Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Mesoporous SiO2 Nanoparticles

2.3. Synthesis of Aminated Mesoporous SiO2 Nanoparticles

2.4. Preparation of Aminated Mesoporous SiO2 Nanoparticles Loaded with Inactivated Newcastle Disease Virus

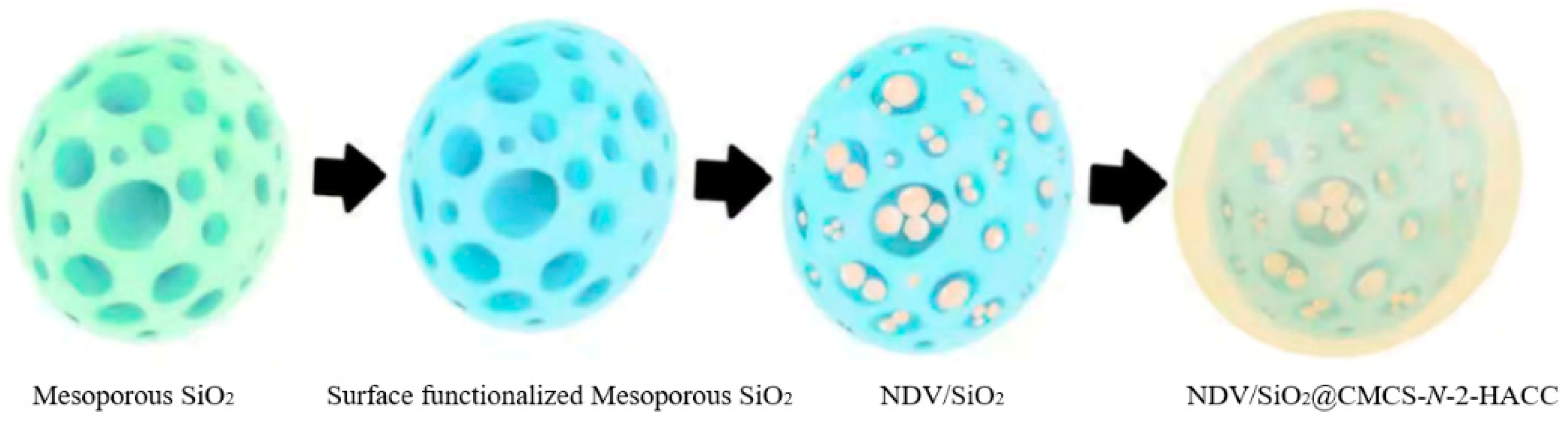

2.5. Synthesis of NDV/SiO2@CMCS-N-2-HACC

2.6. Analysis of Physical and Chemical Properties of the SiO2@CMCS-N-2-HACC Nanoparticles

2.7. Cytotoxicity of the NDV/SiO2@CMCS-N-2-HACC

2.8. Integrity Assay of NDV Encapsulated in the SiO2@CMCS-N-2-HACC Nanoparticles

2.9. Stability of the SiO2@CMCS-N-2-HACC Nanoparticles and SiO2 Nanoparticles Coated Antigen

2.9.1. Determination of Acid Resistance

2.9.2. Determination of Enteric Solubility

2.9.3. Determination of Bile Salt Tolerance

2.9.4. Influence of pH and Ion Concentration on Stability

2.10. In Vitro Release

3. Results

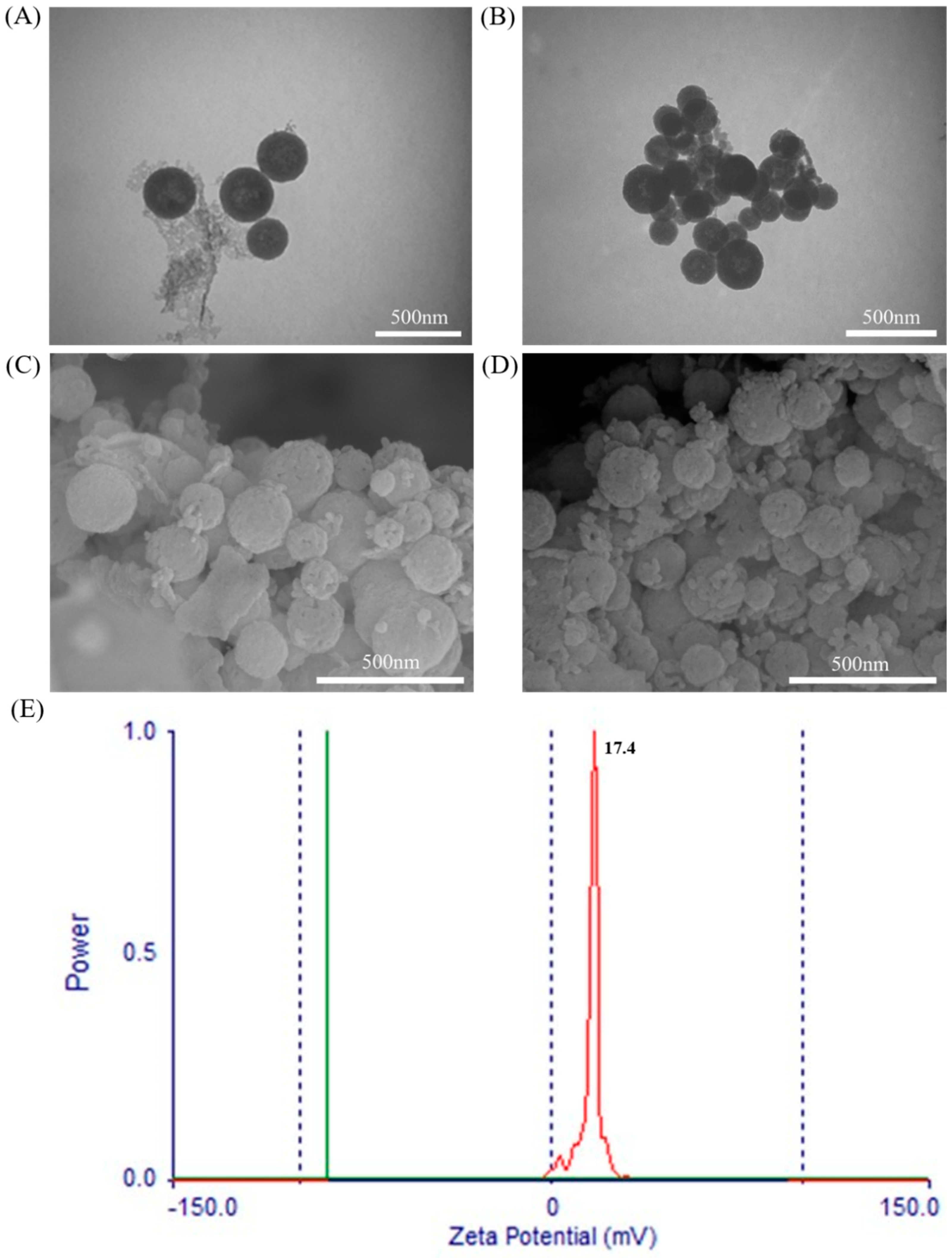

3.1. Characterization of the Mesoporous SiO2 Nanoparticles

3.2. Characterization of the Aminated Mesoporous SiO2 Nanoparticles

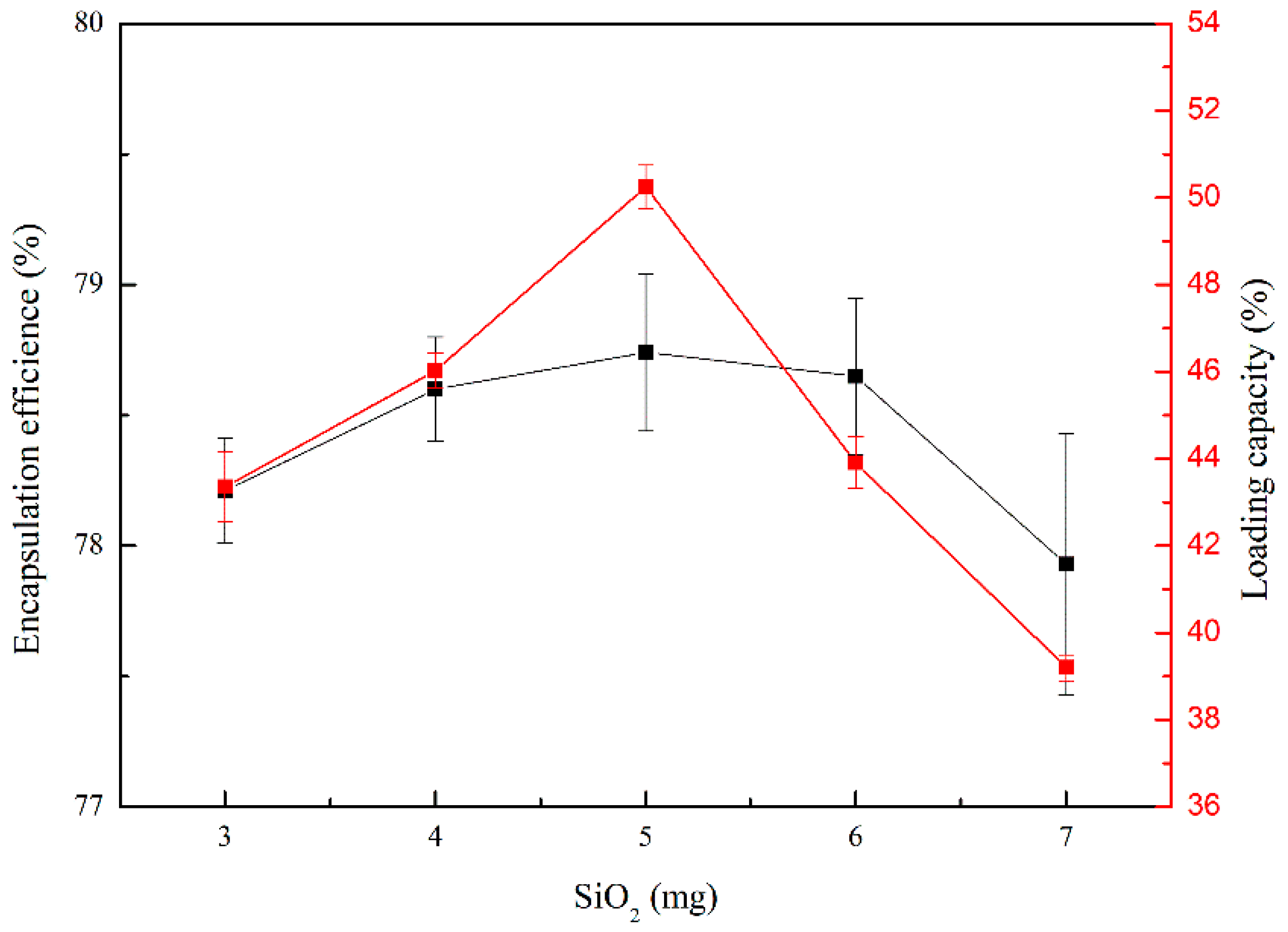

3.3. Characterization of the NDV/SiO2 Nanoparticles

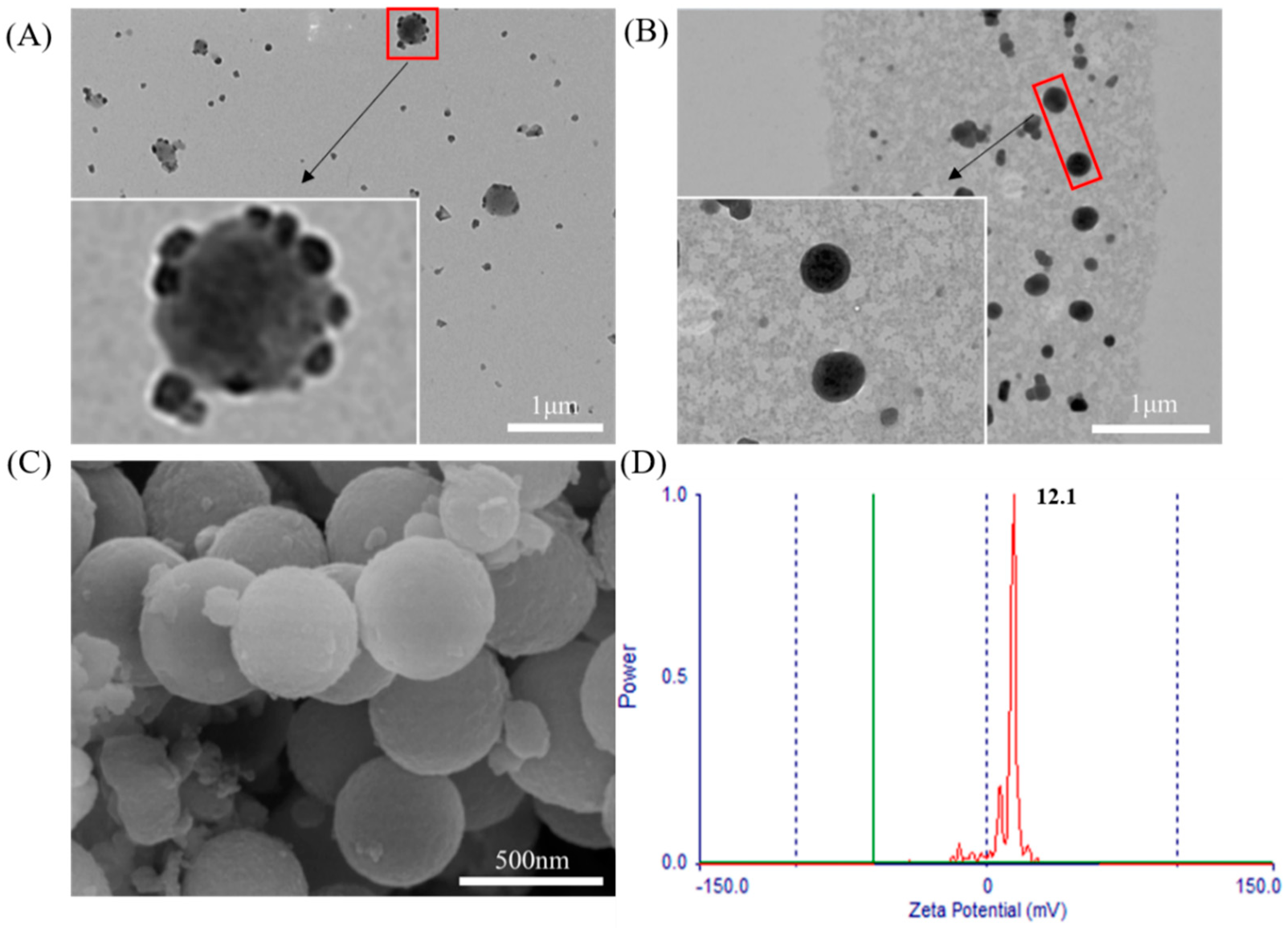

3.4. Physiochemical Characteristics of the NDV/SiO2@CMCS-N-2-HACC

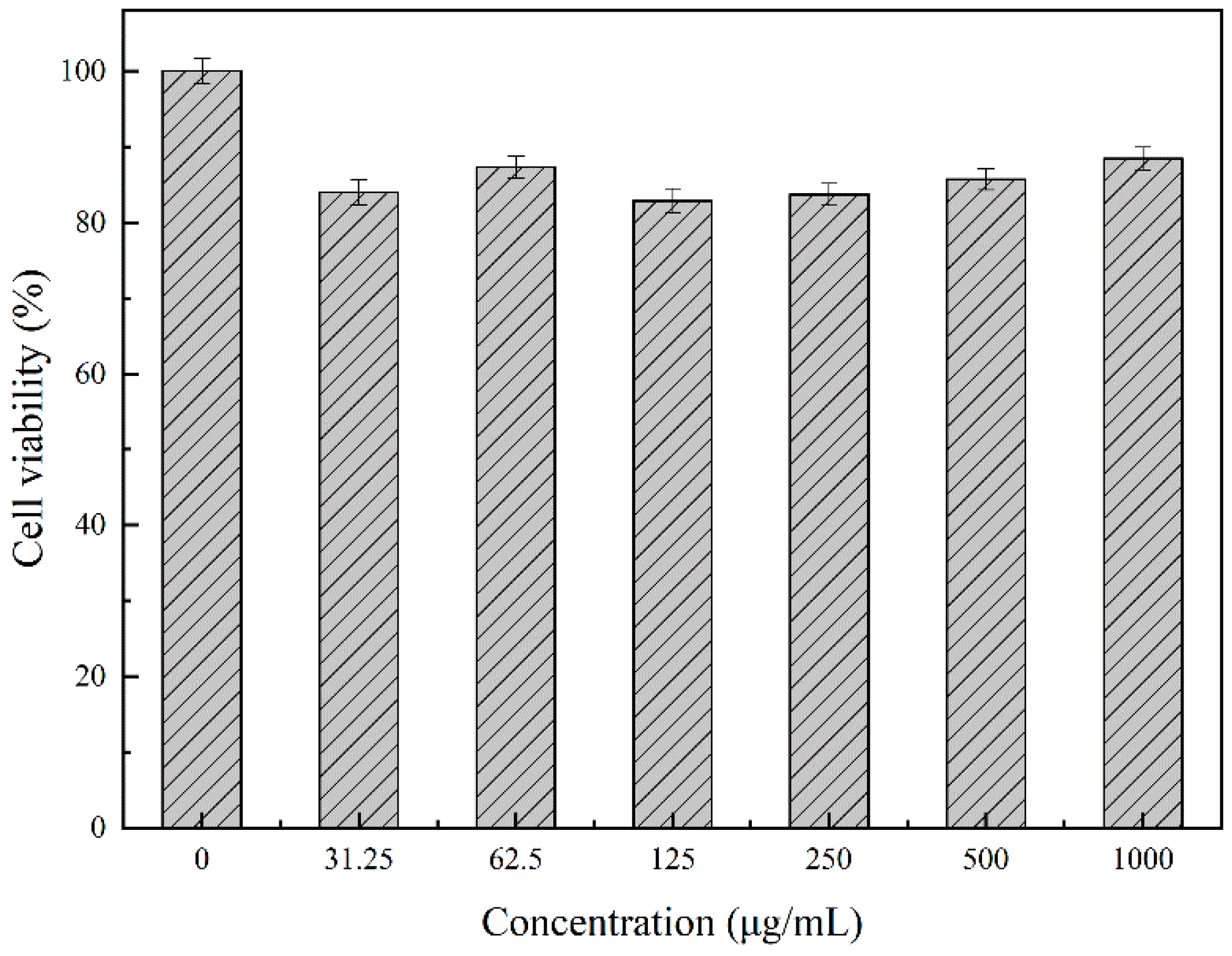

3.5. Cytotoxicity of the NDV/SiO2@CMCS-N-2-HACC

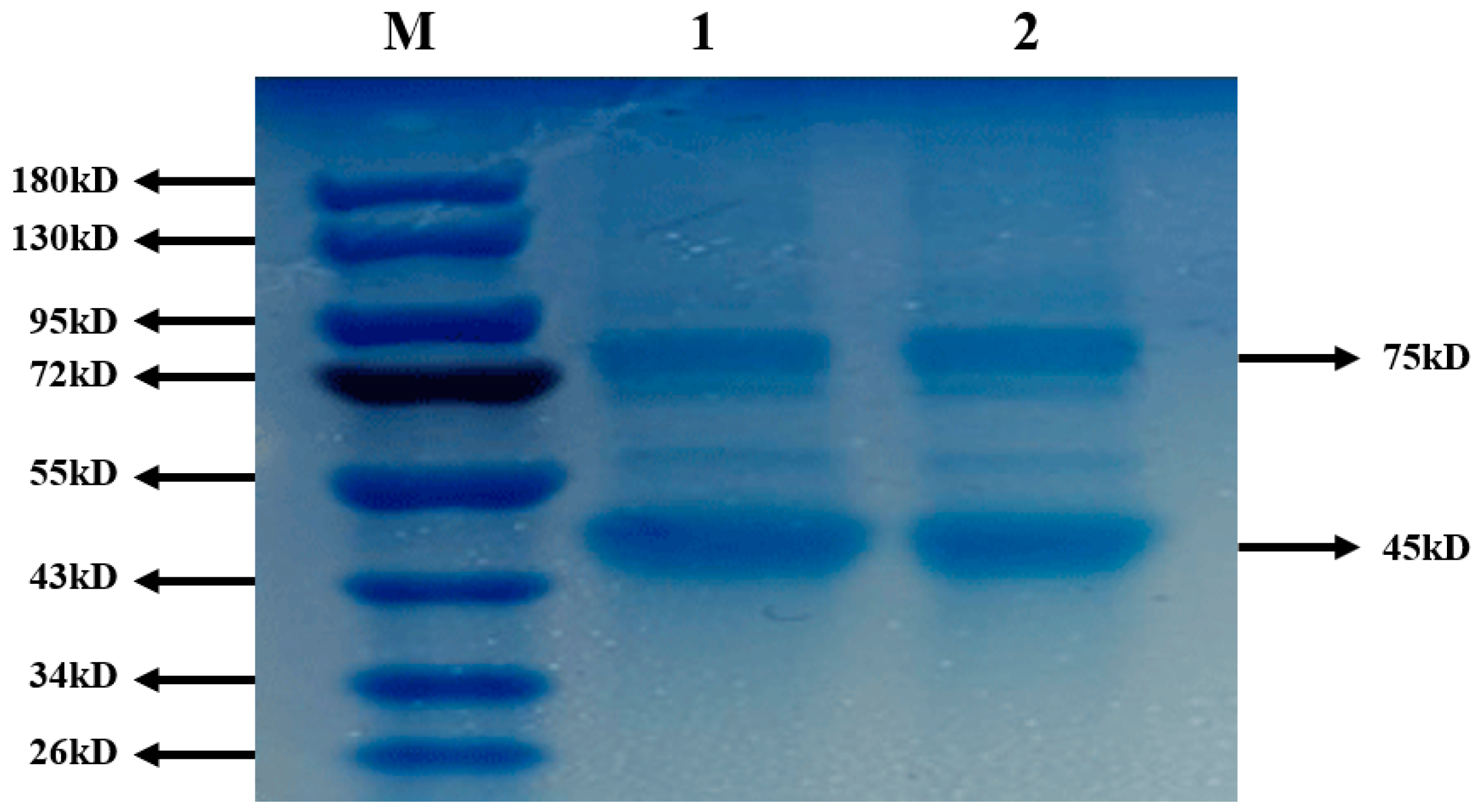

3.6. Integrity of NDV in the SiO2@CMCS-N-2-HACC

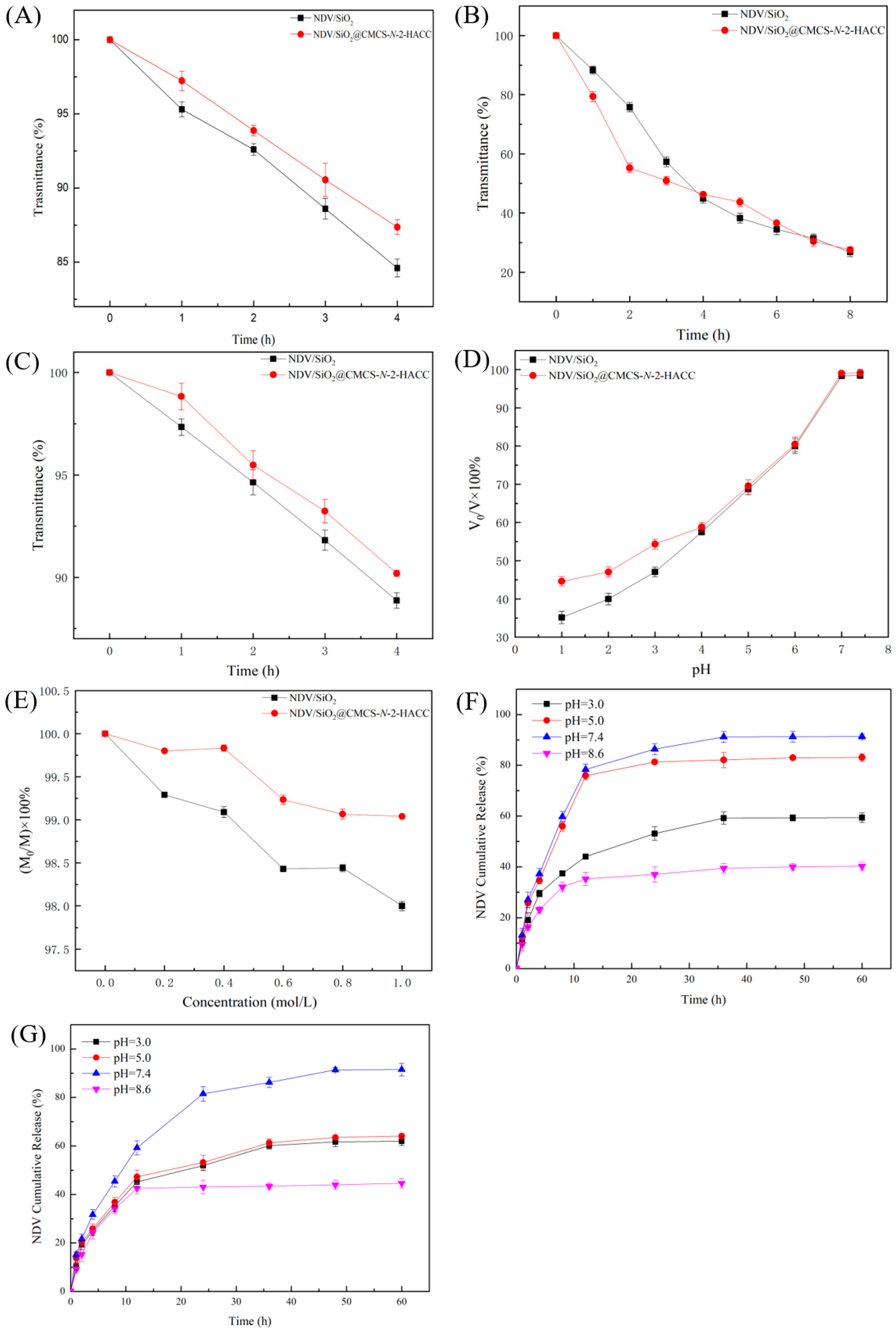

3.7. Stability of the SiO2@CMCS-N-2-HACC Nanoparticles and SiO2 Nanoparticles Coated Antigen

3.8. Influence of pH and Ion Concentration on the Stability of SiO2@CMCS-N-2-HACC Nanoparticles and SiO2 Nanoparticles Coated Antigen

3.9. In Vitro Release of the SiO2@CMCS-N-2-HACC Nanoparticles and SiO2 Nanoparticles Coated Antigen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Chuan, D.; Jin, T.; Fan, R.; Zhou, L.; Guo, G. Chitosan for gene delivery: Methods for improvement and applications. Adv. Colloid Interface Sci. 2019, 268, 25–38. [Google Scholar] [CrossRef]

- Javan, B.; Atyabi, F.; Shahbazi, M. Hypoxia-inducible bidirectional shRNA expression vector delivery using PEI/chitosan-TBA copolymers for colorectal Cancer gene therapy. Life Sci. 2018, 202, 140–151. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.; Hu, Y.; Meng, T.; Tan, Y.; Zhan, M.; Dai, S.; Yusn, H.; Hu, F. Redox-responsive polymer inhibits macrophages uptake for effective intracellular gene delivery and enhanced cancer therapy. Colloids Surf. B Biointerfaces 2019, 175, 392–402. [Google Scholar] [CrossRef] [PubMed]

- Tomer, V.K.; Devi, S.; Malik, R.; Duhan, S. Mesoporous Materials and Their Nanocomposites. Nanomater. Nanocompos. 2016, 223–254. [Google Scholar] [CrossRef]

- Wang, Z.; Mandal, M.; Landskro, K.; Mayanovic, R.A.; Kizzire, D.G.; Dey, S.; Sakidga, R.; Benamara, M. Studies of the mechanical and extreme hydrothermal properties of periodic mesoporous silica and aluminosilica materials. Microporous Mesoporous Mater. 2017, 252, 69–78. [Google Scholar]

- Mohamed Isa, E.D.; Mahmud, I.S.; Ahmad, H.; Abdul-Rahman, M.B. Dependence of mesoporous silica properties on its template. Ceram. Int. 2019, 45, 12149–12153. [Google Scholar] [CrossRef]

- Shin, S.; Kim, H.; Kim, M.; Lee, J.; Park, H.G.; Kim, J. Crowding and confinement effects on enzyme stability in mesoporous silicas. Int. J. Biol. Macromol. 2020, 144, 118–126. [Google Scholar] [CrossRef]

- Borisov, K.M.; Bokova, E.S.; Kalinina, A.A.; Svidchenko, E.A.; Muzafarov, A.M. Formation of hollow silica spheres from molecular silica sols. Mendeleev Commun. 2020, 30, 809–811. [Google Scholar] [CrossRef]

- Teng, Y.; Du, Y.; Shi, J.; Pong, P.W.T. Magnetic iron oxide nanoparticle-hollow mesoporous silica Spheres: Fabrication and potential application in drug delivery. Curr. Appl. Phys. 2020, 20, 320–325. [Google Scholar] [CrossRef]

- Wu, H.; Wang, X.; Liang, H.; Zheng, J.; Huang, S.; Zhang, D. Enhanced efficacy of propranolol therapy for infantile hemangiomas based on a mesoporous silica nanoplatform through mediating autophagy dysfunction. Acta Biomater. 2020, 107, 272–285. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Jie, Z.; Huang, Z. Renal interstitial fibrosis induced by high-dose mesoporous silica nanoparticles via the NF-κB signaling pathway. Int. J. Nanomed. 2015, 10, 1–22. [Google Scholar] [CrossRef]

- Park, H.J.; Sohn, J.H.; Kim, Y.J.; Park, Y.H.; Han, H.; Park, K.H.; Lee, K.; Choi, H.; Um, K.; Choi, I.H. Acute exposure to silica nanoparticles aggravate airway inflammation: Different effects according to surface characteristics. Exp. Mol. Med. 2015, 47, 173. [Google Scholar] [CrossRef]

- Talavera-Pech, W.A.; Esparza-Ruiz, A.; Quintana-Owen, P.; Vilchis-Nestor, A.R.; Carrera-Figueiras, C.; Avila-Ortega, A. Effects of different amounts of APTES on physicochemical and structural properties of amino-functionalized MCM-41-MSNs. J. Sol-Gel Sci. Technol. 2016, 80, 1–12. [Google Scholar] [CrossRef]

- Gao, J.; Wu, S.; Tan, F.; Tian, H.; Liu, J.; Lu, G.Q. Nanoengineering of amino-functionalized mesoporous silica nanospheres as nanoreactors. Prog. Nat. Sci. Mater. 2018, 28, 242–245. [Google Scholar] [CrossRef]

- Hikosaka, R.; Nagata, F.; Tomita, M.; Kato, K. Adsorption and desorption characteristics of DNA onto the surface of amino functional mesoporous silica with various particle morphologies. Colloids Surf. B 2016, 140, 262–268. [Google Scholar] [CrossRef]

- Martín, A.; Morales, V.; Ortiz-Bustos, J.; Perez-Garnes, M.; Bautista, F.; Garcia-Muoz, R.A.; Sanz, R. Modelling the adsorption and controlled release of drugs from the pure and amino surface-functionalized mesoporous silica hosts. Microporous Mesoporous Mater. 2018, 262, 23–34. [Google Scholar] [CrossRef]

- Zhuang, W.; Zhang, Y.; He, L.; An, R.; Lu, X. Facile synthesis of amino-functionalized mesoporous TiO2 microparticles for adenosine deaminase immobilization. Microporous Mesoporous Mater. 2016, 239, 158–166. [Google Scholar] [CrossRef]

- Stanzione, M.; Gargiulo, N.; Caputo, D.; Liguori, B.; Cerruti, P.; Amendola, E.; Lavorgna, M.; Buonocore, G.G. Peculiarities of vanillin release from amino-functionalized mesoporous silica embedded into biodegradable composites. Eur. Polym. J. 2017, 89, 88–100. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Fan, N.; Li, J.; Zhang, H.; Shang, L.; He, Z.; Sun, J. Amino functionalized chiral mesoporous silica nanoparticles for improved loading and release of poorly water-soluble drug. Asian J. Pharm. 2019, 14, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wu, W.; Wei, J.; Wang, S.; Yu, Y. Encapsulating quantum dots with amino functionalized mesoporous hollow silica microspheres for the sensitive analysis formaldehyde in seafood. Anal. Methods 2016, 8, 4101–4107. [Google Scholar] [CrossRef]

- Gao, Y.; Zhong, S.; Xu, L.; He, S.; Cui, X. Mesoporous silica nanoparticles capped with graphene quantum dots as multifunctional drug carriers for photo-thermal and redox-responsive release. Microporous Mesoporous Mater. 2019, 278, 130–137. [Google Scholar] [CrossRef]

- Geng, H.; Zhao, Y.; Liu, J. Hollow mesoporous silica as a high drug loading carrier for regulation insoluble drug release. Int. J. Pharm. 2016, 510, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Hanafi-Bojd, M.Y.; Jaafari, M.; Ramezanian, N.; Xue, M.; Amin, M.; Shahtahmassebi, N.; Malaekeh-Nikouei, B. Surface functionalized mesoporous silica nanoparticles as an effective carrier for epirubicin delivery to cancer cells. Eur. J. Pharm. Biopharm. 2015, 89, 248–258. [Google Scholar] [CrossRef]

- Niu, B.; Zhou, Y.; Wen, T.; Qian, G.; Singh, V.; Pan, X.C. Proper functional modification and optimized adsorption conditions improved the DNA loading capacity of mesoporous silica nanoparticles. Colloid Surface A 2018, 548, 98–107. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, L.; Sun, Y. Nanoassembles constructed from mesoporous silica nanoparticles and surface-coated multilayer polyelectrolytes for controlled drug delivery. Microporous Mesoporous Mater. 2014, 185, 245–253. [Google Scholar] [CrossRef]

- Rasekh, B. One-step separation of the recombinant protein by using the amine-functionalized magnetic mesoporous silica nanoparticles; an efficient and facile approach. Int. J. Biol. Macromol. 2019, 135, 600–608. [Google Scholar]

- Iraji, S.; Ganji, F.; Rashidi, L. Surface modified mesoporous silica nanoparticles as sustained-release gallic acid nano-carriers. J. Drug Deliv. Sci. Technol. 2018, 47, 468–476. [Google Scholar] [CrossRef]

- Nguyen, T.N.T.; Nguyen-Tran, D.H.; Bach, L.G.; Du Truong, T.H.; Le, N.T.T.; Nguyen, D.H. Surface PEGylation of hollow mesoporous silica nanoparticles via aminated intermediate. Prog. Nat. Sci. 2019, 29, 612–616. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, S.; Liu, Y.; Lu, Z.; Dong, L. One-step preparation of porous aminated-silica nanoparticles and their antibacterial drug delivery applications. J. Mater. Sci. Technol. 2020, 50, 139–146. [Google Scholar] [CrossRef]

- Yang, B.; Chen, Y.; Shi, J. Mesoporous silica/organosilica nanoparticles: Synthesis, biological effect and biomedical application. Mater. Sci. Eng. R Rep. 2019, 137, 66–105. [Google Scholar] [CrossRef]

- Yang, X.; Wen, Y.; Wu, A.; Xu, M.; Amano, T.; Zheng, L.; Zhao, L. Polyglycerol mediated covalent construction of magnetic mesoporous silica nanohybrid with aqueous dispersibility for drug delivery. Mater. Sci. Eng. C 2017, 80, 517–525. [Google Scholar] [CrossRef]

- Zaharudin, N.; Mohamed, I.E.; Ahmad, H.; Rahman, M.; Jumbri, K. Functionalized mesoporous silica nanoparticles templated by pyridinium ionic liquid for hydrophilic and hydrophobic drug release application. J. Saudi Chem. Soc. 2020, 24, 289–302. [Google Scholar] [CrossRef]

- Ali, I.; Danish, S.M.; Lone, M.N.; Ali, H.S. Recent advances in mesoporous silica and gold based nanovectors in anticancer drug delivery system. Curr. Org. Chem. 2017, 21, 1–16. [Google Scholar] [CrossRef]

- Li, X.; Wu, M.; Pan, L.; Shi, J. Tumor vascular-targeted co-delivery of anti-angiogenesis and chemotherapeutic agents by mesoporous silica nanoparticle-based drug delivery system for synergetic therapy of tumor. Int. J. Nanomed. 2016, 11, 93–105. [Google Scholar] [CrossRef]

- Cardenas-Garcia, S.; Diel, D.G.; Susta, L.; Lucio-Decanini, E.; Yu, Q.; Brown, C.C.; Miller, P.J.; Afonso, C.L. Development of an improved vaccine evaluation protocol to compare the efficacy of Newcastle disease vaccines. Biologicals 2015, 43, 136–145. [Google Scholar] [CrossRef]

- Kamra, M.; Moitra, P.; Ponnalagu, D.; Karande, A.A.; Bhattacharya, S. New water-soluble oxyamino chitosans as biocompatible vectors for efficacious anticancer therapy via co-delivery of gene and drug. ACS Appl. Mater. Interfaces 2019, 11, 37442–37460. [Google Scholar] [CrossRef] [PubMed]

- Karaman, D.S.; Sarwar, S.; Desai, D.; Oden, M.; Chakrabarti, P.; Rosenholm, J.M.; Chakraborti, S. Shape engineering boosts antibacterial activity of chitosan coated mesoporous silica nanoparticle doped with silver: A mechanistic investigation. J. Mater. Chem. B 2016, 4, 3292–3304. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Choi, E. How can doxorubicin loading orchestrate in vitro degradation behaviors of mesoporous silica nanoparticles in a physiological condition? Langmuir 2017, 20, 4974–4980. [Google Scholar]

- Snoussi, Y.; Bastide, S.; Abderrabba, M.; Chehimi, M.M. Sonochemical synthesis of Fe3O4@NH2-mesoporous silica@Polypyrrole/Pd: A core/double shell nanocomposite for catalytic applications. Ultrason. Sonochem. 2018, 41, 551–561. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Xu, X.; Zhou, B.; Hu, P.; Li, Y.; Liu, C. Formation of enzymatic/redox-switching nanogates on mesoporous silica nanoparticles for anticancer drug delivery. Mater. Sci. Eng. C 2019, 100, 855–861. [Google Scholar] [CrossRef]

- Hu, X.; Wang, Y.; Peng, B. Hitosan-capped mesoporous silica nanoparticles as pH-responsive Nanocarriers for controlled drug release. Chem. Asian J. 2014, 9, 319–327. [Google Scholar] [CrossRef] [PubMed]

- Peruzynska, M.; Szelag, S.; Trzeciak, K.; Peruzynska, M.; Szelag, S.; Trzeciak, K.; Kurzawski, M.; Cendrowski, K.; Barylak, M.; Roginska, D.; et al. In vitro and in vivo evaluation of sandwich-like mesoporous silica nanoflakes as promising anticancer drug delivery system. Int. J. Pharm. 2016, 506, 458–468. [Google Scholar] [CrossRef]

- Zheng, J.; Li, W.; Cao, H.; Zhang, X.; Chen, G.; Wu, H.; Guo, C.; Zhang, Y.; Kang, H.; Wang, Y. Antimicrobial activity and cytotoxicity of N-2-HACC and characterization of nanoparticles with N-2-HACC and CMC as a vaccine carrier. Chem. Eng. J. 2013, 221, 331–341. [Google Scholar]

- Cheng, C.A.; Chen, W.; Zhang, L.; Wu, H.H.; Zink, Z.L. A Responsive Mesoporous Silica Nanoparticle Platform for Magnetic Resonance Imaging-Guided High-Intensity Focused Ultrasound-Stimulated Cargo Delivery with Controllable Location, Time, and Dose. J. Am. Chem. Soc. 2019, 141, 17670–17684. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Chi-An, C.; Jeffrey, I.Z. Spatial, Temporal, and Dose Control of Drug Delivery using Noninvasive Magnetic Stimulation. ACS Nano 2019, 13, 1292–1308. [Google Scholar]

- Chou, C.C.; Chen, W.; Hung, Y.; Mou, C.Y. Molecular Elucidation of Biological Response to Mesoporous Silica Nanoparticles in Vitro and in Vivo. ACS Appl. Mater. Interfaces 2017, 9, 22235–22251. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, W.; Hu, G.; Cui, X.; Sun, D.; Jin, Z.; Zhao, K. Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier. Molecules 2021, 26, 2490. https://doi.org/10.3390/molecules26092490

Li Q, Wang W, Hu G, Cui X, Sun D, Jin Z, Zhao K. Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier. Molecules. 2021; 26(9):2490. https://doi.org/10.3390/molecules26092490

Chicago/Turabian StyleLi, Qi, Wenqian Wang, Gaowei Hu, Xianlan Cui, Dejun Sun, Zheng Jin, and Kai Zhao. 2021. "Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier" Molecules 26, no. 9: 2490. https://doi.org/10.3390/molecules26092490

APA StyleLi, Q., Wang, W., Hu, G., Cui, X., Sun, D., Jin, Z., & Zhao, K. (2021). Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier. Molecules, 26(9), 2490. https://doi.org/10.3390/molecules26092490