High-Temperature Oxidation Resistance of PDC Coatings in Synthetic Air and Water Vapor Atmospheres

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Coatings

2.2. Oxidation Tests

2.3. Characterization Methods

3. Results and Discussion

3.1. Weight Changes Measurement

3.2. XRD Measurement

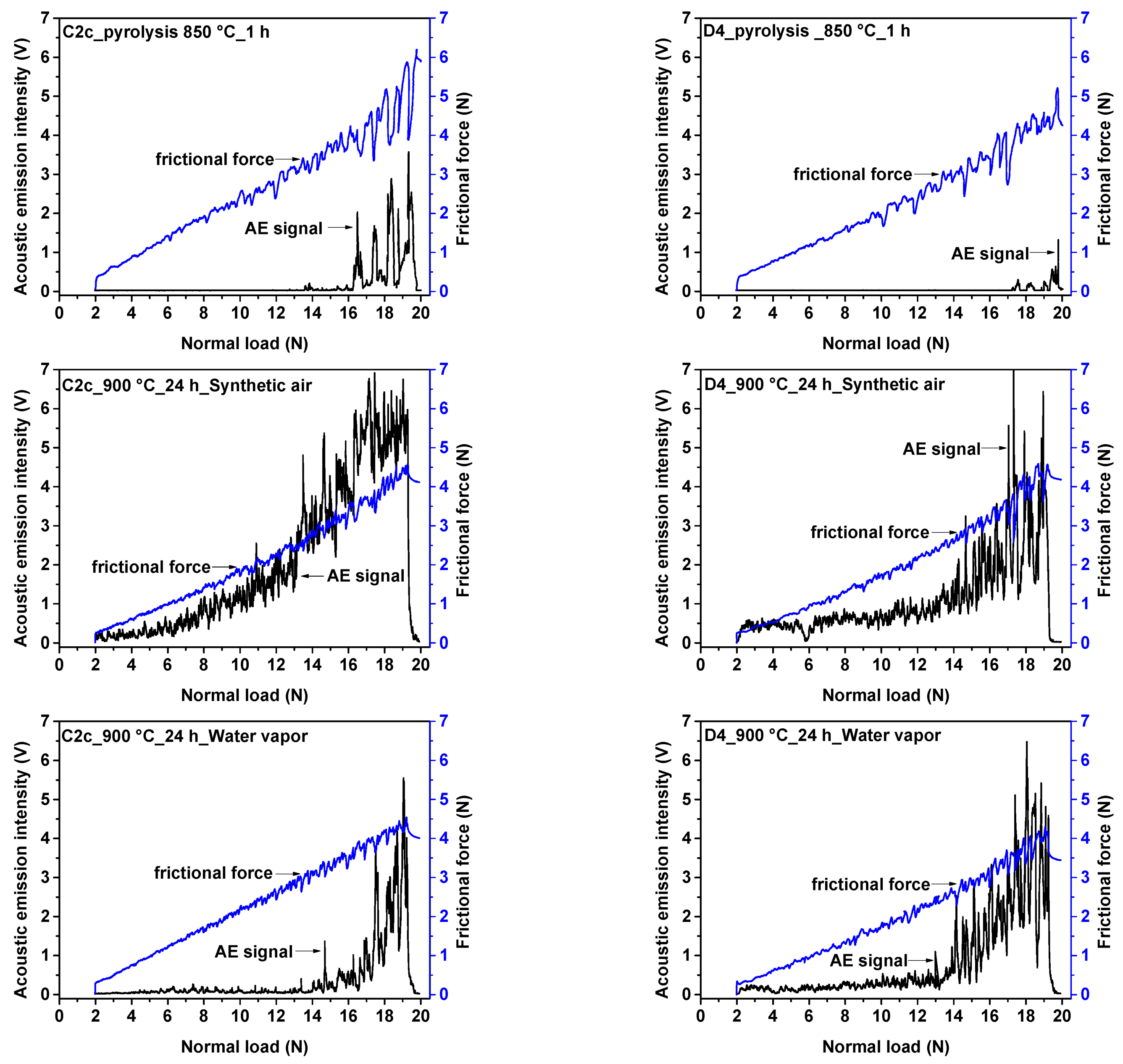

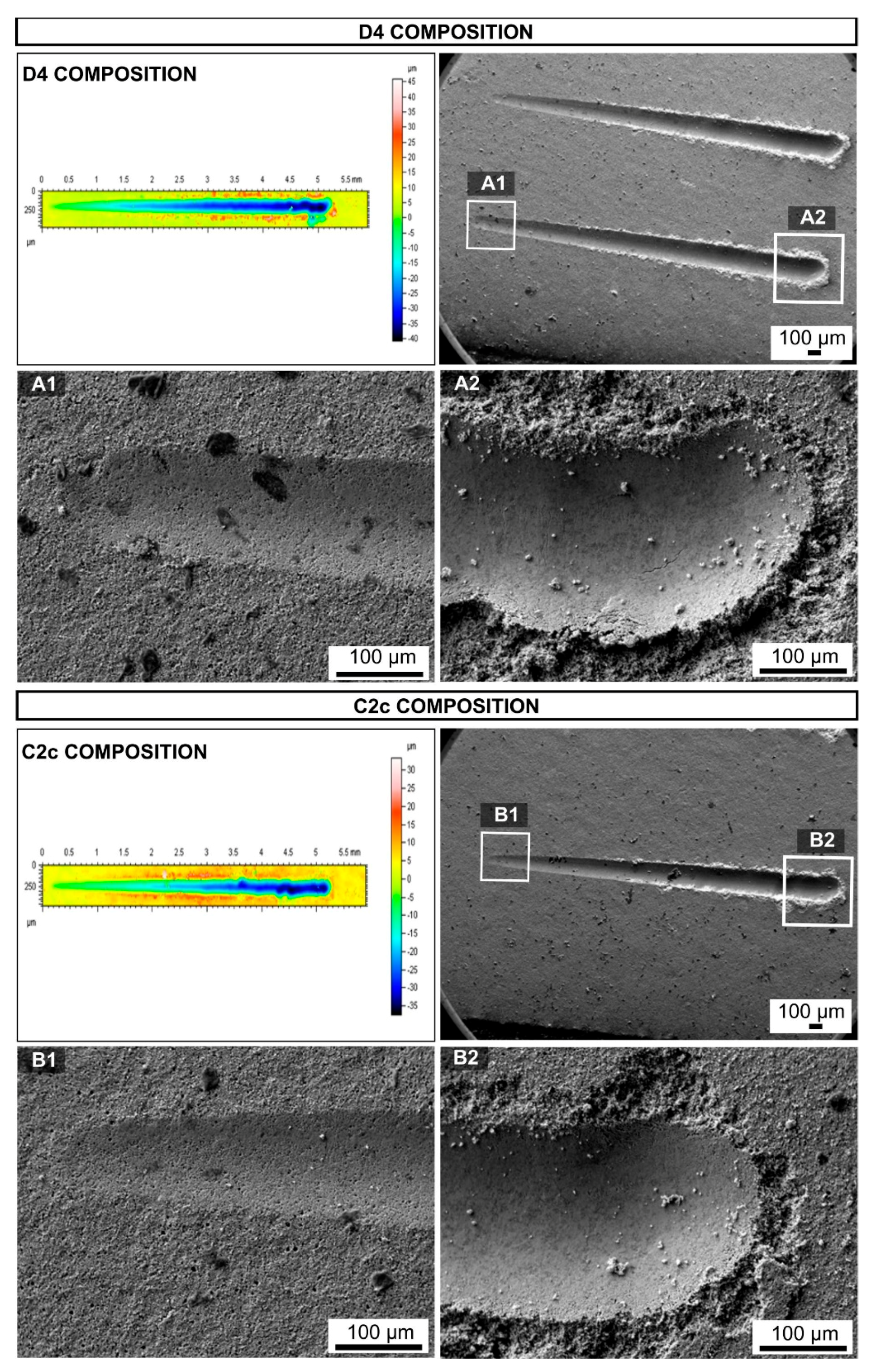

3.3. Adhesion Strength

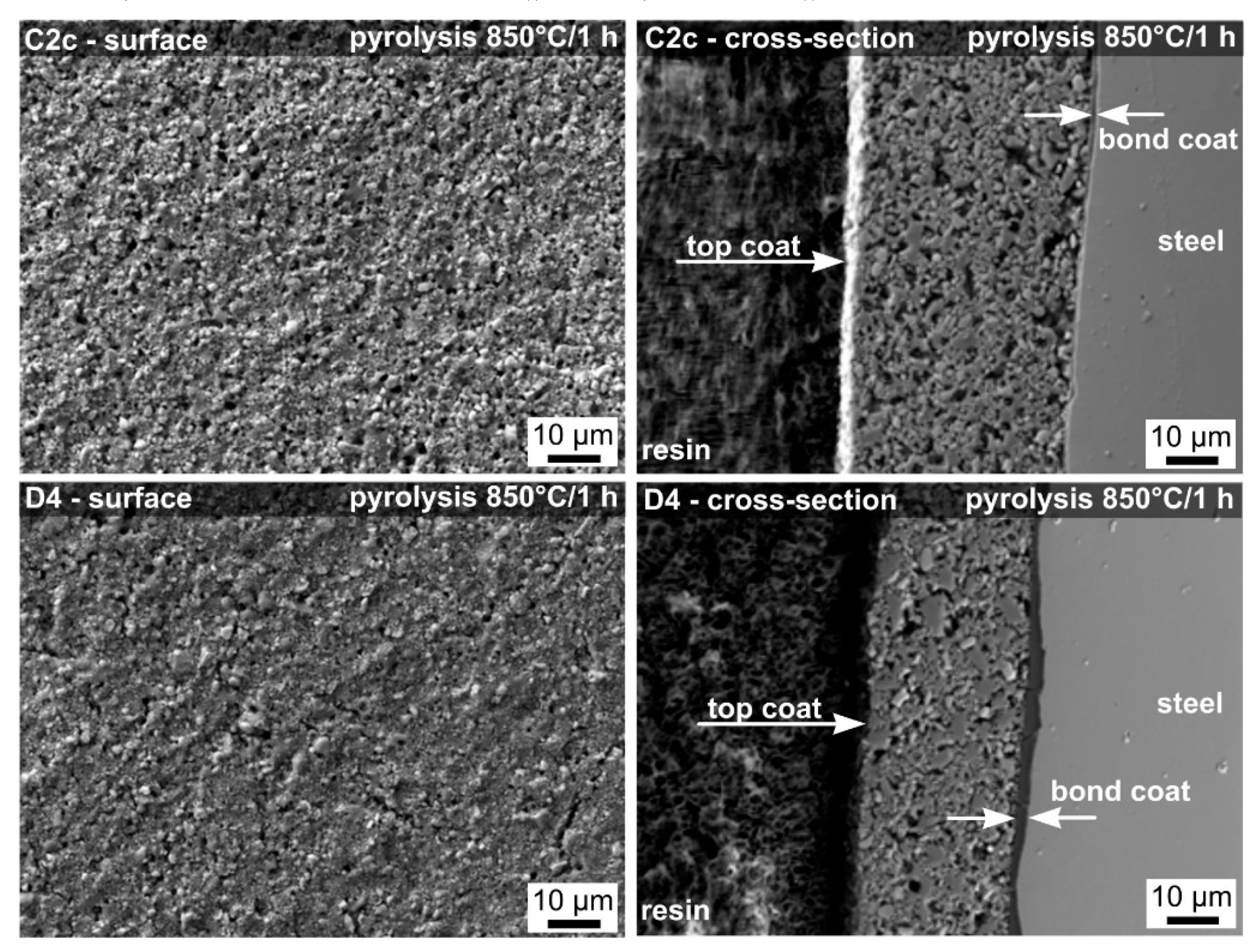

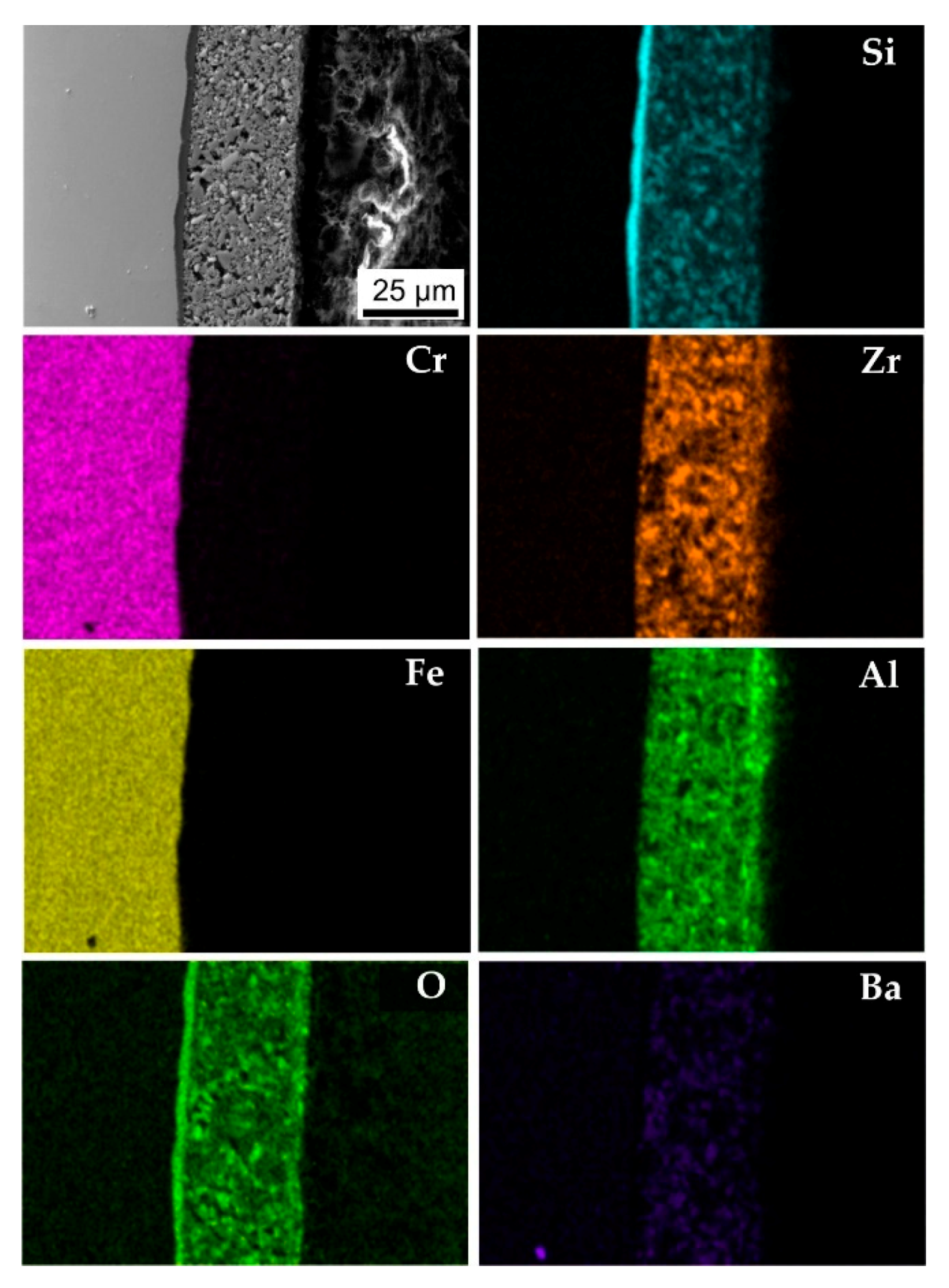

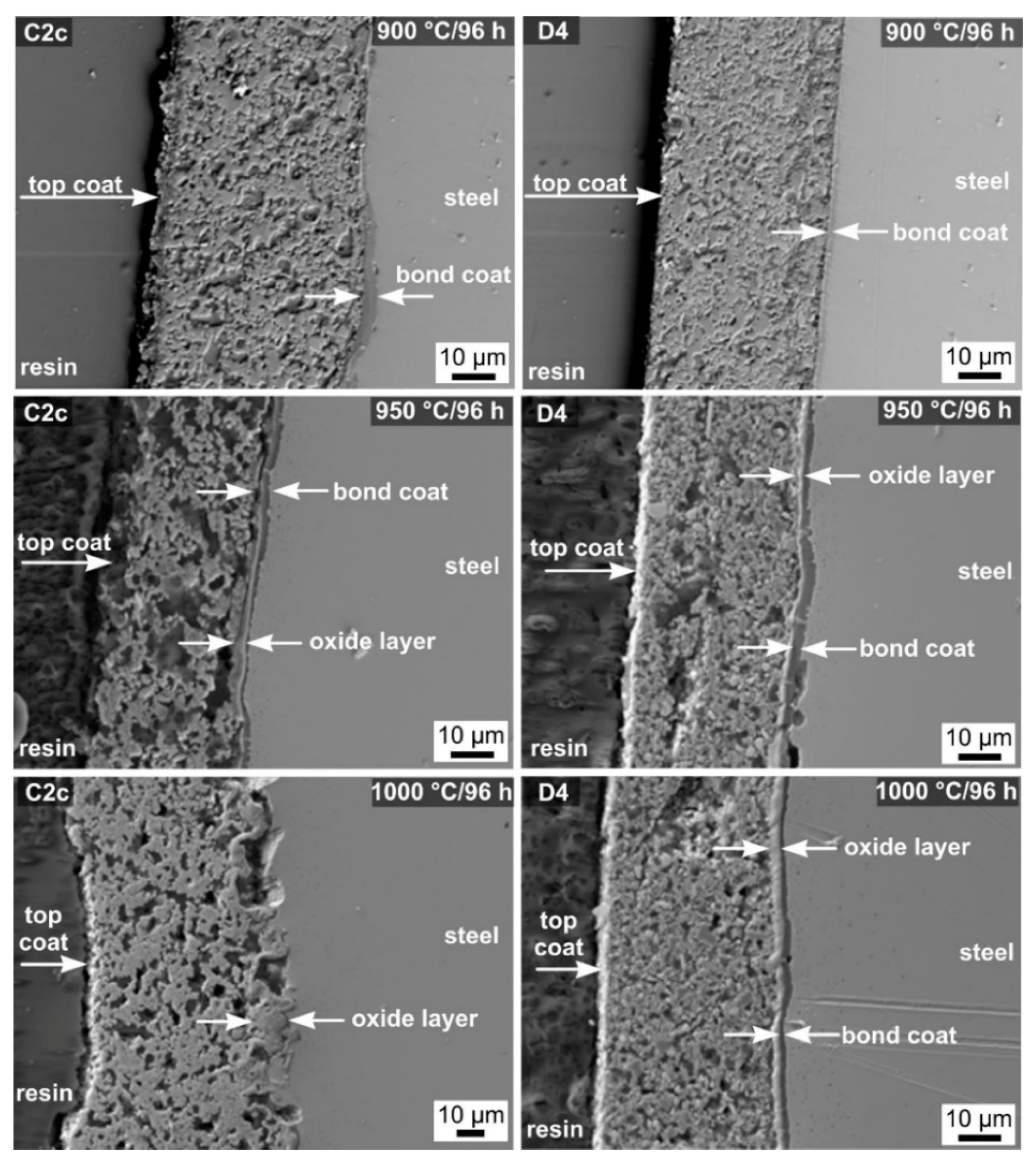

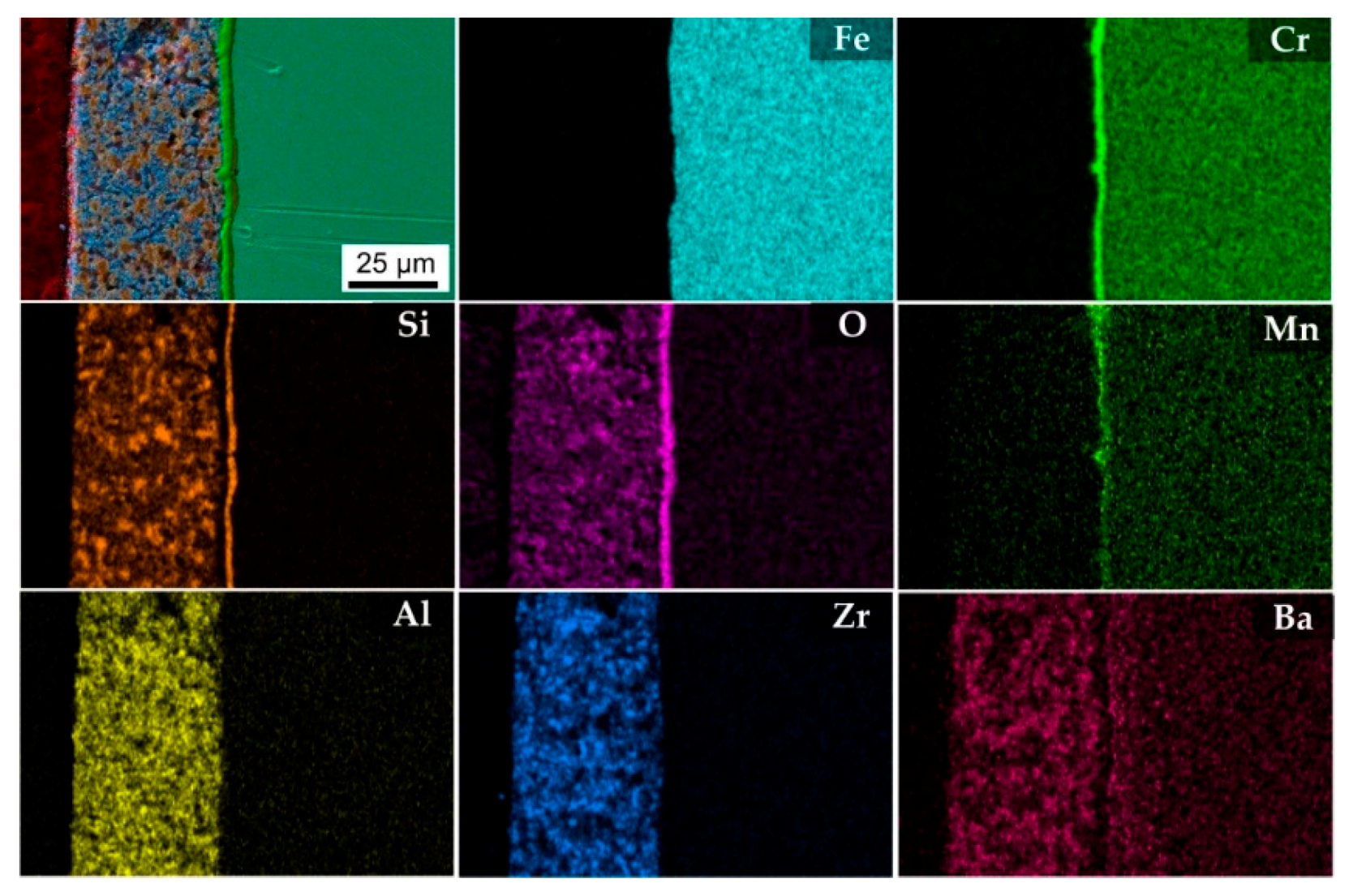

3.4. SEM Investigation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Günthner, M.; Kraus, T.; Dierdorf, A.; Decker, D.; Krenkel, W.; Motz, G. Advanced coatings on the basis of Si(C)N precursors for protection of steel against oxidation. J. Eur. Ceram. Soc. 2009, 29, 2061–2068. [Google Scholar] [CrossRef]

- Probst, D.; Hoche, H.; Zhou, Y.; Hauser, R.; Stelzner, T.; Scheerer, H.; Broszeit, E.; Berger, C.; Riedel, R.; Stafast, H.; et al. Development of PE-CVD Si/C/N:H films for tribological and corrosive complex-load conditions. Surf. Coat. Technol. 2005, 200, 355–359. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Alizadeh, Z.; Todi, R.M.; Desai, V.H. Investigations on hardness of rf sputter deposited SiCN thin films. Mater. Sci. Eng. 2004, 368, 103–108. [Google Scholar] [CrossRef]

- Sarmento, V.H.V.; Schiavetto, M.G.; Hammer, P.; Benedetti, A.V.; Fugivara, C.S.; Suegama, P.H.; Pulcinelli, S.H.; Santilli, C.V. Corrosion protection of stainless steel by polysiloxane hybrid coatings prepared using the sol–gel process. Surf. Coat. Technol. 2010, 204, 2689–2701. [Google Scholar] [CrossRef]

- Chou, T.P.; Chandrasekaran, C. Sol-Gel-Derived Hybrid Coatings for Corrosion Protection. J. Sol-Gel Sci. Technol. 2003, 204, 321–327. [Google Scholar] [CrossRef]

- Mera, G.; Gallei, M.; Bernard, S.; Ionescu, E. Ceramic Nanocomposites from Tailor-Made. Nanomaterials 2015, 5, 468–540. [Google Scholar] [CrossRef] [PubMed]

- Torrey, J.D.; Bordia, R.K. Processing of polymer-derived ceramic composite coatings on steel. J. Am. Ceram. Soc. 2008, 91, 41–45. [Google Scholar] [CrossRef]

- Colombo, P.; Paulson, T.E.; Pantano, C.G. Synthesis of Silicon Carbide Thin Films with Polycarbosilane (PCS). J. Am. Ceram. Soc. 2005, 40, 2333–2340. [Google Scholar] [CrossRef]

- Wang, K.; Günthner, M.; Motz, G.; Flinn, B.D.; Bordia, R.K. Control of surface energy of silicon oxynitride films. Langmuir 2013, 29, 2889–2896. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Mera, G.; Riedel, R.; Soraru, G.D. Polymer-derived ceramics: 40 Years of research and innovation in advanced ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Greil, P. Polymer Derived Engineering Ceramics. Adv. Eng. Mater. 2000, 2, 339–348. [Google Scholar] [CrossRef]

- Goerke, O.; Feike, E.; Heine, T.; Trampert, A.; Schubert, H. Ceramic coatings processed by spraying of siloxane precursors (polymer-spraying). J. Eur. Ceram. Soc. 2004, 24, 2141–2147. [Google Scholar] [CrossRef]

- Konegger, T.; Tsai, C.; Bordia, R.K. Preparation of Polymer-Derived Ceramic Coatings by Dip-Coating Preparation of polymer-derived ceramic coatings by dip-coating. Mater. Sci. Forum 2015, 825–826, 645–652. [Google Scholar] [CrossRef]

- Barroso, G.S.; Krenkel, W.; Motz, G. Low thermal conductivity coating system for application up to 1000 °C by simple PDC processing with active and passive fillers. J. Eur. Ceram. Soc. 2015, 35, 3339–3348. [Google Scholar] [CrossRef]

- Hotza, D.; Geffroy, P.M. Tape casting of preceramic polymers toward advanced ceramics: A review. Int. J. Ceram. Eng. Sci. 2019, 1, 21–41. [Google Scholar] [CrossRef]

- Pscherer, M.; Gunthner, M.; Kaufmann, C.A.; Rahm, A.; Motz, G. Thin-film silazane/alumina high emissivity double layer coatings for flexible Cu(In,Ga)Se2 solar cells. Sol. Energy Mater. Sol. Cells 2015, 132, 296–302. [Google Scholar] [CrossRef]

- Morlier, A.; Cros, S.; Garandet, J.P.; Alberola, N. Thin gas-barrier silica layers from perhydropolysilazane obtained through low temperature curings: A comparative study. Thin Solid Film. 2012, 524, 62–66. [Google Scholar] [CrossRef]

- Petríková, I.; Parchovianský, M.; Švančárek, P.; Lenz-Leite, M.; Motz, G.; Galusek, D. Passive filler loaded polysilazane-derived glass / ceramic coating system applied to AISI 441 stainless steel, part 1: Processing and characterization. Int. J. Appl. Ceram. Technol. 2020, 17, 998–1009. [Google Scholar] [CrossRef]

- Torrey, J.D.; Bordia, R.K. Mechanical properties of polymer-derived ceramic composite coatings on steel. J. Eur. Ceram. Soc. 2008, 28, 253–257. [Google Scholar] [CrossRef]

- Mori, H.; Mase, S.; Yoshimura, N.; Hotta, T.; Ayama, K.; Tsubaki, J.I. Fabrication of supported Si3N4 membranes using the pyrolysis of liquid polysilazane precursor. J. Membr. Sci. 1998, 147, 23–33. [Google Scholar] [CrossRef]

- Flores, B.O.; Bordia, R.K.; Nestler, D.; Krenkel, W. Ceramic Fibers Based on SiC and SiCN Systems: Current Research, Development, and Commercial Status **. Adv. Eng. Mater. 2014, 16, 621–636. [Google Scholar] [CrossRef]

- Günthner, M.; Wang, K.; Bordia, R.K.; Motz, G. Conversion behaviour and resulting mechanical properties of polysilazane-based coatings. J. Eur. Ceram. Soc. 2012, 32, 1883–1892. [Google Scholar] [CrossRef]

- Greil, P. Active Filler Controlled Pyrolysis of Preceramic Polymers. J. Am. Ceram. Soc. 1995, 78, 835–848. [Google Scholar] [CrossRef]

- Wang, K.; Günthner, M.; Motz, G.; Bordia, R.K. High performance environmental barrier coatings, Part II: Active filler loaded SiOC system for superalloys. J. Eur. Ceram. Soc. 2011, 31, 3011–3020. [Google Scholar] [CrossRef]

- Wang, K.; Unger, J.; Torrey, J.D.; Flinn, B.D.; Bordia, R.K. Corrosion resistant polymer derived ceramic composite environmental barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 3597–3606. [Google Scholar] [CrossRef]

- Günthner, M.; Kraus, T.; Krenkel, W.; Motz, G.; Dierdorf, A.; Decker, D. Particle-Filled PHPS silazane-based coatings on steel. Int. J. Appl. Ceram. Technol. 2009, 6, 373–380. [Google Scholar] [CrossRef]

- Günthner, M.; Schütz, A.; Glatzel, U.; Wang, K.; Bordia, R.K.; Greißl, O.; Krenkel, W.; Motz, G. High performance environmental barrier coatings, Part I: Passive filler loaded SiCN system for steel. J. Eur. Ceram. Soc. 2011, 31, 3003–3010. [Google Scholar] [CrossRef]

- Labrousse, M.; Nanot, M.; Boch, P.; Chassagneux, E. Ex-polymer SiC coatings with Al2O3 particulates as filler materials. Ceram. Int. 1993, 19, 259–267. [Google Scholar] [CrossRef]

- Lenz Leite, M.; Barroso, G.; Parchovianský, M.; Galusek, D.; Ionescu, E.; Krenkel, W.; Motz, G. Synthesis and characterization of yttrium and ytterbium silicates from their oxides and an oligosilazane by the PDC route for coating applications to protect Si3N4 in hot gas environments. J. Eur. Ceram. Soc. 2017, 37, 5177–5191. [Google Scholar] [CrossRef]

- Parchovianský, M.; Petríková, I.; Barroso, G.S.; Galuskova, D.; Motz, G.; Galusek, D. Corrosion and oxidation behavior of polymer derived ceramic coatings with passive glass fillers on AISI 441. Ceram. Silik. 2018, 62, 146–157. [Google Scholar] [CrossRef]

- Smokovych, I.; Krüger, M.; Sche, M. Polymer derived ceramic materials from Si, B and MoSiB fi ller-loaded perhydropolysilazane precursor for oxidation protection. J. Eur. Ceram. Soc. 2019, 39, 3634–3642. [Google Scholar] [CrossRef]

- Parchovianský, M.; Petríková, I.; Švančárek, P.; Lenz-Leite, M.; Motz, G.; Galusek, D. Passive filler loaded polysilazane-derived glass / ceramic coating system applied to AISI 441 stainless steel, part 2: Oxidation behavior in synthetic air. Int. J. Appl. Ceram. Technol. 2020, 17, 1675–1687. [Google Scholar] [CrossRef]

- Yang, Z.; Xia, G.G.; Wang, C.M.; Nie, Z.; Templeton, J.; Stevenson, J.W.; Singh, P. Investigation of iron-chromium-niobium-titanium ferritic stainless steel for solid oxide fuel cell interconnect applications. J. Power Sources 2008, 183, 660–667. [Google Scholar] [CrossRef]

- Ebrahimifar, H.; Ebrahimifar, A. Investigation of the oxidation behavior of Mn-coated AISI 441 steel for SOFCs interconnect application. J. Phys. Chem. Electrochem. 2012, 1, 1–4. [Google Scholar]

- Opila, E.J.; Myers, D.L.; Jacobson, N.S.; Nielsen, I.M.B.; Johnson, D.F.; Olminsky, J.K.; Allendorf, M.D. Theoretical and Experimental Investigation of the Thermochemistry of CrO2(OH)2 (g). J. Phys. Chem. A 2007, 2, 1971–1980. [Google Scholar] [CrossRef]

- Yamauchi, A.; Kurokawa, K.; Takahashi, H. Evaporation of Cr2O3 in Atmospheres containing H2O. Oxid. Met. 2003, 59, 517–527. [Google Scholar] [CrossRef]

- Cheng, X.; Jiang, Z.; Wei, D.; Zhao, J.; Monaghan, B.J.; Longbottom, R.J.; Jiang, L. Characteristics of oxide scale formed on ferritic stainless steels in simulated reheating atmosphere. Surf. Coat. Technol. 2014, 258, 257–267. [Google Scholar] [CrossRef]

- Opila, E.J.; Jacobson, N.S.; Myers, D.L.; Copland, E.H.; Total, M. Predicting Oxide Stability in High-Temperature Water Vapor. Jom 2006, 58, 22–28. [Google Scholar] [CrossRef]

- Nakagiri, T.; Kurokawa, K. Evaporation Behavior of SiO2 in N2-O2-H2O Atmospheres. Mater. Trans. 2004, 45, 334–337. [Google Scholar] [CrossRef]

| Compositions | Durazane1800 | YSZ | Glass G018-281 | AYZ | CTE |

|---|---|---|---|---|---|

| C2c | 30 | 35 | 35 | - | 10.1 |

| D4 | 30 | 17.5 | 35 | 17.5 | 9.4 |

| Passive Fillers | d50 (µm) | ρ (g/cm3) | CTE (10−6/K) |

|---|---|---|---|

| 8YSZ | 0.5 | 6.1 | 11.5 |

| AYZ | 1–10 | 4.6 | 8.6 |

| Glass G018-281 | 0.5–5 | 2.7 | 12.1 |

| Synthetic Air | Water Vapor | ||||||

|---|---|---|---|---|---|---|---|

| Composition | 900 °C | 950 °C | 1000 °C | 900 °C | 950 °C | 1000 °C | |

| AISI 441 | 24 h | 0.21 | 0.44 | 0.72 | 0.21 | 0.38 | 0.70 |

| 96 h | 0.45 | 0.77 | 1.21 | 0.48 | 0.80 | 15.46 | |

| C2c | 24 h | −0.11 | −1.33 | −4.95 | −0.24 | −0.20 | −0.13 |

| 96 h | −0.14 | −5.06 | −5.48 | −0.1 | 0.12 | 13.33 | |

| D4 | 24 h | −0.07 | −0.03 | 0.03 | −0.11 | −0.14 | −0.01 |

| 96 h | 0 | 0.15 | 0.27 | −0.05 | 0 | 0.56 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parchovianský, M.; Parchovianská, I.; Švančárek, P.; Medveď, D.; Lenz-Leite, M.; Motz, G.; Galusek, D. High-Temperature Oxidation Resistance of PDC Coatings in Synthetic Air and Water Vapor Atmospheres. Molecules 2021, 26, 2388. https://doi.org/10.3390/molecules26082388

Parchovianský M, Parchovianská I, Švančárek P, Medveď D, Lenz-Leite M, Motz G, Galusek D. High-Temperature Oxidation Resistance of PDC Coatings in Synthetic Air and Water Vapor Atmospheres. Molecules. 2021; 26(8):2388. https://doi.org/10.3390/molecules26082388

Chicago/Turabian StyleParchovianský, Milan, Ivana Parchovianská, Peter Švančárek, David Medveď, Mateus Lenz-Leite, Günter Motz, and Dušan Galusek. 2021. "High-Temperature Oxidation Resistance of PDC Coatings in Synthetic Air and Water Vapor Atmospheres" Molecules 26, no. 8: 2388. https://doi.org/10.3390/molecules26082388

APA StyleParchovianský, M., Parchovianská, I., Švančárek, P., Medveď, D., Lenz-Leite, M., Motz, G., & Galusek, D. (2021). High-Temperature Oxidation Resistance of PDC Coatings in Synthetic Air and Water Vapor Atmospheres. Molecules, 26(8), 2388. https://doi.org/10.3390/molecules26082388