Use of Thermal Black as Eco-Filler in Thermoplastic Composites and Hybrids for Injection Molding and 3D Printing Applications

Abstract

1. Introduction

2. Results and Discussion

2.1. Thermoplastic Composites Containing TB

2.1.1. Morphology of PP, PA6, and PPS Composites

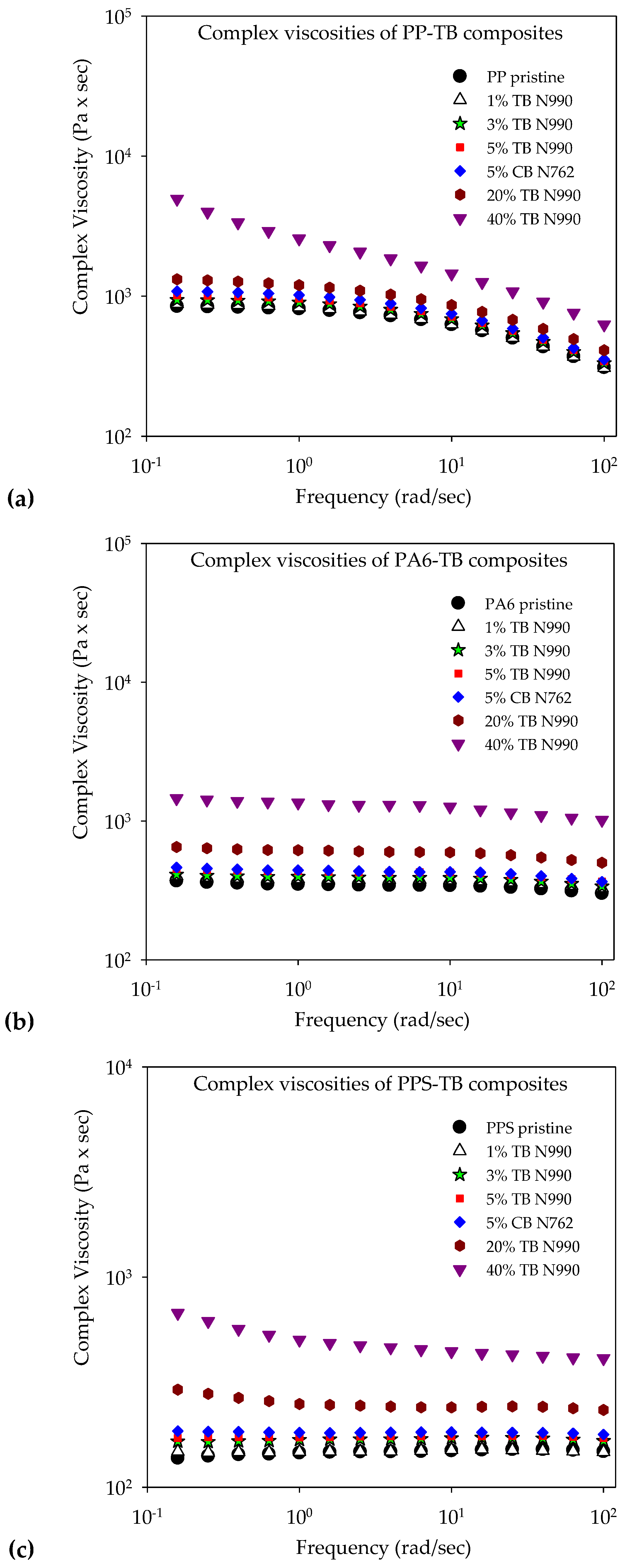

2.1.2. Rheology of PP, PA6, and PPS Compounds

2.1.3. Mechanical and Thermal Properties of PP, PA6, and PPS Compounds

2.1.4. Electrical Conductivity of PP, PA6, and PPS Compounds

2.2. Thermoplastic Hybrids Containing TB/CF

2.2.1. Morphology of TB/CF Hybrids Based on PP, PA6, and PPS

2.2.2. Rheology of TB/CF Hybrids Based on PP, PA6, and PPS

2.2.3. Mechanical and Thermal Properties of TB/CF Hybrids Based on PP, PA6, and PPS

2.3. Thermoplastic Composites and Hybrids Containing TB for 3D Printing

2.3.1. Morphology of Composites and Hybrids Based on PA6 and ABS for 3D Printing

2.3.2. 3D printed Composites and Hybrids Based on PA6 and ABS

2.3.3. Properties of PA6 and ABS Injection Molded and 3D Printed Specimens

3. Material and Methods

3.1. Materials

3.2. Processing Methods

3.2.1. Extrusion Process

3.2.2. Injection Molding

3.2.3. Filament Extrusion

3.2.4. 3D Printing by Fused Filament Fabrication

3.3. Characterization Methods

3.3.1. Morphology

3.3.2. Rheology Measurements

3.3.3. Mechanical Properties

3.3.4. Heat Deflection Temperature

3.3.5. Electrical Resistivity Measurement

3.3.6. Cost Calculation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- OECDiLibrary. Nanotechnology and Tyres: Greening Industry and Transport; OECD Publishing: Paris, Franch; Available online: http://www.oecd-ilibrary.org/science-and-technology/nanotechnology-and-tyres_9789264209152-en (accessed on 16 January 2020).

- Merchant Research & Consulting ltd. Carbon Black (BC): 2020 World Market Outlook and Forecast up to 2029. Available online: https://mcgroup.co.uk/researches/carbon-black-bc (accessed on 15 December 2019).

- Black Bear Carbon. Available online: http://blackbearcarbon.com/ (accessed on 28 August 2019).

- Long, C.L.; Nascarella, M.A.; Valberg, P.A. Carbon black vs. black carbon and other airborne materials containing elemental carbon: Physical and chemical distinctions. Environ. Pollut. 2013, 181, 271. [Google Scholar] [CrossRef] [PubMed]

- Volume of Emissions in Carbon Black Processes, Climate Policy Watcher: Emission Factors. 18 August 2019. Available online: https://www.climate-policy-watcher.org/emission-factors/introduction-dpn.html (accessed on 10 September 2019).

- Crump, E.L. Economic Impact Analysis for the Proposed Carbon Black Manufacturing NESHAP, (2000). Available online: https://www3.epa.gov/ttnecas1/regdata/EIAs/carbonblackeia.pdf (accessed on 28 August 2019).

- Patnaik, T.; Brown, B. Carbon black: Why quality matters. Rubber Plast. News 2010, 40. Available online: http://search.ebscohost.com/login.aspx?direct=true&db=bth&AN=60312798&lang=fr&site=ehost-live (accessed on 28 August 2019).

- Waste Heat Recovery Power Plant. Available online: http://www.cancarb.com/docs/pdf/Waste_Heat_Recovery_Power_Plant.pdf (accessed on 10 December 2019).

- Kiraly, A.; Ronkay, F. Development of electrically conductive polymers. In Materials Science Forum; Berecz, T., Majlinger, K., Orbulov, I.N., Szabo, P.J., Eds.; (Materials Science, Testing and Informatics); Trans Tech Publication Ltd.: Stafa Zurich, Switzerland, 2013; Volume 729, pp. 397–402. [Google Scholar] [CrossRef]

- King, J.A.; Johnson, B.A.; Via, M.D.; Ciarkowski, C.J. Electrical conductivity of carbon-filled polypropylene-based resins. J. Appl. Polym. Sci. 2009, 112, 425–433. [Google Scholar] [CrossRef]

- Zhou, S.; Hrymak, A.; Kamal, M. Electrical and morphological properties of microinjection molded polypropylene/carbon nanocomposites. J. Appl. Polym. Sci. 2017, 134, 45462. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Q.; Huang, Y.; Liao, X.; Niu, Y. Synergistic effect of multiwalled carbon nanotubes and carbon black on rheological behaviors and electrical conductivity of hybrid polypropylene nanocomposites. Polym. Compos. 2018, 39, E723–E732. [Google Scholar] [CrossRef]

- Gong, T.; Peng, S.-P.; Bao, R.-Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Low percolation threshold and balanced electrical and mechanical performances in polypropylene/carbon black composites with a continuous segregated structure. Compos. Part. B Eng. 2016, 99, 348–357. [Google Scholar] [CrossRef]

- Zhansakova, K.S.; Mitryaeva, N.S.; Strizhak, E.A. Study of the effect of carbon black pigment grades on properties of polypropylene-based composites. Presented at AIP Conference Proceedings, Omsk, Russia, 26 February–2 March 2018; 2007 (1, Oil and Gas Engineering (OGE-2018)) 2018. pp. 040016-1–040016-5. [Google Scholar]

- Spahr, M.E.; Rothon, R. Carbon Black as a Polymer Filler. In Polymers and Polymeric Composites: A Reference Series; Palsule, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Wang, M.-J.; Gray, C.A.; Reznek, S.A.; Mahmud, K.; Kutsovsky, Y. Carbon black. In Kirk-Othmer Encyclopedia of Chemical Technology, 5th ed.; Seidel, A., Ed.; Wiley: Hoboken, NJ, USA, 2004; pp. 761–803. [Google Scholar]

- Kanbur, Y.; Kucukyavuz, Z. Electrical and mechanical properties of polypropylene/carbon black composites. J. Reinf. Plast. Compos. 2009, 28, 2251–2260. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, W.; Zhu, J.; Wang, C.; Sheng, S. Polyamide 6/modified carbon black nanocomposites prepared via in situ polymerization. J. Macromol. Sci. Part. B Phys. 2015, 54, 469–480. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, W.; Liu, J.; Shen, W. Effect of carbon black self-networking on surface-morphological and electrical properties of immiscible polypropylene/polyamide 6 blends. Mater. Res. Express 2019, 6, 035314. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Wang, Y.; Wu, W. Effect of polyamide 6 on the morphology and electrical conductivity of carbon black-filled polypropylene composites. R. Soc. Open Sci. 2017, 4, 170769. [Google Scholar] [CrossRef]

- Sun, X.; Yu, Q.; Shen, J.; Gao, S.; Li, J.; Guo, S. In situ microfibrillar morphology and properties of polypropylene/polyamide/carbon black composites prepared through multistage stretching extrusion. J. Mater. Sci. 2013, 48, 1214–1224. [Google Scholar] [CrossRef]

- Garmabi, H.; Naficy, S. Developing electrically conductive polypropylene/polyamide6/carbon black composites with microfibrillar morphology. J. Appl. Polym. Sci. 2007, 106, 3461–3467. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and its anisotropy characterization of 3D-printed acrylonitrile butadiene styrene copolymer (ABS)/carbon black (CB) composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Jayanth, N.; Senthil, P. Application of 3D printed ABS based conductive carbon black composite sensor in void fraction measurement. Compos. Part. B Eng. 2019, 159, 224–230. [Google Scholar] [CrossRef]

- Martinez Borja, A.L.; Perez Bueno, J.d.J.; Mendoza Lopez, M.L. Composite materials with graphenic materials by extrusion for 3D printing. Mrs Adv. 2018, 3, 3891–3898. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Cancarb website - Applications. Available online: http://www.cancarb.com/thermal-carbon-black/applications/index.html (accessed on 10 September 2019).

- Darmstadt, H.; Cao, N.-Z.; Pantea, D. Reactivity and Chemistry of Thermal Carbon Blacks in Comparison to Furnace Carbon Blacks-report; Institut Pyrovac Inc./Parc technologique du Québec métropolitain: Québec, QC, Canada, 1998. [Google Scholar]

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Roy, C. Electrical conductivity of conductive carbon blacks: Influence of surface chemistry and topology. Appl. Surf. Sci. 2003, 217, 18–193. [Google Scholar] [CrossRef]

- Tchoudakov, R.; Breuer, O.; Narkis, M. Conductive Polymer Blends with Low Carbon Black, Loading: Polypropylene/Polyamide. Polym. Eng. Sci. 1996, 36, 1336–1346. [Google Scholar] [CrossRef]

- Mackay, M.; Dao, T.; Tuteja, A.; Ho, D.L.; Van Horn, B.; Kim, H.C.; Hawker, C.J. Nanoscale effects leading to non-Einstein-like decrease in viscosity. Nat. Mater. 2003, 2, 762–766. [Google Scholar] [CrossRef]

- Patti, A. Molecular Dynamics of Spherical Nanoparticles in Dense Polymer Melts. J. Phys. Chem. B 2014, 118, 3731–3742. [Google Scholar] [CrossRef]

- Parvin, N.; Ullah, S.; Mina, F.; Gafur, A. Structures and mechanical properties of talc and carbon black reinforced high density polyethylene composites, effects of organic and inorganic fillers. J. Bangladesh Acad. Sci. 2013, 37, 11–20. [Google Scholar] [CrossRef]

- Liu, K.; Stadlbauer, W.; Zitzenbacher, G.; Paulik, C.; Burgstaller, C. Effects of surface modification of talc on mechanical properties of polypropylene/talc composites. Presented at AIP Conference Proceedings 1713, 31th International Conference of the Polymer Processing Society, ICC Jeju, Jeju, Korea, 7–11 June 2015. 120008 (2016). [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A 2015, 73, 204–231. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Matrix | TB N990 wt. % | CB N762 wt. % | ||||

|---|---|---|---|---|---|---|

| PP | 1 | 3 | 5 | 20 | 40 | 5 |

| PA6 | 1 | 3 | 5 | 20 | 40 | 5 |

| PPS | 1 | 3 | 5 | 20 | 40 | 5 |

| Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | HDT (°C) | Material Cost ($/lb) | |

|---|---|---|---|---|---|---|

| PP PD702 | 31.0 | 1100 | 910.0 | 3.2 | 88 | 1.000 |

| 1 wt. % N990 | 27.2 (0.7) | 1158 (19) | 928.3 (1.3) | 2.7 (0.6) | 96 (1) | 0.999 |

| 3 wt. % N990 | 28.7 (0.8) | 1408 (130) | 931.8 (2.2) | 3.6 (0.3) | 97 (1) | 0.997 |

| 5 wt. % N990 | 28.9 (0.5) | 1459 (51) | 932.5 (0.4) | 2.5 (0.5) | 100 (1) | 0.995 |

| 5 wt. % N762 | 28.4 (0.4) | 1348 (98) | 928.8 (0.4) | 2.2 (0.5) | 98 (2) | 0.995 |

| 20 wt. % N990 | 27.2 (0.2) | 1834 (60) | 95.3 (0.2) | 2.4 (0.3) | 100 (1) | 0.981 |

| 40 wt. % N990 | 26.1 (0.2) | 2717 (133) | 3.9 (0.2) | 1.0 (0.3) | 105 (1) | 0.872 |

| PP/40 wt. % talc Accutech HP0334T40L | 26.0 | 2600 | 12.0 | 3.0 | 125 | ~ 1.000 |

| Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | HDT (°C) | Material Cost ($/lb) | |

|---|---|---|---|---|---|---|

| PA6 B27 | 80.0 | 3000 | 15.0 | 2.4 | 160 | 3.75 |

| 1 wt. % N990 | 73.0 (0.6) | 2974 (53) | 109.5 (63) | 3.8 (0.5) | 148 (45) | 3.72 |

| 3 wt. % N990 | 76.5 (1.5) | 3295 (60) | 39.3 (16) | 3.5 (0.6) | 189 (1) | 3.66 |

| 5 wt. % N990 | 77.3 (0.6) | 3376 (54) | 45.8 (17) | 3.6 (0.5) | 187 (1) | 3.61 |

| 5 wt. % N762 | 77.4 (0.5) | 3178 (49) | 98.4 (54) | 2.6 (0.7) | 186 (1) | 3.61 |

| 20 wt. % N990 | 78.2 (0.2) | 3687 (95) | 12.6 (1.2) | 2.6 (0.3) | 183 (5) | 3.18 |

| 40 wt. % N990 | 74.5 (6.2) | 4851 (117) | 2.7 (0.9) | 2.6 (0.1) | 181 (2) | 2.52 |

| PA6/30 wt. % mineral Ultramid B3M6 | 80.0 | 4600 | 5.0 | 6.4 | 195 | ~ 3.00 |

| Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | HDT (°C) | Material Cost ($/ lb) | |

|---|---|---|---|---|---|---|

| PPS | 82.1 (3.0) | 3661 (120) | 3.3 (0.9) | 2.7 (0.1) | 167 (16) | 12.50 |

| 1 wt. % N990 | 72.3 (2.1) | 3780 (128) | 2.3 (0.1) | 2.6 (0.1) | 172 (3) | 12.38 |

| 3 wt. % N990 | 68.6 (4.0) | 3819 (37) | 2.1 (0.2) | 2.5 (0.4) | 185 (6) | 12.15 |

| 5 wt. % N990 | 70.4 (3.7) | 4030 (123) | 2.1 (0.1) | 2.6 (0.1) | 190 (2) | 11.92 |

| 5 wt. % N762 | 72.0 (4.6) | 4097 (205) | 2.1 (0.2) | 2.4 (0.4) | 189 (5) | 11.92 |

| 20 wt. % N990 | 62.0 (7.6) | 4994 (144) | 1.4 (0.2) | 1.5 (0.1) | 196 (4) | 10.18 |

| 40 wt. % N990 | 53.4 (11.1) | 7056 (84) | 0.8 (0.2) | 1.5 (0.4) | 217 (6) | 7.77 |

| PPS/fiberglass/minerals Fortron® 6450A6 | 90 | 10,000 | 1.5 | 6.0 | ~ 220 | ~ 12.50 |

| Matrix | CF/TB N990 wt. %/wt. % (+ CA) | ||||

|---|---|---|---|---|---|

| PP | 20/0 | 17/3 | 15/5 | 10/10 | 0/20 |

| + CA | + CA | + CA | + CA | + CA | |

| PA6 | 20/0 | 17/3 | 15/5 | 10/10 | 0/20 |

| PPS | 20/0 | 17/3 | 15/5 | 10/10 | 0/20 |

| TS (MPa) | TM (MPa) | ε (%) | IS (kJ/m2) | HDT (°C) | |

|---|---|---|---|---|---|

| PP/CF/TB Hybrid Composites | |||||

| 100% PP | 31 | 1100 | 910 | 3.2 | 88 |

| PP + 20 wt. % CF | 34 (0.3) | 9148 (283) | 6.3 (1.3) | 3.0 (0.1) | 149 (0.1) |

| PP + 20 wt. % CF + 5 wt. % CA | 80 (0.6) | 8929 (268) | 8.3 (0.3) | 5.1 (0.3) | 156 (0.3) |

| PP + 17 wt. % CF + 3 wt. % TB | 37 (0.4) | 7913 (299) | 4.4 (0.4) | 2.7 (0.1) | 151 (0.3) |

| PP + 17 wt. % CF + 3 wt. % TB + 5 wt. % CA | 74 (0.5) | 8047 (176) | 8.5 (0.4) | 4.8 (0.1) | 155 (0.2) |

| PP + 15 wt. % CF + 5 wt. % TB | 38 (0.2) | 7208 (379) | 5.4 (0.2) | 2.7 (0.1) | 154 (0.1) |

| PP + 15 wt. % CF + 5 wt. % TB + 5 wt. % CA | 71 (0.4) | 7238 (97) | 9.3 (0.2) | 4.4 (0.2) | 151 (0.3) |

| PP + 10 wt. % CF + 10 wt. % TB | 31 (0.3) | 5636 (118) | 12.4 (1.6) | 2.3 (0.1) | 140 (0.4) |

| PP + 10 wt. % CF + 10 wt. % TB + 5 wt. % CA | 60 (0.3) | 5276 (220) | 11.1 (0.3) | 3.3 (0.3) | 152 (0.2) |

| PP + 20 wt. % TB | 27 (0.2) | 1834 (60) | 95.3 (3) | 2.4 (0.3) | 100 (1.1) |

| PP + 20 wt. % TB + 5 wt. % CA | 32 (0.2) | 1861 (72) | 28.5 (4.8) | 0.7 (0.0) | 108 (0.2) |

| PA6/CF/TB Hybrid Composites | |||||

| 100% PA6 | 80 | 3000 | 15.0 | 2.4 (0.2) | 160 |

| PA6 + 20 wt. % CF | 145 (1.8) | 11420 (457) | 10.9 (0.0) | 4.4 (0.3) | 216 (0.3) |

| PA6 + 17 wt. % CF + 3 wt. % TB | 147 (1.0) | 11592 (110) | 10.1 (0.2) | 3.7 (0.3) | 213 (0.1) |

| PA6 + 15 wt. % CF + 5 wt. % TB | 135 (0.8) | 10284 (273) | 10.6 (0.3) | 3.7 (0.5) | 214 (0.4) |

| PA6 + 10 wt. % CF + 10 wt. % TB | 114 (0.8) | 8211 (285) | 11.2 (0.2) | 2.3 (0.2) | 210 (0.8) |

| PA6 + 20 wt. % TB | 78 (0.2) | 3687 (95) | 12.6 (1.2) | 2.6 (0.3) | 183 (4.6) |

| PPS/CF/TB Hybrid Composites | |||||

| 100% PPS | 82 (3.0) | 3661 (120) | 3.3 (0.9) | 2.7 (0.1) | 167 (15.7) |

| PPS + 20 wt. % CF | 151 (14.8) | 19994 (1063) | 4.3 (0.7) | 4.3 (0.3) | 274 (0.2) |

| PPS + 17 wt. % CF + 3 wt. % TB | 144 (7.7) | 17116 (2446) | 4.7 (0.4) | 3.6 (0.3) | 272 (1.0) |

| PPS + 15 wt. % CF + 5 wt. % TB | 131 (4.3) | 17254 (1146) | 3.9 (0.3) | 3.5 (0.1) | 273 (0.7) |

| PPS + 10 wt. % CF + 10 wt. % TB | 105 (3.6) | 13449 (1183) | 3.9 (0.3) | 2.7 (0.1) | 269 (0.8) |

| PPS + 20 wt. % TB | 62 (7.6) | 4994 (144) | 1.4 (0.2) | 1.5 (0.1) | 196 (4.4) |

| Thermoplastic Matrix | CF/TB N990 (wt. %/wt. %) | ||||

|---|---|---|---|---|---|

| 20/0 Composite | 17/3 Hybrid | 15/5 Hybrid | 10/10 Hybrid | 0/20 Composite | |

| PP (0.75 USD/lb) | 2.4 | 2.15 | 1.99 | 1.58 | 0.8 |

| PA6 (3.75 USD/lb) | 4.8 | 4.6 | 4.4 | 4.0 | 3.2 |

| PPS (12.5 USD/lb) | 11.8 | 11.6 | 11.4 | 11.0 | 10.2 |

| Matrix | TB N990 wt. % | TB N990/CF wt. %/wt. % | |

|---|---|---|---|

| PA6 | 10 | 20 | 10/10 |

| ABS | 10 | 20 | 10/10 + Add |

| TS (MPa) | TM (MPa) | ε (%) | IS (kJ/m2) | |

|---|---|---|---|---|

| PA6 composites and hybrids | ||||

| PA6 pristine, IM | 80.0 | 3000 | 15.0 | 8.9 (2.5) |

| PA6/10 wt. % TB, IM | 69.2 (2.7) | 3077 (38) | 21.0 (9.5) | 4.1 (1.0) |

| PA6/10 wt. % TB, 3DP | 45.8 (2.1) | 2795 (345) | 3.4 (0.7) | 3.0 (0.9) |

| PA6/20 wt. % TB, IM | 74.7 (2.1) | 3594 (113) | 22.9 (9.3) | 2.7 (0.8) |

| PA6/20 wt. % TB, 3DP | 38.5 (3.9) | 2485 (191) | 3.8 (0.8) | 3.3 (0.8) |

| PA6/10 wt. % TB/10 wt. % CF, IM | 109.9 (0.9) | 7550 (208) | 4.9 (0.2) | 2.4 (0.2) |

| PA6/10 wt. % TB/10 wt. % CF, 3DP | 53.9 (3.6) | 3641 (567) | 5.5 (1.1) | 4.5 (1.4) |

| PA6/CF, commercial, 3DP | 33.9 (2.7) | 2226 (204) | 3.3 (0.7) | 4.1 (0.8) |

| PA6, commercial, 3DP | 42.4 (0.5) | 1945 (163) | 21.0 (0.6) | 12.8 (2.1) |

| PA6 composites and hybrids | ||||

| ABS pristine, IM | 32.8 (0.4) | 2070 (42) | 10.9 (3.4) | 11.5 (0.4) |

| ABS/10 wt. % TB, IM | 34.0 (0.7) | 2449 (74) | 3.3 (1.2) | 3.6 (0.3) |

| ABS/10 wt. % TB, 3DP | 29.5 (0.6) | 2228 (44) | 4.3 (0.3) | 6.2 (0.7) |

| ABS/20 wt. % TB, IM | 36.0 (1.0) | 3010 (108) | 2.4 (0.2) | 1.5 (0.3) |

| ABS/20 wt. % TB, 3DP | 20.5 (2.9) | 2162 (208) | 1.4 (0.5) | 2.5 (0.2) |

| ABS/10 wt. % TB/10 wt. % CF, IM | 66.1 (1.1) | 7552 (171) | 2.0 (0.3) | 3.0 (0.1) |

| ABS/10 wt. % TB/10 wt. %CF/Add, 3DP | 17.5 (0.7) | 1731 (113) | 2.3 (0.2) | 4.3 (0.3) |

| ABS, commercial, 3DP | 31.2 (0.9) | 1582 (88) | 9.9 (0.8) | 4.1 (0.8) |

| Physico-Chemical Test | Minimum | Maximum | Effective Value |

|---|---|---|---|

| Nitrogen Surface Area (m2/g) | 7.0 | 12.0 | 8.5 |

| Oil Absorption Number (mL/100 g) | 35.0 | 44.0 | 37.8 |

| pH | 9.0 | 11.0 | 10.0 |

| Ash Content (%) | - | 0.20 | 0.10 |

| Heat Loss (%) | - | 0.10 | 0.05 |

| Fines Content (%) | - | 8.0 | 3.0 |

| Sieve Residue, 325 mesh (ppm) | - | 15.0 | 2.0 |

| Pellet Hardness, Average (g) | - | 30.0 | 19.0 |

| Toluene Extract (%) | - | 0.50 | 0.12 |

| Physico-Chemical Test | Minimum | Maximum | Effective Value |

|---|---|---|---|

| Iodine Adsorption Number (g/kg) | 22.0 | 32.0 | 25.0 |

| Nitrogen Surface Area (m2/g) | 23.0 | 33.0 | 26.6 |

| Oil Absorption Number (mL/100g) | 60.0 | 70.0 | 64.0 |

| pH | 6.0 | 9.0 | 7.9 |

| Ash Content (%) | - | 0.70 | 0.17 |

| Heat Loss (%) | - | 1.0 | 0.5 |

| Fines content (%) | - | 9.0 | 4.0 |

| Sieve Residue, 325 mesh (ppm) | - | 150 | 50 |

| Pellet Hardness, Average (g) | - | 45 | 23 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihai, M.; Stoeffler, K.; Norton, E. Use of Thermal Black as Eco-Filler in Thermoplastic Composites and Hybrids for Injection Molding and 3D Printing Applications. Molecules 2020, 25, 1517. https://doi.org/10.3390/molecules25071517

Mihai M, Stoeffler K, Norton E. Use of Thermal Black as Eco-Filler in Thermoplastic Composites and Hybrids for Injection Molding and 3D Printing Applications. Molecules. 2020; 25(7):1517. https://doi.org/10.3390/molecules25071517

Chicago/Turabian StyleMihai, Mihaela, Karen Stoeffler, and Edward Norton. 2020. "Use of Thermal Black as Eco-Filler in Thermoplastic Composites and Hybrids for Injection Molding and 3D Printing Applications" Molecules 25, no. 7: 1517. https://doi.org/10.3390/molecules25071517

APA StyleMihai, M., Stoeffler, K., & Norton, E. (2020). Use of Thermal Black as Eco-Filler in Thermoplastic Composites and Hybrids for Injection Molding and 3D Printing Applications. Molecules, 25(7), 1517. https://doi.org/10.3390/molecules25071517