Pyrrolidinium Containing Ionic Liquid Electrolytes for Li-Based Batteries

Abstract

:1. Introduction

2. Ionic Liquids (IL) for Energy Storage Applications

3. Overview of Ionic Liquids

4. N-ethyl-N-methylpyrrolidinium (C2mpyr)-Based ILs

4.1. PVDF-HFP/PEO Containing Polymer Electrolytes

4.2. Other Polymer Matrices

4.3. Encapsulation of Electrode Particles

4.4. Alternative Cation/Anion Combinations

5. N-propyl-N-Methylpyrrolidinium (C3mpyr)-Based ILs

5.1. Liquid Electrolyte

5.1.1. C3mpyrFSI/Cathode Compatibility

5.1.2. C3mpyrTFSI and C3mpyrFSI Electrolyte Mixtures

5.1.3. C3mpyrTFSI/Cathode Compatibility

5.1.4. Anode Compatibility

5.1.5. Full Cell Studies

5.2. Polymer Gel Analogue

5.2.1. Polymers Incorporating PVDF-HFP

5.2.2. Polymers Incorporating PEO

5.2.3. Polymers with Coagulation or Cross-Linking

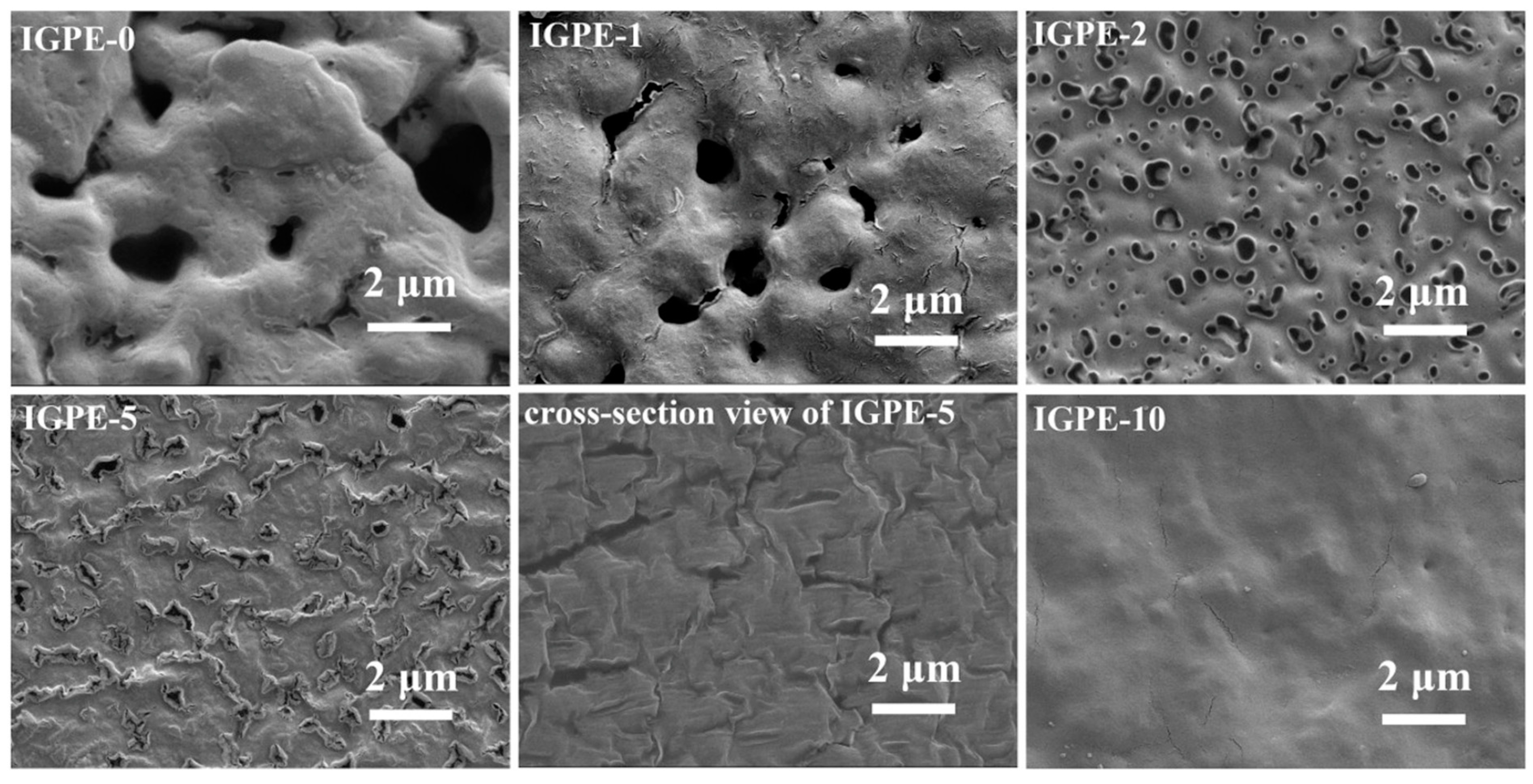

5.2.4. Polymers Incorporating Inorganic Materials

6. N-butyl-N-Methylpyrrolidinium (C4mpyr)-Based ILs

6.1. Liquid Electrolyte

6.1.1. TFSAM-Anion Studies

6.1.2. Interlayers

6.1.3. Cosolvents

6.1.4. Sole Electrolyte

6.2. Polymer Gel Analogue

6.2.1. C4mpyrFSI-Based Polymers

6.2.2. C4mpyrTFSI-Based Polymers

6.3. Full Cell Studies

6.4. Electrodeposition Medium

7. Ether Functionalized Pyrrolidinium-Based ILs

7.1. Liquid Electrolyte

7.2. Polymer Gel Analogue

8. Other Pyrrolidinium-Based ILs

9. Conclusions

Funding

Conflicts of Interest

References

- Statista. Internet of Things (IoT) Connected Devices Installed Base Worldwide from 2015 to 2025 (In Billions). Available online: https://www.statista.com/statistics/471264/iot-number-of-connected-devices-worldwide/ (accessed on 27 October 2020).

- Cook-Chennault, K.A.; Thambi, N.; Sastry, A.M. Powering MEMS portable devices—A review of non-regenerative and regenerative power supply systems with special emphasis on piezoelectric energy harvesting systems. Smart Mater. Struct. 2008, 17, 043001. [Google Scholar] [CrossRef] [Green Version]

- Gogotsi, Y.; Simon, P. True Performance Metrics in Electrochemical Energy Storage. Science 2011, 334, 917–918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.; Jiang, J.; Feng, Y.; Meng, G.; Ding, H.; Huang, X. Three-Dimensional Ni/SnOx/C Hybrid Nanostructured Arrays for Lithium-Ion Microbattery Anodes with Enhanced Areal Capacity. ACS Appl. Mater. Interfaces 2013, 5, 2634–2640. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Tian, M.; Abdulagatov, A.; George, S.M.; Lee, Y.-C.; Yang, R. Three-Dimensional Ni/TiO2 Nanowire Network for High Areal Capacity Lithium Ion Microbattery Applications. Nano Lett. 2012, 12, 655–660. [Google Scholar] [CrossRef] [PubMed]

- Barrera, P. Top Cobalt Reserves by Country. Available online: https://investingnews.com/daily/resource-investing/battery-metals-investing/cobalt-investing/cobalt-producer-cobalt-reserves/ (accessed on 10 February 2020).

- Economics, T. Cobalt 2010-2020 Data. Available online: https://tradingeconomics.com/commodity/cobalt (accessed on 10 February 2020).

- Chen, R.-J.; Zhang, Y.-B.; Liu, T.; Xu, B.-Q.; Lin, Y.-H.; Nan, C.-W.; Shen, Y. Addressing the Interface Issues in All-Solid-State Bulk-Type Lithium Ion Battery via an All-Composite Approach. ACS Appl. Mater. Interfaces 2017, 9, 9654–9661. [Google Scholar] [CrossRef]

- Hovington, P.; Lagacé, M.; Guerfi, A.; Bouchard, P.; Mauger, A.; Julien, C.M.; Armand, M.; Zaghib, K. New Lithium Metal Polymer Solid State Battery for an Ultrahigh Energy: Nano C-LiFePO4 versus Nano Li1.2V3O8. Nano Lett. 2015, 15, 2671–2678. [Google Scholar] [CrossRef]

- Porcarelli, L.; Aboudzadeh, M.A.; Rubatat, L.; Nair, J.R.; Shaplov, A.S.; Gerbaldi, C.; Mecerreyes, D. Single-ion triblock copolymer electrolytes based on poly(ethylene oxide) and methacrylic sulfonamide blocks for lithium metal batteries. J. Power Sources 2017, 364, 191–199. [Google Scholar] [CrossRef]

- Bouchet, R.; Maria, S.; Meziane, R.; Aboulaich, A.; Lienafa, L.; Bonnet, J.-P.; Phan, T.N.T.; Bertin, D.; Gigmes, D.; Devaux, D.; et al. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nat. Mater. 2013, 12, 452–457. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Mertens, A.; Tempel, H.; Schierholz, R.; Kungl, H.; Eichel, R.-A. Monolithic All-Phosphate Solid-State Lithium-Ion Battery with Improved Interfacial Compatibility. ACS Appl. Mater. Interfaces 2018, 10, 22264–22277. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Peng, G.; Mwizerwa, J.P.; Wan, H.; Cai, L.; Xu, X.; Yao, X. Nickel sulfide anchored carbon nanotubes for all-solid-state lithium batteries with enhanced rate capability and cycling stability. J. Mater. Chem. A 2018, 6, 12098–12105. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Li, X.; Yao, X.; Wang, C.; Li, Y.; Xue, W.; Yu, D.; Kim, S.Y.; Yang, F.; et al. Li metal deposition and stripping in a solid-state battery via Coble creep. Nature 2020, 578, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Hsu, S.-T.; Tran, B.T.; Subramani, R.; Nguyen, H.T.T.; Rajamani, A.; Lee, M.-Y.; Hou, S.-S.; Lee, Y.-L.; Teng, H. Free-standing polymer electrolyte for all-solid-state lithium batteries operated at room temperature. J. Power Sources 2020, 449, 227518. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, R.; He, Z.; Zhao, K.; Pan, L. Printing 3D Gel Polymer Electrolyte in Lithium-Ion Microbattery Using Stereolithography. J. Electrochem. Soc. 2017, 164, A1852–A1857. [Google Scholar] [CrossRef]

- Matsuda, Y.; Kuwata, N.; Kawamura, J. Thin-film lithium batteries with 0.3–30 μm thick LiCoO2 films fabricated by high-rate pulsed laser deposition. Solid State Ionics 2018, 320, 38–44. [Google Scholar] [CrossRef]

- Matsuda, Y.; Kuwata, N.; Okawa, T.; Dorai, A.; Kamishima, O.; Kawamura, J. In Situ Raman spectroscopy of LixCoO2 cathode in Li/Li3PO4/LiCoO2 all-solid-state thin-film lithium battery. Solid State Ionics 2019, 335, 7–14. [Google Scholar] [CrossRef]

- Honghe, Z.; Jianhua, Q.; Yang, Z.; Takeshi, A.; Zempachi, O. Temperature dependence of the electrochemical behavior of LiCoO2 in quaternary ammonium-based ionic liquid electrolyte. Solid State Ionics 2005, 176, 2219–2226. [Google Scholar] [CrossRef]

- Sakaebe, H.; Matsumoto, H.; Tatsumi, K. Discharge–charge properties of Li/LiCoO2 cell using room temperature ionic liquids (RTILs) based on quaternary ammonium cation—Effect of the structure. J. Power Sources 2005, 146, 693–697. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, H.; Fu, Y.; Abe, T.; Ogumi, Z. Temperature Effects on the Electrochemical Behavior of Spinel LiMn2O4 in Quaternary Ammonium-Based Ionic Liquid Electrolyte. J. Phys. Chem. B 2005, 109, 13676–13684. [Google Scholar] [CrossRef]

- Zheng, H.; Li, B.; Fu, Y.; Abe, T.; Ogumi, Z. Compatibility of quaternary ammonium-based ionic liquid electrolytes with electrodes in lithium ion batteries. Electrochim. Acta 2006, 52, 1556–1562. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, Y.; Dong, T.; Chen, S.; Lu, X. Triethylbutylammonium bis(trifluoromethanesulphonyl)imide ionic liquid as an effective electrolyte additive for Li-ion batteries. Ionics 2013, 19, 887–894. [Google Scholar] [CrossRef]

- Egashira, M.; Okada, S.; Yamaki, J.-i.; Dri, D.A.; Bonadies, F.; Scrosati, B. The preparation of quaternary ammonium-based ionic liquid containing a cyano group and its properties in a lithium battery electrolyte. J. Power Sources 2004, 138, 240–244. [Google Scholar] [CrossRef]

- Egashira, M.; Tanaka-Nakagawa, M.; Watanabe, I.; Okada, S.; Yamaki, J.-i. Charge–discharge and high temperature reaction of LiCoO2 in ionic liquid electrolytes based on cyano-substituted quaternary ammonium cation. J. Power Sources 2006, 160, 1387–1390. [Google Scholar] [CrossRef]

- Katayama, Y.; Yukumoto, M.; Miura, T. Electrochemical Intercalation of Lithium into Graphite in Room-Temperature Molten Salt Containing Ethylene Carbonate. Electrochem. Solid State Lett. 2003, 6, A96. [Google Scholar] [CrossRef]

- Zheng, H.; Jiang, K.; Abe, T.; Ogumi, Z. Electrochemical intercalation of lithium into a natural graphite anode in quaternary ammonium-based ionic liquid electrolytes. Carbon 2006, 44, 203–210. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, G.; Battaglia, V. Film-Forming Properties of Propylene Carbonate in the Presence of a Quaternary Ammonium Ionic Liquid on Natural Graphite Anode. J. Phys. Chem. C 2010, 114, 6182–6189. [Google Scholar] [CrossRef]

- Chakrapani, V.; Rusli, F.; Filler, M.A.; Kohl, P.A. Quaternary Ammonium Ionic Liquid Electrolyte for a Silicon Nanowire-Based Lithium Ion Battery. J. Phys. Chem. C 2011, 115, 22048–22053. [Google Scholar] [CrossRef]

- Löwe, R.; Hanemann, T.; Hofmann, A. Polymerizable Ionic Liquids for Solid-State Polymer Electrolytes. Molecules 2019, 24, 324. [Google Scholar] [CrossRef] [Green Version]

- Egashira, M.; Todo, H.; Yoshimoto, N.; Morita, M. Lithium ion conduction in ionic liquid-based gel polymer electrolyte. J. Power Sources 2008, 178, 729–735. [Google Scholar] [CrossRef]

- Ogawa, H.; Mori, H. In-situ formation of poly(ionic liquid)s with ionic liquid-based plasticizer and lithium salt in electrodes for solid-state lithium batteries. Polymer 2019, 178, 121614. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S.; Yang, J.; Wang, J.; Yao, L.; Yao, X.; Cui, P.; Xu, X. Interface Re-Engineering of Li10GeP2S12 Electrolyte and Lithium anode for All-Solid-State Lithium Batteries with Ultralong Cycle Life. ACS Appl. Mater. Interfaces 2018, 10, 2556–2565. [Google Scholar] [CrossRef]

- Xie, D.; Chen, S.; Zhang, Z.; Ren, J.; Yao, L.; Wu, L.; Yao, X.; Xu, X. High ion conductive Sb2O5-doped β-Li3PS4 with excellent stability against Li for all-solid-state lithium batteries. J. Power Sources 2018, 389, 140–147. [Google Scholar] [CrossRef]

- Teranishi, T.; Inohara, M.; Kano, J.; Hayashi, H.; Kishimoto, A.; Yoda, K.; Motobayashi, H.; Tasaki, Y. Synthesis of nano-crystalline LiNbO3-decorated LiCoO2 and resulting high-rate capabilities. Solid State Ionics 2018, 314, 57–60. [Google Scholar] [CrossRef]

- Seki, S.; Kobayashi, Y.; Miyashiro, H.; Ohno, Y.; Usami, A.; Mita, Y.; Watanabe, M.; Terada, N. Highly reversible lithium metal secondary battery using a room temperature ionic liquid/lithium salt mixture and a surface-coated cathode active material. Chem. Commun. 2006, 544–545. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Wu, F.; Mariani, A.; Passerini, S. Concentrated Ionic-Liquid-Based Electrolytes for High-Voltage Lithium Batteries with Improved Performance at Room Temperature. Chem. Sus. Chem. 2019, 12, 4185–4193. [Google Scholar] [CrossRef] [Green Version]

- Elia, G.A.; Ulissi, U.; Mueller, F.; Reiter, J.; Tsiouvaras, N.; Sun, Y.-K.; Scrosati, B.; Passerini, S.; Hassoun, J. A Long-Life Lithium Ion Battery with Enhanced Electrode/Electrolyte Interface by Using an Ionic Liquid Solution. Chem. A Eur. J. 2016, 22, 6808–6814. [Google Scholar] [CrossRef]

- Elia, G.A.; Ulissi, U.; Jeong, S.; Passerini, S.; Hassoun, J. Exceptional long-life performance of lithium-ion batteries using ionic liquid-based electrolytes. Energy Environ. Sci. 2016, 9, 3210–3220. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Yang, B.; Wang, L.; Zhang, Y.; Zhang, Z.; Fang, S.; Zhang, Z. New polymerized ionic liquid (PIL) gel electrolyte membranes based on tetraalkylammonium cations for lithium ion batteries. J. Membr. Sci. 2013, 447, 222–227. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.; Yang, B.; Du, T.; Zhang, Y. Facile preparation of polymer electrolytes based on the polymerized ionic liquid poly((4-vinylbenzyl)trimethylammonium bis(trifluoromethanesulfonylimide)) for lithium secondary batteries. Electrochim. Acta 2014, 123, 296–302. [Google Scholar] [CrossRef]

- Zhou, N.; Wang, Y.; Zhou, Y.; Shen, J.; Zhou, Y.; Yang, Y. Star-shaped multi-arm polymeric ionic liquid based on tetraalkylammonium cation as high performance gel electrolyte for lithium metal batteries. Electrochim. Acta 2019, 301, 284–293. [Google Scholar] [CrossRef]

- Sato, T.; Marukane, S.; Narutomi, T.; Akao, T. High rate performance of a lithium polymer battery using a novel ionic liquid polymer composite. J. Power Sources 2007, 164, 390–396. [Google Scholar] [CrossRef]

- Fang, S.; Qu, L.; Luo, D.; Shen, S.; Yang, L.; Hirano, S.-i. Novel mixtures of ether-functionalized ionic liquids and non-flammable methylperfluorobutylether as safe electrolytes for lithium metal batteries. RSC Adv. 2015, 5, 33897–33904. [Google Scholar] [CrossRef]

- Han, H.-B.; Liu, K.; Feng, S.-W.; Zhou, S.-S.; Feng, W.-F.; Nie, J.; Li, H.; Huang, X.-J.; Matsumoto, H.; Armand, M.; et al. Ionic liquid electrolytes based on multi-methoxyethyl substituted ammoniums and perfluorinated sulfonimides: Preparation, characterization, and properties. Electrochim. Acta 2010, 55, 7134–7144. [Google Scholar] [CrossRef]

- Fang, S.; Jin, Y.; Yang, L.; Hirano, S.-i.; Tachibana, K.; Katayama, S. Functionalized ionic liquids based on quaternary ammonium cations with three or four ether groups as new electrolytes for lithium battery. Electrochim. Acta 2011, 56, 4663–4671. [Google Scholar] [CrossRef]

- Gupta, H.; Na, S.; Balo, L.; Singh, V.K.; Singh, S.K.; Tripathi, A.K.; Verma, Y.L.; Singh, R.K. Effect of temperature on electrochemical performance of ionic liquid based polymer electrolyte with Li/LiFePO4 electrodes. Solid State Ionics 2017, 309, 192–199. [Google Scholar] [CrossRef]

- Cheng, H.; Zhu, C.; Huang, B.; Lu, M.; Yang, Y. Synthesis and electrochemical characterization of PEO-based polymer electrolytes with room temperature ionic liquids. Electrochim. Acta 2007, 52, 5789–5794. [Google Scholar] [CrossRef]

- Yang, P.; Liu, L.; Li, L.; Hou, J.; Xu, Y.; Ren, X.; An, M.; Li, N. Gel polymer electrolyte based on polyvinylidenefluoride-co-hexafluoropropylene and ionic liquid for lithium ion battery. Electrochim. Acta 2014, 115, 454–460. [Google Scholar] [CrossRef]

- Park, J.; Lee, C.; Kwon, K.; Kim, H. Electrodeposition of Silicon from 1-butyl-3-methyl-pyridinium bis(trifluromethylsulfonyl) imide ionic liquid. Int. J. Electrochem. Sci. 2013, 8, 4206–4214. [Google Scholar]

- Belhocine, T.; Forsyth, S.A.; Gunaratne, H.Q.N.; Nieuwenhuyzen, M.; Nockemann, P.; Puga, A.V.; Seddon, K.R.; Srinivasan, G.; Whiston, K. 3-Methylpiperidinium ionic liquids. Phys. Chem. Chem. Phys 2015, 17, 10398–10416. [Google Scholar] [CrossRef]

- Fang, L.; Hu, Y.; Qi, J.; Chen, Y.; Zhang, H.; Huang, H. The physical and electrochemical properties of the ionic liquids based on N-ethylpiperidinium cations and TFSI anion. Electrochim. Acta 2014, 133, 440–445. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y.H.; Shin, H.C. 1-Ethyl-1-methyl piperidinium bis(trifluoromethanesulfonyl)imide as a co-solvent in Li-ion batteries. J. Power Sources 2013, 225, 113–118. [Google Scholar] [CrossRef]

- Berger, C.A.; Ceblin, M.U.; Jacob, T. Lithium Deposition from a Piperidinium–based Ionic Liquid: Rapping Dendrites on the Knuckles. Chem. Electro. Chem. 2017, 4, 261–265. [Google Scholar] [CrossRef]

- Sakaebe, H.; Matsumoto, H. N-Methyl-N-propylpiperidinium bis(trifluoromethanesulfonyl)imide (PP13–TFSI)—Novel electrolyte base for Li battery. Electrochem. Commun. 2003, 5, 594–598. [Google Scholar] [CrossRef]

- Xu, J.; Yang, J.; NuLi, Y.; Wang, J.; Zhang, Z. Additive-containing ionic liquid electrolytes for secondary lithium battery. J. Power Sources 2006, 160, 621–626. [Google Scholar] [CrossRef]

- Liu, Q.; Su, X.; Lei, D.; Qin, Y.; Wen, J.; Guo, F.; Wu, Y.; Rong, Y.; Kou, R.; Xiao, X.; et al. Approaching the capacity limit of lithium cobalt oxide in lithium ion batteries via lanthanum and aluminium doping. Nat. Energy 2018, 3. [Google Scholar] [CrossRef]

- Sun, X.G.; Dai, S. Electrochemical investigations of ionic liquids with vinylene carbonate for applications in rechargeable lithium ion batteries. Electrochim. Acta 2010, 55, 4618–4626. [Google Scholar] [CrossRef]

- Reiter, J.; Nádherná, M.; Dominko, R. Graphite and LiCo1/3Mn1/3Ni1/3O2 electrodes with piperidinium ionic liquid and lithium bis(fluorosulfonyl)imide for Li-ion batteries. J. Power Sources 2012, 205, 402–407. [Google Scholar] [CrossRef]

- Borgel, V.; Markevich, E.; Aurbach, D.; Semrau, G.; Schmidt, M. On the application of ionic liquids for rechargeable Li batteries: High voltage systems. J. Power Sources 2009, 189, 331–336. [Google Scholar] [CrossRef]

- Solvionic. 1-Butyl-1-Methylpyrrolidinium Bis(Trifluoromethanesulfonyl)imide 99.9%. Available online: https://en.solvionic.com/products/1-butyl-1-methylpyrrolidinium-bistrifluoromethanesulfonylimide-99.9 (accessed on 27 October 2020).

- Solvionic. N-propyl-N-Methylpiperidinium Bis(trifluoromethanesulfonyl)imide 99.9%. Available online: https://en.solvionic.com/products/n-propyl-n-methylpiperidinium-bistrifluoromethanesulfonylimide-99.9 (accessed on 27 October 2020).

- Liang, F.; Yu, J.; Wang, D.; Dong, L.; Ma, C.; Chen, J.; Yang, B.; Zhu, C.; Gao, Y.; Li, C. Exceptional cycling performance of a graphite/Li1.1Ni0.25Mn0.65O2 battery at high voltage with ionic liquid-based electrolyte. Electrochim. Acta 2019, 307, 83–91. [Google Scholar] [CrossRef]

- Rangasamy, V.S.; Thayumanasundaram, S.; Locquet, J.P. Solid polymer electrolytes with poly(vinyl alcohol) and piperidinium based ionic liquid for Li-ion batteries. Solid State Ion. 2019, 333, 76–82. [Google Scholar] [CrossRef]

- Gauthier, C.; Plesse, C.; Vidal, F.; Pelletier, J.-M.; Chevrot, C.; Teyssié, D. Polybutadiene/poly(ethylene oxide) based IPNs, Part II: Mechanical modelling and LiClO4 loading as tools for IPN morphology investigation. Polymer 2007, 48, 7476–7483. [Google Scholar] [CrossRef]

- Rosol, Z.P.; German, N.J.; Gross, S.M. Solubility, ionic conductivity and viscosity of lithium salts in room temperature ionic liquids. Green Chem. 2009, 11, 1453–1457. [Google Scholar] [CrossRef]

- Selvasekarapandian, S.; Baskaran, R.; Kamishima, O.; Kawamura, J.; Hattori, T. Laser Raman and FTIR studies on Li+ interaction in PVAc–LiClO4 polymer electrolytes. Spectrochim. Acta Part A 2006, 65, 1234–1240. [Google Scholar] [CrossRef] [PubMed]

- Thayumanasundaram, S.; Rangasamy, V.S.; Seo, J.W.; Locquet, J.-P. Lithium Polymer Electrolytes Based on Sulfonated Poly(ether ether ketone) for Lithium Polymer Batteries. Eur. J. Inorg. Chem. 2015, 2015, 5395–5404. [Google Scholar] [CrossRef]

- Libo, L.; Jiesi, L.; Shuo, Y.; Shaowen, G.; Peixia, Y. Gel polymer electrolytes containing ionic liquids prepared by radical polymerization. Colloids Surf. A 2014, 459, 136–141. [Google Scholar] [CrossRef]

- Pan, X.; Liu, T.; Kautz, D.J.; Mu, L.; Tian, C.; Long, T.E.; Yang, P.; Lin, F. High-performance N-methyl-N-propylpiperidinium bis(trifluoromethanesulfonyl)imide/poly(vinylidene fluoride-hexafluoropropylene) gel polymer electrolytes for lithium metal batteries. J. Power Sources 2018, 403, 127–136. [Google Scholar] [CrossRef]

- Gao, K.; Li, S.-D. Li4Ti5O12 coated graphite anodes with piperidinium-based hybrid electrolytes for lithium ion batteries. J. Power Sources 2014, 270, 304–311. [Google Scholar] [CrossRef]

- Korf, K.S.; Lu, Y.; Kambe, Y.; Archer, L.A. Piperidinium tethered nanoparticle-hybrid electrolyte for lithium metal batteries. J. Mater. Chem. A 2014, 2, 11866–11873. [Google Scholar] [CrossRef]

- Rodrigues, M.T.F.; Kalaga, K.; Gullapalli, H.; Babu, G.; Reddy, A.L.M.; Ajayan, P.M. Hexagonal Boron Nitride-Based Electrolyte Composite for Li-Ion Battery Operation from Room Temperature to 150 °C. Adv. Energy Mater. 2016, 6. [Google Scholar] [CrossRef]

- Lu, Y.; Das, S.K.; Moganty, S.S.; Archer, L.A. Ionic Liquid-Nanoparticle Hybrid Electrolytes and their Application in Secondary Lithium-Metal Batteries. Adv. Mater. 2012, 24, 4430–4435. [Google Scholar] [CrossRef]

- Lu, Y.; Korf, K.; Kambe, Y.; Tu, Z.; Archer, L.A. Ionic-Liquid–Nanoparticle Hybrid Electrolytes: Applications in Lithium Metal Batteries. Angew. Chem. Int. Ed. 2014, 53, 488–492. [Google Scholar] [CrossRef]

- Lu, Y.; Moganty, S.S.; Schaefer, J.L.; Archer, L.A. Ionic liquid-nanoparticle hybrid electrolytes. J. Mater. Chem. 2012, 22, 4066–4072. [Google Scholar] [CrossRef]

- Ababtain, K.; Babu, G.; Lin, X.; Rodrigues, M.-T.F.; Gullapalli, H.; Ajayan, P.M.; Grinstaff, M.W.; Arava, L.M.R. Ionic Liquid–Organic Carbonate Electrolyte Blends To Stabilize Silicon Electrodes for Extending Lithium Ion Battery Operability to 100 °C. ACS Appl. Mater. Interfaces 2016, 8, 15242–15249. [Google Scholar] [CrossRef] [PubMed]

- Tong, J.; Wu, S.; von Solms, N.; Liang, X.; Huo, F.; Zhou, Q.; He, H.; Zhang, S. The Effect of Concentration of Lithium Salt on the Structural and Transport Properties of Ionic Liquid-Based Electrolytes. Front. Chem. 2020, 7. [Google Scholar] [CrossRef] [PubMed]

- Kamiyama, Y.; Shibata, M.; Kanzaki, R.; Fujii, K. Lithium-ion coordination-induced conformational change of PEG chains in ionic-liquid-based electrolytes. Phys. Chem. Chem. Phys 2020, 22, 5561–5567. [Google Scholar] [CrossRef] [PubMed]

- Sayah, S.; Ghamouss, F.; Santos-Pena, J.; Tran-Van, F.; Lemordant, D. The Intriguing Properties of 1-Ethyl-3-methylimidazolium bis(fluorosulfonyl)imide Ionic Liquid. J. Solut. Chem. 2019, 48, 992–1008. [Google Scholar] [CrossRef]

- Yambou, E.P.; Gorska, B.; Béguin, F. Binary mixtures of ionic liquids based on EMIm cation and fluorinated anions: Physico-chemical characterization in view of their application as low-temperature electrolytes. J. Mol. Liq. 2020, 298, 111959. [Google Scholar] [CrossRef]

- Seki, S.; Kobayashi, Y.; Miyashiro, H.; Ohno, Y.; Usami, A.; Mita, Y.; Kihira, N.; Watanabe, M.; Terada, N. Lithium Secondary Batteries Using Modified-Imidazolium Room-Temperature Ionic Liquid. J. Phys. Chem. B 2006, 110, 10228–10230. [Google Scholar] [CrossRef]

- Yamagata, M.; Tanaka, K.; Tsuruda, Y.; Sone, Y.; Fukuda, S.; Nakasuka, S.; Kono, M.; Ishikawa, M. The First Lithium-ion Battery with Ionic Liquid Electrolyte Demonstrated in Extreme Environment of Space. Electrochemistry 2015, 83, 918–924. [Google Scholar] [CrossRef] [Green Version]

- Balo, L.; Gupta, H.; Singh, S.K.; Singh, V.K.; Tripathi, A.K.; Srivastava, N.; Tiwari, R.K.; Mishra, R.; Meghnani, D.; Singh, R.K. Development of gel polymer electrolyte based on LiTFSI and EMIMFSI for application in rechargeable lithium metal battery with GO-LFP and NCA cathodes. J. Solid State Electrochem. 2019, 23, 2507–2518. [Google Scholar] [CrossRef]

- Egashira, M.; Kanetomo, A.; Yoshimoto, N.; Morita, M. Charge-discharge rate of spinel lithium manganese oxide and olivine lithium iron phosphate in ionic liquid-based electrolytes. J. Power Sources 2011, 196, 6419–6424. [Google Scholar] [CrossRef]

- Le, L.T.M.; Vo, T.D.; Ngo, K.H.P.; Okada, S.; Alloin, F.; Garg, A.; Le, P.M.L. Mixing ionic liquids and ethylene carbonate as safe electrolytes for lithium-ion batteries. J. Mol. Liq. 2018, 271, 769–777. [Google Scholar] [CrossRef]

- Karuppasamy, K.; Vikraman, D.; Hwang, I.-T.; Kim, H.-J.; Nichelson, A.; Bose, R.; Kim, H.-S. Nonaqueous liquid electrolytes based on novel 1-ethyl-3-methylimidazolium bis (nonafluorobutane-1-sulfonyl imidate) ionic liquid for energy storage devices. J. Mater. Res. Technol. 2020, 9, 1251–1260. [Google Scholar] [CrossRef]

- Singh, S.K.; Na, S.; Balo, L.; Gupta, H.; Singh, V.K.; Tripathi, A.K.; Verma, Y.L.; Singh, R.K. Improved electrochemical performance of EMIMFSI ionic liquid based gel polymer electrolyte with temperature for rechargeable lithium battery. Energy 2018, 150, 890–900. [Google Scholar] [CrossRef]

- Yang, P.; Cui, W.; Li, L.; Liu, L.; An, M. Characterization and properties of ternary P(VdF-HFP)-LiTFSI-EMITFSI ionic liquid polymer electrolytes. Solid State Sci. 2012, 14, 598–606. [Google Scholar] [CrossRef]

- Tseng, Y.-C.; Wu, Y.; Tsao, C.-H.; Teng, H.; Hou, S.-S.; Jan, J.-S. Polymer electrolytes based on Poly(VdF-co-HFP)/ionic liquid/carbonate membranes for high-performance lithium-ion batteries. Polymer 2019, 173, 110–118. [Google Scholar] [CrossRef]

- Liao, Y.; Li, G.; Xu, N.; Chen, T.; Wang, X.; Li, W. Synergistic effect of electrolyte additives on the improvement in interfacial stability between ionic liquid based gel electrolyte and LiFePO4 cathode. Solid State Ion. 2019, 329, 31–39. [Google Scholar] [CrossRef]

- Safa, M.; Chamaani, A.; Chawla, N.; El-Zahab, B. Polymeric Ionic Liquid Gel Electrolyte for Room Temperature Lithium Battery Applications. Electrochim. Acta 2016, 213, 587–593. [Google Scholar] [CrossRef]

- Safa, M.; Adelowo, E.; Chamaani, A.; Chawla, N.; Baboukani, A.R.; Herndon, M.; Wang, C.; El-Zahab, B. Poly(Ionic Liquid)-Based Composite Gel Electrolyte for Lithium Batteries. Chem. Electro. Chem. 2019, 6, 3319–3326. [Google Scholar] [CrossRef]

- Ui, K.; Minami, T.; Ishikawa, K.; Idemoto, Y.; Koura, N. Development of non-flammable lithium secondary battery with ambient-temperature molten salt electrolyte: Performance of binder-free carbon-negative electrode. J. Power Sources 2005, 146, 698–702. [Google Scholar] [CrossRef]

- Yamagata, M.; Nishigaki, N.; Nishishita, S.; Matsui, Y.; Sugimoto, T.; Kikuta, M.; Higashizaki, T.; Kono, M.; Ishikawa, M. Charge–discharge behavior of graphite negative electrodes in bis(fluorosulfonyl)imide-based ionic liquid and structural aspects of their electrode/electrolyte interfaces. Electrochim. Acta 2013, 110, 181–190. [Google Scholar] [CrossRef]

- Matsui, Y.; Yamagata, M.; Murakami, S.; Saito, Y.; Higashizaki, T.; Ishiko, E.; Kono, M.; Ishikawa, M. Design of an electrolyte composition for stable and rapid charging–discharging of a graphite negative electrode in a bis(fluorosulfonyl)imide-based ionic liquid. J. Power Sources 2015, 279, 766–773. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Domi, Y.; Usui, H.; Shimizu, M.; Morishita, S.; Yodoya, S.; Sakata, T.; Sakaguchi, H. Effect of Film-Forming Additive in Ionic Liquid Electrolyte on Electrochemical Performance of Si Negative-Electrode for LIBs. J. Electrochem. Soc. 2019, 166, A268–A276. [Google Scholar] [CrossRef] [Green Version]

- Chapman Varela, J.; Sankar, K.; Hino, A.; Lin, X.; Chang, W.-S.; Coker, D.; Grinstaff, M. Piperidinium ionic liquids as electrolyte solvents for sustained high temperature supercapacitor operation. Chem. Commun. 2018, 54, 5590–5593. [Google Scholar] [CrossRef] [PubMed]

- Galiński, M.; Lewandowski, A.; Stępniak, I. Ionic liquids as electrolytes. Electrochim. Acta 2006, 51, 5567. [Google Scholar]

- Sakaebe, H.; Matsumoto, H.; Tatsumi, K. Application of room temperature ionic liquids to Li batteries. Electrochim. Acta 2007, 53, 1048–1054. [Google Scholar] [CrossRef]

- Mun, J.; Jung, Y.S.; Yim, T.; Lee, H.Y.; Kim, H.J.; Kim, Y.G.; Oh, S.M. Electrochemical stability of bis(trifluoromethanesulfonyl)imide-based ionic liquids at elevated temperature as a solvent for a titanium oxide bronze electrode. J. Power Sources 2009, 194, 1068–1074. [Google Scholar] [CrossRef]

- Liu, K.; Zhou, Y.X.; Han, H.B.; Zhou, S.S.; Feng, W.F.; Nie, J.; Li, H.; Huang, X.J.; Armand, M.; Zhou, Z.B. Ionic liquids based on (fluorosulfonyl)(pentafluoroethanesulfonyl)imide with various oniums. Electrochim. Acta 2010, 55, 7145–7151. [Google Scholar] [CrossRef]

- Nguyen, D.Q.; Hwang, J.; Lee, J.S.; Kim, H.; Lee, H.; Cheong, M.; Lee, B.; Kim, H.S. Multi-functional zwitterionic compounds as additives for lithium battery electrolytes. Electrochem. Commun. 2007, 9, 109–114. [Google Scholar] [CrossRef]

- Dong, T.; Zhang, L.; Chen, S.; Lu, X.; Zhang, S. A piperidinium-based ionic liquid electrolyte to enhance the electrochemical properties of LiFePO4 battery. Ionics 2015, 21, 2109–2117. [Google Scholar] [CrossRef]

- Bucher, N.; Hartung, S.; Arkhipova, M.; Yu, D.; Kratzer, P.; Maas, G.; Srinivasan, M.; Hoster, H.E. A novel ionic liquid for Li ion batteries-uniting the advantages of guanidinium and piperidinium cations. RSC Adv. 2014, 4, 1996–2003. [Google Scholar] [CrossRef]

- Elamin, K.; Shojaatalhosseini, M.; Danyliv, O.; Martinelli, A.; Swenson, J. Conduction mechanism in polymeric membranes based on PEO or PVdF-HFP and containing a piperidinium ionic liquid. Electrochim. Acta 2019, 299, 979–986. [Google Scholar] [CrossRef]

- Vélez, J.F.; Vázquez-Santos, M.B.; Amarilla, J.M.; Herradón, B.; Mann, E.; del Río, C.; Morales, E. Geminal pyrrolidinium and piperidinium dicationic ionic liquid electrolytes. Synthesis, characterization and cell performance in LiMn2O4 rechargeable lithium cells. J. Power Sources 2019, 439, 227098. [Google Scholar] [CrossRef]

- Liu, S.; Liedel, C.; Tarakina, N.V.; Osti, N.C.; Akcora, P. Dynamics of ionic liquids in the presence of polymer-grafted nanoparticles. Nanoscale 2019, 11, 19832–19841. [Google Scholar] [CrossRef]

- Morales-Ugarte, J.E.; Benayad, A.; Santini, C.C.; Bouchet, R. Electrochemical Impedance Spectroscopy and X-ray Photoelectron Spectroscopy Study of Lithium Metal Surface Aging in Imidazolium-Based Ionic Liquid Electrolytes Performed at Open-Circuit Voltage. ACS Appl. Mater. Interfaces 2019, 11, 21955–21964. [Google Scholar] [CrossRef] [PubMed]

- Vallet, P.; Parajó, J.J.; Sotuela, F.; López, M.V.; Cabeza, Ó.; Varela, L.M.; Salgado, J. Comparison of the Ionic Conductivity of Pure Imidazolium Nitrate and That Doped with a Lithium Nitrate Salt in Liquid and Gel Forms as Potential Electrolytes. Proceedings 2019, 41, 56. [Google Scholar] [CrossRef] [Green Version]

- Ge, J.; Liang, H.; Zhou, M.; Zhao, C.; Zheng, Z.; Yan, Y.; Zhao, L.; Tang, K. Phosphonate-functionalized Ionic Liquid: A Novel Electrolyte Additive for Eenhanced Cyclic Stability and Rate Capability of LiCoO2 Cathode at High Voltage. Chem. Sel. 2019, 4, 9959–9965. [Google Scholar] [CrossRef]

- Chen, N.; Guan, Y.; Shen, J.; Guo, C.; Qu, W.; Li, Y.; Wu, F.; Chen, R. Heteroatom Si Substituent Imidazolium-Based Ionic Liquid Electrolyte Boosts the Performance of Dendrite-Free Lithium Batteries. ACS Appl. Mater. Interfaces 2019, 11, 12154–12160. [Google Scholar] [CrossRef]

- Bose, P.; Deb, D.; Bhattacharya, S. Lithium-polymer battery with ionic liquid tethered nanoparticles incorporated P(VDF-HFP) nanocomposite gel polymer electrolyte. Electrochim. Acta 2019, 319, 753–765. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, X.; Zhou, Q.; Li, X.; Zhang, X.; Li, S. Ionic Liquids: Physicochemical Properties; Elsevier Science: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Fernández-Miguez, L.; Vallet, P.; Tasende-Rodríguez, L.C.; Doval, A.; Villanueva, M.; Cabeza, Ó.; Varela, L.M.; Salgado, J.; Parajó, J.J. Thermophysical Characterization of TFSI Based Ionic Liquid and Lithium Salt Mixtures. Proceedings 2019, 41, 57. [Google Scholar] [CrossRef] [Green Version]

- Eftekhari, A. Comment on “A Linear Actuation of Polymeric Nanofibrous Bundle for Artificial Muscles”. Chem. Mater. 2010, 22, 2689–2690. [Google Scholar] [CrossRef]

- Eftekhari, A. Comments on “Li diffusion in LiNi0.5Mn0.5O2 thin film electrodes prepared by pulsed laser deposition” by Xia et al. Electrochim. Acta 2010, 55, 3434. [Google Scholar] [CrossRef]

- Eftekhari, A. Comment on “Carbon nanowalls as material for electrochemical transducers” [Appl. Phys. Lett. 95, 014104 (2009)]. Appl. Phys. Lett. 2010, 96, 126102. [Google Scholar] [CrossRef] [Green Version]

- Endres, F.; Höfft, O.; Borisenko, N.; Gasparotto, L.H.; Prowald, A.; Al-Salman, R.; Carstens, T.; Atkin, R.; Bund, A.; Zein El Abedin, S. Do solvation layers of ionic liquids influence electrochemical reactions? Phys. Chem. Chem. Phys 2010, 12, 1724–1732. [Google Scholar] [CrossRef] [PubMed]

- Hollóczki, O.; Malberg, F.; Welton, T.; Kirchner, B. On the origin of ionicity in ionic liquids. Ion pairing versus charge transfer. Phys. Chem. Chem. Phys 2014, 16, 16880–16890. [Google Scholar] [CrossRef]

- Katsuta, S.; Imai, K.; Kudo, Y.; Takeda, Y.; Seki, H.; Nakakoshi, M. Ion Pair Formation of Alkylimidazolium Ionic Liquids in Dichloromethane. J. Chem. Eng. Data 2008, 53, 1528–1532. [Google Scholar] [CrossRef]

- Kirchner, B.; Malberg, F.; Firaha, D.S.; Hollóczki, O. Ion pairing in ionic liquids. J. Phys. Condens. Matter 2015, 27, 463002. [Google Scholar] [CrossRef]

- Ma, K.; Forsman, J.; Woodward, C.E. Influence of ion pairing in ionic liquids on electrical double layer structures and surface force using classical density functional approach. J. Chem. Phys. 2015, 142, 174704. [Google Scholar] [CrossRef]

- Zhao, W.; Leroy, F.; Heggen, B.; Zahn, S.; Kirchner, B.; Balasubramanian, S.; Müller-Plathe, F. Are There Stable Ion-Pairs in Room-Temperature Ionic Liquids? Molecular Dynamics Simulations of 1-n-Butyl-3-methylimidazolium Hexafluorophosphate. J. Am. Chem. Soc. 2009, 131, 15825–15833. [Google Scholar] [CrossRef]

- Eftekhari, A.; Liu, Y.; Chen, P. Different roles of ionic liquids in lithium batteries. J. Power Sources 2016, 334, 221–239. [Google Scholar] [CrossRef]

- Sun, L.; Morales-Collazo, O.; Xia, H.; Brennecke, J.F. Effect of Structure on Transport Properties (Viscosity, Ionic Conductivity, and Self-Diffusion Coefficient) of Aprotic Heterocyclic Anion (AHA) Room-Temperature Ionic Liquids. 1. Variation of Anionic Species. J. Phys. Chem. B 2015, 119, 15030–15039. [Google Scholar] [CrossRef] [PubMed]

- Hayyan, M.; Mjalli, F.S.; Hashim, M.A.; AlNashef, I.M.; Mei, T.X. Investigating the electrochemical windows of ionic liquids. J. Ind. Eng. Chem. 2013, 19, 106–112. [Google Scholar] [CrossRef]

- Eshetu, G.G.; Grugeon, S.; Laruelle, S.; Boyanov, S.; Lecocq, A.; Bertrand, J.-P.; Marlair, G. In-depth safety-focused analysis of solvents used in electrolytes for large scale lithium ion batteries. Phys. Chem. Chem. Phys 2013, 15, 9145–9155. [Google Scholar] [CrossRef] [PubMed]

- Wasserscheid, P.; Welton, T. Outlook. In Ionic Liquids in Synthesis; Wiley-VCH: Weinheim, Germany, 2008; Volume 1, pp. 348–355. [Google Scholar]

- Balducci, A. Ionic Liquids in Lithium-Ion Batteries. Top. Curr. Chem. 2017, 375, 20. [Google Scholar] [CrossRef] [PubMed]

- Kirchner, B.; di Dio, P.J.; Hutter, J. Real-World Predictions from Ab Initio Molecular Dynamics Simulations. In Multiscale Molecular Methods in Applied Chemistry; Kirchner, B., Vrabec, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 109–153. [Google Scholar]

- Arnaiz, M.; Huang, P.; Ajuria, J.; Rojo, T.; Goikolea, E.; Balducci, A. Protic and Aprotic Ionic Liquids in Combination with Hard Carbon for Lithium-Ion and Sodium-Ion Batteries. Batter. Supercaps 2018, 1, 204–208. [Google Scholar] [CrossRef]

- Fleshman, A.M.; Mauro, N.A. Temperature-dependent structure and transport of ionic liquids with short-and intermediate-chain length pyrrolidinium cations. J. Mol. Liq. 2019, 279, 23–31. [Google Scholar] [CrossRef]

- Domańska, U.; Królikowska, M.; Paduszyński, K. Physico-chemical properties and phase behaviour of piperidinium-based ionic liquids. Fluid Phase Equilib. 2011, 303, 1–9. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, X.; Zhu, H.; Armand, M.; Forsyth, M.; Greene, G.W.; Pringle, J.M.; Howlett, P.C. N-ethyl-N-methylpyrrolidinium bis(fluorosulfonyl)imide-electrospun polyvinylidene fluoride composite electrolytes: Characterization and lithium cell studies. Phys. Chem. Chem. Phys 2017, 19, 2225–2234. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, X.; Zhu, H.; Yoshizawa-Fujita, M.; Miyachi, Y.; Armand, M.; Forsyth, M.; Greene, G.W.; Pringle, J.M.; Howlett, P.C. Solid-State Lithium Conductors for Lithium Metal Batteries Based on Electrospun Nanofiber/Plastic Crystal Composites. Chem. Sus. Chem. 2017, 10, 3135–3145. [Google Scholar] [CrossRef]

- Choi, J.; Manthiram, A. Role of Chemical and Structural Stabilities on the Electrochemical Properties of Layered LiNi1/3Mn1/3Co1/3O2 Cathodes. J. Electrochem. Soc. 2005, 152, A1714. [Google Scholar] [CrossRef]

- Ohno, H.; Ito, K. Room-Temperature Molten Salt Polymers as a Matrix for Fast Ion Conduction. Chem. Lett. 1998, 27, 751–752. [Google Scholar] [CrossRef]

- Shaplov, A.S.; Marcilla, R.; Mecerreyes, D. Recent Advances in Innovative Polymer Electrolytes based on Poly(ionic liquid)s. Electrochim. Acta 2015, 175, 18–34. [Google Scholar] [CrossRef]

- Li, X.W.; Zhang, Z.X.; Li, S.J.; Yang, K.H.; Yang, L. Polymeric ionic liquid-ionic plastic crystal all-solid-state electrolytes for wide operating temperature range lithium metal batteries. J. Mater. Chem. A 2017, 5, 21362–21369. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Yamada, H.; Takeoka, Y.; Rikukawa, M.; Yoshizawa-Fujita, M. Synthesis of pyrrolidinium-based plastic crystals exhibiting high ionic conductivity at ambient temperature. New J. Chem. 2019, 43, 4008–4012. [Google Scholar] [CrossRef]

- Yoshizawa-Fujita, M.; Kishi, E.; Suematsu, M.; Takekawa, T.; Rikukawa, M. A Plastic Electrolyte Material in a Highly Desirable Temperature Range: N-Ethyl-N-methylpyrrolidinium Bis(fluorosulfonyl)amide. Chem. Lett. 2014, 43, 1909–1911. [Google Scholar] [CrossRef]

- Janikowski, J.; Razali, M.R.; Forsyth, C.M.; Nairn, K.M.; Batten, S.R.; MacFarlane, D.R.; Pringle, J.M. Physical Properties and Structural Characterization of Ionic Liquids and Solid Electrolytes Utilizing the Carbamoylcyano(nitroso)methanide Anion. ChemPlusChem 2013, 78, 486–497. [Google Scholar] [CrossRef]

- Hill, A.J.; Huang, J.; Efthimiadis, J.; Meakin, P.; Forsyth, M.; MacFarlane, D.R. Microstructural and molecular level characterisation of plastic crystal phases of pyrrolidinium trifluoromethanesulfonyl salts. Solid State Ionics 2002, 154–155, 119–124. [Google Scholar] [CrossRef] [Green Version]

- MacFarlane, D.R.; Meakin, P.; Amini, N.; Forsyth, M. Structural studies of ambient temperature plastic crystal ion conductors. J. Phys. Condens. Matter 2001, 13, 8257–8267. [Google Scholar] [CrossRef]

- Pas, S.J.; Huang, J.; Forsyth, M.; MacFarlane, D.R.; Hill, A.J. Defect-assisted conductivity in organic ionic plastic crystals. J. Chem. Phys. 2005, 122, 064704. [Google Scholar] [CrossRef] [Green Version]

- Asha, S.; Vijayalakshmi, K.P.; George, B.K. Pyrrolidinium-based ionic liquids as electrolytes for lithium batteries: A Computational Study. Int. J. Quantum Chem. 2019, 119, 12. [Google Scholar] [CrossRef]

- Pandian, S.; Hariharan, K.S.; Adiga, S.P.; Kolake, S.M. Evaluation of Electrochemical Stability and Li-ion Interactions in Ether Functionalized Pyrrolidinium and Phospholanium Ionic Liquids. J. Electrochem. Soc. 2020, 167, 070550. [Google Scholar] [CrossRef] [Green Version]

- Eshetu, G.G.; Jeong, S.; Pandard, P.; Lecocq, A.; Marlair, G.; Passerini, S. Comprehensive Insights into the Thermal Stability, Biodegradability, and Combustion Chemistry of Pyrrolidinium-Based Ionic Liquids. ChemSusChem 2017, 10, 3146–3159. [Google Scholar] [CrossRef] [PubMed]

- Francis, C.; Louey, R.; Sammut, K.; Best, A.S. Thermal Stability of Pyrrolidinium-FSI Ionic Liquid Electrolyte and Lithium-Ion Electrodes at Elevated Temperatures. J. Electrochem. Soc. 2018, 165, A1204–A1221. [Google Scholar] [CrossRef]

- Francis, C.F.J.; Kyratzis, I.L.; Best, A.S. Lithium-Ion Battery Separators for Ionic-Liquid Electrolytes: A Review. Adv. Mater. 2020, 1904205. [Google Scholar] [CrossRef] [PubMed]

- Eftekharnia, M.; Hasanpoor, M.; Forsyth, M.; Kerr, R.; Howlett, P.C. Toward Practical Li Metal Batteries: Importance of Separator Compatibility Using Ionic Liquid Electrolytes. ACS Appl. Energy Mater. 2019, 2, 6655–6663. [Google Scholar] [CrossRef]

- Zheng, B.Z.; Zhu, J.P.; Wang, H.C.; Feng, M.; Umeshbabu, E.; Li, Y.X.; Wu, Q.H.; Yang, Y. Stabilizing Li10SnP2S12/Li Interface via an in Situ Formed Solid Electrolyte Interphase Layer. ACS Appl. Mater. Interfaces 2018, 10, 25473–25482. [Google Scholar] [CrossRef]

- Heist, A.; Hafner, S.; Lee, S.H. High-Energy Nickel-Rich Layered Cathode Stabilized by Ionic Liquid Electrolyte. J. Electrochem. Soc. 2019, 166, A873–A879. [Google Scholar] [CrossRef]

- Lewandowski, A.P.; Hollenkamp, A.F.; Donne, S.W.; Best, A.S. Cycling and rate performance of Li–LiFePO4 cells in mixed FSI–TFSI room temperature ionic liquids. J. Power Sources 2010, 195, 2029–2035. [Google Scholar] [CrossRef]

- Moreno, M.; Simonetti, E.; Appetecchi, G.B.; Carewska, M.; Montanino, M.; Kim, G.T.; Loeffler, N.; Passerini, S. Ionic Liquid Electrolytes for Safer Lithium Batteries. J. Electrochem. Soc. 2016, 164, A6026–A6031. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.W.; Lee, Y.Y.; Gurkan, B. Pyrrolidinium Ionic Liquid Electrolyte with Bis(trifluoromethylsulfonyl)imide and Bis(fluorosulfonyl)imide Anions: Lithium Solvation and Mobility, and Performance in Lithium Metal-Lithium Iron Phosphate Batteries. Ind. Eng. Chem. Res. 2019, 58, 22587–22597. [Google Scholar] [CrossRef]

- Dahiya, P.P.; Patra, J.; Chang, J.K.; Sahoo, K.; Majumder, S.B.; Basu, S. Electrochemical characteristics of 0.3Li(2)MnO(3)-0.7LiMn(1.5)Ni(0.5)O(4) composite cathode in pyrrolidinium-based ionic liquid electrolytes. J. Taiwan Inst. Chem. Eng. 2019, 95, 195–201. [Google Scholar] [CrossRef]

- Wang, J.-Z.; Chou, S.-L.; Chew, S.-Y.; Sun, J.-Z.; Forsyth, M.; MacFarlane, D.R.; Liu, H.-K. Nickel sulfide cathode in combination with an ionic liquid-based electrolyte for rechargeable lithium batteries. Solid State Ionics 2008, 179, 2379–2382. [Google Scholar] [CrossRef]

- Chou, S.-L.; Wang, J.-Z.; Sun, J.-Z.; Wexler, D.; Forsyth, M.; Liu, H.-K.; MacFarlane, D.R.; Dou, S.-X. High Capacity, Safety, and Enhanced Cyclability of Lithium Metal Battery Using a V2O5 Nanomaterial Cathode and Room Temperature Ionic Liquid Electrolyte. Chem. Mater. 2008, 20, 7044–7051. [Google Scholar] [CrossRef]

- Sälzer, F.; Pateras Pescara, L.; Franke, F.; Müller, C.; Winkler, J.; Schwalm, M.; Roling, B. Assessing the Ion Transport Properties of Highly Concentrated Non-Flammable Electrolytes in a Commercial Li-Ion Battery Cell. Batter. Supercaps 2020, 3, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Seki, S.; Kobayashi, Y.; Miyashiro, H.; Ohno, Y.; Mita, Y.; Terada, N.; Charest, P.; Guerfi, A.; Zaghib, K. Compatibility of N-Methyl-N-propylpyrrolidinium Cation Room-Temperature Ionic Liquid Electrolytes and Graphite Electrodes. J. Phys. Chem. C 2008, 112, 16708–16713. [Google Scholar] [CrossRef]

- Park, J.H.; Moon, J.; Han, S.; Park, S.; Lim, J.W.; Yun, D.J.; Kim, D.Y.; Park, K.; Son, I.H. Formation of Stable Solid-Electrolyte Interphase Layer on Few-Layer Graphene-Coated Silicon Nanoparticles for High-Capacity Li-Ion Battery Anodes. J. Phys. Chem. C 2017, 121, 26155–26162. [Google Scholar] [CrossRef]

- Domi, Y.; Usui, H.; Yamaguchi, K.; Yodoya, S.; Sakaguchi, H. Silicon-Based Anodes with Long Cycle Life for Lithium-Ion Batteries Achieved by Significant Suppression of Their Volume Expansion in Ionic-Liquid Electrolyte. ACS Appl. Mater. Interfaces 2019, 11, 2950–2960. [Google Scholar] [CrossRef]

- Yodoya, S.; Domi, Y.; Usui, H.; Sakaguchi, H. Applicability of an Ionic Liquid Electrolyte to a Phosphorus-Doped Silicon Negative Electrode for Lithium-Ion Batteries. Chemistry Select 2019, 4, 1375–1378. [Google Scholar] [CrossRef]

- Nguyen, C.C.; Song, S.-W. Characterization of SEI layer formed on high performance Si–Cu anode in ionic liquid battery electrolyte. Electrochem. Commun. 2010, 12, 1593–1595. [Google Scholar] [CrossRef]

- Nair, J.R.; Colò, F.; Kazzazi, A.; Moreno, M.; Bresser, D.; Lin, R.; Bella, F.; Meligrana, G.; Fantini, S.; Simonetti, E.; et al. Room temperature ionic liquid (RTIL)-based electrolyte cocktails for safe, high working potential Li-based polymer batteries. J. Power Sources 2019, 412, 398–407. [Google Scholar] [CrossRef]

- Singh, S.K.; Dutta, D.; Singh, R.K. Enhanced structural and cycling stability of Li2CuO2-coated LiNi0.33Mn0.33Co0.33O2 cathode with flexible ionic liquid-based gel polymer electrolyte for lithium polymer batteries. Electrochim. Acta 2020, 343, 136122. [Google Scholar] [CrossRef]

- Gupta, H.; Kataria, S.; Balo, L.; Singh, V.K.; Singh, S.K.; Tripathi, A.K.; Verma, Y.L.; Singh, R.K. Electrochemical study of Ionic Liquid based polymer electrolyte with graphene oxide coated LiFePO4 cathode for Li battery. Solid State Ion. 2018, 320, 186–192. [Google Scholar] [CrossRef]

- Guerfi, A.; Dontigny, M.; Kobayashi, Y.; Vijh, A.; Zaghib, K. Investigations on some electrochemical aspects of lithium-ion ionic liquid/gel polymer battery systems. J. Solid State Electrochem. 2008, 13, 1003. [Google Scholar] [CrossRef]

- Li, L.B.; Yang, X.Y.; Li, J.S.; Xu, Y.P. A novel and shortcut method to prepare ionic liquid gel polymer electrolyte membranes for lithium-ion battery. Ionics 2018, 24, 735–741. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, Q.; Wang, D.; Ma, C.; Chen, Z.; Zhu, C.; Gao, Y.; Li, C. Decoupling the mechanical strength and ionic conductivity of an ionogel polymer electrolyte for realizing thermally stable lithium-ion batteries. J. Membr. Sci. 2020, 595, 117549. [Google Scholar] [CrossRef]

- Kim, D.; Liu, X.; Yu, B.; Mateti, S.; O’Dell, L.A.; Rong, Q.; Chen, Y. Amine-Functionalized Boron Nitride Nanosheets: A New Functional Additive for Robust, Flexible Ion Gel Electrolyte with High Lithium-Ion Transference Number. Adv. Funct. Mater. 2020, 30, 1910813. [Google Scholar] [CrossRef]

- Wen, Z.; Li, Y.; Zhao, Z.; Qu, W.; Chen, N.; Xing, Y.; Ma, Y.; Li, L.; Wu, F.; Chen, R. A leaf-like Al2O3-based quasi-solid electrolyte with a fast Li+ conductive interface for stable lithium metal anodes. J. Mater. Chem. A 2020, 8. [Google Scholar] [CrossRef]

- Preibisch, Y.; Horsthemke, F.; Winter, M.; Nowak, S.; Best, A.S. Is the Cation Innocent? An Analytical Approach on the Cationic Decomposition Behavior of N-Butyl-N-methylpyrrolidinium Bis(trifluoromethanesulfonyl)imide in Contact with Lithium Metal. Chem. Mater. 2020, 32, 2389–2398. [Google Scholar] [CrossRef]

- Pyschik, M.; Schultz, C.; Passerini, S.; Winter, M.; Nowak, S. Aging of Cations of Ionic Liquids Monitored by Ion Chromatography hyphenated to an Electrospray Ionization Mass Spectrometer. Electrochim. Acta 2015, 176, 1143–1152. [Google Scholar] [CrossRef]

- Pyschik, M.; Winter, M.; Nowak, S. Determination and quantification of cations in ionic liquids by capillary electrophoresis-mass spectrometry. J. Chromatogr. A 2017, 1485, 131–141. [Google Scholar] [CrossRef]

- Kroon, M.C.; Buijs, W.; Peters, C.J.; Witkamp, G.-J. Decomposition of ionic liquids in electrochemical processing. Green Chem. 2006, 8, 241–245. [Google Scholar] [CrossRef]

- Grande, L.; von Zamory, J.; Koch, S.L.; Kalhoff, J.; Paillard, E.; Passerini, S. Homogeneous Lithium Electrodeposition with Pyrrolidinium-Based Ionic Liquid Electrolytes. ACS Appl. Mater. Interfaces 2015, 7, 5950–5958. [Google Scholar] [CrossRef] [PubMed]

- Nürnberg, P.; Lozinskaya, E.I.; Shaplov, A.S.; Schönhoff, M. Li Coordination of a Novel Asymmetric Anion in Ionic Liquid-in-Li Salt Electrolytes. J. Phys. Chem. B 2020, 124, 861–870. [Google Scholar] [CrossRef] [PubMed]

- Hoffknecht, J.P.; Drews, M.; He, X.; Paillard, E. Investigation of the N-butyl-N-methyl pyrrolidinium trifluoromethanesulfonyl-N-cyanoamide (PYR(14)TFSAM) ionic liquid as electrolyte for Li-ion battery. Electrochim. Acta 2017, 250, 25–34. [Google Scholar] [CrossRef]

- Pervez, S.A.; Kim, G.; Vinayan, B.P.; Cambaz, M.A.; Kuenzel, M.; Hekmatfar, M.; Fichtner, M.; Passerini, S. Overcoming the Interfacial Limitations Imposed by the Solid–Solid Interface in Solid-State Batteries Using Ionic Liquid-Based Interlayers. Small 2020, 16, 2000279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, W.; Park, J.; Kim, K.; Yu, J.-S.; Jeong, G. Sulfide-Compatible Conductive and Adhesive Glue-Like Interphase Engineering for Sheet-Type All-Solid-State Battery. Small 2019, 6, 1902138. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Downie, L.E.; Ma, L.; Qiu, W.; Dahn, J.R. Study of the Failure Mechanisms of LiNi0.8Mn0.1Co0.1O2Cathode Material for Lithium Ion Batteries. J. Electrochem. Soc. 2015, 162, A1401–A1408. [Google Scholar] [CrossRef]

- Balducci, A.; Jeong, S.S.; Kim, G.T.; Passerini, S.; Winter, M.; Schmuck, M.; Appetecchi, G.B.; Marcilla, R.; Mecerreyes, D.; Barsukov, V.; et al. Development of safe, green and high performance ionic liquids-based batteries (ILLIBATT project). J. Power Sources 2011, 196, 9719–9730. [Google Scholar] [CrossRef]

- Di Lecce, D.; Hassoun, J. Lithium Metal Battery Using LiFe0.5Mn0.5PO4 Olivine Cathode and Pyrrolidinium-Based Ionic Liquid Electrolyte. ACS Omega 2018, 3, 8583–8588. [Google Scholar] [CrossRef] [Green Version]

- McGrath, L.M.; Rohan, J.F. High-Rate Lithium-Ion Cycling in Electrodeposited Binder-Free Thin-Film Vanadium Oxide Cathodes with Lithium Metal Anodes in Ionic Liquid and Polymer Gel Analogue Electrolytes. Batter. Supercaps 2020. [Google Scholar] [CrossRef]

- Sanchez-Ramirez, N.; Assresahegn, B.D.; Torresi, R.M.; Bélanger, D. Producing high-performing silicon anodes by tailoring ionic liquids as electrolytes. Energy Storage Mater. 2020, 25, 477–486. [Google Scholar] [CrossRef]

- Piper, D.M.; Evans, T.; Leung, K.; Watkins, T.; Olson, J.; Kim, S.C.; Han, S.S.; Bhat, V.; Oh, K.H.; Buttry, D.A.; et al. Stable silicon-ionic liquid interface for next-generation lithium-ion batteries. Nat. Commun. 2015, 6, 6230. [Google Scholar] [CrossRef] [PubMed]

- Kerner, M.; Johansson, P. Pyrrolidinium FSI and TFSI-Based Polymerized Ionic Liquids as Electrolytes for High-Temperature Lithium-Ion Batteries. Batteries 2018, 4, 10. [Google Scholar] [CrossRef] [Green Version]

- Appetecchi, G.B.; Kim, G.T.; Montanino, M.; Carewska, M.; Marcilla, R.; Mecerreyes, D.; De Meatza, I. Ternary polymer electrolytes containing pyrrolidinium-based polymeric ionic liquids for lithium batteries. J. Power Sources 2010, 195, 3668–3675. [Google Scholar] [CrossRef]

- Kimura, K.; Matsumoto, H.; Hassoun, J.; Panero, S.; Scrosati, B.; Tominaga, Y. A QuaternaryPoly(ethylene carbonate)-Lithium Bis(trifluoromethanesulfonyl)imide-Ionic Liquid-Silica Fiber Composite Polymer Electrolyte for Lithium Batteries. Electrochim. Acta 2015, 175, 134–140. [Google Scholar] [CrossRef]

- Kim, J.-K.; Niedzicki, L.; Scheers, J.; Shin, C.-R.; Lim, D.-H.; Wieczorek, W.; Johansson, P.; Ahn, J.-H.; Matic, A.; Jacobsson, P. Characterization of N-butyl-N-methyl-pyrrolidinium bis(trifluoromethanesulfonyl)imide-based polymer electrolytes for high safety lithium batteries. J. Power Sources 2013, 224, 93–98. [Google Scholar] [CrossRef]

- Choi, S.W.; Jo, S.M.; Lee, W.S.; Kim, Y.-R. An Electrospun Poly(vinylidene fluoride) Nanofibrous Membrane and Its Battery Applications. Adv. Mater. 2003, 15, 2027–2032. [Google Scholar] [CrossRef]

- McGrath, L.M.; Jones, J.; Carey, E.; Rohan, J.F. Ionic Liquid Based Polymer Gel Electrolytes for Use with Germanium Thin Film Anodes in Lithium Ion Batteries. ChemistryOpen 2019, 8, 1429–1436. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.T.; Jeong, S.S.; Xue, M.Z.; Balducci, A.; Winter, M.; Passerini, S.; Alessandrini, F.; Appetecchi, G.B. Development of ionic liquid-based lithium battery prototypes. J. Power Sources 2012, 199, 239–246. [Google Scholar] [CrossRef]

- Lahiri, A.; Borisenko, N.; Borodin, A.; Olschewski, M.; Endres, F. Characterisation of the solid electrolyte interface during lithiation/delithiation of germanium in an ionic liquid. Phys. Chem. Chem. Phys. 2016, 18, 5630–5637. [Google Scholar] [CrossRef] [Green Version]

- Sano, M.; Tachikawa, N.; Yoshii, K.; Serizawa, N.; Katayama, Y. Electrodeposition of Tin in an Amide Type Ionic Liquid Containing Chloride Ion. Electrochemistry 2018, 86, 260–264. [Google Scholar] [CrossRef]

- Wu, M.; Brooks, N.R.; Schaltin, S.; Binnemans, K.; Fransaer, J. Electrodeposition of germanium from the ionic liquid 1-butyl-1-methylpyrrolidinium dicyanamide. Phys. Chem. Chem. Phys 2013, 15, 4955–4964. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, M.; Vanhoutte, G.; Brooks, N.R.; Binnemans, K.; Fransaer, J. Electrodeposition of germanium at elevated temperatures and pressures from ionic liquids. Phys. Chem. Chem. Phys 2015, 17, 12080–12089. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lahiri, A.; Willert, A.; Abedin, S.Z.E.; Endres, F. A simple and fast technique to grow free-standing germanium nanotubes and core-shell structures from room temperature ionic liquids. Electrochim. Acta 2014, 121, 154–158. [Google Scholar] [CrossRef]

- Al-Salman, R.; Mallet, J.; Molinari, M.; Fricoteaux, P.; Martineau, F.; Troyon, M.; El Abedin, S.Z.; Endres, F. Template assisted electrodeposition of germanium and silicon nanowires in an ionic liquid. Phys. Chem. Chem. Phys 2008, 10, 6233–6237. [Google Scholar] [CrossRef]

- Martineau, F.; Namur, K.; Mallet, J.; Delavoie, F.; Endres, F.; Troyon, M.; Molinari, M. Electrodeposition at room temperature of amorphous silicon and germanium nanowires in ionic liquid. IOP Conf. Ser. Mater. Sci. Eng. 2009, 6, 012012. [Google Scholar] [CrossRef]

- Link, S.; Ivanov, S.; Dimitrova, A.; Krischok, S.; Bund, A. Understanding the initial stages of Si electrodeposition under diffusion kinetic limitation in ionic liquid-based electrolytes. J. Cryst. Growth 2020, 531, 125346. [Google Scholar] [CrossRef]

- Choi, N.-S.; Lee, Y.; Kim, S.-S.; Shin, S.-C.; Kang, Y.-M. Improving the electrochemical properties of graphite/LiCoO2 cells in ionic liquid-containing electrolytes. J. Power Sources 2010, 195, 2368–2371. [Google Scholar] [CrossRef]

- Lu, W.; Goering, A.; Qu, L.; Dai, L. Lithium-ion batteries based on vertically-aligned carbon nanotube electrodes and ionic liquid electrolytes. Phys. Chem. Chem. Phys 2012, 14, 12099–12104. [Google Scholar] [CrossRef]

- Hofmann, A.; Schulz, M.; Hanemann, T. Effect of Conducting Salts in Ionic Liquid based Electrolytes: Viscosity, Conductivity, and Li-Ion Cell Studies. Int. J. Electrochem. Sci. 2013, 8, 10170–10189. [Google Scholar]

- Mei, X.Y.; Yue, Z.; Tufts, J.; Dunya, H.; Mandal, B.K. Synthesis of new fluorine-containing room temperature ionic liquids and their physical and electrochemical properties. J. Fluorine Chem. 2018, 212, 26–37. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Jiang, N.; Li, X.; Pasupath, S.; Fang, Y.; Liu, Q.; Dang, D. Rational Design of an Ionic Liquid-Based Electrolyte with High Ionic Conductivity Towards Safe Lithium/Lithium-Ion Batteries. Chem. An. Asian J. 2019, 14, 2810–2814. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Zhang, Z.; Jin, Y.; Yang, L.; Hirano, S.-i.; Tachibana, K.; Katayama, S. New functionalized ionic liquids based on pyrrolidinium and piperidinium cations with two ether groups as electrolytes for lithium battery. J. Power Sources 2011, 196, 5637–5644. [Google Scholar] [CrossRef]

- Vogl, T.; Menne, S.; Kühnel, R.-S.; Balducci, A. The beneficial effect of protic ionic liquids on the lithium environment in electrolytes for battery applications. J. Mater. Chem. A 2014, 2, 8258–8265. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, S.; Quartarone, E.; Mustarelli, P.; Magistris, A.; Fagnoni, M.; Protti, S.; Gerbaldi, C.; Spinella, A. Lithium ion conducting PVdF-HFP composite gel electrolytes based on N-methoxyethyl-N-methylpyrrolidinium bis(trifluoromethanesulfonyl)-imide ionic liquid. J. Power Sources 2010, 195, 559–566. [Google Scholar] [CrossRef]

- Sirisopanaporn, C.; Fernicola, A.; Scrosati, B. New, ionic liquid-based membranes for lithium battery application. J. Power Sources 2009, 186, 490–495. [Google Scholar] [CrossRef]

- Fernicola, A.; Weise, F.C.; Greenbaum, S.G.; Kagimoto, J.; Scrosati, B.; Soleto, A. Lithium-Ion-Conducting Electrolytes: From an Ionic Liquid to the Polymer Membrane. J. Electrochem. Soc. 2009, 156, A514–A520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernicola, A.; Croce, F.; Scrosati, B.; Watanabe, T.; Ohno, H. LiTFSI-BEPyTFSI as an improved ionic liquid electrolyte for rechargeable lithium batteries. J. Power Sources 2007, 174, 342–348. [Google Scholar] [CrossRef]

- Mei, X.Y.; Yue, Z.; Ma, Q.; Dunya, H.; Mandal, B.K. Synthesis and electrochemical properties of new dicationic ionic liquids. J. Mol. Liq. 2018, 272, 1001–1018. [Google Scholar] [CrossRef]

- Al-Masri, D.; Yunis, R.; Zhu, H.J.; Jin, L.Y.; Bruce, P.; Hollenkamp, A.F.; Pringle, J.M. A new approach to very high lithium salt content quasi-solid state electrolytes for lithium metal batteries using plastic crystals. J. Mater. Chem. A 2019, 7, 25389–25398. [Google Scholar] [CrossRef]

| Cation Structure | Name | Abbreviations |

|---|---|---|

| N-ethyl-N-methylpyrrolidinium | C2mpyr, C2PYrr, P12 |

| N-propyl-N-methylpyrrolidinium | C3mpyr, C3PYrr, P13, PYR13, PMP, PMPyr |

| N-butyl-N-methylpyrrolidinium | C4mpyr, C4PYrr, P14, PYR14, BMP, BMPyr |

| N-n-butyl-N-ethylpyrrolidinium | BEPy, P24 |

| Diethylpyrrolidinium | C2epyr |

| Functionalized pyrrolidinium cations | ||

| N-ethyl(methylether)-N-methylpyrrolidinium | PYRA1(2o1) |

| 1-(2-ethoxyethyl)-1-methylpyrrolidinium | PYR1(2o2) |

| N-(methoxyethyl)-N-(ethoxyethyl)pyrrolidinium | P(2o1)(2o2) |

| Anion Structure | Name | Abbreviations |

| Carbamoylcyano(nitroso)methanide | ccnm |

| Dicyanamide | DCA |

| Bis(fluorosulfonyl)imide | FSI, FSA |

| Bis(trifluoromethylsulfonyl)imide/Bis(trifluoromethane)sulfonimide | TFSI, TFSA, NTf2 |

| Trifluoromethylsulfonyl-N-cyanoamide | TFSAM |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McGrath, L.M.; Rohan, J.F. Pyrrolidinium Containing Ionic Liquid Electrolytes for Li-Based Batteries. Molecules 2020, 25, 6002. https://doi.org/10.3390/molecules25246002

McGrath LM, Rohan JF. Pyrrolidinium Containing Ionic Liquid Electrolytes for Li-Based Batteries. Molecules. 2020; 25(24):6002. https://doi.org/10.3390/molecules25246002

Chicago/Turabian StyleMcGrath, Louise M., and James F. Rohan. 2020. "Pyrrolidinium Containing Ionic Liquid Electrolytes for Li-Based Batteries" Molecules 25, no. 24: 6002. https://doi.org/10.3390/molecules25246002

APA StyleMcGrath, L. M., & Rohan, J. F. (2020). Pyrrolidinium Containing Ionic Liquid Electrolytes for Li-Based Batteries. Molecules, 25(24), 6002. https://doi.org/10.3390/molecules25246002