A Comparative Analysis of Conventional and Deep Eutectic Solvent (DES)-Mediated Strategies for the Extraction of Chitin from Marine Crustacean Shells

Abstract

:1. Introduction

2. Methodology

3. Chitin

3.1. Chitin Properties

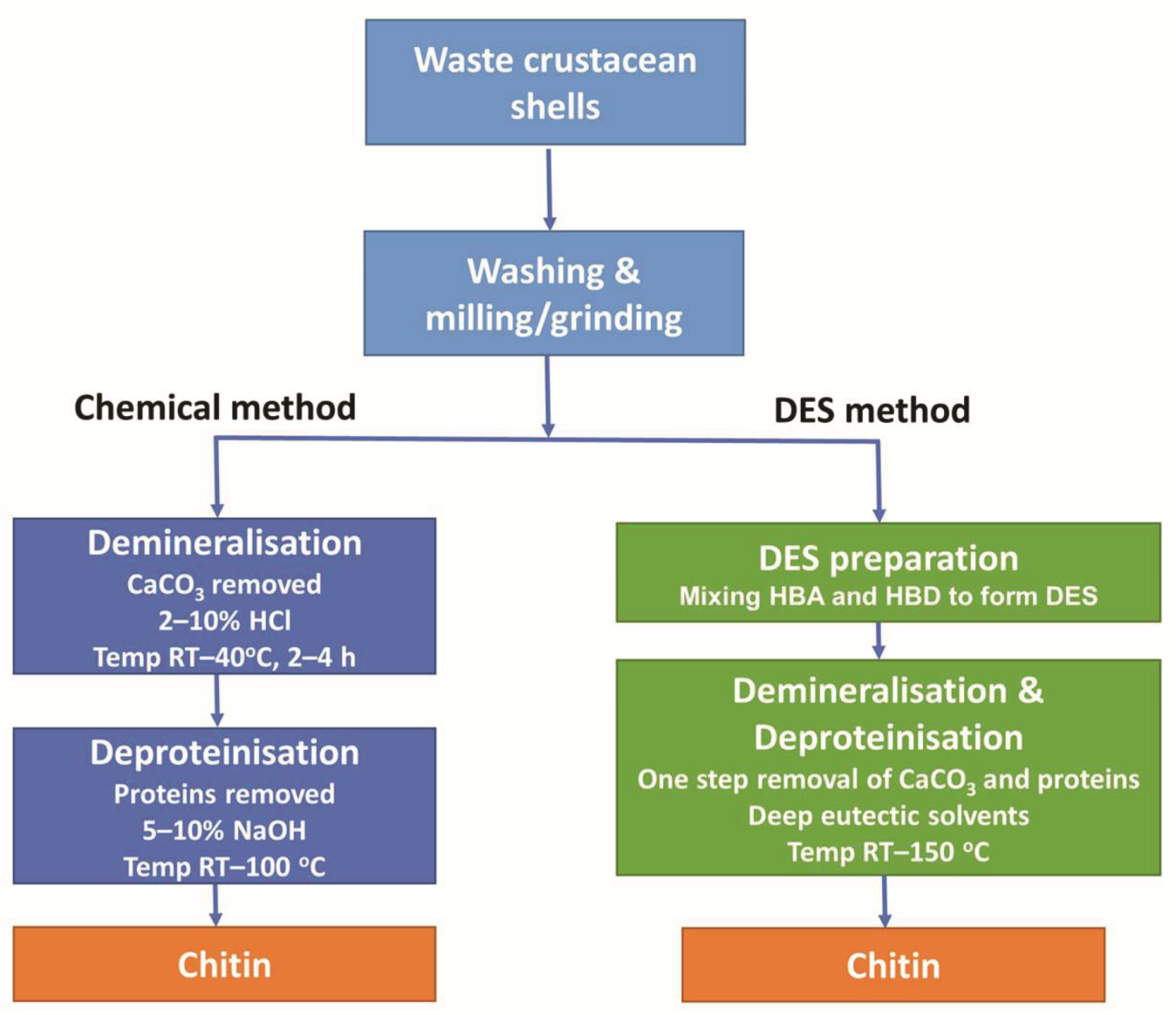

3.2. Extraction of Chitin

3.3. Measurement of Chitin Purity

| Marine Habitat | Chitin Source | CaCO3 (%) | Protein (%) | Other (%) | Purity (%) | Yield (%) | Reference |

|---|---|---|---|---|---|---|---|

| All seas except polar | Lobster shells (Nephropidae) | 0.39 ± 0.23 | 2.22 ± 0.24 | 3.93 ± 0.09 | 93 | 17.21 ± 0.28 | [22] |

| All seas except polar | Lobster shells (Nephropidae) | 0.30 ± 0.20 | 2.90 ± 0.25 | 4.17 ± 0.03 | 93 | 16.53 ± 2.35 | [1] |

| Indian and North Pacific Ocean | Shrimp shells (Marsupenaeus japonicus) | 0.45 ± 0.10 | 1.13 ± 0.01 | 1.32 ± 0.00 | 97 | 16.08 ± 0.57 | [2] |

| Eastern Pacific Ocean | Shrimp shells (Litopenaeus vannamei) | 0.1 | 0.95 | - | - | - | [23] |

| Eastern Pacific Ocean | Shrimp shells (Litopenaeus vannamei) | 0.2 | 0.92 | - | - | - | [23] |

| Marine Habitat | Source | Chitin (%) | CaCO3 (%) | Protein (%) | Other (%) | Reference |

|---|---|---|---|---|---|---|

| Marine: Eastern Atlantic Ocean and Mediterranean Sea | Lobster shells (Homarus) | 60–75 | - | - | - | [24] |

| Marine: Eastern Atlantic Ocean and Mediterranean Sea | Lobster shells (Nephron norvegicus) | 69.8 | - | - | - | [24] |

| Shrimp shells (species unknown, Egypt) | 36.43 | 32.46 | 32.77 | - | [12] | |

| Marine: Indian and Pacific Ocean | Shrimp shells (Solenocera crassicornis) | 35.8 | 56.1 | 8.1 | - | [3] |

| Atlantic East and West coasts | Shrimp shells (Parapenaeus longirostris) | 26.98 | 25.06 | 29.23 | 18.73 | [12] |

| Marine: Western Atlantic and North Pacific | Crab shells (Chionoecetes) | 26.6 | - | - | - | [24] |

| Marine: All seas except polar | Lobster shells (Nephropidae) China | 26.23 | 40.64 | 25.83 | 7.3 | [1] |

| Marine: All seas except polar | Lobster shells (Nephropidae) China | 26.23 | 40.64 | 25.83 | 7.3 | [23] |

| Marine: Antarctic | Krill shells (Euphausia superba) | 24 | - | - | - | [24] |

| Marine: Western Atlantic | Shrimp shells (Penaeus durarum) | 23.72 | 42.26 | 34.02 | - | [25] |

| Marine: Eastern Atlantic Ocean | Shrimp shells (Penaeus aztecus) | 21.53 | 48.97 | 29.5 | - | [25] |

| Marine: Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | 19.21 | 31.76 | 36.47 | 12.56 | [2] |

| Marine: Eastern Atlantic Ocean and Mediterranean Sea | Shrimp shells (Crangon crangon) | 17.8 | - | - | - | [24] |

| Crab shells (species unknown, Egypt) | 16.73 | 66.58 | 16.68 | - | [25] |

| Marine Habitat | Chitin Source | DES Composition [Molar Ratio] | Shell: Solvent Ratio | Temp °C | Time (Hours) | CaCO3 (%) | Protein (%) | Other (%) | Yield (%) | Purity (%) | MW (kDA) | DA (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coastal mud shrimp | Shrimp shells (Solenocera crassicornis) | Choline chloride: Malonic acid [1:40] | 1:20 | 150 | 3 | 0.3–0.4 | 0.5–0.6 | - | 4.9 ± 1 | 99.1 ± 0.1 | 61 | [3] | |

| Coastal mud shrimp | Shrimp shells (Solenocera crassicornis) | Choline chloride: Malonic acid [1:2] | 1:20 | 150 | 3 | 0.6–0.7 | 0.7–0.8 | - | 13.2 ± 1.1 | 98.6 ± 0.2 | 312 | 46 | [3] |

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Malonic acid [1:40] | 1:40 | 80 | 2 | 0.74 | 0.74 ± 0.02 | 1.53 ± 0.02 | 3.72 ± 0.05 | 23.86 ± 0.07 | [2] | ||

| North Atlantic Ocean | Shrimp shells (Pandalus borealis) | Choline chloride: Malonic acid [1:1] | 1:20 | 70 | 3 | 0.56 | 0.98 | 0.46 | 19–20 | 98 ± 1 | [4] | ||

| All seas except polar | Lobster shells (Nephropidae) | Choline chloride: Malonic acid [1:2] | 1:10 | 50 | 2 | 0.21 ± 0.31 | 1.81 ± 0.14 | 4.12 ± 0.21 | 22.21 ± 0.27 | 93 | 312 | 94.33 | [22] |

| All seas except polar | Lobster shells (Nephropidae) | Choline chloride: Malonic acid [1:2] | 1:10 | 70 | 2 | 0.34 ± 0.22 | 1.77 ± 0.22 | 3.88 ± 0.11 | 21.01 ± 0.23 | 93 | 278 | 94.21 | [22] |

| All seas except polar | Lobster shells (Nephropidae) | Choline chloride: Malonic acid [1:2] | 1:10 | 100 | 2 | 0.24 ± 0.16 | 1.75 ± 0.17 | 4.11 ± 0.23 | 19.01 ± 0.24 | 93 | 199 | 95.05 | [22] |

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Malic acid [1:2] | 1:40 | 80 | 2 | 1.44 ± 0.01 | 3.59 ± 0.02 | 1.92 ± 0.01 | 25.00 ± 0.60 | 93 | [2] | ||

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Citric acid [1:2] | 1:40 | 80 | 2 | 1.18 ± 0.01 | 8.37 ± 0.05 | 2.32 ± 0.06 | 25.18 ± 0.38 | 88 | [2] | ||

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Malonic acid [1:2] | 1:40 | 80 | 2 | 3.60 ± 0.14 | 13.05 ± 0.20 | 1.25 ± 0.04 | 25.22 ± 0.90 | 82 | [2] | ||

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Urea [1:2] | 1:40 | 80 | 2 | 41.01 ± 1.80 | 15.34 ± 0.18 | 4.56 ± 0.02 | 50.54 ± 1.07 | 39 | [2] | ||

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: Ethylene glycol [1:2] | 1:40 | 80 | 2 | 44.34 ± 3.40 | 13.50 ± 0.12 | 4.42 ± 0.04 | 52.45 ± 2.01 | 38 | [2] | ||

| Indian and North Pacific Oceans | Japanese tiger prawn (Marsupenaeus japonicus) | Choline chloride: 1,6-Hexanediol [1:2] | 1:40 | 80 | 2 | 46.19 ± 1.90 | 16.14 ± 0.10 | 6.42 ± 0.09 | 52.55 ± 0.70 | 31 | [2] |

3.4. Chitin Purity

4. The Conditions of the Extraction Process

4.1. Duration, Temperature, and Solvent Concentration

4.2. The Importance of Crustacean Shell Type

5. Further Considerations

5.1. Yield

5.1.1. Losses Purity Is Not the Only Considerationuring Extraction

5.1.2. Differences in Chitin Content in Shells

5.1.3. Purity Is Not the Only Consideration

5.2. Advantages and Disadvantages of the Chemical and DES-Mediated Processes

5.3. Economic Potential of Chitin

5.4. Application of Chitin and Chitin Derivatives Such as Chitosan

6. Conclusions and Recommendations

7. Future Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, P.; Gu, Z.; Hong, S.; Lian, H. One-pot production of chitin with high purity from lobster shells using choline chloride-malonic acid deep eutectic solvent. Carbohydr. Polym. 2017, 177, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Saravana, P.S.; Ho, T.C.; Chae, S.J.; Cho, Y.J.; Park, J.S.; Lee, H.J.; Chun, B.S. Deep eutectic solvent-based extraction and fabrication of chitin films from crustacean waste. Carbohydr. Polym. 2018, 195, 622–630. [Google Scholar] [CrossRef] [PubMed]

- Feng, M.; Lu, X.; Zhang, J.; Li, Y.; Shi, C.; Lu, L.; Zhang, S. Direct conversion of shrimp shells to O-acylated chitin with antibacterial and anti-tumor effects by natural deep eutectic solvents. Green Chem. 2019, 21, 87–98. [Google Scholar] [CrossRef]

- Bradić, B.; Novak, U.; Likozar, B. Crustacean shell bio-refining to chitin by natural deep eutectic solvents. Green Process. Synth. 2020, 9, 13–25. [Google Scholar] [CrossRef]

- Hülsey, M.J. Shell biorefinery: A comprehensive introduction. Green Energy Environ. 2018, 3, 318–327. [Google Scholar] [CrossRef]

- Abbott, A.P.; Capper, G.; Davies, D.L.; Munro, H.L.; Rasheed, R.K.; Tambyrajah, V. Preparation of novel, moisture-stable, Lewis-acidic ionic liquids containing quaternary ammonium salts with functional side chains. Chem. Commun. 2001, 2010–2011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, P.; Zheng, G.-W.; Zong, M.-H.; Li, N.; Lou, W.-Y. Recent progress on deep eutectic solvents in biocatalysis. Bioresour. Bioprocess. 2017, 4, 34. [Google Scholar] [CrossRef] [PubMed]

- Torregrosa-Crespo, J.; Marset, X.; Guillena, G.; Ramón, D.J.; María Martínez-Espinosa, R. New guidelines for testing “Deep eutectic solvents” toxicity and their effects on the environment and living beings. Sci. Total Environ. 2020, 704, 135382. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Huang, W.-C.; Guo, N.; Zhang, S.; Xue, C.; Mao, X. Two-Step Separation of Chitin from Shrimp Shells Using Citric Acid and Deep Eutectic Solvents with the Assistance of Microwave. Polymers 2019, 11, 409. [Google Scholar] [CrossRef] [Green Version]

- Clarke, C.J.; Tu, W.-C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800. [Google Scholar] [CrossRef] [PubMed]

- Feng, M.; Lu, X.; Hou, D.; Zhang, S. Chapter 4-Solubility, chain characterization, and derivatives of chitin. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 101–129. [Google Scholar]

- Dutta, P.K.; Dutta, J.; Tripathi, V.S. Chitin and chitosan: Chemistry, properties and applications. J. Sci. Ind. Res. 2004, 63, 20–31. [Google Scholar]

- Rudall, K.M. Chitin and its association with other molecules. J. Polym. Sci. Part C Polym. Symp. 1969, 28, 83–102. [Google Scholar] [CrossRef]

- El Knidri, H.; Laajeb, A.; Lahsini, A. Chapter 2-Chitin and chitosan: Chemistry, solubility, fiber formation, and their potential applications. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 35–57. [Google Scholar]

- Kalhor, P.; Ghandi, K. Deep Eutectic Solvents for Pretreatment, Extraction, and Catalysis of Biomass and Food Waste. Molecules 2019, 24, 4012. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Edelson, P.J.; Duncan, R.A. Lowry And Bradford Assays for Protein. In Methods for Studying Mononuclear Phagocytes; Adams, D.O., Edelson, P.J., Koren, H.S., Eds.; Academic Press: New York, NY, USA, 1981; pp. 337–343. [Google Scholar]

- GBIF The Global Biodiversity Information Facility. Available online: https://www.gbif.org/ (accessed on 24 November 2021).

- Food and Agriculture Organisation of the United Nations Parapenaeus Longirostris. Available online: https://www.fao.org/fishery/species/2598/en (accessed on 24 November 2021).

- Food and Agriculture Organisation of the United Nations Penaeus Duorarum. Available online: https://www.fao.org/fishery/species/3402/en (accessed on 24 November 2021).

- Food and Agriculture Organisation of the United Nations Chionoecetes Opilio. Available online: https://www.fao.org/fishery/species/2644/en (accessed on 24 November 2021).

- The Marine Life Information Network Norway Lobster (Nephrops Norvegicus). Available online: https://www.marlin.ac.uk/ (accessed on 24 November 2021).

- Hong, S.; Yuan, Y.; Yang, Q.; Zhu, P.; Lian, H. Versatile acid base sustainable solvent for fast extraction of various molecular weight chitin from lobster shell. Carbohydr. Polym. 2018, 201, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Trung, T.S.; Tram, L.H.; Van Tan, N.; Van Hoa, N.; Minh, N.C.; Loc, P.T.; Stevens, W.F. Improved method for production of chitin and chitosan from shrimp shells. Carbohydr. Res. 2020, 489, 107913. [Google Scholar] [CrossRef] [PubMed]

- Abdou, E.S.; Nagy, K.S.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from local sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, S.; Anand, S.C.; Rigby, A.J. 5-Textiles for healthcare and medical applications. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 135–168. [Google Scholar]

- El Knidri, H.; Belaabed, R.; Addaou, A.; Laajeb, A.; Lahsini, A. Extraction, chemical modification and characterization of chitin and chitosan. Int. J. Biol. Macromol. 2018, 120, 1181–1189. [Google Scholar] [CrossRef] [PubMed]

- Hamed, I.; Özogul, F.; Regenstein, J.M. Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): A review. Trends Food Sci. Technol. 2016, 48, 40–50. [Google Scholar] [CrossRef]

- Yan, N.; Chen, X. Sustainability: Don’t waste seafood waste. Nature 2015, 524, 155–157. [Google Scholar] [CrossRef]

- Younes, I.; Rinaudo, M. Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oyatogun, G.M.; Esan, T.A.; Akpan, E.I.; Adeosun, S.O.; Popoola, A.P.I.; Imasogie, B.I.; Soboyejo, W.O.; Afonja, A.A.; Ibitoye, S.A.; Abere, V.D.; et al. Chapter 11-Chitin, chitosan, marine to market. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 341–381. [Google Scholar]

- Thomas, S.; Pius, A.; Gopi, S. Handbook of Chitin and Chitosan: Volume 3: Chitin- and Chitosan-Based Polymer Materials for Various Applications; Elsevier Science: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Mutreja, R.; Thakur, A.; Goyal, A. Chapter 13-Chitin and chitosan: Current status and future opportunities. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 401–417. [Google Scholar]

- Zubair, M.; Arshad, M.; Ullah, A. Chapter 25-Chitosan-based materials for water and wastewater treatment. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 773–809. [Google Scholar]

- Panonnummal, R.; Antony, N.; Sabitha, M. Chapter 17-Drug delivery and tissue engineering applications of chitosan-based biomaterial systems. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 555–588. [Google Scholar]

- Zubair, M.; Arshad, M.; Pradhan, R.A.; Ullah, A. Chapter 20-Chitosan/chitin-based composites for food packaging applications. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 641–670. [Google Scholar]

- Sahraee, S.; Milani, J.M. Chapter 8-Chitin and chitosan-based blends, composites, and nanocomposites for packaging applications. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 247–271. [Google Scholar]

- Bosquez-Molina, E.; Zavaleta-Avejar, L. Chapter 2-New Bioactive Biomaterials Based on Chitosan. In Chitosan in the Preservation of Agricultural Commodities; Bautista-Baños, S., Romanazzi, G., Jiménez-Aparicio, A., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 33–64. [Google Scholar]

- Kamilya, D.; Khan, M.I.R. Chapter 24-Chitin and chitosan as promising immunostimulant for aquaculture. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 761–771. [Google Scholar]

- Islam, M.S.; Rahman, M.S.; Ahmed, T.; Biswas, S.; Haque, P.; Rahman, M.M. Chapter 23-Chitosan and chitosan-based biomaterials for wound management. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 721–759. [Google Scholar]

- Lopes, P.P.; Tanabe, E.H.; Bertuol, D.A. Chapter 13-Chitosan as biomaterial in drug delivery and tissue engineering. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 407–431. [Google Scholar]

- Anraku, M.; Ifuku, S.; Iohara, D.; Hirayama, F.; Otagiri, M.; Gebicki, J.M. Chapter 18-Future aspects of biomedical applications of chitin and chitosan in diseases associated with oxidative stress. In Handbook of Chitin and Chitosan; Gopi, S., Thomas, S., Pius, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 589–608. [Google Scholar]

- ClinicalTrials.gov Repository Search on “Chitosan”. Available online: https://clinicaltrials.gov/ct2/results?cond=&term=chitosan&cntry=&state=&city=&dist= (accessed on 24 November 2021).

| DES Extraction | Chemical Extraction | Reference |

|---|---|---|

| Single step for simultaneous removal of protein and minerals | Two or three steps required to remove protein and minerals | [2] |

| Solvent recycling possible | Large quantities of waste generated, high cost of treatment | [4] |

| Calcium carbonate recoverable | Calcium carbonate lost to waste stream | [28] |

| Proteins and amino acids recoverable | Protein lost to waste stream | [27] |

| Molecular weight of chitin conserved | Molecular weight reduced during processing | [29] |

| No deacetylation | Some deacetylation unavoidable | [29] |

| High solvent viscosity causes difficulty at large scale | Low viscosity suited to large scale applications | [15] |

| Industry | Favourable Properties | Use | Reference |

|---|---|---|---|

| Cosmetics | Biocompatibility, non-toxic, high thermostability, good solubility in acidic media and cosmetic bases, stability in pH range, neutral or pleasant odour with low volatility. | Component of the following products: Shampoos, rinses, colourants, hair lotions, spray, and tonics. Sunscreens, moisturiser foundation, eyeshadow, lipstick, cleansing materials, and bath agent, toothpaste, mouthwashes, and chewing gum as a dental filler. | [32] |

| Water | Flocculating, and negative charge (chelating agent). | Wastewater treatment for removing heavy metal ions and decontamination. | [32,33] |

| Paper industry | Structural integrity. | Production of recycled paper and packaging material. | [32] |

| Textile industry | Structural integrity. | Dye removal. | [32] |

| Food industry | Adsorbent and antioxidant. | Nonabsorbable carrier, thickener, and gelling agent, emulsifying agent, antioxidant agent. | [32,34] |

| Food industry | Ability to form films, antimicrobial activity. | Semipermeable, tough, long-lasting, flexible films, used as food wrapping. | [34,35,36] |

| Agriculture | Antifungal | Antifungal treatment for plant pests. Fruit preservative. Controlled delivery of fertilisers, pesticides, and insecticides. | [37] |

| Aquaculture | Immunostimulant | Aquaculture feed. | [38] |

| Photography | Fixing agent. | [32] | |

| Medicine: Tissue engineering | Nontoxicity, biocompatibility, biodegradability, structural integrity, mechanical properties. | Repair, replacement, maintenance, or enhancement of the function of a particular tissue or organ. Bone repair. | [39,40] |

| Medicine: Wound healing/wound dressing | Nontoxicity, biocompatibility, biodegradability, structural integrity, film formation. | Semipermeable to oxygen, tough, wound dressings for burns etc. | [39,40] |

| Medicine: Drug delivery | Adsorbable and nontoxicity. | Slow release of drugs, for more efficient drug delivery. | [39,40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morgan, K.; Conway, C.; Faherty, S.; Quigley, C. A Comparative Analysis of Conventional and Deep Eutectic Solvent (DES)-Mediated Strategies for the Extraction of Chitin from Marine Crustacean Shells. Molecules 2021, 26, 7603. https://doi.org/10.3390/molecules26247603

Morgan K, Conway C, Faherty S, Quigley C. A Comparative Analysis of Conventional and Deep Eutectic Solvent (DES)-Mediated Strategies for the Extraction of Chitin from Marine Crustacean Shells. Molecules. 2021; 26(24):7603. https://doi.org/10.3390/molecules26247603

Chicago/Turabian StyleMorgan, Kellie, Colin Conway, Sheila Faherty, and Cormac Quigley. 2021. "A Comparative Analysis of Conventional and Deep Eutectic Solvent (DES)-Mediated Strategies for the Extraction of Chitin from Marine Crustacean Shells" Molecules 26, no. 24: 7603. https://doi.org/10.3390/molecules26247603