Development of a High-Fibre Multigrain Bar Technology with the Addition of Curly Kale

Abstract

:1. Introduction

2. Results

2.1. Development of the Recipe Composition and Production Technology of Multigrain Bars

2.2. Water Activity and Its Content in Multigrain Bars

2.3. The Effect of the Addition of Kale and Fibre Preparation on the Texture of the Multigrain Bars

2.3.1. Compression Test

2.3.2. Texture Profile Analysis (TPA) Test

2.4. The Effect of the Addition of Kale and Fibre Preparation on the Color of the Multigrain Bars

2.5. The Effect of the Addition of Kale and Fibre on the Antioxidant Content of Multigrain Bars

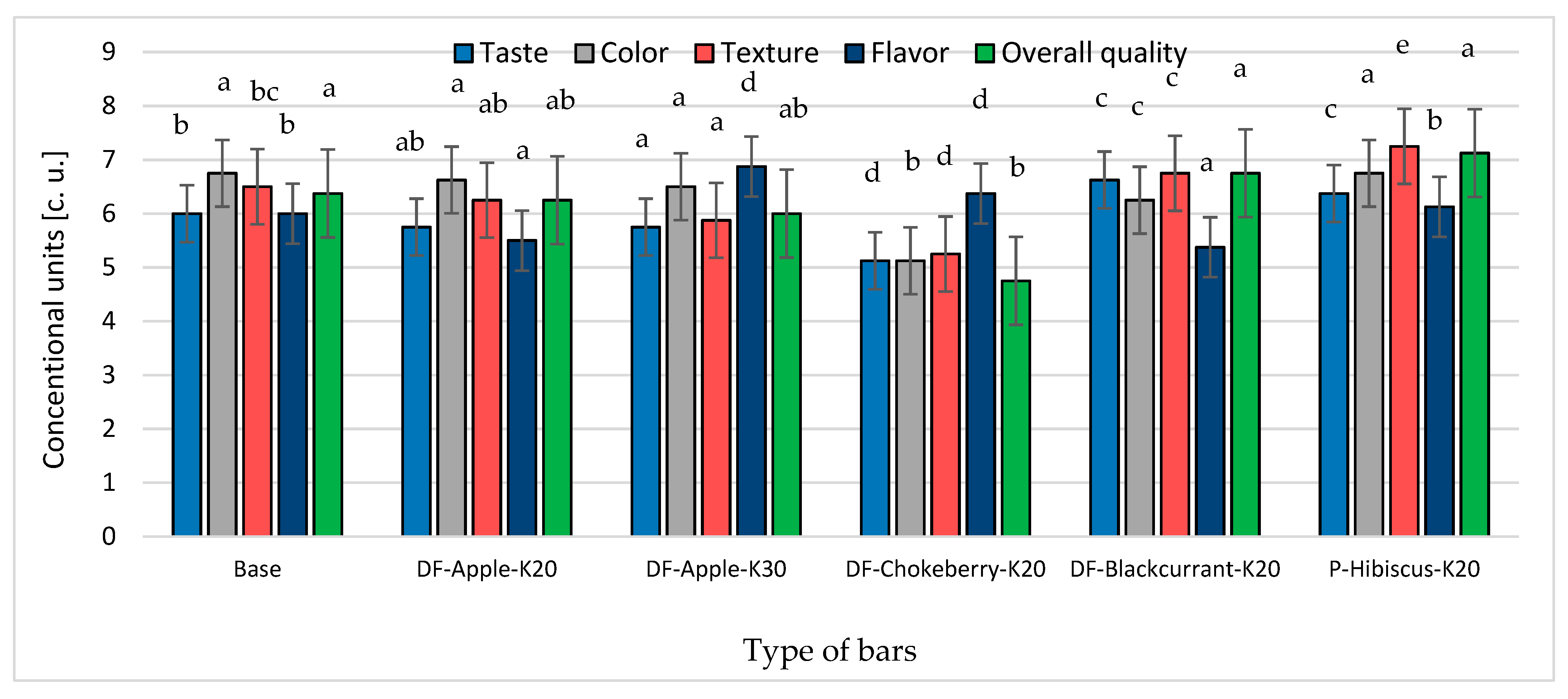

2.6. The Effect of the Addition of Kale and Fibre on the Sensory Quality of the Multigrain Bars

3. Discussion

4. Materials and Methods

4.1. Material

4.2. Experimental Procedure

4.2.1. Preparation of BARS

4.2.2. Baking

4.3. Analytical Methods

4.3.1. Determination of Dry Matter Content

4.3.2. Determination of Water Activity

4.3.3. Colour Parameters

4.3.4. Examination of Bars Structure

Compression Test

Texture Profile Analysis (TPA) Test

- ■

- Hardness—the maximum value of the force used during the test [N];

- ■

- Elasticity—the ratio of the compression time in the second cycle to the compression time in the first test cycle;

- ■

- Cohesiveness (compressibility)—the ratio of the compression work in the second cycle to the compression work in the first cycle;

- ■

- Gumminess—the product of hardness and cohesiveness [N];

- ■

- Chewiness—product of gumminess and elasticity [N].

4.3.5. Chemical Determinations

Nutritional Value

Determination of Protein Content

Determination of Fat Content

Determination of Ash Content

Determination of Total Dietary Fibre Content

Calculation of Carbohydrates Content, Including Sugars

- H—humidity of the sample, [g/100 g d.m];

- A—ash content of the sample, [g/100 g d.m];

- F—fat content of the sample, [g/100 g d.m];

- P—protein content of the sample, [g/100 g d.m];

- DF—dietary fibre content of the sample, [g/100 g d.m].

Calculation of Energy Value

- P—protein content of the sample [g/100 g];

- CC—carbohydrates content of the sample [g/100 g];

- F—fat content of the sample [g/100 g];

- DF—dietary fibre content of the sample [g/100 g].

Determination of DPPH Radical Scavenging Activity

- A1—absorbance of the DPPH radical with acetone extract from the sample;

- A0—absorbance of the DPPH radical with acetone (control sample).

Determination of Total Polyphenol Content by the Folin–Ciocaletau Method

Determination of Carotenoids and Chlorophyll A and B Content

- CC—content of carotenoids in acetone extract [μg/mL];

- CA—content of chlorophyll A in acetone extract [μg/mL];

- CB—content of chlorophyll B in the acetone extract [μg/mL];

- CA+B—content of chlorophyll (total A + B) in the acetone extract [μg/mL];

- A663—absorbance of acetone extract measured at wavelength λ = 663 nm;

- A647—absorbance of acetone extract measured at a wavelength of λ = 647 nm;

- A470—absorbance of acetone extract measured at wavelength λ = 470 nm.

Sensory Evaluation

4.4. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Murugesan, K.; Mulugeta, K.; Hailu, E.; Tamene, W.; Yadav, S.A. Insights for integrative medicinal potentials of Ethiopian Kale (Brassica carinata): Investigation of antibacterial, antioxidant potential and phytocompounds composition of its leaves. Chin. Herb. Med. 2021, 13, 250–254. [Google Scholar] [CrossRef]

- Sun, B.; Liu, N.; Zhao, Y.; Yan, H.; Wang, Q. Variation of glucosinolates in three edible parts of Chinese kale (Brassica alboglabra Bailey) varieties. Food Chem. 2011, 124, 941–947. [Google Scholar] [CrossRef]

- Asakage, M.; Tsuno, N.H.; Kitayama, J.; Tsuchiya, T.; Yoneyama, S.; Yamada, J.; Okaji, Y.; Kaisaki, S.; Osada, T.; Takahashi, K.; et al. Sulforaphane induces inhibition of human umbilical vein endothelial cells proliferation by apoptosis. Angiogenesis 2006, 9, 83–91. [Google Scholar] [CrossRef] [PubMed]

- Flaczyk, E.; Przeor, M.; Kobus-Cisowska, J.; Biegańska-Marecik, R. Assessment of the sensory quality of new kale dishes (Brassica Oleracea). Bromatol. Toxicol. Chem. 2014, 47, 392–396. [Google Scholar]

- Korus, A. Changes in the content of minerals, B-group vitamins and tocopherols in processed kale leaves. J. Food Compos. Anal. 2020, 89, 103464. [Google Scholar] [CrossRef]

- Bąk-Sypień, I.I.; Karmańska, A.; Kubiak, K.; Karwowski, B.T. Antioxidant activity of fresh and thermal processed green and red cultivares of curly kale (Brassica oleracea L.). Bromatol. Toxicol. Chem. 2017, 50, 246–251. (In Polish) [Google Scholar]

- Son, Y.-J.; Park, J.-E.; Kim, J.; Yoo, G.; Lee, T.-S.; Nho, C.W. Production of low potassium kale with increased glucosinolate content from vertical farming as a novel dietary option for renal dysfunction patients. Food Chem. 2021, 339, 128092. [Google Scholar] [CrossRef]

- Rose, P.; Huang, Q.; Ong, C.N.; Whiteman, M. Broccoli and watercress suppress matrix metalloproteinase-9 activity and invasiveness of human MDA-MB-231 breast cancer cells. Toxicol. Appl. Pharmacol. 2005, 209, 105–113. [Google Scholar] [CrossRef]

- Szwejda-Grzybowska, J. Anticarcinogenic components of cruciferous vegetables and their importance in the prevention of neoplastic diseases. Bromatol. Toxicol. Chem. 2011, 4, 1039–1046. (In Polish) [Google Scholar]

- Michalak, M.; Szwajgier, D.; Paduch, R.; Kukula-Koch, W.; Waśko, A.; Polak-Berecka, M. Fermented curly kale as a new source of gentisic and salicylic acids with antitumor potential. J. Funct. Foods 2020, 67, 103866. [Google Scholar] [CrossRef]

- Mazzeo, T.; N’Dri, D.; Chiavaro, E.; Visconti, A.; Fogliano, V.; Pellegrini, N. Effect of two cooking procedures on phytochemical compounds, total antioxidant capacity and colour of selected frozen vegetables. Food Chem. 2011, 128, 627–633. [Google Scholar] [CrossRef]

- Godula, K.; Czerniejewska-Surma, K.; Dmytrów, I.; Plust, D.; Surma, O. Possible applications of dietary fibre in functional food production. Food Sci. Technol. Qual. 2019, 2, 5–17. [Google Scholar] [CrossRef]

- Rana, V.; Bachheti, R.K.; Chand, T.; Barman, A. Dietary fibre and human health. Int. J. Food Saf. Nutr. Public Health 2011, 4, 101. [Google Scholar] [CrossRef]

- Yangilar, F. The application of dietary fibre in food industry: Structural features, effects on health and definitione, obtaining and analysis of dietary fibre: A review. J. Food Nutr. Res. 2013, 1, 13–23. [Google Scholar] [CrossRef]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Górecka, D.; Anioła, J.; Dziedzic, K.; Ławniczak, P. Impact of particle size reduction degree of micronizated high-fibre prep-arations on their selected functional properties. Food Sci. Technol. Qual. 2008, 3, 89–95. (In Polish) [Google Scholar]

- Wojtasik, A.; Pietraś, E.; Kunachowicz, H. Dietary fiber. In Nutrition Standards for the Polish Population and Their Application; Jarosz, M., Rychlik, E., Charzewska, J., Eds.; Food and Nutrition Institute: Warsaw, Poland, 2020; pp. 148–170. Available online: https://www.pzh.gov.pl/wp-content/uploads/2020/12/Normy_zywienia_2020web-1.pdf (accessed on 17 June 2021). (In Polish)

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. 2006R1924—EN—13.12.2014—004.001. ANNEX: Nutrition Claims and Conditions Applying to Them. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A32006R1924 (accessed on 31 January 2021).

- Commission Regulation (EU) No 1047/2012 of 8 November 2012 Amending Regulation (EC) No 1924/2006 with Regard to the List of Nutrition Claims. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32012R1047 (accessed on 17 June 2021).

- Sharma, S.K.; Bansal, S.; Mangal, M.; Dixit, A.K.; Gupta, R.K.; Mangal, A.K. Utilization of food processing by products as dietary, functional, and novel fiber: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1647–1661. [Google Scholar] [CrossRef] [PubMed]

- Korus, A. Kale (Brassica oleracea L. var. acephala DC.): A valuable Brassica vegetable. Part I. Origin, cultivation and utilization. Fermentation Fruits Veg. Ind. 2015, 59, 11–12. (In Polish) [Google Scholar]

- Olsen, H.; Grimmer, S.; Aaby, K.; Saha, S.; Borge, G.I.A. Antiproliferative Effects of Fresh and Thermal Processed Green and Red Cultivars of Curly Kale (Brassica oleracea L. convar. acephala var. sabellica). J. Agric. Food Chem. 2012, 60, 7375–7383. [Google Scholar] [CrossRef]

- Stokman, H.; Gevers, T.; Koenderink, J. Color Measurement by Imaging Spectrometry. Comput. Vis. Image Underst. 2000, 79, 236–249. [Google Scholar] [CrossRef]

- Tiveron, A.P.; Melo, P.S.; Bergamaschi, K.B.; Vieira, T.M.F.D.S.; Regitano-D’Arce, M.A.B.; De Alencar, S.M. Antioxidant Activity of Brazilian Vegetables and Its Relation with Phenolic Composition. Int. J. Mol. Sci. 2012, 13, 8943–8957. [Google Scholar] [CrossRef] [Green Version]

- Nawirska, A.; Kwaśniewska, M. Dietary fibre fractions from fruit and vegetable processing waste. Food Chem. 2005, 91, 221–225. [Google Scholar] [CrossRef]

- Márquez-Villacorta, L.F.; Vásquez, C.C.P. Evaluación de características de calidad en barras de cereales con alto contenido de fibra y proteína. Biotecnol. Sect. Agropecu. Agroind. 2018, 16, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Sun-Waterhouse, D.; Teoh, A.; Massarotto, C.; Wibisono, R.; Wadhwa, S. Comparative analysis of fruit-based functional snack bars. Food Chem. 2010, 119, 1369–1379. [Google Scholar] [CrossRef]

- Charron, C.S.; Novotny, J.A.; Jeffery, E.H.; Kramer, M.; Ross, S.A.; Seifried, H.E. Consumption of baby kale increased cytochrome P450 1A2 (CYP1A2) activity and influenced bilirubin metabolism in a randomized clinical trial. J. Funct. Foods 2020, 64, 103624. [Google Scholar] [CrossRef]

- Vatankhah, M.; Garavand, F.; Mohammadi, B.; Elhamirad, A.H. Quality attributes of reduced-sugar Iranian traditional sweet bread containing stevioside. J. Food Meas. Charact. 2017, 11, 1233–1239. [Google Scholar] [CrossRef]

- Ibrahim, S.; Fidan, H.; Aljaloud, S.; Stankov, S.; Ivanov, G. Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar. Foods 2021, 10, 918. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, H.; Marzec, A.; Kowalska, J.; Samborska, K.; Tywonek, M.; Lenart, A. Development of apple chips technology. Heat Mass Transf. 2018, 54, 3573–3586. [Google Scholar] [CrossRef] [Green Version]

- Błońska, A.; Marzec, A.; Błaszczyk, A. Instrumental Evaluation of Acoustic and Mechanical Texture Properties of Short-Dough Biscuits with Different Content of Fat and Inulin. J. Texture Stud. 2014, 45, 226–234. [Google Scholar] [CrossRef]

- Pałacha, Z.; Makarewicz, M. Water activity of selected groups of food products. Technol. Prog. Food Process. 2011, 2, 24–29. (In Polish) [Google Scholar]

- Pałacha, Z.; Mazur, P. Analysis of water activity in selected fruit products. Technol. Prog. Food Process. 2019, 1, 18–22. (In Polish) [Google Scholar]

- Reid, D.S. Water Activity: Fundamentals and Relationships. In Water Activity in Foods: Fundamentals and Applications; Barbosa-Cánovas, G.V., Fontana, A.J., Jr., Schmidt, S.J., Labuza, T.P., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2020; pp. 13–26. [Google Scholar] [CrossRef]

- Miastowski, K.; Bakoniuk, R.; Czaplicka, M.; Obidziński, S. Charakterystyka wiązania wody przez błonnik kakaowy. Technol. Prog. Food Process. 2015, 1, 15–19. (In Polish) [Google Scholar]

- Kubiak, M.S.; Dolik, K. Instrumental texture profile analysis test. J. Eng. Sci. Technol. 2013, 3, 23–28. (In Polish) [Google Scholar]

- Nikmaram, N.; Garavand, F.; Elhamirad, A.H.; Beiraghi-Toosi, S.; Goli-Movahhed, G. Production of high quality expanded corn extrudates containing sesame seed using response surface methodology. Qual. Assur. Saf. Crop. Foods 2015, 7, 713–720. [Google Scholar] [CrossRef]

- Kowalczewski, P.; Ivanišová, E. Effect of the addition of dried berries on the characteristics of gluten-free muffins. Postępy Nauk. Technol. Przem. Rolno—Spoz. 2018, 73, 61–71. (In Polish) [Google Scholar]

- Wójtowicz, A.; Baltyn, P. Assessment of selected quality features of popular potato snacks. Food Sci. Technol. Qual. 2006, 2, 112–123. (In Polish) [Google Scholar]

- Kubiak, M.S.; Dolik, K. Instrumental texture profile analysis test. LAB Lab. Appar. Res. 2017, 22, 23–28. [Google Scholar]

- Heo, Y.; Kim, M.-J.; Lee, J.-W.; Moon, B. Muffins enriched with dietary fiber from kimchi by-product: Baking properties, physical-chemical properties, and consumer acceptance. Food Sci. Nutr. 2019, 7, 1778–1785. [Google Scholar] [CrossRef]

- Goetzke, B.; Nitzko, S.; Spiller, A. Consumption of organic and functional food. A matter of well-being and health? Appetite 2014, 77, 96–105. [Google Scholar] [CrossRef]

- Nawirska, A.; Sokół-Łętowska, A.; Kucharska, A.Z. Antioxidant characteristics of pomace from different fruits. Food Sci. Technol. Qual. 2007, 4, 120–125. (In Polish) [Google Scholar]

- Biegańska-Marecik, R.; Radziejewska-Kubzdela, E.; Marecik, R. Characterization of phenolics, glucosinolates and antioxidant activity of beverages based on apple juice with addition of frozen and freeze-dried curly kale leaves (Brassica oleracea L. var. acephala L.). Food Chem. 2017, 230, 271–280. [Google Scholar] [CrossRef]

- Satheesh, N.; Fanta, S.W. Kale: Review on nutritional composition, bio-active compounds, anti-nutritional factors, health beneficial properties and value-added products. Cogent Food Agric. 2020, 6, 1811048. [Google Scholar] [CrossRef]

- Karwowska, K.; Skotnicka, M.; Pieszko, M. Bioactive substances in the „green” dietary supplements. Bromatol. Toxicol. Chem. 2020, 53, 129–136. (In Polish) [Google Scholar]

- Sikora, J.; Markowicz, M.; Makiciuk-Olasik, E. The role and healing properties of black chokeberry in the prevention of civilization diseases. Bromatol. Toxicol. Chem. 2009, 42, 10–17. (In Polish) [Google Scholar]

- Regulation of the European Parliament and of the Council (EU) No. 1169/2011 of 25 October 2011. Official Journal of the EU L 304 of 22.11.2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R1169&from=EN (accessed on 17 June 2021).

- Urbańska, B.; Szafrański, T.; Kowalska, H.; Kowalska, J. Study of Polyphenol Content and Antioxidant Properties of Various Mix of Chocolate Milk Masses with Different Protein Content. Antioxidants 2020, 9, 299. [Google Scholar] [CrossRef] [Green Version]

- Wong, S.P.; Leong, L.P.; Koh, J.H.W. Antioxidant activities of aqueous extracts of selected plants. Food Chem. 2006, 99, 775–783. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K.; Buschmann, C. Chlorophylls and Carotenoids: Measurement and Characterization by UV-VIS Spectroscopy. Curr. Protoc. Food Anal. Chem. 2001, 1, F4.3.1–F4.3.8. [Google Scholar] [CrossRef]

| Chemical Characteristics | Fresh Kale | Base Bar − Baking | Bar + Kale 30% | Bar + Dried Kale 10% |

|---|---|---|---|---|

| Humidity, g/100 g | 87.1 | 27 | 39.2 | 30.5 |

| Total protein (N × 6.25), g/100 g | 3.3 | 14.3 | 12.2 | 13.9 |

| Total protein (N × 6.25), g/100 g d.m. | 25.9 | 19.6 | 20.1 | 20 |

| Fat (no hydrolysis), g/100 g | 0.4 | 21.2 | 17 | 19.2 |

| Fat (no hydrolysis), g/100 g d.m. | 3.2 | 29 | 28 | 27.7 |

| Total ash, g/100 g | 1.1 | 1.9 | 1.9 | 2.3 |

| Total ash, g/100 g d.m. | 8.3 | 2.6 | 3.2 | 3.3 |

| Total dietary fibre, g/100 g | 5.1 | 11.6 | 9.1 | 11.4 |

| Total dietary fibre, g/100 g d.m. | 39.5 | 15.8 | 15 | 16.4 |

| including: soluble fibre fraction, g/100 g | 0.3 | 2.5 | 2 | 2.2 |

| soluble fibre fraction, g/100 g d.m. | 2.4 | 3.4 | 3.3 | 3.1 |

| insoluble fibre fraction, g/100 g | 4.8 | 9.1 | 7.1 | 9.2 |

| insoluble fibre fraction, g/100 g d.m. | 37 | 12.4 | 11.7 | 13.3 |

| Total carbohydrates, g/100 g | 3 | 24 | 20.5 | 22.6 |

| Total carbohydrates, g/100 g d.m. | 23.3 | 32.9 | 33.8 | 32.5 |

| including: sugars, g/100 g | 2.6 | 12.9 | 10.6 | 12.5 |

| sugars, g/100 g d.m. | 19.9 | 17.7 | 17.5 | 18 |

| Energy value, kcal/100 g | 39 | 367 | 302 | 342 |

| Energy value, kJ/100 g | 164 | 1528 | 1259 | 1424 |

| Type of Bars | Water Activity [-] | Water Content [%] | Compression Work [mJ] |

|---|---|---|---|

| Control (based) | 0.857 ± 0.000 A | 17.34 ± 1.13 A | 604.3 ± 33.6 |

| DF-apple-K20 | 0.944 ± 0.001 cB | 29.86 ± 0.87 abB | 383.5 ± 64.3 |

| DF-apple-K30 | 0.953 ± 0.003 C | 41.12 ± 2.63 C | 271.4 ± 21.2 |

| DF-blackcurrant-K20 | 0.931 ± 0.001 b | 27.48 ± 2.27 a | 360.3 ± 45.2 |

| DF-chokeberry-K20 | 0.943 ± 0.000 c | 27.54 ± 2.57 a | 438.3 ± 41.4 |

| P-hibiscus-K20 | 0.916 ± 0.001 a | 35.39 ± 0.23 b | 268.6 ±95.8 |

| One-way analysis of variance (ANOVA) | |||

| Factors | p-value | ||

| Kale addition (A,B,C) | 0.0001 * | 0.0020 * | 0.0000 * |

| Type of fibre (a,b,c) | 0.0001 * | 0.0310 * | 0.0138 * |

| Type of Bars | Hardness [N] | Elasticity [-] | Cohesiveness [-] | Guminess [N] | Chewing [N] |

|---|---|---|---|---|---|

| Control | 298.2 ± 25.4 B | 0.54 ± 0.03 B | 0.48 ±0.064 B | 145.0 ± 29.0 B | 77.0 ± 15.7 B |

| DF-Apple-K20 | 121.5 ± 16.0 aA | 0.40 ± 0.03 A | 0.26 ± 0.021 aA | 32.2 ± 4.7 aA | 12.9 ± 1.9 aA |

| DF-Apple-K30 | 94.6 ± 21.3 A | 0.38 ± 0.06 A | 0.40 ± 0.070 A | 38.4 ± 15.4 A | 14.4 ± 2.5 A |

| DF-Blackcurrant-K20 | 171.9 ± 21.4 b | 0.46 ± 0.02 | 0.43 ± 0.063 bc | 75.7 ± 18.8 b | 35.1 ± 9.5 b |

| DF-Chokeberry-K20 | 184.4 ± 25.4 b | 0.48 ± 0.03 | 0.48 ± 0.021 c | 88.8 ± 13.6 b | 44.9 ± 5.8 b |

| P-Hibiscus-K20 | 89.5 ± 24.8 a | 0.42 ± 0.02 | 0.37 ± 0.031 b | 33.0 ± 9.052 a | 13.8 ± 3.1 a |

| One-way analysis of variance (ANOVA) | |||||

| Factors | p-value | ||||

| Kale addition (A,B,C) | 0.0000 * | 0.0013 * | 0.0013 * | 0.0000 * | 0.0000 * |

| Type of fibre (a,b,c) | 0.0002 * | 0.1201 | 0.0000 * | 0.0000 * | 0.0000 * |

| Ingredient | Content [%] | Code bars |

|---|---|---|

| Whole grain oatmeal (Kupiec, Poland) | 20 | |

| Flaxeed (Kresto, Russia) | 20 | |

| Sunflower seeds (Bakaland, Poland) | 20 | |

| Pumpkin seeds (Bakaland, Poland) | 20 | |

| Fresh kale (VitalFresh, Poland) | 20 or 30 | K20 or K30 |

| Honey (Huzar, Poland) | 10 | |

| Water (tap water) | 25 | |

| m-40 * apple fibre; | 10 | DF-Apple |

| m-40 * chokeberry fibre; | 10 | DF-Chokeberry |

| m-40 * blackcurrant fibre | 10 | DF-Blackcurrant |

| Dried hibiscus flower—powder (GreenField, Poland) | 10 | P-Hibiscus |

| Sensory Discriminants | Definition | Boundary Terms |

|---|---|---|

| Colour | Bar colour (colouring) | 10 points—desirable, even 0 points—undesirable, uneven surface colouring |

| Smell | Intensity of perceived smell | 10 points—characteristic for cereal snacks, mild 0 points—imperceptible, atypical |

| Texture | Fragility and porosity | 10 points—desirable, brittle, porous 0 points—undesirable, non-brittle, non-porous, too cohesive |

| Taste | Taste felt after biting and chewing | 10 points—characteristics of cereal snacks 0 points—imperceptible, alien |

| General suitability | General impression of the quality of the bars | 10 points—very desirable 0 points—unacceptable |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalska, H.; Kowalska, J.; Ignaczak, A.; Masiarz, E.; Domian, E.; Galus, S.; Ciurzyńska, A.; Salamon, A.; Zając, A.; Marzec, A. Development of a High-Fibre Multigrain Bar Technology with the Addition of Curly Kale. Molecules 2021, 26, 3939. https://doi.org/10.3390/molecules26133939

Kowalska H, Kowalska J, Ignaczak A, Masiarz E, Domian E, Galus S, Ciurzyńska A, Salamon A, Zając A, Marzec A. Development of a High-Fibre Multigrain Bar Technology with the Addition of Curly Kale. Molecules. 2021; 26(13):3939. https://doi.org/10.3390/molecules26133939

Chicago/Turabian StyleKowalska, Hanna, Jolanta Kowalska, Anna Ignaczak, Ewelina Masiarz, Ewa Domian, Sabina Galus, Agnieszka Ciurzyńska, Agnieszka Salamon, Agnieszka Zając, and Agata Marzec. 2021. "Development of a High-Fibre Multigrain Bar Technology with the Addition of Curly Kale" Molecules 26, no. 13: 3939. https://doi.org/10.3390/molecules26133939

APA StyleKowalska, H., Kowalska, J., Ignaczak, A., Masiarz, E., Domian, E., Galus, S., Ciurzyńska, A., Salamon, A., Zając, A., & Marzec, A. (2021). Development of a High-Fibre Multigrain Bar Technology with the Addition of Curly Kale. Molecules, 26(13), 3939. https://doi.org/10.3390/molecules26133939