Comparative Studies of Selected Criteria Enabling Optimization of the Extraction of Polar Biologically Active Compounds from Alfalfa with Supercritical Carbon Dioxide

Abstract

1. Introduction

2. Results

3. Discussion

4. Materials and Methods

4.1. Chemicals and Reagents

4.2. Plant Material

4.3. Extraction and Optimization

4.4. HPLC-MS/MS Analysis

4.5. Total Phenolics Content (TPC) and Total Flavonoids Content (TFC)

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Abbreviations

References

- Wrona, O.; Rafińska, K.; Walczak-Skierska, J.; Możeński, C.; Buszewski, B. Extraction and Determination of Polar Bioactive Compounds from Alfalfa (Medicago sativa L.) Using Supercritical Techniques. Molecules 2019, 24, 4608. [Google Scholar] [CrossRef]

- Mukhopadhyay, M. Department of Chemical Engineering, Indian Institute of Technology, Bombay, Powai Natural. In Extract Using Supercritical Carbon Dioxide; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Wrona, O.; Rafińska, K.; Możeński, C.; Buszewski, B. Supercritical carbon dioxide extraction of Solidago gigantean Ait.: Optimization at quarter-technical scale and scale up the process to half-technical plant. Ind. Crop Prod. 2019, 130, 316–324. [Google Scholar] [CrossRef]

- Wrona, O.; Rafińska, K.; Możeński, C.; Buszewski, B. Supercritical fluid extraction of bioactive compounds from plant materials. J. AOAC Int. 2017, 100, 1624–1635. [Google Scholar] [CrossRef] [PubMed]

- Rafińska, K.; Pomastowski, P.; Wrona, O.; Górecki, R.; Buszewski, B. Medicago sativa as a source of secondary metabolites for agriculture andpharmaceutical industry. Phytochemistry 2017, 20, 520–539. [Google Scholar] [CrossRef]

- Reverchon, E.; De Marco, I. Supercritical fluid extraction and fractionation of natural matter. J. Supercrit. Fluids 2006, 38, 146–166. [Google Scholar] [CrossRef]

- Biesaga, M. Influence of extraction methods on stability of flavonoids. J. Chromatogr. A 2011, 1218, 2505–2512. [Google Scholar] [CrossRef]

- Oniuszuk, A.; Podgórski, R. Influence of different extraction methods on the quantification of selected flavonoids and phenolic acids from Tiliacordata inflorescence. Ind. Crops Prod. 2015, 76, 509–514. [Google Scholar] [CrossRef]

- Zarena, A.S.; Manohar, B.; Sankar, K.U. Optimization of supercritical carbon dioxide extraction of xanthones from mangosteen pericarp by response surface methodology. Food Bioprocess Technol. 2012, 5, 1181–1188. [Google Scholar] [CrossRef]

- Maran, J.P.; Manikandan, S.; Priya, B.; Gurumoorthi, P. Box-Behnken design based multi-response analysis and optimization of supercritical carbon dioxide extraction of bioactive flavonoid compounds from tea (Camellia sinensis L.) leaves. J. Food Sci. Technol. Mysore 2015, 52, 92–104. [Google Scholar] [CrossRef]

- Wrona, O.; Rafińska, K.; Możeński, C.; Buszewski, B. Supercritical fluid extraction as a technique for isolation of biologically active compounds from plant material of industrial importance. Przem. Chem. 2018, 97, 1246–1252. [Google Scholar]

- Martínez, J.; Rosa, P.T.V.; Meireles, M.A.A. Extraction of Clove and Vetiver Oils with Supercritical Carbon Dioxide: Modeling and Simulation. Open Chem. Eng. J. 2007, 1, 1. [Google Scholar] [CrossRef]

- Oniszczuk, A.; Podgórski, R.; Oniszczuk, T.; Zukiewicz-Sobczak, W.; Nowak, R.; Waksmundzka-Hajnos, M. Extraction methods for the determination of phenolic compounds from Equisetum arvense L. herb. Ind. Crops Prod. 2014, 61, 377–381. [Google Scholar] [CrossRef]

- Shortle, E.; Kerry, J.; Furey, A.; Gilroy, D. Optimisation of process variables for antioxidant components from Crataegus monogyna by supercritical fluid extraction (CO2) using Box-Behnken experimental design. J. Supercrit. Fluids 2013, 81, 112–118. [Google Scholar] [CrossRef]

- Rudyk, S.; Spirov, P.; Tyrovolas, A. Effect of temperature on crude oil extraction by SC-CO2 at 40–70 °C and 40–60 MPa. J. CO₂ Util. 2018, 24, 471–478. [Google Scholar] [CrossRef]

- Ghasemi, E.; Raofie, F.; Najafi, N.M. Application of response surface methodology and central composite design for the optimisation of supercritical fluid extraction of essential oils from Myrtuscommunis L. leaves. Food Chem. 2011, 126, 1449–1453. [Google Scholar] [CrossRef]

- Kryževičiūtė, N.; Kraujalis, P.; Venskutonis, P.R. Optimization of high pressure extraction processes for the separation of raspberry pomace into lipophilic and hydrophilic fractions. J. Supercrit. Fluids 2016, 108, 61–68. [Google Scholar] [CrossRef]

- Hadidi, M.; Ibarz, A.; Conde, J.; Pagan, J. Optimisation of steam blanching on enzymatic activity, color and protein degradation of alfalfa (Medicago sativa) to improve some quality characteristics of its edible protein. Food Chem. 2019, 276, 591–598. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yang, B.; Du, X.; Yi, C. Optimisation of supercritical fluid extraction of flavonoids from Pueraria lobata. Food Bioprod. Process. 2008, 108, 737–741. [Google Scholar] [CrossRef]

- Gatouillat, G.; Alabdul, M.A.; Bertinc, E.; Okiemy-Akeliad, M.G.; Morjaniae, H.; Lavaudf, K.; Madoulet, K. Cytotoxicity and apoptosis induced by alfalfa (Medicago sativa) leaf extracts in sensitive and multidrug-resistant tumor cells. Nutr. Cancer 2014, 66, 483–491. [Google Scholar] [CrossRef]

- Stochmal, A.; Oleszek, W. Seasonal and structural changes of flavones in alfalfa (Medicago sativa) aerial parts. J. Food Agric. Environ. 2007, 5, 170–174. [Google Scholar]

- Krakowska, A.; Rafińska, K.; Walczak, J.; Buszewski, B. Enzyme-assisted optimized supercritical fluid extraction to improve Medicago sativa polyphenolics isolation. Ind. Crops Prod. 2018, 124, 931–940. [Google Scholar] [CrossRef]

- Andrés, V.; Villanueva, M.J.; Tenorio, M.D. Simultaneous determination of tocopherols, retinol, ester derivatives and β-carotene in milk - and soy-juice based beverages by HPLC with diode-array detection. LWT Food Sci. Technol. 2014, 2, 1–6. [Google Scholar] [CrossRef]

- Karpińska, J.; Mikołuć, B.; Motkowski, R.; Piotrowska-Jastrzębska, J. HPLC method for simultaneous determination of retinol, α-tocopherol and coenzyme Q10 in human plasma. J. Pharm. Biomed. Sci. 2006, 42, 232–236. [Google Scholar] [CrossRef] [PubMed]

- Mesquita, E.; Monteiro, M. Simultaneous HPLC determination of flavonoids and phenolic acids profile in Pêra-Rio orange juice. Food Res. Int. 2018, 106, 54–63. [Google Scholar] [CrossRef]

- Lin, X.; Wu, L.; Wang, X.; Yao, L.; Wang, L. Ultrasonic-assisted extraction for flavonoid compounds content and antioxidant activities of India Moringa oleifera L. leaves: Simultaneous optimization, HPLC characterization and comparison with other methods. J. Appl. Res. Med. Aromat. Plants 2021, 20, 100284. [Google Scholar] [CrossRef]

- Oleszek, W.A. Saponins. In Natural Food Antimicrobial Systems; Naidu, A.S., Ed.; CRC Press, Inc.: Boca Raton, FL, USA, 2000; pp. 295–324. [Google Scholar]

- Silva, E.O.; Batista, R. Ferulic Acid and Naturally Occurring Compounds Bearing a Feruloyl Moiety: A Review on Their Structures, Occurrence, and Potential Health Benefits. Compr. Rev. Sci. Food Saf. 2017, 15, 570–616. [Google Scholar] [CrossRef]

- Randjelović, P.; Veljković, S.; Stojiljković, N.; Sokolović, D.; Ilić, I.; Laketić, D.; Randjelović, N. The Beneficial Biological Properties of Salicylic Acid. Acta Fac. Med. Naissensis 2015, 32, 259–265. [Google Scholar] [CrossRef]

- Salehi, B.; Venditti, A.; Sharifi-Rad, M.; Kregiel, D.; Sharifi-Rad, J.; Durazzo, A.; Lucarini, M.; Santini, A.; Souto, E.; Novellino, E.; et al. The Therapeutic Potential of Apigenin. Int. J. Mol. Sci. 2019, 20, 1305. [Google Scholar] [CrossRef] [PubMed]

- Anand, A.; Arulmoli, R.; Parasuraman, S. Overviews of Biological Importance of Quercetin: A Bioactive Flavonoid. Pharmacogn. Rev. 2016, 10, 84–89. [Google Scholar] [CrossRef]

| Compounds | Number of Extraction Experiments | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 | E13 | E14 | E15 | |

| Coumaric acid | 5.98 | 3.93 | 0.64 | 5.22 | 2.69 | 2.41 | 2.38 | 2.70 | 2.63 | 1.18 | 4.25 | 2.49 | 1.85 | 0.45 | 4.07 |

| Salicylic acid | 103.18 | 225.70 | 54.80 | 87.86 | 64.48 | 84.84 | 66.38 | 2.00 | 96.87 | 43.07 | 58.49 | 91.34 | 119.56 | 45.01 | 221.41 |

| Caffeic acid | 0.78 | 0.97 | 0.42 | 0.36 | 0.58 | 0.47 | 0.60 | 0.61 | 0.38 | 0.27 | 0.15 | 0.26 | 0.60 | 0.25 | 1.24 |

| Syringic acid | 9.64 | 6.81 | 3.34 | 8.13 | 5.07 | 5.56 | 4.97 | 5.18 | 7.79 | 4.49 | 4.59 | 4.99 | 6.84 | 2.34 | 6.75 |

| Ferulic acid | 108.73 | 101.86 | 26.89 | 119.73 | 69.04 | 74.12 | 78.90 | 75.64 | 117.76 | 32.10 | 73.91 | 78.69 | 119.59 | 34.60 | 87.75 |

| Protocatechuic acid | 0.31 | 0.30 | 0.19 | 0.29 | 0.25 | 0.22 | 0.24 | 0.25 | 0.23 | 0.17 | 0.12 | 0.09 | 0.26 | 0.07 | 0.43 |

| Sinapic acid | 1.32 | 1.27 | 0.23 | 1.52 | 0.95 | 0.86 | 0.99 | 0.95 | 1.05 | 0.25 | 0.27 | 0.33 | 1.62 | 0.24 | 0.80 |

| 4-hydroxybenzoic acid | 0.86 | 0.97 | 2.36 | 1.17 | 1.86 | 1.12 | 1.93 | 2.02 | 3.16 | 0.51 | n.d. | n.d. | n.d. | 0.24 | 0.36 |

| Biochanin A | 0.34 | 0.12 | 0.04 | 0.10 | 0.15 | 0.08 | 0.16 | 0.15 | 0.14 | 0.06 | 0.05 | 0.16 | 0.45 | 0.07 | 0.19 |

| Esculetin | 0.22 | 0.12 | 0.07 | 0.07 | 0.11 | 0.08 | 0.10 | 0.11 | 0.13 | 0.09 | 0.04 | 0.03 | 0.06 | 0.08 | 0.15 |

| Esculin | 0.01 | n.d. | n.d. | n.d. | 0.01 | n.d. | 0.01 | 0.01 | 0.01 | n.d. | 0.01 | 0.01 | 0.02 | n.d. | n.d. |

| Naringenin | 0.28 | 0.18 | 0.03 | 0.09 | 0.16 | 0.14 | 0.17 | 0.17 | 0.15 | 0.07 | 0.02 | 0.12 | 0.23 | 0.03 | 0.26 |

| Naringin | 0.01 | 0.01 | n.d. | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | n.d. | n.d. | 0.02 | n.d. | 0.01 |

| Quercetin | 2.04 | 0.86 | 0.28 | 0.96 | 0.55 | 0.73 | 0.56 | 0.59 | 0.73 | 0.32 | 0.66 | 0.68 | 2.23 | 0.40 | 1.36 |

| Rutin | n.d. | n.d. | n.d. | 0.01 | 0.02 | 0.00 | 0.02 | 0.02 | n.d. | n.d. | n.d. | n.d. | 0.01 | n.d. | n.d. |

| Luteolin | 0.14 | 0.17 | n.d. | 0.02 | 0.05 | 0.08 | 0.05 | 0.05 | 0.10 | n.d. | n.d. | 0.01 | 0.13 | n.d. | 0.11 |

| Apigenin | 2.60 | 1.22 | 0.08 | 0.02 | 0.46 | 0.98 | 0.55 | 0.49 | 1.57 | 0.47 | n.d. | 0.89 | 2.19 | 0.22 | 1.33 |

| Σ= | 236.44 | 344.49 | 89.37 | 225.56 | 146.44 | 171.7 | 158.02 | 90.95 | 232.71 | 83.06 | 142.56 | 180.09 | 255.66 | 84.00 | 326.22 |

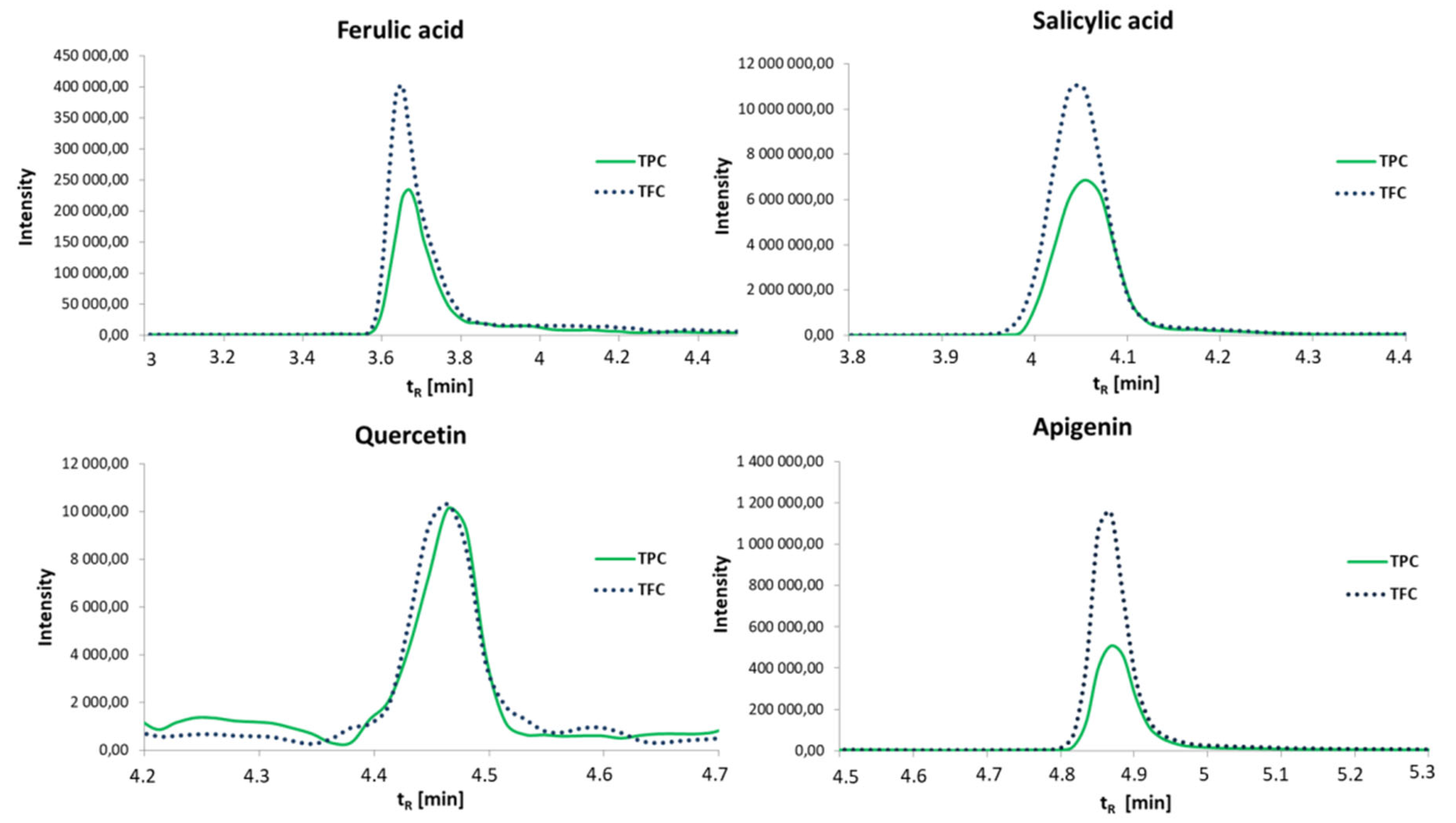

| Compounds | tR (min) | MRM (m/z) | µg g−1 | |

|---|---|---|---|---|

| TPC | TFC | |||

| Coumaric acid | 3.550 | 163–93 | 1.93 | 5.50 |

| Salicylic acid | 4.054 | 137–93 | 157.77 | 220.63 |

| Caffeic acid | 3.177 | 179–134 | 0.31 | 0.66 |

| Syringic acid | 3.243 | 197–95 | 7.87 | 8.64 |

| Ferulic acid | 3.682 | 193–133 | 83.73 | 106.22 |

| Protocatechuic acid | 2.582 | 153–108 | 0.13 | 0.17 |

| Sinapic acid | 3.653 | 223–121 | 0.97 | 0.84 |

| 4-hydroxybenzoic acid | 2.940 | 137–65 | n.d. | 0.07 |

| Biochanin A | 5.672 | 283–211 | 2.40 | 0.84 |

| Esculetin | 3.183 | 177–89 | n.d. | 0.10 |

| Esculin | 2.592 | 339–177 | n.d. | n.d. |

| Naringenin | 4.844 | 271–119 | 0.15 | 0.21 |

| Naringin | 3.528 | 579–271 | 0.01 | 0.01 |

| Quercetin | 4.462 | 301–227 | 1.53 | 1.76 |

| Rutin | 3.506 | 609–300 | n.d. | n.d. |

| Luteolin | 4.543 | 285–133 | 0.04 | 0.12 |

| Apigenin | 4.864 | 269–117 | 1.26 | 2.14 |

| Σ = 258.11 | Σ = 347.91 | |||

| Compounds | Optimal Conditions | Predicted Value, µg g−1 | |||

|---|---|---|---|---|---|

| T, K | T, °C | P, MPa | F, kg h−1 | ||

| Coumaric acid | 352.02 | 78.87 | 72.61 | 6.7 | 6.14 |

| Salicylic acid | 351.45 | 78.3 | 79.8 | 6.51 | 242.29 |

| Caffeic acid | 353.1 | 79.95 | 73.45 | 6.81 | 1.307 |

| Syringic acid | 353.15 | 80 | 78.46 | 6.98 | 9.98 |

| Ferulic acid | 317.26 | 44.11 | 77.69 | 3.94 | 124.37 |

| Protocatechuic acid | 353 | 79.85 | 59.2 | 6.98 | 0.44 |

| Sinapic acid | 328.74 | 55.59 | 78.72 | 3.2 | 1.65 |

| 4-hydroxybenzoic acid | 313.15 | 40 | 80 | 5.011 | 2.94 |

| Biochanin A | 331 | 57.85 | 80 | 3 | 0.36 |

| Esculetin | 351 | 77.85 | 79.88 | 6.97 | 0.23 |

| Esculin | 328.22 | 55.07 | 80 | 3 | 0.02 |

| Naringenin | 350.7 | 77.55 | 70.1 | 6.93 | 0.28 |

| Naringin | 331.5 | 58.35 | 80 | 3 | 0.019 |

| Quercetin | 353.15 | 80 | 79.99 | 7 | 1.99 |

| Rutin | 330.3 | 57.15 | 51.62 | 4.82 | 0.014 |

| Luteolin | 352.49 | 79.34 | 79.3 | 6.61 | 0.19 |

| Apigenin | 327.6 | 54.45 | 80 | 7 | 2.57 |

| Σ = 394.79 | |||||

| Box–Behnken Design | |||

|---|---|---|---|

| T, K | P, MPa | F, kg h−1 | |

| E1 | 333.15 (0) | 80.00 (1) | 7.00 (1) |

| E2 | 353.15 (1) | 80.00 (1) | 5.00 (0) |

| E3 | 353.15 (1) | 20.00 (−1) | 5.00 (0) |

| E4 | 313.15 (−1) | 50.00 (0) | 3.00 (−1) |

| E5 | 333.15 (0) | 50.00 (0) | 5.00 (0) |

| E6 | 353.15 (1) | 50.00 (0) | 3.00 (−1) |

| E7 | 333.15 (0) | 50.00 (0) | 5.00 (0) |

| E8 | 333.15 (0) | 50.00 (0) | 5.00 (0) |

| E9 | 313.15 (−1) | 80.00 (1) | 5.00 (0) |

| E10 | 333.15 (0) | 20.00 (−1) | 3.00 (−1) |

| E11 | 313.15 (−1) | 20.00 (−1) | 5.00 (0) |

| E12 | 313.15 (−1) | 50.00 (0) | 7.00 (1) |

| E13 | 333.15 (0) | 80.00 (1) | 3.00 (−1) |

| E14 | 333.15 (0) | 20.00 (−1) | 7.00 (1) |

| E15 | 353.15 (1) | 50.00 (0) | 7.00 (1) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wrona, O.; Rafińska, K.; Krakowska-Sieprawska, A.; Buszewski, B. Comparative Studies of Selected Criteria Enabling Optimization of the Extraction of Polar Biologically Active Compounds from Alfalfa with Supercritical Carbon Dioxide. Molecules 2021, 26, 2994. https://doi.org/10.3390/molecules26102994

Wrona O, Rafińska K, Krakowska-Sieprawska A, Buszewski B. Comparative Studies of Selected Criteria Enabling Optimization of the Extraction of Polar Biologically Active Compounds from Alfalfa with Supercritical Carbon Dioxide. Molecules. 2021; 26(10):2994. https://doi.org/10.3390/molecules26102994

Chicago/Turabian StyleWrona, Olga, Katarzyna Rafińska, Aneta Krakowska-Sieprawska, and Bogusław Buszewski. 2021. "Comparative Studies of Selected Criteria Enabling Optimization of the Extraction of Polar Biologically Active Compounds from Alfalfa with Supercritical Carbon Dioxide" Molecules 26, no. 10: 2994. https://doi.org/10.3390/molecules26102994

APA StyleWrona, O., Rafińska, K., Krakowska-Sieprawska, A., & Buszewski, B. (2021). Comparative Studies of Selected Criteria Enabling Optimization of the Extraction of Polar Biologically Active Compounds from Alfalfa with Supercritical Carbon Dioxide. Molecules, 26(10), 2994. https://doi.org/10.3390/molecules26102994