Environmentally Friendly Surface Modification Treatment of Flax Fibers by Supercritical Carbon Dioxide

Abstract

:1. Introduction

2. Results and Discussion

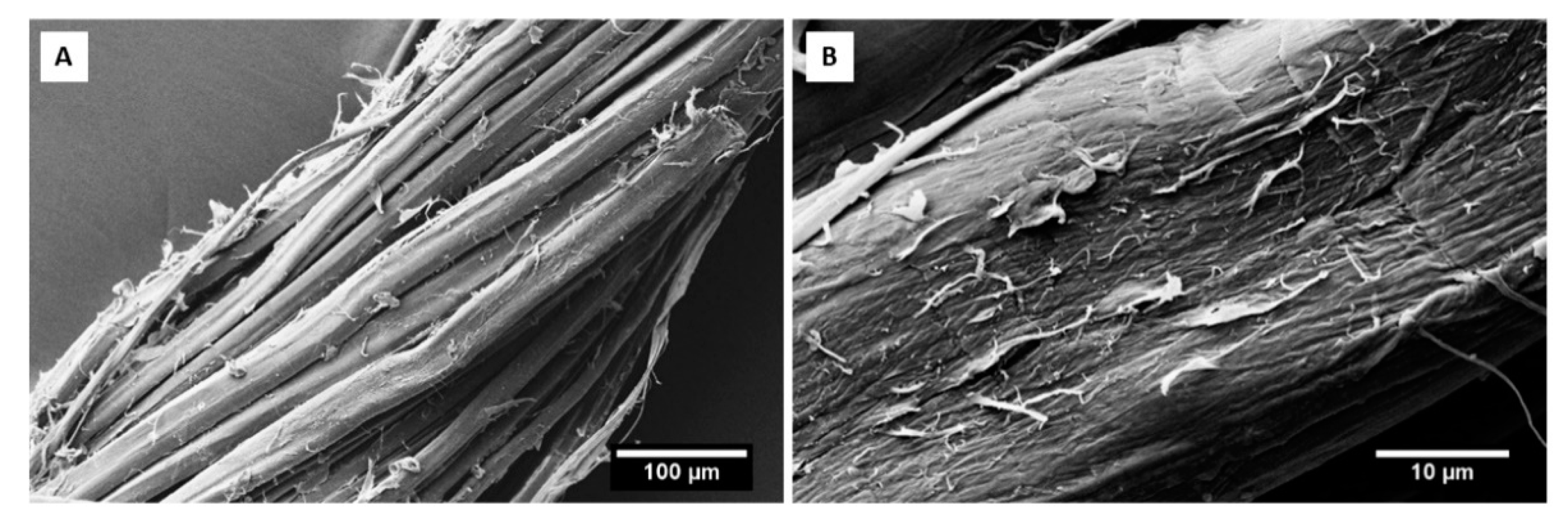

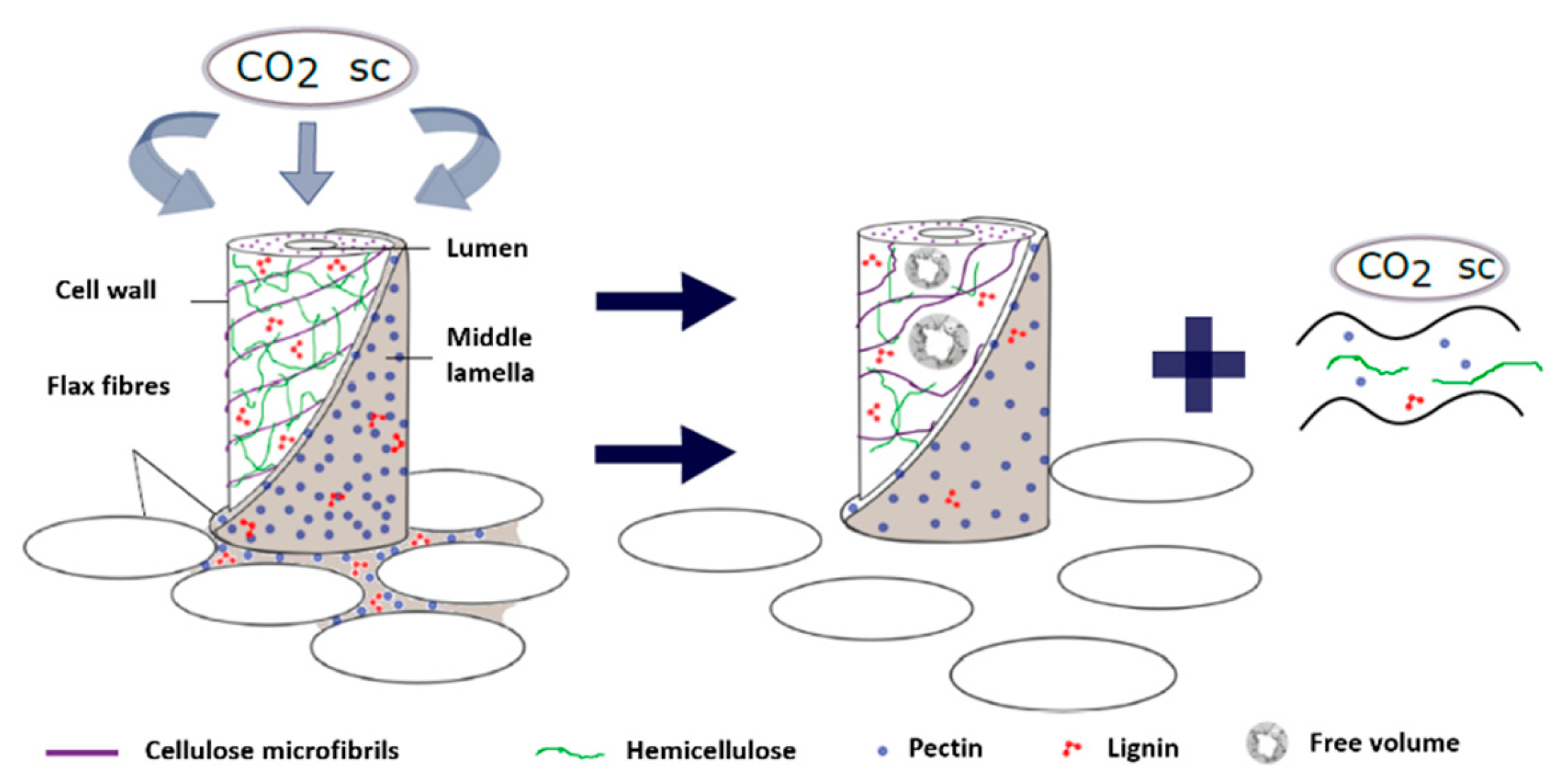

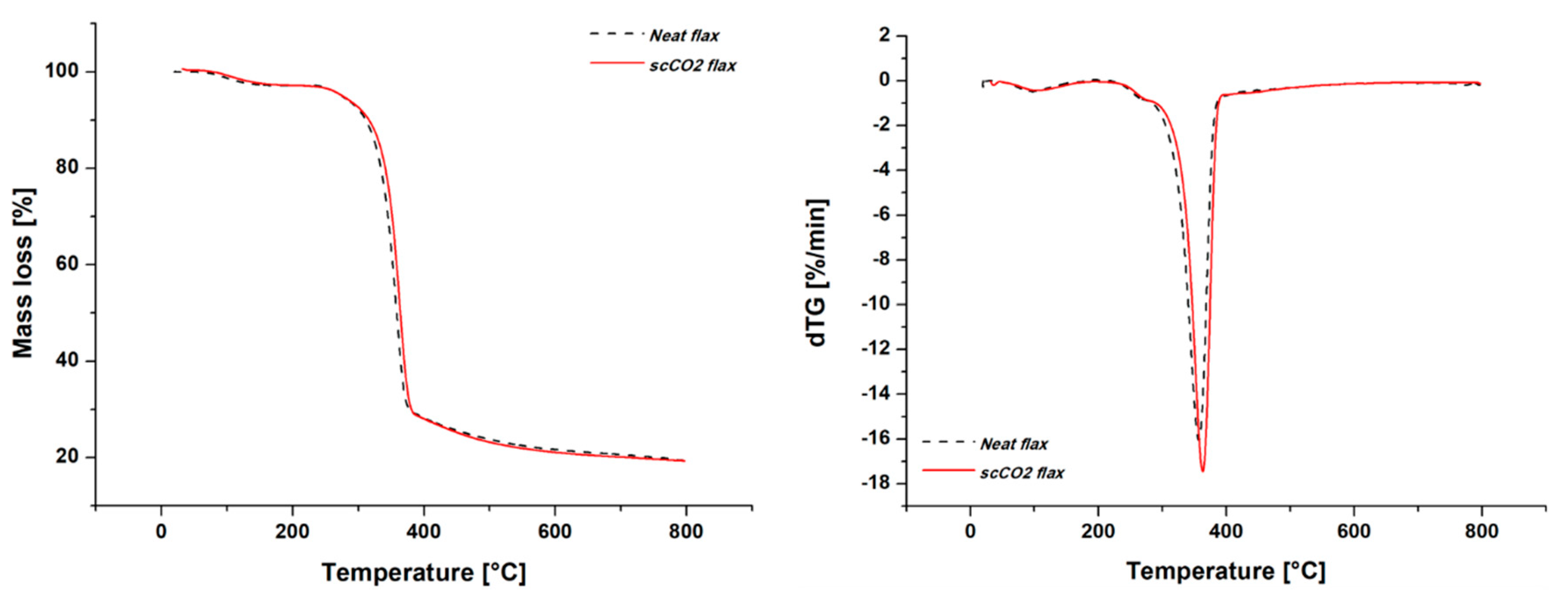

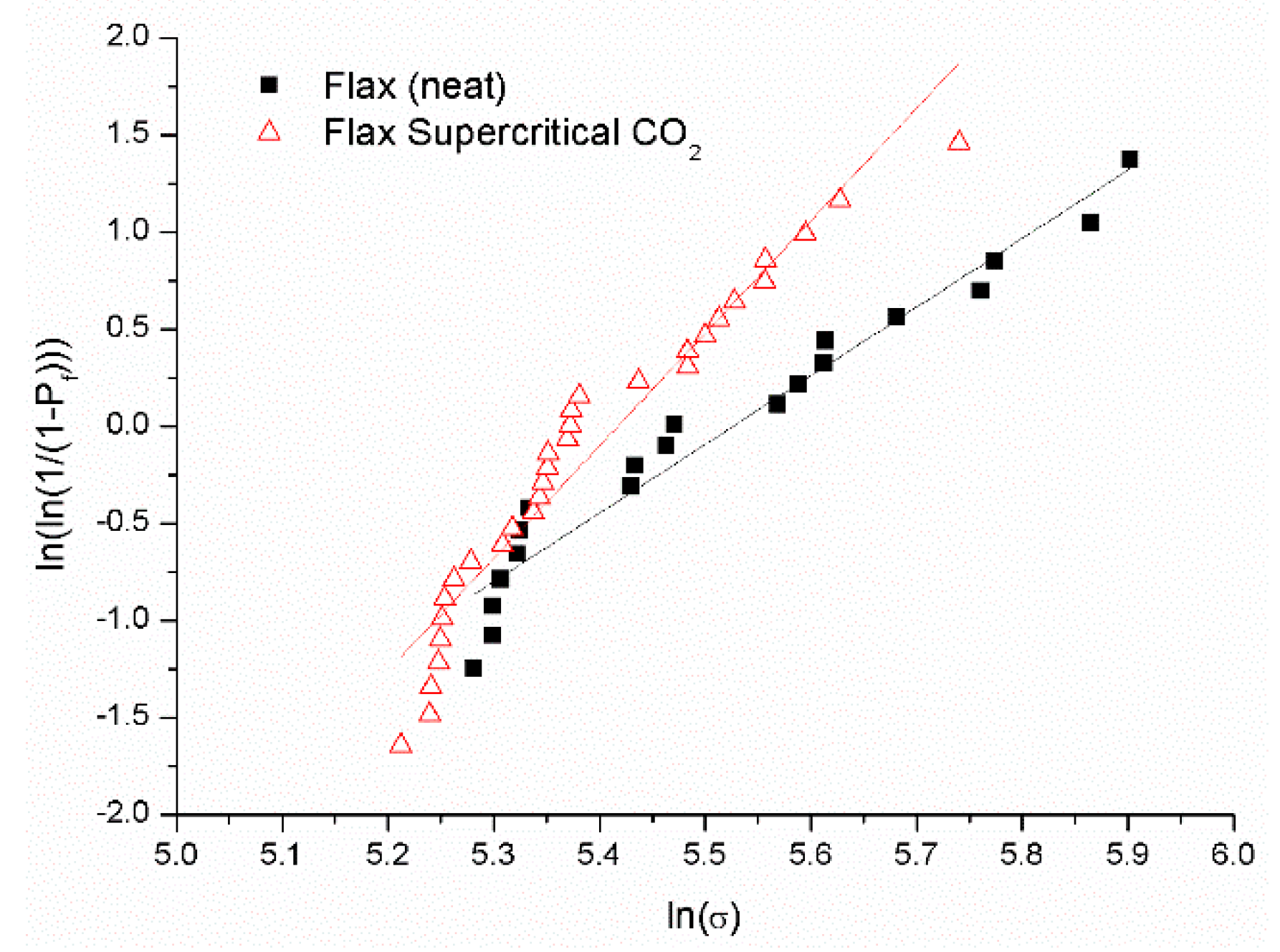

2.1. Characterization of Flax Yarns after scCO2 Treatment

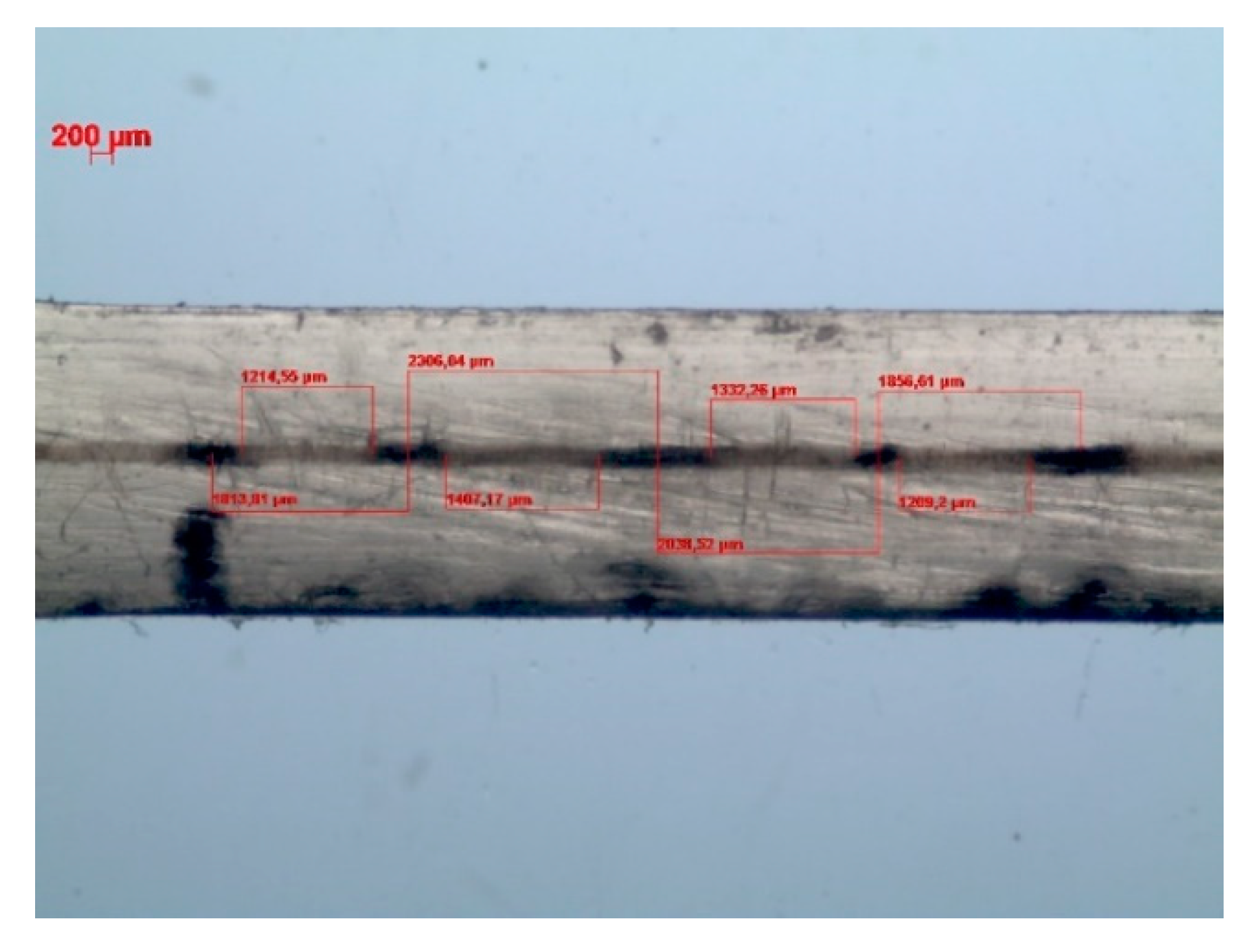

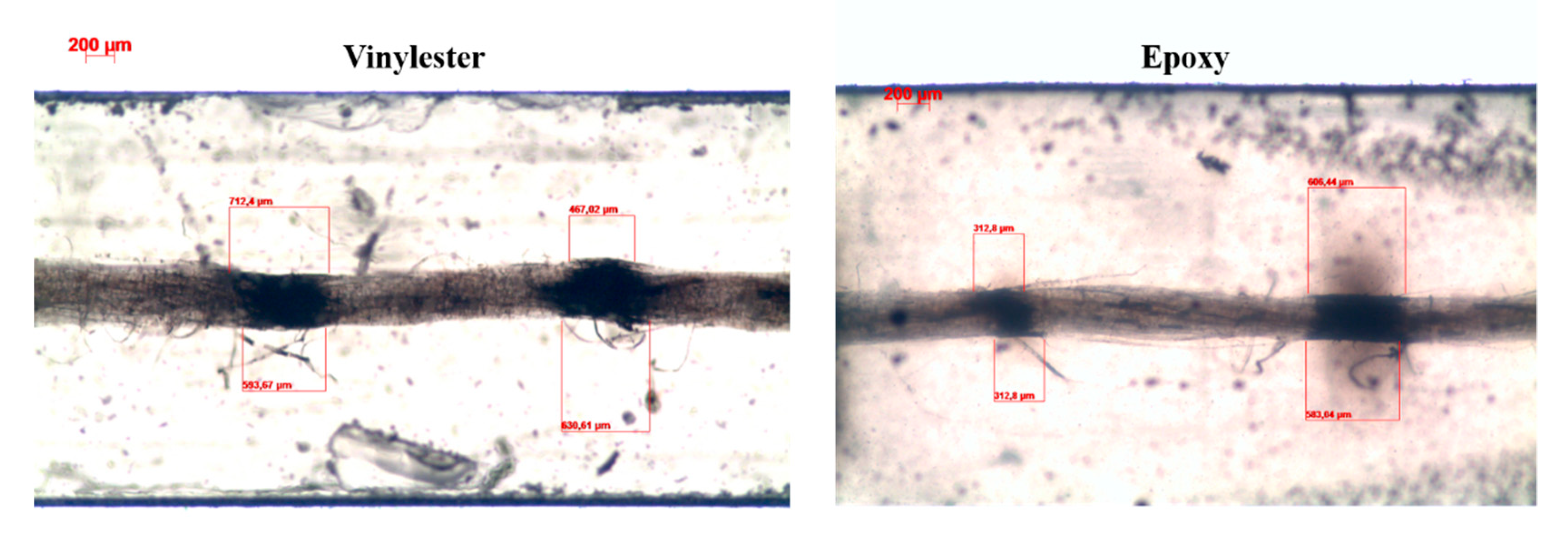

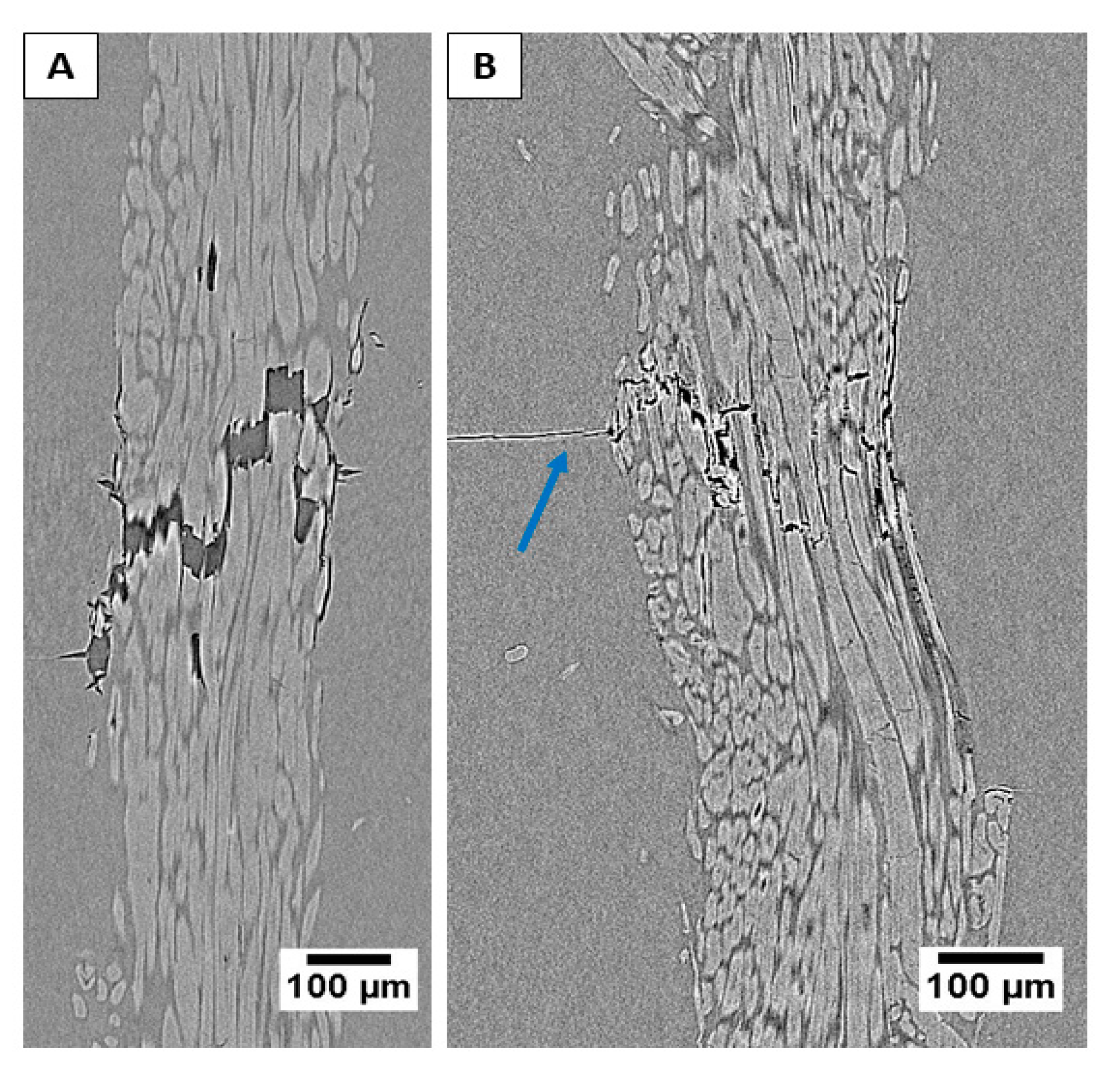

2.2. Interfacial Quality Assessment by Single Yarn Fragmentation Test

3. Materials and Methods

3.1. Raw Materials

3.2. Supercritical Carbon Dioxide (scCO2) Treatment of Flax Yarns

3.3. Tensile Testing of Flax Yarns

3.4. Fourier Transform Infrared Spectroscopy Analysis (FT-IR)

3.5. Thermogravimetric Analysis (TGA)

3.6. Single Yarn Fragmentation Test

3.7. X-ray Microtomography

3.8. Optical and FE-SEM Observations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bourmaud, A.; Beaugrand, J.; Shaf, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Drapier, S.; Ferreira, M.; Le Duigou, A.; Liotier, P.J.; Ouagne, P.; Soulat, D.; et al. Specific features of flax fibres used to manufacture composite materials. Int. J. Mater. Form. 2019, 12, 1023–1052. [Google Scholar] [CrossRef] [Green Version]

- Haag, K.; Padovani, J.; Fita, S.; Trouvé, J.P.; Pineau, C.; Hawkins, S.; De Jong, H.; Deyholos, M.K.; Chabbert, B.; Müssig, J.; et al. Influence of flax fibre variety and year-to-year variability on composite properties. Ind. Crops Prod. 2017, 98, 1–9. [Google Scholar] [CrossRef]

- Morvan, C.; Andème-Onzighi, C.; Girault, R.; Himmelsbach, D.S.; Driouich, A.; Akin, D.E. Building flax fibres: More than one brick in the walls. Plant Physiol. Biochem. 2003, 41, 935–944. [Google Scholar] [CrossRef]

- Bourmaud, A.; Gibaud, M.; Lefeuvre, A.; Morvan, C.; Baley, C. Influence of the morphology characters of the stem on the lodging resistance of Marylin flax. Ind. Crops Prod. 2015, 66, 27–37. [Google Scholar] [CrossRef]

- Goudenhooft, C.; Bourmaud, A.; Baley, C. Varietal selection of flax over time: Evolution of plant architecture related to influence on the mechanical properties of fibers. Ind. Crops Prod. 2017, 97, 56–64. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crops Prod. 2019, 111984. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef] [Green Version]

- Huo, S.; Thapa, A.; Ulven, C.A. Effect of surface treatments on interfacial properties of flax fiber-reinforced composites. Adv. Compos. Mater. 2013, 22, 109–121. [Google Scholar] [CrossRef]

- Sinha, E.; Rout, S.K. Influence of fibre-surface treatment on structural, thermal and mechanical properties of jute fibre and its composite. Bull. Mater. Sci. 2009, 32, 65–76. [Google Scholar] [CrossRef]

- Bulut, Y.; Aksit, A. A comparative study on chemical treatment of jute fiber: Potassium dichromate, potassium permanganate and sodium perborate trihydrate. Cellulose 2013, 20, 3155–3164. [Google Scholar] [CrossRef]

- Amiri, A.; Ulven, C.; Huo, S. Effect of Chemical Treatment of Flax Fiber and Resin Manipulation on Service Life of Their Composites Using Time-Temperature Superposition. Polymers 2015, 7, 1965–1978. [Google Scholar] [CrossRef] [Green Version]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdoĝan, Ü.H.; Erden, S. Surface treatments of jute fabric: The influence of surface characteristics on jute fabrics and mechanical properties of jute/polyester composites. Ind. Crops Prod. 2012, 35, 22–30. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Chi Truong, T.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Yuan, X.; Jayaraman, K.; Bhattacharyya, D. Plasma treatment of sisal fibres and its effects on tensile strength and interfacial bonding. J. Adhes. Sci. Technol. 2002, 16, 703–727. [Google Scholar] [CrossRef]

- Bozaci, E.; Sever, K.; Sarikanat, M.; Seki, Y.; Demir, A.; Ozdogan, E.; Tavman, I. Effects of the atmospheric plasma treatments on surface and mechanical properties of flax fiber and adhesion between fiber-matrix for composite materials. Compos. Part B Eng. 2013, 45, 565–572. [Google Scholar] [CrossRef]

- Kim, S.W.; Oh, S.; Lee, K. Variation of mechanical and thermal properties of the thermoplastics reinforced with natural fibers by electron beam processing. Radiat. Phys. Chem. 2007, 76, 1711–1714. [Google Scholar] [CrossRef]

- Seghini, M.C.; Touchard, F.; Sarasini, F.; Chocinski-Arnault, L.; Tirillò, J.; Bracciale, M.P.; Zvonek, M.; Cech, V. Effects of oxygen and tetravinylsilane plasma treatments on mechanical and interfacial properties of flax yarns in thermoset matrix composites. Cellulose 2019, 27, 511–530. [Google Scholar] [CrossRef]

- Wang, W.; Xian, G.; Li, H. Surface modification of ramie fibers with silanized CNTs through a simple spray-coating method. Cellulose 2019, 26, 8165–8178. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-Performance Graphene-Based Natural Fiber Composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Ajith, A.; Xian, G.; Li, H.; Sherief, Z.; Thomas, S. Surface grafting of flax fibres with hydrous zirconia nanoparticles and the effects on the tensile and bonding properties. J. Compos. Mater. 2016, 50, 627–635. [Google Scholar] [CrossRef]

- Lakshmanan, A.; Chakraborty, S. Coating of silver nanoparticles on jute fibre by in situ synthesis. Cellulose 2017, 24, 1563–1577. [Google Scholar] [CrossRef]

- Zhuang, R.C.; Doan, T.T.L.; Liu, J.W.; Zhang, J.; Gao, S.L.; Mäder, E. Multi-functional multi-walled carbon nanotube-jute fibres and composites. Carbon 2011, 49, 2683–2692. [Google Scholar] [CrossRef]

- Wang, H.; Xian, G.; Li, H. Grafting of nano-TiO2 onto flax fibers and the enhancement of the mechanical properties of the flax fiber and flax fiber/epoxy composite. Compos. Part A Appl. Sci. Manuf. 2015, 76, 172–180. [Google Scholar] [CrossRef]

- Zhang, X.; Heinonen, S.; Levänen, E. Applications of supercritical carbon dioxide in materials processing and synthesis. RSC Adv. 2014, 4, 61137–61152. [Google Scholar] [CrossRef]

- Sanli, D.; Bozbag, S.E.; Erkey, C. Synthesis of nanostructured materials using supercritical CO2: Part I. Physical transformations. J. Mater. Sci. 2012, 47, 2995–3025. [Google Scholar] [CrossRef]

- Yeo, S.D.; Kiran, E. Formation of polymer particles with supercritical fluids: A review. J. Supercrit. Fluids 2005, 34, 287–308. [Google Scholar] [CrossRef]

- Campbell, M.L.; Apodaca, D.L.; Yates, M.Z.; McCleskey, T.M.; Birnbaum, E.R. Metal Extraction from Heterogeneous Surfaces Using Carbon Dioxide Microemulsions. Langmuir 2001, 17, 5458–5463. [Google Scholar] [CrossRef]

- Narayanaswamy, N.; Faik, A.; Goetz, D.J.; Gu, T. Supercritical carbon dioxide pretreatment of corn stover and switchgrass for lignocellulosic ethanol production. Bioresour. Technol. 2011, 102, 6995–7000. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Kiran, E. Interaction of supercritical fluids with lignocellulosic materials. Ind. Eng. Chem. Res. 1988, 27, 1301–1312. [Google Scholar] [CrossRef]

- Schmidt, A.; Bach, E.; Schollmeyer, E. Damage to Natural and Synthetic Fibers Treated in Supercritical Carbon Dioxide at 300 bar and Temperatures up to 160 °C. Text. Res. J. 2002, 72, 1023–1032. [Google Scholar] [CrossRef]

- Daza Serna, L.V.; Orrego Alzate, C.E.; Cardona Alzate, C.A. Supercritical fluids as a green technology for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, M.C.; Rosa, P.d.T.V.; De Paoli, M.A.; Felisberti, M.I. Biocompósitos de acetato de celulose e fibras curtas de Curauá tratadas com CO2 supercrítico. Polimeros 2012, 22, 295–302. [Google Scholar] [CrossRef] [Green Version]

- Francois, C.; Plasseraud, L.; Pourchet, S.; Boni, G.; Placet, V.; Fontaine, S.; Beaugrand, J.; Champion, D. Étude d’un procédé de traitement innovant des fibres de chanvre sous condition de fluide supercritique et propriétés induites. In Proceedings of the Journées Nationales sur les Composites 20, Champs sur Marne, France, 28–30 July 2017; pp. 1–10. [Google Scholar]

- Francois, C.; Placet, V.; Beaugrand, J.; Pourchet, S.; Boni, G.; Champion, D.; Fontaine, S.; Plasseraud, L. Can supercritical carbon dioxide be suitable for the green pretreatment of plant fibres dedicated to composite applications? J. Mater. Sci. 2020, 55, 4671–4684. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, H.; Zheng, L. Effect of treatment temperature on structures and properties of flax rove in supercritical carbon dioxide. Text. Res. J. 2018, 88, 155–166. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Reddy, K.R.; Shukla, M.; Muzenda, E.; Rajulu, A.V. Effect of Chemical Treatment and Fiber Loading on Mechanical Properties of Borassus (Toddy Palm) Fiber/Epoxy Composites. Int. J. Polym. Anal. Charact. 2015, 20, 612–626. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Gao, S.H.; Yu, C.W. Effects of supercritical carbon dioxide on morphology of apocynum venetum fibers. Therm. Sci. 2015, 19, 1279–1282. [Google Scholar] [CrossRef]

- Abidi, N.; Manike, M. X-ray diffraction and FTIR investigations of cellulose deposition during cotton fiber development. Text. Res. J. 2018, 88, 719–730. [Google Scholar] [CrossRef]

- Abidi, N.; Cabrales, L.; Haigler, C.H. Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr. Polym. 2014, 100, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Van de Velde, K.; Baetens, E. Thermal and Mechanical Properties of Flax Fibres as Potential Composite Reinforcement. Macromol. Mater. Eng. 2001, 286, 342–349. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Ind. Crops Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Spinacé, M.A.S.; Lambert, C.S.; Fermoselli, K.K.G.; De Paoli, M.A. Characterization of lignocellulosic curaua fibres. Carbohydr. Polym. 2009, 77, 47–53. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Seghini, M.C.; Touchard, F.; Sarasini, F.; Chocinski-Arnault, L.; Mellier, D.; Tirillò, J. Interfacial adhesion assessment in flax/epoxy and in flax/vinylester composites by single yarn fragmentation test: Correlation with micro-CT analysis. Compos. Part A Appl. Sci. Manuf. 2018, 113, 66–75. [Google Scholar] [CrossRef]

- Fraser, W.A.; Ancker, F.H.; Dibenedetto, A.T.; Elbirli, B. Evaluation of surface treatments for fibers in composite materials. Polym. Compos. 1983, 4, 238–248. [Google Scholar] [CrossRef]

- Bénéthuilière, T.; Duchet-Rumeau, J.; Gérard, J.F.; Dubost, E.; Peyre, C. Physico-chemistry of vinylester/glass fiber interfaces used in SMC composites. In Proceedings of the 20th International Conference on Composite Materials (ICCM20), Copenhagen, Denmark, 19–24 July 2015; pp. 1–12. [Google Scholar]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Kim, B.W.; Nairn, J.A. Observations of Fiber Fracture and Interfacial Debonding Phenomena Using the Fragmentation Test in Single Fiber Composites. J. Compos. Mater. 2002, 36, 1825–1858. [Google Scholar] [CrossRef]

- Ramirez, F.A.; Carlsson, L.A.; Acha, B.A. Evaluation of water degradation of vinylester and epoxy matrix composites by single fiber and composite tests. J. Mater. Sci. 2008, 43, 5230–5242. [Google Scholar] [CrossRef]

- Joffe, R.; Andersons, J.; Wallström, L. Interfacial shear strength of flax fiber/thermoset polymers estimated by fiber fragmentation tests. J. Mater. Sci. 2005, 40, 2721–2722. [Google Scholar] [CrossRef]

Sample Availability: Samples of the tested specimens are available from the authors. |

| Wavenumber (cm−1) | Band Assignments * |

|---|---|

| 3700–3000 | νOH |

| 2990–2754 | νCH of cellulose and hemicellulose |

| 1742 | νC=O of hemicellulose |

| 1637 | δHOH of water in crystalline cellulose |

| 1597, 1514, 1450 | νC=C and dCH in methyl, methylene and methoxyl groups of lignin |

| 1427, 1368, 1314 | δCH2, δCH of cellulose and ωCH2 in cellulose and hemicellulose |

| 1278 | τC-H2 of cellulose |

| 1248, 1160, 1104, 1029 | νC-O-C and νC-C of polysaccharide components (mainly cellulose) |

| 1053 | νC-OH of cellulose and hemicellulose |

| 897 | β-glycosidic linkages between the sugars units in cellulose |

| Maximum Degradation Temperature [°C] | Temperature of 10% Weight Loss [°C] | |

|---|---|---|

| Flax yarn (neat) | 357.2 | 311.3 |

| Flax supercritical CO2 | 363.4 | 313.9 |

| Specimen | Fmax [N] | Diameter [µm] | σf [MPa] | εf [%] | Characteristic Strength σ0 [MPa] | Weibull Modulus, m |

|---|---|---|---|---|---|---|

| Neat flax | 19.8 ± 4.8 | 327 ± 96 | 236 ± 57 | 3.40 ± 0.42 | 257 | 5.02 |

| scCO2 flax | 20.4 ± 3.5 | 350 ± 68 | 211 ± 36 | 1.40 ± 0.15 | 226.1 | 7.10 |

| Matrix | Flax Yarn | lc [µm] | ldebonding [µm] |

|---|---|---|---|

| Epoxy | Neat | 2687 ± 631 | 444 ± 49 |

| scCO2 | 2587 ± 623 | 429 ± 39 | |

| Vinylester | Neat | 3942 ± 807 | 830 ± 343 |

| scCO2 | 3345 ± 490 | 673 ± 145 |

| Matrix | Flax Yarn | σf (lc) [MPa] | IFSS [MPa] |

|---|---|---|---|

| Epoxy | Neat | 406 ± 18 | 19.3 ± 3.7 |

| scCO2 | 312 ± 10 | 15.7 ± 2.1 | |

| Vinylester | Neat | 376 ± 15 | 13.9 ± 2.8 |

| scCO2 | 300 ± 6 | 14.3 ± 2.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seghini, M.C.; Touchard, F.; Chocinski-Arnault, L.; Placet, V.; François, C.; Plasseraud, L.; Bracciale, M.P.; Tirillò, J.; Sarasini, F. Environmentally Friendly Surface Modification Treatment of Flax Fibers by Supercritical Carbon Dioxide. Molecules 2020, 25, 438. https://doi.org/10.3390/molecules25030438

Seghini MC, Touchard F, Chocinski-Arnault L, Placet V, François C, Plasseraud L, Bracciale MP, Tirillò J, Sarasini F. Environmentally Friendly Surface Modification Treatment of Flax Fibers by Supercritical Carbon Dioxide. Molecules. 2020; 25(3):438. https://doi.org/10.3390/molecules25030438

Chicago/Turabian StyleSeghini, Maria Carolina, Fabienne Touchard, Laurence Chocinski-Arnault, Vincent Placet, Camille François, Laurent Plasseraud, Maria Paola Bracciale, Jacopo Tirillò, and Fabrizio Sarasini. 2020. "Environmentally Friendly Surface Modification Treatment of Flax Fibers by Supercritical Carbon Dioxide" Molecules 25, no. 3: 438. https://doi.org/10.3390/molecules25030438

APA StyleSeghini, M. C., Touchard, F., Chocinski-Arnault, L., Placet, V., François, C., Plasseraud, L., Bracciale, M. P., Tirillò, J., & Sarasini, F. (2020). Environmentally Friendly Surface Modification Treatment of Flax Fibers by Supercritical Carbon Dioxide. Molecules, 25(3), 438. https://doi.org/10.3390/molecules25030438