Aging Process Effects on the Characteristics of Vacuum Residue Oxidation Products with the Addition of Crumb Rubber

Abstract

1. Introduction

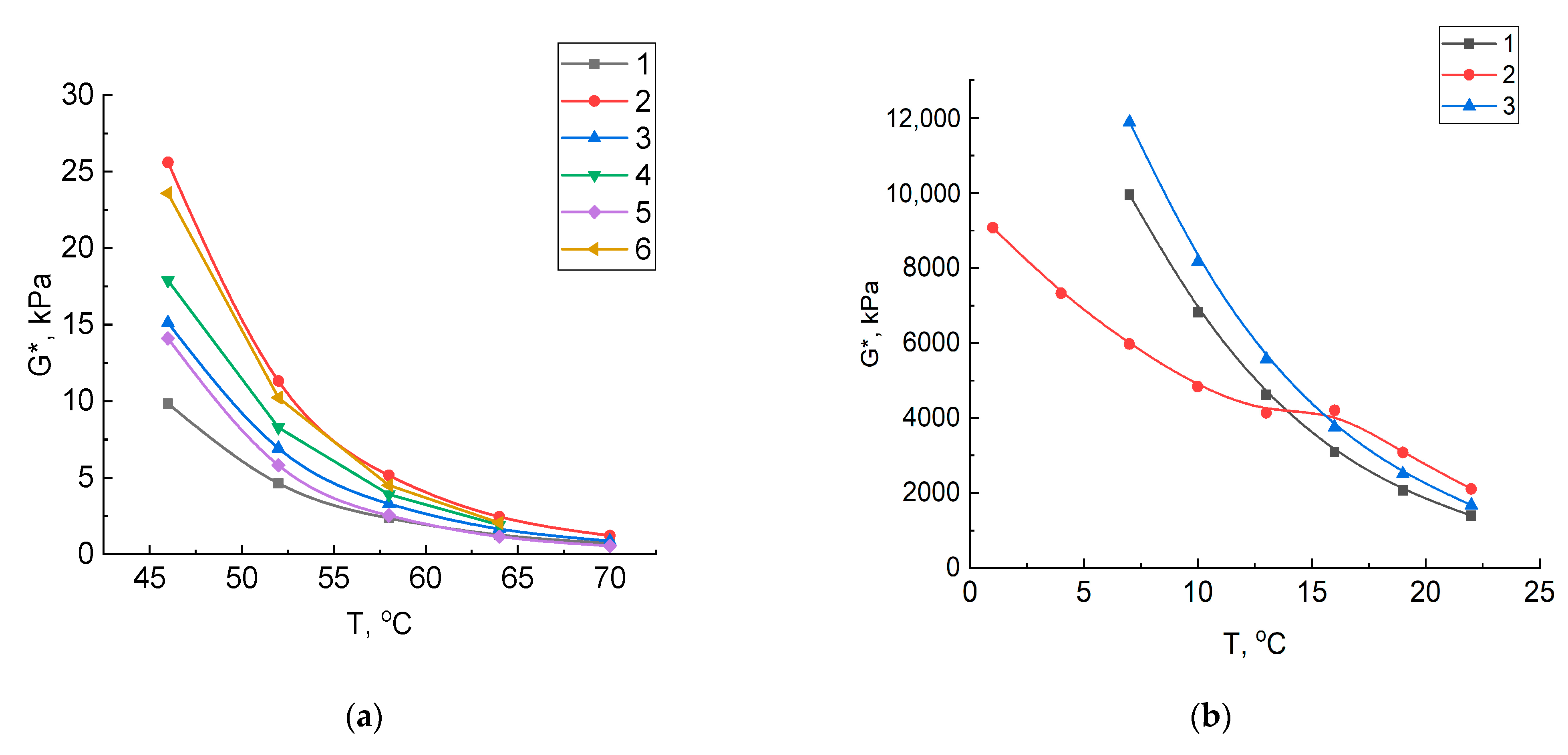

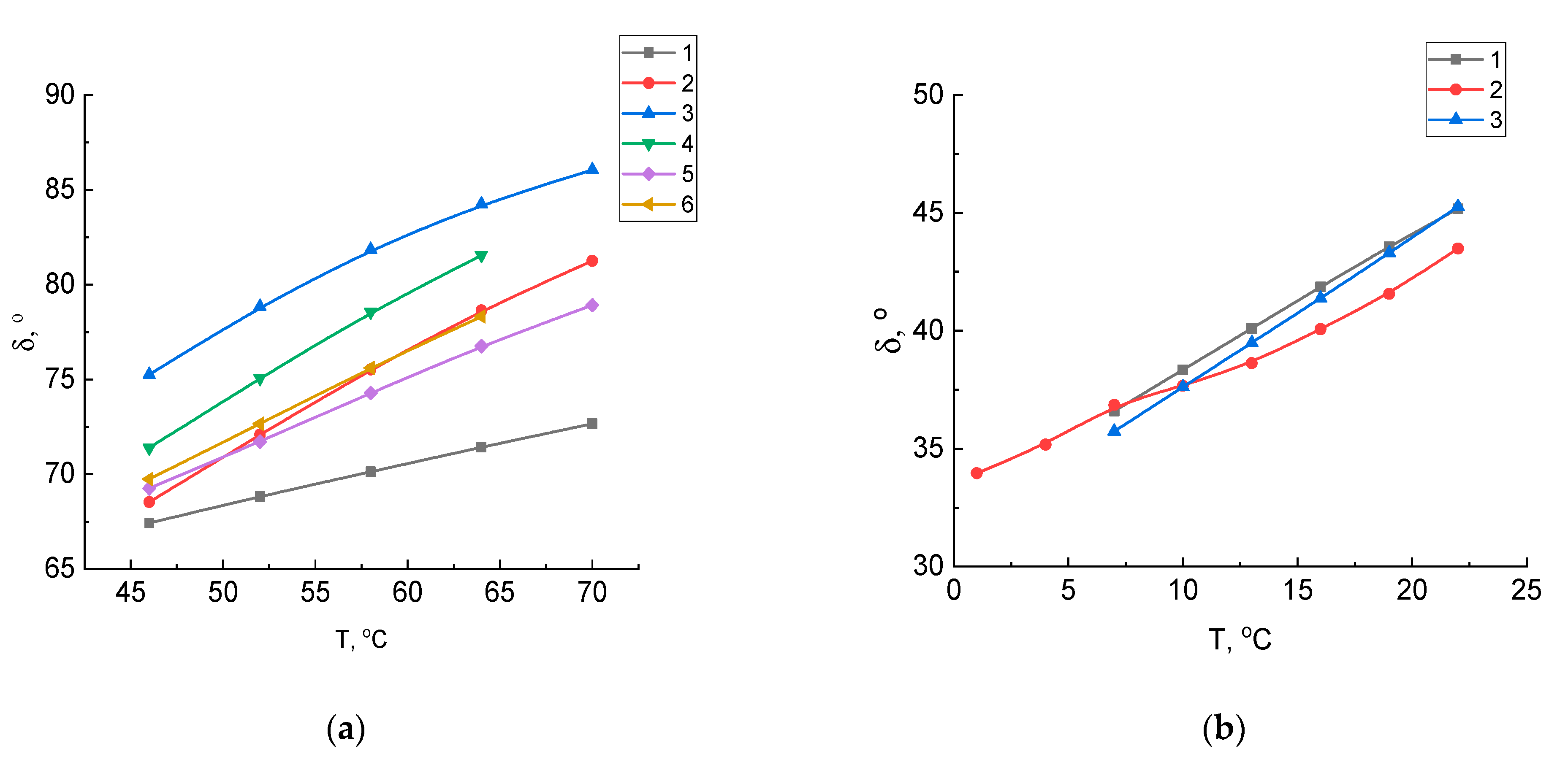

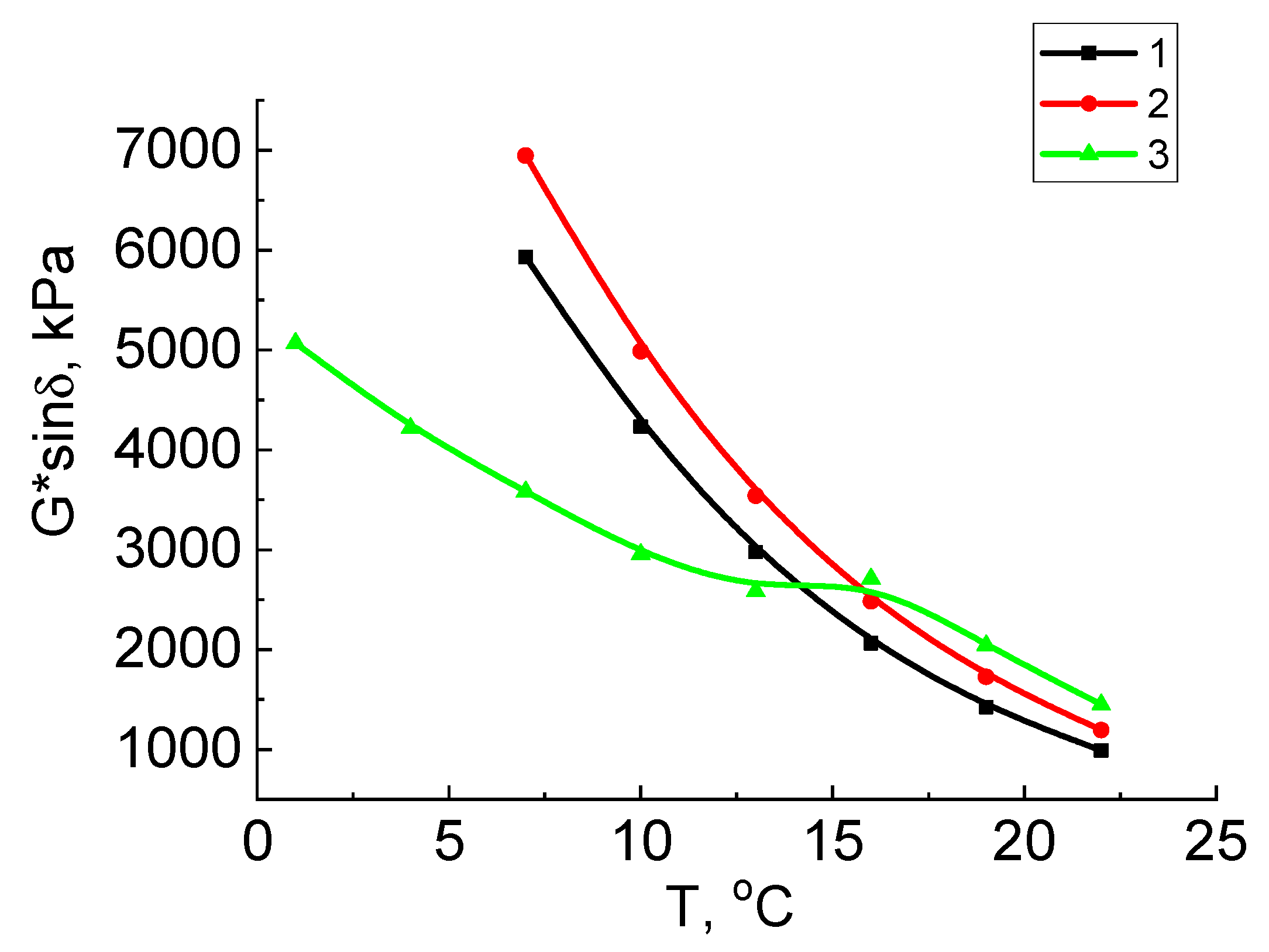

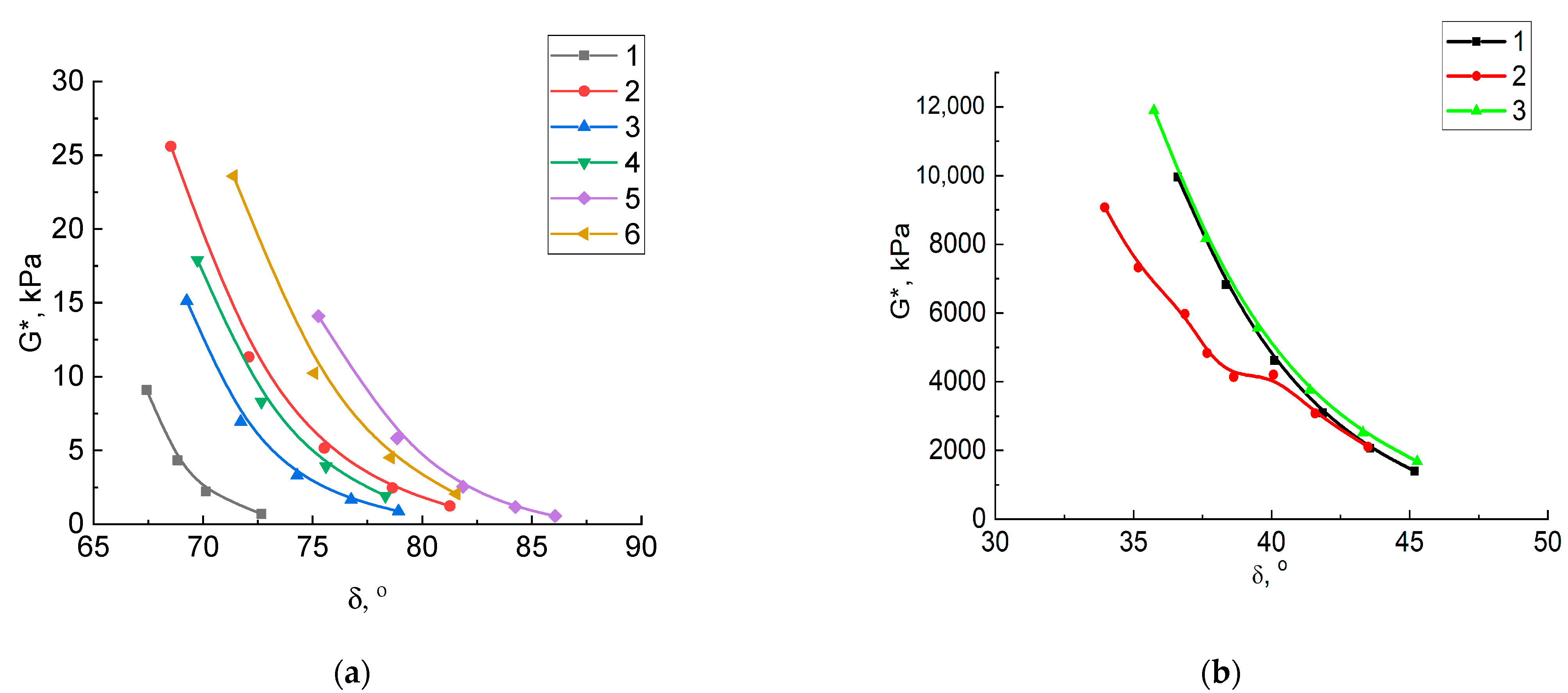

2. Results and Discussion

3. Materials and Methods

3.1. Materials

3.2. Oxidation Process

3.3. Aging Process

3.4. Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Zhambolova, A.; Vocaturo, A.L.; Tileuberdi, Y.; Ongarbayev, Y.; Caputo, P.; Aiello, I.; Rossi, C.O.; Godbert, N. Functionalization and Modification of Bitumen by Silica Nanoparticles. Appl. Sci. 2020, 10, 6065. [Google Scholar] [CrossRef]

- Speight, J.G. Asphalt Materials Science and Technology; Butterworth-Heinemann: London, UK, 2016. [Google Scholar] [CrossRef]

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM D6521; Revision 19A. Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Lesueur, D. The Colloidal Structure of Bitumen: Consequences on the Rheology and on the Mechanisms of Bitumen Modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Behzadfar, E.; Hatzikiriakos, S.G. Viscoelastic properties and constitutive modelling of bitumen. Fuel 2013, 108, 391–399. [Google Scholar] [CrossRef]

- Soenen, H.; Lu, X.; Laukkanen, O.V. Oxidation of bitumen: Molecular characterization and influence on rheological properties. Rheol. Acta 2016, 55, 315–326. [Google Scholar] [CrossRef]

- Mouillet, V.; Lamontagne, J.; Durrieu, F.; Planche, J.-P.; Lapalu, L. Infrared microscopy investigation of oxidation and phase evolution in bitumen modified with polymers. Fuel 2008, 87, 1270–1280. [Google Scholar] [CrossRef]

- Caputo, P.; Porto, M.; Loise, V.; Teltayev, B.; Rossi, C.O. Analysis of Mechanical Performance of Bitumen Modified with Waste Plastic and Rubber Additives by Rheology and Self Diffusion NMR Experiments. Eurasian Chem. Technol. J. 2019, 21, 235–239. [Google Scholar] [CrossRef]

- Lima, C.; Tom, L.; Filho, C.; Soares, S.; Soares Lima, J. Aging studies of asphalt-rubber binder. In Proceedings of the Asphalt Rubber 2006, Palm Springs, CA, USA, 25–27 October 2006. [Google Scholar]

- Peralta, J.; Hilliou, L.; Silva, H.; Machado, A.V.; Williams, R.C. Rheological changes in the bitumen caused by heating and interaction with rubber during asphalt-rubber production. Rheol. Acta 2014, 53, 143–157. [Google Scholar] [CrossRef][Green Version]

- Mohamed, A.A.; Hamzah, M.O.; Ismail, H.; Omar, H. Rheological properties of crumb rubber modified bitumen containing antioxidant. Arab. J. Sci. Eng. 2009, 34, 3–12. [Google Scholar]

- Lan, W.; Yongming, X.; Chunqing, C. Microscopic and Dynamic Rheological Characteristics of Crumb Rubber Modified Asphalt. J. Wuhan Univ. Technol. 2010, 25, 1022–1026. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. Effect of crumb rubber concentration on the physical and rheological properties of rubberised bitumen binders. Int. J. Phys. Sci. 2011, 6, 684–690. [Google Scholar]

- Nikolskii, V.G.; Dudareva, T.V.; Krasotkina, I.A.; Zvereva, U.G.; Bekeshev, V.G.; Rochev, V.Y.; Kaplan, A.M.; Chekunaev, N.I.; Vnukova, L.V.; Styrikovich, N.M.; et al. Development and Properties of New Nanomodifiers for Road Pavement. Rus. J. Phys. Chem. B 2014, 8, 577–583. [Google Scholar] [CrossRef]

- Hofko, B.; Falchetto, A.C.; Grenfell, J.; Huber, L.; Lu, X.; Porot, L.; Poulikakos, L.D. Effect of short-term aging temperature on bitumen properties. Road Mater. Pav. Des. 2017, 18, 108–117. [Google Scholar] [CrossRef]

- Pasandin, A.R.; Perez, I.; Oliveira, J.R.M.; Silva, H.M.R.D.; Pereira, P.A.A. Influence of ageing on the properties of bitumen from asphalt mixture with recycled concrete aggregates. J. Clean. Prod. 2015, 101, 165–173. [Google Scholar] [CrossRef]

- Airey, G.D. Factors affecting the rheology of polymer modified bitumen (PMB). In Polymer Modified Bitumen; McNally, T., Ed.; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Turco Liveri, V.; Oliviero Rossi, C. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Calandra, P.; Giordano, C.; Ruggirello, A.; Turco Liveri, V. Physicochemical investigation of acrylamide solubilization in sodium bis(2-ethylhexyl)sulfosuccinate and lecithin reversed micelles. J. Colloid Interface Sci. 2004, 277, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Calandra, P.; Di Marco, G.; Ruggirello, A.; Turco Liveri, V. Physico-chemical investigation of nanostructures in liquid phases: Nickel chloride ionic clusters confined in sodium bis(2-ethylhexyl) sulfosuccinate reverse micelles. J. Colloid Interface Sci. 2009, 336, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Tarsi, G.; Caputo, P.; Porto, M.; Sangiorgi, C. A Study of Rubber-REOB Extender to Produce Sustainable Modified Bitumens. Appl. Sci. 2020, 10, 1204. [Google Scholar] [CrossRef]

- Szerb, S.; Nicotera, I.; Teltayev, B.; Vaiana, R.; Oliviero Rossi, C. Highly stable surfactant-crumb rubber modified bitumen: NMR and Rheological investigation. Road Mater. Pav. Des. 2018, 19, 1192–1202. [Google Scholar] [CrossRef]

- AASHTO T 315-08; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State and Highway Transportation Officials: Washington, DC, USA, 2008.

- Tshoegl, N.W. The Phenomenological Theory of Linear Viscoelastic Behavior. An Introduction; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar]

| Indicator | Rubber Bitumen Binder | Requirements of ST RK 2028–2010 for RBB 60/90 |

|---|---|---|

| Needle penetration depth at 25 °C, 0.1 mm | 77.0 | 61–90 |

| Softening point under ring and ball, °C | 52.0 | not below than 52 |

| Ductility, cm: at 25 °C at 0 °C | 16.0 6.0 | notlessthan 12 not less than 6 |

| Elasticity at 25 °C, °C | 60.0 | not less than 30 |

| Fraas point, °C | −23.0 | not higher than −18 |

| Flashpoint, °C | 260.0 | not below than 250 |

| Softening point variation after heating, °C | 4.2 | not more than 5 |

| Sample | Maximum Design Temperature, °C | Average Design Temperature, °C | |

|---|---|---|---|

| Original | Aged in RTFO | Aged in PAV | |

| Vacuum residue | 63.0 | 65.2 | 10.0 |

| Vacuum residue oxidation product | 63.5 | 66.5 | 8.5 |

| Vacuum residue oxidation product with crumb rubber | 65.1 | 68.8 | 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ongarbayev, Y.; Zhambolova, A.; Tileuberdi, Y.; Mansurov, Z.; Oliviero Rossi, C.; Calandra, P.; Teltayev, B. Aging Process Effects on the Characteristics of Vacuum Residue Oxidation Products with the Addition of Crumb Rubber. Molecules 2022, 27, 3284. https://doi.org/10.3390/molecules27103284

Ongarbayev Y, Zhambolova A, Tileuberdi Y, Mansurov Z, Oliviero Rossi C, Calandra P, Teltayev B. Aging Process Effects on the Characteristics of Vacuum Residue Oxidation Products with the Addition of Crumb Rubber. Molecules. 2022; 27(10):3284. https://doi.org/10.3390/molecules27103284

Chicago/Turabian StyleOngarbayev, Yerdos, Ainur Zhambolova, Yerbol Tileuberdi, Zulkhair Mansurov, Cesare Oliviero Rossi, Pietro Calandra, and Bagdat Teltayev. 2022. "Aging Process Effects on the Characteristics of Vacuum Residue Oxidation Products with the Addition of Crumb Rubber" Molecules 27, no. 10: 3284. https://doi.org/10.3390/molecules27103284

APA StyleOngarbayev, Y., Zhambolova, A., Tileuberdi, Y., Mansurov, Z., Oliviero Rossi, C., Calandra, P., & Teltayev, B. (2022). Aging Process Effects on the Characteristics of Vacuum Residue Oxidation Products with the Addition of Crumb Rubber. Molecules, 27(10), 3284. https://doi.org/10.3390/molecules27103284