Nanomaterials in Cementitious Composites: An Update

Abstract

:1. Introduction

2. Nanomaterials Typically Used in Cement-Based Materials

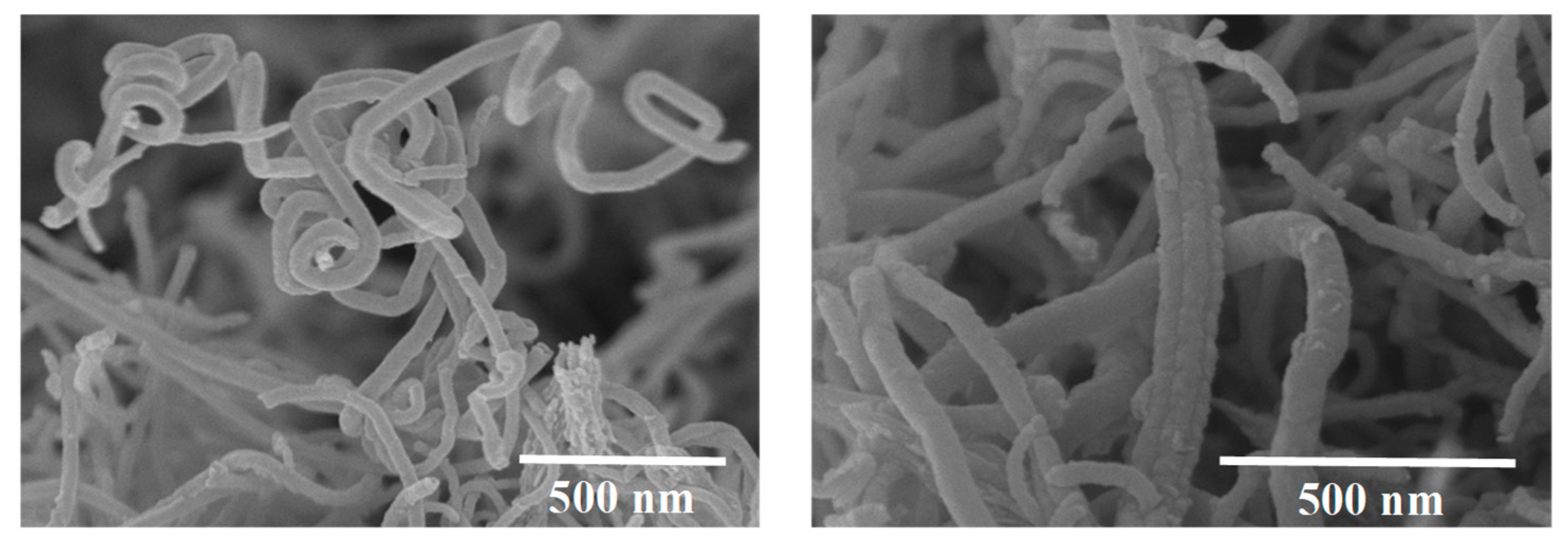

2.1. Carbon Nanotubes

2.1.1. Dispersion

2.1.2. Cement Hydration

2.1.3. Porosity, Water Absorption, Permeability and Microstructure

2.1.4. Mechanical Properties

2.1.5. Electrical Properties

2.1.6. Durability

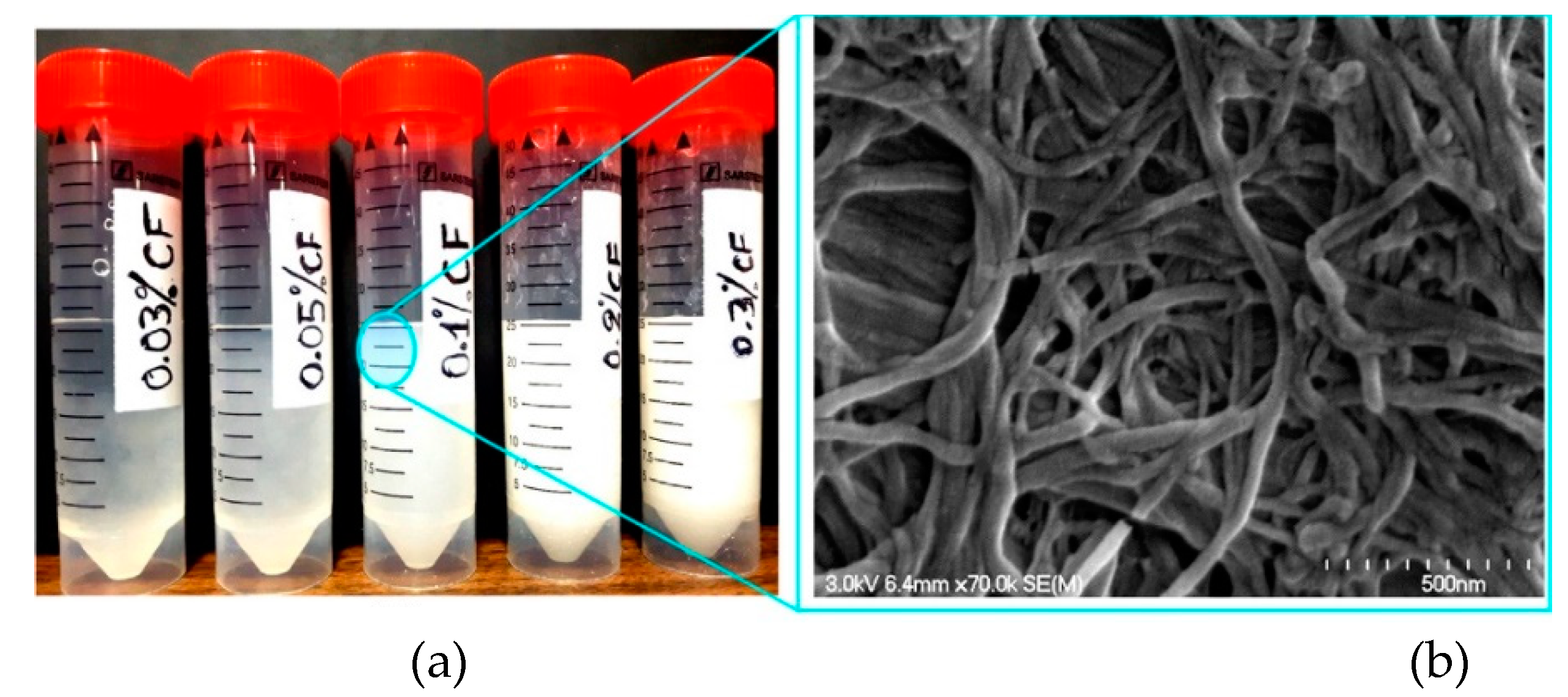

2.2. Cellulose

2.2.1. Cellulose Nanocrystals

2.2.2. Cellulose Filaments

2.2.3. Cellulose Nanofibers

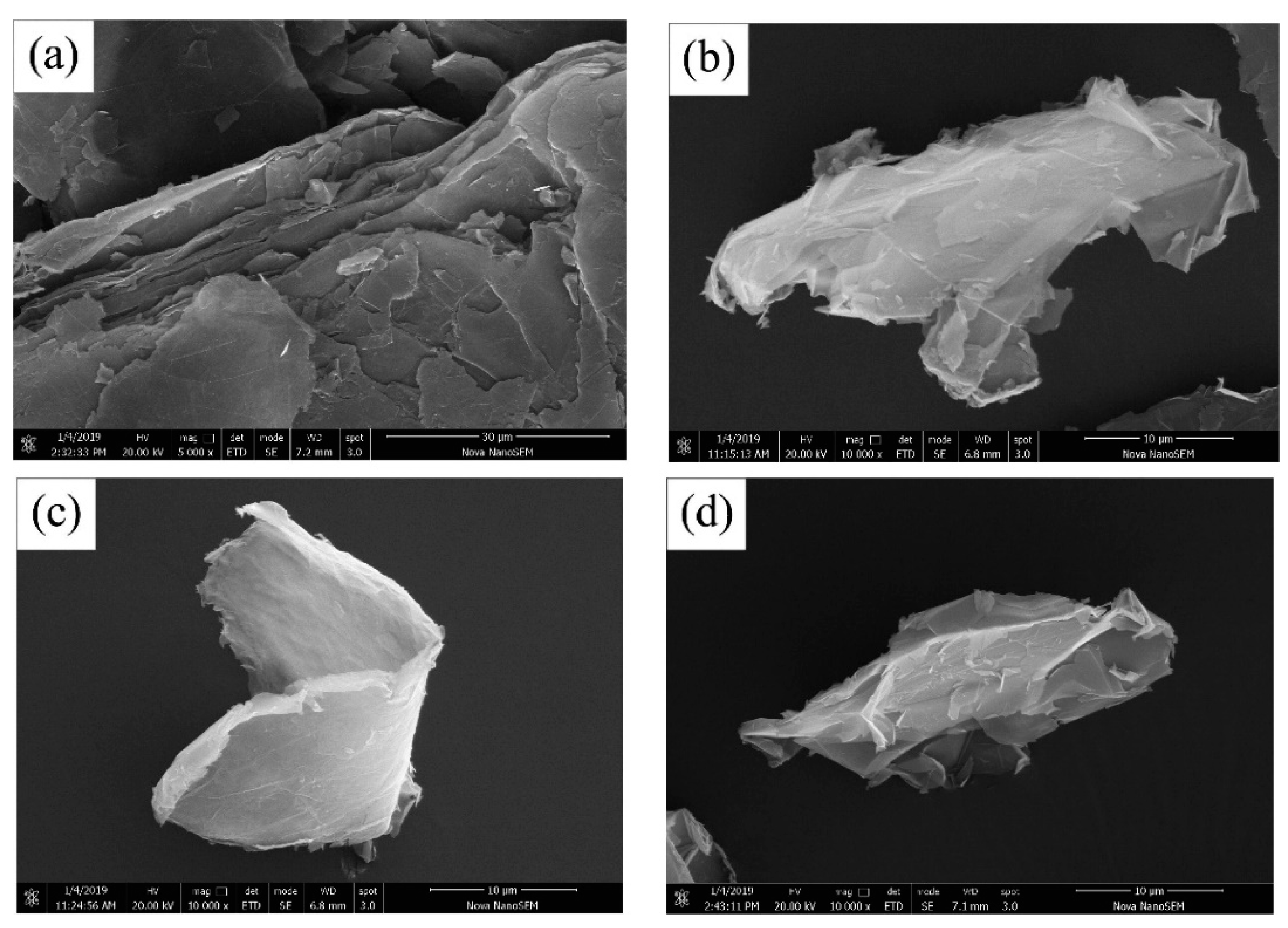

2.3. Graphene

2.3.1. Graphene Nanoplatelets

2.3.2. Graphene Oxide (GO)

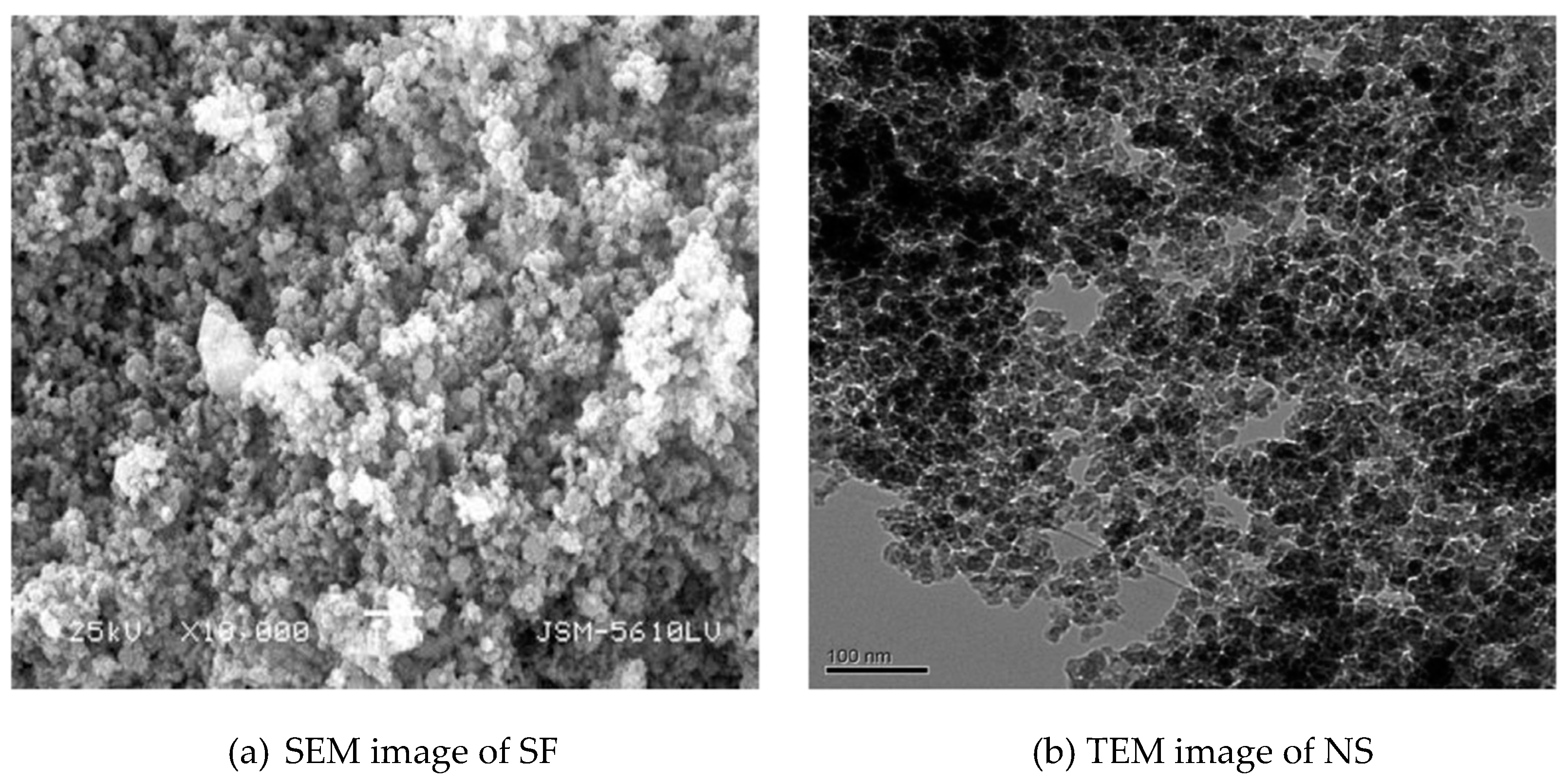

2.4. Nanosilica

2.5. Nano Titanium Dioxide

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Suzette, M.K. USGS Mineral Commodity Summaries 2016; U.S. Geological Survey: Reston, VA, USA, 2016; pp. 44–46.

- Larrard, F.D. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Zhang, B.; Tan, H.; Shen, W.; Xu, G.; Ma, B.; Ji, X. Nano-silica and silica fume modified cement mortar used as Surface Protection Material to enhance the impermeability. Cem. Concr. Compos. 2018, 92, 7–17. [Google Scholar] [CrossRef]

- Ollivier, J.P.; Maso, J.C.; Bourdette, B. Interfacial transition zone in concrete. Adv. Cem. Based Mater. 1995, 2, 30–38. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Haga, K.; Sutou, S.; Hironaga, M.; Tanaka, S.; Nagasaki, S. Effects of porosity on leaching of Ca from hardened ordinary Portland cement paste. Cem. Concr. Res. 2005, 35, 1764–1775. [Google Scholar] [CrossRef]

- Neville, A.Μ.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical: Harlow, UK, 1987. [Google Scholar]

- Makul, N. Advanced smart concrete—A review of current progress, benefits and challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- Peigney, A.; Laurent, C.; Flahaut, E.; Basca, R.R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Lin, D.; Xing, B. Adsorption of phenolic compounds by carbon nanotubes: Role of aromaticity and substitution of hydroxyl groups. Environ. Sci. Technol. 2008, 42, 7254–7259. [Google Scholar] [CrossRef] [PubMed]

- Cota, F.D.P.; Panzera, T.H.; Schiavon, M.A.; Christoforo, A.L.; Borges, P.H.R.; Bowen, C.; Scarpa, F. Full factorial design analysis of carbon nanotube polymer-cement composites. Mater. Res. 2012, 15, 573–580. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Chandra, A.; Mathur, R.; Dhawan, S. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Nadiv, R.; Shtein, M.; Peled, A.; Regev, O. WS 2 nanotube–reinforced cement: Dispersion matters. Constr. Build. Mater. 2015, 98, 112–118. [Google Scholar] [CrossRef]

- Kim, H.; Nam, I.; Lee, H. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume. Compos. Struct. 2014, 107, 60–69. [Google Scholar] [CrossRef]

- Materazzi, A.L.; Ubertini, F.; D’Alessandro, A. Carbon nanotube cement-based transducers for dynamic sensing of strain. Cem. Concr. Compos. 2013, 37, 2–11. [Google Scholar] [CrossRef]

- Ubertini, F.; Materazzi, A.L.; D’Alessandro, A.; Laflamme, S. Natural frequencies identification of a reinforced concrete beam using carbon nanotube cement based sensors. Eng. Struct. 2014, 60, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.J.; Zou, B.; Collins, F.; Zhao, X.L.; Majumber, M.; Duan, W.H. Predicting the influence of ultrasonication energy on the reinforcing efficiency of carbon nanotubes. Carbon 2014, 77, 1–10. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Parveen, S.H.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Seo, J.-W.T.; Konsta-Gdoutos, M.S.; Hersam, M.C.; Shah, S.P. Highly concentrated carbon nanotube admixture for nano-fiber reinforced cementitious materials. Cem. Concr. Compos. 2012, 34, 612–617. [Google Scholar] [CrossRef]

- Yu, J.; Grossiord, N.; Koning, C.E.; Loos, J. Controlling the dispersion of multi-wall carbon nanotubes in aqueous surfactant solution. Carbon 2007, 45, 618–623. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, L.; Sun, J. Production of aqueous colloidal dispersions of carbon nanotubes. J. Colloid Interface Sci. 2003, 260, 89–94. [Google Scholar] [CrossRef]

- Grossiord, N.; Regev, O.; Loos, J.; Meuldijk, J.; Koning, C.E. Time-dependent study of the exfoliation process of carbon nanotubes in aqueous dispersions by using UV-visible spectroscopy. Anal. Chem. 2005, 77, 5135–5139. [Google Scholar] [CrossRef]

- Kataura, H.; Kumazawa, Y.; Maniwa, Y.; Umezu, I.; Suzuki, S.; Ohtsuka, Y.; Achiba, Y. Optical properties of single-wall carbon nanotubes. Synth. Metals 1999, 103, 2555–2558. [Google Scholar] [CrossRef]

- Ryabenko, A.; Dorofeeva, T.; Zvereva, G. UV–VIS–NIR spectroscopy study of sensitivity of single-wall carbon nanotubes to chemical processing and Vander- Waals SWNT/SWNT interaction. Verification of the SWNT content measurements by absorption spectroscopy. Carbon 2004, 42, 1523–1535. [Google Scholar] [CrossRef]

- Markar, J.M.; Beaudoin, J.J. Carbon nanotubes and their applications in the construction industry. In Nanotechnology in Construction, Proceedings of the 1st International Symposium on Nanotechnology in Construction, Paisley, Scotland, 22–25 June 2003; Bartos, P.J.M., Hughes, J.J., Trtik, P., Zhu, W., Eds.; Royal Society of Chemistry: Cambridge, UK, 2004; pp. 331–341. [Google Scholar]

- Markar, J.M.; Margeson, J.C.; Luh, J. Carbon nanotube/cement composites–early results and potential applications. NRC Publications Record. In Proceedings of the 3rd International Conference on Construction Materials: Performing Innovations and Structural Implications, Vancouver, BC, Canada, 22–24 August 2005; pp. 1–10. [Google Scholar]

- Stynoski, P.; Mondal, P.; Marsh, C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced Portland cement. Cem. Concr. Compos. 2015, 55, 232–240. [Google Scholar] [CrossRef]

- Cui, H.; Yang, S.; Memon, S.A. Development of carbon nanotube modified cement paste with microencapsulated phase-change material for structural-functional integrated application. Int. J. Mol. Sci. 2015, 26, 8027–8039. [Google Scholar] [CrossRef]

- Amin, M.S.; El-Gamal, S.M.A.; Hashem, F.S. Fire resistance and mechanical properties of carbon nanotubes—Clay bricks wastes (Homra) composites cement. Constr. Build. Mater. 2015, 98, 237–249. [Google Scholar] [CrossRef]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Chaipanich, A.; Nochaiya, T.; Wongkeo, W.; Torkittikul, P. Compressive strength and microstructure of carbon nanotubes-fly ash cement composites. Mater. Sci. Eng. A 2010, 527, 1063–1067. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Gao, F.; Tian, W.; Wang, Z.; Wang, F. Effect of diameter of multi-walled carbon nanotubes on mechanical properties and microstructure of the cement-based materials. Constr. Build. Mater. 2020, 260, 120452. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Koumoulos, E.; Karatza, A.; Charitidis, C. Pore and phase identification through nanoindentation mapping and micro-computed tomography in nanoenhanced cement. Cem. Concr. Compos. 2020, 114, 103741. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudžionis, Z.; Rajapriya, R. The Effect of carbon nanotubes on the flowability, mechanical, microstructural and durability properties of cementitious composite: An overview. Sustainability 2020, 12, 8362. [Google Scholar] [CrossRef]

- Nasibulina, L.I.; Anoshkin, I.V.; Nasibulin, A.G.; Cwirzen, A.; Penttala, V.; Kauppinen, E.I. Effect of carbon nanotube aqueous dispersion quality on mechanical properties of cement composite. J. Nanomater. 2012, 2012, 169262. [Google Scholar] [CrossRef] [Green Version]

- Ruan, Y.; Han, B.; Yu, X.; Zhang, W.; Wang, D. Carbon nanotubes reinforced reactive powder concrete. Compos. Part A Appl. Sci. Manuf. 2018, 112, 371–382. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Salim, S.; Rabie, M. Carbon nanotubes dosage optimization for strength enhancement of cementitious composites. Procedia Manuf. 2020, 44, 366–370. [Google Scholar] [CrossRef]

- Barodawala, Q.I.; Shah, S.G. Modifying the strength and durability of self compacting concrete using carbon nanotubes. In Proceedings of the International Conference on Advances in Construction Materials and Structures (ACMS-2018) IIT Roorkee, Roorkee, Uttarakhand, India, 7–8 March 2018. [Google Scholar]

- Guan, X.; Bai, S.; Li, H.; Ou, J. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cementitious composites under the early-age freezing conditions. Constr. Build. Mater. 2020, 233, 117317. [Google Scholar] [CrossRef]

- Zhan, M.; Pan, G.; Zhou, F.; Mi, R.; Shah, S.P. In situ-grown carbon nanotubes enhanced cement-based materials with multifunctionality. Cem. Concr. Compos. 2020, 108, 103518. [Google Scholar] [CrossRef]

- Vesmawala, G.R.; Vaghela, A.R.; Yadav, K.; Patil, Y. Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Mater. Today Proc. 2020, 28, 1170–1174. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Gdoutos, E.E.; Shah, S.P. Strength, energy absorption capability and self-sensing properties of multifunctional carbon nanotube reinforced mortars. Constr. Build. Mater. 2016, 120, 265–274. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Shah, S.P. Relationship between the carbon nanotube dispersion state, electrochemical impedance and capacitance and mechanical properties of percolative nanoreinforced OPC mortars. Carbon 2019, 145, 218–228. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Corazza, F. The influence of AC and DC electrical resistance and piezoresistivity measurements of CNTs/Cement composites. In Proceedings of the Résumé & Actes—Abstracts & Proceedings International Congress on Materials & Structural Stability-Congrès International Matériaux & Stabilité Structurelle, Rabat, Morocco, 27–30 November 2013. [Google Scholar]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Batis, G.P.; Danoglidis, P.; Zacharopoulou, A.K.; Zacharopoulou, E.K.; Falara, M.G.; Shah, S.P. Effect of CNT and CNF loading and count on the corrosion resistance, conductivity and mechanical properties of nanomodified OPC mortars. Constr. Build. Mater. 2017, 147, 48–57. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Falara, M.G.; Nitodas, S.F. Fresh and mechanical properties, and strain sensing of nanomodified cement mortars: The effects of MWCNT aspect ratio, density and functionalization. Cem. Concr. Compos. 2017, 82, 137–151. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Corazza, F. Electrical properties of carbon nanotubes cement composites for monitoring stress conditions in concrete structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.-Y.; You, I.; Zi, G.; Lee, S.-J. Effects of carbon nanomaterial type and amount on self-sensing capacity of cement paste. Measurement 2019, 134, 750–761. [Google Scholar] [CrossRef]

- Liew, K.; Kai, M.; Zhang, L. Carbon nanotube reinforced cementitious composites: An overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Kim, G.; Yoon, H.; Lee, H. Autogenous shrinkage and electrical characteristics of cement pastes and mortars with carbon nanotube and carbon fiber. Constr. Build. Mater. 2018, 177, 428–435. [Google Scholar] [CrossRef]

- Blandine, F.; Habermehi-Cwirzen, K.; Cwirzen, A. Contribution of CNTs/CNFs morphology to reduction of autogenous shrinkage of Portland cement paste. Front. Struct. Civ. Eng. 2016, 10, 224–235. [Google Scholar] [CrossRef]

- Li, W.; Ji, W.-M.; Wang, Y.-C.; Liu, Y.; Shen, R.-X.; Xing, F. Investigation on the mechanical properties of a cement-based material containing carbon nanotube under drying and freeze-thaw conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef] [Green Version]

- Hawreen, A.; Bogas, J.A.; Dias, A.P.S. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Souza, D.J.; Yamashita, L.Y.; Dranka, F.; Medeiros, M.H.F.; Medeiros-Junior, R.A. Repair mortars incorporating multiwalled carbon nanotubes: Shrinkage and sodium sulfate attack. J. Mater. Civ. Eng. 2017, 29, 04017246. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dalla, P.T.; Tragazikis, I.K.; Barkoula, N.-M.; Matikas, T.E. Rapid chloride permeability test for durability study of carbon nanoreinforced mortar. In Smart Sensor Phenomena, Technology, Networks, and Systems Integration 2015; International Society for Optics and Photonics: San Diego, CA, USA, 2015; Volume 9436. [Google Scholar]

- Wang, X.; Rhee, I.; Wang, Y.; Xi, Y. Compressive strength, chloride permeability, and freeze-thaw resistance of MWNT concretes under diferent chemical treatments. Sci. World J. 2014, 2014, 572102. [Google Scholar]

- Dalla, P.T.; Tragazikis, I.K.; Exarchos, D.A.; Dassios, K.G.; Barkoula, N.-M.; Matikas, T.E. Effect of carbon nanotubes on chloride penetration in cement mortars. Appl. Sci. 2019, 9, 1032. [Google Scholar] [CrossRef] [Green Version]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Lee, H.-J.; Kim, W. Long-term durability evaluation of fiber-reinforced ECC using wood based cellulose nanocrystals. Constr. Build. Mater. 2020, 238, 117754. [Google Scholar] [CrossRef]

- Habibi, Y.; Dufresne, A. Highly filled bionanocomposites from functionalized polysaccharide nanocrystals. Biomacromolecules 2008, 9, 1974–1980. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Fu, T.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The influence of cellulose nanocrystals on the hydration and flexural strength of Portland cement pastes. Polymers 2017, 9, 424. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Tian, N.; Bahr, D.; Zavattieri, P.D.; Youngblood, J.; Moon, R.J.; Weiss, J. The influence of cellulose nanocrystals on the microstructure of cement paste. Cem. Concr. Compos. 2016, 74, 164–173. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef] [Green Version]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Szymańska-Chargot, M.; Łagód, G. Effect of eco-friendly cellulose nanocrystals on physical properties of cement mortars. Polymers 2019, 11, 2088. [Google Scholar] [CrossRef] [Green Version]

- Ramakrishnan, A.; Ravishankar, K.; Dhamodharan, R. Preparation of nanofibrillated cellulose and nanocrystalline cellulose from surgical cotton and cellulose pulp in hot-glycerol medium. Cellulose 2019, 26, 3127–3141. [Google Scholar] [CrossRef]

- Vanin, D.V.F.; Andrade, V.D.; Fiorentin, T.A.; Recouvreux, D.O.Z.; Carminatti, C.A.; Al-Qureshi, H.A. Cement pastes modified by cellulose nanocrystals: A dynamic moduli evolution assessment by the Impulse Excitation Technique. Mater. Chem. Phys. 2020, 239, 122038. [Google Scholar] [CrossRef]

- Flores, J.; Kamali, M.; Ghahremaninezhad, A. An investigation into the properties and microstructure of cement mixtures modified with cellulose nanocrystal. Materials 2017, 10, 498. [Google Scholar] [CrossRef] [Green Version]

- Montes, F.; Fu, T.; Youngblood, J.P.; Weiss, J. Rheological impact of using cellulose nanocrystals (CNC) in cement pastes. Constr. Build. Mater. 2020, 235, 117497. [Google Scholar] [CrossRef]

- Liu, Q.; Peng, Y.; Liang, L.; Dong, X.; Li, H. Effect of cellulose nanocrystals on the properties of cement paste. J. Nanomater. 2019, 2019, 8318260. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Wilson, W.; Sorelli, L.; Tolnai, B.; Tagnit-Hamou, A. Nanocellulose for improved concrete performance: A macro-to-micro investigation for disclosing the effects of cellulose filaments on strength of cement systems. Constr. Build. Mater. 2019, 206, 84–96. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Basic, N.; Omran, A.F.; Tagnit-Hamou, A. Feasibility of using cellulose filaments as a viscosity modifying agent in self-consolidating concrete. Cem. Concr. Compos. 2018, 94, 327–340. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Soliman, N.; Tolnaic, B.; Tagnit-Hamou, A. Nano-engineered ultra-high performance concrete for controlled autogenous shrinkage using nanocellulose. Cem. Concr. Res. 2020, 137, 106217. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Omran, A.F.; Tagnit-Hamou, A. Influence of cellulose filaments on cement pastes and concrete. J. Mater. Civ. Eng. 2018, 30, 04018109. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Gindl, W. Review: Current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Isogai, A.; Saito, T.; Fukuzumi, H. TEMPO-oxidized cellulose nanofibers. Nanoscale 2011, 3, 71–85. [Google Scholar] [CrossRef] [PubMed]

- Pei, A.; Butchosa, N.; Berglund, L.A.; Zhou, Q. Surface quaternized cellulose nanofibrils with high water absorbency and adsorption capacity for anionic dyes. Soft Matter 2013, 9, 2047–2055. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of nanofibre reinforced cement composites. Constr. Build. Mater. 2014, 63, 119–124. [Google Scholar] [CrossRef]

- Jiao, L.; Su, M.; Chen, L.; Wang, Y.; Zhu, H.; Dai, H. Natural cellulose nanofibers as sustainable enhancers in construction cement. PLoS ONE 2016, 11, e0168422. [Google Scholar] [CrossRef] [Green Version]

- Aloulou, F.; Alila, S. Characterization and influence of nanofiber flours of wood modified on fresh state properties of cement based mortars. J. Renew. Mater. 2019, 7, 557–566. [Google Scholar] [CrossRef] [Green Version]

- Aloulou, F.; Alila, S.; Sammouda, H. Stabilization and evaluation of modified nanofiber flour wood on the properties of cement-based mortar. J. Renew. Mater. 2019, 7, 763–774. [Google Scholar] [CrossRef] [Green Version]

- Aloulou, F.; Sabrine, A.; Sammouda, H. Influence and dispersion of nanofiber of wood modified on properties of cement based mortars. J. Renew. Mater. 2019, 7, 631–641. [Google Scholar] [CrossRef] [Green Version]

- Hoyos, C.G.; Zuluaga, R.; Gañán, P.; Pique, T.M.; Vazquez, A. Cellulose nanofibrils extracted from fique fibers as bio-based cement additive. J. Clean. Prod. 2019, 235, 1540–1548. [Google Scholar] [CrossRef]

- Peters, S.; Rushing, T.; Landis, E.; Cummins, T. Nanocellulose and microcellulose fibres for concrete. J. Transp. Res. Board 2010, 2142, 25–28. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Cristia, E.; Vázquez, A. Effect of cellulose microcrystalline particles on properties of cement based composites. Mater. Des. 2013, 51, 810–881. [Google Scholar] [CrossRef]

- Alzoubi, H.H.; Albiss, B.A.; Abu sini, S.S. Performance of cementitious composites with nano PCMs and cellulose nano fibers. Constr. Build. Mater. 2020, 236, 117483. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Nishiwaki, T. Compressive and flexural strength behavior of ultra-high performance mortar reinforced with cellulose nano-fibers. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 365–372. [Google Scholar] [CrossRef]

- Akhlaghi, M.A.; Bagherpour, R.; Kalhori, H. Application of bacterial nanocellulose fibers as reinforcement in cement composites. Constr. Build. Mater. 2020, 241, 118061. [Google Scholar] [CrossRef]

- Cengiz, A.; Kaya, M.; Bayramgil, N.P. Flexural stress enhancement of concrete by incorporation of algal cellulose nanofibers. Constr. Build. Mater. 2017, 149, 289–295. [Google Scholar] [CrossRef]

- Bakkari, M.E.; Bindiganavile, V.; Goncalves, J.; Boluk, Y. Preparation of cellulose nanofibers by TEMPO-oxidation of bleached chemi-thermomechanical pulp for cement applications. Carbohydr. Polym. 2019, 203, 238–245. [Google Scholar] [CrossRef] [PubMed]

- Goncalves, J.; El-Bakkari, M.; Boluk, Y.; Bindiganavile, V. Cellulose nanofibres (CNF) for sulphate resistance in cement based systems. Cem. Concr. Compos. 2019, 99, 100–111. [Google Scholar] [CrossRef]

- Correia, V.C.; Santos, S.F.; Teixeira, R.S.; Junior, H.S. Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 2018, 160, 376–384. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.A.; Geim, A.K.; Morozov, S.; Jiang, D.; Katsnelson, M.; Grigorieva, I.; Firsov, A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, properties and potential of graphene. Carbon 2010, 48, 2127–2150. [Google Scholar] [CrossRef] [Green Version]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef] [Green Version]

- Kuila, T.; Bose, S.; Hong, C.E.; Uddin, M.E.; Khanra, P.; Kim, N.H.; Lee, J.H. Preparation of functionalized graphene/linear low density polyethylene composites by a solution mixing method. Carbon 2011, 49, 1033–1037. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Jiménez-Suárez, A.; Moriche, R.; Ureña, A. Graphene nanoplatelets thickness and lateral size influence on the morphology and behavior of epoxy composites. Eur. Polym. J. 2014, 53, 292–301. [Google Scholar] [CrossRef]

- Wang, B.; Pang, B. Mechanical property and toughening mechanism of water reducing agents modified graphene nanoplatelets reinforced cement composites. Constr. Build. Mater. 2019, 226, 699–711. [Google Scholar] [CrossRef]

- Metaxa, Z.S. Polycarboxylate based superplasticizers as dispersant agents for exfoliated graphene nanoplatelets reinforcing cement based materials. J. Eng. Sci. Technol. Rev. 2015, 8, 1–5. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Dispersion and stability of graphene nanoplatelet in water and its influence on cement composites. Constr. Build. Mater. 2018, 167, 403–413. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Jiang, Z.; Harris, D.K. Exploring scalable fabrication of self-sensing cementitious composites with graphene nanoplatelets. Smart Mater. Struct. 2018, 27, 115029. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Kourkoulis, S.K. Dispersion of graphene nanoplatelets reinforcing type II cement paste. Procedia Struct. Integr. 2018, 13, 2011–2016. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the Mechanical Properties and Microstructure of Graphene Nanoplatelet-Cement Composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Bai, S.; Jiang, L.; Xu, N.; Jin, M.; Jiang, S. Enhancement of mechanical and electrical properties of graphene/cement composite due to improved dispersion of graphene by addition of silica fume. Constr. Build. Mater. 2018, 164, 433–441. [Google Scholar] [CrossRef]

- Wang, B.; Shuang, D. Effect of graphene nanoplatelets on the properties, pore structure and microstructure of cement composites. Mater. Express 2018, 8, 407–416. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, R. Effect of graphene nano-sheets on the chloride penetration and microstructure of the cement based composite. Constr. Build. Mater. 2018, 161, 715–722. [Google Scholar] [CrossRef]

- Liu, J.; Fu, J.; Yang, Y.; Gu, C. Study on dispersion, mechanical and microstructure properties of cement paste incorporating graphene sheets. Constr. Build. Mater. 2019, 199, 1–11. [Google Scholar] [CrossRef]

- Baomin, W.; Shuang, D. Effect and mechanism of graphene nanoplatelets on hydration reaction, mechanical properties and microstructure of cement composites. Constr. Build. Mater. 2019, 228, 116720. [Google Scholar] [CrossRef]

- Tao, J.; Wang, X.; Wang, Z.; Zeng, Q. Graphene nanoplatelets as an effective additive to tune the microstructures and piezoresistive properties of cement-based composites. Constr. Build. Mater. 2019, 209, 665–678. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Javed, M.F.; Khushnood, R.A. A sustainable graphene based cement composite. Sustainability 2017, 9, 1229. [Google Scholar] [CrossRef] [Green Version]

- Rehman, S.K.U.; Ibrahim, Z.; Jameel, M.; Memon, S.A.; Javed, M.F.; Aslam, M.; Mehmood, K.; Nazar, S. Assessment of rheological and piezoresistive properties of graphene based cement composites. Int. J. Concr. Struct. Mater. 2018, 12, 1–23. [Google Scholar] [CrossRef]

- Silva, R.A.; Guetti, P.C.; Luz, M.S.; Rouxinol, F.; Gelamo, R.V. Enhanced properties of cement mortars with multilayer graphene nanoparticles. Constr. Build. Mater. 2017, 149, 378–385. [Google Scholar] [CrossRef]

- Sun, S.; Ding, S.; Han, B.; Dong, S.; Yu, X.; Zhou, D.; Ou, J. Multi-layer graphene-engineered cementitious composites with multifunctionality/intelligence. Compos. Part B Eng. 2017, 129, 221–232. [Google Scholar] [CrossRef]

- Tragazikis, I.K.; Dassios, K.G.; Dalla, P.T.; Exarchos, D.A.; Matikas, T.E. Acoustic emission investigation of the effect of graphene on the fracture behavior of cement mortars. Eng. Fract. Mech. 2019, 210, 444–451. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, R.; Zhang, T. Pore structure and durability of cement-based composites doped with graphene nanoplatelets. Mater. Express 2018, 8, 149–156. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Wanga, J.; Tao, J.; Li, L.; Zhou, C.; Zeng, Q. Thinner fillers, coarser pores? A comparative study of the pore structure alterations of cement composites by graphene oxides and graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105750. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Sedaghat, A.; Ram, M.K.; Zayed, A.; Kamal, R.; Shanahan, N. Investigation of physical properties of graphene-cement composite for structural applications. Open J. Compos. Mater. 2014, 4, 12–21. [Google Scholar] [CrossRef] [Green Version]

- Pisello, A.L.; D’Alessandro, A.; Sambuco, S.; Rallini, M.; Ubertini, F.; Asdrubali, F.; Materazzi, A.L.; Cotana, F. Multipurpose experimental characterization of smart nanocomposite cement-based materials for thermal-energy efficiency and strain-sensing capability. Sol. Energy Mater. Sol. Cells 2017, 161, 77–88. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, Q.; Yu, Q.; Gao, R.; Tong, T. Experimental investigation on mechanical and piezoresistive properties of cementitious materials containing graphene and graphene oxide nanoplatelets. Constr. Build. Mater. 2016, 127, 565–576. [Google Scholar] [CrossRef]

- Chougan, M.; Marotta, E.; Lamastra, F.R.; Vivio, F.; Montesperelli, G.; Ianniruberto, U.; Bianco, A. A systematic study on EN-998-2 premixed mortars modified with graphene-based materials. Constr. Build. Mater. 2019, 227, 116701. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, D. Pressure-sensitive properties of emulsion modified graphene nanoplatelets/cement composites. Cem. Concr. Compos. 2017, 84, 74–82. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.; Wang, W. Electric induced curing of graphene/cement-based composites for structural strength formation in deep-freeze low temperature. Mater. Des. 2018, 160, 783–793. [Google Scholar] [CrossRef]

- Le, J.L.; Du, H.; Pang, S.D. Use of 2D graphene nanoplatelets (GNP) in cement composites for structural health evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Metaxa, Z.S. Exfoliated graphene nanoplatelet cement-based nanocomposites as piezoresistive sensors: Influence of nanoreinforcement lateral size on monitoring capability. Cienc. Tecnol. Mater. 2016, 28, 73–79. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, W.; Xiao, J.; Tian, Y.; Chen, J.; Singh, A. Correlation between damage evolution and resistivity reaction of concrete in-filled with graphene nanoplatelets. Constr. Build. Mater. 2019, 208, 482–491. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Du, C. Study on the three dimensional mechanism of graphene oxide nanosheets modified cement. Constr. Build. Mater. 2016, 126, 730–739. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Shamsaei, E.; Souza, F.B.; Yao, X.; Benhelal, E.; Akbari, A.; Duan, W. Graphene-based nanosheets for stronger and more durable concrete: A review. Constr. Build. Mater. 2018, 183, 642–660. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Song, L.; Song, Y.; Dai, G.; Liu, J. An intensive review on the role of graphene oxide in cement-based materials. Constr Build. Mater. 2020, 241, 117939. [Google Scholar] [CrossRef]

- Li, D.; Müller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G.G. Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol. 2008, 3, 101–105. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Chuah, S.; Li, W.G.; Chen, S.J.; Sanjayan, J.G.; Duan, W.H. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments. Constr. Build. Mater. 2018, 161, 519–527. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Liu, Y.; Ge, C.; Chen, Z.; Guo, L.; Shu, X.; Liu, J. Investigation of dispersion behavior of GO modified by different water reducing agents in cement pore solution. Carbon 2018, 127, 255–269. [Google Scholar] [CrossRef]

- Yang, H.; Monasterio, M.; Cui, H.; Han, N. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite. Compos. Part A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- Babak, F.; Abolfazl, H.; Alimorad, R.; Parviz, G. Preparation and mechanical properties of graphene oxide: Cement nanocomposites. Sci. World J. 2014, 2014, 276323. [Google Scholar] [CrossRef]

- Lu, Z.; Hanif, A.; Ning, C.; Shao, H.; Yin, R.; Li, Z. Steric stabilization of graphene oxide in alkaline cementitious solutions: Mechanical enhancement of cement composite. Mater. Des. 2017, 127, 154–161. [Google Scholar] [CrossRef]

- Lee, S.-J.; Jeong, S.-H.; Kim, D.-U.; Won, J.-P. Effects of graphene oxide on pore structure and mechanical properties of cementitious composites. Compos. Struct. 2020, 234, 111709. [Google Scholar] [CrossRef]

- Sun, H.; Ren, Ζ.; Ling, L.; Memon, S.A.; Ren, J.; Liu, B.; Xing, F. Influence of graphene oxide on interfacial transition zone of mortar. J. Nanomater. 2020, 2020, 8919681. [Google Scholar] [CrossRef]

- Wang, N.; Wang, S.; Tang, L.; Ye, L.; Cullbrand, B.; Zehri, A.; Tebikachew, B.E.; Liu, J. Improved interfacial bonding strength and reliability of functionalized graphene oxide for cement reinforcement applications. Chem. Eur. J. 2020, 26, 6561–6568. [Google Scholar] [CrossRef]

- Indukuri, C.S.R.; Nerella, R.; Madduru, S.R.C. Workability, microstructure, strength properties and durability properties of graphene oxide reinforced cement paste. Aust. J. Civ. Eng. 2020, 18, 73–81. [Google Scholar] [CrossRef]

- Pan, Z.; Duan, W.; Li, D.; Collins, F. Graphene Oxide Reinforced Cement and Concrete. Patent WO2013096990A1, 4 July 2013. [Google Scholar]

- Prabavathy, S.; Jeyasubramanian, K.; Prasanth, S.; Hikku, G.S.; Robert, R.B.J. Enhancement in behavioral properties of cement mortar cubes admixed with reduced graphene oxide. J. Build. Eng. 2020, 28, 101082. [Google Scholar] [CrossRef]

- Jing, G.; Ye, Z.; Wu, J.; Wang, S.; Cheng, X.; Strokova, V.; Nelyubova, V. Introducing reduced graphene oxide to enhance the thermal properties of cement composites. Cem. Concr. Compos. 2020, 109, 103559. [Google Scholar] [CrossRef]

- Hou, P.; Cheng, X.; Qian, J. Effects and mechanisms of surface treatment of hardened cement-based materials with colloidal nanoSiO2 and its precursor. Constr. Build. Mater. 2004, 53, 66–73. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K. Influence of dispersants and dispersion on properties of nanosilica modified cement-based materials. Cem. Concr. Compos. 2021, 118, 103969. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Ye, Q.; Zhang, Z.; Kong, D. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar]

- Jo, B.W.; Kim, C.H.; Tae, G.; Park, G.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of nucleation seeding on the hydration mechanisms of tricalcium silicate and cement. J. Phys. Chem. 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Hou, P.; Qian, J.; Cheng, X.; Shah, S.P. Effects of the pozzolanic reactivity of nanoSiO2 on cement-based materials. Cem. Concr. Compos. 2015, 55, 250–258. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Jiang, G. Effects of nano-SiO2 particles on the mechanical and microstructural properties of ultra-high performance cementitious composites. Cem. Concr. Compos. 2015, 56, 25–31. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, X.; Liu, D.; Zhao, L.; Zhao, M. Modification of water absorption and pore structure of high-volume fly ash cement pastes by incorporating nanosilica. J. Build. Eng. 2021, 33, 101638. [Google Scholar] [CrossRef]

- Sikora, P.; Rucinska, T.; Stephan, D.; Chung, S.-Y.; Abd Elrahman, M. Evaluating the effects of nanosilica on the material properties of lightweight and ultra-lightweight concrete using image-based approaches. Constr Build. Mater. 2020, 264, 120241. [Google Scholar] [CrossRef]

- Li, W.G.; Huang, Z.Y.; Cao, F.L.; Sun, Z.H.; Shah, S.P. Effects of nanosilica and nanolimestone on flowability and mechanical properties of ultra high performance concrete matrix. Construct. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Hamdy, D.A.; Berry, A.S.; Saleh, A.M.; Nashwa, M.M. Chemical and engineering properties of blended cement containing micro and nanosilica. Am. J. Chem. Eng. 2017, 5, 111–121. [Google Scholar]

- Hamdy, D.; Ahmed, A.A.; Tarek, M.S.; Samir, H. Hydration and characteristics of metakaolin pozzolanic cement pastes. Hous. Build. Natl. Res. Cent. J. 2018, 14, 150–158. [Google Scholar]

- Stefanidou, M. Influence of nanosilica on the portland cement pastes. Compos. Part B Eng. 2012, 43, 2706–2710. [Google Scholar] [CrossRef]

- Raheem, A.A.; Abdulwahab, R.; Kareem, M.A. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete- A review. J. Clean. Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Yu, X.; Han, B.; Ou, J. Multifunctional cementitious composites modified with nano titanium dioxide: A review. Compos. Part A Appl. Sci. Manuf. 2018, 111, 115–137. [Google Scholar] [CrossRef]

- Rahim, A.; Nair, S.R. Influence of nano-materials in high strength concrete. J. Chem. Pharm. Sci. 2016, 974, 15–22. [Google Scholar]

- Han, B.; Li, Z.; Zhang, L.; Zeng, S.; Yu, X.; Han, B.; Ou, J. Reactive powder concrete reinforced with nano SiO2-coated TiO2. Constr. Build. Mater. 2017, 148, 104–112. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effect of TiO2 nanoparticles on water permeability and thermal and mechanical properties of high strength self-compacting concrete. Mater. Sci. Eng. A 2010, 528, 756–763. [Google Scholar] [CrossRef]

- Yang, L.Y.; Jia, Z.J.; Zhang, Y.M.; Dai, J.G. Effects of nano-TiO2 on strength, shrinkage and microstructure of alkali activated slag pastes. Cem. Concr. Compos. 2015, 57, 1–7. [Google Scholar] [CrossRef]

- Ma, B.; Li, H.; Mei, J.; Li, X.; Chen, F. Effects of nano-TiO2 on the toughness and durability of cement-based material. Adv. Mater. Sci. Eng. 2015, 583106. [Google Scholar]

- Jalal, M.; Fathi, M.; Farzad, M. Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self compacting concrete. Mech. Mater. 2013, 61, 11–27. [Google Scholar] [CrossRef]

- Soleymani, F. Assessments of the effects of lime water on water permeability of TiO2 nanoparticles binary blended palm oil clinker aggregate-based concrete. J. Am. Sci. 2012, 8, 698–702. [Google Scholar]

- Guerrini, G.L.; Peccati, E. Photocatalytic cementitious roads for depollution. In Proceedings of the International RILEM Symposium on Photocatalysis, Environment and Construction Materials—TDP 2007, Florence, Italy, 8–9 October 2007; Baglioni, P., Casssar, L., Eds.; RILEM Publications SARL: Paris, France, 2017; pp. 179–186, ISBN 978-2-35158-056-1. [Google Scholar]

- Demeestere, K.; Dewulf, J.; Witte, B.D.; Beeldens, A.; Langenhove, H.V. Heterogeneous photocatalytic removal of toluene from air on building materials enriched with TiO2. Build. Environ. 2008, 43, 406–414. [Google Scholar] [CrossRef]

- Gammampila, R.; Mendis, P.; Ngo, T.; Aye, L.; Jayalath, A.S.; Rupasinghe, R.A.M. Application of nanomaterials in the sustainable built environment. In Proceedings of the International Conference on Sustainable Built Environment (ICSBE-2010), Kandy, Sri Lanka, 13–14 December 2010; pp. 20–27. [Google Scholar]

- He, J.; Hoyano, A. A numerical simulation method for analyzing the thermal improvement effect of super-hydrophilic photocatalyst-coated building surfaces with water film on the urban/built environment. Energy Build. 2008, 40, 968–978. [Google Scholar] [CrossRef]

- Ohko, Y.; Donald, A.T.; Hashimoto, A.K.; Fujishima, A. Autoxidation of acetaldehyde initiated by TiO2 photocatalysis under weak UV illumination. J. Phys. Chem. B 1998, 102, 2699–2704. [Google Scholar] [CrossRef]

- Chen, H.; Gu, L.; Liao, B.; Zhou, X.; Cheng, L.; Ren, B. Advances of anti-caries nanomaterials. [Review]. Molecules 2020, 25, 5047. [Google Scholar] [CrossRef]

- Curulli, A. Nanomaterials in electrochemical sensing area: Applications and challenges in food analysis. Molecules 2020, 25, 5759. [Google Scholar] [CrossRef]

- Kweitsu, E.O.; Armoo, S.K.; Kan-Dapaah, K.; Abavare, E.K.K.; Dodoo-Arhin, D.; Yaya, A. Comparative study of phosgene gas sensing using carbon and boron nitride nanomaterials-A DFT approach. Molecules 2020, 26, 120. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Ma, B.; Wang, W. Peptide-based nanomaterials for tumor immunotherapy. Molecules 2020, 26, 132. [Google Scholar] [CrossRef]

- Lombardo, S.; Villares, A. Engineered multilayer microcapsules based on polysaccharides nanomaterials. Molecules 2020, 25, 4420. [Google Scholar] [CrossRef] [PubMed]

- Palma, P.J.; Marques, J.A.; Antunes, M.; Falacho, R.I.; Sequeira, D.; Roseiro, L.; Santos, J.M.; Ramos, J.C. Institute of Endodontics, Faculty of Effect of restorative timing on shear bond strength of composite resin/calcium silicate–based cements adhesive interfaces. Clin. Oral Investig. 2020. [Google Scholar] [CrossRef] [PubMed]

- Palma, P.J.; Messias, A.; Cerqueira, A.R.; Tavares, L.D.; Caramelo, F.; Roseiro, L.; Santos, J.M. Cyclic fatigue resistance of three rotary file systems in a dynamic model after immersion in sodium hypochlorite. Odontology 2019, 107, 324–332. [Google Scholar] [CrossRef] [PubMed]

- He, F.; Meng, A.; Cheng, B.; Ho, W.; Yu, J. Enhanced photocatalytic H2-production activity of WO3/TiO2 step-scheme heterojunction by graphene modification. Chin. J. Catal. 2020, 41, 9–20. [Google Scholar] [CrossRef]

- Zhang, R.; Cui, G.; Su, X.; Yu, X.; Li, Z. A novel functionally graded Ni-graphene coating and its corrosion resistance. J. Alloys Compd. 2020, 829, 154495. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metaxa, Z.S.; Tolkou, A.K.; Efstathiou, S.; Rahdar, A.; Favvas, E.P.; Mitropoulos, A.C.; Kyzas, G.Z. Nanomaterials in Cementitious Composites: An Update. Molecules 2021, 26, 1430. https://doi.org/10.3390/molecules26051430

Metaxa ZS, Tolkou AK, Efstathiou S, Rahdar A, Favvas EP, Mitropoulos AC, Kyzas GZ. Nanomaterials in Cementitious Composites: An Update. Molecules. 2021; 26(5):1430. https://doi.org/10.3390/molecules26051430

Chicago/Turabian StyleMetaxa, Zoi S., Athanasia K. Tolkou, Stefania Efstathiou, Abbas Rahdar, Evangelos P. Favvas, Athanasios C. Mitropoulos, and George Z. Kyzas. 2021. "Nanomaterials in Cementitious Composites: An Update" Molecules 26, no. 5: 1430. https://doi.org/10.3390/molecules26051430

APA StyleMetaxa, Z. S., Tolkou, A. K., Efstathiou, S., Rahdar, A., Favvas, E. P., Mitropoulos, A. C., & Kyzas, G. Z. (2021). Nanomaterials in Cementitious Composites: An Update. Molecules, 26(5), 1430. https://doi.org/10.3390/molecules26051430