Effects of Airflow Ultrafine-Grinding on the Physicochemical Characteristics of Tartary Buckwheat Powder

Abstract

:1. Introduction

2. Results and Discussion

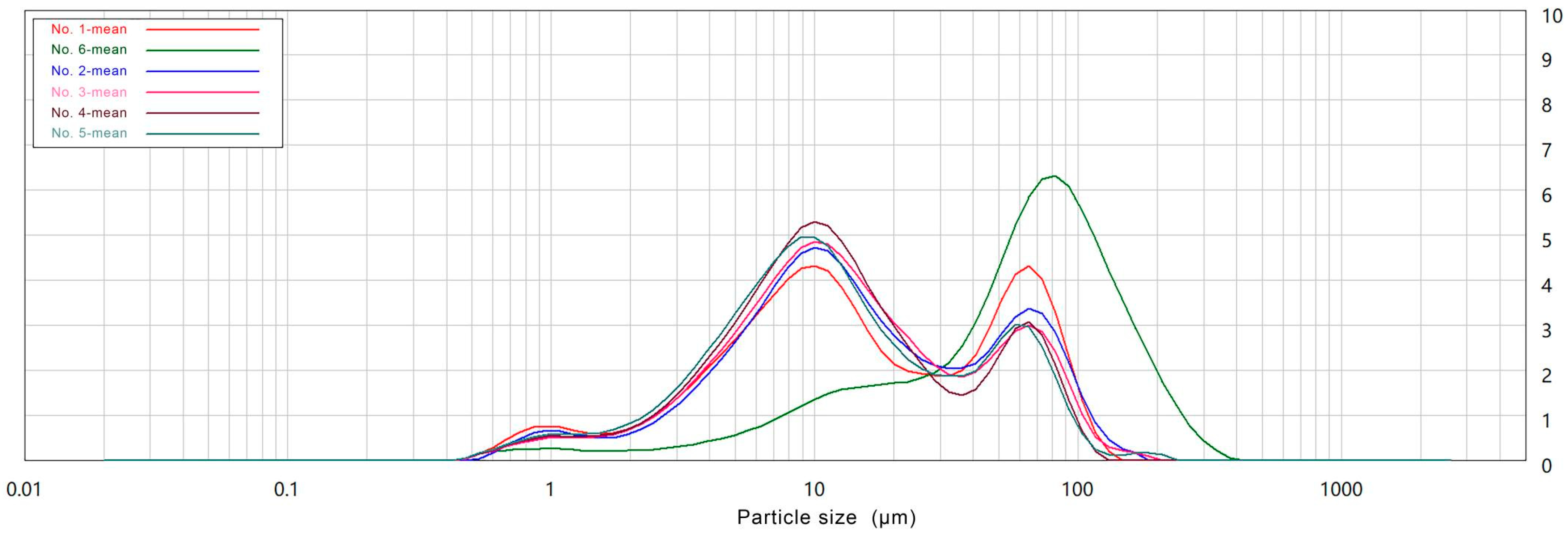

2.1. Particle Size Analysis and Morphological Observation

2.2. Color Difference Analysis

2.3. Chemical Composition of Tartary Buckwheat Flour

2.4. Hydration Properties

2.4.1. Water Holding Capacity Analysis

2.4.2. Swelling Power and Solubility Analysis

3. Materials and Methods

3.1. Main Material

3.2. Preparation of Tartary Buckwheat Ultrafine Milled Flours

3.3. Determination of the Chemical Compositions

3.4. Morphologies Observation of Tartary Buckwheat Flour

3.5. Color Difference Analysis

3.6. Determination of Hydration Properties

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Morishita, T.; Yamaguchi, H.; Degi, K. The contribution of polyphenols to antioxidative activity in common buckwheat and Tartary buckwheat grain. Plant Prod. Sci. 2007, 10, 99–104. [Google Scholar] [CrossRef]

- Sanchez, A.; Schuster, T.M.; Burke, J.M.; Kron, K.A. Taxonomy of Polygonoideae (Polygonaceae): A new tribal classification. Taxon 2011, 60, 151–160. [Google Scholar] [CrossRef]

- Wijngaard, H.H.; Arendt, E.K. Buckwheat. Cereal Chem. 2006, 83, 391–401. [Google Scholar] [CrossRef]

- Kim, S.J.; Zaidul, I.S.M.; Suzuki, T.; Mukasa, Y.; Hashimoto, N.; Takigawa, S.; Yamauchi, H. Comparison of phenolic compositions between common and Tartary buckwheat (Fagopyrum) sprouts. Food Chem. 2008, 110, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Khalid, N.; Ahmad, A.; Abbasi, N.A.; Latif, M.S.Z.; Randhawa, M.A. Phytochemicals and biofunctional properties of buckwheat: A review. J. Agric. Sci. 2014, 152, 349–369. [Google Scholar] [CrossRef]

- Bhinder, S.; Singh, B.; Kaur, A.; Singh, N.; Kaur, M.; Kumari, S.; Yadav, M.P. Effect of infrared roasting on antioxidant activity, phenolic composition and Maillard reaction products of Tartary buckwheat varieties. Food Chem. 2019, 285, 240–251. [Google Scholar] [CrossRef]

- Ruan, J.; Zhou, Y.; Yan, J.; Zhou, M.; Woo, S.H.; Weng, W.; Zhang, K. Tartary buckwheat: An under-utilized edible and medicinal herb for food and nutritional security. Food Rev. Int. 2020, 1–15. [Google Scholar] [CrossRef]

- Bonafaccia, G.; Marocchini, M.; Kreft, I. Composition and technological properties of the flour and bran from common and Tartary buckwheat. Food Chem. 2003, 80, 9–15. [Google Scholar] [CrossRef]

- Zhu, F. Chemical composition and health effects of Tartary buckwheat. Food Chem. 2016, 203, 231–245. [Google Scholar] [CrossRef]

- Ren, Q.; Li, Y.; Wu, C.; Wang, C.; Jin, Y.; Zhang, J. Metabolism of secondary metabolites isolated from Tartary buckwheat and its extract. Food Chem. 2014, 154, 134–144. [Google Scholar] [CrossRef]

- Jin, H.M.; Wei, P. Anti-fatigue properties of Tartary buckwheat extracts in mice. Int. J. Mol. Sci. 2011, 12, 4770–4780. [Google Scholar] [CrossRef] [Green Version]

- Powers, S.K.; Deruisseau, K.C.; Quindry, J.; Hamilton, K.L. Dietary antioxidants and exercise. J. Sports Sci. 2004, 22, 81–94. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.J.; Guo, X.D.; Liu, H.; Xu, B.N.; Wang, M. Cooking, textural, sensorial, and antioxidant properties of common and Tartary buckwheat noodles. Food Sci. Biotechnol. 2013, 22, 153–159. [Google Scholar] [CrossRef]

- Rufa, L. The development and utilization of Tartary buckwheat resources. In Proceedings of the 9th International Symposium on Buckwheat, Prague, Czech Republic, 18–22 August 2004; pp. 252–258. [Google Scholar]

- Zhang, M.; Chen, H.; Li, J.; Pei, Y.; Liang, Y. Antioxidant properties of Tartary buckwheat extracts as affected by different thermal pro-cessing methods. LWT-Food Sci. Technol. 2010, 43, 181–185. [Google Scholar] [CrossRef]

- Baljeet, S.Y.; Ritika, B.Y.; Roshan, L.Y. Studies on functional properties and incorporation of buckwheat flour for biscuit making. Int. Food Res. J. 2010, 17, 1067–1076. [Google Scholar]

- Giménez-Bastida, J.A.; Piskula, M.K.; Zielinski, H. Recent advances in processing and development of buckwheat derived bakery and non-bakery products-a review. Pol. J. Food Nutr. Sci. 2015, 65, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Niu, M.; Hou, G.; Lee, B.; Chen, Z. Effects of fine grinding of millfeeds on the quality attributes of reconstituted whole-wheat flour and its raw noodle products. LWT-Food Sci. Technol. 2014, 57, 58–64. [Google Scholar] [CrossRef]

- Duodu, K.G.; Nunes, A.; Delgadillo, I.; Parker, M.L.; Mills, E.N.C.; Belton, P.S.; Taylor, J.R.N. Effect of grain structure and cooking on sorghum and maize in vitro protein digestibility. J. Cereal Sci. 2002, 35, 161–174. [Google Scholar] [CrossRef]

- Skrabanja, V.; Kreft, I.; Golob, T.; Modic, M.; Ikeda, S.; Ikeda, K.; Kosmelj, K. Nutrient content in buckwheat milling fractions. Cereal Chem. 2004, 81, 172–176. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Ao, Q.; Yang, L.W.; Yang, Y.F.; Sun, J.C.; Gai, G.S. Application of superfine pulverization technology in biomaterial industry. J. Taiwan Inst. Chem. Eng. 2009, 40, 337–343. [Google Scholar] [CrossRef]

- Wu, G.C.; Zhang, M.; Wang, Y.Q.; Mothibe, K.J.; Chen, W.X. Production of silver carp bone powder using superfine grinding technology: Suitable production parameters and its properties. J. Food Eng. 2012, 109, 730–735. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Gai, G.; Yang, Y. Effect of superfine grinding on properties of ginger powder. J. Food Eng. 2009, 91, 217–222. [Google Scholar] [CrossRef]

- Hu, J.; Chen, Y.; Ni, D. Effect of superfine grinding on quality and antioxidant property of fine green tea powders. LWT-Food Sci. Technol. 2012, 45, 8–12. [Google Scholar] [CrossRef]

- Zhu, F.; Du, B.; Xu, B. Superfine grinding improves functional properties and antioxidant capacities of bran dietary fibre from Qingke (hull-less barley) grown in Qinghai-Tibet Plateau, China. J. Cereal Sci. 2015, 65, 43–47. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, C.; Shrestha, S. Study on the preparation technology of superfine ground powder of Agrocybe chaxingu Huang. J. Food Eng. 2005, 67, 333–337. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Wu, Z.; Ameer, K.; Jiang, G. Effects of Superfine Grinding on the Physicochemical Properties and Antioxidant Activities of Sanchi (Panax notoginseng) Flower Powders. J. Food Sci. Technol. 2020, 58, 62–73. [Google Scholar] [CrossRef]

- Zhong, C.; Zu, Y.; Zhao, X.; Li, Y.; Ge, Y.; Wu, W.; Guo, D. Effect of superfine grinding on physicochemical and antioxidant properties of pomegranate peel. Int. J. Food Sci. Technol. 2016, 51, 212–221. [Google Scholar] [CrossRef]

- Tkacova, K.; Stevulova, N. Selected problems of the dispersity analysis of milled ultrafine powders. Freib. Forsch. A (Partik.) A 1998, 841, 14–25. [Google Scholar]

- Villada, J.A.; Sánchez-Sinencio, F.; Zelaya-Ángel, O.; Gutiérrez-Cortez, E.; Rodríguez-García, M.E. Study of the morphological, structural, thermal, and pasting corn transformation during the traditional nixtamalization process: From corn to tortilla. J. Food Eng. 2017, 212, 242–251. [Google Scholar] [CrossRef]

- Liu, F.; He, C.; Wang, L.; Wang, M. Effect of milling method on the chemical composition and antioxidant capacity of Tartary buckwheat flour. Int. J. Food Sci. Technol. 2018, 53, 2457–2464. [Google Scholar] [CrossRef]

- Orumwense, O.A.; Forssberg, E. Superfine and ultrafine grinding—A literature survey. Miner. Process. Extr. Metullargy Rev. 1992, 11, 107–127. [Google Scholar] [CrossRef]

- Li, G.; Guo, W.; Gao, X.; Wang, Y.; Sun, S. Effect of superfine grinding on physicochemical and antioxidant properties of soybean residue powder. Food Sci. Nutr. 2020, 8, 1208–1214. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Dong, Y.; Nisar, T.; Fang, Z.; Wang, Z.C.; Guo, Y. Effect of superfine-grinding on the physicochemical and antioxidant properties of Lycium ruthenicum Murray powders. Powder Technol. 2020, 372, 68–75. [Google Scholar] [CrossRef]

- Li, W.; Cao, F.; Fan, J.; Ouyang, S.; Luo, Q.; Zheng, J.; Zhang, G. Physically modified common buckwheat starch and their physicochemical and structural properties. Food Hydrocoll. 2014, 40, 237–244. [Google Scholar] [CrossRef]

- Zhao, X.; Zhu, H.; Zhang, G.; Tang, W. Effect of superfine grinding on the physicochemical properties and antioxidant activity of red grape pomace powders. Powder Technol. 2015, 286, 838–844. [Google Scholar] [CrossRef]

- Liu, K. Particle size distribution of distillers dried grains with solubles (DDGS) and relationships to compositional and color properties. Bioresour. Technol. 2008, 99, 8421–8428. [Google Scholar] [CrossRef]

- Zhao, X.; Ao, Q.; Du, F.; Zhu, J.; Liu, J. Surface characterization of ginger powder examined by X-ray photoelectron spectroscopy and scanning electron microscopy. Colloids Surf. B Biointerfaces 2010, 79, 494–500. [Google Scholar] [CrossRef]

- Huang, X.; Liang, K.H.; Liu, Q.; Qiu, J.; Wang, J.; Zhu, H. Superfine grinding affects physicochemical, thermal and structural properties of Moringa Oleifera leaf powders. Ind. Crops Prod. 2020, 151, 112472. [Google Scholar] [CrossRef]

- Xu, Q.; Huang, R.; Yang, P.; Wang, L.; Xing, Y.; Liu, H.; Zhang, P. Effect of different superfine grinding technologieson the physicochemical and antioxidant properties of Tartary buckwheat bran powder. RSC Adv. 2021, 11, 30898–30910. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Tharanathan, R.N. Dietary fiber from coconut residue: Effects of different treatments and particle size on the hydration properties. Eur. Food Res. Technol. 2004, 218, 563–567. [Google Scholar] [CrossRef]

- Ting, Y.; Jiang, Y.; Ho, C.T.; Huang, Q. Common delivery systems for enhancing in vivo bioavailability and biological efficacy of nutraceuticals. J. Funct. Foods 2014, 7, 112–128. [Google Scholar] [CrossRef]

- Jiang, L.; Xu, Q.X.; Qiao, M.; Ma, F.F.; Thakur, K.; Wei, Z.J. Effect of superfine grinding on properties of Vaccinium bracteatum Thunb leaves powder. Food Sci. Biotechnol. 2017, 26, 1571–1578. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Du, F.; Zhu, Q.; Qiu, D.; Yin, W.; Ao, Q. Effect of superfine pulverization on properties of Astragalus membranaceus powder. Powder Technol. 2010, 203, 620–625. [Google Scholar] [CrossRef]

- Yan, L.; Li, T.; Liu, C.; Zheng, L. Effects of high hydrostatic pressure and superfine grinding treatment on physicochemi-cal/functional properties of pear pomace and chemical composition of its soluble dietary fibre. LWT-Food Sci. Technol. 2019, 107, 171–177. [Google Scholar] [CrossRef]

- Li, W.; Guo, H.; Wang, P.; Tian, X.; Zhang, W.; Saleh, A.S.; Zhang, G. Physicochemical characteristics of high pressure gelatinized mung bean starch during re-crystallization. Carbohydr. Polym. 2015, 131, 432–438. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Hsieh, F.; Huff, H.E. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995, 22, 185–194. [Google Scholar] [CrossRef]

- Kusumayanti, H.; Handayani, N.A.; Santosa, H. Swelling power and water solubility of cassava and sweet potatoes flour. Procedia Environ. Sci. 2015, 23, 164–167. [Google Scholar] [CrossRef] [Green Version]

- Tester, R.F.; Morrison, W.R. Swelling and gelatinization of cereal starches. I. Effects of amylopectin, amylose, and lipids. Cereal Chem. 1990, 67, 551–557. [Google Scholar]

- Huang, Y.; Sun, X.; Guo, H.; He, X.; Jiang, J.; Zhang, G.; Li, W. Changes in the thermal, pasting, morphological and structural characteristic of common buckwheat starch after ultrafine milling. Int. J. Food Sci. Technol. 2021, 56, 2696–2707. [Google Scholar] [CrossRef]

- Xia, W.; Yang, H.U.; Ji-Hua, L.I.; Wei, X.Y.; Wang, F.; Lin, Y.Y. Effects of superfine grinding on retrogradation properties of tapioca starch. Sci. Technol. Food Ind. 2017, 24, 44–47. [Google Scholar]

- Zhao, Y.; Wu, X.; Wang, Y.; Jing, R.; Yue, F. Comparing physicochemical properties of hawthorn superfine and fine powders. J. Food Process. Preserv. 2017, 41, e12834. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Martin-Sánchez, A.; Sánchez-Zapata, E.; Fernández-López, J.; Sendra, E.; Pérez-Álvarez, J.A. Chemical, physico-chemical and functional properties of pomegranate (Punica granatum L.) bagasses powder co-product. J. Food Eng. 2012, 110, 220–224. [Google Scholar] [CrossRef]

- Pandord, J.A.; Williams, P.C.; DeMan, J.M. Analysis of oilseeds for protein, oil, fiber and moisture by near-infrared reflectance spectroscopy. J. Am. Oil Chem. Soc. 1988, 65, 1627–1634. [Google Scholar] [CrossRef]

- Weber, C.W.; Gentry, H.S.; Kohlhepp, E.A.; McCrohan, P. The nutritional and chemical evaluation of chia seeds. Ecol. Food Nutr. 1991, 26, 119–125. [Google Scholar] [CrossRef]

- Liu, H.; Lv, M.; Peng, Q.; Shan, F.; Wang, M. Physicochemical and textural properties of Tartary buckwheat starch after heat–moisture treatment at different moisture levels. Starch-Stärke 2015, 67, 276–284. [Google Scholar] [CrossRef]

- Senanayake, S.A.; Ranaweera, K.K.D.S.; Gunaratne, A.; Bamunuarachchi, A. Comparative analysis of nutritional quality of five different cultivars of sweet potatoes (I pomea batatas (L) Lam) in S ri L anka. Food Sci. Nutr. 2013, 1, 284–291. [Google Scholar] [CrossRef]

- Leghari, M.H.; Sheikh, S.A.; Kumbhar, M.B.; Baloch, A.F. Mineral content in dehydrated mango powder. J. Basic Appl. Sci. 2013, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Özcan, M.; Arslan, D.; Ünver, A. Effect of drying methods on the mineral content of basil (Ocimum basilicum L.). J. Food Eng. 2005, 69, 375–379. [Google Scholar] [CrossRef]

- Tsai, M.L.; Li, C.F.; Lii, C.Y. Effects of granular structures on the pasting behaviors of starches. Cereal Chem 1997, 74, 750–757. [Google Scholar] [CrossRef]

| Sample | D10 (μm) | D50 (μm) | D90 (μm) |

|---|---|---|---|

| No. 1 | 3.03 ± 0.01c | 10.97 ± 0.04c | 60.64 ± 0.44d |

| No. 2 | 3.21 ± 0.05bc | 11.19 ± 0.15c | 61.07 ± 0.59d |

| No. 3 | 3.33 ± 0.05bc | 12.24 ± 0.18bc | 67.49 ± 1.15c |

| No. 4 | 3.42 ± 0.04b | 13.18 ± 0.07b | 72.27 ± 0.38b |

| No. 5 | 2.96 ± 0.02c | 13.07 ± 0.06b | 71.83 ± 0.46b |

| No. 6 | 8.93 ± 0.48a | 61.84 ± 2.36a | 151.97 ± 2.20a |

| Sample | L* | a* | b* |

|---|---|---|---|

| No. 1 (UMF) | 95.52 ± 0.07a | 1.02 ± 0.09d | 14.90 ± 0.21d |

| No. 2 (UMF) | 93.91 ± 0.07c | 1.74 ± 0.04b | 17.29 ± 0.11b |

| No. 3 (UMF) | 95.32 ± 0.06a | 1.47 ± 0.04c | 15.57 ± 0.13c |

| No. 4 (UMF) | 94.80 ± 0.03b | 1.44 ± 0.03c | 15.61 ± 0.20c |

| No. 5 (UMF) | 93.37 ± 0.15d | 1.70 ± 0.04b | 17.29 ± 0.26b |

| No. 6 (TBCF) | 88.95 ± 0.26e | 2.36 ± 0.12a | 22.07 ± 0.37a |

| Nutrient Contents | No. 1 (UMF) | No. 2 (UMF) | No. 3 (UMF) | No. 4 (UMF) | No. 5 (UMF) | No. 6 (TBCF) |

|---|---|---|---|---|---|---|

| Moisture (g/100gDW) | 7.66 ± 0.02c | 8.22 ± 0.04b | 7.42 ± 0.03d | 8.15 ± 0.04b | 8.19 ± 0.02b | 10.05 ± 0.11a |

| Total starch (g/100gDW) | 58.24 ± 0.38e | 62.19 ± 0.42d | 65.4 ± 0.47c | 67.12 ± 0.41b | 67.64 ± 0.40b | 68.88 ± 0.54a |

| Protein (%) | 12.32 ± 0.10d | 12.91 ± 0.15b | 12.59 ± 0.05c | 12.04 ± 0.03e | 13.16 ± 0.07a | 13.03 ± 0.03ab |

| Crude fat (g/100gDW) | 1.18 ± 0.12a | 1.16 ± 0.14a | 1.17 ± 0.14a | 1.26 ± 0.11a | 1.27 ± 0.22a | 1.24 ± 0.02a |

| Crude fibre (%) | — | — | — | — | — | 0.30 ± 0.10 |

| Ca (mg/L) | 13.41 ± 0.15c | 14.14 ± 0.09b | 13.95 ± 0.24b | 13.37 ± 0.07c | 12.16 ± 0.07d | 14.65 ± 0.08a |

| Fe (mg/L) | 1.85 ± 0.03a | 1.48 ± 0.02c | 1.16 ± 0.01d | 0.63 ± 0.00e | 0.39 ± 0.01f | 1.80 ± 0.03b |

| Mn (mg/L) | 0.54 ± 0.01ab | 0.47 ± 0.00c | 0.52 ± 0.02b | 0.56 ± 0.02a | 0.54 ± 0.00ab | 0.54 ± 0.01ab |

| Zn (mg/L) | 1.21 ± 0.02a | 1.18 ± 0.01b | 1.16 ± 0.03b | 1.15 ± 0.02b | 0.99 ± 0.00c | 1.24 ± 0.01a |

| Cu (mg/L) | 0.20 ± 0.00a | 0.20 ± 0.00a | 0.19 ± 0.00b | 0.20 ± 0.01a | 0.19 ± 0.00b | 0.20 ± 0.00a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Q.; Zheng, F.; Cao, X.; Yang, P.; Xing, Y.; Zhang, P.; Liu, H.; Zhou, G.; Liu, X.; Bi, X. Effects of Airflow Ultrafine-Grinding on the Physicochemical Characteristics of Tartary Buckwheat Powder. Molecules 2021, 26, 5841. https://doi.org/10.3390/molecules26195841

Xu Q, Zheng F, Cao X, Yang P, Xing Y, Zhang P, Liu H, Zhou G, Liu X, Bi X. Effects of Airflow Ultrafine-Grinding on the Physicochemical Characteristics of Tartary Buckwheat Powder. Molecules. 2021; 26(19):5841. https://doi.org/10.3390/molecules26195841

Chicago/Turabian StyleXu, Qinglian, Faying Zheng, Xiaotong Cao, Ping Yang, Yage Xing, Ping Zhang, Hong Liu, Guangchao Zhou, Xiaocui Liu, and Xiufang Bi. 2021. "Effects of Airflow Ultrafine-Grinding on the Physicochemical Characteristics of Tartary Buckwheat Powder" Molecules 26, no. 19: 5841. https://doi.org/10.3390/molecules26195841

APA StyleXu, Q., Zheng, F., Cao, X., Yang, P., Xing, Y., Zhang, P., Liu, H., Zhou, G., Liu, X., & Bi, X. (2021). Effects of Airflow Ultrafine-Grinding on the Physicochemical Characteristics of Tartary Buckwheat Powder. Molecules, 26(19), 5841. https://doi.org/10.3390/molecules26195841