Fabrication and Mechanical Performance of Non-Crimp Unidirectional Jute-Yarn Preform-Based Composites

Abstract

:1. Introduction

2. Materials and Methods

Materials

3. Methods

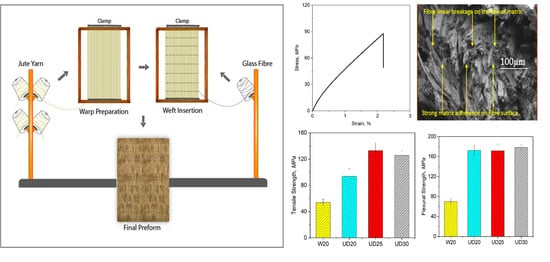

3.1. The Preform Development

3.2. Composite Fabrication

3.3. Measurement of Fibre Volume Fraction and Composite Density

3.4. Characterisation of Composites

3.4.1. Tensile Test

3.4.2. Flexural Test

3.4.3. Dynamic Mechanical Thermal Analysis

3.4.4. Scanning Electron Microscope

4. Results and Discussion

4.1. Physical Properties of Yarns, Developed Preforms and Composites

4.2. Tensile Properties

4.3. Flexural Properties

4.4. Theoretical Analysis of the Tensile Properties of Composites

4.5. Fractographic Observation

4.6. Thermomechanical Analysis of Composites

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khondker, O.A.; Ishiaku, U.S.; Nakai, A.; Hamada, H. Fabrication Mechanical Properties of Unidirectional Jute/PP Composites Using Jute Yarns by Film Stacking Method. J. Polym. Environ. 2005, 13, 115–126. [Google Scholar] [CrossRef]

- Shah, D. Natural fibre composites: Comprehensive Ashby-type materials selection charts. Mater. Des. 2014, 62, 21–31. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Manufacture and characterisation of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos. Part A Appl. Sci. Manuf. 2013, 50, 93–101. [Google Scholar] [CrossRef]

- Madsen, B. Properties of Plant Fibre Yarn Polymer Composites: An Experimental Study; Technical University of Denmark: Copenhagen, Denmark, 2004. [Google Scholar]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-Performance Graphene-Based Natural Fiber Composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Kandola, B.; Sarker, F.; Luangtriratana, P.; Myler, P. Thermal Protection of Carbon Fiber-Reinforced Composites by Ceramic Particles. Coatings 2016, 6, 22. [Google Scholar] [CrossRef] [Green Version]

- Madsen, B.; Hoffmeyer, P.; Lilholt, H. Hemp yarn reinforced composites—II. Tensile properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2204–2215. [Google Scholar] [CrossRef]

- Zaidi, B.M.; Zhang, J.; Magniez, K.; Gu, H.; Miao, M. Optimizing twisted yarn structure for natural fiber-reinforced polymeric composites. J. Compos. Mater. 2017, 52, 373–381. [Google Scholar] [CrossRef]

- Ashadujjaman, M.; Saifullah, A.; Shah, D.; Zhang, M.; Akonda, M.; Karim, N.; Sarker, F. Enhancing the mechanical properties of natural jute yarn suitable for structural applications. Mater. Res. Express 2021, 8, 055503. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of Flax Fibre based Textile Reinforcements for Composite Applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Khalfallah, M.; Abbes, B.; Abbès, F.; Guo, Y.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative flax tapes reinforced Acrodur biocomposites: A new alternative for automotive applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Akonda, M.H.; Shah, D.U.; Gong, R.H. Natural fibre thermoplastic tapes to enhance reinforcing effects in composite structures. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105822. [Google Scholar] [CrossRef]

- Lebrun, G.; Couture, A.; Laperrière, L. Tensile and impregnation behavior of unidirectional hemp/paper/epoxy and flax/paper/epoxy composites. Compos. Struct. 2013, 103, 151–160. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Chi Truong, T.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Hasan, M.; Saifullah, A.; Dhakal, H.N.; Khandaker, S.; Sarker, F. Improved mechanical performances of unidirectional jute fibre composites developed with new fibre architectures. RSC Adv. 2021, 11, 23010–23022. [Google Scholar] [CrossRef]

- Sarker, F.; Potluri, P.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Karim, N. Ultrahigh Performance of Nanoengineered Graphene-Based Natural Jute Fiber Composites. ACS Appl. Mater. Interfaces 2019, 11, 21166–21176. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. Mechanical Property Characterization of Aligned Plant Yarn Reinforced Thermoset Matrix Composites Manufactured via Vacuum Infusion. Polym. Technol. Eng. 2014, 53, 239–253. [Google Scholar] [CrossRef]

- Karim, N.; Sarker, F.; Afroj, S.; Zhang, M.; Potluri, P.; Novoselov, K.S. Sustainable and Multifunctional Composites of Graphene-Based Natural Jute Fibers. Adv. Sustain. Syst. 2021, 5. [Google Scholar] [CrossRef]

- Khondker, O.A.; Ishiaku, U.S.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute yarns. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Vanleeuw, B.; Carvelli, V.; Barburski, M.; Lomov, S.V.; van Vuure, A.W. Quasi-unidirectional flax composite reinforcement: Deformability and complex shape forming. Compos. Sci. Technol. 2015, 110, 76–86. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Sarkar, F.; Akonda, M.; Shah, D.U. Mechanical Properties of Flax Tape-Reinforced Thermoset Composites. Materials 2020, 13, 5485. [Google Scholar] [CrossRef] [PubMed]

- Jawaid, M.; Abdul Khalil, H.P.S.; Abu Bakar, A. Woven hybrid composites: Tensile and flexural properties of oil palm-woven jute fibres based epoxy composites. Mater. Sci. Eng. A 2011, 528, 5190–5195. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Zainudin, E.S.; Yan, L.H.; Haniffah, W.H.; Jawaid, M.; Alothman, O.Y. Effect of coir fiber loading on mechanical and morphological properties of oil palm fibers reinforced polypropylene composites. Polym. Compos. 2014, 35, 1418–1425. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Modelling the effect of yarn twist on the tensile strength of unidirectional plant fibre yarn composites. J. Compos. Mater. 2013, 47, 425–436. [Google Scholar] [CrossRef]

- Garkhail, S.; Heijenrath, R.; Peijs, T. Mechanical Properties of Natural-Fibre-Mat- Reinforced Thermoplastics based on Flax Fibres and Polypropylene. Appl. Compos. Mater. 2000, 7, 351–372. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. The mechanical properties of vinylester resin matrix composites reinforced with alkali-treated jute fibres. Compos. Part A Appl. Sci. Manuf. 2001, 32, 119–127. [Google Scholar] [CrossRef]

- Madsen, B.; Thygesen, A.; Lilholt, H. Plant fibre composites—porosity and stiffness. Compos. Sci. Technol. 2009, 69, 1057–1069. [Google Scholar] [CrossRef]

- Cox, H. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Licence, P.; Clifford, M.J. Determining the minimum, critical and maximum fibre content for twisted yarn reinforced plant fibre composites. Compos. Sci. Technol. 2012, 72, 1909–1917. [Google Scholar] [CrossRef] [Green Version]

- Afaghi-Khatibi, A.; Mai, Y.-W. Characterisation of fibre/matrix interfacial degradation under cyclic fatigue loading using dynamic mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1585–1592. [Google Scholar] [CrossRef]

| Resin | Viscosity [mPas] | Gel Time at 25 °C [mins] | Cured Density ρm [gcm−3] | Tensile Modulus Em [GPa] | Tensile Strength σm [MPa] | Failure Strain εm [%] |

|---|---|---|---|---|---|---|

| Polyester | 160 | 85 | 1.12 | 3.58 | 66 | 2.5 |

| Glass fibre | - | - | 2.6 | 73 | 3400 | 2.25 |

| Type of Preform | Warp Jute Yarns | Weft Glass Yarn | Preform Thicknesses [mm] | Preform Area Density [g/m2] | ||

|---|---|---|---|---|---|---|

| Yarn Direct Count [lb/spyndle] | Linear Density [Tex] | Twist per Meter [TPM] | Weft Yarn Spacing [mm] | |||

| W20 | 20 | 701 (±65) | 171 (±25) | 1.5 | 2.31 (±0.25) | 950 (±102) |

| UD20 | 20 | 701 (±65) | 171 (±25) | 20 | 1.39 (±0.15) | 540 (±95) |

| UD25 | 25 | 877 (±92) | 94 (±14) | 20 | 1.67 (±0.22) | 641 (±74) |

| UD30 | 30 | 1052 (±89) | 78 (±17) | 20 | 2.31 (±0.26) | 854 (±88) |

| Composite Type | No of Layer | Weight of Fibre [gm] | Composite Weight [gm] | Fibre Volume Fraction [Vf] | Composite Density Measured [g/cm3] | Composite Density Theoretical [g/cm3] | Void Volume Fraction [%] |

|---|---|---|---|---|---|---|---|

| W20 | 2 | 23 | 62 | 38.45 | 1.22 | 1.26 | 2.80 |

| UD20 | 2 | 27.19 | 51.23 | 51.37 | 1.28 | 1.30 | 2.14 |

| UD25 | 2 | 34.59 | 57.17 | 58.86 | 1.30 | 1.32 | 1.85 |

| UD30 | 2 | 44.58 | 72.46 | 59.88 | 1.31 | 1.33 | 1.95 |

| Composite | Matrix Resin | Fibre Tensile Modulus GPa | Fibre Tensile Strength MPa | Fibre Length lf | Fibre Diameter D | Fibre Aspect Ratio Lf/D | Critical Fibre Length lc | Length Efficiency for Stiffness ɳIE | Length Efficiency for Strength ɳiS | Theoretical StiffnessEc GPa | Theoretical Tensile Strength σc MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| W20 | POLYESTER | 10 | 170 | 220 | 53 | 4150 | 0.53 | 0.997 | 0.999 | 3.9 | 72 |

| U20 | POLYESTER | 12 | 170 | 220 | 53 | 4150 | 0.53 | 0.997 | 0.999 | 7.2 | 118 |

| U25 | POLYESTER | 15 | 200 | 216 | 48 | 4500 | 0.63 | 0.997 | 0.999 | 9.4 | 146 |

| U30 | POLYESTER | 12 | 190 | 170 | 45 | 3777 | 0.61 | 0.997 | 0.999 | 8 | 131 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, Y.; Faisal, A.; Saifullah, A.; Dhakal, H.N.; Alimuzzaman, S.; Sarker, F. Fabrication and Mechanical Performance of Non-Crimp Unidirectional Jute-Yarn Preform-Based Composites. Molecules 2021, 26, 6664. https://doi.org/10.3390/molecules26216664

Ali Y, Faisal A, Saifullah A, Dhakal HN, Alimuzzaman S, Sarker F. Fabrication and Mechanical Performance of Non-Crimp Unidirectional Jute-Yarn Preform-Based Composites. Molecules. 2021; 26(21):6664. https://doi.org/10.3390/molecules26216664

Chicago/Turabian StyleAli, Yeasin, Atik Faisal, Abu Saifullah, Hom N. Dhakal, Shah Alimuzzaman, and Forkan Sarker. 2021. "Fabrication and Mechanical Performance of Non-Crimp Unidirectional Jute-Yarn Preform-Based Composites" Molecules 26, no. 21: 6664. https://doi.org/10.3390/molecules26216664

APA StyleAli, Y., Faisal, A., Saifullah, A., Dhakal, H. N., Alimuzzaman, S., & Sarker, F. (2021). Fabrication and Mechanical Performance of Non-Crimp Unidirectional Jute-Yarn Preform-Based Composites. Molecules, 26(21), 6664. https://doi.org/10.3390/molecules26216664