Influence of Plant Extract Addition to Marinades on Polycyclic Aromatic Hydrocarbon Formation in Grilled Pork Meat

Abstract

:1. Introduction

2. Materials and Methods

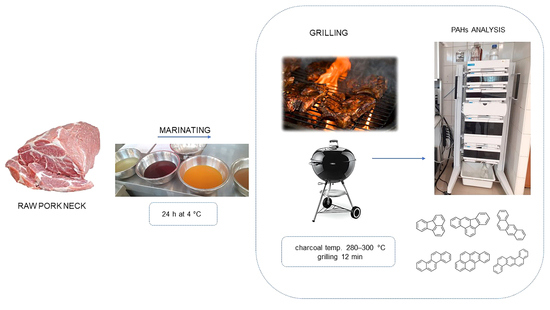

2.1. Sample Preparation and Grilling Procedure

2.2. Chemical Composition Analysis

2.3. pH Measurement

2.4. Colour Measurement

2.5. Texture Measurement

2.6. Determination of the Radical Scavenging of Meat Samples by DPPH Assay

2.7. Determination of the Total Phenolic Content (TPC) in Meat Samples

2.8. Standards and Calibration Solution

2.9. PAH Extraction and Quantification

2.10. Recovery Studies

2.11. Analysis of Volatile Compound Profile

2.12. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition of Grilled Meat

3.2. pH of Marinated Meat

3.3. Colour Measurement

3.4. Texture Measurement

3.5. DPPH Scavenging Activities and TPC of Meat Samples

3.6. Effect of Marinades on PAH Formation

3.7. Volatile Compound Profile of Grilled Meat

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Xie, Y.; Wang, H.; Bai, Y.; Dai, C.; Li, C.; Zhou, G. The influence of natural antioxidants on polycyclic aromatic hydrocarbon formation in charcoal-grilled chicken wings. Food Control 2019, 98, 34–41. [Google Scholar] [CrossRef]

- Park, K.C.; Pyo, H.; Kim, W.; Yoon, K.S. Effects of cooking methods and tea marinades on the formation of benzo [a] pyrene in grilled pork belly (Samgyeopsal). Meat Sci. 2017, 129, 1–8. [Google Scholar] [CrossRef]

- Ge, X.; Zhang, L.; Zhong, H.; Gao, T.; Jiao, Y.; Liu, Y. The effects of various Chinese processing methods on the nutritional and safety properties of four kinds of meats. Innov. Food Sci. Emerg. Technol. 2021, 70, 102674. [Google Scholar] [CrossRef]

- Hamidi, E.N.; Hajeb, P.; Selamat, J.; Razis, A.F.A. Polycyclic aromatic hydrocarbons (PAHs) and their bioaccessibility in meat: A tool for assessing human cancer risk. Asian Pac. J. Cancer Prev. 2016, 17, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Chen, Y.; Feng, Y.; Song, W.; Cao, F.; Zhang, Y.; Chen, J. Different formation mechanisms of PAH during wood and coal combustion under different temperatures. Atmos. Environ. 2020, 222, 117084. [Google Scholar] [CrossRef]

- Reizer, E.; Csizmadia, I.G.; Palotás, Á.B.; Viskolcz, B.; Fiser, B. Formation mechanism of benzo (a) pyrene: One of the most carcinogenic polycyclic aromatic hydrocarbons (PAH). Molecules 2019, 24, 1040. [Google Scholar] [CrossRef] [Green Version]

- Molognoni, L.; Daguer, H.; Motta, G.E.; Merlo, T.C.; Lindner, J.D.D. Interactions of preservatives in meat processing: Formation of carcinogenic compounds. analytical methods. and inhibitory agents. Food Res. Int. 2019, 125, 108608. [Google Scholar] [CrossRef] [PubMed]

- Viegas, O.; Novo, P.; Pinto, E.; Pinho, O.; Ferreira, I.M.P.L.V.O. Effect of charcoal types and grilling conditions on formation of heterocyclic aromatic amines (HAs) and polycyclic aromatic hydrocarbons (PAHs) in grilled muscle foods. Food Chem. Toxicol. 2012, 50, 2128–2134. [Google Scholar] [CrossRef] [PubMed]

- Yebra-Pimentel, I.; Fernández-González, R.; Martínez-Carballo, E.; Simal-Gándara, J. A critical review about the health risk assessment of PAHs and their metabolites in foods. Crit. Rev. Food Sci. Nutr. 2015, 55, 1383–1405. [Google Scholar] [CrossRef]

- Singh, L.; Varshney, J.G.; Agarwal, T. Polycyclic aromatic hydrocarbons’ formation and occurrence in processed food. Food Chem. 2016, 199, 768–781. [Google Scholar] [CrossRef]

- Plaza-Bolaños, P.; Frenich, A.G.; Vidal, J.L.M. Polycyclic aromatic hydrocarbons in food and beverages. Analytical methods and trends. J. Chromatogr. A 2010, 1217, 6303–6326. [Google Scholar] [CrossRef]

- Pluta-Kubica, A.; Filipczak-Fiutak, M.; Domagała, J.; Duda, I.; Migdał, W. Contamination of traditionally smoked cheeses with polycyclic aromatic hydrocarbons and biogenic amines. Food Control 2020, 112, 107115. [Google Scholar] [CrossRef]

- Błaszczyk, E.; Mielżyńska-Švach, D. Polycyclic aromatic hydrocarbons and PAH-related DNA adducts. J. Appl. Genetics 2017, 58, 321–330. [Google Scholar] [CrossRef] [Green Version]

- Lu, F.; Kuhnle, G.K.; Cheng, Q. The effect of common spices and meat type on the formation of heterocyclic amines and polycyclic aromatic hydrocarbons in deep-fried meatballs. Food Control 2018, 92, 399–411. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, H.; Geng, N.; Ren, X.; Zhang, B.; Gong, Y.; Chen, J. A metabolomics strategy to assess the combined toxicity of polycyclic aromatic hydrocarbons (PAHs) and short-chain chlorinated paraffins (SCCPs). Environ. Pollut. 2018, 234, 572–580. [Google Scholar] [CrossRef] [PubMed]

- Zachara, A.; Gałkowska, D.; Juszczak, L. Contamination of smoked meat and fish products from Polish market with polycyclic aromatic hydrocarbons. Food Control 2017, 80, 45–51. [Google Scholar] [CrossRef]

- Onopiuk, A.; Kołodziejczak, K.; Szpicer, A.; Wojtasik-Kalinowska, I.; Wierzbicka, A.; Półtorak, A. Analysis of factors that influence the PAH profile and amount in meat products subjected to thermal processing. Trends Food Sci. Technol. 2021, 115, 366–379. [Google Scholar] [CrossRef]

- Kim, H.J.; Cho, J.; Jang, A. Effect of charcoal type on the formation of polycyclic aromatic hydrocarbons in grilled meats. Food Chem. 2021, 343, 128453. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xie, Y.; Qi, J.; Yu, Y.; Bai, Y.; Dai, C.; Zhou, G. Effect of Tea Marinades on the formation of polycyclic aromatic hydrocarbons in charcoal-grilled chicken wings. Food Control 2018, 93, 325–333. [Google Scholar] [CrossRef]

- Cordeiro, T.; Viegas, O.; Silva, M.; Martins, Z.E.; Fernandes, I.; Ferreira, I.M.L.P.V.O.; Pinho, O.; Mateus, N.; Calhau, C. Inhibitory effect of vinegars on the formation of polycyclic aromatic hydrocarbons in charcoal-grilled pork. Meat Sci. 2020, 176, 108083. [Google Scholar] [CrossRef]

- Viegas, O.; Yebra-Pimentel, I.; Martínez-Carballo, E.; Simal-Gandara, J.; Ferreira, I.M. Effect of beer marinades on formation of polycyclic aromatic hydrocarbons in charcoal-grilled pork. J. Agric. Food Chem. 2014, 62, 2638–2643. [Google Scholar] [CrossRef] [PubMed]

- Eldaly, E.; Hussein, M.; El-Gaml, A.; El-Hefny, D.; Mishref, M. Polycyclic aromatic hydrocarbons (PAHs) in charcoal grilled meat (kebab) and Kofta and the effect of marinating on their existence. Zagazig Vet. J. 2016, 44, 40–47. [Google Scholar] [CrossRef] [Green Version]

- Wongmaneepratip, W.; Vangnai, K. Effects of oil types and pH on carcinogenic polycyclic aromatic hydrocarbons (PAHs) in grilled chicken. Food Control 2017, 79, 119–125. [Google Scholar] [CrossRef]

- Farhadian, A.; Jinap, S.; Faridah, A.; Zaidul, I.S.M. Effects of marinating on the formation of polycyclic aromatic hydrocarbons (benzo [a] pyrene. benzo [b] fluoranthene and fluoranthene) in grilled beef meat. Food Control 2012, 28, 420–425. [Google Scholar] [CrossRef]

- Onopiuk, A.; Półtorak, A.; Wierzbicka, A. The impact of muscle and aging time on meat tenderness in the carcasses of Limousin × Holstein-Friesian crossbred bulls. J. Food Process. Preserv. 2018, 42, e13619. [Google Scholar] [CrossRef]

- Gonzalez-Gonzalez, L.; Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M.; Garcia-Galicia, I.A.; Huerta-Jimenez, M.; Paniwnyk, L. Does ultrasound equally improve the quality of beef? An insight into longissimus lumborum. infraspinatus and cleidooccipitalis. Meat Sci. 2020, 160, 107963. [Google Scholar] [CrossRef] [PubMed]

- Szpicer, A.; Onopiuk, A.; Półtorak, A.; Wierzbicka, A. Influence of oat β-glucan and canola oil addition on the physico-chemical properties of low-fat beef burgers. J. Food Process. Preserv. 2018, 42, e13785. [Google Scholar] [CrossRef]

- Wojtasik-Kalinowska, I.; Onopiuk, A.; Szpicer, A.; Wierzbicka, A.; Półtorak, A. Frozen storage quality and flavor evaluation of ready to eat steamed meat products treated with antioxidants. CyTA J. Food 2021, 19, 152–162. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic and phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–147. [Google Scholar]

- Bogdanović, T.; Pleadin, J.; Petričević, S.; Listeš, E.; Sokolić, D.; Marković, K.; Šimat, V. The occurrence of polycyclic aromatic hydrocarbons in fish and meat products of Croatia and dietary exposure. J. Food Compos. Anal. 2019, 75, 49–60. [Google Scholar] [CrossRef]

- Kafouris, D.; Koukkidou, A.; Christou, E.; Hadjigeorgiou, M.; Yiannopoulos, S. Determination of polycyclic aromatic hydrocarbons in traditionally smoked meat products and charcoal grilled meat in Cyprus. Meat Sci. 2020, 164, 108088. [Google Scholar] [CrossRef]

- Onopiuk, A.; Kołodziejczak, K.; Marcinkowska-Lesiak, M.; Poltorak, A. Determination of polycyclic aromatic hydrocarbons using different extraction methods and HPLC-FLD detection in smoked and grilled meat products. Food Chem. 2022, 373, 131506. [Google Scholar] [CrossRef] [PubMed]

- García-Lomillo, J.; Viegas, O.; Gonzalez-SanJose, M.L.; Ferreira, I.M. Influence of red wine pomace seasoning and high-oxygen atmosphere storage on carcinogens formation in barbecued beef patties. Meat Sci. 2017, 125, 10–15. [Google Scholar] [CrossRef]

- O’Neill, C.M.; Cruz-Romero, M.C.; Duffy, G.; Kerry, J.P. Comparative effect of different cooking methods on the physicochemical and sensory characteristics of high pressure processed marinated pork chops. Innov. Food Sci. Emerg. Technol. 2019, 54, 19–27. [Google Scholar] [CrossRef]

- Mozuriene, E.; Bartkiene, E.; Krungleviciute, V.; Zadeike, D.; Juodeikiene, G.; Damasius, J.; Baltusnikiene, A. Effect of natural marinade based on lactic acid bacteria on pork meat quality parameters and biogenic amine contents. LWT Food Sci. Technol. 2016, 69, 319–326. [Google Scholar] [CrossRef]

- Żochowska-Kujawska, J.; Lachowicz, K.; Sobczak, M. Effects of fibre type and kefir. wine lemon. and pineapple marinades on texture and sensory properties of wild boar and deer longissimus muscle. Meat Sci. 2012, 92, 675–680. [Google Scholar] [CrossRef]

- Vitaglione, P.; Fogliano, V. Use of antioxidants to minimize the human health risk associated to mutagenic/carcinogenic heterocyclic amines in food. J. Chromatogr. B 2004, 802, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Janoszka, B. HPLC-fluorescence analysis of polycyclic aromatic hydrocarbons (PAHs) in pork meat and its gravy fried without additives and in the presence of onion and garlic. Food Chem. 2011, 126, 1344–1353. [Google Scholar] [CrossRef]

| Type of Marinade | Latin Plant Name | Source of Extract/Paste | Sample Code | NaCl Content (%) | Extract/Paste Content (g/kg) |

|---|---|---|---|---|---|

| Pork neck, unmarinated | - | - | CON | 5.0 | 0.0 |

| Marinade with bay leaf extract | Laurus nobilis | Result, Poland | BL | 5.0 | 6.0 |

| Marinade with black pepper extract | Piper nigrum | Result, Poland | BP | 5.0 | 6.0 |

| Marinade with turmeric | Curcuma longa | Result, Poland | TU | 5.0 | 6.0 |

| Marinade with tamarind paste | Tamarindus indica | Suree, Thailand | TA | 5.0 | 80.0 |

| Marinade with jalapeno pepper extract | Capsicum annuum | Result, Poland | JP | 5.0 | 6.0 |

| Marinade with a mixture of all extracts | - | - | MX | 5.0 | a mixture of 100 mL of each marinade |

| Commercial marinade | - | Knorr, Poland | C | - | - |

| Picture |  |  |  |  |  |  |

| Extract | Bay leaf | Black pepper | Tamarind paste | Jalapeno peppers | Turmeric | Comercial seasoning for pork neck |

| Biologically active substances | Cyneol Geraniol | Piperine alkaloid | Tartaric acid | Capsaicin | Curcuminoids | No data |

| Concentration of biologically active substances a | 6 mg/100 g | 42–43% | No data | 6.6 ± 0.3% | 7–10% | No data |

| Chromatographic Conditions | |

|---|---|

| Parameter | Value |

| Analytical column | Agilent ZORBAX Eclipse PAH 4.6 × 150 mm, 3.5 µm |

| Column temperature | 25 °C |

| Gradient | (A) Water, (B) Acetonitrile |

| 0 min, 40% B at 1.3 mL/min | |

| 5 min, 40% B | |

| 20 min, 100% B | |

| 30 min, 100% B | |

| 30.1 min, 40% B | |

| Post time 6 min | |

| Injection volume | 5.0 µL |

| Autosampler temperature | 18 °C |

| Diode array detector | 230 nm, band width 4 nm, reference 400 nm, reference band width 100 nm, 10 Hz |

| Fluorescence detector | Multisignal acquisition, set at λex = 260 nm and λem = 350 nm (FLD A), 330 nm (FLD B), 440 nm (FLD C), 500 nm (FLD D), 18.51 Hz |

| PAH Compound | Linearity r2 | Detection Limits LOD (µg/kg) | Detection Limits LOQ (µg/kg) | Recovery (%) | |

|---|---|---|---|---|---|

| Level I (2.0 µg/kg) | Level II (20.00 µg/kg) | ||||

| Fluorene F | 0.9995 | 0.05 | 0.25 | 82.59 | 83.77 |

| Anthracene ANT | 0.9997 | 0.10 | 0.25 | 86.13 | 87.24 |

| Fluoranthene FL | 0.9998 | 0.10 | 0.25 | 90.39 | 92.38 |

| Benzo[b]fluorene BbF | 0.9995 | 0.05 | 0.25 | 85.73 | 86.26 |

| Benz[a]anthracene BaA | 0.9996 | 0.10 | 0.25 | 90.12 | 90.72 |

| Chrysene CHR | 0.9998 | 0.10 | 0.25 | 97.17 | 98.75 |

| Benzo[a]pyrene BaP | 0.9998 | 0.10 | 0.25 | 85.26 | 85.05 |

| Benzo[b]fluoranthene BbFL | 0.9998 | 0.10 | 0.25 | 91.69 | 93.12 |

| Benzo[g,h,i]perylene BghiP | 0.9995 | 0.05 | 0.25 | 83.15 | 86.51 |

| Benzo[k]fluoranthene BkF | 0.9996 | 0.10 | 0.25 | 92.44 | 94.76 |

| Dibenz[a,h]anthracene DBahA | 0.9995 | 0.05 | 0.25 | 95.27 | 96.18 |

| Indeno[1,2,3-cd]pyrene IP | 0.9994 | 0.10 | 0.25 | 81.13 | 81.29 |

| Item | Group | |||||||

|---|---|---|---|---|---|---|---|---|

| CON | BL | BP | TU | TA | JP | MX | C | |

| Moisture (%) | 52.96 b ± 0.08 | 52.92 b ± 0.31 | 49.15 a ± 0.17 | 55.16 d ± 0.32 | 49.55 a ± 0.36 | 55.01 cd ± 0.13 | 52.54 b ± 0.72 | 54.09 c ± 0.16 |

| Fat (%) | 18.22 b ± 0.12 | 19.96 c ± 0.46 | 21.78 d ± 0.08 | 16.47 a ± 0.41 | 18.50 b ± 0.30 | 16.43 a ± 0.05 | 21.59 d ± 0.34 | 18.46 b ± 0.17 |

| Protein (%) | 24.48 c ± 0.24 | 23.63 b ± 0.05 | 25.23 d ± 0.06 | 24.64 c ± 0.20 | 27.62 e ± 0.11 | 23.94 b ± 0.14 | 22.58 a ± 0.15 | 22.52 a ± 0.15 |

| Salt (%) | 2.77 e ± 0.03 | 1.96 b ± 0.06 | 2.09 bc ± 0.04 | 2.23 cd ± 0.05 | 1.50 a ± 0.04 | 2.40 d ± 0.10 | 1.34 a ± 0.18 | 1.52 a ± 0.03 |

| Connective Tissue (%) | 3.31 bc ± 0.14 | 2.84 a ± 0.19 | 2.98 ab ± 0.07 | 3.53 cd ± 0.16 | 2.97 ab ± 0.08 | 3.32bc ± 0.10 | 3.78 d ± 0.20 | 3.22 a ± 0.17 |

| pH | 6.96 f ± 0.03 | 7.02 f ± 0.01 | 7.00 f ± 0.01 | 6.83 e ± 0.01 | 2.31 a ± 0.06 | 4.55 b ± 0.03 | 5.58 c ± 0.06 | 6.02 d ± 0.03 |

| Item | Group | |||||||

|---|---|---|---|---|---|---|---|---|

| CON | BL | BP | TU | TA | JP | MX | C | |

| Surface | ||||||||

| L*(%) | 45.83 cd ± 1.74 | 46.94 d ± 2.71 | 41.91 ab ± 2.53 | 42.15 ab ± 1.50 | 41.91 ab ± 2.68 | 42.71 abc ± 2.69 | 43.88 bcd ± 1.86 | 40.14 a ± 2.11 |

| a*(−) | 8.86 ab ± 0.67 | 8.79 a ± 0.59 | 11.60 c ± 0.93 | 10.25 bc ± 0.86 | 11.14 c ± 0.96 | 11.02 c ± 1.21 | 9.00 ab ± 1.72 | 9.84 abc ± 0.98 |

| b*(−) | 15.31 a ± 1.32 | 14.77 a ± 1.08 | 15.72 a ± 1.54 | 20.60 b ± 1.40 | 15.12 a ± 1.38 | 15.41 a ± 1.42 | 14.02 a ± 2.33 | 15.86 a ± 1.72 |

| Cross-Section | ||||||||

| L*(%) | 61.90 a ± 2.48 | 68.26 b ± 1.55 | 67.62 b ± 2.21 | 63.82 a ± 2.57 | 63.45 a ± 1.13 | 62.24 a ± 2.36 | 63.00 a ± 2.91 | 62.64 a ± 1.69 |

| a*(−) | 10.03 bc ± 1.28 | 8.31a ± 0.88 | 8.22 a ± 0.83 | 10.48 c ± 0.76 | 8.23 a ± 0.88 | 10.31 c ± 0.91 | 9.35 abc ± 0.80 | 8.86 ab ± 0.79 |

| b*(−) | 8.21 a ± 0.60 | 8.63 ab ± 0.70 | 8.52 ab ± 0.46 | 8.46 ab ± 0.66 | 9.19 bc ± 0.52 | 9.69 cd ± 0.75 | 10.32 d ± 0.50 | 9.29 bc ± 0.69 |

| Hardness (N) | 79.84 c ± 9.84 | 69.26 abc ± 3.29 | 60.22 a ± 6.29 | 70.86 abc ± 2.85 | 75.27 b ± 6.42 | 74.83 b ± 2.70 | 71.47 abc ± 2.21 | 66.38 ab ± 3.10 |

| Springiness [−] | 0.37 bc ± 0.02 | 0.30 ab ± 0.06 | 0.48 d ± 0.02 | 0.34 b ± 0.03 | 0.35 b ± 0.05 | 0.45 d ± 0.02 | 0.44 cd ± 0.01 | 0.24 a ± 0.03 |

| Cohesiveness [−] | 0.34 abc ± 0.02 | 0.29 a ± 0.02 | 0.44 d ± 0.01 | 0.40 cd ± 0.01 | 0.33 ab ± 0.03 | 0.42 d ± 0.02 | 0.37 bcd ± 0.02 | 0.33 ab ± 0.06 |

| Gumminess [−] | 27.11 bc ± 3.98 | 20.14a ± 1.86 | 26.42 abc ± 3.29 | 28.32 bc ± 1.35 | 24.82 a ± 3.91 | 31.60 c ± 2.29 | 26.37 abc ± 2.19 | 21.79 ab ± 3.60 |

| Chewiness [N] | 10.04 cd ± 1.40 | 6.07 ab ± 1.55 | 12.59 de ± 1.69 | 9.70 c ± 1.06 | 8.64 bc ± 0.68 | 14.29 e ± 0.48 | 11.48 cde ± 0.63 | 5.32 a ± 1.60 |

| PAH Compound | Abbreviation | PAH Concentration [mg/kg] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CON | BL | BP | TU | TA | JP | MX | C | ||

| Fluorene | F | 0.37 ± 0.03 B | 0.33 ± 0.01 B | 1.39 ± 0.05 C | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 1.88 ± 0.04 D |

| Anthracene | ANT | 0.50 ± 0.07 A | 0.35 ± 0.01 A | 5.14 ± 0.17 D | 0.49 ± 0.01 A | 0.36 ± 0.03 A | 0.54 ± 0.01 A | 0.35 ± 0.04 A | 3.12 ± 0.10 B |

| Fluoranthene | FL | 2.17 ± 0.09 D | 5.93 ± 0.37 F | 1.77 ± 0.12 CD | 0.88 ± 0.02 B | 1.62 ± 0.09 C | 0.28 ± 0.02 A | 1.47 ± 0.03 C | 3.18 ± 0.05 E |

| Benzo[b]fluorene | BbF | 29.57 ± 0.45 G | 16.14 ± 0.43 D | 21.54 ± 0.64 EF | 8.09 ± 0.37 B | 11.72 ± 0.46 C | 2.90 ± 0.11 A | 20.92 ± 0.36 E | 22.39 ± 0.81 F |

| Benz[a]anthracene | BaA | 3.18 ± 0.17 E | 1.62 ± 0.38 C | 2.22 ± 0.08 D | 0.37 ± 0.02 B | 0.00 ± 0.00 A | 0.20 ± 0.01 AB | 0.37 ± 0.03 B | 1.44 ± 0.06 C |

| Chrysene | CHR | 18.79 ± 1.05 F | 7.49 ± 0.06 D | 11.1 ± 0.18 E | 4.86 ± 0.23 C | 5.44 ± 0.21 C | 0.00 ± 0.00 A | 0.70 ± 0.02 B | 18.97 ± 0.29 F |

| Σlight PAHs | 54.58 ± 1.11 H | 31.86 ± 0.93 E | 43.16 ± 0.99 F | 14.69 ± 0.38 B | 19.13 ± 0.64 C | 3.92 ± 0.11 A | 23.81 ± 0.35 D | 50.98 ± 0.66 G | |

| Benzo[a]pyrene | BaP | 1.70 ± 0.08 D | 1.50 ± 0.02 C | 1.46 ± 0.03 C | 1.30 ± 0.06 C | 1.11 ± 0.08 B | 0.00 ± 0.00 A | 1.44 ± 0.11 C | 1.66 ± 0.06 D |

| Benzo[b]fluoranthene | BbFL | 1.15 ± 0.11 F | 0.00 ± 0.00 A | 0.25 ± 0.05 C | 0.47 ± 0.04 DE | 0.13 ± 0.01 B | 0.41 ± 0.03 D | 0.56 ± 0.03 E | 1.47 ± 0.10 G |

| Benzo[g.h.i]perylene | BghiP | 0.79 ± 0.03 C | 0.43 ± 0.04 B | 0.43 ± 0.03 B | 0.00 ± 0.00 A | 0.43 ± 0.03 B | 0.43 ± 0.04 B | 0.45 ± 0.02 B | 1.70 ± 0.03 D |

| Benzo[k]fluoranthene | BkF | 1.47 ± 0.15 B | 0.00 ± 0.00 A | 0.14 ± 0.03 A | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 0.00 ± 0.00 A | 3.04 ± 0.02 C |

| Dibenz[a.h]anthracene | DBahA | 38.14 ± 0.75 F | 7.87 ± 0.26 D | 0.51 ± 0.03 A | 14.97 ± 0.22 E | 0.63 ± 0.04 A | 0.00 ± 0.00 A | 6.64 ± 0.07 C | 2.71 ± 0.08 B |

| Indeno[1.2.3-cd]pyrene | IP | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Σheavy PAHs | 43.90 ± 0.95 E | 9.80 ± 0.24 CD | 2.79 ± 0.03 B | 16.74 ± 0.27 D | 2.30 ± 0.11 B | 0.84 ± 0.06 A | 9.09 ± 0.04 C | 10.58 ± 0.04 D | |

| Σ4 PAHs | 24.82 ± 0.91 G | 10.61 ± 0.36 D | 15.03 ± 0.20 E | 7.00 ± 0.30 C | 6.68 ± 0.15 C | 0.61 ± 0.02 A | 3.07 ± 0.09 B | 23.54 ± 0.30 F | |

| Σ12 PAHs | 98.48 ± 0.81 G | 41.66 ± 1.15 D | 45.95 ± 1.02 E | 31.43 ± 0.60 C | 21.43 ± 0.54 B | 4.76 ± 0.08 A | 32.90 ± 0.37 C | 61.56 ± 0.66 F | |

| 12 PAHs | ANT | BaA | BaP | BbFL | BbF | BghiP | BkF | CHR | DBahA | FL | F | Light PAHs | Heavy PAHs | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DPPH | −0.779 | 0.101 | −0.660 | −0.251 | −0.620 | −0.503 | −0.264 | −0.465 | −0.643 | −0.879 | 0.131 | −0.047 | −0.524 | −0.903 |

| TPC | −0.576 | −0.157 | −0.624 | −0.341 | −0.140 | −0.240 | −0.013 | −0.233 | −0.639 | −0.574 | −0.203 | −0.199 | −0.458 | −0.576 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onopiuk, A.; Kołodziejczak, K.; Marcinkowska-Lesiak, M.; Wojtasik-Kalinowska, I.; Szpicer, A.; Stelmasiak, A.; Poltorak, A. Influence of Plant Extract Addition to Marinades on Polycyclic Aromatic Hydrocarbon Formation in Grilled Pork Meat. Molecules 2022, 27, 175. https://doi.org/10.3390/molecules27010175

Onopiuk A, Kołodziejczak K, Marcinkowska-Lesiak M, Wojtasik-Kalinowska I, Szpicer A, Stelmasiak A, Poltorak A. Influence of Plant Extract Addition to Marinades on Polycyclic Aromatic Hydrocarbon Formation in Grilled Pork Meat. Molecules. 2022; 27(1):175. https://doi.org/10.3390/molecules27010175

Chicago/Turabian StyleOnopiuk, Anna, Klaudia Kołodziejczak, Monika Marcinkowska-Lesiak, Iwona Wojtasik-Kalinowska, Arkadiusz Szpicer, Adrian Stelmasiak, and Andrzej Poltorak. 2022. "Influence of Plant Extract Addition to Marinades on Polycyclic Aromatic Hydrocarbon Formation in Grilled Pork Meat" Molecules 27, no. 1: 175. https://doi.org/10.3390/molecules27010175