Origins of Giant Dielectric Properties with Low Loss Tangent in Rutile (Mg1/3Ta2/3)0.01Ti0.99O2 Ceramic

Abstract

:1. Introduction

2. Results and Discussion

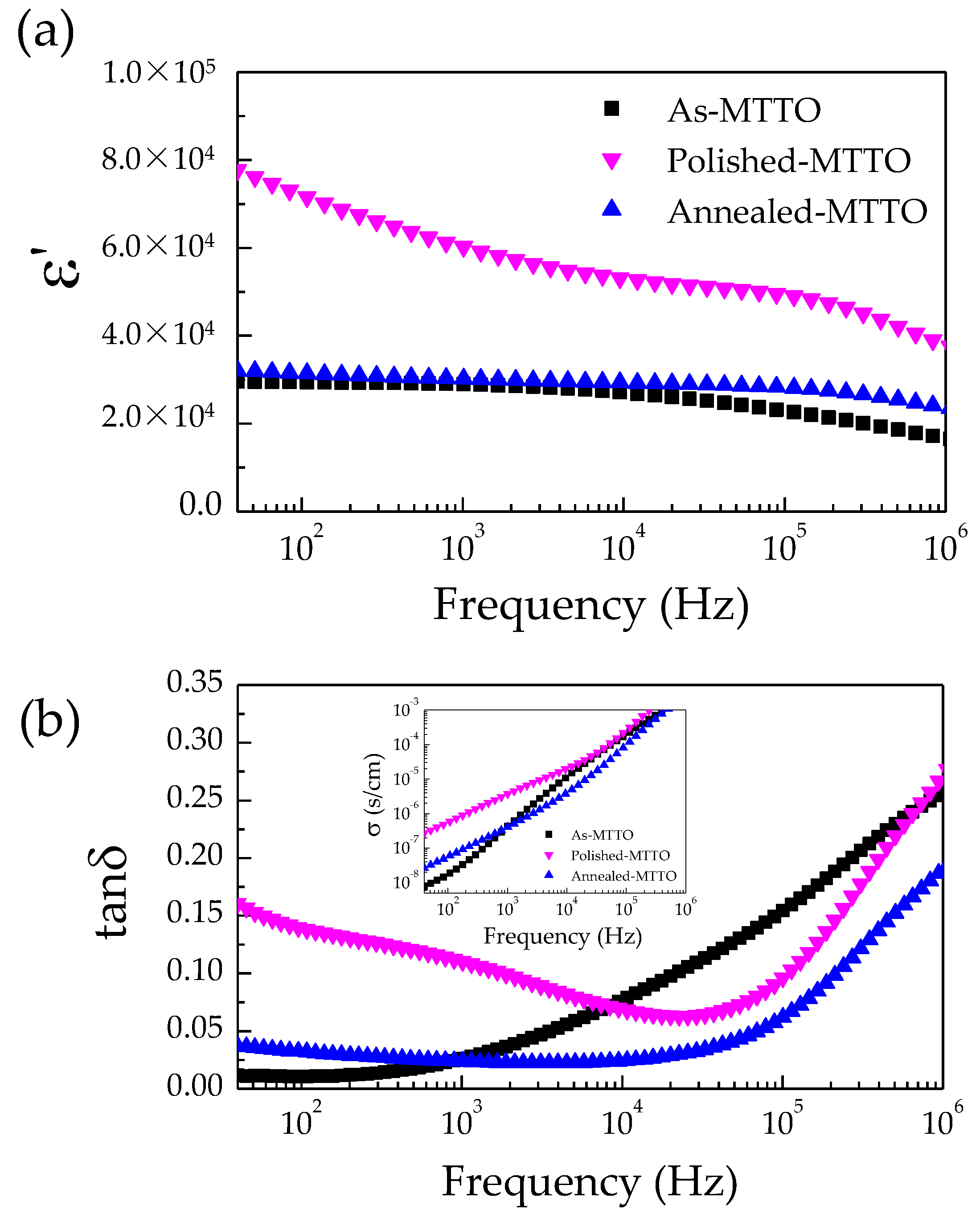

| Codoped TiO2 | ε′ | tanδ | Reference |

|---|---|---|---|

| (Zn1/3Nb2/3)0.05Ti0.95O2 | ~30,000 | ~0.05 | [19] |

| (Ca1/3Nb2/3)0.01Ti0.99O2 | 130,500 | 0.19 | [47] |

| (Mg1/3Tab2/3)0.005Ti0.995O2 | >7000 | 0.002 | [24] |

| (Cu1/3Ta2/3)0.2Ti0.8O2 | 65,314 | >0.1 | [48] |

| (Sr1/3Ta2/3)0.05Ti0.95O2 | 186,000 | 0.15 | [41] |

| (Mg1/3Ta2/3)0.01Ti0.99O2 | 30,249 | 0.024 | This work |

3. Experimental Details

3.1. Sample Preparation

3.2. Dielectric and Electrical Measurements

3.3. Characterizations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Subramanian, M.A.; Li, D.; Duan, N.; Reisner, B.A.; Sleight, A.W. High Dielectric Constant in ACu3Ti4O12 and ACu3Ti3FeO12 Phases. J. Solid State Chem. 2000, 151, 323–325. [Google Scholar] [CrossRef]

- Du, G.; Wei, F.; Li, W.; Chen, N. Co-doping effects of A-site Y3+ and B-site Al3+ on the microstructures and dielectric properties of CaCu3Ti4O12 ceramics. J. Eur. Ceram. Soc. 2017, 37, 4653–4659. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Du, G.; Chen, N. Low temperature preparation of CaCu3Ti4O12 ceramics with high permittivity and low dielectric loss. Ceram. Int. 2017, 43, 9178–9183. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, J.; Lei, X.; Zhu, J.; Xu, S.; Liang, P.; Wei, L.; Wu, D.; Wang, J.; Chao, X.; et al. Colossal dielectric response in CdAlxCu3−xTi4O12 perovskite ceramics. Mater. Chem. Phys. 2021, 258, 123940. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, J.; Zhou, X.; Zhu, J.; Lei, X.; Liang, P.; Chao, X.; Yang, Z. Grain engineering inducing high energy storage in CdCu3Ti4O12 ceramics. Ceram. Int. 2020, 46, 14425–14430. [Google Scholar] [CrossRef]

- Peng, Z.; Zhou, X.; Wang, J.; Zhu, J.; Liang, P.; Chao, X.; Yang, Z. Origin of colossal permittivity and low dielectric loss in Na1/3Cd1/3Y1/3Cu3Ti4O12 ceramics. Ceram. Int. 2020, 46, 11154–11159. [Google Scholar] [CrossRef]

- Sarkar, S.; Jana, P.K.; Chaudhuri, B.K.; Sakata, H. Copper (II) oxide as a giant dielectric material. Appl. Phys. Lett. 2006, 89, 212905. [Google Scholar] [CrossRef]

- Raevski, I.P.; Prosandeev, S.A.; Bogatin, A.S.; Malitskaya, M.A.; Jastrabik, L. High dielectric permittivity in AFe1/2B1/2O3 nonferroelectric perovskite ceramics (A=Ba, Sr, Ca; B=Nb, Ta, Sb). J. Appl. Phys. 2003, 93, 4130. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Nan, C.W.; Lin, Y.; Deng, Y. Giant Dielectric Permittivity Observed in Li and Ti Doped NiO. Phys. Rev. Lett. 2002, 89, 217601. [Google Scholar] [CrossRef]

- Pan, W.; Cao, M.; Qi, J.; Hao, H.; Yao, Z.; Yu, Z.; Liu, H. Defect structure and dielectric behavior in SrTi1−x(Zn1/3Nb2/3)xO3 ceramics. J. Alloys Compd. 2019, 784, 1303–1310. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for High-Energy Density Capacitors: Current Status and Future Perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef]

- Li, W.B.; Zhou, D.; Liu, W.F.; Su, J.Z.; Hussain, F.; Wang, D.W.; Wang, G.; Lu, Z.L.; Wang, Q.P. High-temperature BaTiO3-based ternary dielectric multilayers for energy storage applications with high efficiency. Chem. Eng. J. 2021, 414, 128760. [Google Scholar] [CrossRef]

- Lai, X.; Hao, H.; Liu, Z.; Li, S.; Liu, Y.; Emmanuel, M.; Yao, Z.; Cao, M.; Wang, D.; Liu, H. Structure and dielectric properties of MgO-coated BaTiO3 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 8963–8970. [Google Scholar] [CrossRef]

- Hu, W.; Liu, Y.; Withers, R.L.; Frankcombe, T.J.; Norén, L.; Snashall, A.; Kitchin, M.; Smith, P.; Gong, B.; Chen, H.; et al. Electron-pinned defect-dipoles for high-performance colossal permittivity materials. Nat. Mater. 2013, 12, 821–826. [Google Scholar] [CrossRef]

- Dong, W.; Hu, W.; Berlie, A.; Lau, K.; Chen, H.; Withers, R.L.; Liu, Y. Colossal Dielectric Behavior of Ga+Nb Co-Doped Rutile TiO2. ACS Appl. Mater. Interfaces 2015, 7, 25321–25325. [Google Scholar] [CrossRef] [PubMed]

- Tuichai, W.; Thongyong, N.; Danwittayakul, S.; Chanlek, N.; Srepusharawoot, P.; Thongbai, P.; Maensiri, S. Very low dielectric loss and giant dielectric response with excellent temperature stability of Ga3+ and Ta5+ co-doped rutile-TiO2 ceramics. Mater. Des. 2017, 123, 15–23. [Google Scholar] [CrossRef]

- Hu, W.; Lau, K.; Liu, Y.; Withers, R.L.; Chen, H.; Fu, L.; Gong, B.; Hutchison, W. Colossal Dielectric Permittivity in (Nb+Al) Codoped Rutile TiO2 Ceramics: Compositional Gradient and Local Structure. Chem. Mater. 2015, 27, 4934–4942. [Google Scholar] [CrossRef]

- Wang, X.W.; Zhang, B.H.; Sun, L.Y.; Qiao, W.N.; Hao, Y.D.; Hu, Y.C.; Wang, X.E. Colossal dielectric properties in (Ta0.5Al0.5)xTi1−xO2 ceramics. J. Alloys Compd. 2018, 745, 856–862. [Google Scholar] [CrossRef]

- Wei, X.; Jie, W.; Yang, Z.; Zheng, F.; Zeng, H.; Liu, Y.; Hao, J. Colossal permittivity properties of Zn,Nb co-doped TiO2 with different phase structures. J. Mater. Chem. C 2015, 3, 11005–11010. [Google Scholar] [CrossRef]

- Thongyong, N.; Tuichai, W.; Chanlek, N.; Thongbai, P. Effect of Zn2+ and Nb5+ co-doping ions on giant dielectric properties of rutile-TiO2 ceramics. Ceram. Int. 2017, 43, 15466–15471. [Google Scholar] [CrossRef]

- Peng, H.; Liang, P.; Wu, D.; Zhou, X.; Peng, Z.; Xiang, Y.; Chao, X.; Yang, Z. Simultaneous realization of broad temperature stability range and outstanding dielectric performance in (Ag+, Ta5+) co–doped TiO2 ceramics. J. Alloys Compd. 2019, 783, 423–427. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, D.; Liang, P.; Zhou, X.; Peng, Z.; Chao, X.; Yang, Z. Ag+/W6+ co-doped TiO2 ceramic with colossal permittivity and low loss. J. Alloys Compd. 2021, 856, 157350. [Google Scholar] [CrossRef]

- Zhou, X.; Liang, P.; Zhu, J.; Peng, Z.; Chao, X.; Yang, Z. Enhanced dielectric performance of (Ag1/4Nb3/4)0.01Ti0.99O2 ceramic prepared by a wet-chemistry method. Ceram. Int. 2020, 46, 11921–11925. [Google Scholar] [CrossRef]

- Dong, W.; Chen, D.; Hu, W.; Frankcombe, T.J.; Chen, H.; Zhou, C.; Fu, Z.; Wei, X.; Xu, Z.; Liu, Z.; et al. Colossal permittivity behavior and its origin in rutile (Mg1/3Ta2/3)xTi1−xO2. Sci. Rep. 2017, 7, 9950. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmidt, R.; Stennett, M.C.; Hyatt, N.C.; Pokorny, J.; Prado-Gonjal, J.; Li, M.; Sinclair, D.C. Effects of sintering temperature on the internal barrier layer capacitor (IBLC) structure in CaCu3Ti4O12 (CCTO) ceramics. J. Eur. Ceram. Soc. 2012, 32, 3313–3323. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.; Zhang, X.; Sui, Y.; Zhang, Y.; Liu, Z.; Lv, Z.; Wang, Y.; Xu, P.; Song, B. The contribution of doped-Al to the colossal permittivity properties of AlxNb0.03Ti0.97−xO2 rutile ceramics. J. Mater. Chem. C 2016, 4, 6798–6805. [Google Scholar] [CrossRef]

- Liu, G.; Fan, H.; Xu, J.; Liu, Z.; Zhao, Y. Colossal permittivity and impedance analysis of niobium and aluminum co-doped TiO2 ceramics. RSC Adv. 2016, 6, 48708–48714. [Google Scholar] [CrossRef]

- Nachaithong, T.; Kidkhunthod, P.; Thongbai, P.; Maensiri, S. Surface barrier layer effect in (In + Nb) co-doped TiO2 ceramics: An alternative route to design low dielectric loss. J. Am. Ceram. Soc. 2017, 100, 1452–1459. [Google Scholar] [CrossRef]

- Nachaithong, T.; Thongbai, P.; Maensiri, S. Colossal permittivity in (In1/2Nb1/2)xTi1−xO2 ceramics prepared by a glycine nitrate process. J. Eur. Ceram. Soc. 2017, 37, 655–660. [Google Scholar] [CrossRef]

- Wang, J.; Liu, G.; Jia, B.W.; Liu, X.Q.; Chen, X.M. Giant dielectric response and polaronic hopping in Al-substituted A5/3Sr1/3NiO4 (A = La, Nd) ceramics. Ceram. Int. 2014, 40, 5583–5590. [Google Scholar] [CrossRef]

- Meeporn, K.; Chanlek, N.; Thongbai, P. Effects of DC bias on non-ohmic sample-electrode contact and grain boundary responses in giant-permittivity La1.7Sr0.3Ni1−xMgxO4 ceramics. RSC Adv. 2016, 6, 91377–91385. [Google Scholar] [CrossRef]

- Petzelt, J.; Nuzhnyy, D.; Bovtun, V.; Crandles, D.A. Origin of the colossal permittivity of (Nb + In) co-doped rutile ceramics by wide-range dielectric spectroscopy. Phase Transit. 2018, 91, 932–941. [Google Scholar] [CrossRef]

- Bovtun, V.; Petzelt, J.; Kempa, M.; Nuzhnyy, D.; Savinov, M.; Kamba, S.; Yee, S.M.M.; Crandles, D.A. Wide range dielectric and infrared spectroscopy of (Nb+In) co-doped rutile ceramics. Phys. Rev. Mater. 2018, 2, 075002. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised Effective Ionic Radii and Systematic Studies of Interatomie Distances in Halides and Chaleogenides. Acta Cryst. 1976, A32, 751–767. [Google Scholar] [CrossRef]

- Mathpal, M.C.; Tripathi, A.K.; Singh, M.K.; Gairola, S.P.; Pandey, S.N.; Agarwal, A. Effect of annealing temperature on Raman spectra of TiO2 nanoparticles. Chem. Phys. Lett. 2013, 555, 182–186. [Google Scholar] [CrossRef]

- Parker, J.C.; Siegel, R.W. Calibration of the Raman spectrum to the oxygen stoichiometry of nanophase TiO2. Appl. Phys. Lett. 1990, 57, 943–945. [Google Scholar] [CrossRef]

- Yang, C.; Tse, M.Y.; Wei, X.; Hao, J. Colossal permittivity of (Mg + Nb) co-doped TiO2 ceramics with low dielectric loss. J. Mater. Chem. C 2017, 5, 5170–5175. [Google Scholar] [CrossRef]

- Yang, C.; Wei, X.; Hao, J. Disappearance and recovery of colossal permittivity in (Nb+Mn) co-doped TiO2. Ceram. Int. 2018, 44, 12395–12400. [Google Scholar] [CrossRef]

- Homes, C.C.; Vogt, T. Colossal permittivity materials: Doping for superior dielectrics. Nat. Mater. 2013, 12, 782–783. [Google Scholar] [CrossRef]

- Tuichai, W.; Danwittayakul, S.; Chanlek, N.; Srepusharawoot, P.; Thongbai, P.; Maensiri, S. Origin(s) of the apparent colossal permittivity in (In1/2Nb1/2)xTi1−xO2: Clarification on the strongly induced Maxwell-Wagner polarization relaxation by DC bias. RSC Adv. 2017, 7, 95–105. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Xu, J.; Cui, B.; Yu, Q.; Zhong, S.; Zhang, L.; Du, S.; Xu, D. Colossal permittivity characteristics and mechanism of (Sr, Ta) co-doped TiO2 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 5205–5213. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhao, X.; Zhang, J.L.; Su, W.B.; Liu, J. Huge low-frequency dielectric response of (Nb,In)-doped TiO2 ceramics. Appl. Phys. Lett. 2015, 107, 242904. [Google Scholar] [CrossRef]

- Tuichai, W.; Danwittayakul, S.; Chanlek, N.; Thongbai, P.; Maensiri, S. High-performance giant-dielectric properties of rutile TiO2 co-doped with acceptor-Sc3+ and donor-Nb5+ ions. J. Alloys Compd. 2017, 703, 139–147. [Google Scholar] [CrossRef]

- Li, M.; Feteira, A.; Sinclair, D.C. Relaxor ferroelectric-like high effective permittivity in leaky dielectrics/oxide semiconductors induced by electrode effects: A case study of CuO ceramics. J. Appl. Phys. 2009, 105, 114109. [Google Scholar] [CrossRef]

- Nachaithong, T.; Chanlek, N.; Moontragoon, P.; Thongbai, P. The Primary Origin of Excellent Dielectric Properties of (Co, Nb) Co-Doped TiO2 Ceramics: Electron-Pinned Defect Dipoles vs. Internal Barrier Layer Capacitor Effect. Molecules 2021, 26, 3230. [Google Scholar] [CrossRef] [PubMed]

- Tuichai, W.; Danwittayakul, S.; Maensiri, S.; Thongbai, P. Investigation on temperature stability performance of giant permittivity (In + Nb) in co-doped TiO2 ceramic: A crucial aspect for practical electronic applications. RSC Adv. 2016, 6, 5582–5589. [Google Scholar] [CrossRef]

- Li, Z.; Luo, X.; Wu, W.; Wu, J. Niobium and divalent-modified titanium dioxide ceramics: Colossal permittivity and composition design. J. Am. Ceram. Soc. 2017, 100, 3004–3012. [Google Scholar] [CrossRef]

- Yuan, L.; Li, L.; Li, G.; Wang, S.; Li, J.; Lu, D.; Han, W. Optimizing giant dielectric properties via interface composition: A study of rutile-based ceramics. Ceram. Int. 2019, 45, 17705–17714. [Google Scholar] [CrossRef]

- Adams, T.; Sinclair, D.; West, A. Characterization of grain boundary impedances in fine- and coarse-grained CaCu3Ti4O12 ceramics. Phys. Rev. B 2006, 73, 094124. [Google Scholar] [CrossRef]

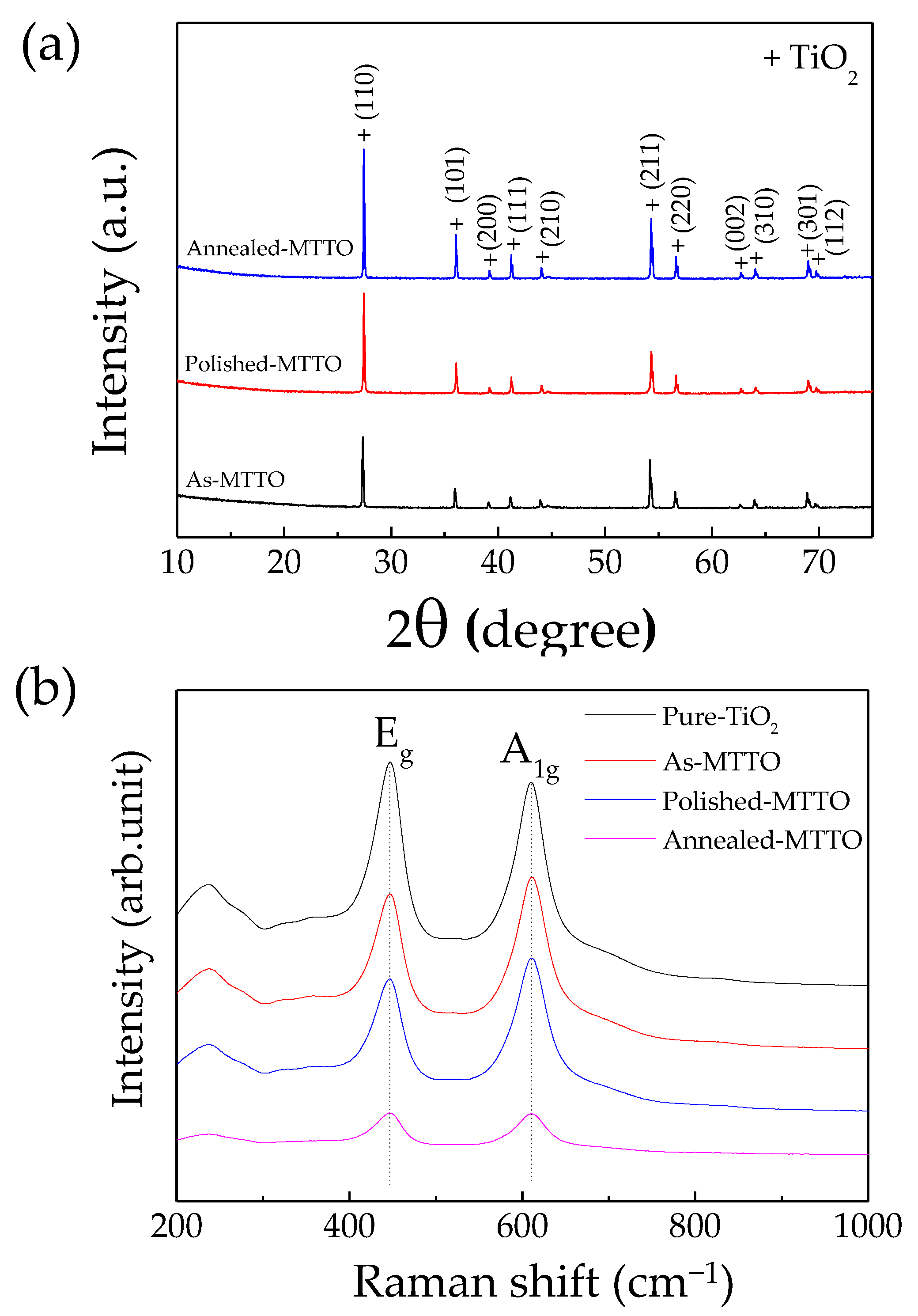

| Sample | Lattice Parameters (Å) | Raman Shift (cm−1) | ||

|---|---|---|---|---|

| a | c | Eg | A1g | |

| Pure TiO2 | - | - | 447 | 610.0 |

| As-MTTO | 4.597 | 2.963 | 447 | 611.5 |

| Polished MTTO | 4.597 | 2.963 | 446.5 | 610.5 |

| Annealed MTTO | 4.597 | 2.963 | 446.5 | 610.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thongyong, N.; Chanlek, N.; Srepusharawoot, P.; Thongbai, P. Origins of Giant Dielectric Properties with Low Loss Tangent in Rutile (Mg1/3Ta2/3)0.01Ti0.99O2 Ceramic. Molecules 2021, 26, 6952. https://doi.org/10.3390/molecules26226952

Thongyong N, Chanlek N, Srepusharawoot P, Thongbai P. Origins of Giant Dielectric Properties with Low Loss Tangent in Rutile (Mg1/3Ta2/3)0.01Ti0.99O2 Ceramic. Molecules. 2021; 26(22):6952. https://doi.org/10.3390/molecules26226952

Chicago/Turabian StyleThongyong, Nateeporn, Narong Chanlek, Pornjuk Srepusharawoot, and Prasit Thongbai. 2021. "Origins of Giant Dielectric Properties with Low Loss Tangent in Rutile (Mg1/3Ta2/3)0.01Ti0.99O2 Ceramic" Molecules 26, no. 22: 6952. https://doi.org/10.3390/molecules26226952