Antioxidant Extracts of Nettle (Urtica dioica) Leaves: Evaluation of Extraction Techniques and Solvents

Abstract

:1. Introduction

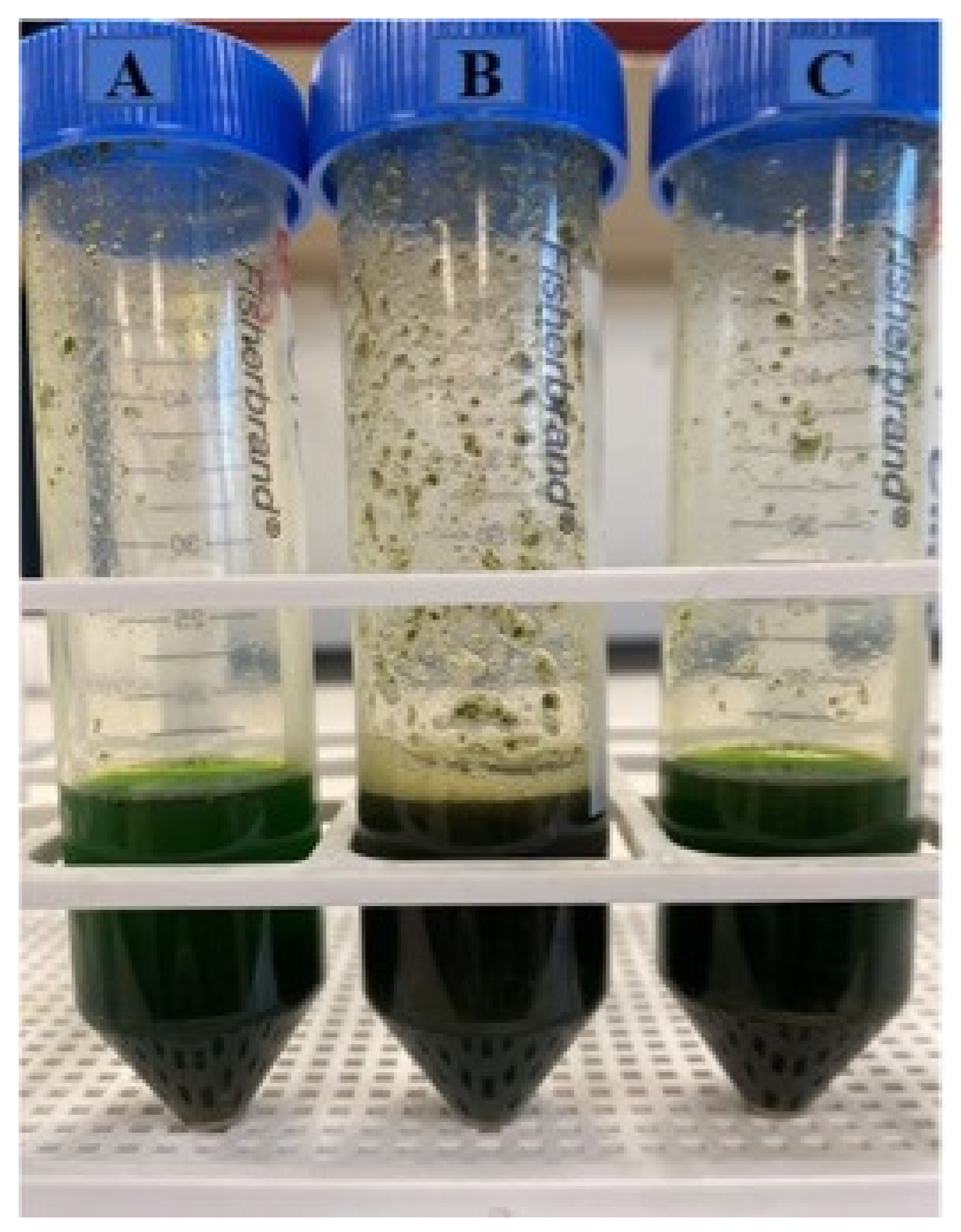

2. Results and Discussion

2.1. Modelling of the Total Phenolic Content (TPC)

2.2. Modelling of DPPH• Radical Scavenging Activity

2.3. Modelling of ABTS•+ Radical Scavenging Activity

2.4. Optimization of the Antioxidant Compounds Extraction of Urtica dioica Nettles

3. Materials and Methods

3.1. Chemicals and Plant Materials

3.2. Determination of Moisture Content of the Dry Matter and Water Activity (Aw)

3.3. Preparation of Extracts

3.4. Determination of Antioxidant Properties

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Yilmaz, Y.; Toledo, R.T. Oxygen radical absorbance capacities of grape/wine industry byproducts and effect of solvent type on extraction of grape seed polyphenols. J. Food Compos. Anal. 2006, 19, 41–48. [Google Scholar] [CrossRef]

- Zam, W. Effect of Alginate and Chitosan Edible Coating Enriched with Olive Leaves Extract on the Shelf Life of Sweet Cherries (Prunus avium L.). J. Food Qual. 2019, 2019, 8192964. [Google Scholar] [CrossRef]

- Merz, B.; Capello, C.; Leandro, G.C.; Moritz, D.E.; Monteiro, A.R.; Valencia, G.A. A novel colorimetric indicator film based on chitosan, polyvinyl alcohol and anthocyanins from jambolan (Syzygium cumini) fruit for monitoring shrimp freshness. Int. J. Biol. Macromol. 2020, 153, 625–632. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yong, H.; Gao, L.; Li, L.; Jin, M.; Liu, J. Preparation and characterization of antioxidant and pH-sensitive films based on chitosan and black soybean seed coat extract. Food Hydrocoll. 2019, 89, 56–66. [Google Scholar] [CrossRef]

- Riaz, A.; Lagnika, C.; Luo, H.; Dai, Z.; Nie, M.; Hashim, M.M.; Liu, C.; Song, J.; Li, D. Chitosan-based biodegradable active food packaging film containing Chinese chive (Allium tuberosum) root extract for food application. Int. J. Biol. Macromol. 2020, 150, 595–604. [Google Scholar] [CrossRef]

- Shan, B.; Cai, Y.-Z.; Brooks, J.D.; Corke, H. Antibacterial and antioxidant effects of five spice and herb extracts as natural preservatives of raw pork. J. Sci. Food Agric. 2009, 89, 1879–1885. [Google Scholar] [CrossRef]

- Mir, S.A.; Dar, B.N.; Wani, A.A.; Shah, M.A. Effect of plant extracts on the techno-functional properties of biodegradable packaging films. Trends Food Sci. Technol. 2018, 80, 141–154. [Google Scholar] [CrossRef]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Mzid, M.; Ben Khedir, S.; Bardaa, S.; Sahnoun, Z.; Rebai, T. Chemical composition, phytochemical constituents, antioxidant and anti-inflammatory activities of Urtica urens L. leaves. Arch. Physiol. Biochem. 2017, 123, 93–104. [Google Scholar] [CrossRef]

- Ćetković, G.S.; Čanadanović-Brunet, J.M.; Djilas, S.M.; Tumbas, V.T.; Markov, S.L.; Cvetković, D.D. Antioxidant potential, lipid peroxidation inhibition and antimicrobial activities of Satureja montana L. subsp. kitaibelii extracts. Int. J. Mol. Sci. 2007, 8, 1013–1027. [Google Scholar] [CrossRef] [Green Version]

- Simopoulos, A.P. Essential fatty acids in health and chronic diseases. Forum Nutr. 2003, 56, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Đurović, S.; Pavlić, B.; Šorgić, S.; Popov, S.; Savić, S.; Petronijević, M.; Radojković, M.; Cvetanović, A.; Zeković, Z. Chemical composition of stinging nettle leaves obtained by different analytical approaches. J. Funct. Foods 2017, 32, 18–26. [Google Scholar] [CrossRef]

- Awad, T.S.; Moharram, H.A.; Shaltout, O.E.; Asker, D.; Youssef, M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar] [CrossRef]

- Gualberto, N.C.; de Oliveira, C.S.; Nogueira, J.P.; de Jesus, M.S.; Araujo, H.C.S.; Rajan, M.; Neta, M.T.S.L.; Narain, N. Bioactive compounds and antioxidant activities in the agro-industrial residues of acerola (Malpighia emarginata L.), guava (Psidium guajava L.), genipap (Genipa americana L.) and umbu (Spondias tuberosa L.) fruits assisted by ultrasonic or shaker extracti. Food Res. Int. 2021, 147, 110538. [Google Scholar] [CrossRef]

- Zhang, Q.-W.; Lin, L.-G.; Ye, W.-C. Techniques for extraction and isolation of natural products: A comprehensive review. Chin. Med. 2018, 13, 20. [Google Scholar] [CrossRef]

- Stanojević, L.P.; Stanković, M.Z.; Cvetković, D.J.; Cakić, M.D.; Ilić, D.P.; Nikolić, L.; Stanojevic, J. The effect of extraction techniques on yield, extraction kinetics, and antioxidant activity of aqueous-methanolic extracts from nettle (Urtica dioica L.) leaves. Sep. Sci. Technol. 2016, 51, 1817–1829. [Google Scholar] [CrossRef]

- Schernthaner, G.; Erd, W.; Ludwig, H. Handbook of Food Preservation; CRC Press: Boca Raton, FL, USA, 1976; Volume 6. [Google Scholar]

- Buchaillot, A.; Caffin, N.; Bhandari, B. Drying of lemon myrtle (Backhousia citriodora) leaves: Retention of volatiles and color. Dry. Technol. 2009, 27, 445–450. [Google Scholar] [CrossRef]

- Saifullah; McCullum, R.; McCluskey, A.; Vuong, Q. Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon 2019, 5, e03044. [Google Scholar] [CrossRef]

- Vázquez, M.; Velazquez, G.; Cazón, P. UV-Shielding films of bacterial cellulose with glycerol and chitosan. Part 1: Equilibrium moisture content and mechanical properties. CyTA J. Food 2021, 19, 105–114. [Google Scholar] [CrossRef]

- Ince, A.E.; Sahin, S.; Sumnu, G. Comparison of microwave and ultrasound-assisted extraction techniques for leaching of phenolic compounds from nettle. J. Food Sci. Technol. 2014, 51, 2776–2782. [Google Scholar] [CrossRef]

- Corbin, C.; Fidel, T.; Leclerc, E.A.; Barakzoy, E.; Sagot, N.; Falguiéres, A.; Renouard, S.; Blondeau, J.-P.; Ferroud, C.; Doussot, J.; et al. Development and validation of an efficient ultrasound assisted extraction of phenolic compounds from flax (Linum usitatissimum L.) seeds. Ultrason. Sonochemistry 2015, 26, 176–185. [Google Scholar] [CrossRef]

- Skotti, E.; Anastasaki, E.; Kanellou, G.; Polissiou, M.; Tarantilis, P.A. Total phenolic content, antioxidant activity and toxicity of aqueous extracts from selected Greek medicinal and aromatic plants. Ind. Crops Prod. 2014, 53, 46–54. [Google Scholar] [CrossRef]

- Oliveira, G.D.A.; de Oliveira, A.E.; da Conceição, E.C.; Leles, M.I. Multiresponse optimization of an extraction procedure of carnosol and rosmarinic and carnosic acids from rosemary. Food Chem. 2016, 211, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, G.; Baj, T.; Kowalski, R.; Szymańska, J. Optimization of Glycerol–Water Extraction of Selected Bioactive Compounds from Peppermint and Common Nettle. Antioxidants 2021, 10, 817. [Google Scholar] [CrossRef] [PubMed]

- Shalaby, E.A.; Shanab, S.M. Comparison of DPPH and ABTS assays for determining antioxidant potential of water and methanol extracts of Spirulina platensis. Indian J. Mar. Sci. 2013, 42, 556–564. [Google Scholar]

- Castañeda-Valbuena, D.; Ayora-Talavera, T.; Luján-Hidalgo, C.; Álvarez-Gutiérrez, P.; Martínez-Galero, N.; Meza-Gordillo, R. Ultrasound extraction conditions effect on antioxidant capacity of mango by-product extracts. Food Bioprod. Process. 2021, 127, 212–224. [Google Scholar] [CrossRef]

- Schlesier, K.; Harwat, M.; Böhm, V.; Bitsch, R. Assessment of antioxidant activity by using different in vitro methods. Free Radic. Res. 2002, 36, 177–187. [Google Scholar] [CrossRef]

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Jakobek, L.; Šeruga, M. Influence of solvent and temperature on extraction of phenolic compounds from grape seed, antioxidant activity and colour of extract. Int. J. Food Sci. Technol. 2009, 44, 2394–2401. [Google Scholar] [CrossRef]

- Spigno, G.; Tramelli, L.; De Faveri, D.M. Effects of extraction time, temperature and solvent on concentration and antioxidant activity of grape marc phenolics. J. Food Eng. 2007, 81, 200–208. [Google Scholar] [CrossRef]

- Antoniewska, A.; Rutkowska, J.; Pineda, M.M.; Adamska, A. Antioxidative, nutritional and sensory properties of muffins with buckwheat flakes and amaranth flour blend partially substituting for wheat flour. LWT Food Sci. Technol. 2018, 89, 217–223. [Google Scholar] [CrossRef]

- Rutkowska, J.; Antoniewska, A.; Martinez-Pineda, M.; Nawirska-Olszańska, A.; Zbikowska, A.; Baranowski, D. Black chokeberry fruit polyphenols: A valuable addition to reduce lipid oxidation of muffins containing xylitol. Antioxidants 2020, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Cook, R.D. Detection of Influential Observation in Linear Regression. Technometrics 1977, 19, 15–18. [Google Scholar] [CrossRef]

| Extraction Time (h) | Method | Solvent | TPC (mg eq Gallic ac/g Dried Nettle) | DPPH• (%) | ABTS•+ (%) |

|---|---|---|---|---|---|

| 1 | Without stirring | Methanol | 7.3 ± 0.1 | 75.0 ± 2.1 | 47.8 ± 1.6 |

| 2 | Without stirring | Methanol | 6.2 ± 0.1 | 66.6 ± 1.1 | 39.6 ± 1.1 |

| 3 | Without stirring | Methanol | 8.1 ± 0.4 | 87.1 ± 1.1 | 58.4 ± 0.9 |

| 4 | Without stirring | Methanol | 7.3 ± 0.1 | 73.1 ± 1.3 | 52.1 ± 0.6 |

| 1 | Without stirring | Water | 11.5 ± 0.1 | 69.7 ± 1.4 | 63.7 ± 0.1 |

| 2 | Without stirring | Water | 12.4 ± 0.2 | 85.4 ± 0.4 | 82.6 ± 4.9 |

| 3 | Without stirring | Water | 15.3 ± 1.1 | 84.5 ± 0.8 | 82.2 ± 2.9 |

| 4 | Without stirring | Water | 13.4 ± 0.6 | 87.7 ± 0.2 | 90.8 ± 1.0 |

| 1 | Without stirring | Ethanol | 3.7 ± 0.3 | 32.9 ± 2.2 | 27.7 ± 1.7 |

| 2 | Without stirring | Ethanol | 3.4 ± 0.2 | 33.7 ± 1.7 | 30.5 ± 0.6 |

| 3 | Without stirring | Ethanol | 3.5 ± 0.2 | 37.1 ± 3.4 | 33.0 ± 1.6 |

| 4 | Without stirring | Ethanol | 4.5 ± 0.6 | 33.6 ± 1.5 | 34.2 ± 1.3 |

| 1 | Ultrasound | Methanol | 5.5 ± 0.3 | 69.4 ± 5.5 | 69.9 ± 5.4 |

| 2 | Ultrasound | Methanol | 10.0 ± 0.6 | 89.1 ± 0.7 | 89.3 ± 0.7 |

| 3 | Ultrasound | Methanol | 13.2 ± 0.4 | 90.2 ± 0.5 | 90.4 ± 0.5 |

| 4 | Ultrasound | Methanol | 12.5 ± 0.5 | 89.5 ± 0.3 | 89.6 ± 0.3 |

| 1 | Ultrasound | Water | 12.8 ± 0.0 | 50.2 ± 1.4 | 32.4 ± 0.4 |

| 2 | Ultrasound | Water | 12.1 ± 0.3 | 78.6 ± 0.7 | 43.0 ± 0.1 |

| 3 | Ultrasound | Water | 24.2 ± 2.1 | 82.8 ± 0.6 | 80.4 ± 1.8 |

| 4 | Ultrasound | Water | 27.0 ± 1.4 | 85.0 ± 1.0 | 91.8 ± 2.6 |

| 1 | Ultrasound | Ethanol | 3.6 ± 0.0 | 29.9 ± 0.3 | 16.4 ± 2.2 |

| 2 | Ultrasound | Ethanol | 7.5 ± 0.4 | 56.7 ± 0.8 | 37.6 ± 0.7 |

| 3 | Ultrasound | Ethanol | 9.3 ± 1.2 | 65.7 ± 0.5 | 42.2 ± 0.5 |

| 4 | Ultrasound | Ethanol | 8.2 ± 0.5 | 52.4 ± 4.4 | 38.5 ± 0.8 |

| 1 | Stirring | Methanol | 11.1 ± 0.6 | 69.0 ± 0.5 | 86.6 ± 0.5 |

| 2 | Stirring | Methanol | 8.6 ± 0.6 | 57.6 ± 2.2 | 74.1 ± 2.6 |

| 3 | Stirring | Methanol | 9.1 ± 0.2 | 54.0 ± 1.7 | 70.3 ± 0.1 |

| 4 | Stirring | Methanol | 8.8 ± 0.3 | 65.3 ± 1.2 | 75.4 ± 4.4 |

| 1 | Stirring | Water | 10.7 ± 0.3 | 25.8 ± 2.0 | 47.5 ± 3.8 |

| 2 | Stirring | Water | 10.9 ± 0.6 | 85.9 ± 0.9 | 33.8 ± 3.6 |

| 3 | Stirring | Water | 13.3 ± 0.6 | 91.1 ± 0.6 | 33.3 ± 1.1 |

| 4 | Stirring | Water | 12.9 ± 0.4 | 85.9 ± 1.0 | 21.8 ± 4.5 |

| 1 | Stirring | Ethanol | 7.4 ± 0.2 | 61.0 ± 0.4 | 30.4 ± 4.7 |

| 2 | Stirring | Ethanol | 5.2 ± 0.6 | 48.8 ± 0.2 | 8.1 ± 0.6 |

| 3 | Stirring | Ethanol | 6.5 ± 0.1 | 66.5 ± 1.2 | 16.9 ± 0.9 |

| 4 | Stirring | Ethanol | 5.9 ± 0.4 | 62.1 ± 0.9 | 13.4 ± 6.2 |

| Source | TPC | %DPPH• | %ABTS•+ | |||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Model | 20.85 | 2.14 × 10−9 | 7.30 | 3.07 × 10−5 | 24.85 | 3.78 × 10−10 |

| A | 20.56 | 1 × 10−4 | 13.09 | 1.6 × 10−3 | 8.77 | 7.1 × 10−3 |

| B | 16.98 | 3.46 × 10−5 | 1.22 | 3.15 × 10−1 | 13.87 | 1 × 10−4 |

| C | 80.10 | 7.94 × 10−11 | 25.55 | 2.37 × 10−6 | 83.84 | 5.10 × 10−11 |

| AB | 14.46 | 9.75 × 10−5 | 1.17 | 3.29 × 10−1 | 15.58 | 6.07 × 10−5 |

| AC | 5.20 | 1.41 × 10−2 | 3.58 | 4.59 × 10−2 | 2.12 | 1.43 × 10−1 |

| BC | 4.24 | 1.06 × 10−2 | 5.25 | 4.2 × 10−3 | 20.85 | 3.17 × 10−7 |

| A2 | 5.17 | 3.34 × 10−2 | ||||

| r2 | 0.92 | 0.82 | 0.93 | |||

| Adjusted r2 | 0.88 | 0.71 | 0.89 | |||

| Predicted r2 | 0.80 | 0.44 | 0.81 | |||

| Adequate precision | 20.28 | 9.00 | 17.94 | |||

| Extraction Method | Solvent | Model |

|---|---|---|

| Without stirring | Methanol | |

| Without stirring | Water | TPC = 9.1 + 1.6 × Time(h) |

| Without stirring | Ethanol | TPC = 4.4 − 0.2 × Time(h) |

| Ultrasound | Methanol | TPC = 3.7 + 2.7 × Time(h) |

| Ultrasound | Water TPC = 7.5 − 0.1 × Time(h) | TPC = 8.1 + 4.4 × Time(h) |

| Ultrasound | Ethanol | TPC = 0.8 + 2.5 × Time(h) |

| Stirring | Methanol | TPC = 10.8 − 0.6 × Time(h) |

| Stirring | Water | TPC = 9.0 + 1.2 × Time(h) |

| Stirring | Ethanol | TPC = 8.0 − 0.7 × Time(h) |

| Without stirring | Methanol | DPPH• (%) = 58.6 + 18.8 × Time(h) − 4.0 × Time2 (h) |

| Without stirring | Water | DPPH• (%) = 41.0 + 28.3 × Time(h) − 4.0 × Time2 (h) |

| Without stirring | Ethanol | DPPH• (%) = 13.9 + 20.2 × Time(h) − 4.0 × Time2 (h) |

| Ultrasound | Methanol | DPPH• (%) = 53.1 + 24.6 × Time(h) − 4.0 × Time2 (h) |

| Ultrasound | Water | DPPH• (%) = 18.9 + 34.2 × Time(h) − 4.0 × Time2 (h) |

| Ultrasound | Ethanol | DPPH• (%) = 16.3 + 25.9 × Time(h) − 4.0 × Time2 (h) |

| Stirring | Methanol | DPPH• (%) = 34.6 + 22.7 × Time(h) − 4.0 × Time2 (h) |

| Stirring | Water | DPPH• (%) = 21.5 + 32.3 × Time(h) − 4.0 × Time2 (h) |

| Stirring | Ethanol | DPPH• (%) = 29.3 + 24.1 × Time(h) − 4.0 × Time2 (h) |

| Without stirring | Methanol | ABTS•+ (%) = 42.1 + 2.8 × Time(h) |

| Without stirring | Water | ABTS•+ (%) = 59.3 + 8.2 × Time(h) |

| Without stirring | Ethanol | ABTS•+ (%) = 24.6 + 2.7 × Time(h) |

| Ultrasound | Methanol | ABTS•+ (%) = 60.1 + 9.9 × Time(h) |

| Ultrasound | Water | ABTS•+ (%) = 23.8 + 15.3 × Time(h) |

| Ultrasound | Ethanol | ABTS•+ (%) = 10.0 + 9.8 × Time(h) |

| Stirring | Methanol | ABTS•+ (%) = 94.1 − 7.0 × Time(h) |

| Stirring | Water | ABTS•+ (%) = 38.2 − 1.6 × Time(h) |

| Stirring | Ethanol | ABTS•+ (%) = 34.9 − 7.1 × Time(h) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flórez, M.; Cazón, P.; Vázquez, M. Antioxidant Extracts of Nettle (Urtica dioica) Leaves: Evaluation of Extraction Techniques and Solvents. Molecules 2022, 27, 6015. https://doi.org/10.3390/molecules27186015

Flórez M, Cazón P, Vázquez M. Antioxidant Extracts of Nettle (Urtica dioica) Leaves: Evaluation of Extraction Techniques and Solvents. Molecules. 2022; 27(18):6015. https://doi.org/10.3390/molecules27186015

Chicago/Turabian StyleFlórez, María, Patricia Cazón, and Manuel Vázquez. 2022. "Antioxidant Extracts of Nettle (Urtica dioica) Leaves: Evaluation of Extraction Techniques and Solvents" Molecules 27, no. 18: 6015. https://doi.org/10.3390/molecules27186015

APA StyleFlórez, M., Cazón, P., & Vázquez, M. (2022). Antioxidant Extracts of Nettle (Urtica dioica) Leaves: Evaluation of Extraction Techniques and Solvents. Molecules, 27(18), 6015. https://doi.org/10.3390/molecules27186015