Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review

Abstract

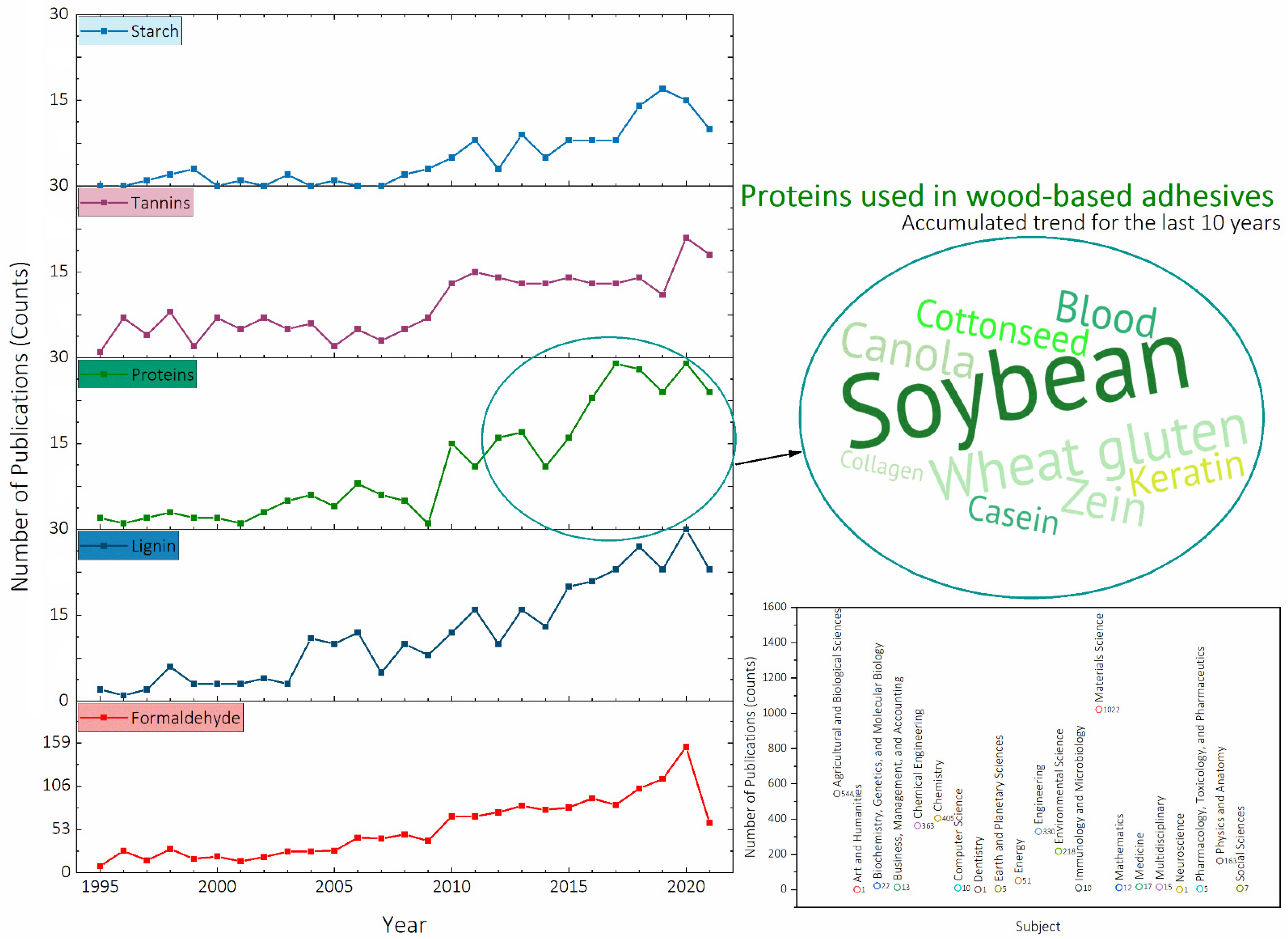

:1. Introduction

2. History of Wood Adhesives

2.1. Evolution of Adhesives: From Natural to Synthetic

2.2. Formaldehyde Legislation

2.3. Current Biobased Wood Adhesives

3. Mechanics behind Bioadhesive Development

3.1. Mechanism of Adhesion

3.2. Wood Bonding and Adhesion Theories

3.3. Wood Adhesion Considerations

4. Protein-Based Adhesives for Wood-Based Composites

4.1. The Shape and Structure of Proteins

4.2. Protein-Based Adhesives: General Approach

4.3. Adhesives from Plant Proteins

4.3.1. Wheat Gluten

4.3.2. Soy Protein

4.3.3. Cotton Protein

4.3.4. Rapeseed Protein

4.3.5. Zein Protein

4.4. Adhesives from Animal Proteins

4.4.1. Casein Protein

4.4.2. Blood Protein

4.4.3. Keratin Protein

4.4.4. Collagen Protein

5. Future Opportunities for Protein-Based Adhesives

5.1. Modification of Protein Adhesion

5.2. Reduced Human and Environmental Toxicity

5.3. Lower Quantities of Adhesive and Avoidance of Organic Solvents

5.4. Commercially Relevant Advantages

6. Perspectives

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Starch-Based Adhesives for Wood/Wood Composite Bonding: Review. Open J. Polym. Chem. 2017, 7, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Hüttermann, A.; Mai, C.; Kharazipour, A. Modification of lignin for the production of new compounded materials. Appl. Microbiol. Biotechnol. 2001, 55, 387–394. [Google Scholar] [CrossRef]

- Zhao, L.F.; Liu, Y.; Xu, Z.D.; Zhang, Y.Z.; Zhao, F.; Zhang, S.B. State of research and trends in development of wood adhesives. For. Stud. China 2011, 13, 321–326. [Google Scholar] [CrossRef]

- Youngquist, J.A. Wood-based composites and panel products. In Wood Handbook: Wood as an Engineering Material; General Technical Report FPL; GTR-113; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; pp. 10.1–10.31. [Google Scholar]

- Rowell, R.; Pettersen, R.; Tshabalala, M. Cell Wall Chemistry, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781439853818. [Google Scholar]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-Based Adhesives and Evaluation for Wood Composites Application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef] [Green Version]

- Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material; General Technical Report (GTR); U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1987; Volume XI.

- Wibowo, E.S.; Lubis, M.A.R.; Park, B.D.; Kim, J.S.; Causin, V. Converting crystalline thermosetting urea.formaldehyde resins to amorphous polymer using modified nanoclay. J. Ind. Eng. Chem. 2020, 87, 78–89. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Athanassiadou, E.T.; Barbu, M.C.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries. Wood Mater. Sci. Eng. 2018, 13, 104–116. [Google Scholar] [CrossRef]

- Kumar, R.N.; Pizzi, A. Environmental Aspects of Adhesives—Emission of Formaldehyde. Adhes. Wood Lignocellul. Mater. 2019, 1, 293–315. [Google Scholar] [CrossRef]

- Guntekin, E.; Karakus, B. Feasibility of using eggplant (Solanum melongena) stalks in the production of experimental particleboard. Ind. Crop. Prod. 2008, 27, 354–358. [Google Scholar] [CrossRef]

- Whitfield, R.M.; Brown, F.C.; Low, R. Socio-Economic Benefits of Formaldehyde to the European Union (EU 25) and Norway; Global Insight: Lexington, MA, USA, 2007. [Google Scholar]

- Zeppenfeld, G.; Dirk, G. Klebstoffe in der Holz-und Möbelindustrie [Glues in the Wooden Industry and Furniture Industry]; DRW-Verlag Weinbrenner GmbH & Co: Leinfelden-Echterdingen, Germany, 2005. [Google Scholar]

- Salthammer, T.; Mentese, S.; Marutzky, R. Formaldehyde in the Indoor Environment. Chem. Rev. 2010, 110, 2536–2572. [Google Scholar] [CrossRef]

- Golden, R. Identifying an indoor air exposure limit for formaldehyde considering both irritation and cancer hazards. Crit. Rev. Toxicol. 2011, 41, 672–721. [Google Scholar] [CrossRef] [Green Version]

- Freeman, L.E.B.; Blair, Ã.A.; Lubin, J.H.; Stewart, P.A.; Hayes, R.B.; Hoover, R.N.; Hauptmann, M. Mortality From Solid Tumors Among Workers in Formaldehyde Industries: An Update of the NCI Cohort. Am. J. Ind. Med. 2013, 56, 1015–1026. [Google Scholar] [CrossRef]

- Cogliano, V.J.; Grosse, Y.; Baan, R.A.; Straif, K.; Secretan, M.B.; El Ghissassi, F.; The Working Group for Volume 88. Meeting Report_ Summary of IARC Monographs on Formaldehyde, 2-Butoxyethanol, and 1-tert-Butoxy-2-Propanol. Environ. Health Perspect. 2005, 113, 1205–1208. [Google Scholar] [CrossRef] [Green Version]

- Technavio Research Technavio Announces Top Three Emerging Trends Impacting the Global Formaldehyde Market through 2020. Available online: https://www.businesswire.com/news/home/20160802005152/en/ (accessed on 29 November 2021).

- Dunky, M. Adhesives based on formaldehyde condensation resins. Macromol. Symp. 2004, 217, 417–430. [Google Scholar] [CrossRef]

- Frihart, C.R. Wood adhesion and adhesives. In Handbook of Wood Chemistry and Wood Composites; USDA, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2012; pp. 216–273. ISBN 9781439853818. [Google Scholar]

- Kües, U. (Ed.) Wood Production, Wood Technology, and Biotechnological Impacts; Universitätsverlag Göttingen: Göttingen, Germany, 2007; ISBN 9783940344113. [Google Scholar]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Navarrete, P.; Kebbi, Z.; Michenot, F.; Lemonon, J.; Rogaume, C.; Masson, E.; Rogaume, Y.; Pizzi, A. Formaldehyde and VOCs emissions from bio-particleboards. J. Adhes. Sci. Technol. 2013, 27, 748–762. [Google Scholar] [CrossRef]

- Valyova, M.; Ivanova, Y.; Koynov, D. Investigation of Free Formaldehyde Quantity in Production of Plywood With Modified Urea-Formaldehyde Resin. Int. J. Wood Des. Technol. 2018, 6, 72–76. [Google Scholar]

- He, Z. Bio-Based Wood Adhesives, 1st ed.; He, Z., Ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9780367782283. [Google Scholar]

- Boran, S.; Usta, M.; Ondaral, S.; Gümüs, E. Composites: Part B The efficiency of tannin as a formaldehyde scavenger chemical in medium density fiberboard. Compos. Part B Eng. 2012, 43, 2487–2491. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Siuda, J.; Dziurka, D. Hemp Flour as a Formaldehyde Scavenger for Melamine-Urea-Formaldehyde Adhesive in Plywood. BioResources 2020, 15, 4052–4064. [Google Scholar] [CrossRef]

- Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar]

- Broeren, M.L.M.; Energy, G. Environmental assessment of bio-based chemicals in early-stage development: A review of methods. Biofuels Bioprod. Biorefin. 2017, 11, 701–718. [Google Scholar] [CrossRef] [Green Version]

- Dunky, M. Wood Adhesives Based on Natural Resources: A Critical Review Part IV. Special Topics. Rev. Adhes. Adhes. 2021, 9, 189–268. [Google Scholar] [CrossRef]

- Cozzone, A.J. Proteins: Fundamental Chemical Properties. In Encyclopedia of Life Sciences; John Wiley & Sons Ltd.: New York, NY, USA, 2002; pp. 1–10. [Google Scholar] [CrossRef]

- Frihart, C.R.; Birkeland, M.J. Soy properties and soy wood adhesives. ACS Symp. Ser. 2014, 1178, 167–192. [Google Scholar] [CrossRef]

- Wadley, L. Putting ochre to the test: Replication studies of adhesives that may have been used for hafting tools in the Middle Stone Age. J. Hum. Evol. 2005, 49, 587–601. [Google Scholar] [CrossRef]

- Lutz, J.F. Wood Veneer: Log Selection, Cutting, and Drying; United States Department of Agriculture, Forest Service: Washington, DC, USA, 1978.

- Frihart, C.R. Wood adhesives: Past, present, and future. For. Prod. J. 2015, 65, 4–8. [Google Scholar] [CrossRef]

- Office of the Federal Register, National Archives and Records Administration. Title 40—Protection of Environment. [Government]. 2003. Available online: https://www.govinfo.gov/app/details/CFR-2003-title40-vol1 (accessed on 29 November 2021).

- APAwood-Europe List of Individual Standards. Available online: https://apawood-europe.org/official-guidelines/european-standards/individual-standards/en-717-2/ (accessed on 29 November 2021).

- Hunt, A.; Dale, N. Economic Valuation in Formaldehyde Regulation; OECD Environment Working Papers 134; OECD Publishing: Paris, France, 2018. [Google Scholar] [CrossRef]

- Pfleiderer ddsONLINE. Available online: https://www.dds-online.de/branche/ein-beherztes-ja-zu-e05/ (accessed on 29 November 2021).

- Ruffing, T.C.; Shi, W.; Brown, N.R.; Smith, P.M. Review of united states and international formaldehyde emission regulations for interior wood composite panels. Wood Fiber Sci. 2011, 43, 21–31. [Google Scholar]

- Tissari, J. Monitoring the Technical and Environmental Standards of Tropical Timber Products in International Markets; Food Agriculture Organization of the United Nations: Rome, Italy, 2010; Available online: https://www.fao.org/forestry/23525-0a5fbd590fc0988ce61f01bffe1b2f019.pdf (accessed on 29 November 2021).

- Koç, K. Formaldehyde emissions and effects on health during arrival of furniture to ultimate consumer. Wood Ind. Eng. 2019, 1, 14–19. [Google Scholar]

- The American Conference of Governmental Industrial Hygienists (ACGIH). ACGIH Decision to Lower Formaldehyde TLVs Lacks Transparency and Scientific Basis; The American Conference of Governmental Industrial Hygienists (ACGIH): Washington, DC, USA, 2017. [Google Scholar]

- World Health Organization, Regional Office for Europe. Risk of Bias Assessment Instrument for Systematic Reviews Informing WHO Global Air Quality Guidelines; World Health Organization, Regional Office for Europe: Copenhagen, Denmark, 2020; Available online: https://apps.who.int/iris/handle/10665/341717 (accessed on 29 November 2021).

- Assembly, F.G. Voluntary Agreement on Workers Exposure to Formaldehyde. Available online: https://www.formacare.eu/voluntary-agreement-and-workplace-safety/ (accessed on 27 July 2021).

- Bolt, H.M.; Morfeld, P. New results on formaldehyde: The 2nd International Formaldehyde Science Conference (Madrid, 19–20 April 2012). Arch. Toxicol. 2013, 87, 217–222. [Google Scholar] [CrossRef] [Green Version]

- Klein, C.L.; Nielsen, G.D.; Johanson, G.; Bolt, H.M.; Papameletiou, D.; Directorate-General for Employment, Social Affairs and Inclusion (European Commission). SCOEL/REC/125 Formaldehyde Recommendation from the Scientific Committee on Occupational Exposure Limits; Publications Office of the European Union: Luxembourg, 2017; ISBN 9789279641510. [Google Scholar]

- GESTIS Database, Formaldehyde. Available online: https://limitvalue.ifa.dguv.de/ (accessed on 20 July 2021).

- Pizzi, A. Natural Adhesives, Binders, and Matrices for Wood and Fiber Composites: Chemistry and Technology. In Research Developments in Wood Engineering and Technology; Aguilera, A., Davim, J., Eds.; IGI Global: Hershey, PA, USA, 2014. [Google Scholar]

- Packham, D.E. Adhesive technology and sustainability. Int. J. Adhes. Adhes. 2009, 29, 248–252. [Google Scholar] [CrossRef]

- Kunaver, M.; Medved, S.; Čuk, N.; Jasiukaityte, E.; Poljanšek, I.; Strnad, T. Application of liquefied wood as a new particle board adhesive system. Bioresour. Technol. 2010, 101, 1361–1368. [Google Scholar] [CrossRef]

- Klašnja, B.; Kopitović, S. Lignin-Phenol-Formaldehyde resins as adhesives in the production of plywood. Holz Als Roh-Und Werkst. 1992, 50, 282–285. [Google Scholar] [CrossRef]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H. Lignin and Lignin-Derived Compounds for Wood Applications—A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef]

- Hazwan Hussin, M.; Aziz, A.A.; Iqbal, A.; Ibrahim, M.N.M.; Latif, N.H.A. Development and characterization novel bio-adhesive for wood using kenaf core (Hibiscus cannabinus) lignin and glyoxal. Int. J. Biol. Macromol. 2019, 122, 713–722. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Cheng, L.; Gu, Z.; Hong, Y.; Li, Z.; Li, C. Preparation, characterization and properties of starch-based adhesive for wood-based panels. Int. J. Biol. Macromol. 2019, 134, 247–254. [Google Scholar] [CrossRef]

- Trosa, A.; Pizzi, A. A no-aldehyde emission hardener for tannin-based wood adhesives for exterior panels. Holz Als Roh -Und Werkst. 2001, 59, 266–271. [Google Scholar] [CrossRef]

- Santos, J.; Antorrena, G.; Freire, M.S.; Pizzi, A.; González-Álvarez, J. Environmentally friendly wood adhesives based on chestnut (Castanea sativa) shell tannins. Eur. J. Wood Wood Prod. 2017, 75, 89–100. [Google Scholar] [CrossRef]

- Ndiwe, B.; Pizzi, A.; Tibi, B.; Danwe, R.; Konai, N.; Amirou, S. African tree bark exudate extracts as biohardeners of fully biosourced thermoset tannin adhesives for wood panels. Ind. Crop. Prod. 2019, 132, 253–268. [Google Scholar] [CrossRef]

- Nath, S.K.; Islam, M.N.; Rahman, K.S.; Rana, M.N. Tannin-based adhesive from Ceriops decandra (Griff.) bark for the production of particleboard. J. Indian Acad. Wood Sci. 2018, 15, 21–27. [Google Scholar] [CrossRef]

- Kong, X.; Liu, G.; Curtis, J.M. Characterization of canola oil based polyurethane wood adhesives. Int. J. Adhes. Adhes. 2011, 31, 559–564. [Google Scholar] [CrossRef]

- Santoni, I.; Pizzo, B. Evaluation of alternative vegetable proteins as wood adhesives. Ind. Crop. Prod. 2013, 45, 148–154. [Google Scholar] [CrossRef]

- Schwarzenbrunner, R.; Barbu, M.C.; Petutschnigg, A.; Tudor, E.M. Water-resistant casein-based adhesives for veneer bonding in biodegradable ski cores. Polymers 2020, 12, 1745. [Google Scholar] [CrossRef]

- Guo, M.; Wang, G. Milk protein polymer and its application in environmentally safe adhesives. Polymers 2016, 8, 324. [Google Scholar] [CrossRef] [Green Version]

- Jancar, J.; Fekete, E.; Hornsby, P.R.; Jancar, J.; Pukánszky, B.; Rothon, R.N. Mineral Fillers in Thermoplastics I; Springer: Berlin/Heidelberg, Germany; GmbH & Co. KG: Berlin, Germany, 1999; ISBN 3540646213. [Google Scholar]

- Qin, R.Y.; Schreiber, H.P. Adhesion at partially restructured polymer surfaces. Colloids Surf. A Physicochem. Eng. Asp. 1999, 156, 85–93. [Google Scholar] [CrossRef]

- Kinloch, A.J. The science of adhesion. J. Mater. Sci. 1980, 15, 2141–2166. [Google Scholar] [CrossRef]

- Hewison, D.; Kuras, M. Book reviews: Book reviews. J. Anal. Psychol. 2005, 50, 395–403. [Google Scholar] [CrossRef]

- Beholz, L.G.; Aronson, C.L.; Zand, A. Adhesion modification of polyolefin surfaces with sodium hypochlorite in acidic media. Polymer 2005, 46, 4604–4613. [Google Scholar] [CrossRef]

- Brown, H.R. The adhesion between polymers. Annu. Rev. Mater. Sci. 1991, 21, 463–489. [Google Scholar] [CrossRef]

- Lippert, T.; Dickinson, J.T. Chemical and spectroscopic aspects of polymer ablation: Special features and novel directions. Chem. Rev. 2003, 103, 453–485. [Google Scholar] [CrossRef] [PubMed]

- Sathyanarayana, M.N.; Yaseen, M. Role of promoters in improving adhesions of organic coatings to a substrate. Prog. Org. Coat. 1995, 26, 275–313. [Google Scholar] [CrossRef]

- Kinloch, A.J. Adhesion and Adhesives, 1st ed.; Chapman & Hall: London, UK, 1987; ISBN 9789048140039. [Google Scholar]

- Charles, R. Frihart Wood Structure and Adhesive Bond Strength. In Characterization of the Cellulosic Cell Wall; Douglas, D., Stokke, L.H.G., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2008; p. 288. ISBN 0470999705/9780470999707. [Google Scholar]

- Gardner, D.J.; Tajvidi, M. Hydrogen bonding in wood-based materials: An update. Wood Fiber Sci. 2016, 48, 234–244. [Google Scholar]

- Pizzi, A. Guest editorial. J. Adhes. Sci. Technol. 2010, 24, 1353–1355. [Google Scholar] [CrossRef]

- Gardner, D.J.; Blumentritt, M.; Wang, L.; Yildirim, N. Adhesion Theories in Wood Adhesive Bonding. Rev. Adhes. Adhes. 2004, 2, 127–172. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Adams, R.D.; Öchsner, A. Handbook of Adhesion Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 9783642011689. [Google Scholar]

- Vick, C.B. Adhesive Bonding of Wood Materials. In Wood Handbook: Wood as an Engineering Material; General technICAL REPOrt FPL; GTR-113; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; pp. 9.1–9.24. [Google Scholar]

- Baldan, A. Adhesion phenomena in bonded joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Ebnesajjad, S. 1 Introduction and Adhesion Theories; Elsevier Inc.: Amsterdam, The Netherlands, 2011; ISBN 9781437744613. [Google Scholar]

- SpecialChem Adhesion Promoters: Adhesion Basics & Material Selection Tips for Adhesives. Available online: https://adhesives.specialchem.com/selection-guide/adhesion-promoters-adhesives-sealants (accessed on 29 November 2021).

- Frihart, C.R.; Hunt, C.G. Adhesives with Wood Materials-Bond Formation and Performance. In Wood Handbook: Wood as an Engineering Material; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 10.1–10.24. [Google Scholar]

- Pizzi, A. Advanced Wood Adhesives Technology; Taylor & Francis, Ed.; CRC Press: Boca Raton, FL, USA, 1994; ISBN 9780824792664. [Google Scholar]

- Mekonnen, T.H.; Mussone, P.G.; Choi, P.; Bressler, D.C. Adhesives from waste protein biomass for oriented strand board composites: Development and performance. Macromol. Mater. Eng. 2014, 299, 1003–1012. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, W.; Zhao, Z.; Guo, M. Novel Whey Protein-Based Aqueous Polymer-Isocyanate Adhesive for Glulam. J. Appl. Polym. Sci. 2011, 120, 220–225. [Google Scholar] [CrossRef]

- Li, K.; Peshkova, S.; Geng, X. Investigation of soy protein-kymene® adhesive systems for wood composites. J. Am. Oil Chem. Soc. 2004, 81, 487–491. [Google Scholar] [CrossRef]

- Cheng, H.N.; Dowd, M.K.; He, Z. Investigation of modified cottonseed protein adhesives for wood composites. Ind. Crop. Prod. 2013, 46, 399–403. [Google Scholar] [CrossRef]

- Lee, L.-H. Fundamentals of Adhesion; Webster: New York, NY, USA, 1991; ISBN 9781489920751. [Google Scholar]

- Harper, C.A. Handbook of Plastics, Elastomers, and Composites; McGraw Hill Professional: New York, NY, USA, 2002; ISBN 9780071384766. [Google Scholar]

- Frihart, C.R. Adhesive penetration of wood and its effect on bond strength. In Proceedings of the 39th Annual Meeting the Adhesion Society, San Antonio, TX, USA, 21–24 February 2016; pp. 1–4. [Google Scholar]

- Helfer, S. Book Review. Int. Diary J. 1997, 11, 487. [Google Scholar] [CrossRef]

- Thomas, E. Creighton Proteins: Structures and Molecular Properties. J. Chem. Technol. Biotechnol. 1985, 68, 88. [Google Scholar] [CrossRef]

- Borasky, R. Introduction: Some Important Aspects of Protein Fiber Research; Academic Press Inc.: Cambridge, MA, USA, 1963. [Google Scholar]

- Chen, N. Folding Proteins with Both Alpha and Beta Structures in a Reduced Model. Ph.D. Thesis, Department of Physics, National Tsing Hua University, Hsinchu, Taiwan, 2006. [Google Scholar]

- Damodaran, S. Food Proteins: An Overview. In Food Proteins and Their Applications; Damodaran, S., Paraf, A., Eds.; Marcel Dekker: New York, NY, USA, 1997; pp. 1–25. ISBN 9788578110796. [Google Scholar]

- Nishinari, K.; Fang, Y.; Guo, S.; Phillips, G.O. Soy proteins: A review on composition, aggregation and emulsification. Food Hydrocoll. 2014, 39, 301–318. [Google Scholar] [CrossRef]

- Arthur, J.C. Evaluation of Peanut Protein for Industrial Utilization. A Review. J. Am. Oil Chem. Soc. 1949, 26, 668–671. [Google Scholar] [CrossRef]

- Wu, Z.; Lei, H.; Du, G. Disruption of soy-based adhesive treated by Ca(OH)2 and NaOH. J. Adhes. Sci. Technol. 2013, 27, 2226–2232. [Google Scholar] [CrossRef]

- Chen, N.; Zheng, P.; Zeng, Q.; Lin, Q.; Rao, J. Characterization and performance of soy-based adhesives cured with epoxy resin. Polymers 2017, 9, 514. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, P.; Chen, N.; Mahfuzul Islam, S.M.; Ju, L.K.; Liu, J.; Zhou, J.; Chen, L.; Zeng, H.; Lin, Q. Development of Self-Cross-Linked Soy Adhesive by Enzyme Complex from Aspergillus Niger for Production of All-Biomass Composite Materials. ACS Sustain. Chem. Eng. 2019, 7, 3909–3916. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhong, Z.; Wang, D.; Ratto, J.A.; Sheng, K.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Khosravi, S.; Khabbaz, F.; Nordqvist, P.; Johansson, M. Protein-based adhesives for particleboards. Ind. Crop. Prod. 2010, 32, 275–283. [Google Scholar] [CrossRef] [Green Version]

- Yue, L.; Meng, Z.; Yi, Z.; Gao, Q.; Mao, A.; Li, J. Effects of different denaturants on properties and performance of soy protein-based adhesive. Polymers 2019, 11, 1262. [Google Scholar] [CrossRef] [Green Version]

- Gennadios, A.E. Protein-Based Films and Coatings, 1st ed.; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9780429135804. [Google Scholar]

- Nordqvist, P.; Thedjil, D.; Khosravi, S.; Lawther, M.; Malmström, E.; Khabbaz, F. Wheat gluten fractions as wood adhesives-glutenins versus gliadins. J. Appl. Polym. Sci. 2012, 123, 1530–1538. [Google Scholar] [CrossRef]

- Lagel, M.C.; Pizzi, A.; Redl, A.; Al-Marzouki, F.M. Phenol-wheat protein-formaldehyde thermoset wood adhesives. Eur. J. Wood Wood Prod. 2015, 73, 439–448. [Google Scholar] [CrossRef]

- D’Amico, S.; Müller, U.; Berghofer, E. Effect of hydrolysis and denaturation of wheat gluten on adhesive bond strength of wood joints. J. Appl. Polym. Sci. 2013, 129, 2429–2434. [Google Scholar] [CrossRef]

- Khosravi, S.; Khabbaz, F.; Nordqvist, P.; Johansson, M. Wheat-gluten-based adhesives for particle boards: Effect of crosslinking agents. Macromol. Mater. Eng. 2014, 299, 116–124. [Google Scholar] [CrossRef]

- Ferreira, A.M.; Pereira, J.; Almeida, M.; Ferra, J.; Paiva, N.; Martins, J.; Magalhães, F.D.; Carvalho, L.H. Biosourced binder for wood particleboards based on spent sulfite liquor and wheat flour. Polymers 2018, 10, 1070. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dunphy, E.J. 5. Planting Decisions. North Carolina Soybean Production Guide; North Carolina State University: Raleigh, NC, USA, 2018; pp. 43–58. [Google Scholar]

- Fukushima, D. Recent progress of soybean protein foods: Chemistry, technology, and nutrition. Food Rev. Int. 1991, 7, 323–351. [Google Scholar] [CrossRef]

- Kalapathy, U.; Hettiarachchy, N.S.; Myers, D.; Hanna, M. Modification of soy proteins and their adhesive properties on woods. J. Am. Oil Chem. Soc. 1995, 72, 507–510. [Google Scholar] [CrossRef]

- Sun, X.; Bian, K. Shear strength and water resistance of modified soy protein adhesives. J. Am. Oil Chem. Soc. 1999, 76, 977–980. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Development and characterization of adhesives from soy protein for bonding wood. Int. J. Adhes. Adhes. 2007, 27, 59–67. [Google Scholar] [CrossRef]

- Chen, N.; Lin, Q.; Rao, J.; Zeng, Q. Water resistances and bonding strengths of soy-based adhesives containing different carbohydrates. Ind. Crop. Prod. 2013, 50, 44–49. [Google Scholar] [CrossRef]

- Huang, W.; Sun, X. Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J. Am. Oil Chem. Soc. 2000, 77, 705–708. [Google Scholar] [CrossRef]

- Zhong, Z.K.; Sun, X.S. Thermal and mechanical properties and water absorption of sodium dodecyl sulfate-modified soy protein (11s). J. Appl. Polym. Sci. 2001, 81, 166–175. [Google Scholar] [CrossRef]

- Xiao, Z.; Li, Y.; Wu, X.; Qi, G.; Li, N.; Zhang, K.; Wang, D.; Sun, X.S. Utilization of sorghum lignin to improve adhesion strength of soy protein adhesives on wood veneer. Ind. Crop. Prod. 2013, 50, 501–509. [Google Scholar] [CrossRef]

- Zakaria, Z.A.; Binod, P.; Aguilar, C.; Kusumaningtyas, R.D. Valorisation of Agro-Industrial Residues—Volume II: Non-Biological Approaches; Springer: Berlin/Heidelberg, Germany, 2020; Volume II, ISBN 9783030392079. [Google Scholar]

- Cheng, H.N.; He, Z.; Ford, C.; Wyckoff, W.; Wu, Q. A Review of Cottonseed Protein Chemistry and Non-Food Applications. Sustain. Chem. 2020, 1, 256–274. [Google Scholar] [CrossRef]

- Hogan, J.T.; Arthur, J.C. Preparation and utilization of cottonseed meal glue for plywood. J. Am. Oil Chem. Soc. 1951, 28, 20–23. [Google Scholar] [CrossRef]

- Hogan, J.T.; Arthur, J.C. Cottonseed and peanut meal glues: Permanence of plywood glue joints as determined by interior and exterior accelerated cyclic service tests. J. Am. Oil Chem. Soc. 1951, 28, 272–274. [Google Scholar] [CrossRef]

- Hogan, J.T.; Arthur, J.C. Cottonseed and peanut meal glues. Resistance of plywood bonds to chemical reagents. J. Am. Oil Chem. Soc. 1952, 29, 16–18. [Google Scholar] [CrossRef]

- Cheng, H.N.; Ford, C.; Dowd, M.K.; He, Z. Use of additives to enhance the properties of cottonseed protein as wood adhesives. Int. J. Adhes. Adhes. 2016, 68, 156–160. [Google Scholar] [CrossRef] [Green Version]

- Frihart, C.R.; Lorenz, L.F. Protein adhesives. In Handbook of Adhesive Technology, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 145–176. [Google Scholar] [CrossRef]

- Tan, S.H.; Mailer, R.J.; Blanchard, C.L.; Agboola, S.O. Canola Proteins for Human Consumption: Extraction, Profile, and Functional Properties. J. Food Sci. 2011, 76, R16–R28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hale, K. The Potential of Canola Protein for Bio-Based Wood Adhesives. Master’s Thesis; Kansas State University: Manhattan, KS, USA, 2013. [Google Scholar]

- Cheng, H.N.; He, Z.H. Canola Protein and Oil-based Wood Adhesives: Preparation, Characterization, and Testing. In Bio-Based Wood Adhesives Preparation, Characterization, and Testing; He, Z., Ed.; CRC Press: Boca Raton, FL, USA, 2017; p. 366. ISBN 9781498740746. [Google Scholar]

- Shukla, R.; Cheryan, M. Zein: The industrial protein from corn. Ind. Crop. Prod. 2001, 13, 171–192. [Google Scholar] [CrossRef]

- Wei, Y.; Yao, J.; Shao, Z.; Chen, X.; Accepted, J. Water-Resistant Zein-based Adhesives. ACS Sustain. Chem. Eng. 2020, 8, 7668–7679. [Google Scholar] [CrossRef]

- Grand View Research. Bioadhesives Market Size Worth $2549.2 Million By 2022; Grand View Research: San Francisco, CA, USA, 2016. [Google Scholar]

- Holt, B.Y.C.; Vies, D.T.D.A.; Law, A.J.R. Effects of colloidal calcium phosphate content and free calcium ion concentration in the milk serum on the dissociation of bovine casein micelles. J. Dairy Res. 1986, 53, 557–572. [Google Scholar] [CrossRef]

- Horne, D.S. Casein micelle structure: Models and muddles. Curr. Opin. Colloid Interface Sci. 2006, 11, 148–153. [Google Scholar] [CrossRef]

- Walstra, P. On the Stability of Casein Micelles 1. J. Dairy Sci. 1990, 73, 1965–1979. [Google Scholar] [CrossRef]

- Panesar, P.S.; Kennedy, J.F.; Gandhi, D.N.; Bunko, K. Bioutilisation of whey for lactic acid production. Food Chem. 2007, 105, 1–14. [Google Scholar] [CrossRef]

- Technology, D. Whey protein polymerisation and its applications in environmentally safe adhesives. Int. J. Dairy Technol. 2011, 69, 481–488. [Google Scholar] [CrossRef]

- Umemura, K.; Mihara, A.; Kawai, S. Development of new natural polymer-based wood adhesives III: Effects of glucose addition on properties of chitosan. J. Wood Sci. 2010, 56, 387–394. [Google Scholar] [CrossRef]

- Gruendler, G.J.; Louis, O.F.S.T. Compositions of Proteins; Compositions of Derivatives Thereof. U.S. Patent US633834A, 26 September 1899. Available online: https://patents.google.com/patent/US633834 (accessed on 29 November 2021).

- Ross, J.E.; Charles, D. Improvement in Processes of Preparing Glue. U.S. Patent US183024A, 10 October 1876. Available online: https://patents.google.com/patent/US183024A/en (accessed on 29 November 2021).

- Shisler, G.M. Adhesive Material Containing Casein. U.S. Patent US1886750A, 8 November 1932. Available online: https://patents.google.com/patent/US1886750A/en (accessed on 29 November 2021).

- Corwin, F.; White, R.C. Bottle Labeling Adhesive. U.S. Patent US2351109A, 13 June 1944. Available online: https://patents.google.com/patent/US2351109A/en (accessed on 29 November 2021).

- Gunasekaran, S.; Lin, H. Glue from Slaughterhouse Animal Blood. U.S. Patent US 8,092,584 B2, 10 January 2012. [Google Scholar]

- Lin, H.; Gunasekaran, S. Cow blood adhesive: Characterization of physicochemical and adhesion properties. Int. J. Adhes. Adhes. 2010, 30, 139–144. [Google Scholar] [CrossRef]

- Detlefsen, W.D. Blood and Casein adhesives for bonding wood. ACS Symp. Ser. 1989, 1900, 445–452. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Luo, J.; Li, K.; Gao, Q.; Li, J. A Novel Eco-friendly Blood Meal-based Bio-adhesive: Preparation and Performance. J. Polym. Environ. 2017, 26, 607–615. [Google Scholar] [CrossRef]

- Brown, C.H. Keratins in invertebrates. Nature 1950, 166, 439. [Google Scholar] [CrossRef]

- Makar, I.A.; Gavrylyak, V.V.; Sedilo, G.M. Genetical and biochemical aspects of keratin synthesis by hair follicles. Cytol. Genet. 2007, 41, 75–79. [Google Scholar] [CrossRef]

- Esparza, Y.; Bandara, N.; Ullah, A.; Wu, J. Hydrogels from feather keratin show higher viscoelastic properties and cell proliferation than those from hair and wool keratins. Mater. Sci. Eng. C 2018, 90, 446–453. [Google Scholar] [CrossRef]

- Zhou, Y.; Zeng, G.; Zhang, F.; Luo, J.; Li, X.; Li, J.; Fang, Z. Toward Utilization of Agricultural Wastes: Development of a Novel Keratin Reinforced Soybean Meal-based Adhesive. ACS Sustain. Chem. Eng. 2021, 9, 22. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Li, J.; Li, K.; Li, J. Perm-Inspired High-Performance Soy Protein Isolate and Chicken Feather Keratin-Based Wood Adhesive without External Crosslinker. Macromol. Mater. Eng. 2021, 1–8. [Google Scholar] [CrossRef]

- Barlak, M.A.; Wilkowski, J.A.; Szkarłat, F.I.; Werner, Z.B.; Zagórski, J.E.; Staszkiewicz, B.O.; Osipiuk, J. The influence of edge defects on the lifetime of wood machining tools. Ann. WULS SGGW For. Wood Technol. 2018, 104, 533–539. [Google Scholar]

- Matyašovský, J.; Sedliačik, J.; Šimon, P.; Novák, I.; Krystofiak, T.; Jurkovič, P.; Duchovič, P.; Sedliačiková, M.; Cibulková, Z.; Mičušík, M.; et al. Antioxidant Activity of Keratin Hydrolysates Studied by DSC. J. Am. Leather Chem. Assoc. 2019, 114, 20–28. [Google Scholar]

- Yamamoto, H.; Takimoto, T. Synthesis and conformational study of cuticle collagen models and application as a bioadhesive. J. Mater. Chem. 1991, 1, 947–954. [Google Scholar] [CrossRef]

- Schellmann, N.C. Animal glues: A review of their key properties relevant to conservation. Stud. Conserv. 2007, 52, 55–66. [Google Scholar] [CrossRef]

- Rivers, S.; Umney, N. Conservation of Furniture, 1st ed.Routledge: London, UK, 2003; ISBN 9780080524641. [Google Scholar]

- Coerdt, A. Zum Leimen zu gebrauchen: Untersuchungen zu kaltflüssigen Glutinleimen, Teil 1. In Restauro: Forum für Restauratoren, Konservatoren und Denkmalpfleger; 2007; Volume 113, pp. 32–38. Available online: https://www.bcin.ca/bcin/detail.app?id=379601&wbdisable=true (accessed on 29 November 2021).

- Przybylo, M. Langzeit-Löslichkeit von Störleim: Tatsache oder Märchen? Beiträge zur Erhalt. von Kunst-und Kult. 2006, 117–123. Available online: https://www.bcin.ca/bcin/detail.app?lang=fr&id=381686&asq=&csq=&csa=&ps=50&pId=1&wbdisable=true (accessed on 29 November 2021).

- Wehlte, K. Werkstoffe und Techniken der Malerei; Verlag, O.M., Ed.; Kremer Pigments Inc.: New York, NY, USA, 2001. [Google Scholar]

- Hedley, G. Relative Humidity and the Stress/Strain Response Of Canvas Paintings: Uniaxial Measurements of Naturally Aged Samples. Stud. Conserv. 1988, 33, 133–148. [Google Scholar]

- Rao, H.; Yang, Y.; Abuduresule, I.; Li, W.; Hu, X. Proteomic identi fi cation of adhesive on a bone sculpture-inlaid wooden artifact from the Xiaohe Cemetery, Xinjiang, China. J. Archaeol. Sci. 2015, 53, 148–155. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, T.; Wang, X.; Liu, C.; Liao, X. A low-cost and water resistant biomass adhesive derived from the hydrolysate of leather waste. RSC Adv. 2017, 7, 4024–4029. [Google Scholar] [CrossRef] [Green Version]

- Nordqvist, P.; Lawther, M.; Malmström, E.; Khabbaz, F. Adhesive properties of wheat gluten after enzymatic hydrolysis or heat treatment—A comparative study. Ind. Crop. Prod. 2012, 38, 139–145. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels-A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Heinrich, L.A. Future Opportunities for Biobased Adhesives. Green Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef] [Green Version]

- Bandara, N.; Akbari, A.; Esparza, Y.; Wu, J. Canola Protein: A Promising Protein Source for Delivery, Adhesive, and Material Applications. JAOCS J. Am. Oil Chem. Soc. 2018, 95, 1075–1090. [Google Scholar] [CrossRef]

- Eckelman, C.A. Brief Survey of Wood Adhesives; Purdue University Cooperative Extension Service: West Lafayette, Indiana, 1999. [Google Scholar]

- Deans, A. A review of adhesives for entomotaxy. PeerJ Prepr. 2018, 15, e27184v1. [Google Scholar] [CrossRef]

- Ostendorf, K.; Reuter, P.; Euring, M. Manufacturing medium-density fiberboards and wood fiber insulation boards using a blood albumin adhesive on a pilot scale. BioResources 2020, 15, 1531–1546. [Google Scholar] [CrossRef]

- Donato, R.K.; Mija, A. Keratin associations with synthetic, biosynthetic and natural polymers: An extensive review. Polymers 2020, 12, 32. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adhikari, B.B.; Chae, M.; Bressler, D.C. utilization of slaughterhouse waste in value-added applications: Recent advances in the development of wood adhesives. Polymers 2018, 10, 176. [Google Scholar] [CrossRef] [Green Version]

- Rathi, S.; Saka, R.; Domb, A.J.; Khan, W. Protein-based bioadhesives and bioglues. Polym. Adv. Technol. 2019, 30, 217–234. [Google Scholar] [CrossRef]

- Nordqvist, P.; Johansson, E.; Khabbaz, F.; Malmström, E. Characterization of hydrolyzed or heat treated wheat gluten by SE-HPLC and 13 C NMR: Correlation with wood bonding performance. Ind. Crop. Prod. 2013, 51, 51–61. [Google Scholar] [CrossRef]

- Park, S.K.; Bae, D.H.; Hettiarachchy, N.S. Protein Concentrate and Adhesives from Meat and Bone Meal. J. Am. Oil Chem. Soc. 2000, 77, 1223–1227. [Google Scholar] [CrossRef]

- Gao, Z.; Yu, G.; Bao, Y.; Guo, M. Whey-protein based environmentally friendly wood adhesives. Pigment. Resin Technol. 2011, 40, 42–48. [Google Scholar] [CrossRef]

- Renkema, J.M.; Gruppen, H.; Van Vliet, T. Influence of pH and Ionic Strength on Heat-Induced Formation and Rheological Properties of Soy Protein Gels in Relation to Denaturation and Their Protein Compositions. J. Agric. Food Chem. 2002, 50, 6064–6071. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Sun, X.S.; Yang, G.; Wang, Y. Improved water resistance of soy protein adhesive at isoelectric point. Trans. ASABE 2009, 52, 173–177. [Google Scholar] [CrossRef]

- Article, O. Development of new natural polymer-based wood adhesives I: Dry bond strength and water resistance of konjac glucomannan, chitosan, and their composites. J. Wood Sci. 2003, 49, 221–226. [Google Scholar]

- Roy, C.; Calve, L.; Lu, X.; Pakdel, H.; Amen-Chen, C. Wood Composite Adhesives from Softwood Bark-Derived Vacuum Pyrolysis Oils. In Biomass, a Growth Opportunity in Green Energy and Value-Added Products, Proceedings of the 4th Biomass Conference of the Americas, Oakland, CA, USA, 29 August–2 September 1999; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

| Countries | TWA (8 h) | ||

|---|---|---|---|

| 2006 | 2015 | 2021 | |

| ppm | ppm | ppm | |

| Austria | 0.3 | 0.5 | 0.3 |

| Belgium | 0.3 | ||

| Denmark | 0.3 | 0.3 | 0.3 |

| Finland | 0.3 | 0.3 | 0.3 |

| France | 0.5 | 0.5 | 0.3 |

| Germany | 0.3 | 0.3 | 0.3 |

| Greece | 2 | ||

| Ireland | 2 | 2 | 0.3 |

| Italy | 0.3 | ||

| Netherlands | 1 | ||

| Theory | Mechanism | Strength of Interaction |

|---|---|---|

| Mechanical interlock | Mechanical forces | Variable |

| Electrostatic | Ion–dipole interactions | Strong |

| Diffusion | Interdiffusion | Variable |

| Adsorption/wettability | Van der Waals, dipole-dipole interactions | Weak, moderate to strong |

| Chemical bonding | Covalent bond | Very strong |

| Weak boundary layer | Defects at interface | Variable |

| Acid-base | H-bonding, dipole–dipole, or ionic interactions | Moderate to strong; very strong |

| Source | Proteins | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Plants | Wheat Gluten | Dispersible in alkali and acid High amount of hydrophobic amino-acids Abundant Cheapest protein source | Water-insoluble Poor shear strength Highly viscous due to swelling of starch by water absorption and release of amylose chains | [25,107,162] |

| Soy meal | Abundant Inexpensive Good strength under drying conditions Cold curing High protein content Good thermal resistance | Limited water resistance Poor wettability High viscosity Long hot-pressing time Sensitive to microbial degradation Not suitable for exterior applications | [6,25,114,163] | |

| Cottonseed | Non-food crop Superior adhesive strength Hot water resistance compared to soy protein | Costly extraction of protein Poor water resistance | [6,120] | |

| Canola | Abundant oilseed crop Non-food crop Chemical resistance to hot water | Needs a lot of chemical modifications | [127,164,165] | |

| Zein | Hydrophobic protein Water-resistant Good adhesive strength Low-cost preparation A lot of chemical modifications is unneeded | Yellow color due to xanthophylls, carotenoids, and other color pigments present in corn Relatively high cost of extraction due to organic solvents needed | [129,165] | |

| Animals | Casein | Strong joints that are largely resistant to water Relatively safe to work with Moderately high dry strength Moderate resistance to water | Take a long time to set Quite susceptible to degradation by fungi and other organisms Relatively expensive due to preservatives Eight gallons of skim milk are required to make one pound of dry casein Short pot life Not suitable for exterior uses | [166,167] |

| Blood | Very rapid setting with heat Moderate to high dry shear strength Moderate to high water resistance Moderate resistance to microorganisms Does not stain wood Can be applied using both hot and cold presses Easy to handle because of its relatively low viscosity | Produce dark glue lines Blood drying is an energy-intensive process Blood meal (BM) is inclined to agglomerate, which is adverse to bonding About half of the amino acid of BM is non-polar, resulting in low bonding capacity The connection of BM protein molecules is mainly hydrogen bond, which leads to bad water resistance of resultant adhesive in the absence of crosslinking agents | [25,145,168] | |

| Keratin | The most abundant among animal sources Cost-effective Hydrophobic Broad chemical tool-set and structural variation Effective filler for composite polymers Available thiol moiety Water resistant Fungal decay protection Appreciable adhesive strength under dry conditions | Non-homogeneous composition Poor solubility and thus unusual extraction processes needed Disinfecting process is needed to apply them | [169,170] | |

| Collagen | Low risk of infection Highly non-polar Globular in nature that minimizes water interaction | Needs processing to separate the collagen from other materials Moisture sensitivity | [171] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules 2021, 26, 7617. https://doi.org/10.3390/molecules26247617

Raydan NDV, Leroyer L, Charrier B, Robles E. Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules. 2021; 26(24):7617. https://doi.org/10.3390/molecules26247617

Chicago/Turabian StyleRaydan, Nidal Del Valle, Leo Leroyer, Bertrand Charrier, and Eduardo Robles. 2021. "Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review" Molecules 26, no. 24: 7617. https://doi.org/10.3390/molecules26247617

APA StyleRaydan, N. D. V., Leroyer, L., Charrier, B., & Robles, E. (2021). Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules, 26(24), 7617. https://doi.org/10.3390/molecules26247617