Characteristics of Dough Rheology and the Structural, Mechanical, and Sensory Properties of Sponge Cakes with Sweeteners

Abstract

:1. Introduction

2. Results and Discussion

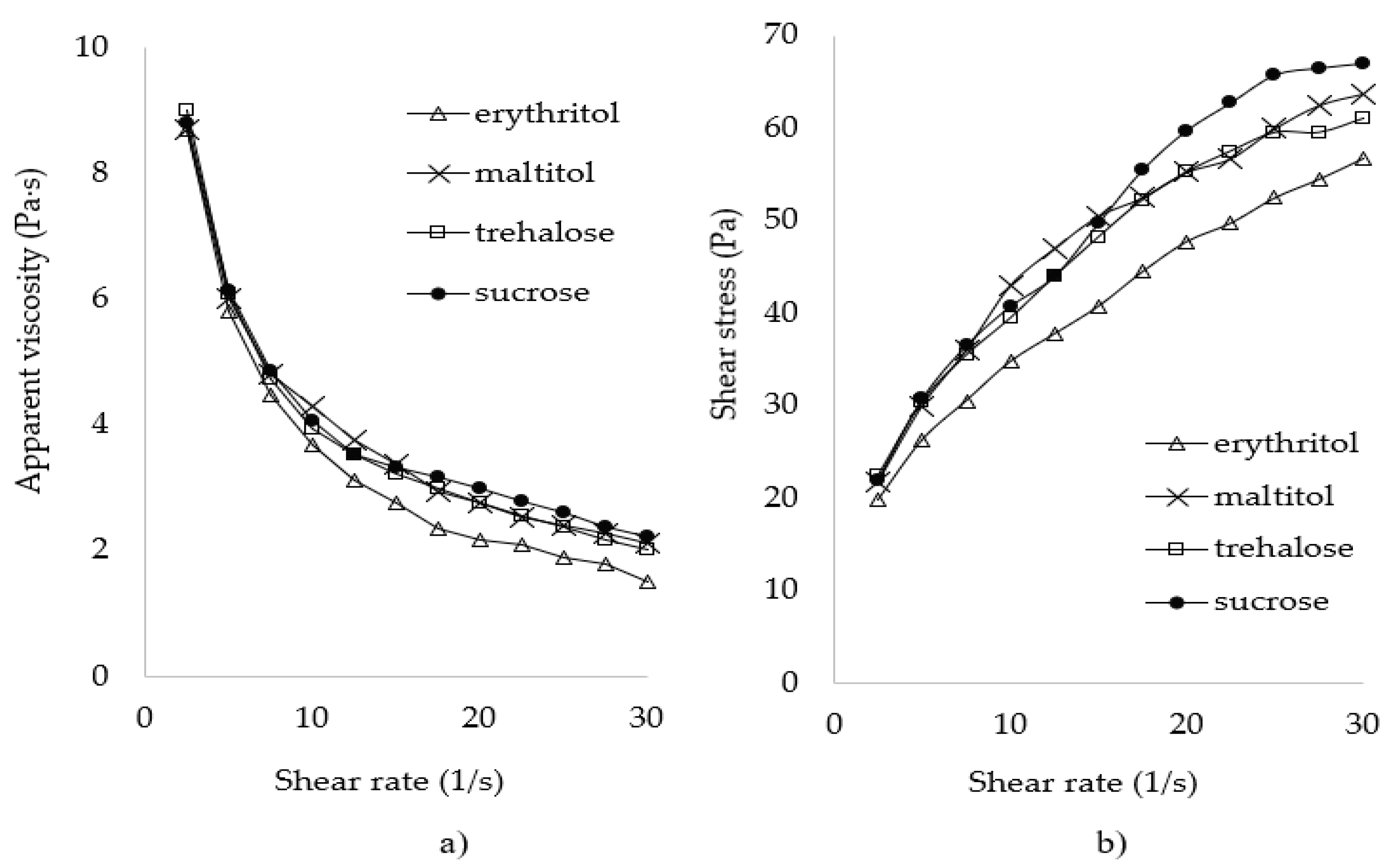

2.1. Rheological Properties, Density, and pH of Dough

2.2. Sponge Cake Water Content, Water Activity, and Color

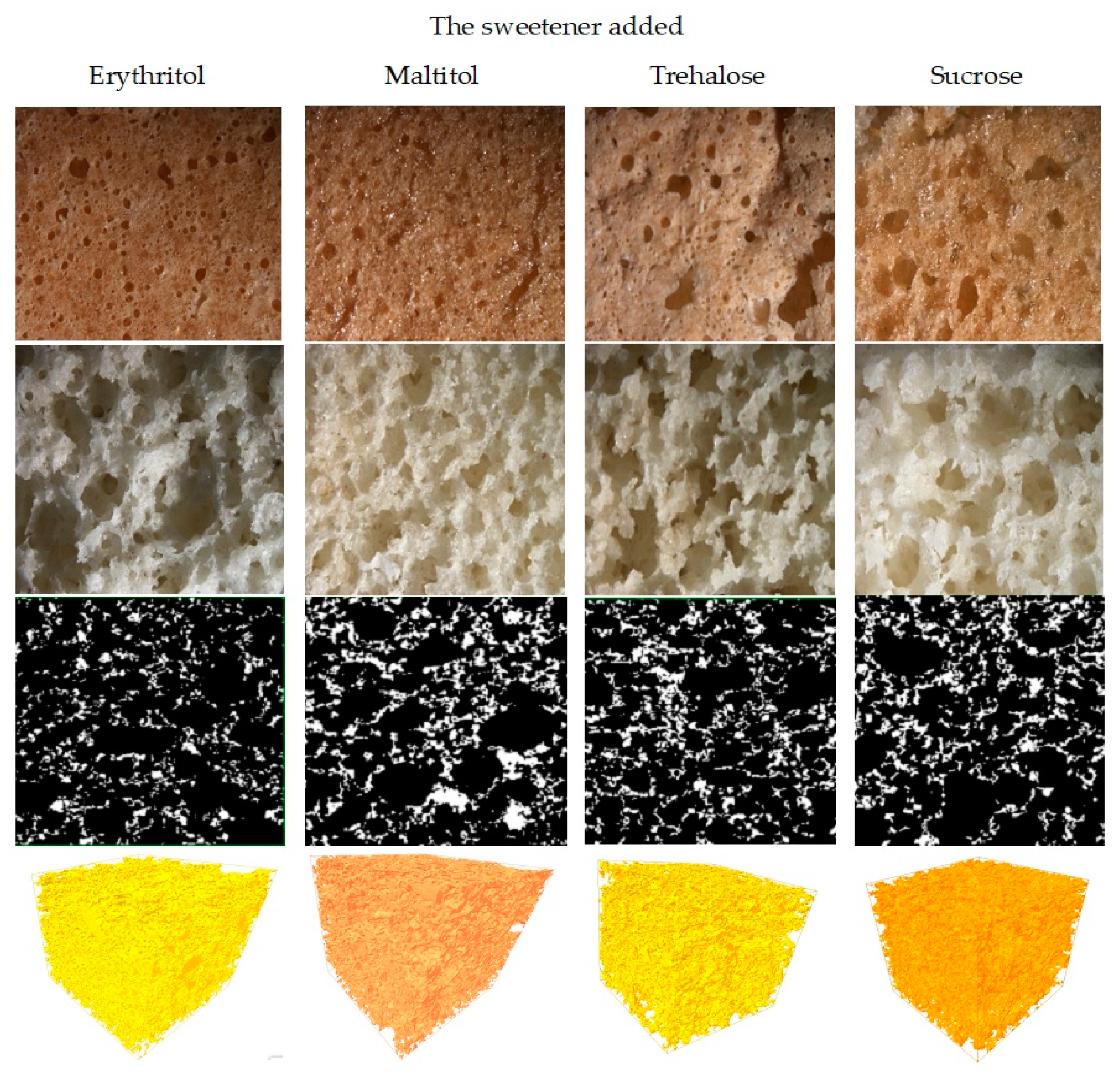

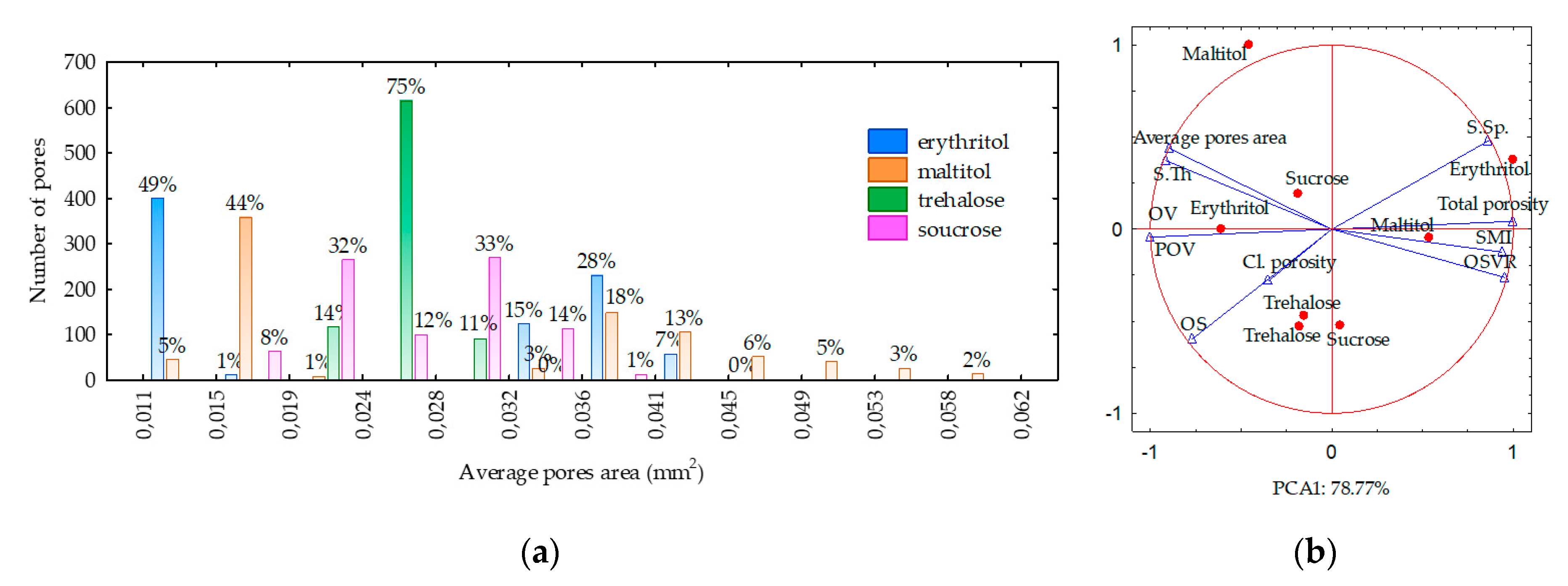

2.3. Real Density, 2D Microstructure, and 3D Microstructure of Sponge Cake

2.4. Sponge Cake Mechanical Properties

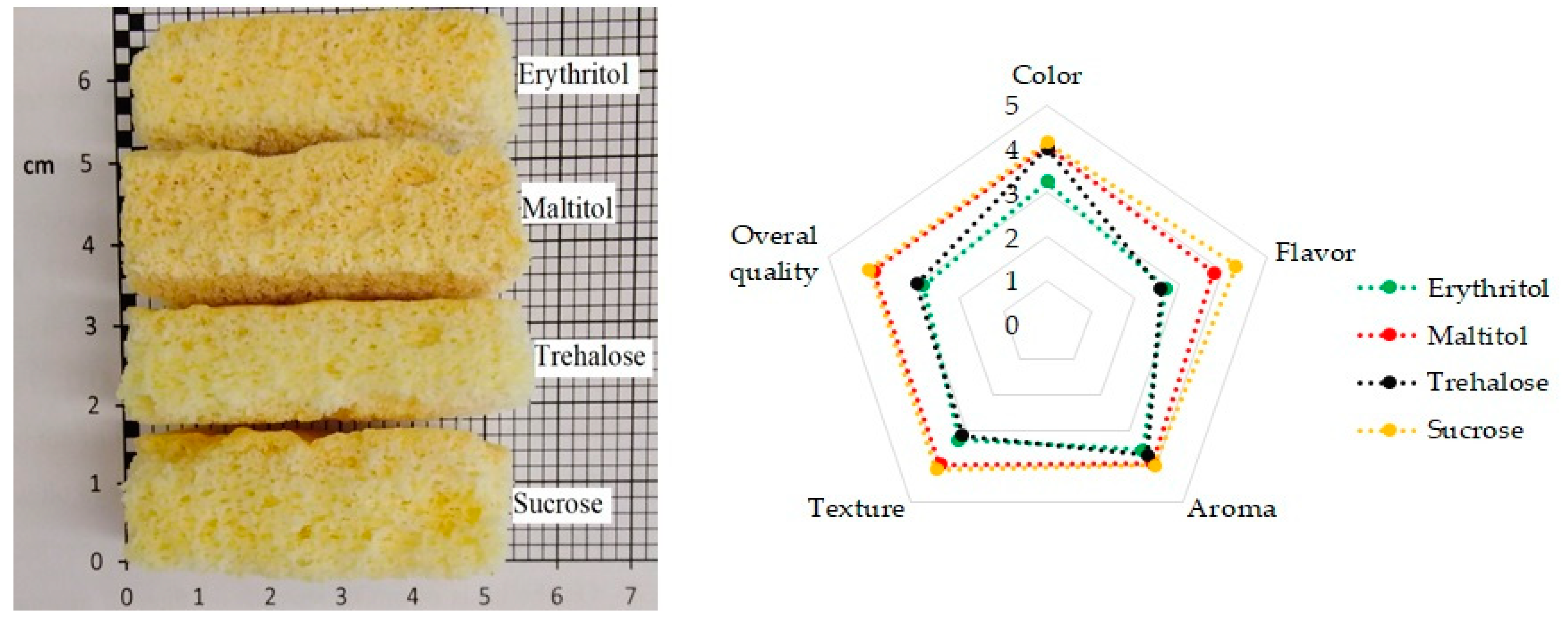

2.5. Sponge Cake Sensory Properties

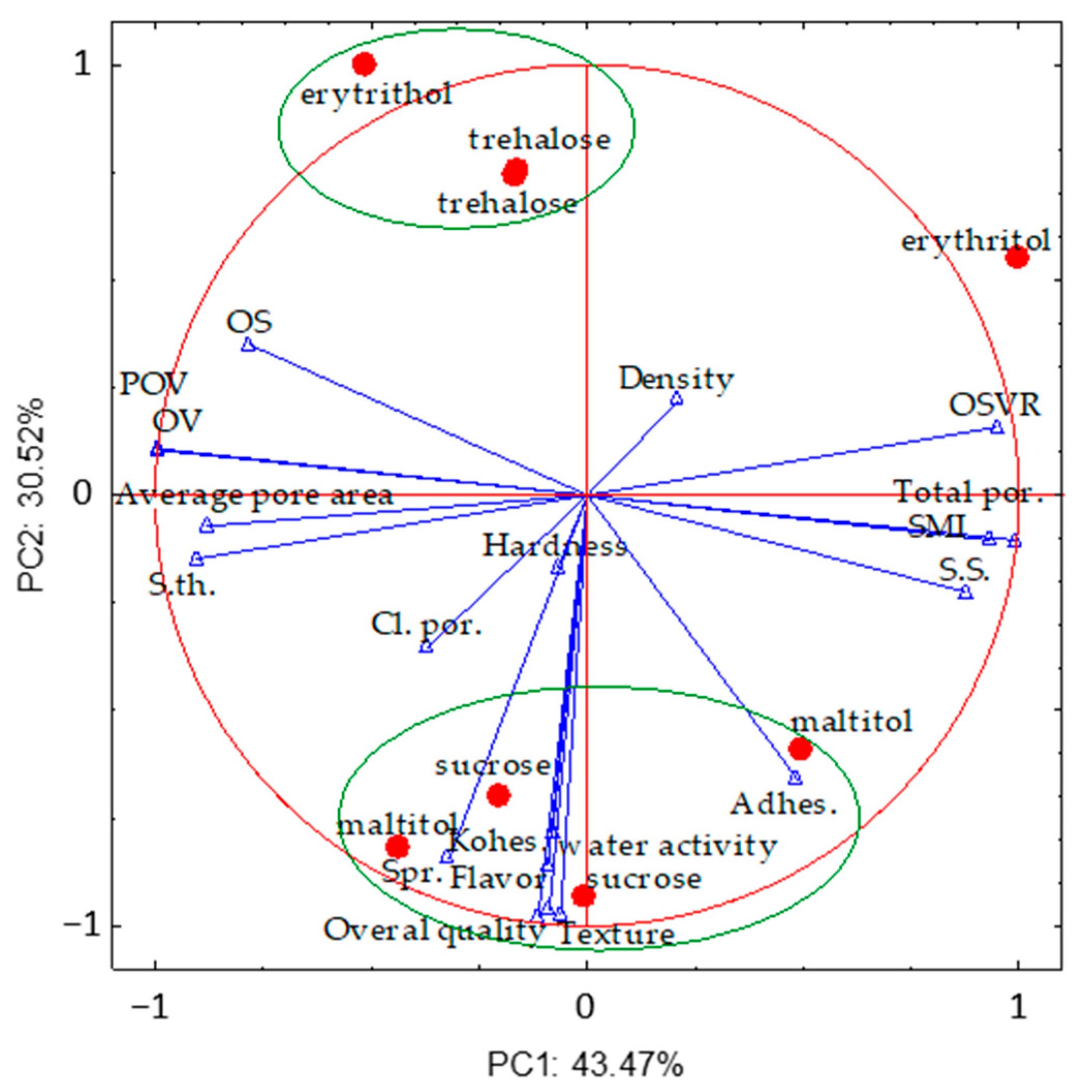

2.6. Correlations between Structural, Mechanical, and Sensory Properties

3. Materials and Methods

3.1. Dough and Sponge Cake Formulation

3.2. Rheological Properties, Density, and pH of the Dough

3.3. Sponge Cake Water Content, Water Activity, and Color

3.4. Real Density and Microstructure of Sponge Cakes

3.5. Sponge Cake Mechanical Properties

3.6. Sensory Properties

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| aw | Water activity |

| τ | Shear stress (Pa) |

| γ | Shear rate (s−1) |

| K | Consistency coefficient (Pa·sn) |

| N | Flow behavior index |

| R2 | determination coefficient |

| L* | Lightness |

| a* | Redness |

| b* | Yellowness |

| C* | Chroma |

| hab | Hue |

| POV | Percent object volume |

| OSVR | Object surface/volume ratio |

| OV | Object volume |

| OS | Object surface |

| SMI | Structure model index |

| DA | Anisotropy coefficient |

| S.Th | Structure thickness |

| S.Sp | Structure separation |

| R | Correlation coefficient |

References

- Sozer, N.; Dogan, H.; Kokini, J.L. Textural properties and their correlation to cell structure in porous food materials. J. Agric. Food Chem. 2011, 59, 1498–1507. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.; Calderón-Domínguez, G.; García-Garibay, M.; Jiménez-Guzmán, J.; Villanueva-Carvajal, A.; de la Paz Salgado-Cruz, M.; Arizmendi-Cotero, D.; Del Moral-Ramírez, E. Effect of whey protein isolate addition on physical, structural and sensory properties of sponge cake. Food Hydroc. 2016, 61, 633–639. [Google Scholar] [CrossRef]

- Pycarelle, S.C.; Bosmans, G.M.; Pareyt, B.; Brijs, K.; Delcour, J.A. The role of intact and disintegrated egg yolk low-density lipoproteins during sponge cake making and their impact on starch and protein mediated structure setting. Foods 2020, 10, 107. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; de Cindio, B.; Cicerelli, L. Modeling of baking behavior of semi-sweet short dough biscuits. Innov. Food Sci. Emerg. Technol. 2014, 25, 40–52. [Google Scholar] [CrossRef]

- Ronda, F.; Oliete, B.; Gómez, M.; Pedro, A.; Caballero, P.A.; Pando, V. Rheological study of layer cake dough made with soybean protein isolate and different starch sources. J. Food Eng. 2011, 102, 271–277. [Google Scholar] [CrossRef]

- Psimouli, V.; Oreopoulou, V. The effect of alternative sweeteners on dough rheology and cake properties. J. Sci. Food Agric. 2012, 92, 99–105. [Google Scholar] [CrossRef]

- Tan, M.C.; Chin, N.L.; Yusof, Y.A.; Taip, F.S.; Abdullah, J. Characterization of improved foam aeration and rheological properties of ultrasonically treated whey protein suspension. Int. Dairy J. 2015, 43, 7–14. [Google Scholar] [CrossRef] [Green Version]

- Edoura-Gaena, R.B.; Allais, I.; Trystram, G.; Gros, J.B. Influence of aeration conditions on physical and sensory properties of aerated cake dough and biscuits. J. Food Eng. 2007, 79, 1020–1032. [Google Scholar] [CrossRef]

- Struck, S.; Jaros, D.; Brennan, C.S.; Rohm, H. Sugar replacement in sweetened bakery goods. Int. J. Food Sci. Tech. 2014, 49, 1963–1976. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, F.; Huang, W.; Tang, X.; Zou, Q.; Li, Z.; Ogawa, A. Sucrose substitution by polyols in sponge cake and their effects on the foaming and thermal properties of egg protein. Food Hydroc. 2016, 57, 153–159. [Google Scholar] [CrossRef]

- Ding, S.; Yang, J. The effects of sugar alcohols on rheological properties, functionalities, and texture in baked products—A review. Trends Food Sci. Technol. 2021, 111, 670–679. [Google Scholar] [CrossRef]

- Amirkaveei, S.; Dai, S.C.; Newberry, M.; Qi, F.; Shahedi, M.; Roger, I.; Tanner, R.I. A Comparison of the Rheology of Four Wheat Flour Doughs via a Damage Function Model. Appl. Rheol. 2009, 19, 34305. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Carrillo-Navas, H.; Pérez-Alonso, C.; Vernon-Carter, E.J.; Alvarez-Ramirez, J. Thermal and rheological properties of sponge cake batters and texture and microstructural characteristics of sponge cake made with native corn starch in partial or total replacement of wheat flour. LWT—Food Sci. Tech. 2016, 70, 46–54. [Google Scholar] [CrossRef]

- Sahin, A.W.; Zannini, E.; Coffey, A.; Arendt, E.K. Sugar reduction in bakery products: Current strategies and sour dough technology as a potential novel approach. Food Res. Int. 2019, 126, 108583. [Google Scholar] [CrossRef]

- Ghosh, S.; Sudha, M.L. A review on polyols: New frontiers for health-based bakery products. Int. J. Food Sci. Nutr. 2012, 63, 372–379. [Google Scholar] [CrossRef]

- Higashiyama, T.; Richards, A.B. Trehalose. In Sweeteners and Sugar Alternatives in Food Technology, 2nd ed.; O’Donnell, K., Kearsley, M.W., Eds.; John Wiley&Sons: Hoboken, NJ, USA, 2012; pp. 417–431. [Google Scholar] [CrossRef]

- Du, J.; Liang, Y.; Xu, F.; Sun, B.; Wang, Z. Trehalose rescues Alzheimer’s diseasephenotypes in APP/PS1 transgenic mice. J. Pharm. Pharmacol. 2013, 65, 1753–1756. [Google Scholar] [CrossRef]

- Peng, B.; Shiyong, Y.; Ding, S.; Yang, J. Characterization of textural, rheological, thermal, microstructural, and water mobility in wheat flour dough and bread affected by trehalose. Food Chem. 2017, 233, 369–377. [Google Scholar] [CrossRef]

- Ronda, F.; Gómez, M.; Blanco, C.A.; Caballero, P.A. Effects of polyols and nondigestible oligosaccharides on the quality of sugar-free sponge cakes. Food Chem. 2005, 90, 549–555. [Google Scholar] [CrossRef]

- Zacharis, C. Xylitol. In Sweeteners and Sugar Alternatives in Food Technology, 2nd ed.; O’Donnell, K., Kearsley, M.W., Eds.; John Wiley&Sons: Hoboken, NJ, USA, 2012; pp. 347–377. [Google Scholar]

- Martínez-Cervera, S.; Sanz, T.; Salvador, A.; Fiszman, S.M. Rheological, textural, and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT-Food Sci. Technol. 2012, 45, 213–220. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, C.; Ma, Y. Volumetric and viscometric properties of amino acids in aqueous maltitol solutions at T = (293.15–323.15) K. J. Chem. Therm. 2017, 111, 52–64. [Google Scholar] [CrossRef]

- Grembecka, M. Sugar alcohols—their role in the modern world of sweeteners: A review. Eur. Food Res. Technol. 2015, 241, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Carly, F.; Vandermies, M.; Telek, S.; Steels, S.; Thomas, S.; Nicaud, J.M.; Fickers, P. Enhancing erythritol productivity in Yarrowia lipolytica using metabolic engineering. Metab. Eng. 2017, 42, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Fernández, A.R.; Santacruz, A.; Jacobo-Velázquez, D.A. The complex relationship between metabolic syndrome and sweeteners. J. Food Sci. 2021, 86, 1511–1531. [Google Scholar] [CrossRef] [PubMed]

- Wölnerhanssen, B.K.; Meyer-Gerspach, A.C.; Beglinger, C.; Islam, M.S. Metabolic effects of the natural sweeteners xylitol and erythritol: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Assad-Bustillo, M.; Guessasma, S.; Réguerre, A.L.; Della Valle, G. Impact of protein reinforcement on the deformation of soft cereal foods under chewing conditions studied by X-ray tomography and finite element modelling. J. Food Eng. 2020, 286, 110108. [Google Scholar] [CrossRef]

- Foegeding, E.A.; Stieger, M.; van de Velde, F. Moving from molecules, to structure, to texture perception. Food Hydroc. 2017, 68, 31–42. [Google Scholar] [CrossRef] [Green Version]

- Cafarelli, B.; Spada, A.; Laverse, J.; Vincenzo Lampignano, V.; Del Nobile, M.A. X-ray microtomography and statistical analysis: Tools to quantitatively classify bread microstructure. J. Food Eng. 2014, 124, 64–71. [Google Scholar] [CrossRef]

- Rodríguez-García, J.; Sahi, S.S.; Hernando, I. Functionality of lipase and emulsifiers in low-fat cakes with inulin. LWT-Food Sci. Technol. 2014, 58, 173–182. [Google Scholar] [CrossRef]

- Fortuna, T.; Gałkowska, D. Effect of saccharide addition on rheological properties of modified starch. Food Sci. Technol. Quality 2006, 4, 5–18. [Google Scholar]

- Domian, E.; Brynda-Kopytowska, A.; Oleksza, A. Rheological properties and physical stability of o/w emulsions stabilized by OSA starch with trehalose. Food Hydroc. 2015, 44, 49–58. [Google Scholar] [CrossRef]

- He, F.; Woods, C.E.; Litowski, J.R.; Roschen, L.A.; Gadgil, H.S.; Razinkov, V.I.; Kerwin, B.A. Effect of sugar molecules on the viscosity of high concentration monoclonal antibody solutions. Pharm. Res. 2011, 28, 1552–1560. [Google Scholar] [CrossRef]

- Cappelli, A.; Bettaccini, L.; Cini, E. The kneading process: A systematic review of the effects on dough rheology and resulting bread characteristics, including improvement strategies. Trends. Food Sci. Technol. 2020, 104, 91–101. [Google Scholar] [CrossRef]

- Fanari, F.; Desogus, F.; Scano, E.A.; Carboni, G.; Grosso, M. The Rheological Properties of Semolina Doughs: Influence of the Relative Amount of Ingredients. Chem. Eng. Trans. 2019, 76, 703–708. [Google Scholar] [CrossRef]

- de la Hera, E.; Ruiz-París, E.; Oliete, B.; Gómez, M. Studies of the quality of cakes made with wheat-lentil composite flours. LWT-Food Sci. Technol. 2012, 49, 48–54. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Tananuwong, K.; Kongpensook, V.; Tantratian, S.; Kokpol, S. Shelf life extension of sponge cake by active packaging as an alternative to direct addition of chemical preservatives. LWT-Food Sci. Technol. 2016, 72, 166–174. [Google Scholar] [CrossRef]

- Allan, M.C.; Rajwa, B.; Mauer, L.J. Effects of sugars and sugar alcohols on the gelatinization temperature of wheat starch. Food Hydroc. 2018, 84, 593–607. [Google Scholar] [CrossRef]

- Hesso, N.; Garnier, C.; Loisel, C.; Chevallier, S.; Bouchet, B.; Le-Bail, A. Formulation effect study on dough and cake microstructure: Correlation with rheology and texture. Food Struct. 2015, 5, 31–41. [Google Scholar] [CrossRef]

- Struck, S.; Gundel, L.; Zahn, S.; Rohm, H. Fiber enriched reduced sugar muffins made from iso-viscous dough. LWT-Food Sci. Technol. 2016, 65, 32–38. [Google Scholar] [CrossRef]

- Joardder, M.U.H.; Kumar, C.; Karim, M.A. Food structure: Its formation and relationships with other properties. Crit. Rev. Food Sci. Nutr. 2017, 57, 1190–1205. [Google Scholar] [CrossRef] [PubMed]

| The Sweetener Added | Consistency IndexK (mPa·sn) | Flow Behavior InDex n (-) | R2 | Density of Dough(g/cm3) | pH |

|---|---|---|---|---|---|

| Erythritol | 10.4 ± 0.7 a | 0.532 ± 0.082 c | 0.999 ± 0.001 | 0.252 ± 0.005 a | 7.81 ± 0.04 b |

| Maltitol | 15.9 ± 1.1 b | 0.424 ± 0.010 b | 0.988 ± 0.006 | 0.437 ± 0.006 c | 7.65 ± 0.04 ab |

| Trehalose | 15.2 ± 0.4 b | 0.353 ± 0.086 a | 0.980 ± 0.021 | 0.313 ± 0.008 b | 7.63 ± 0.01 a |

| Sucrose | 14.0 ± 0.5 b | 0.379 ± 0.119 a | 0.964 ± 0.042 | 0.430 ± 0.010 c | 7.72 ± 0.04 ab |

| The Sweetener Added | Moisture (g/100 g) | Water Activity (aw) | Crust | Crumb | ||||

|---|---|---|---|---|---|---|---|---|

| L* | C* | hab | L* | C* | hab | |||

| Erythritol | 38.3 ± 2.3 a | 0.878 ± 0.061 a | 71.22 ± 0.05 d | 31.35 ± 0.03 b | 1.31 ± 0.00 a | 82.45 ± 0.05 d | 23.59 ± 0.11 d | −1.47 ± 0.00 a |

| Maltitol | 38.5 ± 0.2 a | 0.935 ± 0.028 c | 67.47 ± 0.15 a | 28.68 ± 0.34 a | 1.38 ± 0.00 c | 82.05 ± 0.11 c | 23.02 ± 0.06 b | −1.42 ± 0.00 d |

| Trehalose | 38.3 ± 1.0 a | 0.897 ± 0.028 a | 70.45 ± 0.10 c | 33.83 ± 0.06 c | 1.34 ± 0.00 b | 78.84 ± 0.07 b | 23.31 ± 0.04 c | −1.43 ± 0.00 c |

| Sucrose | 37.0 ± 2.4 a | 0.902 ± 0.030 b | 68.00 ± 0.09 b | 36.77 ± 0.18 d | 1.43 ± 0.00 d | 78.48 ± 0.08 a | 22.80 ± 0.11 a | −1.45 ± 0.00 b |

| Structural and Textural Parameters | The Sweetener Added | |||

|---|---|---|---|---|

| Erythritol | Maltitol | Trehalose | Sucrose | |

| Real density (g/cm3) | 1.595 ± 0.120 b | 1.628 ± 0.027 b | 1.574 ± 0.151 b | 1.502 ± 0.066 a |

| Average pores area (mm2) | 0.025 ± 0.002 a | 0.030 ± 0.014 b | 0.025 ± 0.002 a | 0.026 ± 0.002 a |

| S.Th (mm) | 0.069 ± 0.010 a | 0.075 ± 0.010 c | 0.069 ± 0.002 a | 0.071 ± 0.004 b |

| S.Sp (mm) | 0.351 ± 0.061 a | 0.353 ± 0.010 a | 0.287 ± 0.002 a | 0.316 ± 0.003 a |

| Total porosity (%) | 83.56 ± 7.23 a | 82.83 ± 4.13 b | 81.26 ± 0.28 b | 82.22 ± 082 b |

| Closed porosity (%) | 0.025 ± 0.025 b | 0.025 ± 0.012 b | 0.020 ± 0.002 a | 0.049 ± 0.047 c |

| POV (%) | 16.45 ± 7.23 a | 17.17 ± 4.13 b | 18.74 ± 0.28 b | 17.78 ± 0.82 b |

| OSVR (1/mm) | 41.24 ± 10.34 a | 37.79 ± 8.55 b | 39.69 ± 0.35 b | 38.51 ± 1.50 b |

| SMI (-) | 1.74 ± 0.79 b | 1.69 ± 0.65 b | 1.45 ± 0.04 a | 1.54 ± 0.50 a |

| DA (-) | 0.160 ± 0.049 a | 0.178 ± 0.081 a | 0.158 ± 0.005 a | 0.223 ± 0.004 b |

| Hardness (N) | 7.72 ± 3.41 a | 7.83 ± 1.85 a | 8.38 ± 1.6 a | 8.54 ± 3.36 a |

| Cohesiveness (-) | 0.53 ± 0.04 a | 0.69 ± 0.01 bc | 0.64 ± 0.03 b | 0.73 ± 0.02 c |

| Springiness (mm) | 0.79 ± 0.04 a | 0.94 ± 0.03 c | 0.89 ± 0.04 b | 0.94 ± 0.04 c |

| Adhesiveness (g) | −0.49 ± 0.38 ab | −0.24 ± 0.13 a | −1.32 ± 1.06 b | −0.29 ± 0.15 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzec, A.; Kowalska, J.; Domian, E.; Galus, S.; Ciurzyńska, A.; Kowalska, H. Characteristics of Dough Rheology and the Structural, Mechanical, and Sensory Properties of Sponge Cakes with Sweeteners. Molecules 2021, 26, 6638. https://doi.org/10.3390/molecules26216638

Marzec A, Kowalska J, Domian E, Galus S, Ciurzyńska A, Kowalska H. Characteristics of Dough Rheology and the Structural, Mechanical, and Sensory Properties of Sponge Cakes with Sweeteners. Molecules. 2021; 26(21):6638. https://doi.org/10.3390/molecules26216638

Chicago/Turabian StyleMarzec, Agata, Jolanta Kowalska, Ewa Domian, Sabina Galus, Agnieszka Ciurzyńska, and Hanna Kowalska. 2021. "Characteristics of Dough Rheology and the Structural, Mechanical, and Sensory Properties of Sponge Cakes with Sweeteners" Molecules 26, no. 21: 6638. https://doi.org/10.3390/molecules26216638

APA StyleMarzec, A., Kowalska, J., Domian, E., Galus, S., Ciurzyńska, A., & Kowalska, H. (2021). Characteristics of Dough Rheology and the Structural, Mechanical, and Sensory Properties of Sponge Cakes with Sweeteners. Molecules, 26(21), 6638. https://doi.org/10.3390/molecules26216638