016, 120, 22793–22802. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, J.; Liu, Y.; Xu, Y.; Zhang, A. NIR–UV Responsive Actuator with Graphene Oxide/Microchannel-Induced Liquid Crystal Bilayer Structure for Biomimetic Devices. ACS Appl. Mater. Interfaces 2020, 12, 6727–6735. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Guo, S.; Tong, X.; Xia, H.; Zhao, Y. Tunable Photocontrolled Motions Using Stored Strain Energy in Malleable Azobenzene Liquid Crystalline Polymer Actuators. Adv. Mater. 2017, 29, 1606467. [Google Scholar] [CrossRef] [PubMed]

- Fleming, C.L.; Li, S.; Grøtli, M.; Andréasson, J. Shining New Light on the Spiropyran Photoswitch: A Photocage Decides between cis–trans or Spiro-Merocyanine Isomerization. J. Am. Chem. Soc. 2018, 140, 14069–14072. [Google Scholar] [CrossRef] [Green Version]

- Ge, F.; Yang, R.; Tong, X.; Camerel, F.; Zhao, Y. A Multifunctional Dye-doped Liquid Crystal Polymer Actuator: Light-Guided Transportation, Turning in Locomotion, and Autonomous Motion. Angew. Chem. 2018, 130, 11932–11937. [Google Scholar] [CrossRef]

- Brannum, M.T.; Steele, A.M.; Venetos, M.C.; Korley, L.T.J.; Wnek, G.E.; White, T.J. Light Control with Liquid Crystalline Elastomers. Adv. Opt. Mater. 2019, 7, 1801683. [Google Scholar] [CrossRef]

- Jin, B.; Song, H.; Jiang, R.; Song, J.; Zhao, Q.; Xie, T. Programming a crystalline shape memory polymer network with thermo- and photo-reversible bonds toward a single-component soft robot. Sci. Adv. 2018, 4, eaao3865. [Google Scholar] [CrossRef] [Green Version]

- Yu, Q.; Yang, X.; Chen, Y.; Yu, K.; Gao, J.; Liu, Z.; Cheng, P.; Zhang, Z.; Aguila, B.; Ma, S. Fabrication of Light-Triggered Soft Artificial Muscles via a Mixed-Matrix Membrane Strategy. Angew. Chem. Int. Ed. 2018, 57, 10192–10196. [Google Scholar] [CrossRef]

- Dicker, M.P.M.; Baker, A.B.; Iredale, R.J.; Naficy, S.; Bond, I.P.; Faul, C.; Rossiter, J.M.; Spinks, G.M.; Weaver, P.M. Light-Triggered Soft Artificial Muscles: Molecular-Level Amplification of Actuation Control Signals. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oliver, K.; Seddon, A.; Trask, R.S. Morphing in nature and beyond: A review of natural and synthetic shape-changing materials and mechanisms. J. Mater. Sci. 2016, 51, 10663–10689. [Google Scholar] [CrossRef]

- Datta, S.; Henry, T.; Hall, A.; Chattopadhyay, A. Carbon Nanotube Enhanced Shape Memory Polyurethane for Improved Mechanical Properties and Shape Recovery. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 2233. [Google Scholar]

- Kim, J.; Jeong, H.J.; Park, H.-C.; Jeong, H.; Bae, S.; Kim, B.K. Electroactive shape memory performance of polyurethane/graphene nanocomposites. React. Funct. Polym. 2015, 88, 1–7. [Google Scholar] [CrossRef]

- Gong, X.; Liu, L.; Liu, Y.; Leng, J. An electrical-heating and self-sensing shape memory polymer composite incorporated with carbon fiber felt. Smart Mater. Struct. 2016, 25, 35036. [Google Scholar] [CrossRef]

- Cheng, H.K.F.; Basu, T.; Sahoo, N.G.; Li, L.; Chan, S. Current Advances in the Carbon Nanotube/Thermotropic Main-Chain Liquid Crystalline Polymer Nanocomposites and Their Blends. Polymer 2012, 4, 889–912. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Electroactive polymers as artificial muscles—Reality and challenges. In Proceedings of the 19th AIAA Applied Aerodynamics Conference, Anaheim, CA, USA, 11–14 June 2001; p. 1492. [Google Scholar]

- Stoychev, G.V.; Ionov, L. Actuating Fibers: Design and Applications. ACS Appl. Mater. Interfaces 2016, 8, 24281–24294. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.W.; Kim, J.W.; Jung, Y.C.; Goo, N.S. Electroactive Shape-Memory Polyurethane Composites Incorporating Carbon Nanotubes. Macromol. Rapid Commun. 2005, 26, 412–416. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, C.; Hu, Y.; Cheng, H.; Shi, G.; Qu, L. A Versatile, Ultralight, Nitrogen-Doped Graphene Framework. Angew. Chem. Int. Ed. 2012, 51, 11371–11375. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Ding, C.; Wei, D.-W.; Bao, R.-Y.; Ke, K.; Liu, Z.; Yang, M.-B.; Yang, W. Electro and Light-Active Actuators Based on Reversible Shape-Memory Polymer Composites with Segregated Conductive Networks. ACS Appl. Mater. Interfaces 2019, 11, 30332–30340. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Huang, M.; Li, X.; Wang, C.; Gui, C.-X.; Yu, Z.-Z. Highly compressible anisotropic graphene aerogels fabricated by directional freezing for efficient absorption of organic liquids. Carbon 2016, 100, 456–464. [Google Scholar] [CrossRef]

- Zhou, J.; Li, H.; Liu, W.; Dugnani, R.; Tian, R.; Xue, W.; Chen, Y.; Guo, Y.; Duan, H.; Liu, H. A facile method to fabricate polyurethane based graphene foams/epoxy/carbon nanotubes composite for electro-active shape memory application. Compos. Part A 2016, 91, 292–300. [Google Scholar] [CrossRef]

- Zhan, H.; Garrett, D.J.; Apollo, N.V.; Ganesan, K.; Lau, D.; Prawer, S.; Cervenka, J. Direct fabrication of 3D graphene on nanoporous anodic alumina by plasma-enhanced chemical vapor deposition. Sci. Rep. 2016, 6, 19822. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, H.; Zeng, Q.; Zhang, Y.; Kang, H.; Duan, H.; Guo, Y.; Liu, H. Electro-active shape memory composites enhanced by flexible carbon nanotube/graphene aerogels. J. Mater. Chem. A 2015, 3, 11641–11649. [Google Scholar] [CrossRef]

- Mohan, R.; Subha, J.; Alam, J. Influence of Multiwalled Carbon Nanotubes on Biodegradable Poly(lactic acid) Nanocomposites for Electroactive Shape Memory Actuator. Adv. Polym. Technol. 2016, 37, 256–261. [Google Scholar] [CrossRef]

- Alam, J.; Khan, A.; Alam, M.; Raja, M. Electroactive Shape Memory Property of a Cu-decorated CNT Dispersed PLA/ESO Nanocomposite. Materials 2015, 8, 6391–6400. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ma, T.; Tian, W.; Ye, J.; Wang, X.; Jiang, X.; Lin, L.; Yao, Y. Electroactive shape memory properties of graphene/epoxy-cyanate ester nanocomposites. Pigment. Resin Technol. 2018, 47, 72–78. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Evaluation of the shape memory behavior of a poly(cyclooctene) based nanocomposite device. Polym. Eng. Sci. 2017, 58, 430–437. [Google Scholar] [CrossRef]

- Wang, X.; Sparkman, J.; Gou, J. Electrical actuation and shape memory behavior of polyurethane composites incorporated with printed carbon nanotube layers. Compos. Sci. Technol. 2017, 141, 8–15. [Google Scholar] [CrossRef]

- Liu, W.; Chen, H.; Ge, M.; Ni, Q.-Q.; Gao, Q. Electroactive shape memory composites with TiO2 whiskers for switching an electrical circuit. Mater. Des. 2018, 143, 196–203. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Zhang, Z.; Kong, D.; Ao, X.; Xiao, X. Electroactive High-Temperature Shape Memory Polymers with High Recovery Stress Induced by Ground Carbon Fibers. Macromol. Chem. Phys. 2019, 220. [Google Scholar] [CrossRef]

- Sun, Y.; Chu, M.; Huang, M.; Hegazi, O.; Naguib, H.E. Hybrid Electroactive Shape Memory Polymer Composites with Room Temperature Deformability. Macromol. Mater. Eng. 2019, 304, 1900196. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. High-performance robotic muscles from conductive nylon sewing thread. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 2313–2318. [Google Scholar]

- Peng, Q.; Wei, H.; Qin, Y.; Lin, Z.; Zhao, X.; Xu, F.; Leng, J.; He, X.; Cao, A.; Li, Y. Shape-memory polymer nanocomposites with a 3D conductive network for bidirectional actuation and locomotion application. Nanoscale 2016, 8, 18042–18049. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Lee, J.A.; Ambulo, C.P.; Lee, H.B.; Kim, S.H.; Naik, V.V.; Haines, C.S.; Aliev, A.E.; Ovalle-Robles, R.; Baughman, R.; et al. Intelligently Actuating Liquid Crystal Elastomer-Carbon Nanotube Composites. Adv. Funct. Mater. 2019, 29. [Google Scholar] [CrossRef]

- Sun, Y.-C.; Leaker, B.D.; Lee, J.E.; Nam, R.; Naguib, H.E. Shape programming of polymeric based electrothermal actuator (ETA) via artificially induced stress relaxation. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Jiang, Z.-C.; Tong, X.; Zhao, Y. Biomimetic Locomotion of Electrically Powered “Janus” Soft Robots Using a Liquid Crystal Polymer. Adv. Mater. 2019, 31, e1903452. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Wang, Y.; Minori, A.; Tolley, M.T.; Cai, S. Electrically controlled liquid crystal elastomer–based soft tubular actuator with multimodal actuation. Sci. Adv. 2019, 5, eaax5746. [Google Scholar] [CrossRef] [Green Version]

- Al-Rubaiai, M.; Pinto, T.; Qian, C.; Tan, X. Soft Actuators with Stiffness and Shape Modulation Using 3D-Printed Conductive Polylactic Acid Material. Soft Robot. 2019, 6, 318–332. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Chen, C.; Rehman, H.U.; Zheng, X.; Li, H.; Liu, H.; Hedenqvist, M.S. Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges. Molecules 2020, 25, 4246. https://doi.org/10.3390/molecules25184246

Chen Y, Chen C, Rehman HU, Zheng X, Li H, Liu H, Hedenqvist MS. Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges. Molecules. 2020; 25(18):4246. https://doi.org/10.3390/molecules25184246

Chicago/Turabian StyleChen, Yujie, Chi Chen, Hafeez Ur Rehman, Xu Zheng, Hua Li, Hezhou Liu, and Mikael S. Hedenqvist. 2020. "Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges" Molecules 25, no. 18: 4246. https://doi.org/10.3390/molecules25184246

APA StyleChen, Y., Chen, C., Rehman, H. U., Zheng, X., Li, H., Liu, H., & Hedenqvist, M. S. (2020). Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges. Molecules, 25(18), 4246. https://doi.org/10.3390/molecules25184246