1. Introduction

Traditional Chinese medicine (TCM) has been used in Asia for thousands of years and is beginning to be widely accepted worldwide [

1,

2,

3]. In recent years, Chinese medicine has demonstrated unique efficacy in the treatment of various chronic diseases. Some compounds in TCMs can induce autophagy, which has been found to cure alcoholic liver and neurodegenerative diseases [

4,

5,

6,

7,

8]. Some studies have reported that certain TCMs could regulate components of apolipoprotein and key molecules involved in lipid transportation and uptake, which can help in treating conditions such as obesity and coronary heart disease [

9,

10,

11]. TCMs have also been remarkably effective in treating patients with COVID-19 [

12,

13,

14].

Ginkgo biloba is one of the most commonly used TCMs and has been used to treat a number of diseases, such as ischemic heart disease and cerebrovascular diseases [

15,

16]. Many analyses of ginkgo biloba have been established. They are mostly extracted with methanol or water or their mixtures [

17]. Supercritical fluid extraction [

18,

19] and pressurized water extraction [

20] are also possible. Separation and detection can be performed by RP-HPLC with ELSD, RI, or MS, or by GC/FID or GC/MS after silylation for routine detection [

21]. In the case of evidence-based medicine, the standardized ginkgo biloba extracts (e.g., EGb 761 and Shuxuening Injection) consist of two major fractions with specific pharmacological profiles: terpene trilactones (TTL) and flavonoids [

22,

23]. The TTL compound class is very rare and has only been found in ginkgo biloba [

24,

25]. Reports have shown that ginkgolides and sesquiterpene protect mitochondria from age-related damage and improve mitochondrial function and energy metabolism [

26,

27,

28]. There are two possible molecular mechanisms for mitochondrial protection: antagonism of platelet-activating factor receptor (PAF, 1-O-alkyl-2-acetyl-sn-glycerol-3-phosphocholine) [

29,

30,

31] and chloride channels [

32,

33,

34]. More than 30 genuine flavonoids are found in ginkgo biloba. Some epidemiological data suggest that flavonoids can prevent cardiovascular diseases and treat chronic venous insufficiency [

35,

36,

37]. The positive effects resulted from antioxidative and radical scavenger effects of the flavonoids [

38,

39]. Ginkgo biloba has several ingredients, such as Rutin. The content of each active ingredient can have a significant effect [

40]. For instance, Rutin can cause DNA damage at high doses [

41]. Thus, the content consistency of TCM is important.

However, ginkgo biloba is a natural product. Thus, the variability between samples remains high. In one study, the amount of ginkgolic acid in 11 samples of ginkgo biloba products from different sources differed by 42 times. The content of the remaining compounds could deviate by 2 to 30 times [

42]. Another study of 11 ginkgo biloba products in the U.S. market showed that the difference in bilobalide content between manufacturers could be up to 20 times [

43]. Many countries have proposed many quality standards to control the consistency of herbs’ content [

44]. Even though all products follow the same standards, Mantle et al. found huge differences when comparing G. Biloba produced by different manufacturers [

45]. As TCM is derived from agricultural products and biological organisms, its quality can be influenced by multiple factors, such as variety, origin, climate, growth years, and storage conditions [

46]. Therefore, it is hard to control the consistency of the herb content at the planting stage. To clinically expand the use of herbal medicines, it is necessary to maintain their qualities. In the production of modern chemical drugs, various methods are used to manage the consistency of quality. One is the blending technique [

47]. Blending technology is indispensable to ensure the stability of TCM quality.

Only a few studies of blending technology have been reported in herbal medicine. Liu et al. presented a nonlinear least-squares-based method to blend ten batches of Fructus Gardeniae extracts. They selected seven peaks in the sample for control. The similarity between the calculation results and the target was greater than 99.9%, with less than 3% deviation after computation [

48]. Tang presented a new function to blend 14 batches of Zhou prescription samples. They used Zhou’s compound medicine samples prepared with authentic medicinal materials as the target. The branch samples, after replacing some herbs, were used for mixing. The similarities between different blending schemes increased to the range of 0.9208 to 0.9797 from 0.7338 to 0.8925, and the deviation decreased to the range of 0.1549 to 0.2790 from 0.4768 to 0.6083 [

49,

50].

These studies were enlightening for the herb-blending process, but there are a few areas we seek to improve upon. In the mixing process, the most important thing is how to build the target. Neither of them discusses what a reasonable target should be and the process of setting them. Liu did not discuss how to establish a blending target. At the same time, the mixing process should also ensure that the mixed samples are representative. In fact, the key to blending is to take qualified samples but deviate from the target and blend them in ratios to achieve a high degree of similarity to the target with controlled content deviation. The blending process should avoid samples being too similar to the target and ensure that the samples are qualified. Tang’s target was too similar to their samples, which differed by only one herb. Secondly, these algorithms in these studies did not show flexibility for different blending constraints. Manufacturers may change the mixing constraints for other products’ needs or standards in actual production. The algorithms of Liu and Tang only performed single-condition blending, making it challenging to meet the actual needs of the manufacturer. Furthermore, these articles did not mention how to select blending samples for the blending process. In practice, not all selected samples can be blended to calculate the desired target. For example, when the content of all selected samples is less than the target, it is not possible to obtain the mixing result with equal feeding. Now, there still need to develop a blending process that establishes goals, meets multiple conditions for flexible blending, and can help users to select blending samples effectively.

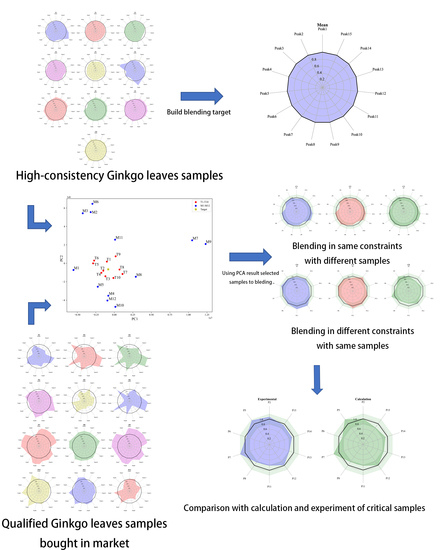

In this study, we developed a new blending method based on a nonlinear optimization algorithm to meet the practical needs of manufacturers. The algorithm calculated the blending recipe to meet the overall similarity and individual content deviation requirements. Samples from different years of origin were compared to illustrate the need for blending. For the target established, high-consistency samples from the manufacturer were the target branch, and qualified samples from the market were used as blending samples. Principal component analysis (PCA) results of samples and targets were established to choose samples for mixing. Multiple sets of computational experiments were designed to demonstrate the flexibility of the nonlinear optimization algorithm for different limits of relative-deviation coefficients (RDCs) or different samples for mixing. Samples at critical conditions were chosen for the experiment, and their deviations from the computational results were analyzed. Finally, the prospect of applying algorithms in the quality control of TCMs was discussed.

2. Results and Discussion

2.1. Optimization of Chromatographic Conditions

To characterize the main components, the extract of the sample was analyzed by high-performance liquid chromatography with an ultraviolet detector and evaporative light-scattering detector (HPLC-UV-ELSD). The most appropriate conditions were screened out based on several chromatographic experiments, including mobile phases, gradients, flow rate, and detection wavelength. The mobile phase was composed of MeOH (A) and 1% FA (

v/v) in H

2O (B). The gradients of mobile phases A and B with respect to time were consistent with

Table 1. The flow rate was 1.0 mL/min. The HPLC-UV-ELSD chromatograms were shown in

Figure S1. After considering the quality standards of commercially available ginkgo biloba extracts such as Shuxuening injection [

22,

51,

52], we chose the chromatograms from 25 min to 60 min and selected 15 peaks as the standard peaks to establish the standard fingerprints used in the production of ginkgo medicine. The fingerprints are shown in

Figure 1. The qualitative attributions of its chromatographic peaks are shown in

Table 2, identified by standard compounds shown in

Table S1. Fifty-three batches of ginkgo biloba were obtained from different manufacturers, and their detailed information is listed in

Table S2. The area of peak 8 in the UV chromatogram was used to calibrate all ELSD peaks. However, using semiquantitative data in blending does not require accurate compound identification. In this process, peak matching and area correction are more important than compound identification.

2.2. Comparison of Ginkgo Leaves from Different Sources

We compared the samples of ginkgo biloba from different origins and years, and the results are shown in

Figure S2. Their average content of components was used as the standard, and the similarity and RDC of each compound were calculated, as shown in

Table S3. The average of each peak was used as the unit of measurement and the number of each peak as the axis. The radar charts are shown in

Figure S3.

To compare the samples of different years or sources, the peaks and peak areas of the samples were classified by different conditions. The results were shown in

Figure 2.

Supplementary S15, S16, and S17 were samples with more than ten years of growth,

Supplementary S5 was a sample with two years of growth, and

Supplementary S11 was a sample with five years of growth, and they all have the same origin.

Figure 2D and

Table S3 show that the samples with more than ten years of growth period differ significantly from the other samples in composition content. The differences in the content of P2, P5, P13, P14, and P15 ranged from 200% to 300%.

Comparing samples from different years and origins shows that the available qualified samples in the market vary greatly, which is unfavorable for quality control and subsequent quantitative research of TCMs. According to Horbowicz M. et al., this may be related to the content of methyl jasmonate in the leaves [

53]. The above results also imply that it is difficult to control the quality of samples from cultivation, indicating the necessity of the blending process.

2.3. Establishing a Blending Target

High-consistency samples were used to establish the target. T1–T10, referred to as the target samples, were the high-quality branch recognized by the factory. Their chromatograms are shown in

Figure S3, and radar plots are shown in

Figure 3. The average value of samples T1–T10 was used as the blending target. Their similarities and RDCs in

Table 3 show that the target samples have a pretty close similarity of 99.3% or higher and relatively small content differences with ±20% or lower. This is why the RDCs were controlled below ±20% in the following calculation.

It can be seen that the compositional content of the samples as targets was in good consistency. Thus, the constraints of our blending process referenced to the target samples to keep the RDCs of the blending results consistent (±20%) or better (±10%) with the target.

2.4. Comparing and Choosing Samples

M1–M11, referred to as the blending samples for mixing, were qualified branches purchased by the factory. Their radar plots are shown in

Figure 4. The similarity and RDC are shown in

Table 4. The blending samples have similarities as low as about 91% and the RDC from −50% to 60%. Compared with the target samples (T1–T10), all the blending samples but M8 have lower similarities. Even in the M8 sample, which was most similar to the target, more than half of its peaks have RDCs over ±20%.

Comparing the target samples with the qualified samples shows significant differences between even the samples of ginkgo biloba that meet the market standards. This illustrates the importance of controlling product quality with blending algorithms.

The goal of our blending algorithm is to blend the qualified but inconsistent samples to improve consistency across batches. Thus, the significance of the blending algorithm is to provide a blending ratio that ensures a high overall fingerprint similarity between the product and the target and controls the RDCs of component contents.

The PCA results for the blending samples (M1–M11), the target samples (T1–T10), and their blended target are shown in

Figure 5. The PCA results show that the consistency of the target samples (T1–T10) was much higher than that of the blending samples (M1–M12).

One great use of PCA results is effectively selecting the samples for a successful blending. If one chooses the blending samples distributed on one side around the target, the mixing will have a lower chance of meeting one given set of the relative deviation content limits as defined in Equation (7). Conversely, the selection of the blending samples symmetrically distributed around the target should be highly likely to meet the blending requirements.

2.5. Calculation of the Blending Method in Different Constraints with the Same Samples

To verify our algorithm to perform blending under different constraints, three different blending constraints were set for mixing. The constraints 1, 2, and 3 were abbreviated as C1, C2, and C3. The RDCs of P2, P5, and P6 with mixed high- and medium-component contents were controlled within ±10% in C1. The RDCs of P11, P12, and P13 with mixed high- and medium-component contents were held within ±10% in C2. The RDCs of P1, P4, and P9 with low-component contents were controlled within ±10% in C3. All information is summarized in

Table 5. Using the PCA results in

Figure 5 qualified samples M1, M2, M5, and M8 were selected as blending ingredients, uniformly distributed around the target. The calculated blending-ratio results are shown in

Table 5, and the projected similarity and RDCs are shown in

Table 6. The radar plot of the calculation results is shown in

Figure 6. The results in

Figure 6 and

Table 6. show that the algorithm can successfully perform blending-optimization calculations under different constraints with 99.9% or higher similarities and ±10% or lower RDCs of the selected components in all three experiments. For P4, the RDC even improved from a minimum of −45.4% to −10% (M2).

These RDCs were lower than that in the target branch. It is difficult to make the RDCs of all peaks more inferior to the target, but it is possible to control some peaks for different application scenarios strictly. The blending results show that the blending algorithm with sample selection can lower the RDCs of chosen peaks in the blending consequence than in the target. No matter how high or low the component contents are to be controlled, with the help of the PCA results, the blending method can effectively select the blending samples and successfully calculate the blending ratio by using the blending-optimization algorithm.

2.6. Calculation of the Blending Method in the Same Constraints with Different Samples

Using different samples for mixing under the same constraints was also verified. According to the actual needs of manufacturers, we took the similarity as the objective function and set the RDC limit less than ±20% for P2, P5, P6, P7, P8, P11, P12, P13, P14, and P15 to meet the product requirements. Using the PCA results, three sets of the blending samples were selected for mixing. The constraints 4, 5, and 6 were abbreviated as C4, C5 and C6. The mixing percentages are shown in

Table 7, and their RDC and similarity are shown in

Table 8. The radar plot of the calculation results is shown in

Figure 7. As shown in

Table 8, the blending ratios in three mixing tests satisfy their blending constraints with similarities higher than 98.5% and the RDCs within ±20%. In C4, the RDC of P7 dropped from 96% to −7.8%, and the RDC of P14 decreased from 93% to −14.3%.

The results show that the nonlinear optimization algorithm can control similarity and RDCs, working well under boundary constraints.

2.7. Experimental Validation of Critical Result in Calculation

Among results in C4–C6, the blending result C4 performs the best and C6 the worst. To verify our algorithm’s actual mixing ability and experimental accuracy, the C6 ratio was used for the experimental verification. The experimental validation results are shown in

Figure 8 and

Table 9. The model predicts results with similarity above 98% and RDC ±20%. The experimental results were consistent with the expected results, with content ratios between 80% and 120% and prediction deviations within the practical error range. The difference between the RDCs of calculations and experimental results was in the range of −3.6% to 12.6%.

The experiments showed that the blending results met the constraints. The RDCs of the blending results were similar to those of the high-quality samples (T1–T10). The deviation between calculations and experiments was mainly caused by the uneven sampling of samples. If the samples can be premixed before extracting, the internal homogeneity of each sample can be improved, and the blending results can be enhanced.

The actual experiments used the calculated marginal results, which made the experiments representative. Admittedly, the results of the actual experiments were less. Still, more experiments were conducted after adjusting the constraints to the producer’s requirements, and pilot and large-scale production were performed. The results of all experiments performed well, which will be shown in a later report.

The above results prove that the nonlinear algorithm effectively controls the similarity and RDCs of chosen peaks in actual productions.