Wave Propagation in Rotating Functionally Graded Microbeams Reinforced by Graphene Nanoplatelets

Abstract

:1. Introduction

2. Theoretical Modeling

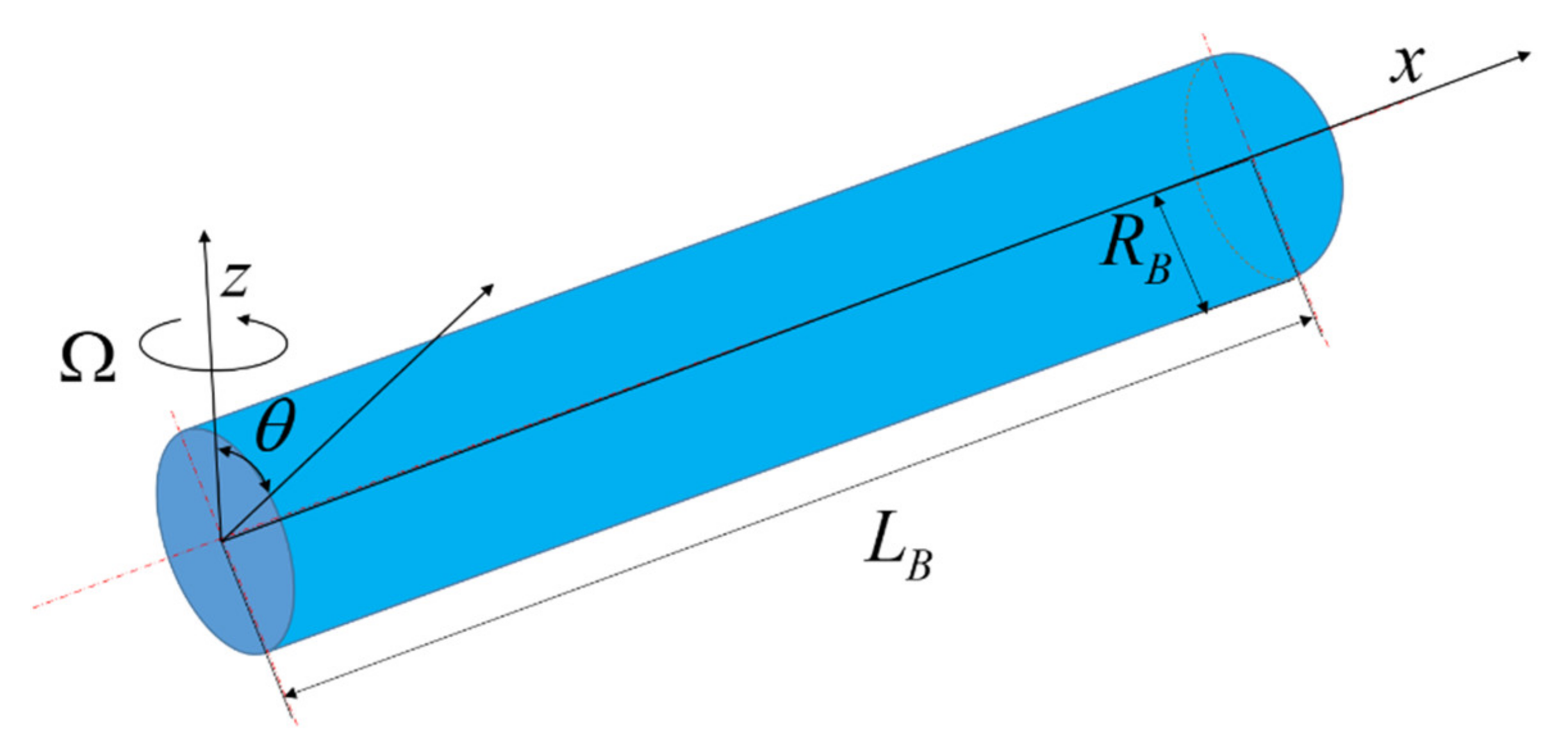

2.1. Physical Model

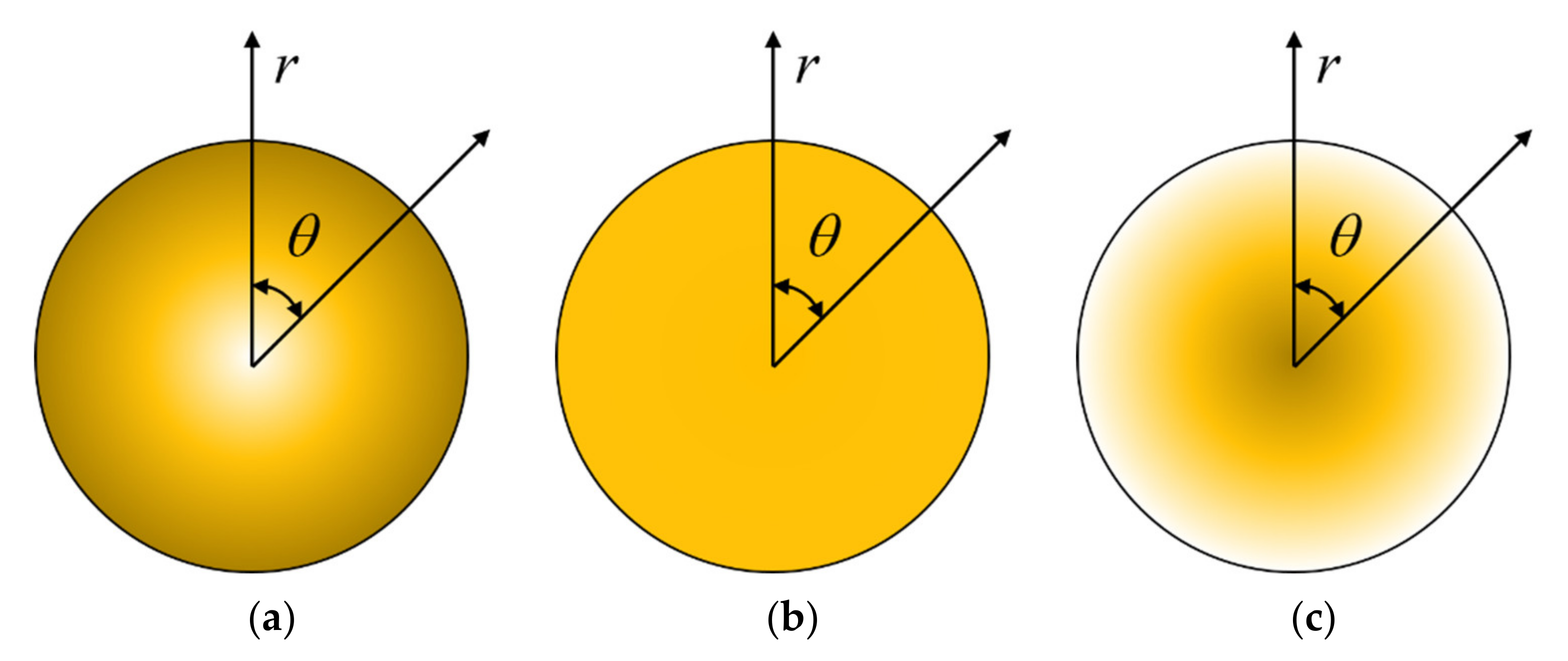

2.2. Material Parameters

2.3. Governing Equations

3. Solution Procedure

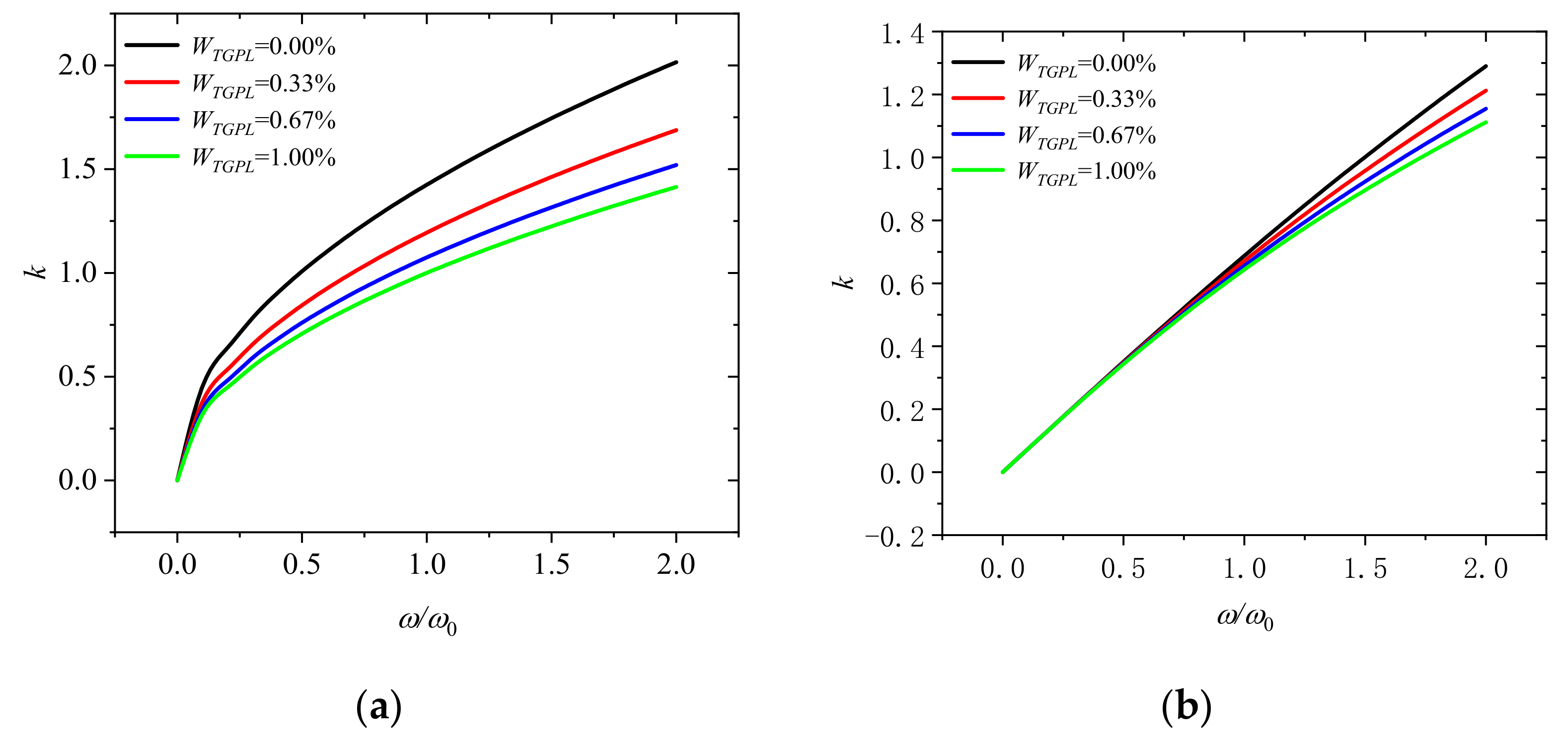

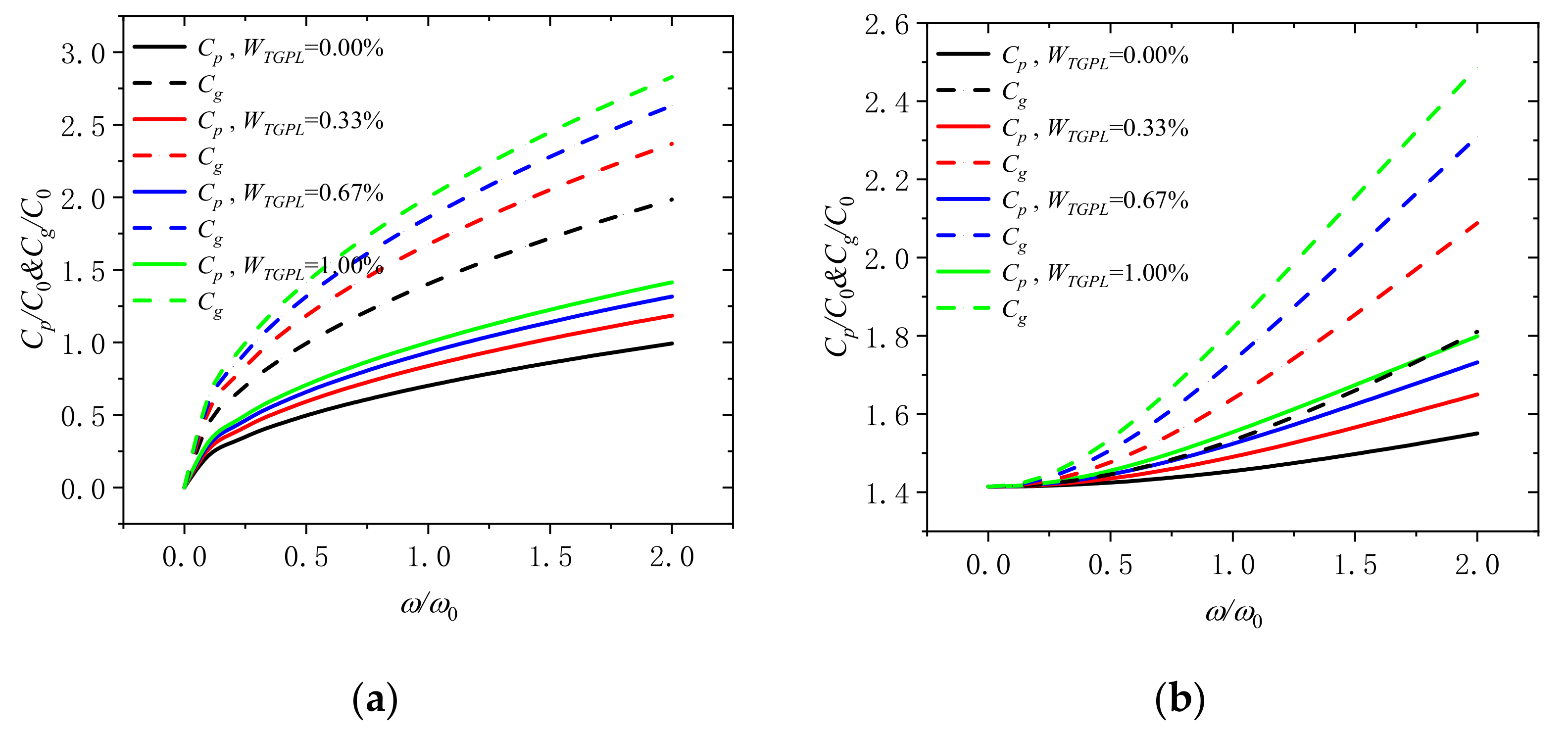

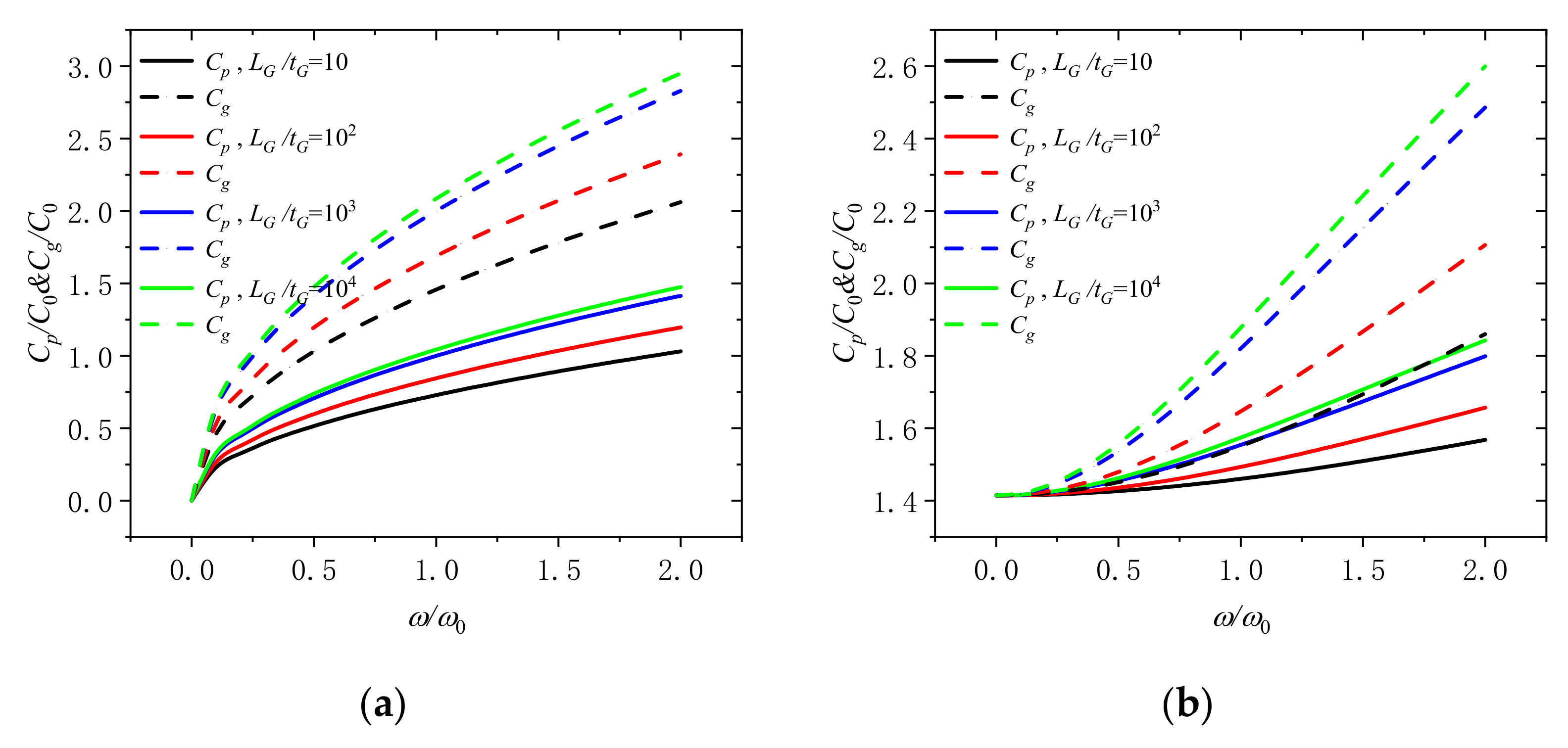

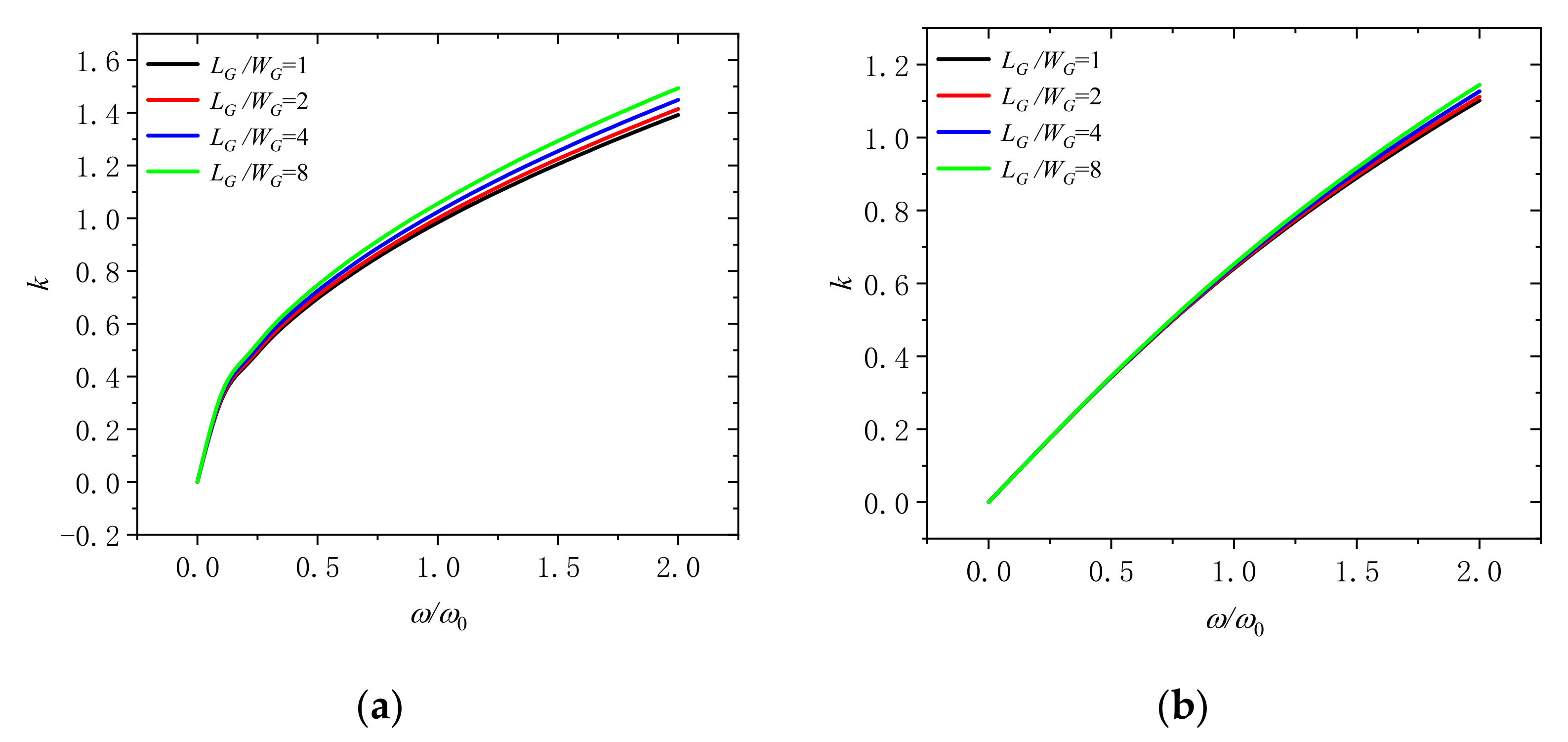

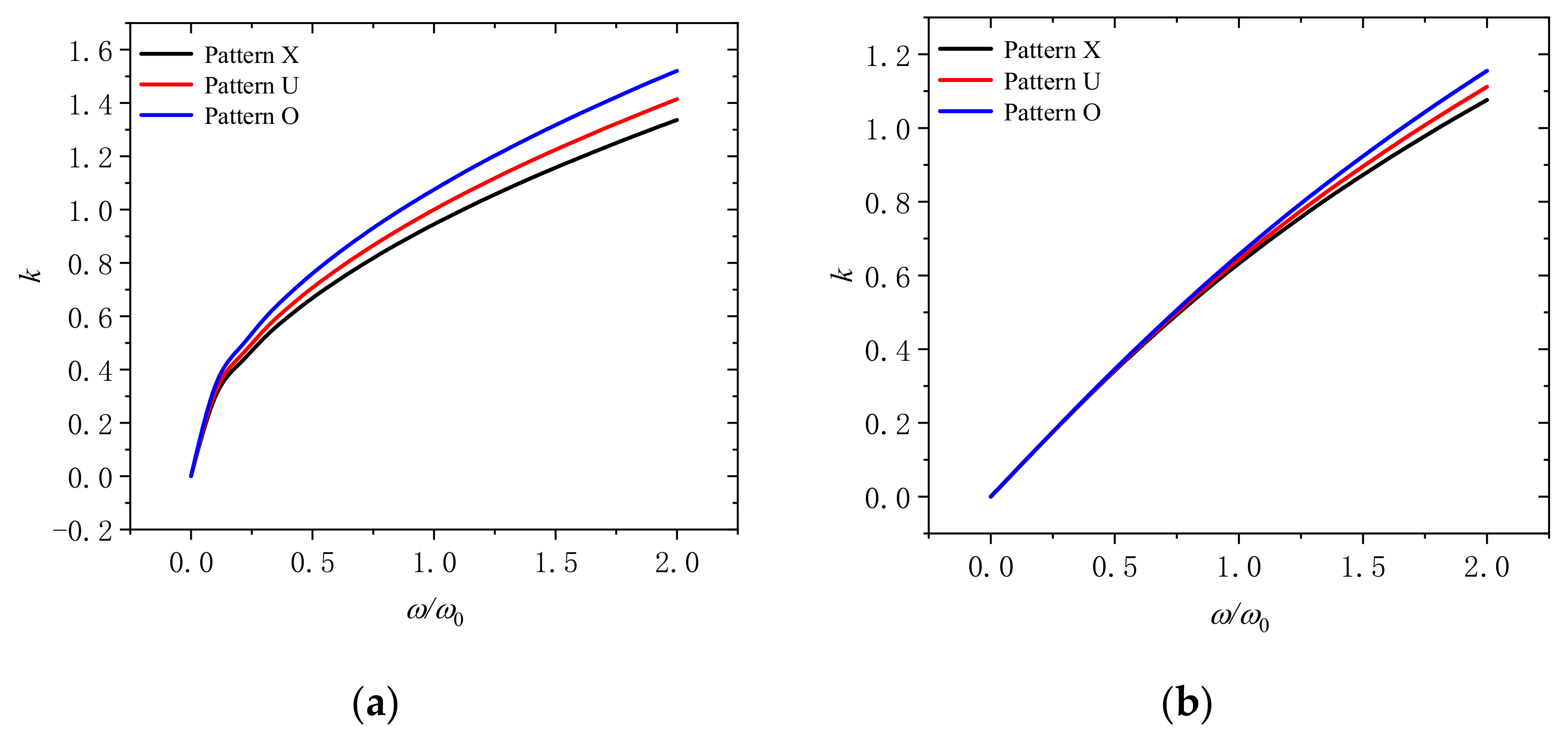

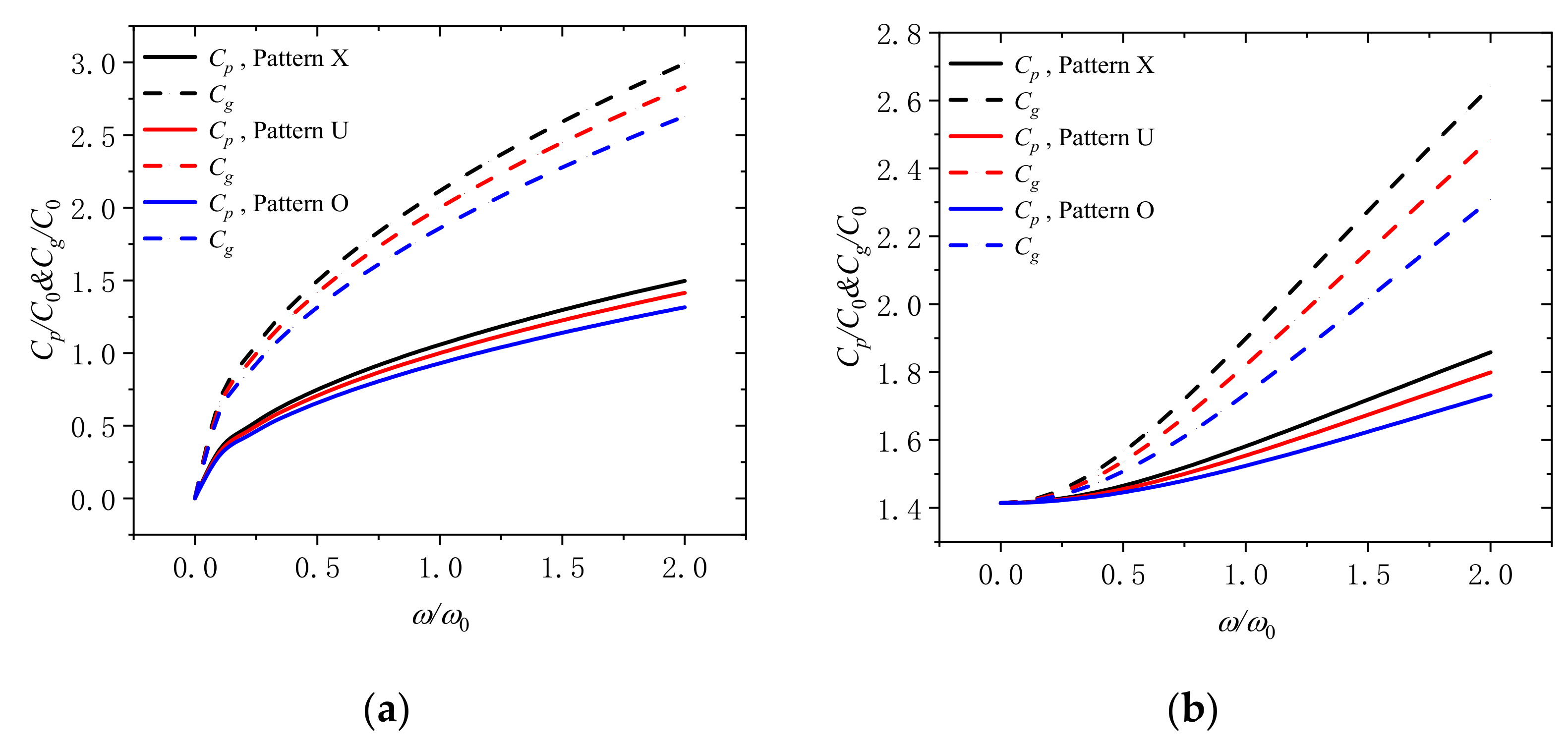

4. Numerical Results and Discussion

5. Conclusions

- (1)

- Adding more GPLs into the microbeam can significantly improve the performance.

- (2)

- Thinner GPLs are suitable to enhance structure performance of the microbeam than ordinary GPLs.

- (3)

- GPLs with larger surface area have a better enhancement effect on the microbeam.

- (4)

- With more GPLs distributed on the surface of the microbeam, the reinforcement effect can be improved while the content of GPLs remains unchanged.

- (5)

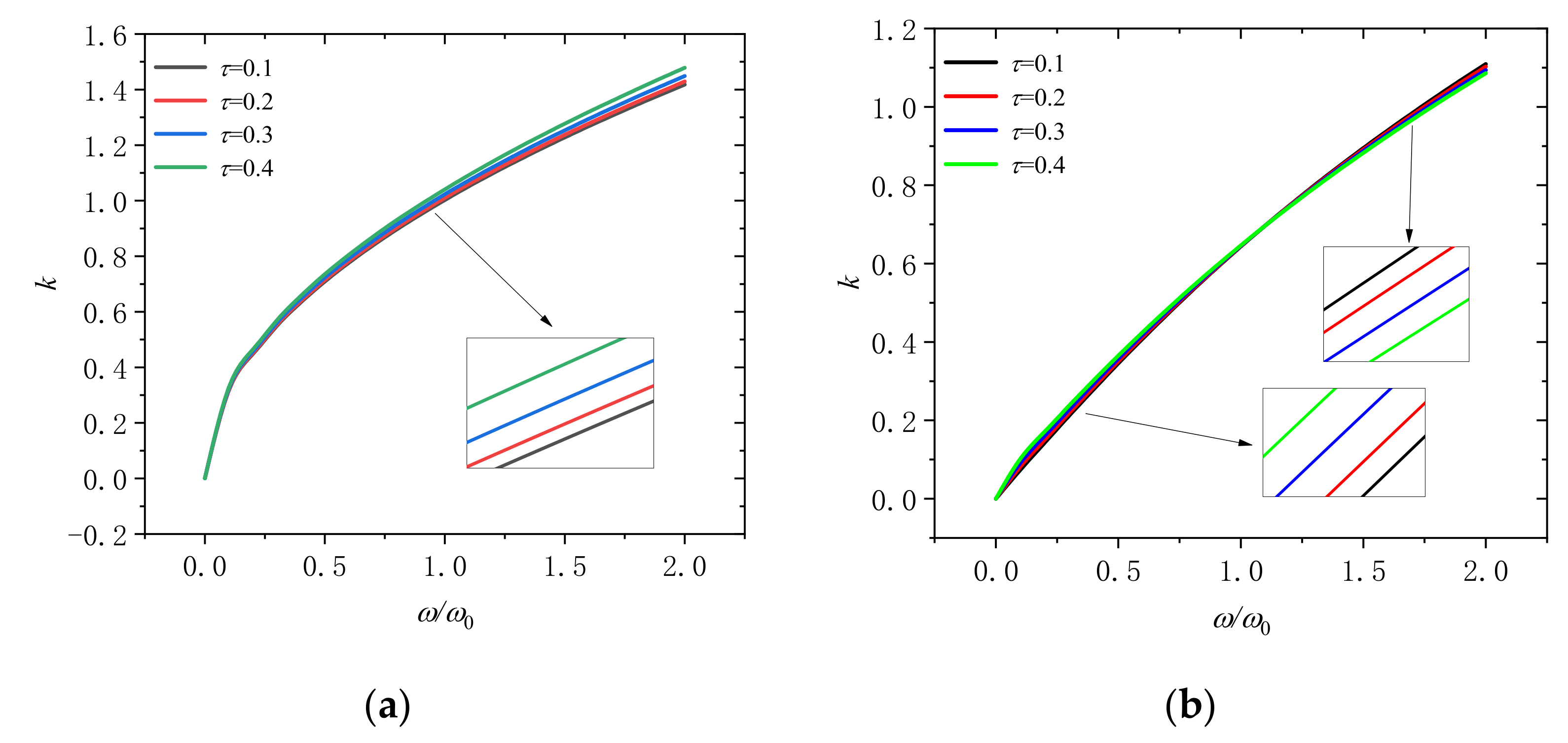

- Nonlocal scaling is a very important parameter, because its influence on the wave number the phase velocity and the group will change with the dimensionless frequency and speed, which we must take it into consideration.

- (6)

- Rotational speed plays an important role in wave propagation. When rotational speed is 0, the wave number, the group velocity and phase velocity are changed nonlinearly with the frequency, which means that the wave number varies dispersedly. However, when the rotational speed increases, the wave number, group velocity, and phase velocity tend to increase linearly, which indicates that the wave will not change its shape when it propagates.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, H.; Zhang, Q.; Ma, J. Thermo-Mechanical Dynamics of Two-Dimensional FG Microbeam Subjected to a Moving Harmonic Load. Acta Astronaut. 2021, 178, 681–692. [Google Scholar] [CrossRef]

- Fang, J.; Gu, J.; Wang, H.; Zhang, X. Thermal Effect on Vibrational Behaviors of Rotating Functionally Graded Microbeams. Eur. J. Mech. A/Solids 2019, 75, 497–515. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Das, D. Free Vibration Analysis of Bidirectional-Functionally Graded and Double-Tapered Rotating Micro-Beam in Thermal Environment Using Modified Couple Stress Theory. Compos. Struct. 2019, 215, 471–492. [Google Scholar] [CrossRef]

- Tlidji, Y.; Zidour, M.; Draiche, K.; Safa, A.; Bourada, M.; Tounsi, A.; Bousahla, A.A.; Mahmoud, S.R. Vibration Analysis of Different Material Distributions of Functionally Graded Microbeam. Struct. Eng. Mech. 2019, 69, 637–649. [Google Scholar] [CrossRef]

- Esen, I.; Özarpa, C.; Eltaher, M.A. Free Vibration of a Cracked FG Microbeam Embedded in an Elastic Matrix and Exposed to Magnetic Field in a Thermal Environment. Compos. Struct. 2021, 261, 113552. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H. On the Dynamic Response of Porous Functionally Graded Microbeam under Moving Load. Int. J. Eng. Sci. 2020, 153, 103317. [Google Scholar] [CrossRef]

- Abouelregal, A.E.; Ahmad, H. Thermodynamic Modeling of Viscoelastic Thin Rotating Microbeam Based on Non-Fourier Heat Conduction. Appl. Math. Model. 2021, 91, 973–988. [Google Scholar] [CrossRef]

- Najar, F.; Ghommem, M.; Abdelkefi, A. A Double-Side Electrically-Actuated Arch Microbeam for Pressure Sensing Applications. Int. J. Mech. Sci. 2020, 178, 105624. [Google Scholar] [CrossRef]

- Chen, X.; Lu, Y.; Li, Y. Free Vibration, Buckling and Dynamic Stability of Bi-Directional FG Microbeam with a Variable Length Scale Parameter Embedded in Elastic Medium. Appl. Math. Model. 2019, 67, 430–448. [Google Scholar] [CrossRef]

- Fang, J.; Gu, J.; Wang, H. Size-Dependent Three-Dimensional Free Vibration of Rotating Functionally Graded Microbeams Based on a Modified Couple Stress Theory. Int. J. Mech. Sci. 2018, 136, 188–199. [Google Scholar] [CrossRef]

- Ghommem, M.; Abdelkefi, A. Nonlinear Analysis of Rotating Nanocrystalline Silicon Microbeams for Microgyroscope Applications. Microsyst. Technol. 2017, 23, 5931–5946. [Google Scholar] [CrossRef]

- Shenas, A.G.; Ziaee, S.; Malekzadeh, P. Post-Buckling and Vibration of Post-Buckled Rotating Pre-Twisted FG Microbeams in Thermal Environment. Thin-Walled Struct. 2019, 138, 335–360. [Google Scholar] [CrossRef]

- Yao, L.Q.; Ji, C.J.; Shen, J.P.; Li, C. Free Vibration and Wave Propagation of Axially Moving Functionally Graded Timoshenko Microbeams. J Braz. Soc. Mech. Sci. Eng. 2020, 42, 137. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Jiang, L.P.; Pan, H.G.; Yang, J.; Kitipornchai, S. Coupled Free Vibration of a Functionally Graded Pre-Twisted Blade-Shaft System Reinforced with Graphene Nanoplatelets. Compos. Struct. 2021, 262, 113362. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Cui, Y.S.; Pan, H.G.; Yuan, H.Q.; Yang, J. Free Vibration Analysis of a Functionally Graded Graphene Nanoplatelet Reinforced Disk-Shaft Assembly with Whirl Motion. Int. J. Mech. Sci. 2021, 197, 106335. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Ma, Y.; Zhang, H.Y.; Pan, H.G.; Cai, Y. Free Vibration Analysis of a Rotating Graphene Nanoplatelet Reinforced Pre-Twist Blade-Disk Assembly with a Setting Angle. Appl. Math. Model. 2021, 93, 578–596. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Cui, Y.S.; Wang, Y.Q.; Pan, H.G. Vibration Characteristics of Graphene Nanoplatelet Reinforced Disk-Shaft Rotor with Eccentric Mass. Mech. Adv. Mater. Struct. 2021, 1–21. [Google Scholar] [CrossRef]

- Zhao, T.; Ma, Y.; Zhang, H.; Yang, J. Coupled Free Vibration of Spinning Functionally Graded Porous Double-Bladed Disk Systems Reinforced with Graphene Nanoplatelets. Materials 2020, 13, 5610. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.Y.; Liu, Z.F.; Pan, H.G.; Zhang, H.Y.; Yuan, H.Q. Vibration Characteristics of Functionally Graded Porous Nanocomposite Blade-Disk-Shaft Rotor System Reinforced with Graphene Nanoplatelets. Appl. Compos. Mater. 2021, 28, 717–731. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Jiang, Z.Y.; Zhao, Z.; Xie, L.Y.; Yuan, H.Q. Modeling and Free Vibration Analysis of Rotating Hub-Blade Assemblies Reinforced with Graphene Nanoplatelets. J. Strain Anal. Eng. Des. 2021. [Google Scholar] [CrossRef]

- Zhao, T.; Yang, Y.; Pan, H.; Zhang, H.; Yuan, H. Free Vibration Analysis of a Spinning Porous Nanocomposite Blade Reinforced with Graphene Nanoplatelets. J. Strain Anal. Eng. Des. 2021. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Zhang, W. Vibration and Flutter Characteristics of GPL-Reinforced Functionally Graded Porous Cylindrical Panels Subjected to Supersonic Flow. Acta Astronaut. 2021, 183, 89–100. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Ye, C.; Zu, J.W. Nonlinear Vibration of Metal Foam Cylindrical Shells Reinforced with Graphene Platelets. Aerosp. Sci. Technol. 2019, 85, 359–370. [Google Scholar] [CrossRef]

- Kitipornchai, S.; Chen, D.; Yang, J. Free Vibration and Elastic Buckling of Functionally Graded Porous Beams Reinforced by Graphene Platelets. Mater. Des. 2017, 116, 656–665. [Google Scholar] [CrossRef]

- Muni Rami Reddy, R.; Karunasena, W.; Lokuge, W. Free Vibration of Functionally Graded-GPL Reinforced Composite Plates with Different Boundary Conditions. Aerosp. Sci. Technol. 2018, 78, 147–156. [Google Scholar] [CrossRef]

- Sahmani, S.; Fattahi, A.M.; Ahmed, N.A. Analytical Treatment on the Nonlocal Strain Gradient Vibrational Response of Postbuckled Functionally Graded Porous Micro-/Nanoplates Reinforced with GPL. Eng. Comput. 2020, 36, 1559–1578. [Google Scholar] [CrossRef]

- Lori, E.S.; Ebrahimi, F.; Supeni, E.E.B.; Habibi, M.; Safarpour, H. Frequency Characteristics of a GPL-Reinforced Composite Microdisk Coupled with a Piezoelectric Layer. Eur. Phys. J. Plus 2020, 135, 144. [Google Scholar] [CrossRef]

- Li, C.; Han, Q. Analyzing Wave Propagation in Graphene-Reinforced Nanocomposite Annular Plates by the Semi-Analytical Formulation. Mech. Adv. Mater. Struct. 2020, 1–14. [Google Scholar] [CrossRef]

- Amirabadi, H.; Farhatnia, F.; Eftekhari, S.A.; Hosseini-Ara, R. Wave Propagation in Rotating Functionally Graded GPL-Reinforced Cylindrical Shells Based on the Third-Order Shear Deformation Theory. Waves Random Complex Media 2021, 1–27. [Google Scholar] [CrossRef]

- Gao, W.; Qin, Z.; Chu, F. Wave Propagation in Functionally Graded Porous Plates Reinforced with Graphene Platelets. Aerosp. Sci. Technol. 2020, 102, 105860. [Google Scholar] [CrossRef]

- Liu, D.; Kitipornchai, S.; Chen, W.; Yang, J. Three-Dimensional Buckling and Free Vibration Analyses of Initially Stressed Functionally Graded Graphene Reinforced Composite Cylindrical Shell. Compos. Struct. 2018, 189, 560–569. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.Y.; Wang, Y.X.; Yu, Y.X.; Cai, Y.; Wang, Y.Q. Nonlinear Modeling and vibration analysis of a spinning assembled beam–plate structure reinforced by graphene nanoplatelets. Acta Mech. 2021, 1–17. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, T.; Ma, Y.; Zhou, J.; Fu, Y. Wave Propagation in Rotating Functionally Graded Microbeams Reinforced by Graphene Nanoplatelets. Molecules 2021, 26, 5150. https://doi.org/10.3390/molecules26175150

Zhao T, Ma Y, Zhou J, Fu Y. Wave Propagation in Rotating Functionally Graded Microbeams Reinforced by Graphene Nanoplatelets. Molecules. 2021; 26(17):5150. https://doi.org/10.3390/molecules26175150

Chicago/Turabian StyleZhao, Tianyu, Yu Ma, Jiannan Zhou, and Yanming Fu. 2021. "Wave Propagation in Rotating Functionally Graded Microbeams Reinforced by Graphene Nanoplatelets" Molecules 26, no. 17: 5150. https://doi.org/10.3390/molecules26175150

APA StyleZhao, T., Ma, Y., Zhou, J., & Fu, Y. (2021). Wave Propagation in Rotating Functionally Graded Microbeams Reinforced by Graphene Nanoplatelets. Molecules, 26(17), 5150. https://doi.org/10.3390/molecules26175150