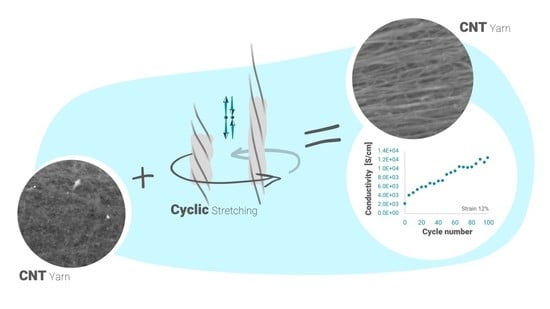

Electrical Properties Enhancement of Carbon Nanotube Yarns by Cyclic Loading

Abstract

:1. Introduction

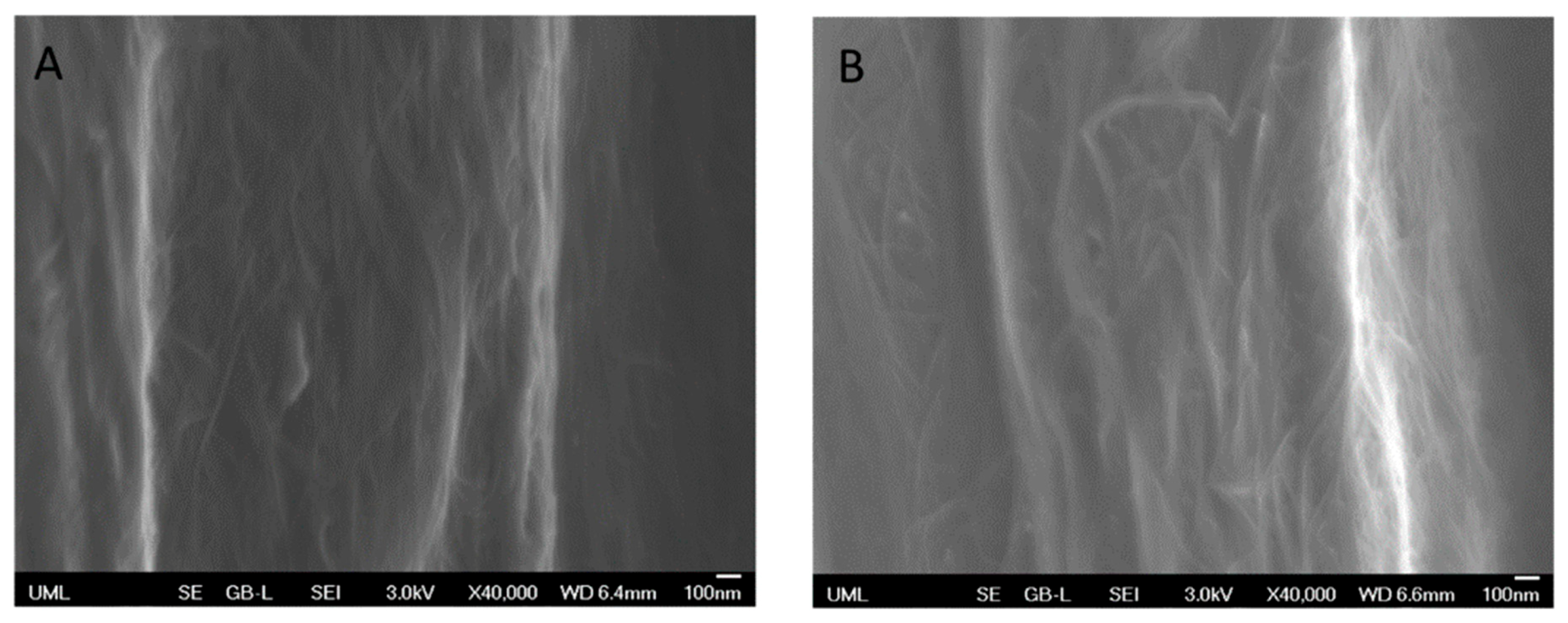

2. Experimental

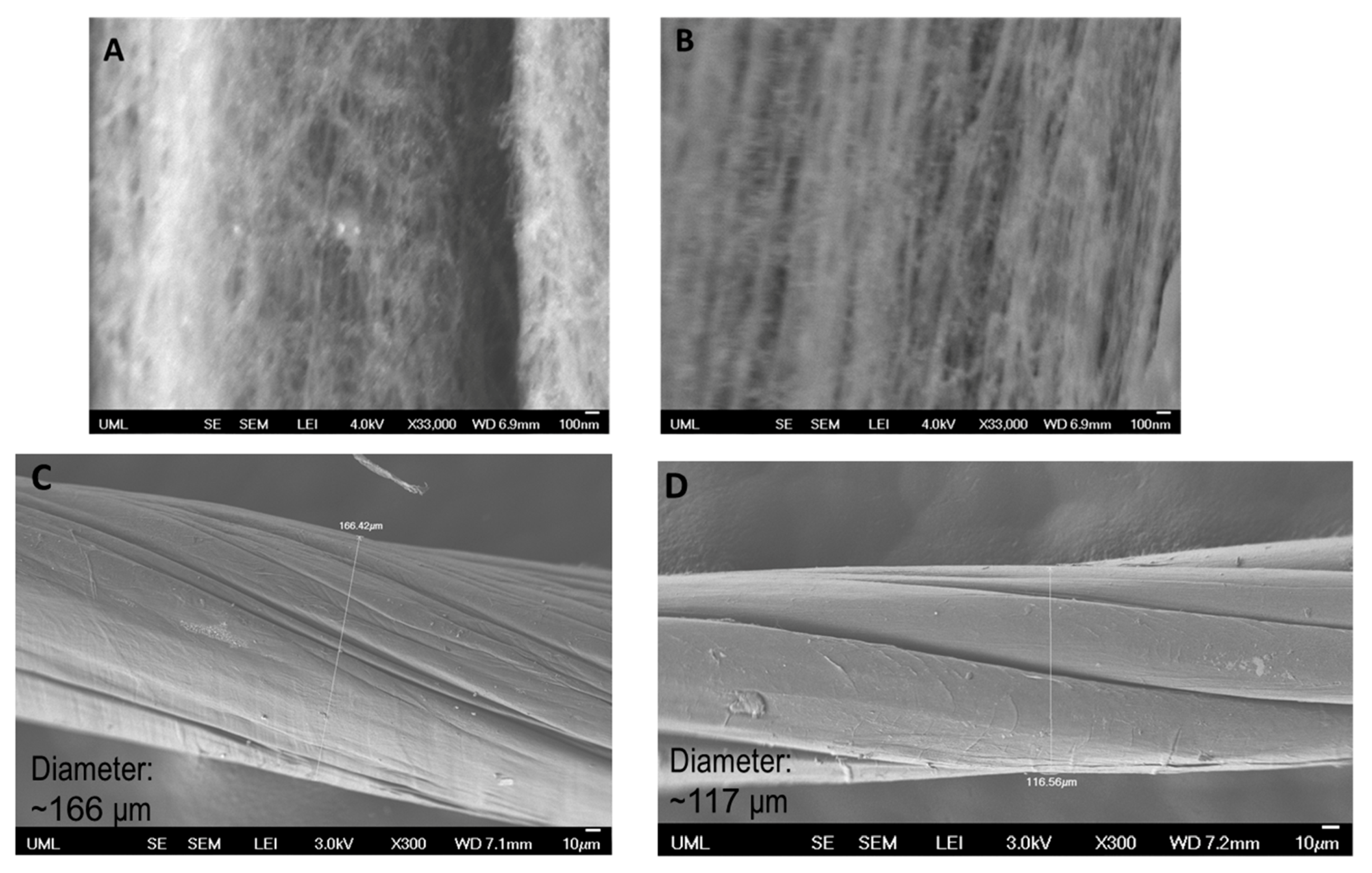

2.1. Materials

2.2. Methods

3. Results and Discussion

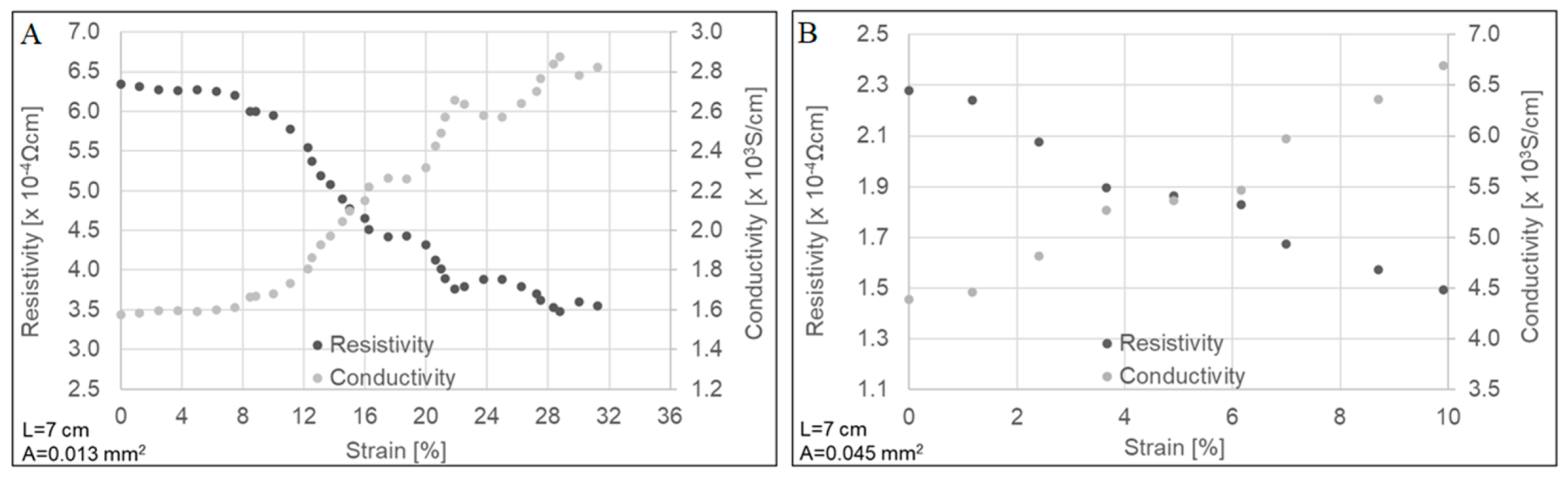

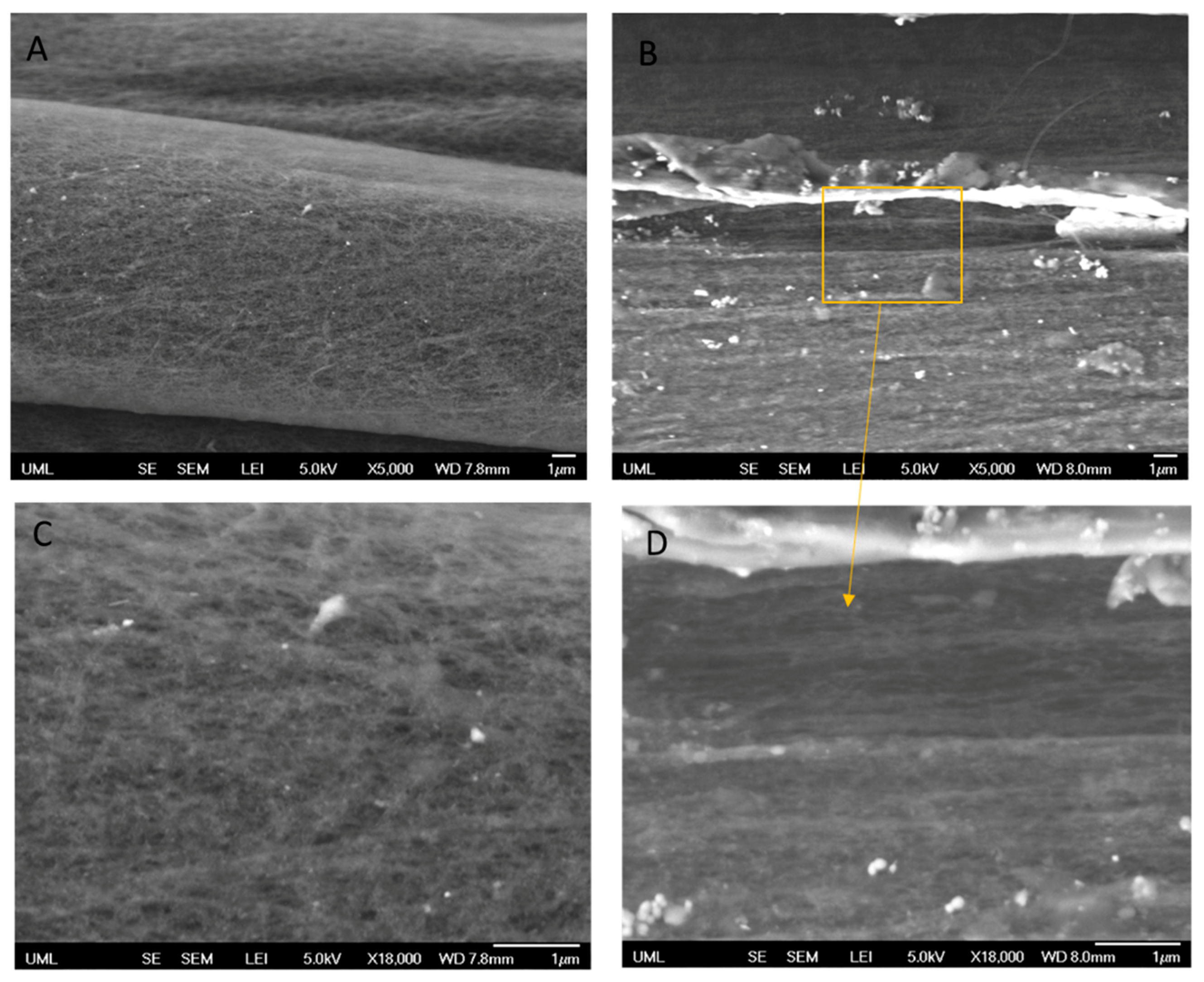

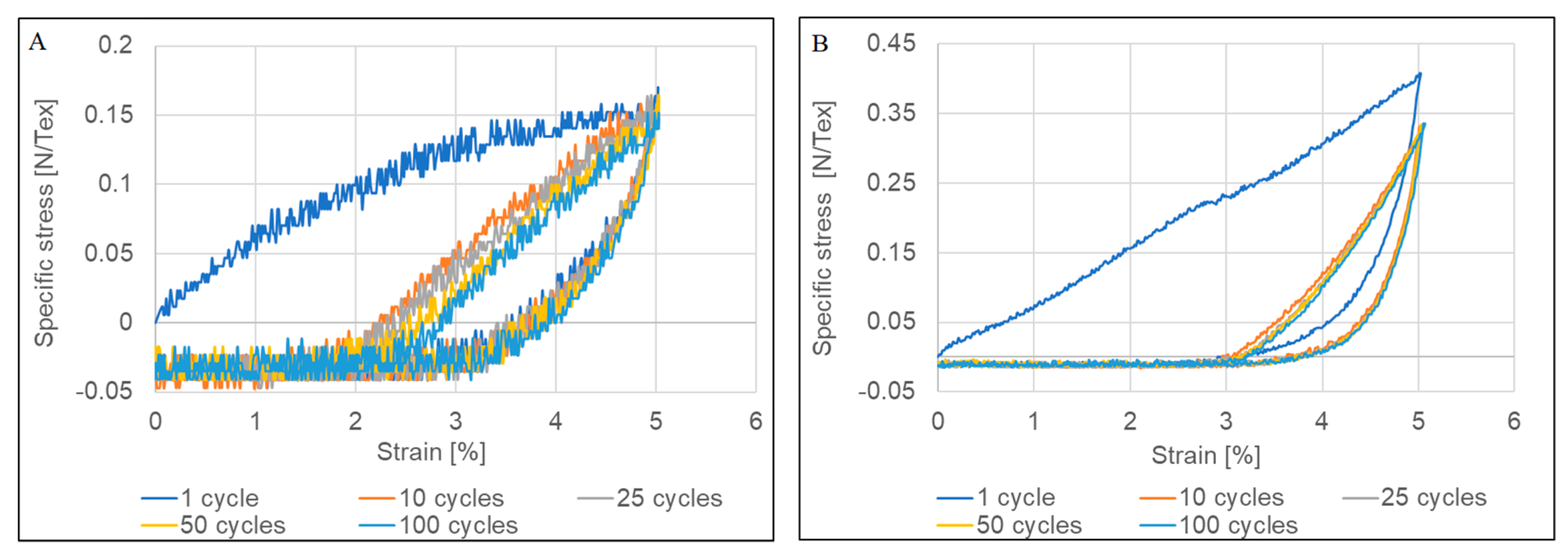

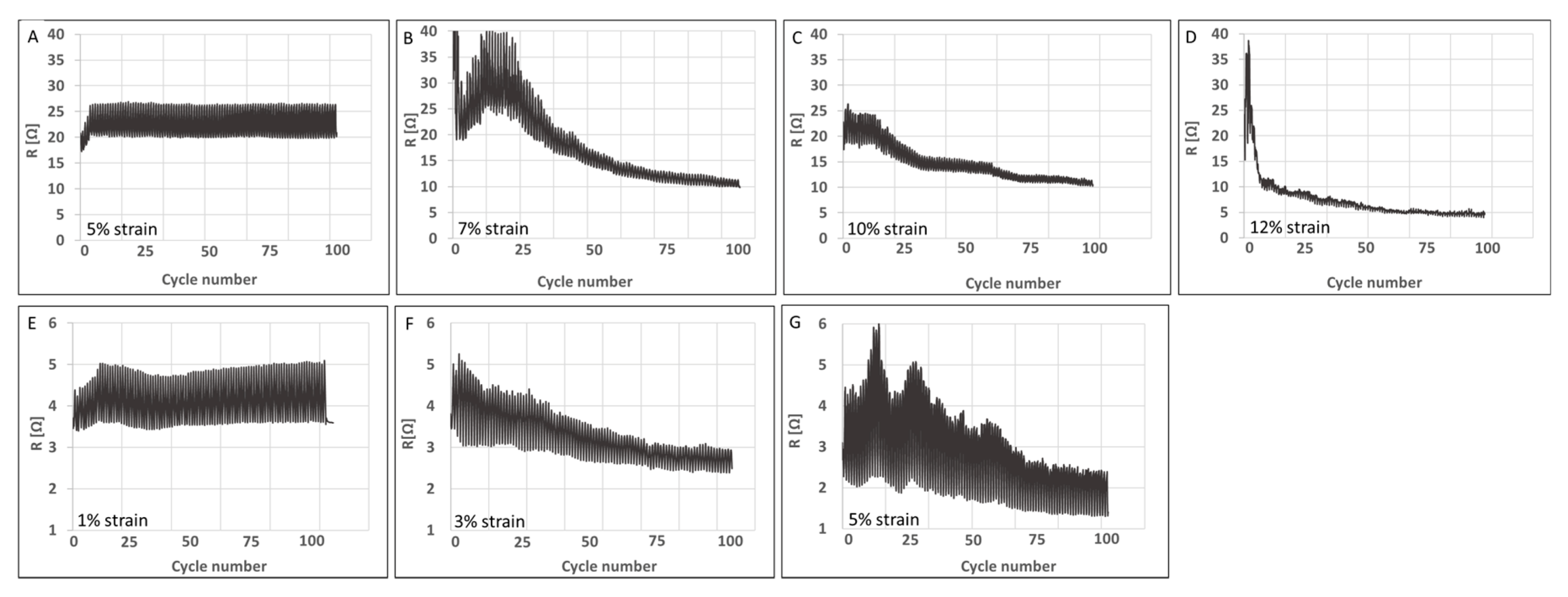

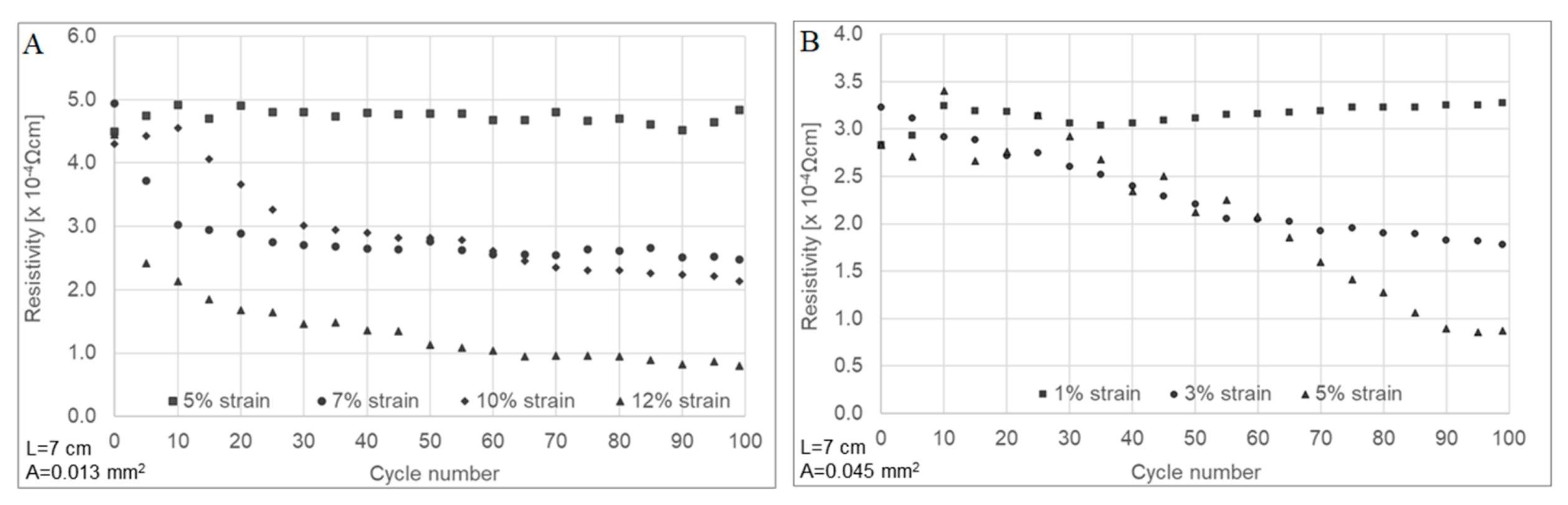

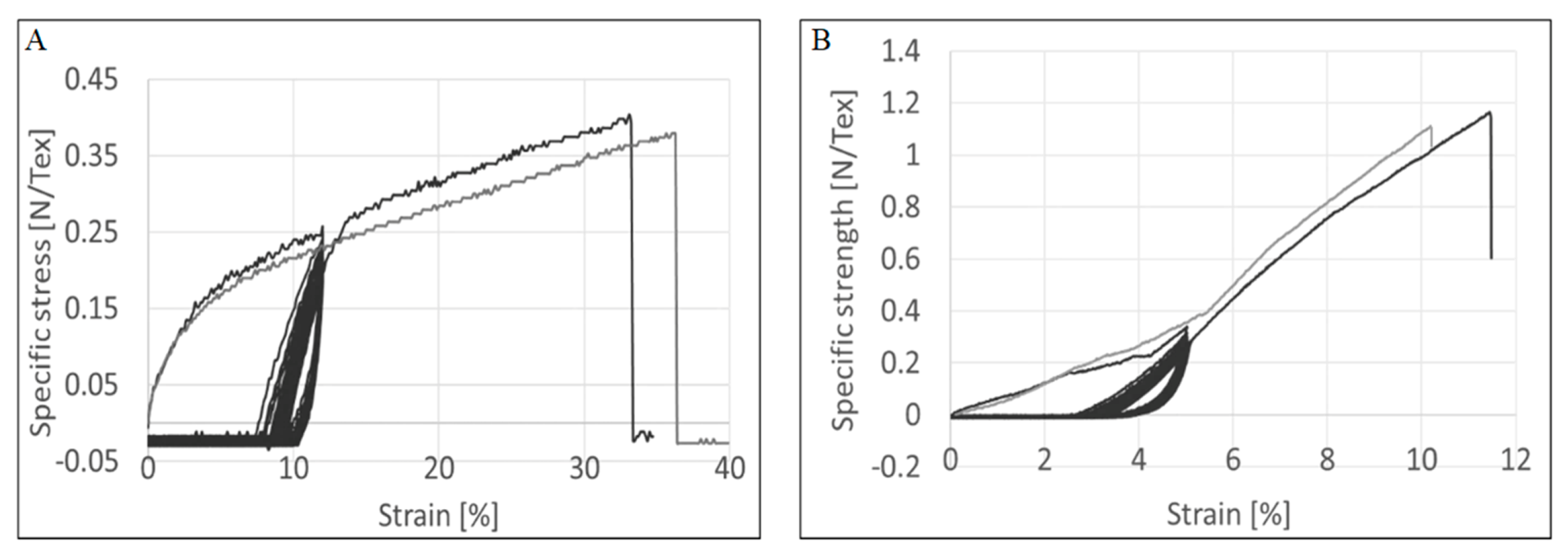

Cyclic Loading of CNTYs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cai, L.; Wang, C. Carbon Nanotube Flexible and Stretchable Electronics. Nanoscale Res. Lett. 2015, 10, 1–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mendoza, A.; Asrat, T.; Liu, F.; Wonnenberg, P.; Zestos, A.G. Carbon Nanotube Yarn Microelectrodes Promote High Temporal Measurements of Serotonin Using Fast Scan Cyclic Voltammetry. Sensors 2020, 20, 1173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mello, L.A.M.; Cardoso, V.F.; Rosa, R.L.S.; Kuebler, D.A.; Brodeur, G.E.; Alotaibi, A.H.; Coene, M.P.; Coene, L.M.; Jean, E.; Santiago, R.C.; et al. Foil Strain Gauges Using Piezoresistive Carbon. Sensors 2018, 18, 464. [Google Scholar]

- Zestos, A.G. Carbon Nanoelectrodes for the Electrochemical Detection of Neurotransmitters. Int. J. Electrochem. 2018, 2018, 3679627. [Google Scholar] [CrossRef] [Green Version]

- Raju, D.; Mendoza, A.; Sarbanes, M.; Truong, C.; Wonnenberg, P.; Mohanaraj, S.; Zestos, A.G. Polymer modified carbon fiber-microelectrodes and waveform modifications enhance neurotransmitter metabolite detection. Anal. Methods 2019, 11, 1620–1630. [Google Scholar] [CrossRef]

- Lekawa-Raus, A.; Patmore, J.; Kurzepa, L.; Bulmer, J.; Koziol, K. Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv. Funct. Mater. 2014, 24, 3661–3682. [Google Scholar] [CrossRef]

- Kuznetsov, A.A.; Fonseca, A.F.; Baughman, R.H.; Zakhidov, A.A. Structural model for dry-drawing of sheets and yarns from carbon nanotube forests. ACS Nano 2011, 5, 985–993. [Google Scholar] [CrossRef]

- Zhang, M.; Atkinson, K.R.; Baughman, R.H. Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science 2004, 306, 1358–1361. [Google Scholar] [CrossRef]

- Evora, M.C.; Lu, X.; Hiremath, N.; Kang, N.; Hong, K.; Uribe, R.; Bhat, G.; Mays, J. Single-step process to improve the mechanical properties of carbon nanotube yarn. Beilstein J. Nanotechnol. 2018, 13, 545–554. [Google Scholar] [CrossRef] [Green Version]

- Miller, S.G.; Williams, T.S.; Baker, J.S.; Solá, F.; Lebron-Colon, M.; McCorkle, L.S.; Wilmoth, N.G.; Gaier, J.; Chen, M.; Meador, M.A. Increased tensile strength of carbon nanotube yarns and sheets through chemical modification and electron beam irradiation. ACS Appl. Mater. Interfaces 2014, 6, 6120–6126. [Google Scholar] [CrossRef] [Green Version]

- Lu, X. Effect of Crosslinking on Carbon Nanotube Materials through Chemical Treatment and Irradiation. Nanotechnology 2017, 28, 14. [Google Scholar]

- Bekyarova, E.; Thostenson, E.T.; Yu, A.; Kim, H.; Gao, J.; Tang, J.; Hahn, H.T.; Chou, T.W.; Itkis, M.E.; Haddon, R.C. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites. Langmuir 2007, 23, 3970–3974. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.R.; Park, J.; Jeong, Y.; Park, J.S. Improved Mechanical and Electrical Properties of Carbon Nanotube Yarns by Wet Impregnation and Multi-ply Twisting. Fibers Polym. 2018, 19, 2478–2482. [Google Scholar] [CrossRef]

- Zhao, Y.; Wei, J.; Vajtai, R.; Ajayan, P.M.; Barrera, E.V. Iodine doped carbon nanotube cables exceeding specific electrical conductivity of metals. Sci. Rep. 2011, 1, 1–5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, K.; Sun, Y.; Zhou, R.; Zhu, H.; Wang, J.; Liu, L.; Fan, S.; Jiang, K. Carbon nanotube yarns with high tensile strength made by a twisting and shrinking method. Nanotechnology 2010, 21, 7. [Google Scholar] [CrossRef]

- Jiang, K.; Li, Q.; Fan, S. Spinning continuous carbon nanotube yarns. Nature 2002, 419, 1274014. [Google Scholar] [CrossRef] [PubMed]

- Miao, M. Particuology Yarn spun from carbon nanotube forests: Production, structure, properties and applications. Particuology 2013, 11, 378–393. [Google Scholar] [CrossRef]

- Liu, L.; Ma, W.; Zhang, Z. Macroscopic Carbon Nanotube Assemblies: Preparation, Properties, and Potential Applications. Nano Micro Small 2011, 7, 1504–1520. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Shioya, M.; Matsumoto, H.; Minagawa, M.; Tanioka, A. Structure changes during tensile deformation and mechanical properties of a twisted carbon nanotube yarn. Carbon N. Y. 2013, 60, 193–201. [Google Scholar] [CrossRef]

- Lu, W.; Zu, M.; Byun, J.H.; Kim, B.S.; Chou, T.W. State of the art of carbon nanotube fibers: Opportunities and challenges. Adv. Mater. 2012, 24, 1805–1833. [Google Scholar] [CrossRef]

- Xin, W.; Severino, J.; Venkert, A.; Yu, H.; Knorr, D.; Yang, J.; Carlson, L.; Hicks, R.; Rosa, I. De Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly (dicyclopentadiene). Nanomaterials 2020, 10, 717. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, P.; Hu, D.C.M.; Tran, T.Q.; Jewell, D.; Duong, H.M. Colloids and Surfaces A: Physicochemical and Engineering Aspects Electrical property enhancement of carbon nanotube fibers from post treatments. Colloids Surf. A Physicochem. Eng. Asp. 2016, 509, 384–389. [Google Scholar] [CrossRef]

- Schauler, M.W.; Erick, C.; Towle, R.S. Carbon Nanotubes Structures and Methods for Production Thereof. U.S. Patent WO2016126818A1, 11 August 2016. [Google Scholar]

- Singleton, J.W.; Cobb, G.R.; Misak, H.E.; Kemnitz, R.A. Quantifying the Electrical Behavior of Carbon Nanotube Sheet Enhanced with Acid Functionalization and Polymer Intercalation. Results Mater. 2020, 100059. [Google Scholar] [CrossRef]

- Weizman, J.L.O.; Mead, H.; Kenig, D.; Kenig, S. Enhancement of the Electrical Properties of Directly Spun CNT Yarns by Cyclic Loading. U.S. Patent Application No. 62,944,018, 5 December 2019. [Google Scholar]

- Miralon Yarn. Available online: https://www.miralon.com/yarn (accessed on 1 September 2020).

- Zhao, Z.L.; Zhao, H.P.; Wang, J.S.; Zhang, Z.; Feng, X.Q. Mechanical properties of carbon nanotube ropes with hierarchical helical structures. J. Mech. Phys. Solids 2014, 71, 64–83. [Google Scholar] [CrossRef]

- Li, Y.-H.; Wei, J.; Zhang, X.; Xu, C.; Wu, D.; Lu, L.; Wci, B. Mechanical and electrical properties of carbon nanotube ribbons. Chem. Phys. Lett. 2002, 365, 95–100. [Google Scholar] [CrossRef]

- Umr, L.C.; Paris, E.C. Tensile behaviour of a twisted carbon nanotube yarns. Int. J. Nanosci. 2010, 9, 69–73. [Google Scholar]

- Miao, M. Carbon Nanotube Fibres and Yarns: Production, Properties and Applications in Smart Textiles; Woodhead Publishing: Cambridge, UK, 2019; ISBN 9780081026861. [Google Scholar]

- Davis, V.A.; Ericson, L.M.; Parra-vasquez, A.N.G.; Fan, H.; Wang, Y.; Prieto, V.; Longoria, J.A.; Ramesh, S.; Saini, R.K.; Kittrell, C.; et al. Phase Behavior and Rheology of SWNTs in Superacids. Macromolecules 2004, 37, 154–160. [Google Scholar] [CrossRef]

- Talmon, Y. Direct Imaging of Carbon Nanotube Liquid-Crystalline Phase Development in True Solutions. Langmuir 2017, 33, 4011–4018. [Google Scholar]

- Zhao, H.; Zhang, Y.; Bradford, P.D.; Zhou, Q.; Jia, Q.; Yuan, F.-G.; Zhu, Y. Carbon nanotube yarn strain sensors. Nanotechnology 2010, 21, 305502. [Google Scholar] [CrossRef]

- Badaire, S.; Pichot, V.; Zakri, C.; Poulin, P.; Launois, P.; Vavro, J.; Guthy, C.; Chen, M.; Fischer, J.E.; Badaire, S.; et al. Correlation of properties with preferred orientation in coagulated and stretch-aligned single-wall carbon nanotubes. Appl. Phys. 2004, 96, 7509. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, N.T.; Miller, P.; Haase, M.R.; Lobo, R.; Malik, R.; Shanov, V. Tailoring Physical Properties of Carbon Nanotube Threads During Assembly. Carbon 2019, 144, 55–62. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress—Strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Lee, K.; Kim, K. Stress-Strain Behavior of the Electrospun Thermoplastic Polyurethane Elastomer Fiber Mats. Macromol. Res. 2005, 13, 441–445. [Google Scholar] [CrossRef]

- Sui, T.; Salvati, E.; Ying, S.; Sun, G.; Dolbnya, I.P.; Dragnevski, K.; Prisacariu, C.; Korsunsky, A.M. Strain softening of nano-scale fuzzy interfaces causes Mullins effect in thermoplastic polyurethane. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Shang, Y.; Li, Y.; He, X.; Zhang, L.; Li, Z.; Li, P.; Shi, E.; Wu, S.; Cao, A. Elastic carbon nanotube straight yarns embedded with helical loops. Nanoscale 2013, 5, 2403–2410. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Yang, Q.S.; Liu, X.; Shang, J.J. Experimental investigation on tensile properties of carbon nanotube wires. Mech. Mater. 2017, 105, 42–48. [Google Scholar] [CrossRef]

| Extension | Load | Specific Stress | Tensile Strain | |

|---|---|---|---|---|

| (mm) | (N) | (N/Tex) | (%) | |

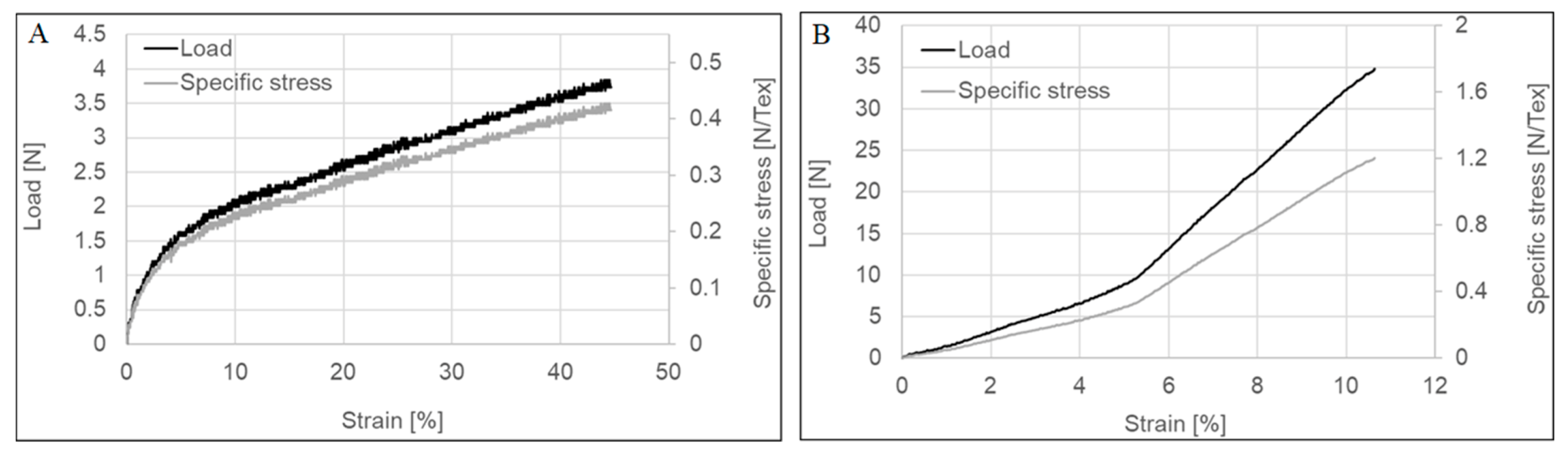

| Untreated CNTYs | 27.4 ± 0.46 | 3.8 ± 0.04 | 0.4 ± 0.01 | 45.7 ± 0.77 |

| Post treated CNTYs | 6.4 ± 0.17 | 33.8 ± 1.34 | 1.2 ± 0.05 | 10.6 ± 0.28 |

| Maximum Strain for Cyclic Stretching [%] | Apparent Young’s Modulus at the First Cycle [N/Tex] | Apparent Young’s Modulus at the 100th Cycle [N/Tex] | Specific STRESS at the first Cycle for the Max. Strain * [N/Tex] | Specific Stress at the 100th Cycle for the Max. Strain * [N/Tex] | |

|---|---|---|---|---|---|

| Untreated CNTYs | 5 | 7.38 ± 0.38 | 8.05 ± 0.58 | 0.17 ± 0.00 | 0.15 ± 0.01 |

| 7 | 8.82 ± 0.86 | 0.20 ± 0.02 | 0.22 ± 0.04 | ||

| 10 | 8.52 ± 0.22 | 0.23 ± 0.02 | 0.21 ± 0.08 | ||

| 12 | 8.60 ± 0.05 | 0.24 ± 0.01 | 0.21 ± 0.04 | ||

| Post treated CNTYs | 1 | 13.54 ± 1.22 | 14.63 ± 1.01 | 0.10 ± 0.08 | 0.14 ± 0.01 |

| 3 | 15.60 ± 0.22 | 0.27 ± 0.10 | 0.27 ± 0.10 | ||

| 5 | 16.86 ± 0.06 | 0.41 ± 0.14 | 0.36 ± 0.15 |

Sample Availability: Samples of the compounds are not available from the authors. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weizman, O.; Mead, J.; Dodiuk, H.; Kenig, S. Electrical Properties Enhancement of Carbon Nanotube Yarns by Cyclic Loading. Molecules 2020, 25, 4824. https://doi.org/10.3390/molecules25204824

Weizman O, Mead J, Dodiuk H, Kenig S. Electrical Properties Enhancement of Carbon Nanotube Yarns by Cyclic Loading. Molecules. 2020; 25(20):4824. https://doi.org/10.3390/molecules25204824

Chicago/Turabian StyleWeizman, Orli, Joey Mead, Hanna Dodiuk, and Samuel Kenig. 2020. "Electrical Properties Enhancement of Carbon Nanotube Yarns by Cyclic Loading" Molecules 25, no. 20: 4824. https://doi.org/10.3390/molecules25204824

APA StyleWeizman, O., Mead, J., Dodiuk, H., & Kenig, S. (2020). Electrical Properties Enhancement of Carbon Nanotube Yarns by Cyclic Loading. Molecules, 25(20), 4824. https://doi.org/10.3390/molecules25204824