Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors

Abstract

:1. Introduction

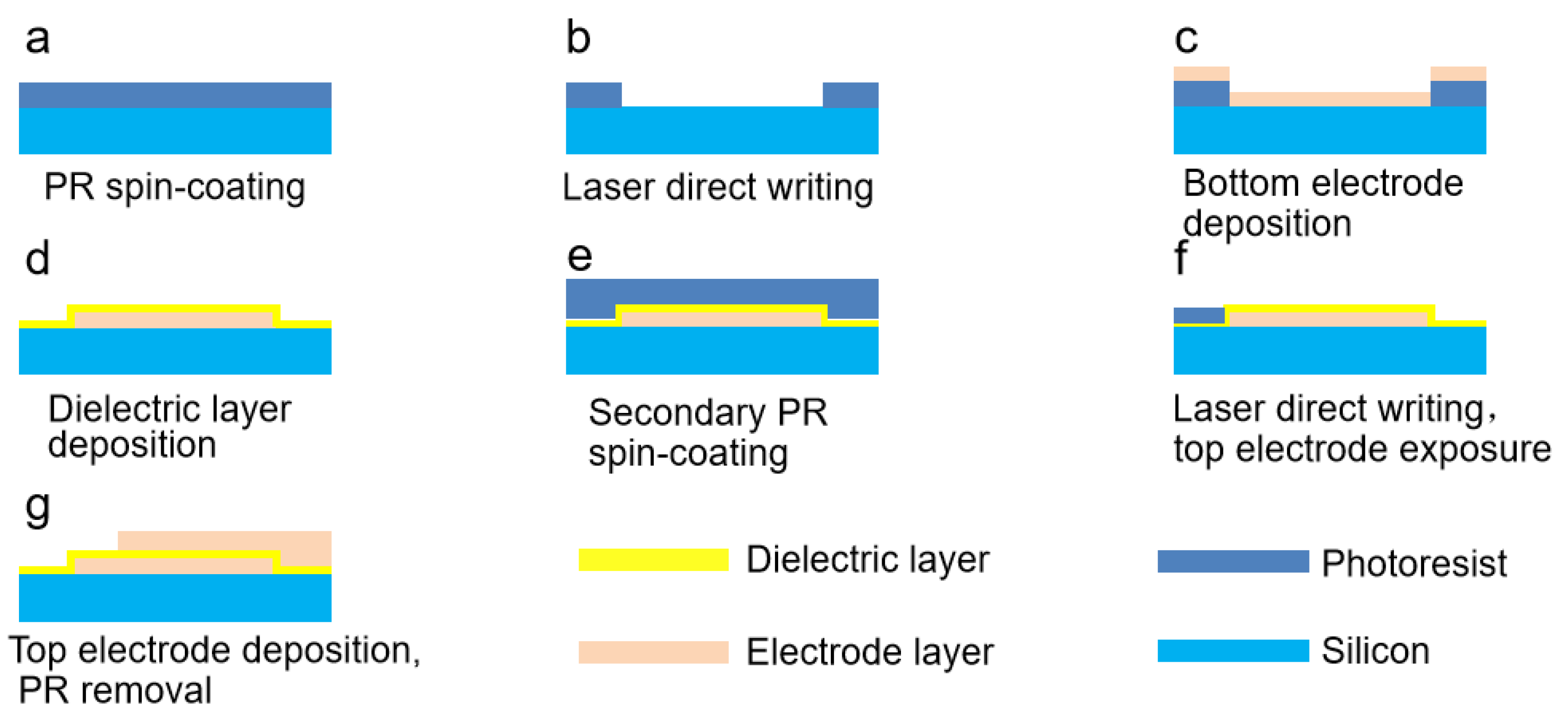

2. Experimental Section

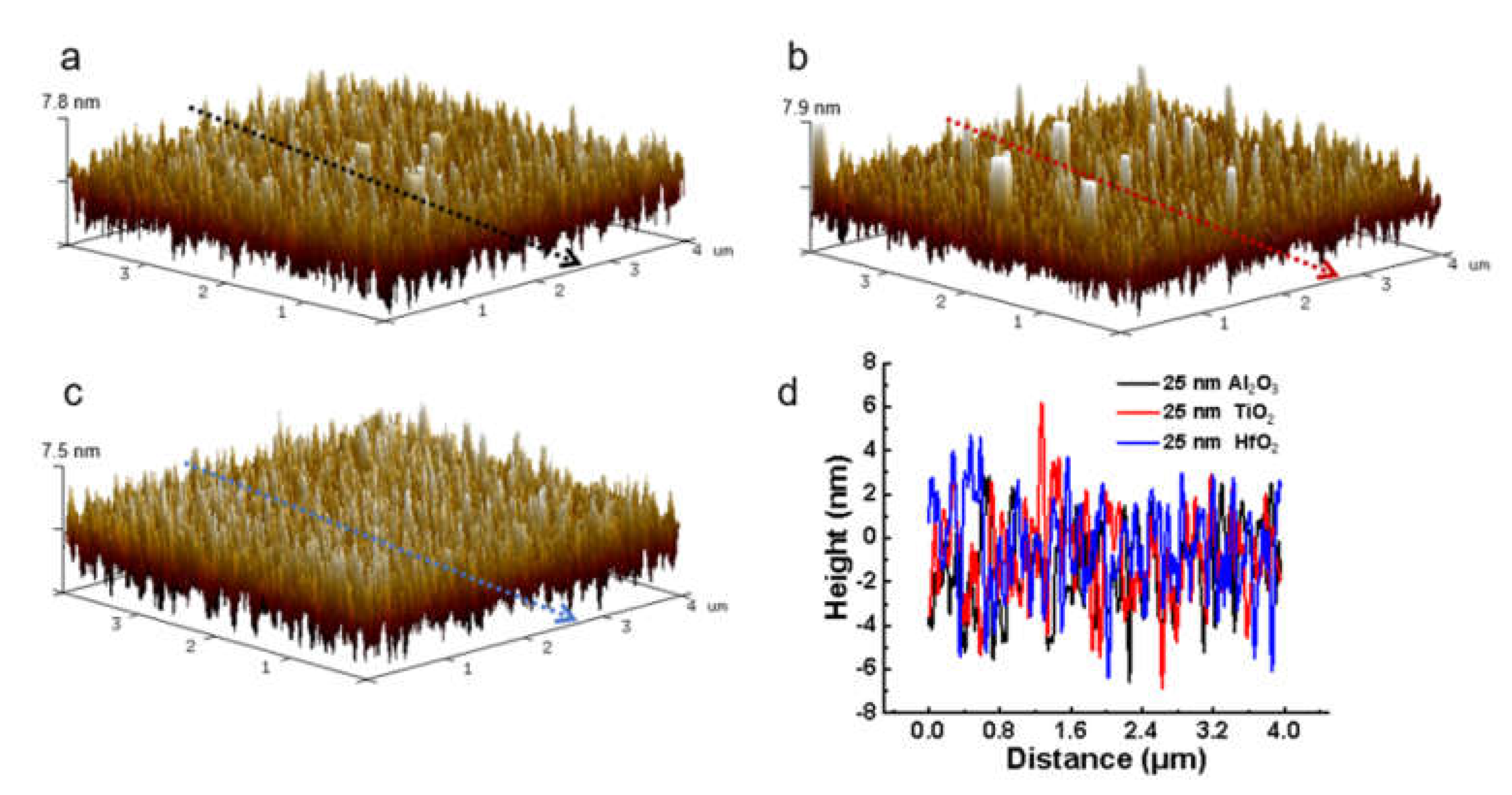

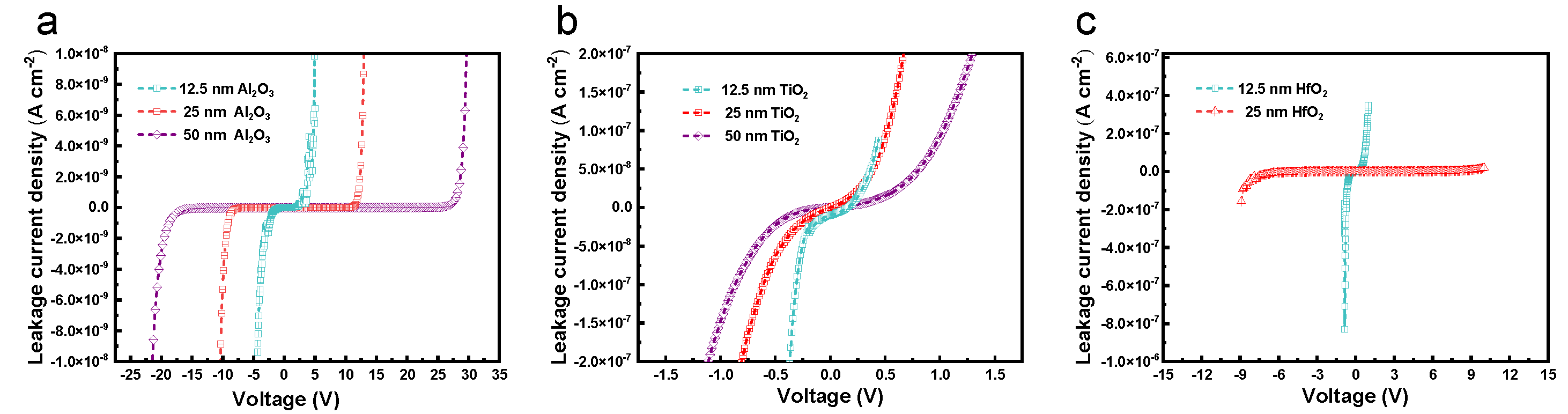

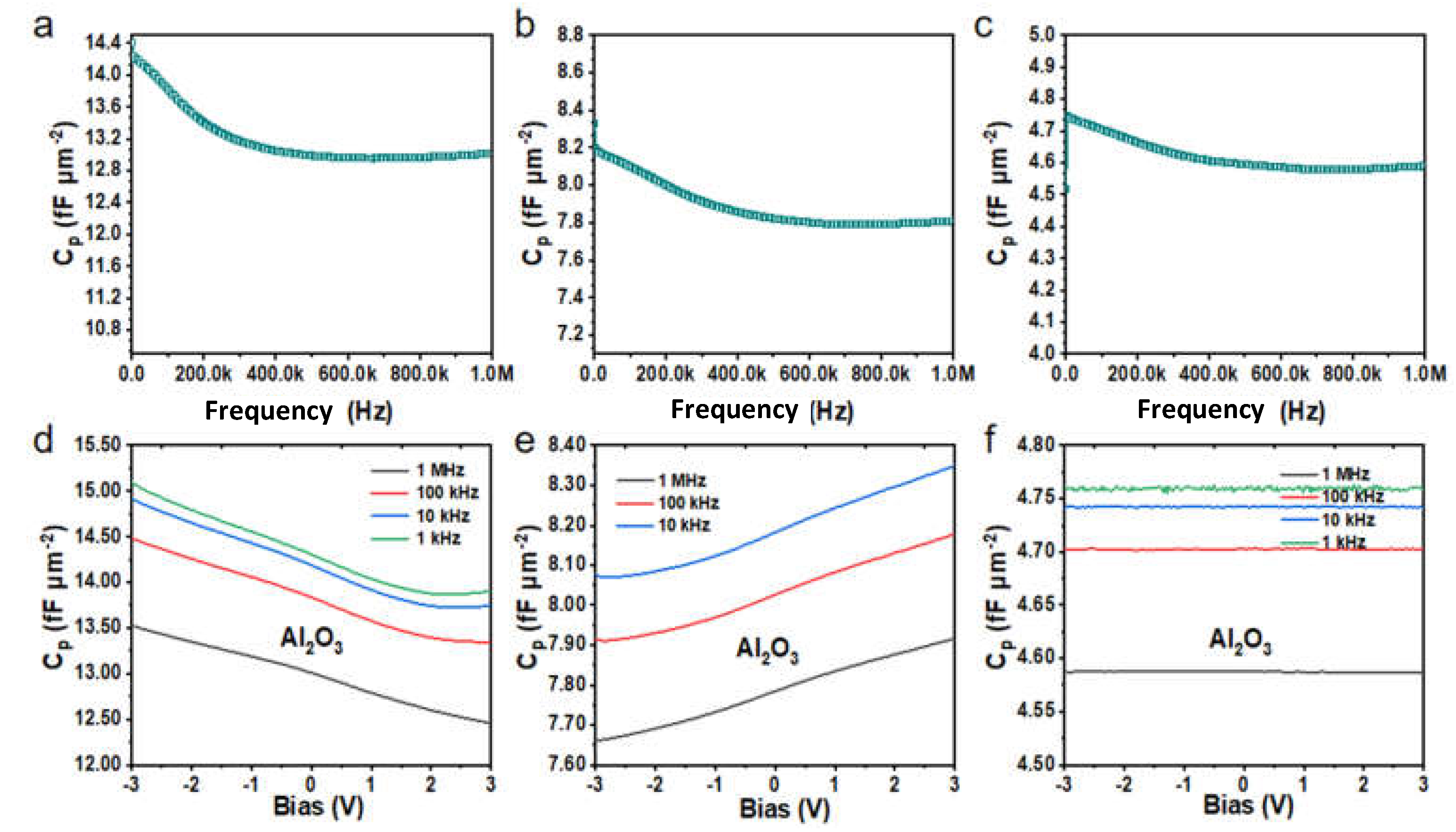

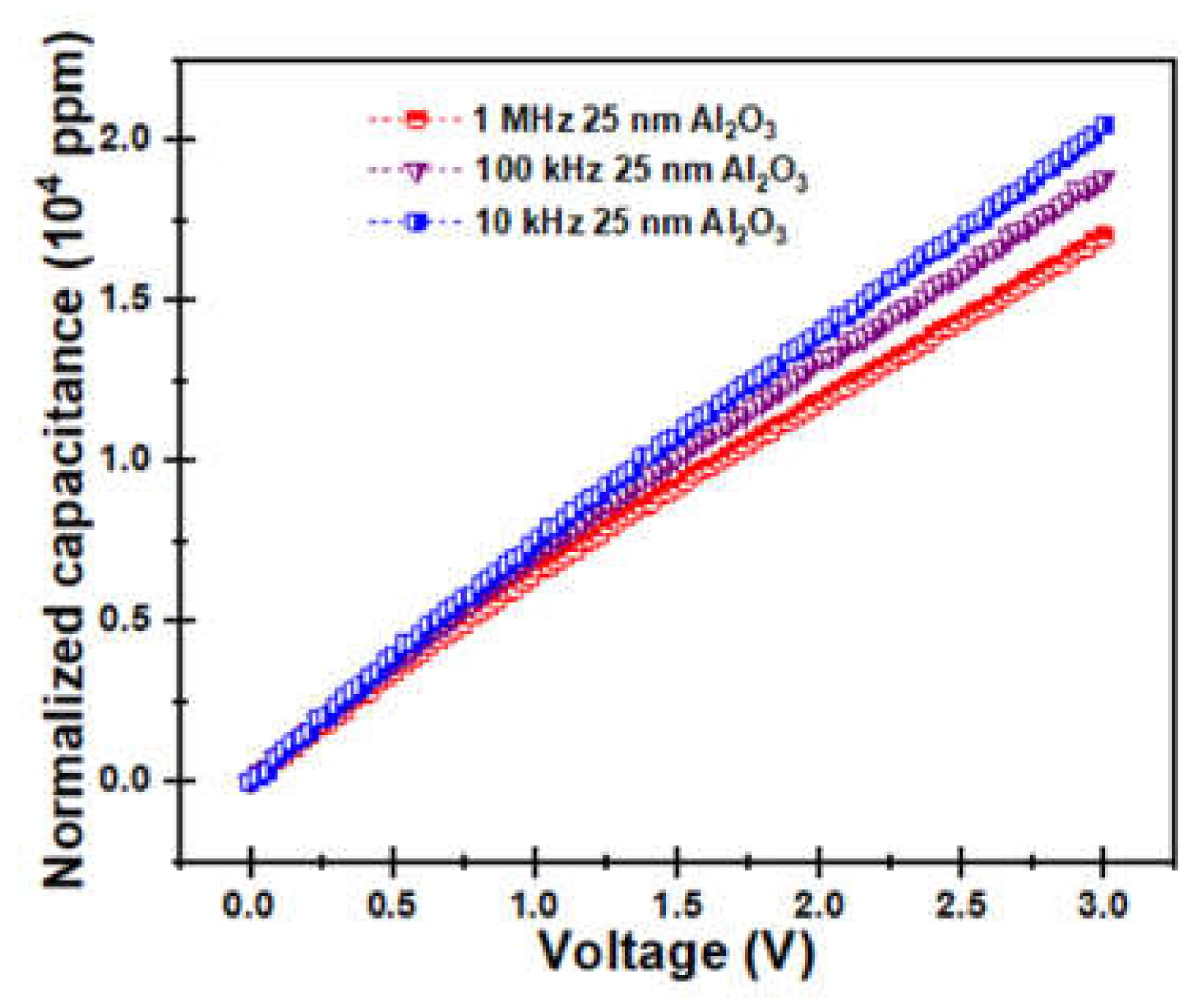

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qu, X.L.; He, Y.C.; Qu, M.H.; Ruan, T.Y.; Chu, F.H.; Zheng, Z.L.; Ma, Y.B.; Chen, Y.P.; Ru, X.N.; Xu, X.X.; et al. Identification of embedded nanotwins at c-Si/a-Si: H interface limiting the performance of high-efficiency silicon heterojunction solar cells. Nat. Energy 2021, 6, 194–202. [Google Scholar] [CrossRef]

- Bertaud, T.; Blonkowski, S.; Bermond, C.; Vallee, C.; Gonon, P.; Gros-Jean, M.; Flechet, B. Frequency effect on voltage linearity of ZrO2-based RF metal-insulator-metal capacitors. IEEE Electron Device Lett. 2009, 31, 114–116. [Google Scholar] [CrossRef]

- Mondal, S.; Shih, S.J.; Chen, F.H.; Pan, T.M. Structural and electrical characteristics of Lu2O3 dielectric embedded MIM capacitors for analog IC applications. IEEE Trans. Electron Devices 2012, 59, 1750–1756. [Google Scholar] [CrossRef]

- Dou, L.; Lin, Y.H.; Nan, C.W. An overview of linear dielectric polymers and their nanocomposites for energy storage. Molecules 2021, 26, 6148. [Google Scholar] [CrossRef]

- Mu, J.; Chou, X.; Ma, Z.; He, J.; Xiong, J. High-performance MIM capacitors for a secondary power supply application. Micromachines 2018, 9, 69. [Google Scholar] [CrossRef] [Green Version]

- Khaldi, O.; Jomni, F.; Gonon, P.; Mannequin, C.; Yangui, B. Investigation of electrical properties of HfO2 metal–insulator–metal (MIM) devices. Appl. Phys. A 2014, 116, 1647–1653. [Google Scholar] [CrossRef]

- Chen, T.W.; Shuang, Z.W.; Hu, J.; Zhao, Y.L.; Wei, D.H.; Ye, J.H.; Zhang, G.H.; Duan, H.G. Freestanding 3D metallic micromesh for high-performance flexible transparent solid-state zinc batteries. Small 2022, 18, 2201628. [Google Scholar] [CrossRef]

- He, G.; Gao, J.; Chen, H.-S.; Cui, J.-B.; Sun, Z.-Q.; Chen, X.-S. Modulating the interface quality and electrical properties of HfTiO/InGaAs gate stack by atomic-layer-deposition-derived Al2O3 passivation layer. ACS Appl. Mater. Interfaces 2014, 6, 22013–22025. [Google Scholar] [CrossRef]

- Zhang, G.H.; Hu, J.; Nie, Y.; Zhao, Y.L.; Wang, L.; Li, Y.Z.; Liu, H.Z.; Tang, L.Z.; Zhang, X.N.; Li, D.; et al. Integrating flexible ultralight 3D Ni micromesh current collector with NiCo bimetallic hydroxide for smart hybrid supercapacitors. Adv. Funct. Mater. 2021, 31, 2100290. [Google Scholar] [CrossRef]

- Wu, C.R.; Zhang, F.; Xiao, X.S.; Chen, J.Y.; Sun, J.Q.; Gandla, D.; Ein-Ein, Y.; Tan, D.Q. Enhanced electrochemical performance of supercapacitors via atomic layer deposition of ZnO on the activated carbon electrode material. Molecules 2021, 26, 4188. [Google Scholar] [CrossRef]

- Askari, M.B.; Salarizadeh, P.; Beheshti-Marnani, A.; Di Bartolomeo, A. NiO-Co3O4-rGO as an efficient electrode material for supercapacitors and direct alcoholic fuel cells. Adv. Mater. Interfaces 2021, 8, 2100149. [Google Scholar] [CrossRef]

- Oakes, L.; Westover, A.; Mares, J.W.; Chatterjee, S.; Erwin, W.R.; Bardhan, R.; Weiss, S.M.; Pint, C.L. Surface engineered porous silicon for stable, high performance electrochemical supercapacitors. Sci. Rep. 2013, 3, 3020. [Google Scholar] [CrossRef]

- Li, W.; Liu, Q.; Fang, Z.; Wang, L.; Chen, S.; Gao, F.; Ji, Y.; Yang, W.; Fang, X. All-solid-state on-chip supercapacitors based on free-standing 4H-SiC nanowire arrays. Adv. Energy Mater. 2019, 9, 1900073. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, G.; Zheng, X.; Chen, F.; Duan, H. Emerging miniaturized energy storage devices for microsystem applications: From design to integration. Int. J. Extrem. Manuf. 2020, 2, 042001. [Google Scholar] [CrossRef]

- Ho, C.S.; Chang, S.J.; Chen, S.C.; Liou, J.; Li, H. A reliable Si3N4/Al2O3-HfO2 stack MIM capacitor for high-voltage analog applications. IEEE Trans. Electron Devices 2014, 61, 2944–2949. [Google Scholar]

- Strambini, L.; Paghi, A.; Mariani, S.; Sood, A.; Kalliomäki, J.; Järvinen, P.; Toia, F.; Scurati, M.; Morelli, M.; Lamperti, A. Three-dimensional silicon-integrated capacitor with unprecedented areal capacitance for on-chip energy storage. Nano Energy 2020, 68, 104281. [Google Scholar] [CrossRef]

- Spahr, H.; Nowak, C.; Hirschberg, F.; Reinker, J.; Kowalsky, W.; Hente, D.; Johannes, H. Enhancement of the maximum energy density in atomic layer deposited oxide based thin film capacitors. Appl. Phys. Lett. 2013, 103, 042907. [Google Scholar] [CrossRef]

- He, G.; Liu, J.; Chen, H.; Liu, Y.; Sun, Z.; Chen, X.; Liu, M.; Zhang, L. Interface control and modification of band alignment and electrical properties of HfTiO/GaAs gate stacks by nitrogen incorporation. J. Mater. Chem. C 2014, 2, 5299–5308. [Google Scholar] [CrossRef]

- Yu, X.; Zhu, C.; Hu, H.; Chin, A.; Li, M.F.; Cho, B.J.; Kwong, D.L.; Foo, P.D.; Yu, M.B. A high-density MIM capacitor (13 fF/μm2) using ALD HfO2 dielectrics. IEEE Electron Device Lett. 2003, 24, 63–65. [Google Scholar]

- Ding, S.J.; Huang, Y.J.; Huang, Y.; Pang, S.H.; Zhang, W.; Wang, L.K. High density Al2O3/TaN-based metal–insulator–metal capacitors in application to radio frequency integrated circuits. Chin. Phys. 2007, 16, 2803. [Google Scholar]

- Hudec, B.; Hušeková, K.; Tarre, A.; Han, J.H.; Han, S.; Rosová, A.; Lee, W.; Kasikov, A.; Song, S.J.; Aarik, J.; et al. Electrical properties of TiO2-based MIM capacitors deposited by TiCl4 and TTIP based atomic layer deposition processes. Microelectron. Eng. 2011, 88, 1514–1516. [Google Scholar] [CrossRef]

- Wu, Y.H.; Ou, W.Y.; Lin, C.C.; Wu, J.R.; Wu, M.L.; Chen, L.L. MIM capacitors with crystalline-TiO2/SiO2 stack featuring high capacitance density and low voltage coefficient. IEEE Electron Device Lett. 2011, 33, 104–106. [Google Scholar] [CrossRef]

- Lee, S.K.; Kim, K.S.; Kim, S.W.; Park, S.J.; Kim, S. Characterizing voltage linearity and leakage current of high density Al2O3/HfO2/Al2O3 MIM capacitors. IEEE Electron Device Lett. 2011, 32, 384–386. [Google Scholar] [CrossRef]

- Suárez-Campos, G.; Cabrera-German, D.; Castelo-González, A.O.; Avila-Avendano, C.; Ríos, J.F.; Quevedo-López, M.A.; Aceves, R.; Hu, H.; Sotelo-Lerma, M. Characterization of aluminum oxide thin films obtained by chemical solution deposition and annealing for metal–insulator–metal dielectric capacitor applications. Appl. Surf. Sci. 2020, 513, 145879. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, B.E.; Thompson, D.; Choe, M.; Lee, Z.; Oh, I.K.; Kim, W.H.; Kim, H. Improved interface quality of atomic-layer-deposited ZrO2 metal-insulator-metal capacitors with Ru bottom electrodes. Thin Solid Film. 2020, 701, 137950. [Google Scholar] [CrossRef]

- Bylund, M.; Andersson, R.; Krause, S.; Saleem, A.M.; Marknäs, V.; Passalacqua, E.; Kabir, M.S.; Desmaris, V. Robustness of carbon nanofiber-based MIM capacitors with ultra-high capacitance density to electrical and thermal stress. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 2139–2144. [Google Scholar]

- Kun, P.; Biao, W.; Deyuan, X.; Shengfen, Q.; Lin, D.C.; Ping, W.; Yang, S.F. TDDB improvement by optimized processes on metal–insulator–silicon capacitors with atomic layer deposition of Al2O3 and multi layers of TiN film structure. J. Semicond. 2009, 30, 082005. [Google Scholar] [CrossRef]

- Iatsunskyi, I.; Kempinski, M.; Jancelewicz, M.; Zaleski, K.; Jurga, S.; Smyntyna, V. Structural and XPS characterization of ALD Al2O3 coated porous silicon. Vacuum 2015, 113, 52–58. [Google Scholar] [CrossRef]

- Yubero, F.; Holgado, J.P.; Barranco, A.; Gonzalez-Elipe, A.R. Determination of surface nanostructure from analysis of electron plasmon losses in XPS. Surf. Sci. Anal. 2002, 34, 201–205. [Google Scholar] [CrossRef]

- Zheng, L.; Cheng, X.H.; Cao, D.; Wang, G.; Wang, Z.J.; Xu, D.W.; Xia, C.; Shen, L.Y.; Yu, Y.H.; Shen, D.S. Improvement of Al2O3 Films on Graphene Grown by Atomic Layer Deposition with Pre-H2O Treatment. ACS Appl. Mater. Interfaces 2014, 6, 7014–7019. [Google Scholar] [CrossRef]

- Wu, Y.; Mayer, J.T.; Garfunkel, E.; Madey, T.E. X-ray photoelectron spectroscopy study of water adsorption on BaF2(111) and CaF2(111) surfaces. Langmuir 1994, 10, 1482–1487. [Google Scholar] [CrossRef]

- Mu, J.; Chou, X.; He, T.; Ma, Z.; He, J.; Xiong, J. Fabrication of high aspect ratio silicon micro-structures based on aluminum mask patterned by IBE and RIE processing. Microsyst. Technol. 2016, 22, 215–222. [Google Scholar] [CrossRef]

- Yao, S.; Yuan, J.; Gheeraert, E.; Sylvestre, A. Carbon nanotube forest based electrostatic capacitor with excellent dielectric performances. Carbon 2017, 116, 648–654. [Google Scholar] [CrossRef]

- Zhang, J.W.; He, G.; Zhou, L.; Chen, H.S.; Chen, X.S.; Chen, X.F.; Chen, B.D.; Lv, J.G.; Sun, Z.Q. Microstructure optimization and optical and interfacial properties modulation of sputtering-derived HfO2 thin films by TiO2 incorporation. J. Alloy. Compd. 2014, 611, 253–259. [Google Scholar] [CrossRef]

- Takeda, K.I.; Hinode, K.; Oodake, I.; Oohashi, N.; Yamaguchi, H. Enhanced dielectric breakdown lifetime of the copper/silicon nitride/silicon dioxide structure. In Proceedings of the 36th Annual 1998 IEEE International Reliability Physics Symposium Proceedings, Reno, NV, USA, 31 March–2 April 1998; pp. 36–41. [Google Scholar]

- Kwak, H.Y.; Kwon, H.M.; Jung, Y.J.; Kwon, S.K.; Jang, J.H.; Choi, W.I.; Ha, M.L.; Lee, J.I.; Lee, S.J.; Lee, H.D. Characterization of Al2O3–HfO2–Al2O3 sandwiched MIM capacitor under DC and AC stresses. Solid State Electron. 2013, 79, 218–222. [Google Scholar] [CrossRef]

- Soo, C.K.; Sang, K.L.; Seung, M.K.; Hyeon, J.H.; Byoung, H.L. Quantitative defect density extraction method for metal-insulator-metal capacitor. Semicond. Sci. Technol. 2020, 35, 115025. [Google Scholar]

- Rosenbaum, E.; Wu, J. Trap generation and breakdown processes in very thin gate oxides. Microelectron. Reliab. 2001, 41, 625–632. [Google Scholar] [CrossRef]

- Padmanabhan, R.; Bhat, N.; Mohan, S. High-performance metal–insulator–metal capacitors using europium oxide as dielectric. IEEE Trans. Electron Devices 2012, 59, 1364–1370. [Google Scholar] [CrossRef]

- Smitha, P.S.; Babu, V.S.; Shiny, G. Annealing effects on capacitance density and voltage coefficient of capacitance (VCC) of thin-film capacitor for energy harvesting application. In Proceedings of the 2019 TEQIP III Sponsored International Conference on Microwave Integrated Circuits, Photonics and Wireless Networks (IMICPW), Tiruchirappalli, India, 22–24 May 2019; pp. 223–227. [Google Scholar]

- Hourdakis, E.; Nassiopoulou, A.G. High performance MIM capacitor using anodic alumina dielectric. Microelectron. Eng. 2012, 90, 12–14. [Google Scholar] [CrossRef]

- Mahata, C.; Bera, M.K.; Hota, M.K.; Das, T.; Mallik, S.; Majhi, B.; Verma, S.; Bose, P.K.; Maiti, C.K. High performance TaYOx-based MIM capacitors. Microelectron. Eng. 2009, 86, 2180–2186. [Google Scholar] [CrossRef]

- Hourdakis, E.; Travlos, A.; Nassiopoulou, A.G. High-performance MIM capacitors with nanomodulated electrode surface. IEEE Trans. Electron Devices 2015, 62, 1568–1573. [Google Scholar] [CrossRef]

- Huang, Y.J.; Huang, Y.; Ding, S.J.; Zhang, W.; Ran, L. Electrical characterization of metal-insulator-metal capacitors with atomic-layer-deposited HfO2 dielectrics for radio frequency integrated circuit application. Chin. Phys. Lett. 2007, 24, 2942–2944. [Google Scholar]

- Kim, S.J.; Cho, B.J.; Li, M.F.; Ding, S.J.; Yu, M.B.; Zhu, C.X.; Chin, A.; Kwong, D.L. Engineering of voltage nonlinearity in high-k MIM capacitor for analog/mixed-signal ICs. In Proceedings of the 2004 Symposium on VLSI Technology, Honolulu, HI, USA, 15–17 June 2004; pp. 218–219. [Google Scholar]

- Dornisch, D.; Wilk, G.; Li, G.; Ring, K.M.; Howard, D.J.; Racanelli, M. Investigation of scaling limits for PECVD SiN and ALD HfO2/Al2O3 integrated MIM capacitors. ECS Trans. 2019, 6, 755–772. [Google Scholar] [CrossRef]

- Chernikova, A.G.; Markeev, A.M.; Lebedinskii, Y.Y.; Kozodaev, M.G.; Zablotskiy, A.V. Structural, chemical and electrical properties of ALD-grown HfxAl1-xOy thin films for MIM capacitors. Phys. Status Solidi 2015, 252, 701–708. [Google Scholar] [CrossRef]

- Ding, S.J.; Hu, H.; Lim, H.F.; Kim, S.J.; Yu, X.F.; Zhu, C.; Li, M.F.; Cho, B.J.; Chan, D.S.; Rustagi, S.C. High-performance MIM capacitor using ALD high-k HfO2-Al2O3 laminate dielectrics. IEEE Electron Device Lett. 2003, 24, 730–732. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, L.; Hu, J.; Yang, Z.; Li, X.; Zhang, H.; Zhang, G. Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors. Molecules 2022, 27, 3951. https://doi.org/10.3390/molecules27123951

Xiong L, Hu J, Yang Z, Li X, Zhang H, Zhang G. Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors. Molecules. 2022; 27(12):3951. https://doi.org/10.3390/molecules27123951

Chicago/Turabian StyleXiong, Li, Jin Hu, Zhao Yang, Xianglin Li, Hang Zhang, and Guanhua Zhang. 2022. "Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors" Molecules 27, no. 12: 3951. https://doi.org/10.3390/molecules27123951

APA StyleXiong, L., Hu, J., Yang, Z., Li, X., Zhang, H., & Zhang, G. (2022). Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors. Molecules, 27(12), 3951. https://doi.org/10.3390/molecules27123951