Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of LPRs

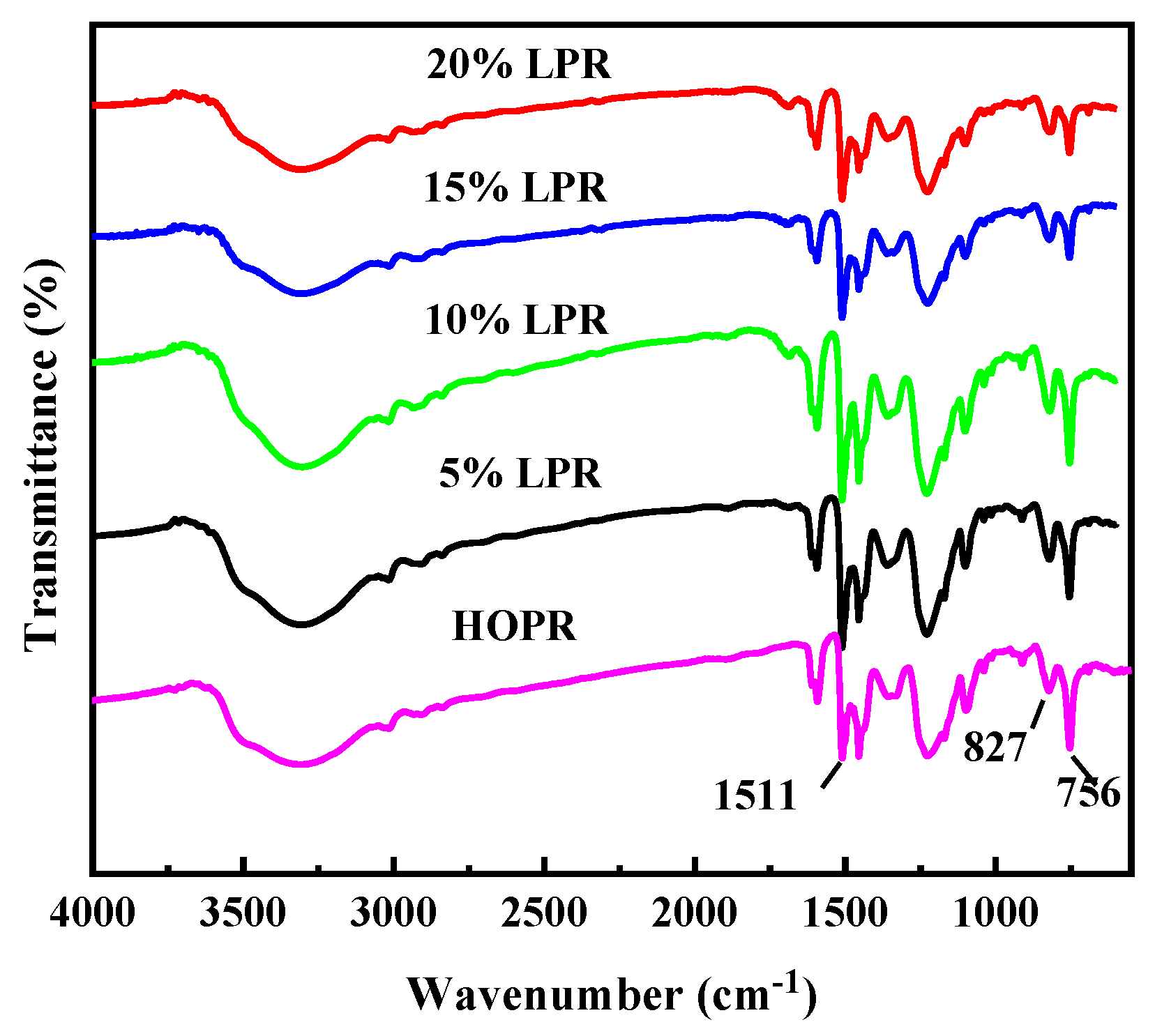

2.1.1. FT-IR Characterization of the LPRs

2.1.2. 13C-NMR Analysis of the LPRs

2.1.3. Molecular Weights (GPC) and Spinnabilities of the LPRs

2.2. Characterization of the LPFs

2.2.1. TG–DTG Characterization of the LPFs

2.2.2. Characterization of Structural and Tensile Properties of the LPFs

2.2.3. SEM Characterization of the LPFs

3. Materials and Methods

3.1. Chemicals

3.2. Preparation

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Jiang, L.; Sheng, L.; Fan, Z. Biomass-derived carbon materials with structural diversities and their applications in energy storage. Sci. China Mater. 2018, 61, 133–158. [Google Scholar] [CrossRef] [Green Version]

- Ren, N.-Q.; Zhao, L.; Chen, C.; Guo, W.-Q.; Cao, G.-L. A review on bioconversion of lignocellulosic biomass to H2: Key challenges and new insights. Bioresour. Technol. 2016, 215, 92–99. [Google Scholar] [CrossRef]

- Yoo, C.G.; Dumitrache, A.; Muchero, W.; Natzke, J.; Akinosho, H.; Li, M.; Sykes, R.W.; Brown, S.D.; Davison, B.; Tuskan, G.A. Significance of lignin S/G ratio in biomass recalcitrance of Populus trichocarpa variants for bioethanol production. ACS Sustain. Chem. Eng. 2018, 6, 2162–2168. [Google Scholar] [CrossRef]

- Schutyser, W.; Renders, A.T.; Van den Bosch, S.; Koelewijn, S.F.; Beckham, G.T.; Sels, B.F. Chemicals from lignin: An interplay of lignocellulose fractionation, depolymerisation, and upgrading. Chem. Soc. Rev. 2018, 47, 852–908. [Google Scholar] [CrossRef]

- Turunen, M.; Alvila, L.; Pakkanen, T.T.; Rainio, J. Modification of phenol–formaldehyde resol resins by lignin, starch, and urea. J. Appl. Polym. Sci. 2003, 88, 582–588. [Google Scholar] [CrossRef]

- Hu, L.; Pan, H.; Zhou, Y.; Zhang, M. Methods to improve lignin’s reactivity as a phenol substitute and as replacement for other phenolic compounds: A brief review. BioResources 2011, 6, 3515–3525. [Google Scholar] [CrossRef]

- Pinheiro, F.G.C.; Soares, A.K.L.; Santaella, S.T.; e Silva, L.M.A.; Canuto, K.M.; Cáceres, C.A.; de Freitas Rosa, M.; de Andrade Feitosa, J.P.; Leitão, R.C. Optimization of the acetosolv extraction of lignin from sugarcane bagasse for phenolic resin production. Ind. Crop. Prod. 2017, 96, 80–90. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Zhang, J.; Sui, W.; Jang, J.; Si, C. One-pot lignin depolymerization and activation by solid acid catalytic phenolation for lightweight phenolic foam preparation. Ind. Crop. Prod. 2018, 124, 216–225. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Zhang, S.; Gao, Q.; Li, J.; Zhang, W. Alkali lignin depolymerization under eco-friendly and cost-effective NaOH/urea aqueous solution for fast curing bio-based phenolic resin. Ind. Crop. Prod. 2018, 120, 25–33. [Google Scholar] [CrossRef]

- Vithanage, A.E.; Chowdhury, E.; Alejo, L.D.; Pomeroy, P.C.; DeSisto, W.J.; Frederick, B.G.; Gramlich, W.M. Renewably sourced phenolic resins from lignin bio-oil. J. Appl. Polym. Sci. 2017, 134, 44827. [Google Scholar] [CrossRef]

- Kalami, S.; Chen, N.; Borazjani, H.; Nejad, M. Comparative analysis of different lignins as phenol replacement in phenolic adhesive formulations. Ind. Crop. Prod. 2018, 125, 520–528. [Google Scholar] [CrossRef]

- Tachon, N.; Benjelloun-Mlayah, B.; Delmas, M. Organosolv wheat straw lignin as a phenol substitute for green phenolic resins. BioResources 2016, 11, 5797–5815. [Google Scholar] [CrossRef] [Green Version]

- Economy, J.; Clark, R.A. Fibers from Novolacs. U.S. Patent 3650102, 21 March 1972. [Google Scholar]

- Chen, R.; Xu, X.; Zhang, Y.; Lu, S.; Lo, S. Characterization of ignition and combustion characteristics of phenolic fiber-reinforced plastic with different thicknesses. J. Therm. Anal. Calorim. 2020, 140, 645–655. [Google Scholar] [CrossRef]

- Jiao, M.; Yang, K.; Cao, J.; Diao, Q.; Zhang, W.; Yu, M. Influence of epichlorohydrin content on structure and properties of high-ortho phenolic epoxy fibers. J. Appl. Polym. Sci. 2016, 133, 43375. [Google Scholar] [CrossRef]

- Marliana, M.M.; Hassan, A.; Yuziah, M.Y.N.; Khalil, H.P.S.A.; Inuwa, I.M.; Syakir, M.I.; Haafiz, M.K.M. Flame retardancy, Thermal and mechanical properties of Kenaf fiber reinforced Unsaturated polyester/Phenolic composite. Fibers Polym. 2016, 17, 902–909. [Google Scholar] [CrossRef]

- Bulgakov, B.; Kalugin, D.; Babkin, A.; Makarenko, I.; Malakho, A.; Kepman, A.; Avdeev, V.; Garadja, N.; Rogozin, A. Propargylated novolac resins for fibre-reinforced plastics: Processing aspects. Can. J. Chem. Eng. 2016, 94, 46–52. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, J.; Guo, Q.; Song, Y.; Liu, L. Studies on hollownesss regulation and properties of crosslinked hollow phenolic fibers. Fibers Polym. 2012, 13, 495–500. [Google Scholar] [CrossRef]

- Worasuwannarak, N.; Hatori, S.; Nakagawa, H.; Miura, K. Effect of oxidation pre-treatment at 220 to 270 C on the carbonization and activation behavior of phenolic resin fiber. Carbon 2003, 41, 933–944. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Z.-H.; Yue, M.; Li, M.; Wang, M.; Kang, F. Preparation of flexible phenolic resin-based porous carbon fabrics by electrospinning. Chem. Eng. J. 2013, 218, 232–237. [Google Scholar] [CrossRef]

- Zheng, W.; Hu, J.; Rappeport, S.; Zheng, Z.; Wang, Z.; Han, Z.; Langer, J.; Economy, J. Activated carbon fiber composites for gas phase ammonia adsorption. Microporous Mesoporous Mater. 2016, 234, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Yi, Z.; Zhang, J.; Zhang, S.; Gao, Q.; Li, J.; Zhang, W. Synthesis and mechanism of metal-mediated polymerization of phenolic resins. Polymers 2016, 8, 159. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Xu, M.; Ge, Q.; Lin, M.; Lin, Q.; Chen, Y.; Chu, J.; Dai, L.; Zou, Y. Controlled synthesis of high-ortho-substitution phenol–formaldehyde resins. J. Appl. Polym. Sci. 2005, 97, 652–658. [Google Scholar] [CrossRef]

- Asim, M.; Saba, N.; Jawaid, M.; Nasir, M.; Pervaiz, M.; Alothman, O.Y. A review on phenolic resin and its composites. Curr. Anal. Chem. 2018, 14, 185–197. [Google Scholar] [CrossRef]

- Emik, S.; Yılmaz, B.Y.; İyim, T.B. Investigation of the Usage of Depolymerized Nylon 66 Intermediate in Phenolic Resin Modification. Polym. Plast. Technol. Mater. 2019, 58, 454–463. [Google Scholar] [CrossRef]

- Hu, X.M.; Zhao, Y.Y.; Cheng, W.M. Effect of formaldehyde/phenol ratio (F/P) on the properties of phenolic resins and foams synthesized at room temperature. Polym. Compos. 2015, 36, 1531–1540. [Google Scholar] [CrossRef]

- Shudo, Y.; Izumi, A.; Takeuchi, T.; Nakao, T.; Shibayama, M. Dynamic light scattering study of the curing mechanisms of novolac-type phenolic resins. Polym. J. 2015, 47, 428–433. [Google Scholar] [CrossRef]

- Xu, Y.; Guo, L.; Zhang, H.; Zhai, H.; Ren, H. Research status, industrial application demand and prospects of phenolic resin. RSC Adv. 2019, 9, 28924–28935. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Bu, Z.; Sun, J.; Fan, H.; Wan, J.; Li, B. New insights into high-ortho phenolic novolac: Elucidating dependence between molecular structure, curing kinetics and thermal stability. Thermochim. Acta 2013, 557, 77–86. [Google Scholar] [CrossRef]

- Gioia, C.; Colonna, M.; Tagami, A.; Medina, L.; Sevastyanova, O.; Berglund, L.A.; Lawoko, M. Lignin-based epoxy resins: Unravelling the relationship between structure and material properties. Biomacromolecules 2020, 21, 1920–1928. [Google Scholar] [CrossRef]

- Jiang, Y.; Ding, D.; Zhao, S.; Zhu, H.; Kenttämaa, H.I.; Abu-Omar, M.M. Renewable thermoset polymers based on lignin and carbohydrate derived monomers. Green Chem. 2018, 20, 1131–1138. [Google Scholar] [CrossRef]

- Meng, Y.; Lu, J.; Cheng, Y.; Li, Q.; Wang, H. Lignin-based hydrogels: A review of preparation, properties, and application. Int. J. Biol. Macromol. 2019, 135, 1006–1019. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yu, B.; Xu, X.; Bourbigot, S.; Wang, H.; Song, P. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem. 2020, 22, 2129–2161. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, T.; Hao, C.; Wang, L.; Han, J.; Liu, H.; Zhang, J. Preparation of a lignin-based vitrimer material and its potential use for recoverable adhesives. Green Chem. 2018, 20, 2995–3000. [Google Scholar] [CrossRef]

- Parit, M.; Jiang, Z. Towards lignin derived thermoplastic polymers. Int. J. Biol. Macromol. 2020, 165, 3180–3197. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Kelley, S.S.; Venditti, R.A. Lignin-based thermoplastic materials. ChemSusChem 2016, 9, 770–783. [Google Scholar] [CrossRef]

- Chen, F.; Liu, W.; Seyed Shahabadi, S.I.; Xu, J.; Lu, X. Sheet-like lignin particles as multifunctional fillers in polypropylene. ACS Sustain. Chem. Eng. 2016, 4, 4997–5004. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Xiang, H.; Zhou, Z.; Chang, T.; Zhu, M. Low cost carbon fibers from bio-renewable lignin/poly (lactic acid)(PLA) blends. Compos. Sci. Technol. 2015, 119, 20–25. [Google Scholar] [CrossRef]

- Kai, D.; Zhang, K.; Liow, S.S.; Loh, X.J. New dual functional PHB-grafted lignin copolymer: Synthesis, mechanical properties, and biocompatibility studies. ACS Appl. Bio Mater. 2018, 2, 127–134. [Google Scholar] [CrossRef]

- Ren, Y.; Lin, X.; Shi, Z.; Zheng, Y.; Liu, J.; Zheng, Z.; Liu, C. Improving the Thermal and Mechanical Properties of Phenolic Fiber over Boron Modified High-Ortho Phenolic Resin. High Perform. Polym. 2020. [Google Scholar] [CrossRef]

- Ren, Y.; Lin, X.; Wang, W.; Shi, Z.; Zheng, Z.; Liu, C. Preparation of high molecular weight thermoplastic bio-based phenolic resin and fiber based on lignin liquefaction. Mater. Res. Express 2021, 8, 015308. [Google Scholar] [CrossRef]

- Zhou, D.; Liu, D.; Wang, H.; Lian, Y.; Luo, Y. Nonisothermal curing behaviors of novolac-type phenolic resins of varied ortho to para ratios. Polym. Plast. Technol. Eng. 2011, 50, 983–989. [Google Scholar] [CrossRef]

- Windeisen, E.; Wegener, G. Lignin as Building Unit for Polymers. In Polymer Science: A Comprehensive Reference, 1st ed.; Moeller, M., Matyjaszewski, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 255–265. [Google Scholar]

| Sample | O/P Value | Mn | Mw | PDI |

|---|---|---|---|---|

| 0% | 3.40 | 12,736 | 14,929 | 1.17 |

| 5% | 1.55 | 1350 | 4528 | 3.36 |

| 10% | 1.28 | 1553 | 4263 | 2.74 |

| 15% | 1.26 | 1324 | 4059 | 3.06 |

| 20% | 1.15 | 1373 | 3853 | 2.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Xie, J.; He, X.; Shi, R.; Liu, C. Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers. Molecules 2021, 26, 3993. https://doi.org/10.3390/molecules26133993

Ren Y, Xie J, He X, Shi R, Liu C. Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers. Molecules. 2021; 26(13):3993. https://doi.org/10.3390/molecules26133993

Chicago/Turabian StyleRen, Yu, Jin Xie, Xiahong He, Rui Shi, and Can Liu. 2021. "Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers" Molecules 26, no. 13: 3993. https://doi.org/10.3390/molecules26133993

APA StyleRen, Y., Xie, J., He, X., Shi, R., & Liu, C. (2021). Preparation of Lignin-Based High-Ortho Thermoplastic Phenolic Resins and Fibers. Molecules, 26(13), 3993. https://doi.org/10.3390/molecules26133993