Lysinibacillus Isolate MK212927: A Natural Producer of Allylamine Antifungal ‘Terbinafine’

Abstract

:1. Introduction

2. Results

2.1. Screening for the Production of Antifungal Metabolite(s)

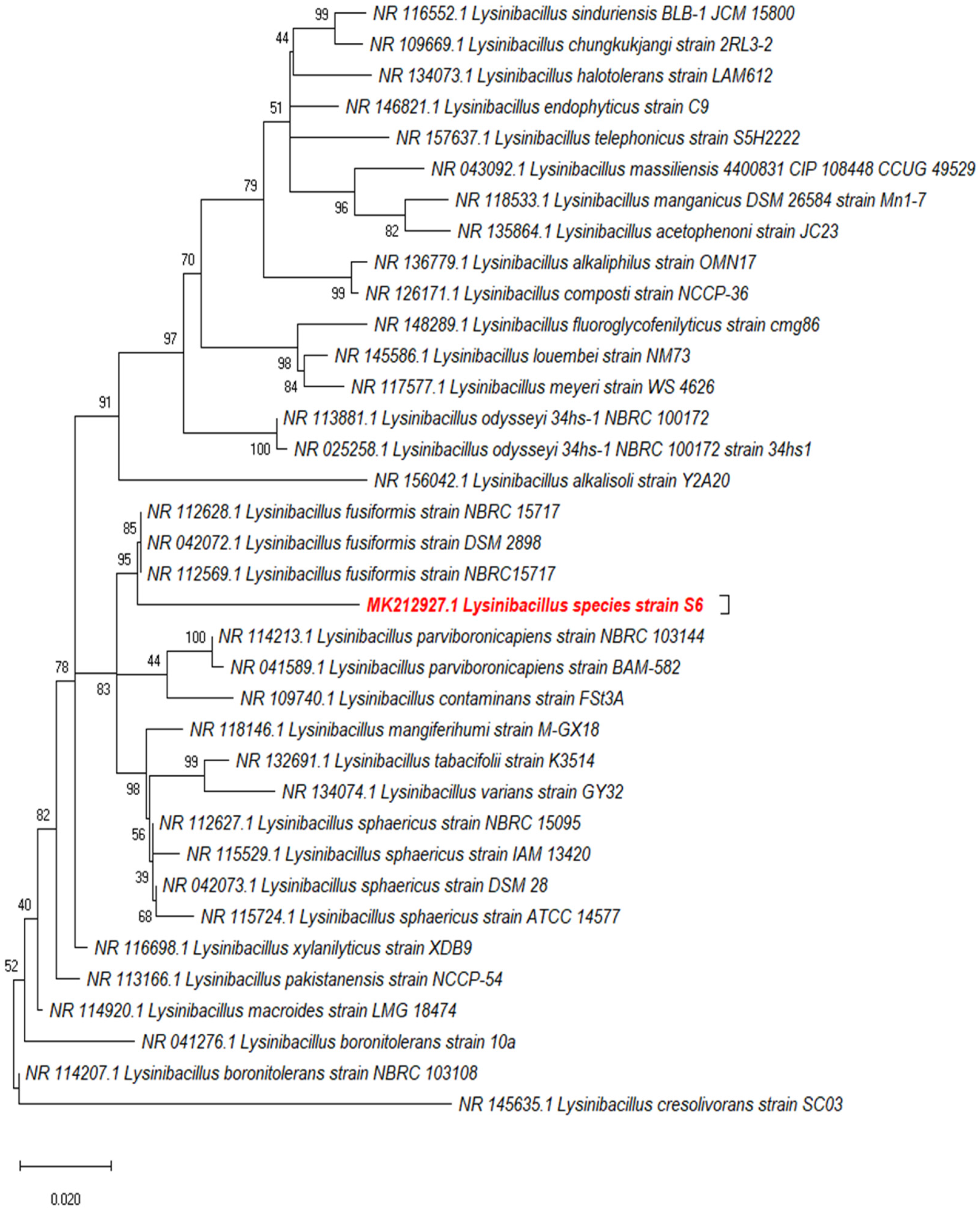

2.2. Identification of the Isolate S6

2.3. Extraction of the Antifungal Metabolite(s)

2.4. Purification of the Bioactive Metabolite(s) by Silica Gel Column Chromatography

2.5. Correlation between the Metabolite(s) Concentration and Inhibition Zone Diameters Using Agar Well Diffusion

2.6. Thermal, Enzymes, Detergents, and pH Stability of the Antifungal Metabolite

2.7. Evaluation of the Antifungal Activity of the Lysinibacillus Isolate MK212927 Metabolite Compared to the Commercially Available Antifungal Agents

2.8. Spectral Analyses of the Purified Antifungal Compound

3. Discussion

4. Materials and Methods

4.1. Soil Sampling and Isolation of Bacterial Isolates

4.2. Screening for Production of Metabolites with Antifungal Activity

4.3. Identification of the Selected Isolate

4.4. Production of the Antifungal Metabolite(s)

4.5. Extraction of the Antifungal Metabolite(s)

4.6. Thin Layer Chromatography (TLC) Analysis

4.7. Purification of the Bioactive Metabolite(s) through Activity Guided Fractionation

4.8. Correlation between the Metabolite Concentration and Diameter of Inhibition Zone Using Agar Well Diffusion

4.9. Effect of Heat, pH, Detergents and Enzymes on Stability and Activity of the Antifungal Compound

4.10. Investigation for Fungicidal and/or Fungistatic Mode of Action

4.11. Evaluation of the Antifungal Activity of the Metabolite

4.12. Minimal Inhibitory Concentration (MIC) Determination

4.13. Spectral Analyses of the Antifungal Compound Assay

4.14. Statistical Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Fuller, J.; Dingle, T.C.; Bull, A.; Shokoples, S.; Laverdière, M.; Baxter, M.R.; Adam, H.J.; Karlowsky, J.A.; Zhanel, G.G. Species distribution and antifungal susceptibility of invasive Candida isolates from Canadian hospitals: Results of the CANWARD 2011–16 study. J. Antimicrob. Chemother. 2019, 74, iv48–iv54. [Google Scholar] [CrossRef]

- Shishodia, S.K.; Tiwari, S.; Shankar, J. Resistance mechanism and proteins in Aspergillus species against antifungal agents. Mycology 2019, 10, 151–165. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Cantero, A.; López-Fernández, L.; Guarro, J.; Capilla, J. Azole resistance mechanisms in Aspergillus: Update and recent advances. Int. J. Antimicrob. Agents 2020, 55, 105807. [Google Scholar] [CrossRef]

- Pfavayi, L.T.; Denning, D.W.; Baker, S.; Sibanda, E.N.; Mutapi, F. Determining the burden of fungal infections in Zimbabwe. Sci. Rep. 2021, 11, 13240. [Google Scholar] [CrossRef]

- Lass-Flörl, C.; Samardzic, E.; Knoll, M. Serology anno 2021–fungal infections: From invasive to chronic. Clin. Microbiol. Infect. 2021, 27, 1230–1241. [Google Scholar] [CrossRef] [PubMed]

- Lamoth, F.; Lockhart, S.R.; Berkow, E.L.; Calandra, T. Changes in the epidemiological landscape of invasive candidiasis. J. Antimicrob. Chemother. 2018, 73, i4–i13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmidt-Westhausen, A.M.; Priepke, F.; Bergmann, F.J.; Reichart, P.A. Decline in the rate of oral opportunistic infections following introduction of highly active antiretroviral therapy. J. Oral Pathol. Med. 2000, 29, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Oliscovicz, N.; Pomarico, L.; de Araújo Castro, G.F.; Souza, I.P. Effect of highly active antiretroviral therapy use on oral manifestations in pediatric patients infected with HIV. Indian J. Dent. Res. 2015, 26, 200–204. [Google Scholar]

- Quindos, G.; Gil-Alonso, S.; Marcos-Arias, C.; Sevillano, E.; Mateo, E.; Jauregizar, N.; Eraso, E. Therapeutic tools for oral candidiasis: Current and new antifungal drugs. Med. Oral Patol. Oral Cir. Bucal 2019, 24, e172–e180. [Google Scholar] [CrossRef]

- Bod, P.; Terdy, L.; Trischler, F.; Fekecs, E.; Demeter, M.; Lauko, A.; Domany, G.; Komlosi, G.S.; Varga, K. Process for Preparing a Substituted Allylamine Derivative and the Salts Thereof. Google Patents US20030028032A1. 2004. Available online: https://patents.google.com/patent/US20030028032A1/en (accessed on 4 December 2021).

- Stuetz, A.; Petranyi, G. Synthesis and antifungal activity of (E)-N-(6,6-dimethyl-2-hepten-4-ynyl)-N-methyl-1-naphthalenemethanamine (SF 86-327) and related allylamine derivatives with enhanced oral activity. J. Med. Chem. 1984, 27, 1539–1543. [Google Scholar] [CrossRef] [PubMed]

- Fuglseth, E.; Otterholt, E.; Høgmoen, H.; Sundby, E.; Charnock, C.; Hoff, B.H. Chiral derivatives of Butenafine and Terbinafine: Synthesis and antifungal activity. Tetrahedron 2009, 65, 9807–9813. [Google Scholar] [CrossRef] [Green Version]

- Gupta, B.; Ravindra Babu, B.; Gyanda, K.; Panda, S.S.; Jain, S.C. Stereoselective methodology for the synthesis of an antifungal allylamine: Terbinafine. Lett. Org. Chem. 2014, 11, 141–144. [Google Scholar] [CrossRef]

- Hergert, T.; Mátravölgyi, B.; Örkényi, R.; Éles, J.; Faigl, F. Multistep batch-flow hybrid synthesis of a terbinafine precursor. J. Flow Chem. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- Da Matta, D.; Souza, A.; Colombo, A. Revisiting species distribution and antifungal susceptibility of Candida bloodstream isolates from Latin American medical centers. J. Fungi 2017, 3, 24. [Google Scholar] [CrossRef] [Green Version]

- Shah, A.M.; Rasool, S.; Majeed, A.; Mushtaq, S.; Khan, M.H.; Hussain, A.; Shah, A.; Hassan, Q.P. Reappraisal of actinomycetes for novel bioactive metabolites. Ann. Phytomed. 2017, 6, 13–19. [Google Scholar] [CrossRef] [Green Version]

- Monciardini, P.; Iorio, M.; Maffioli, S.; Sosio, M.; Donadio, S. Discovering new bioactive molecules from microbial sources. Microb. Biotechnol. 2014, 7, 209–220. [Google Scholar] [CrossRef] [PubMed]

- Milshteyn, A.; Schneider, J.S.; Brady, S.F. Mining the metabiome: Identifying novel natural products from microbial communities. Chem. Biol. 2014, 21, 1211–1223. [Google Scholar] [CrossRef] [Green Version]

- Charlop-Powers, Z.; Owen, J.G.; Reddy, B.V.B.; Ternei, M.A.; Brady, S.F. Chemical-biogeographic survey of secondary metabolism in soil. Proc. Natl. Acad. Sci. USA 2014, 111, 3757–3762. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Sayed, S.E.; Abdelaziz, N.A.; El-Housseiny, G.S.; Aboshanab, K.M. Octadecyl 3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propanoate, an antifungal metabolite of Alcaligenes faecalis strain MT332429 optimized through response surface methodology. Appl. Microbiol. Biotechnol. 2020, 104, 10755–10768. [Google Scholar] [CrossRef] [PubMed]

- Nam, Y.-D.; Seo, M.-J.; Lim, S.-I.; Lee, S.-Y. Genome sequence of Lysinibacillus boronitolerans F1182, isolated from a traditional Korean fermented soybean product. J. Bacteriol. 2012, 194, 5988. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, I.; Yokota, A.; Yamazoe, A.; Fujiwara, T. Proposal of Lysinibacillus boronitolerans gen. nov. sp. nov., and transfer of Bacillus fusiformis to Lysinibacillus fusiformis comb. nov. and Bacillus sphaericus to Lysinibacillus sphaericus comb. nov. Int. J. Syst. Evol. Microbiol. 2007, 57, 1117–1125. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Ma, Z.; Zhang, J.; Yang, L. Antifungal Compounds against Candida Infections from Traditional Chinese Medicine. Biomed. Res. Int. 2017, 2017, 4614183. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, M.; Soran, H.; Beyatli, Y. Antimicrobial activities of some Bacillus spp. strains isolated from the soil. Microbiol. Res. 2006, 161, 127–131. [Google Scholar] [CrossRef]

- Caulier, S.; Nannan, C.; Gillis, A.; Licciardi, F.; Bragard, C.; Mahillon, J. Overview of the antimicrobial compounds produced by members of the Bacillus subtilis group. Front. Microbiol. 2019, 10, 302. [Google Scholar] [CrossRef] [Green Version]

- Jin, P.; Wang, H.; Tan, Z.; Xuan, Z.; Dahar, G.Y.; Li, Q.X.; Miao, W.; Liu, W. Antifungal mechanism of bacillomycin D from Bacillus velezensis HN-2 against Colletotrichum gloeosporioides Penz. Pestic. Biochem. Physiol. 2020, 163, 102–107. [Google Scholar] [CrossRef]

- Xiao, J.; Guo, X.; Qiao, X.; Zhang, X.; Chen, X.; Zhang, D. Activity of fengycin and iturin A isolated from Bacillus subtilis Z-14 on Gaeumannomyces graminis var. tritici and soil microbial diversity. Front. Microbiol. 2021, 12, 682437. [Google Scholar] [CrossRef] [PubMed]

- Lei, S.; Zhao, H.; Pang, B.; Qu, R.; Lian, Z.; Jiang, C.; Shao, D.; Huang, Q.; Jin, M.; Shi, J. Capability of iturin from Bacillus subtilis to inhibit Candida albicans in vitro and in vivo. Appl. Microbiol. Biotechnol. 2019, 103, 4377–4392. [Google Scholar] [CrossRef] [PubMed]

- Ypucef-Ali, M.; Chaouche, N.K.; Dehimat, L.; Bataiche, I.; Mounira, K.; Cawoy, H.E.; Thonart, P. Antifungal activity and bioactive compounds produced by Bacillus mojavensis and Bacillus subtilis. Afr. J. Microbiol. Res. 2014, 8, 476–484. [Google Scholar]

- Jiang, J.; Gao, L.; Bie, X.; Lu, Z.; Liu, H.; Zhang, C.; Lu, F.; Zhao, H. Identification of novel surfactin derivatives from NRPS modification of Bacillus subtilis and its antifungal activity against Fusarium moniliforme. BMC Microbiol. 2016, 16, 31. [Google Scholar] [CrossRef] [Green Version]

- Sumi, C.D.; Yang, B.W.; Yeo, I.-C.; Hahm, Y.T. Antimicrobial peptides of the genus Bacillus: A new era for antibiotics. Can. J. Microbiol. 2015, 61, 93–103. [Google Scholar] [CrossRef]

- Awais, M.; Shah, A.A.; Hameed, A.; Hasan, F. Isolation, identification and optimization of bacitracin produced by Bacillus sp. Pak. J. Bot. 2007, 39, 1303. [Google Scholar]

- Mikkola, R. Food and Indoor Air Isolated Bacillus Non-Protein Toxins: Structures, Physico-Chemical Properties and Mechanisms of Effects on Eukaryotic Cells. Ph.D. Thesis, Universitatis Helsingiensis in Viikki, Helsinki, Finland, 2006. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.407.3810&rep=rep1&type=pdf (accessed on 4 December 2021).

- Devi, S.; Kiesewalter, H.T.; Kovács, R.; Frisvad, J.C.; Weber, T.; Larsen, T.O.; Kovács, Á.T.; Ding, L. Depiction of secondary metabolites and antifungal activity of Bacillus velezensis DTU001. Synth. Syst. Biotechnol. 2019, 4, 142–149. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, D.; Shen, L.; Jing, C.; Zhang, C. Application and Mechanisms of Bacillus subtilis in Biological Control of Plant Disease. In Role of Rhizospheric Microbes in Soil; Meena, V., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Hossain, A.S.M.; Sil, B.C.; Iliopoulos, F.; Lever, R.; Hadgraft, J.; Lane, M.E. Preparation, Characterisation, and Topical Delivery of Terbinafine. Pharmaceutics 2019, 11, 548. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.; Kumar, A.; Singh, R.; Pandey, K.D. Endophytic bacteria: A new source of bioactive compounds. 3 Biotech 2017, 7, 315. [Google Scholar] [CrossRef]

- Mahendran, S.; Vijayabaskar, P.; Saravanan, S.; An, K.; Shankar, T. Structural characterization and biological activity of exopolysaccharide from Lysinibacillus fusiformis. Afr. J. Microbiol. Res. 2013, 7, 4666–4676. [Google Scholar]

- Naureen, Z.; Rehman, N.U.; Hussain, H.; Hussain, J.; Gilani, S.A.; Al Housni, S.K.; Mabood, F.; Khan, A.L.; Farooq, S.; Abbas, G. Exploring the potentials of Lysinibacillus sphaericus ZA9 for plant growth promotion and biocontrol activities against phytopathogenic fungi. Front. Microbiol. 2017, 8, 1477. [Google Scholar] [CrossRef]

- Ahmad, V.; Iqbal, A.N.; Haseeb, M.; Khan, M.S. Antimicrobial potential of bacteriocin producing Lysinibacillus jx416856 against foodborne bacterial and fungal pathogens, isolated from fruits and vegetable waste. Anaerobe 2014, 27, 87–95. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, D.P.; Solanki, M.K.; Singh, P.; Srivastva, A.K.; Kumar, S.; Kashyap, P.L.; Saxena, A.K.; Singhal, P.K.; Arora, D.K. Optimization of media components for chitinase production by chickpea rhizosphere associated Lysinibacillus fusiformis B-CM18. J. Basic Microbiol. 2013, 53, 451–460. [Google Scholar] [CrossRef]

- El-Sayed, S.E.; El-Housseiny, G.S.; Abdelaziz, N.A.; El-Ansary, M.R.; Aboshanab, K.M. Optimized Production of the Allylamine Antifungal “Terbinafine” by Lysinibacillus Isolate MK212927 Using Response Surface Methodology. Infect. Drug Resist. 2020, 13, 3613. [Google Scholar] [CrossRef]

- Parthasarathi, S.; Sathya, S.; Bupesh, G.; Manikandan, M.; Kim, C.; Manikandan, T.; Balakrishnan, K. Isolation, Characterization and Extraction of antimicrobial compound from marine actinomycete Streptomyces hygroscopicus BDUS 49. Res. J. Biotechnol. 2012, 8, 3. [Google Scholar]

- Thangadurai, D.; Murthy, K.; Prasad, P.; Pullaiah, T. Antimicrobial screening of Decalepis hamiltonii wight and arn.(Asclepiadaceae) root extracts against food-related microorganisms. J. Food Saf. 2004, 24, 239–245. [Google Scholar] [CrossRef]

- Chawawisit, K.; Bhoopong, P.; Phupong, W.; Lertcanawanichakul, M. 2,4-Di-tert-butylphenol, the bioactive compound produced by Streptomyces sp. KB1. J. Appl. Pharm. Sci. 2015, 5, 007–012. [Google Scholar]

- Motta, A.; Brandelli, A. Characterization of an antibacterial peptide produced by Brevibacterium linens. J. Appl. Microbiol. 2002, 92, 63–70. [Google Scholar] [CrossRef] [Green Version]

- Morschhäuser, J. The development of fluconazole resistance in Candida albicans—An example of microevolution of a fungal pathogen. J. Microbiol. 2016, 54, 192–201. [Google Scholar] [CrossRef]

- Ali, G.S.; El-Sayed, A.S.; Patel, J.S.; Green, K.B.; Ali, M.; Brennan, M.; Norman, D. Ex Vivo Application of Secreted Metabolites Produced by Soil-Inhabiting Bacillus spp. Efficiently Controls Foliar Diseases Caused by Alternaria spp. Appl. Environ. Microbiol. 2016, 82, 478–490. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Zarychanski, R.; Pisipati, A.; Kumar, A.; Kethireddy, S.; Bow, E.J. Fungicidal versus fungistatic therapy of invasive Candida infection in non-neutropenic adults: A meta-analysis. Mycology 2018, 9, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.K.; Drummond-Main, C. Meta-analysis of randomized, controlled trials comparing particular doses of griseofulvin and terbinafine for the treatment of tinea capitis. Pediatr. Dermatol. 2013, 30, 1–6. [Google Scholar] [CrossRef]

- Muharram, M.; Abdel-Kader, M. Taxonomic characterization and chemical study of the antifungal constituents of Streptomyces sp. KH-F12. J. Biol. Sci. 2014, 14, 403–413. [Google Scholar] [CrossRef] [Green Version]

- Kind, T.; Fiehn, O. Advances in structure elucidation of small molecules using mass spectrometry. Bioanal. Rev. 2010, 2, 23–60. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Rahman, S.M.; Nahata, M.C. Oral terbinafine: A new antifungal agent. Ann. Pharmacother. 1997, 31, 445–456. [Google Scholar] [CrossRef]

- Maxfield, L.; Preuss, C.V.; Bermudez, R. Terbinafine; StatPearls Publishing: Treasure Island, FL, USA, 2021. Available online: https://www.ncbi.nlm.nih.gov/books/NBK545218/ (accessed on 4 December 2021).

- Elewski, B.; Tavakkol, A. Safety and tolerability of oral antifungal agents in the treatment of fungal nail disease: A proven reality. Ther. Clin. Risk Manag. 2005, 1, 299. [Google Scholar]

- Chubukov, V.; Mukhopadhyay, A.; Petzold, C.J.; Keasling, J.D.; Martín, H.G. Synthetic and systems biology for microbial production of commodity chemicals. NPJ Syst. Biol. Appl. 2016, 2, 16009. [Google Scholar] [CrossRef]

- Abdel-Kader, M.S.; Muharram, M.M. New microbial source of the antifungal allylamine “Terbinafine”. Saudi Pharm. J. 2017, 25, 440–442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hossain, N.; Rahman, M. Antagonistic activity of antibiotic producing Streptomyces sp. against fish and human pathogenic bacteria. Braz. Arch. Biol. Technol. 2014, 57, 233–237. [Google Scholar] [CrossRef]

- Rahman, M.A.; Islam, M.Z.; Islam, M.A. Antibacterial activities of actinomycete isolates collected from soils of rajshahi, bangladesh. Biotechnol. Res. Int. 2011, 2011, 857925. [Google Scholar] [CrossRef] [Green Version]

- Peela, S.; Kurada, V.B.; Terli, R. Studies on antagonistic marine actinomycetes from the Bay of Bengal. World J. Microbiol. Biotechnol. 2005, 21, 583–585. [Google Scholar] [CrossRef]

- Tiru, M.; Muleta, D.; Bercha, G.; Adugna, G. Antagonistic effect of rhizobacteria against coffee wilt disease caused by Gibberella xylarioides. Asian J. Plant Pathol. 2013, 7, 109–122. [Google Scholar] [CrossRef] [Green Version]

- Montealegre, J.R.; Reyes, R.; Pérez, L.M.; Herrera, R.; Silva, P.; Besoain, X. Selection of bioantagonistic bacteria to be used in biological control of Rhizoctonia solani in tomato. Electron. J. Biotechnnol. 2003, 6, 115–127. [Google Scholar] [CrossRef]

- Magaldi, S.; Mata-Essayag, S.; Hartung de Capriles, C.; Perez, C.; Colella, M.T.; Olaizola, C.; Ontiveros, Y. Well diffusion for antifungal susceptibility testing. Int. J. Infect. Dis. 2004, 8, 39–45. [Google Scholar] [CrossRef] [Green Version]

- Wiegand, I.; Hilpert, K.; Hancock, R.E. Agar and broth dilution methods to determine the minimal inhibitory concentration (MIC) of antimicrobial substances. Nat. Protoc. 2008, 3, 163. [Google Scholar] [CrossRef]

- Bundale, S.; Begde, D.; Nashikkar, N.; Kadam, T.; Upadhyay, A. Isolation of aromatic polyketide producing soil Streptomyces using combinatorial screening strategies. Open Access Libr. J. 2014, 1, 1–16. [Google Scholar] [CrossRef]

- Rojas, J.J.; Ochoa, V.J.; Ocampo, S.A.; Muñoz, J.F. Screening for antimicrobial activity of ten medicinal plants used in Colombian folkloric medicine: A possible alternative in the treatment of non-nosocomial infections. BMC Complement. Altern. Med. 2006, 6, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moreno-Arribas, M.V.; Polo, M.C. Occurrence of lactic acid bacteria and biogenic amines in biologically aged wines. Food Microbiol. 2008, 25, 875–881. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Stecher, G.; Li, M.; Knyaz, C.; Tamura, K. MEGA X: Molecular Evolutionary Genetics Analysis across Computing Platforms. Mol. Biol. Evol. 2018, 35, 1547–1549. [Google Scholar] [CrossRef] [PubMed]

- Kimura, M. A simple method for estimating evolutionary rates of base substitutions through comparative studies of nucleotide sequences. J. Mol. Evol. 1980, 16, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Bhosale, H.; Kadam, T.; Mirajgave, R.; Holkar, S. Optimization and characterization of antifungal metabolite from a soil actinomycete Streptomyces indiaensis SRT1. Indian J. Biotechnol. 2018, 17, 261–271. [Google Scholar]

- Kumar, P.S.; Duraipandiyan, V.; Ignacimuthu, S. Isolation, screening and partial purification of antimicrobial antibiotics from soil Streptomyces sp. SCA 7. Kaohsiung J. Med. Sci. 2014, 30, 435–446. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balouiri, M.; Bouhdid, S.; Harki, E.; Sadiki, M.; Ouedrhiri, W.; Ibnsouda, S.K. Antifungal activity of Bacillus spp. isolated from Calotropis procera AIT. Rhizosphere against Candida albicans. Asian J. Pham. Clin. Res. 2015, 8, 213–217. [Google Scholar]

- Augustine, S.; Bhavsar, S.; Kapadnis, B. A non-polyene antifungal antibiotic from Streptomyces albidoflavus PU 23. J. Biosci. 2005, 30, 201–211. [Google Scholar] [CrossRef]

- Munimbazi, C.; Bullerman, L. Isolation and partial characterization of antifungal metabolites of Bacillus pumilus. J. Appl. Microbiol. 1998, 84, 959–968. [Google Scholar] [CrossRef]

- Shahidi Bonjar, G.; Rashid Farrokhi, P.; Aghighi, S.; Shahidi Bonjar, L.; Aghelizadeh, A. Antifungal characterization of actinomycetes isolated from Kerman, Iran and their future prospects in biological control strategies in greenhouse and field conditions. Plant Pathol. J. 2005, 4, 78–84. [Google Scholar]

- Navi, S.; Rajasab, A.; Yang, X. In Vitro evaluation of commercial fungicides against some of the major soil borne pathogens of soybean. J. Plant Pathol. Microbiol. 2016, 7, 340–347. [Google Scholar] [CrossRef]

- CLSI. Reference Method for Broth Dilution Antifungal Susceptibility Testing of Yeasts, Approved Standard, 2nd ed.; (M27-A3); Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2008. Available online: https://clsi.org/media/1897/m27ed4_sample.pdf (accessed on 4 December 2021).

| Pooled Fractions (PFs) | n-Hexane: Ethyl Acetate (EA) | Elutes Recovered | Retardation Factor (RF) | Dry Weight of Each PF (mg) | Mean Inhibition Zones (mm) ± SD | |

|---|---|---|---|---|---|---|

| C. albicans | A. niger | |||||

| 1 | n-hexane 100% | 1–7 | 0.96 | 1.4 | - | - |

| 2 | 95:5 | 8–19 | 0.93 | 1.8 | - | - |

| 3 | 90:10 | 20–25 | 0.88 | 4.6 | 16 ± 0.25 | 14 ± 0.25 |

| 4 | 85:15 | 26–36 | 0.84 | 2 | 21 ± 0.45 | 20 ± 0.36 |

| 5 | 80:20 | 37–42 | 0.78 | 3.33 | 22 ± 0.36 | 14 ± 0.25 |

| 6 | 75:25 | 43–47 | 0.71 | 4.1 | 31 ± 0.58 | 29 ± 0.58 |

| 7 | 70:30 | 48–53 | 0.69 | 2.4 | 30 ± 0.36 | 27 ± 0.36 |

| 8 | 65:35 | 54–59 | 0.63 | 4.22 | 29 ± 0.58 | 28 ± 0.58 |

| 9 | 60:40 | 60–64 | 0.60 | 2.6 | 13 ± 0.25 | 15 ± 0.36 |

| 10 | 55:45 | 65–69 | 0.58 | 0.99 | - | - |

| 11 | 50:50 | 70–76 | 0.52 | 0.89 | - | - |

| 12 | 45:55 | 77–82 | 0.49 | 4 | - | - |

| 13 | 40:60 | 83–88 | 0.46 | 3.9 | - | - |

| 14 | 35:65 | 89–94 | 0.43 | 3.7 | 17 ± 0.45 | 19 ± 0.58 |

| 15 | 30:70 | 95–99 | 0.39 | 1.67 | 18 ± 0.45 | 15 ± 0.25 |

| 16 | 25:75 | 100–106 | 0.35 | 2.78 | 14 ± 0.36 | 16 ± 0.36 |

| 17 | 20:80 | 107–112 | 0.31 | 4.4 | 12 ± 0.25 | 11 ± 0.25 |

| 18 | 15:85 | 113–119 | 0.28 | 1.8 | 15 ± 0.45 | 17 ± 0.36 |

| 19 | 10:90 | 120–125 | 0.23 | 1.01 | 20 ± 0.36 | 18 ± 0.36 |

| 20 | 5:95 | 126–130 | 0.14 | 5.2 | 19 ± 0.45 | 20 ± 0.58 |

| 21 | EA 100% | 131–136 | 0.12 | 4.9 | 23 ± 0.58 | 21 ± 0.36 |

| C. albicans Isolate | Inhibition Zone Diameter (mm) ± SD | |||

|---|---|---|---|---|

| 110 µg/mL | 150 µg/mL | 190 µg/mL | 250 µg/mL | |

| Fluconazole | ||||

| 1 | 0 | 0 | 11 ± 0.33 | 15 ± 0.26 |

| 2 | 12 ± 0.58 | 14 ± 0.26 | 17 ± 0.33 | 20 ± 0.33 |

| 3 | 0 | 11 ± 0.33 | 13 ± 0.33 | 16 ± 0.58 |

| 4 | 11 ± 0.25 | 14 ± 0.25 | 17 ± 0.58 | 19 ± 0.33 |

| 5 | 23 ± 0.58 | 25 ± 0.58 | 28 ± 0.58 | 30 ± 0.33 |

| 6 | 14 ± 0.58 | 16 ± 0.58 | 19 ± 0.58 | 21 ± 0.58 |

| Miconazole | ||||

| 1 | 0 | 11 ± 0.33 | 14 ± 0.33 | 16 ± 0.33 |

| 2 | 13 ± 0.33 | 15 ± 0.33 | 17 ± 0.33 | 19 ± 0.67 |

| 3 | 11 ± 0.33 | 12 ± 0.46 | 13 ± 0.33 | 14 ± 0.26 |

| 4 | 11. ± 0.33 | 14 ± 0.36 | 16 ± 0.33 | 18 ± 0.33 |

| 5 | 18 ± 0.33 | 19 ± 0.67 | 23 ± 0.26 | 24 ± 0.33 |

| 6 | 14 ± 0.46 | 15. ± 0.33 | 17 ± 0.33 | 19 ± 0.33 |

| Lamisil | ||||

| 1 | 0 | 11 ± 0.33 | 14 ± 0.26 | 17 ± 0.33 |

| 2 | 11 ± 0.33 | 15 ± 0.33 | 16 ± 0.58 | 19. ± 0.67 |

| 3 | 0 | 0 | 11 ± 0.33 | 14 ± 0.58 |

| 4 | 15 ± 0.33 | 18 ± 0.5 | 21 ± 0.33 | 25 ± 0.58 |

| 5 | 19 ± 0.67 | 23 ± 0.33 | 26 ± 0.33 | 29 ± 0.6 |

| 6 | 13 ± 0.33 | 15 ± 0.33 | 17 ± 0.33 | 19 ± 0.6 |

| Antifungal metabolite | ||||

| 1 | 0 | 11 ± 0.33 | 14 ± 0.33 | 16 ± 0.33 |

| 2 | 13 ± 0.33 | 15 ± 0.66 | 17 ± 0.33 | 19 ± 0.69 |

| 3 | 11 ± 0.33 | 12 ± 0.33 | 13 ± 0.33 | 14 ± 0.45 |

| 4 | 11 ± 0.33 | 14 ± 0.33 | 16 ± 0.2 | 18 ± 0.33 |

| 5 | 18 ± 0.6 | 19 ± 0.67 | 23 ± 0.3 | 24 ± 0.33 |

| 6 | 14 ± 0.6 | 15 ± 0.33 | 17 ± 0.3 | 19 ± 0.67 |

| Antifungal Product | Susceptibility (μg/mL) | |||

|---|---|---|---|---|

| Range | Median c | MIC50 a | MIC90 b | |

| Fluconazole | 1–128 | 24 | 16 | 128 |

| Miconazole | 2–128 | 48 | 32 | 64 |

| Lamisil | 1–128 | 24 | 16 | 32 |

| Antifungal metabolite | 0.5–32 | 16 | 16 | 32 |

| Position | δH (MeOD, 400 MHz, J in Hz) | δC (MeOD, 100 MHz) |

|---|---|---|

| 1 | - | 132.1 (C) |

| 2 | 7.54 (m) | 125.9 (CH) |

| 3 | 7.64 (m) | 126.6 (CH) |

| 4 | 8.2 (m) | 123.4 (CH) |

| 5 | - | 134 (C) |

| 6 | 7.54 (m) | 126.1 (CH) |

| 7 | 7.93 (m) | 128.7 (CH) |

| 8 | 7.93 (m) | 129.7 (CH) |

| 9 | 7.64 (m) | 129.6 (CH) |

| 10 | - | 131.9 (C) |

| 11 | 4.4 (s) | 56.8 (C) |

| 12 | 3.6 (d, 7) | 58.2 (CH2) |

| 13 | 5.9 (d, 15.9) | 118.2 (CH) |

| 14 | 6.1 (m) | 131.7 (CH) |

| 15 | - | 76.6 (C) |

| 16 | - | 100.1 (C) |

| 17 | - | 27.6 (C) |

| 18–20 | 1.23 (s) | 29.9 (CH3) |

| 21 (N-CH3) | 2.52 (s) | 39.9 (CH3) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Sayed, S.E.; Abdelaziz, N.A.; Osman, H.-E.H.; El-Housseiny, G.S.; Aleissawy, A.E.; Aboshanab, K.M. Lysinibacillus Isolate MK212927: A Natural Producer of Allylamine Antifungal ‘Terbinafine’. Molecules 2022, 27, 201. https://doi.org/10.3390/molecules27010201

El-Sayed SE, Abdelaziz NA, Osman H-EH, El-Housseiny GS, Aleissawy AE, Aboshanab KM. Lysinibacillus Isolate MK212927: A Natural Producer of Allylamine Antifungal ‘Terbinafine’. Molecules. 2022; 27(1):201. https://doi.org/10.3390/molecules27010201

Chicago/Turabian StyleEl-Sayed, Sayed E., Neveen A. Abdelaziz, Hosam-Eldin Hussein Osman, Ghadir S. El-Housseiny, Ahmed E. Aleissawy, and Khaled M. Aboshanab. 2022. "Lysinibacillus Isolate MK212927: A Natural Producer of Allylamine Antifungal ‘Terbinafine’" Molecules 27, no. 1: 201. https://doi.org/10.3390/molecules27010201

APA StyleEl-Sayed, S. E., Abdelaziz, N. A., Osman, H.-E. H., El-Housseiny, G. S., Aleissawy, A. E., & Aboshanab, K. M. (2022). Lysinibacillus Isolate MK212927: A Natural Producer of Allylamine Antifungal ‘Terbinafine’. Molecules, 27(1), 201. https://doi.org/10.3390/molecules27010201