Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording

Abstract

1. Introduction

2. Polymers for Holographic Recording

2.1. Holographic Polymer-Dispersed Liquid Crystal

2.2. Azo Polymer

2.3. Photorefractive Polymer

2.4. Photopolymer

3. Applications of PQ/PMMA Photopolymers

3.1. Principle of Holographic Data Storage

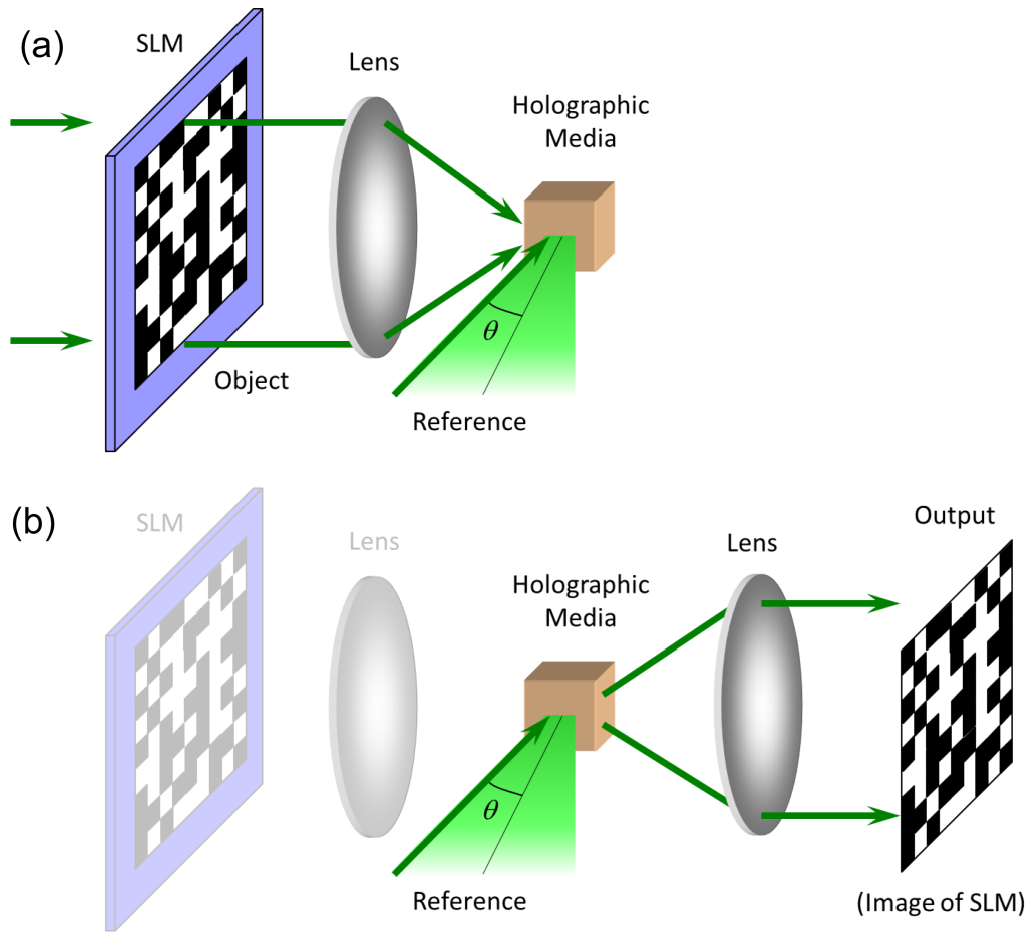

3.1.1. Recording

3.1.2. Reading

3.2. Multiplexing Technology

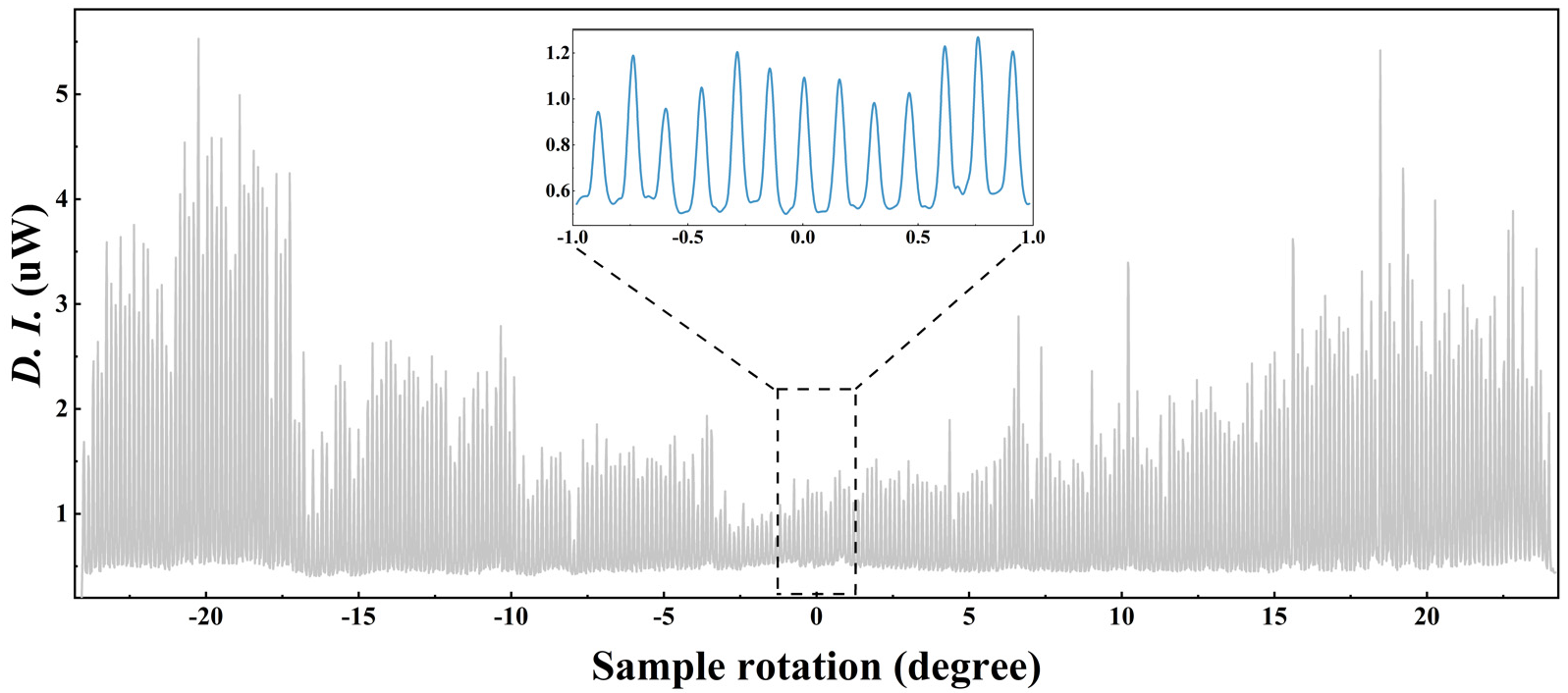

- Angle multiplexing [44,45] uses signal light and reference light to record at the same wavelength and different reference light angles with the material in the same position and generates multiple holograms with multiple signal lights. For a 1.5 cm thick doped modified PQ/PMMA photopolymer, 532 nm green light was used as the recording and reference light, with an angular selectivity of roughly 0.15°, achieving a 321-frame hologram recording in a −24 to 24° range [46], as shown in Figure 2,

- Shift multiplexing [47,48] helps to separate and multiplex different holograms in space; that is, after recording a hologram somewhere, it can move a certain distance and then record the next hologram. It takes advantage of the sharp decrease in the diffraction efficiency after Bragg condition mismatch, and the number of multiplexes is limited by separating the hologram in the position space. Shift multiplexing technology is mostly used in photopolymer materials, which can work well with optical disk holographic data storage systems, and it is a highly compatible multiplexing method,

- Wavelength multiplexing [49] uses planar waves with different wavelengths as recorded light and reference light, thereby recording and generating multiple holograms in a material. Photopolymer materials have different levels of sensitivity to different wavelengths, and the response is not a simple linear relationship. Wavelength multiplexing is generally suitable for inorganic photorefractive crystal materials,

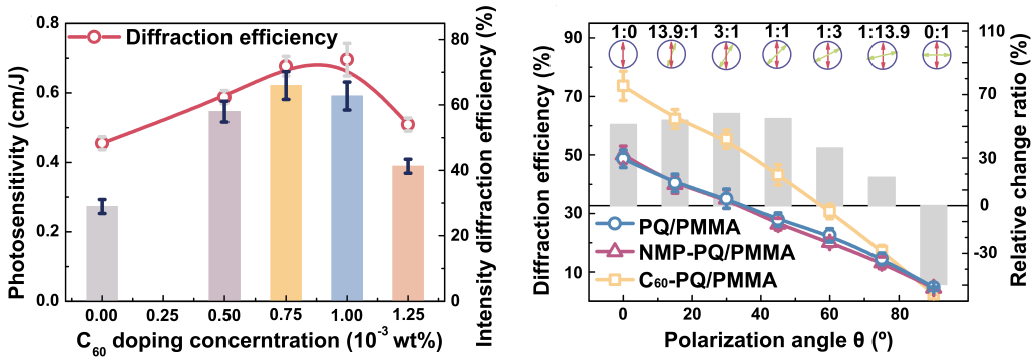

- In polarization multiplexing [52], polarized light in different polarization states is used as a recording light and a reference light to generate multiple holograms, which requires the recording material to have polarization sensitivity.

3.3. Collinear Holographic Storage System

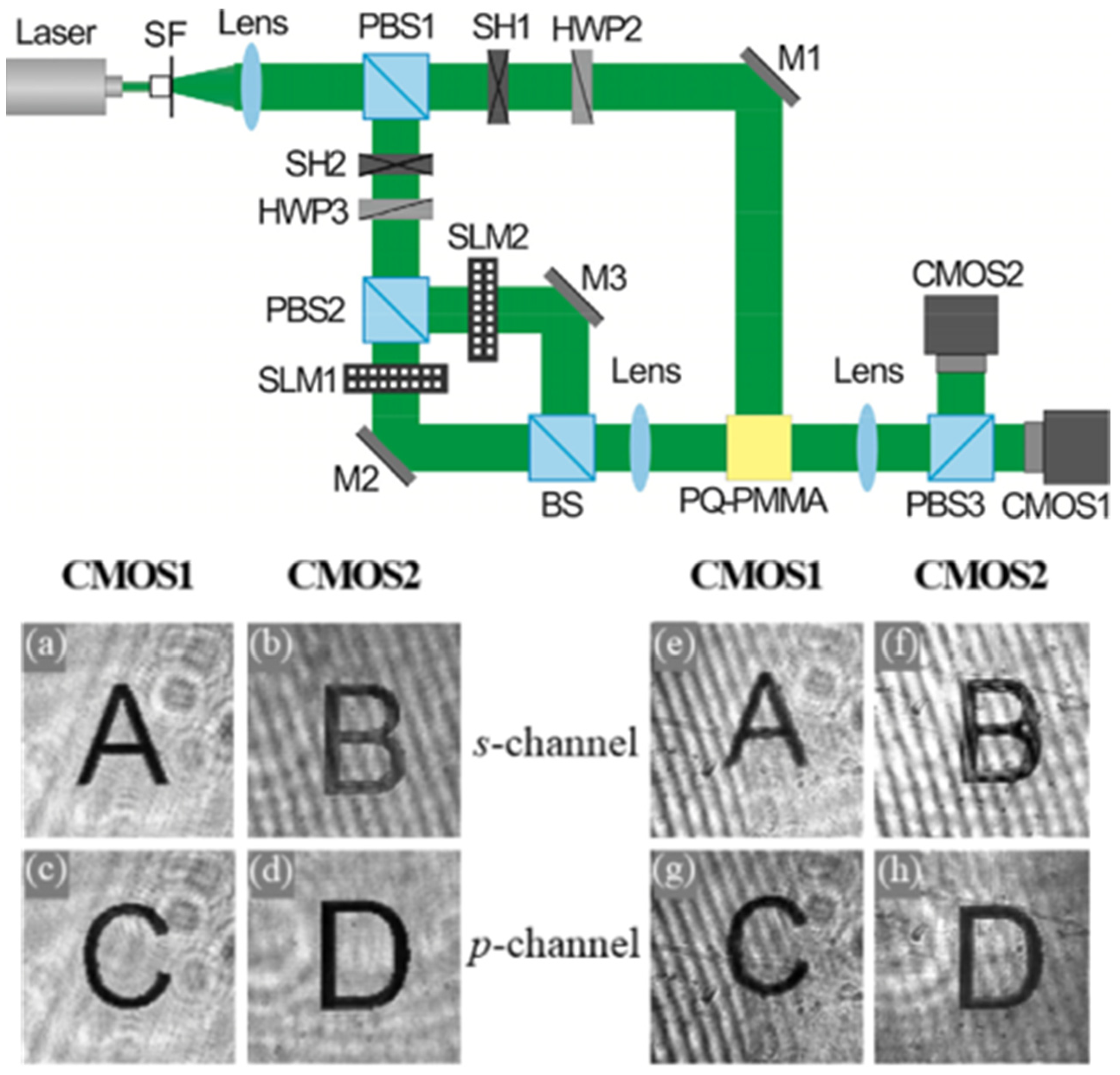

3.4. Polarization Holography

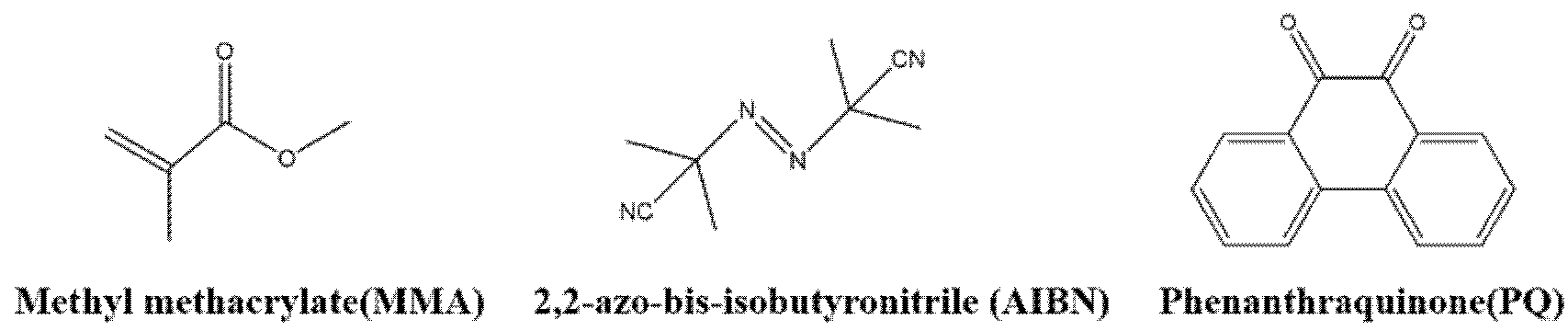

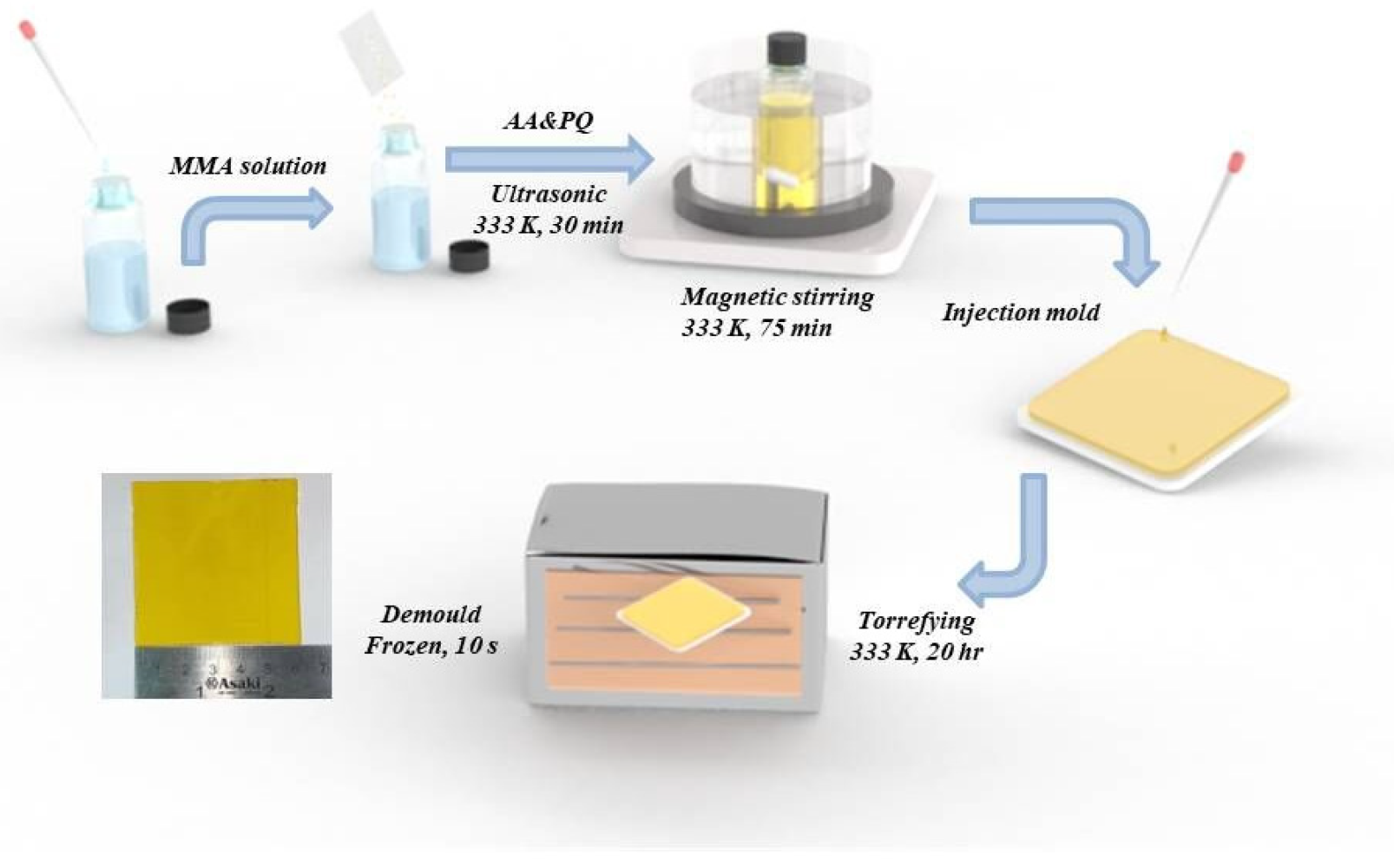

4. PQ/PMMA Materials and Preparation

- (1)

- The weighted MMA is added to a transparent glass bottle,

- (2)

- The PQ photosensitizer (1.0 wt %) and the AIBN thermo-initiator (1.0 wt %) are added. Their proportion in the mixture is maintained at MMA:AIBN:PQ = 100:1:1,

- (3)

- All the components are ultrasonically shaken in a water bath at 333 K for 20 min to form a homogeneous multi-component solution,

- (4)

- During stirring pre-polymerization, the glass bottle is placed on a magnetic stirrer and kept at a constant temperature (333 K) for 75 min to make each solution homogeneously viscid,

- (5)

- The viscous solutions are poured into glass molds with spacers of a specific thickness, and the glass molds are placed horizontally in an oven at 333 K for 20 h until complete solidification. Finally, a yellow transparent solid PQ/PMMA material is obtained. The thickness of the PQ/PMMA material can be regulated by controlling the thickness of the spacers.

5. PQ/PMMA Operational Principle

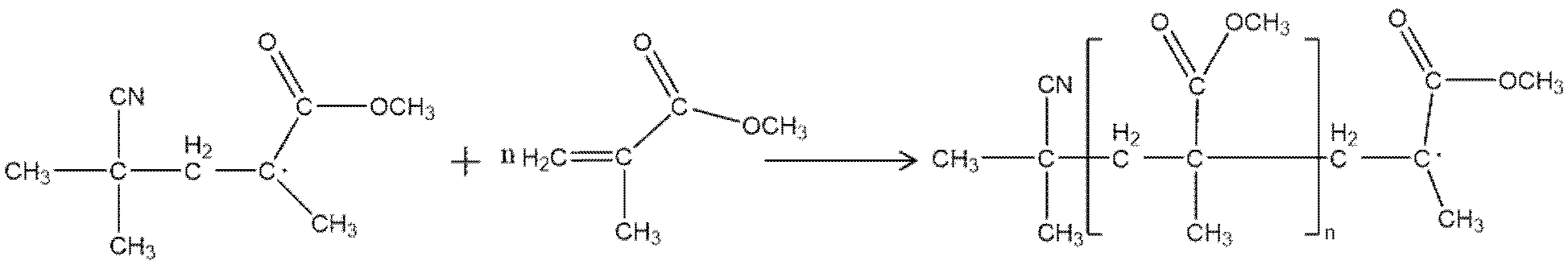

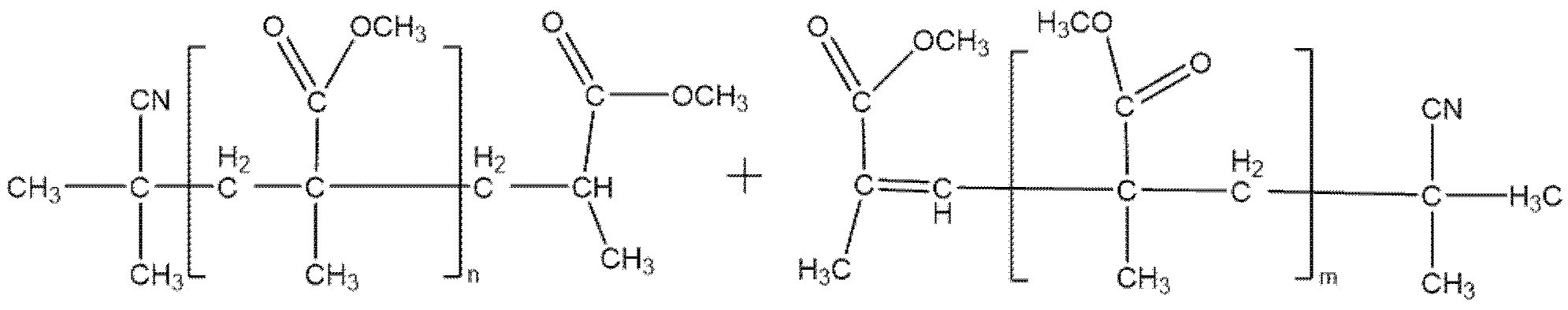

5.1. Thermal Polymerization

5.1.1. Chain Initiation

5.1.2. Chain Growth

5.1.3. Chain Termination

5.2. Photoreaction Process

6. Optical Performance Characterization Parameters of PQ/PMMA

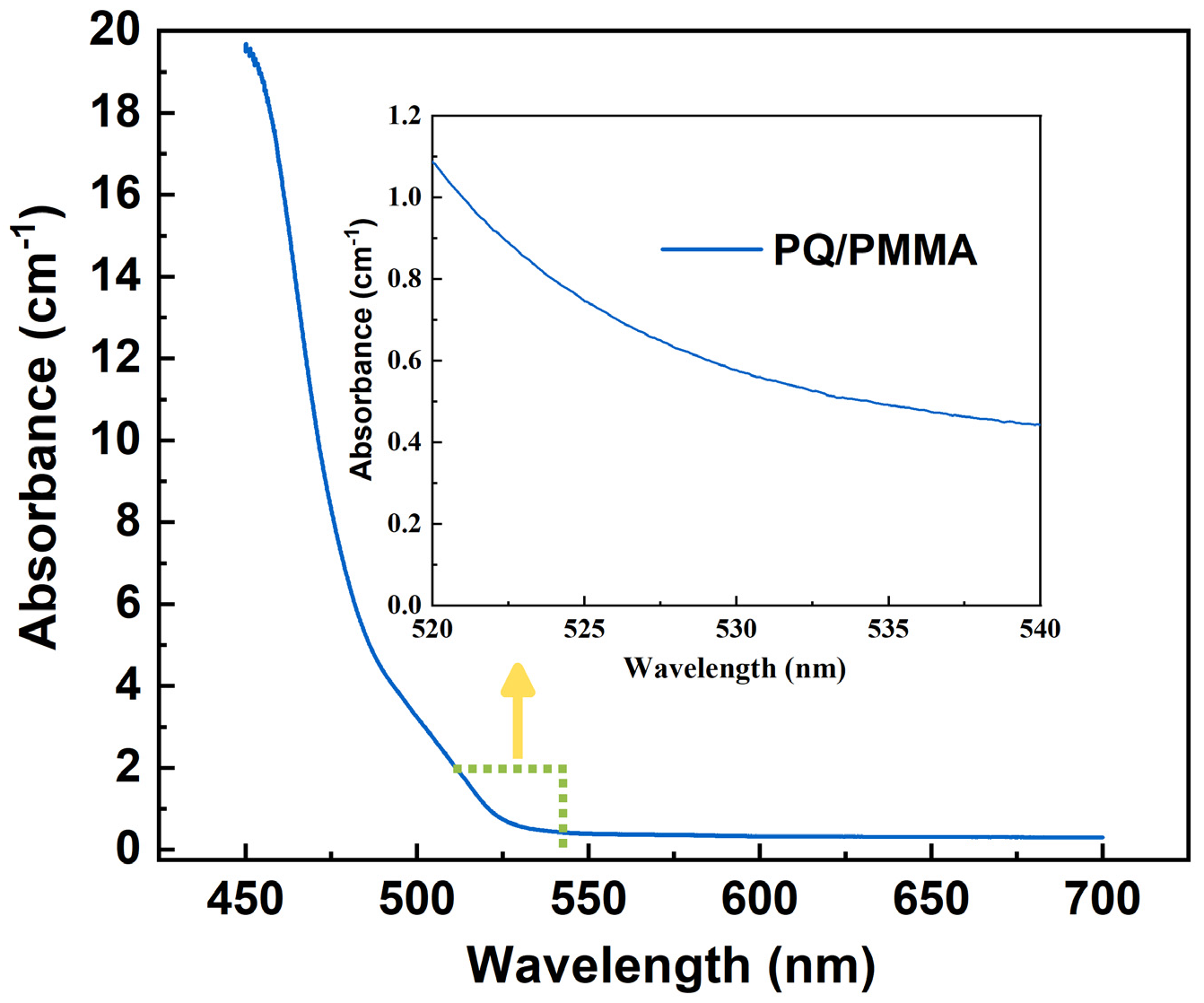

6.1. Ultraviolet Absorption Spectrum

6.2. Diffraction Efficiency

- (1)

- Define diffraction efficiency η1 (external diffraction efficiency) as the ratio of the effective diffraction flux of first-level diffraction to the effective incident luminous flux of grating reproduction diffraction.

- (2)

- Ignore the effect of reflection and absorption of materials on recorded light and define the diffraction efficiency η2 (internal diffraction efficiency) as the ratio of reproducing diffracted light intensity to incident light intensity. The calculation formulas for η1 and η2 are as follows:

6.3. Photosensitivity

6.4. Refractive Index Modulation

6.5. Dynamic Range

6.6. Volumetric Shrinkage

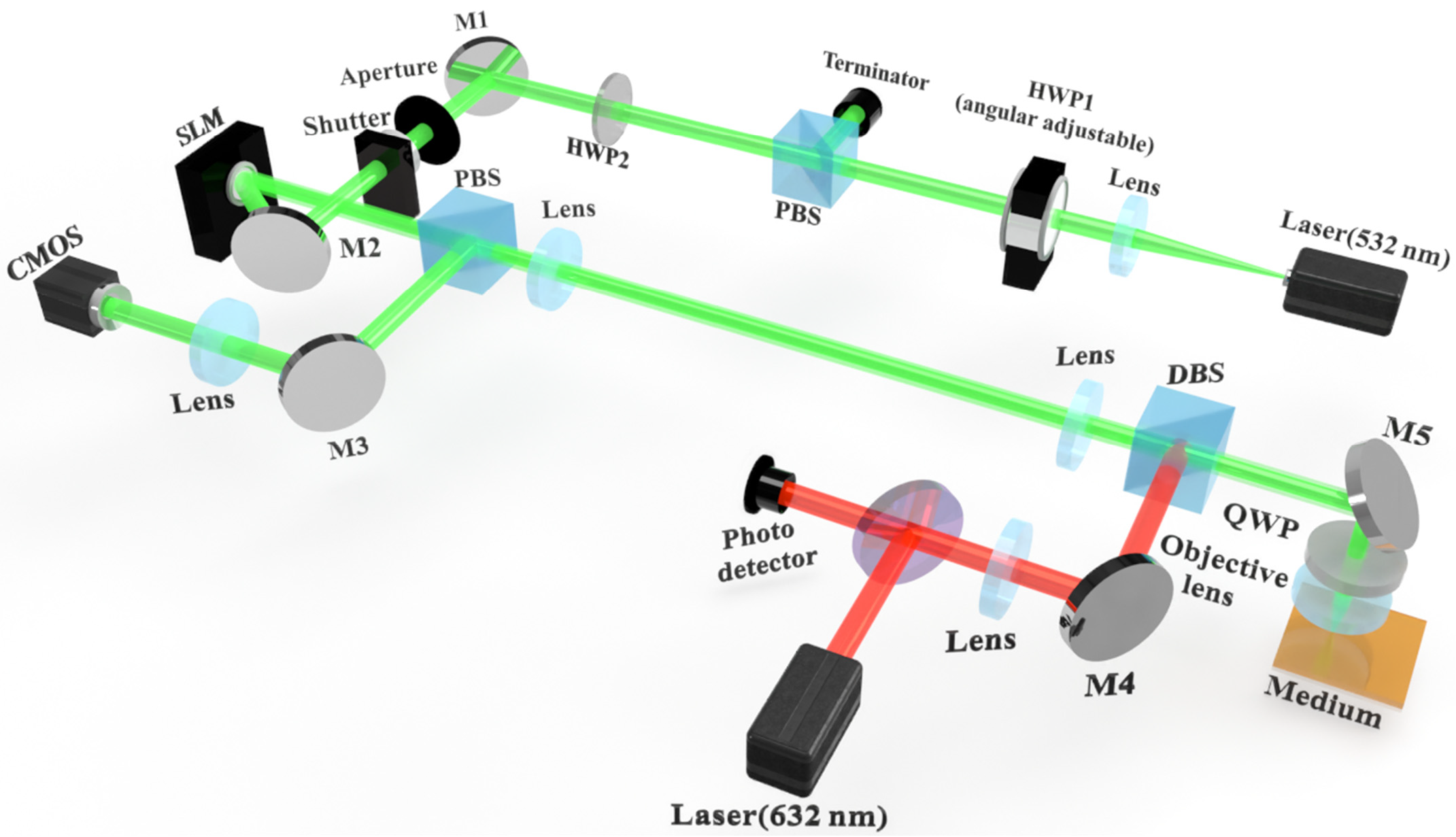

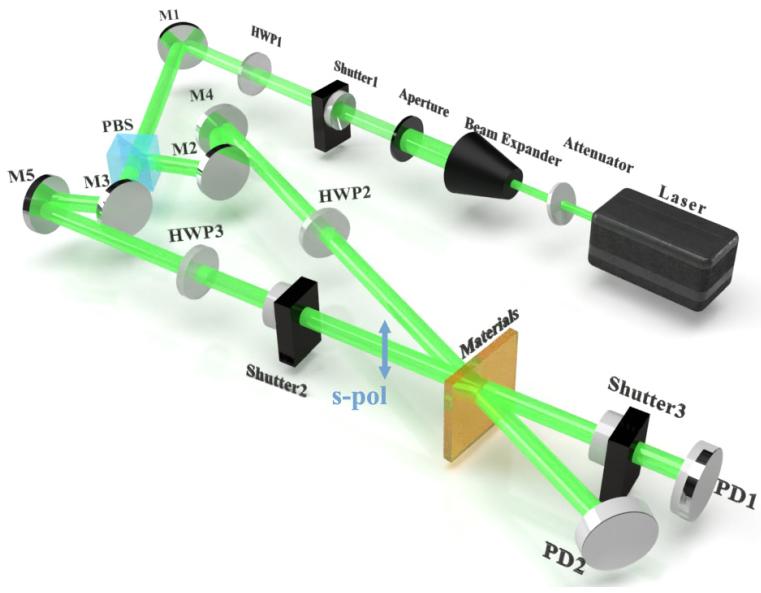

7. Holographic Test Device

7.1. Diffraction Efficiency

7.2. Photoinduced Birefringence

8. Origins of PQ/PMMA and Performance Improvement Measures

- (1)

- The photosensitizer absorbs the photons to be excited to form free radicals and reacts with macromolecules to produce photoproducts, which results in nonlinear changes in gratings,

- (2)

- The spread of PQ molecules from dark to bright areas during exposure enhances holograms,

- (3)

- The movement of the polymer chain is limited by space, causing rapid partial attenuation of the grating,

- (4)

- The diffusion of large molecules in the later stage leads to gentle decay of the grating. This analysis provides an important basis for in-depth study of the photochemical reaction process of polymer samples.

- (1)

- the time-dependent photon absorption of PQ molecules, including single excited 1PQ* molecules,

- (2)

- recovery/regeneration and bleaching of excited PQ molecules,

- (3)

- non-local effects, and

- (4)

- the diffusion effects of ground- and excited-state PQ molecules and methyl methacrylate (MMA). Subsequently, they applied the model to fit experimental data from PQ/PMMA layers containing three different initial PQ concentrations to test the validity of the proposed model and verify the theoretical results [96].

8.1. Doped Comonomers

8.2. Nanoparticle Doping

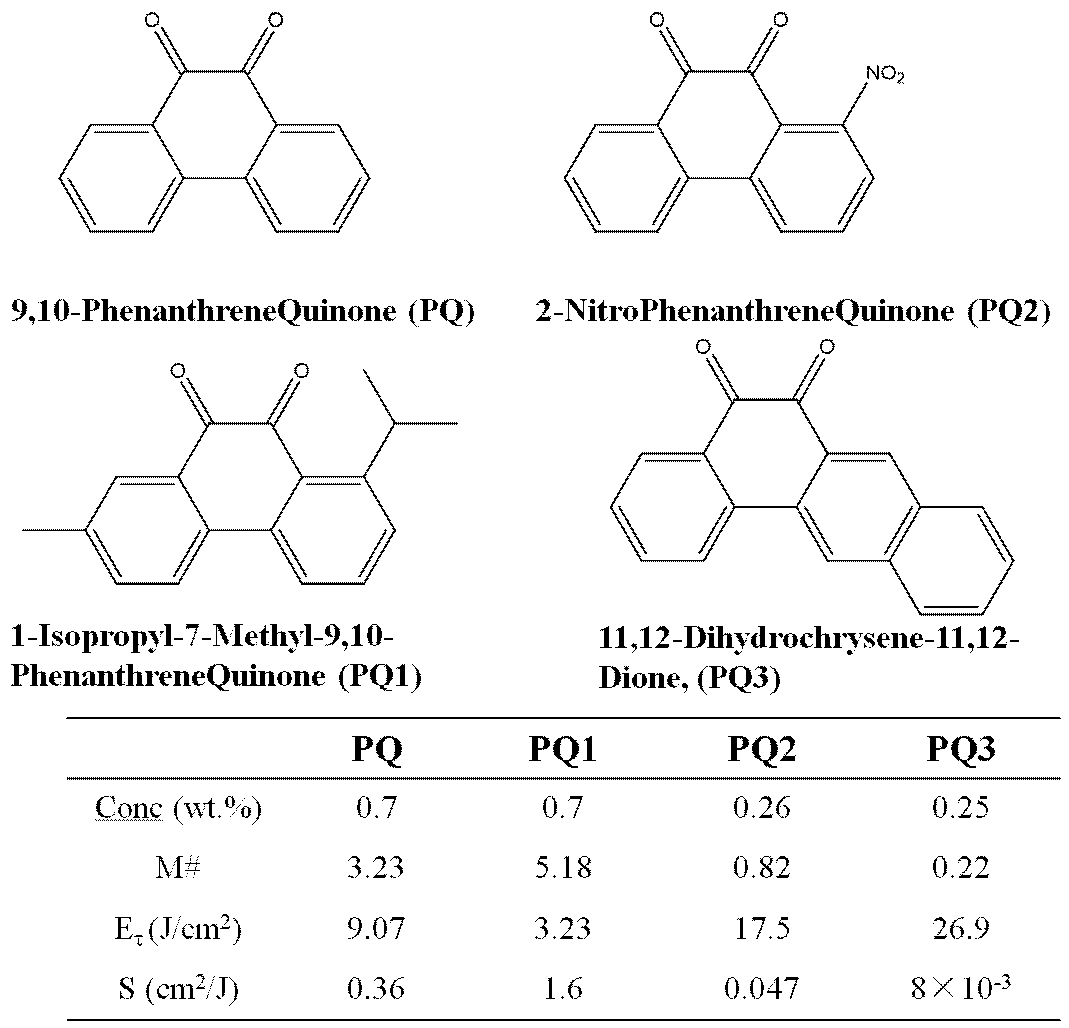

8.3. Replace the Photosensitizer

8.4. Optimize Preparation Conditions

- (1)

- The thermal initiator AIBN decomposes to produce nitrogen, and during the polymerization process, the liquid sample gradually becomes viscous, resulting in the inability of the bubbles to be discharged,

- (2)

- When MMA is converted into PMMA, the energy released by the formation of σ bonds is greater than the energy absorbed when the π bonds break and the boiling point of MMA is low, so MMA boiling produces bubbles,

- (3)

- When MMA is completely converted into PMMA, there are different degrees of shrinkage, and when the sample solidifies, air will be sucked in at the edge of the mold due to negative pressure and bubbles will be generated. The experimental analysis can act as a guide in PQ/PMMA material preparation.

9. Conclusions

- (1)

- doping by comonomers,

- (2)

- introduction of nanoparticles,

- (3)

- replacement of the photosensitizer,

- (4)

- and optimization of preparation conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Gabor, D. A new microscopic principle. Nature 1948, 161, 777–779. [Google Scholar] [CrossRef] [PubMed]

- Maiman, T.H. Optical and Microwave-Optical Experiments in Ruby. Phys. Rev. Lett. 1960, 4, 564–566. [Google Scholar] [CrossRef]

- Tay, S.; Blanche, P.-A.; Voorakaranam, R.; Tunc, A.V.; Lin, W.; Rokutanda, S.; Gu, T.; Flores, D.; Wang, P.; Li, G.; et al. An updatable holographic three-dimensional display. Nature 2008, 451, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Blanche, P.A.; Bablumian, A.; Voorakaranam, R.; Christenson, C.; Lin, W.; Gu, T.; Flores, D.; Wang, P.; Hsieh, W.-Y.; Kathaperumal, M.; et al. Holographic three-dimensional telepresence using large-area photorefractive polymer. Nature 2010, 468, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.G.; Xiao, R.; Liu, J.; Wang, L.; Zhong, H.; Wang, Y. Large-area rainbow holographic diffraction gratings on a curved surface using transferred photopolymer films. Opt. Lett. 2018, 43, 675–678. [Google Scholar] [CrossRef] [PubMed]

- Hardwick, B.; Jackson, W.; Wilson, G.; Mau, A.W.H. Advanced Materials for Banknote Applications. Adv. Mater. 2001, 13, 12–13. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, W.; Zhou, X.; Wu, W.; Liu, Q.; Peng, H.; Zhu, J.; Smalyukh, I.I.; Xie, X. Holographic polymer nanocomposites with simultaneously boosted diffraction efficiency and upconversion photoluminescence. Compos. Sci. Technol. 2019, 181. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, X.; Li, M.D.; Li, Z.; Peng, H.; Xie, X. Crosstalk-Free Patterning of Cooperative-Thermoresponse Images by the Synergy of the AIEgen with the Liquid Crystal. Angew. Chem. Int. Ed. Engl. 2020, 59, 10066–10072. [Google Scholar] [CrossRef]

- Leith, E.N.; Kozma, A.; Upatnieks, J.; Marks, J.; Massey, N. Holographic Data Storage in Three-Dimensional Media. Appl. Opt. 1966, 5, 1303–1311. [Google Scholar] [CrossRef]

- Heanue, J.F.; Bashaw, M.C.; Hesselink, L. Volume holographic storage and retrieval of digital data. Science 1994, 265, 749–752. [Google Scholar] [CrossRef]

- Haw, M. Holographic data storage: The light fantastic. Nature 2003, 422, 556–558. [Google Scholar] [CrossRef] [PubMed]

- Bunning, T.J.; Natarajan, L.V.; Tondiglia, V.P.; Sutherland, R.L. Holographic Polymer-Dispersed Liquid Crystals (H-PDLCs). Annu. Rev. Mater. Sci. 2000, 30, 83–115. [Google Scholar] [CrossRef]

- Vita, F.; Lucchetta, D.E.; Castagna, R.; Criante, L.; Simoni, F. Effects of resin addition on holographic polymer dispersed liquid crystals. J. Opt. A Pure Appl. Opt. 2009, 11, 024021. [Google Scholar] [CrossRef]

- Tomita, Y.; Aoi, T.; Hasegawa, S.; Xia, F.; Wang, Y.; Oshima, J. Very high contrast volume holographic gratings recorded in photopolymerizable nanocomposite materials. Opt. Express 2020, 28, 28366–28382. [Google Scholar] [CrossRef]

- Castagna, R.; Nucara, L.; Simoni, F.; Greci, L.; Rippa, M.; Petti, L.; Lucchetta, D.E. An Unconventional Approach to Photomobile Composite Polymer Films. Adv. Mater. 2017, 29, 1604800. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Donato, A.D.; Paturzo, M.; Singh, G.; Castagna, R. Light-Induced Dynamic Holography. Micromachines 2022, 13, 297. [Google Scholar] [CrossRef]

- Castagna, R.; Donato, A.D.; Strangi, G.; Lucchetta, D.E. Light controlled bending of a holographic transmission phase grating. Smart Mater. Struct. 2022, 31, 03LT02. [Google Scholar] [CrossRef]

- White, T.J.; Natarajan, L.V.; Tondiglia, V.P.; Lloyd, P.F.; Bunning, T.J.; Guymon, C.A. Holographic polymer dispersed liquid crystals (HPDLCs) containing triallyl isocyanurate monomer. Polymer 2007, 48, 5979–5987. [Google Scholar] [CrossRef]

- Meng, S.; Duran, H.; Hu, J.; Kyu, T.; Natarajan, L.V.; Tondiglia, V.P.; Sutherland, R.L.; Bunning, T.J. Influence of Photopolymerization Reaction Kinetics on Diffraction Efficiency of H-PDLC Undergoing Photopatterning Reaction in Mixtures of Acrylic Monomer/Nematic Liquid Crystals. Macromolecules 2007, 40, 3190–3197. [Google Scholar] [CrossRef]

- Luo, W.; Ni, M.; Zhou, X.; Peng, H.; Xie, X. Holographic polymer nanocomposites with both high diffraction efficiency and bright upconversion emission by incorporating liquid crystals and core-shell structured upconversion nanoparticles. Compos. Part B Eng. 2020, 199, 108290. [Google Scholar] [CrossRef]

- Geelhaar, T.; Griesar, K.; Reckmann, B. 125 Years of Liquid Crystals—A Scientific Revolution in the Home. Angew. Chem. Int. Ed. 2013, 52, 2–14. [Google Scholar] [CrossRef]

- Dimitrov, D.Z.; Chen, Z.F.; Marinova, V.; Petrova, D.; Ho, C.Y.; Napoleonov, B.; Blagoev, B.; Strijkova, V.; Hsu, K.Y.; Lin, S.H.; et al. ALD Deposited ZnO:Al Films on Mica for Flexible PDLC Devices. Nanomaterials 2021, 11, 1011. [Google Scholar] [CrossRef] [PubMed]

- Ni, M.; Chen, G.; Sun, H.; Peng, H.; Yang, Z.; Liao, Y.; Ye, Y.; Yang, Y.; Xie, X. Well-structured holographic polymer dispersed liquid crystals by employing acrylamide and doping ZnS nanoparticles. Mater. Chem. Front. 2017, 1, 294–303. [Google Scholar] [CrossRef]

- Peng, H.; Chen, G.; Ni, M.; Yan, Y.; Zhuang, J.; Roy, V.A.L.; Li, R.K.Y.; Xie, X. Classical photopolymerization kinetics, exceptional gelation, and improved diffraction efficiency and driving voltage in scaffolding morphological H-PDLCs afforded using a photoinitibitor. Polym. Chem. 2015, 6, 8259–8269. [Google Scholar] [CrossRef]

- Benkhaya, S.; M’Rabet, S.; El Harfi, A. Classifications, properties, recent synthesis and applications of azo dyes. Heliyon 2020, 6, e03271. [Google Scholar] [CrossRef] [PubMed]

- Kilosanidze, B.; Kakauridze, G.; Chaganava, I. Dynamic polarization holography: Methods and applications. J. Hologr. Speckle 2009, 5, 52–61. [Google Scholar] [CrossRef]

- Shishido, A. Rewritable holograms based on azobenzene-containing liquid-crystalline polymers. Polym. J. 2010, 42, 525–533. [Google Scholar] [CrossRef]

- Razali, N.A.; Jamain, Z. Liquid Crystals Investigation Behavior on Azo-Based Compounds: A Review. Polymers 2021, 13, 3462. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Xue, C.; Weis, P.; Suzuki, Y.; Huang, S.; Koynov, K.; Auernhammer, G.K.; Berger, R.; Butt, H.J.; Wu, S. Photoswitching of glass transition temperatures of azobenzene-containing polymers induces reversible solid-to-liquid transitions. Nat. Chem. 2017, 9, 145–151. [Google Scholar] [CrossRef]

- Chen, F.S.; LaMacchia, J.T.; Fraser, D.B. Holographic Storage in Lithium Niobate. Appl. Phys. Lett. 1968, 13, 223–225. [Google Scholar] [CrossRef]

- Lynn, B.; Blanche, P.-A.; Peyghambarian, N. Photorefractive polymers for holography. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 193–231. [Google Scholar] [CrossRef]

- Close, D.H.; Jacobson, A.D.; Margerum, J.D.; Brault, R.G.; McClung, F.J. Hologram Recording on Photopolymer Materials. Appl. Phys. Lett. 1969, 14, 159–160. [Google Scholar] [CrossRef]

- Murciano, A.; Blaya, S.; Carretero, L.; Madrigal, R.F.; Fimia, A. Holographic reflection gratings in photopolymerizable solgel materials. Opt. Lett. 2006, 31, 2317–2319. [Google Scholar] [CrossRef]

- Malallah, R.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef]

- Hsu, K.Y.; Lin, S.H. Holographic data storage using photopolymer. In Proceedings of the SPIE—The International Society for Optical Engineering, Bellingham, WA, USA, 1 October 2003; pp. 142–148. [Google Scholar]

- Zhu, J.; Wang, G.; Hao, Y.; Xie, B.; Cheng, A.Y.S. Highly sensitive and spatially resolved polyvinyl alcohol/acrylamide photopolymer for real-time holographic applications. Opt. Express 2010, 18, 18106–18112. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Liu, H.; Yu, D.; Sun, X.; Zhang, J. Study of effective optical thickness in photopolymer for application. Opt. Lett. 2012, 37, 2241–2243. [Google Scholar] [CrossRef]

- Blaya, S.; Carretero, L.; Fimia, A.; Mallavia, R.; Madrigal, R.F.; Sastre, R.; Amat-guerri, F. Optimal composition of an acrylamide and N,N′-methylenebisacrylamide holographic recording material. J. Mod. Opt. 1998, 45, 2573–2584. [Google Scholar] [CrossRef]

- Carretero, L.; Murciano, A.; Blaya, S.; Ulibarrena, M.; Fimia, A. Acrylamide-N,N’-methylenebisacrylamide silica glass holographic recording material. Opt. Express 2004, 12, 1780–1787. [Google Scholar] [CrossRef]

- Trentler, T.J.; Boyd, J.E.; Colvin, V.L. Epoxy Resin-Photopolymer Composites for Volume Holography. Chem. Mater. 2000, 12, 1431–1438. [Google Scholar] [CrossRef]

- Sabol, D.; Gleeson, M.R.; Liu, S.; Sheridan, J.T. Photoinitiation study of Irgacure 784 in an epoxy resin photopolymer. J. Appl. Phys. 2010, 107, 053113. [Google Scholar] [CrossRef]

- Jeong, Y.-C.; Lee, S.; Park, J.-K. Holographic diffraction gratings with enhanced sensitivity based on epoxy-resin photopolymers. Opt. Express 2007, 15, 1497–1504. [Google Scholar] [CrossRef]

- Lin, X.; Hao, J.; Zheng, M.; Dai, T.; Li, H.; Ren, Y. Optical holographic data storage—The time for new development. Opto-Electron. Eng. 2019, 46, 180642. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Z.; Cao, L.; Zhang, H.; Jin, G. Volume holographic display technology based on angular multiplexing. J. Appl. Opt. 2017, 38, 215–219. [Google Scholar] [CrossRef]

- Darsky, A.M.; Markov, V.B. Angular sensitivity of holograms with a reference speckle wave. In Proceedings of the SPIE—Three-Dimensional Holography: Science, Culture, Education, Kiev, Ukraine, 1 February 1991; pp. 54–62. [Google Scholar]

- Hu, P.; Chen, Y.; Li, J.; Wang, J.; Liu, J.; Wu, T.; Tan, X. Impact of fullerene on the holographic properties of PQ/PMMA photopolymer. Compos. Sci. Technol. 2022, 221, 109335. [Google Scholar] [CrossRef]

- Psaltis, D.; Levene, M.; Pu, A.; Barbastathis, G.; Curtis, K. Holographic storage using shift multiplexing. Opt. Lett. 1995, 20, 782–784. [Google Scholar] [CrossRef]

- Steckman, G.J.; Pu, A.; Psaltis, D. Storage density of shift-multiplexed holographic memory. Appl. Opt. 2001, 40, 3387–3394. [Google Scholar] [CrossRef]

- Rakuljic, G.A.; Leyva, V.; Yariv, A. Optical data storage by using orthogonal wavelength-multiplexed volume holograms. Opt. Lett. 1992, 17, 1471–1473. [Google Scholar] [CrossRef]

- Denz, C.; Pauliat, G.; Roosen, G.; Tschudi, T. Volume hologram multiplexing using a deterministic phase encoding method. Opt. Commun. 1991, 85, 171–176. [Google Scholar] [CrossRef]

- Renu, J.; Joby, J.; Kehar, S. Holographic digital data storage using phase-modulated pixels. Opt. Lasers Eng. 2005, 43, 183–194. [Google Scholar] [CrossRef]

- Zang, J.; Kang, G.; Li, P.; Liu, Y.; Fan, F.; Hong, Y.; Huang, Y.; Tan, X.; Wu, A.; Shimura, T.; et al. Dual-channel recording based on the null reconstruction effect of orthogonal linear polarization holography. Opt. Lett. 2017, 42, 1377–1380. [Google Scholar] [CrossRef]

- Horimai, H.; Tan, X. Holographic versatile disc system. In Proceedings of the Conference on Organic Holographic Materials and Applications III, San Diego, CA, USA, 1 September 2005. [Google Scholar]

- Horimai, H.; Tan, X.; Li, J. Collinear holography. Appl. Opt. 2005, 44, 2575–2579. [Google Scholar] [CrossRef] [PubMed]

- Kuroda, K.; Matsuhashi, Y.; Fujimura, R.; Shimura, T. Theory of Polarization Holography. Opt. Rev. 2011, 18, 374–382. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, Y.; Song, H.; Tan, X. Faithful reconstruction in polarization holography suitable for high-speed recording and reconstructing. Opt. Lett. 2020, 45, 6282–6285. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; He, Y.; Dai, T.; Zhu, L.; Tan, X. Null reconstruction in orthogonal elliptical polarization holography read by non-orthogonal reference wave. Opt. Lasers Eng. 2020, 131, 106144. [Google Scholar] [CrossRef]

- Nikolova, L.; Ramanujam, P.S. Polarization Holography; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Huang, Z.; Wu, C.; Chen, Y.; Lin, X.; Tan, X. Faithful reconstruction in orthogonal elliptical polarization holography read by different polarized waves. Opt. Express 2020, 28, 23679–23689. [Google Scholar] [CrossRef]

- Cerda, T.; Ruiz, U.; Pagliusi, P.; Cipparrone, G. Shaping Airy beams by using tunable polarization holograms. J. Opt. Soc. Am. B Opt. Phys. 2019, 36, D103–D106. [Google Scholar] [CrossRef]

- Cipparrone, G.; Pagliusi, P.; Provenzano, C.; Shibaev, V.P. Polarization Holographic Recording in Amorphous Polymer with Photoinduced Linear and Circular Birefringence. J. Phys. Chem. B 2010, 114, 8900–8904. [Google Scholar] [CrossRef]

- Trofimova, A.V.; Stankevich, A.I.; Mogil’nyi, V.V. Phenanthrenequinone–Polymethylmethacrylate Composite for Polarization Phase Recording. J. Appl. Spectrosc. 2009, 76, 615–621. [Google Scholar] [CrossRef]

- Zang, J.; Fan, F.; Liu, Y.; Wei, R.; Tan, X. Four-channel volume holographic recording with linear polarization holography. Opt. Lett. 2019, 44, 4107–4110. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.H.; Cho, S.L.; Chou, S.F.; Lin, J.H.; Lin, C.M.; Chi, S.; Hsu, K.Y. Volume polarization holographic recording in thick photopolymer for optical memory. Opt. Express 2014, 22, 14944–14957. [Google Scholar] [CrossRef]

- Li, C.; Cao, L.; Wang, Z.; Jin, G. Hybrid polarization-angle multiplexing for volume holography in gold nanoparticle-doped photopolymer. Opt. Lett. 2014, 39, 6891–6894. [Google Scholar] [CrossRef]

- Wang, J.; Tan, X.; Qi, P.; Wu, C.; Huang, L.; Xu, X.; Huang, Z.; Zhu, L.; Zhang, Y.; Lin, X.; et al. Linear polarization holography. Opto-Electron. Sci. 2022, 1, 210009. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Cheng, H.; Tian, J.; Chen, S. Multidimensional manipulation of wave fields based on artificial microstructures. Opto-Electron. Adv. 2020, 3, 200002. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, Y.; Zhang, Q.; Chen, Y.; Chen, X.; Huang, Z.; Lin, X.; Tan, X. Generation of a vector light field based on polarization holography. Opt. Lett. 2021, 46, 4542–4545. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Liu, H.; Lin, A.; Xu, X.; Ke, S.; Song, H.; Zhang, Y.; Huang, Z.; Tan, X. Scalar vortex beam produced through faithful reconstruction of polarization holography. Opt. Express 2021, 29, 43193–43202. [Google Scholar] [CrossRef]

- Beliaev, L.Y.; Takayama, O.; Melentiev, P.N.; Lavrinenko, A.V. Photoluminescence control by hyperbolic metamaterials and metasurfaces: A review. Opto-Electron. Adv. 2021, 4, 210031. [Google Scholar] [CrossRef]

- Steckman, G.J.; Solomatine, I.; Zhou, G.; Psaltis, D. Characterization of phenanthrenequinone-doped poly(methyl methacrylate) for holographic memory. Opt. Lett. 1998, 23, 1310–1312. [Google Scholar] [CrossRef]

- Hsiao, Y.-N.; Whang, W.-T.; Lin, S.H. Analyses on physical mechanism of holographic recording in phenanthrenequinone-doped poly(methyl methacrylate) hybrid materials. Opt. Eng. 2004, 43, 1993–2002. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part I: Short exposure. Opt. Commun. 2014, 330, 191–198. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part II: Consecutive exposure and dark decay. Opt. Commun. 2014, 330, 199–207. [Google Scholar] [CrossRef]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T.; Tolstik, E.; Matusevich, V.; Kowarschik, R. Modeling the photochemical kinetics induced by holographic exposures in PQ/PMMA photopolymer material. J. Opt. Soc. Am. B 2011, 28, 2833–2843. [Google Scholar] [CrossRef]

- Li, C.; Cao, L.; He, Q.; Jin, G. Holographic kinetics for mixed volume gratings in gold nanoparticles doped photopolymer. Opt. Express 2014, 22, 5017–5028. [Google Scholar] [CrossRef] [PubMed]

- Sheridan, J.T.; O’Neill, F.T.; Kelly, J.V. Holographic data storage: Optimized scheduling using the nonlocal polymerization-driven diffusion model. J. Opt. Soc. Am. B-Opt. Phys. 2004, 21, 1443–1451. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Gleeson, M.G.; Kelly, J.V.; O’Neill, F.T. Nonlocal polymerization-driven diffusion-model-based examination of the scaling law for holographic data storage. Opt. Lett. 2005, 30, 239–241. [Google Scholar] [CrossRef] [PubMed]

- Sheridan, J.T.; Kelly, J.V.; Gleeson, M.R.; Close, C.E.; O’Neill, F.T. Optimized holographic data storage: Diffusion and randomization. J. Opt. A Pure Appl. Opt. 2006, 8, 236–243. [Google Scholar] [CrossRef]

- Castagna, R.; Vita, F.; Lucchetta, D.E.; Criante, L.; Simoni, F. Superior-Performance Polymeric Composite Materials for High-Density Optical Data Storage. Adv. Mate. 2009, 21, 589–592. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Wu, A.; Zang, J.; Kang, G.; Tan, X.; Shimura, T. Volume holographic recording in Al nanoparticles dispersed phenanthrenequinone-doped poly(methyl methacrylate) photopolymer. Nanotechnology 2019, 30, 145202. [Google Scholar] [CrossRef]

- Kogelnik, H. Coupled Wave Theory for Thick Hologram Gratings. Bell Syst. Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Peng, H.; Wang, C.; Xi, W.; Kowalsk, B.A.; Gong, T.; Xie, X.; Wang, W.; Nair, D.P.; McLeod, R.R.; Bowman, C.N. Facile image patterning via sequential thiol–Michael-thiol–yne click reactions. Chem. Mater. 2014, 26, 6819–6826. [Google Scholar] [CrossRef]

- Wang, J.; Qi, P.; Lin, A.; Chen, Y.; Zhang, Y.; Huang, Z.; Tan, X.; Kuroda, K. Exposure response coefficient of polarization-sensitive media using tensor theory of polarization holography. Opt. Lett. 2021, 46, 4789–4792. [Google Scholar] [CrossRef]

- Todorov, T.; Nikolova, L.; Tomova, N. Polarization holography 2: Polarization holographic gratings in photoanisotropic materials with and without intrinsic birefringence. Appl. Opt. 1984, 23, 4588–4591. [Google Scholar] [CrossRef] [PubMed]

- Veniaminov, A.V.; Sedunov, Y.N. Diffusion of phenanthrenequinone in poly(methyl methacrylate): Holographic measurements. Polym. Sci. Ser. A Chem. Phys. 1996, 38, 59–63. [Google Scholar]

- Lin, S.H.; Hsu, K.Y.; Chen, W.-Z.; Whang, W.T. Exposure schedule for multiplexing holograms in photopolymer. In Proceedings of the SPIE—Photorefractive Fiber and Crystal Devices: Materials, Optical Properties, and Applications V, Denver, CO, USA, 20 September 1999. [Google Scholar]

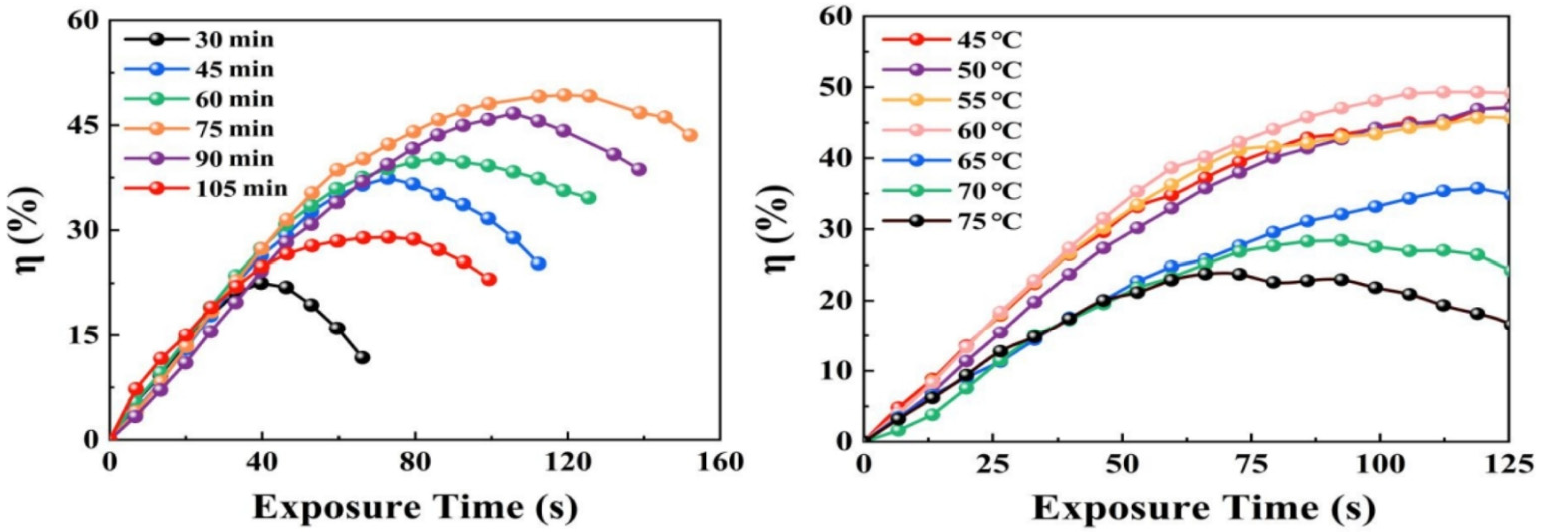

- Lin, S.-H.; Hsu, K.Y. Temperature effect in PQ:PMMA photopolymer. In Proceedings of the SPIE—The International Society for Optical Engineering, Bellingham, WA, USA, 19 October 2000. [Google Scholar]

- Lin, S.H.; Hsu, K.Y.; Chen, W.-Z.; Whang, W.T. Phenanthrenequinone-doped poly(methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef] [PubMed]

- Hsu, K.Y.; Lin, S.H.; Hsiao, Y.-N.; Whang, W.T. Experimental characterization of phenanthrenequinone-doped poly(methyl methacrylate) photopolymer for volume holographic storage. Opt. Eng. 2003, 42, 1390–1396. [Google Scholar] [CrossRef]

- Lin, S.-H. Doped PMMA Photopolymer for Volume Holographic Recording. In Proceedings of the SPIE—Photorefractive Fiber and Crystal Devices: Materials, Optical Properties, and Applications, Bellingham, WA, USA, 21 October 2003. [Google Scholar]

- Veniaminov, A.V.; Bartsch, E.; Popov, A.P. Postexposure Evolution of a Photoinduced Grating in a Polymer Material with Phenanthrenequinone. Opt. Spectrosc. 2005, 99, 744–750. [Google Scholar] [CrossRef]

- Sun, X.; Hou, L.; Wang, J.; Gai, Y.; Zhang, J.; Jiang, Y. The temperature effect of holographic recording in phenanthrenequinone-doped poly(methyl methacrylate) materials. In Proceedings of the International Society for Optics and Photonics, Bellingham, WA, USA, 15 September 2005. [Google Scholar]

- Yu, D.; Liu, H.; Jiang, Y.; Sun, X. Holographic storage stability in PQ-PMMA bulk photopolymer. Opt. Commun. 2010, 283, 4219–4223. [Google Scholar] [CrossRef]

- Qi, Y.; Li, H.; Tolstik, E.; Guo, J.; Gleeson, M.R.; Matusevich, V.; Kowarschik, R.; Sheridan, J.T. Study of PQ/PMMA photopolymer Part 1: Theoretical modeling. J. Opt. Soc. Am. B 2013, 30, 3289–3307. [Google Scholar] [CrossRef]

- Qi, Y.; Tolstik, E.; Li, H.; Guo, J.; Gleeson, M.R.; Matusevich, V.; Kowarschik, R.; Sheridan, J.T. Study of PQ/PMMA photopolymer Part 2: Experimental results. J. Opt. Soc. Am. B 2013, 30, 3308–3315. [Google Scholar] [CrossRef]

- Chuang, C.-I.; Hsiao, Y.-N.; Lin, S.-H.; Chao, Y.-F. Real-time measurement of photo-induced effects in 9,10-phenanthrenequinone-doped poly(methyl methacrylate) photopolymer by phase-modulated ellipsometry. Opt. Commun. 2010, 283, 3279–3283. [Google Scholar] [CrossRef]

- Lin, S.H.; Chen, P.-L.; Chuang, C.-I.; Chao, Y.-F.; Hsu, K.Y. Volume polarization holographic recording in thick phenanthrenequinone-doped poly(methyl methacrylate) photopolymer. Opt. Lett. 2011, 36, 3039–3041. [Google Scholar] [CrossRef]

- Chen, X.; Song, H.; Chen, Y.; Wang, K.; Qiu, X.; Tan, X.; Lin, X. Influence of pre-polymerization process on optical properties of phenanthrenequinone-doped polymethyl methacrylate photopolymer. In Proceedings of the Ultra-High-Definition Imaging Systems IV, Online, 6–11 March 2021. [Google Scholar]

- Peng, H.; N, M.; Bi, S.; Liao, Y.; Xie, X. Highly diffractive, reversibly fast responsive gratings formulated through holography. RSC Adv. 2014, 4, 4420–4426. [Google Scholar] [CrossRef]

- Lin, S.H.; Lin, J.-H.; Chen, P.-L.; Shiao, Y.-N.; Hsu, K.Y. Doped poly(methyl methacrylate) photopolymers for holographic data storage. J. Nonlinear Opt. Phys. Mater. 2006, 15, 239–252. [Google Scholar] [CrossRef]

- Krul, L.P.; Matusevich, V.; Hoff, D.; Kowarschik, R.; Matusevich, Y.I.; Butovskaya, G.V.; Murashko, E.A. Modified polymethylmethacrylate as a base for thermostable optical recording media. Opt. Express 2007, 15, 8543–8549. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Wang, H.; Wang, J.; Jiang, Y.; Sun, X. Improvement of holographic thermal stability in phenanthrenequinone-doped poly(methyl methacrylate-co-methacrylic acid) photopolymer. Opt. Eng. 2011, 50, 085803. [Google Scholar] [CrossRef]

- Ko, C.-J.; Chang, Y.-L.; Hsiao, Y.-N.; Chen, P.-L.; Lin, S.-H.; Whang, W.-T.; Hsu, K.-Y.; Tsai, M.-H.; Tsang, W.-Y. Co-doping with polysquaraine enhances the holographic optical data storage of PMMA/PQ photopolymers. J. Mod. Opt. 2011, 58, 1215–1219. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Wu, A.; Zhao, T.; Kang, G.; Tan, X.; Shimura, T. Improving the polarization-holography performance of PQ/PMMA photopolymer by doping with THMFA. Opt. Express 2018, 26, 17794–17803. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Kang, G.; Zhao, T.; Tan, X. Highly concentrated phenanthrenequinone-doped poly(MMA-co-ACMO) for volume holography. Chin. Opt. Lett. 2018, 16. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Kang, G.; Zhao, T.; Tan, X.; Shimura, T. Volume Polarization Holographic Recording in Phenanthrenequinone Doped Poly(MMA-co-BzMA) Photopolymer. Chem. Lett. 2018, 47, 520–523. [Google Scholar] [CrossRef]

- Hu, P.; Li, J.; Jin, J.; Lin, X.; Tan, X. Highly Sensitive Photopolymer for Holographic Data Storage Containing Methacryl Polyhedral Oligomeric Silsesquioxane. ACS Appl. Mater. Interfaces 2022, 14, 21544–21554. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, N.; Tomita, Y.; Kojima, T. Holographic recording in TiO2 nanoparticle-dispersed methacrylate photopolymer films. Appl. Phys. Lett. 2002, 81, 4121–4123. [Google Scholar] [CrossRef]

- Tomita, Y.; Chikama, K.; Nohara, Y.; Chikama, K.; Nohara, Y. Two-dimensional imaging of atomic distribution morphology created by holographically induced mass transfer of monomer molecules and nanoparticles in a silica-nanoparticle-dispersed photopolymer film. Opt. Lett. 2005, 31, 1402–1404. [Google Scholar] [CrossRef]

- Tomita, Y.; Suzuki, N.; Chikama, K. Holographic manipulation of nanoparticle distribution morphology in nanoparticle-dispersed photopolymers. Opt. Lett. 2005, 30, 839–841. [Google Scholar] [CrossRef]

- Tomita, Y.; Furushima, K.; Endoh, Y.; Hidaka, M.; Ohmori, K.; Chikama, K. Volume holographic recording in multicomponent photopolymers with hyperbranched polymers as organic nanoparticles. In Proceedings of the SPIE—Photon Management II, Strasbourg, France, 25 April 2006. [Google Scholar]

- Suzuki, N.; Tomita, Y.; Ohmori, K.; Hidaka, M.; Chikama, K. Highly transparent ZrO2 nanoparticle-dispersed acrylate photopolymers for volume holographic recording. Opt. Express 2006, 14, 12712–12719. [Google Scholar] [CrossRef]

- Hsiao, Y.-N.; Whang, W.-T.; Lin, S.H. Effect of ZnMA on Optical and Holographic Characteristics of Doped PQ/PMMA Photopolymer. Jpn. J. Appl. Phys. 2005, 44, 914–919. [Google Scholar] [CrossRef]

- Hsiao, Y.-N.; Whang, W.T.; Lin, S.-H.; Hsu, K.Y. Holographic characteristics of organo-metallic compound-doped PQ: PMMA photopolymers. In Proceedings of the SPIE—Photorefractive Fiber and Crystal Devices: Materials, Optical Properties, and Applications IX, Bellingham, WA, USA, 22 October 2004. [Google Scholar]

- Chen, Y.-F.; Hsiao, Y.-N.; Lin, S.H.; Hsu, K.Y.; Cheng, W.-S.; Whang, W.-T. Effect of lanthanoid organometallic compounds on holographic storage characteristics of doped PQ/poly(hydroxyethyl methacrylate-co-methyl methacrylate) hybrids. J. Opt. A Pure Appl. Opt. 2009, 11, 125409. [Google Scholar] [CrossRef]

- Hata, E.; Tomita, Y. Order-of-magnitude polymerization-shrinkage suppression of volume gratings recorded in nanoparticle-polymer composites. Opt. Lett. 2010, 35, 396–398. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Jiang, Y.; Sun, X. Mutual diffusion dynamics with nonlocal response in SiO2 nanoparticles dispersed PQPMMA bulk photopolymer. Opt. Express 2011, 19, 13787–13792. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Wang, L. Holographic response characteristics influenced by an absorptive diffusion polymerization model in bulk TI/PMMAs. Appl. Opt. 2019, 58, 8622–8630. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Tan, X. SiO2 NPs-PQ/PMMA Photopolymer Material Doped with a High-Concentration Photosensitizer for Holographic Storage. Polymers 2020, 12, 816. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, P.; Huang, Z.; Wang, J.; Song, H.; Chen, X.; Lin, X.; Wu, T.; Tan, X. Significant Enhancement of the Polarization Holographic Performance of Photopolymeric Materials by Introducing Graphene Oxide. ACS Appl. Mater. Interfaces 2021, 13, 27500–27512. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.-H.; Chen, P.-L.; Hsiao, Y.-N.; Whang, W.-T. Fabrication and characterization of poly(methyl methacrylate) photopolymer doped with 9,10-phenanthrenequinone (PQ) based derivatives for volume holographic data storage. Opt. Commun. 2008, 281, 559–566. [Google Scholar] [CrossRef]

- Hsiao, Y.N.; Hsu, K.Y.; Lin, S.H. An irgacure 784 doped photopolymers for display holograms recording at 532 nm. Opt. Mem. Neural Netw. 2010, 18, 253–259. [Google Scholar] [CrossRef]

- Ando, T.; Masaki, K.; Shimizu, T. Page Data Multiplexing for Vector Wave Memories Having Polarization Recording Material Doped with Aromatic Ketone Derivative. Jpn. J. Appl. Phys. 2013, 52, 09ld15. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Zang, J.; Kang, G.; Tan, X. Volume holographic recording in Irgacure 784-doped PMMA photopolymer. Opt. Express 2017, 25, 20654–20662. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Wang, L.; Zhao, Y.; Li, Z.; Sun, X. Holographic memory performances of titanocene dispersed poly (methyl methacrylate) photopolymer with different preparation conditions. Opt. Mater. Express 2018, 8, 1441. [Google Scholar] [CrossRef]

- Liu, P.; Wang, L.; Zhao, Y.; Li, Z.; Sun, X. Cationic photo-initiator titanocene dispersed PMMA photopolymers for holographic memories. OSA Contin. 2018, 1, 783. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Zhao, Y.; Li, Z. Holographic stability and storage capacity on bulk green-light sensitive TI/PMMA materials. AIP Adv. 2019, 9, 035034. [Google Scholar] [CrossRef]

- Liu, H.; Yu, D.; Li, X.; Luo, S.; Jiang, Y.; Sun, X. Diffusional enhancement of volume gratings as an optimized strategy for holographic memory in PQ-PMMA photopolymer. Opt. Express 2010, 18, 6447–6454. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y.; Song, H.; Lin, X.; Huang, Z.; Kuroda, K.; Tan, X. Generation of circular polarization with an arbitrarily polarized reading wave. Opt. Express 2021, 29, 2613–2623. [Google Scholar] [CrossRef]

- Zheng, S.; Ke, S.; Liu, H.; Xu, X.; Zhang, Y.; Yang, Y.; Huang, Z.; Tan, X. Simple method for generating special beams using polarization holography. Opt. Express 2022, 30, 16159–16173. [Google Scholar] [CrossRef]

| Holographic Recording Material | Diffraction Efficiency | Photosensitivity | Thickness | Recording Wavelength (Power) |

|---|---|---|---|---|

| 0.1PQ-PQ/PMMA [99] | ≈50% | ≈0.3 cm/J | ≈1.5 mm | 532 nm (100 mw/cm2) |

| PVA/AA [36] | ≈94% | ≈8 mJ/cm2 | ≈60 um | 632 nm (1 mw/cm2) |

| Epoxy–Resin [40] | ≈92% | ≈11.7 × 10−3 cm2/J | ≈0.25 mm | 532 nm (2 mw/cm2) |

| HPDLCs [100] | ≈82% | 2.3 cm/mJ | Liquid | 442 nm (8.8 mw/cm2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Hu, P.; Zeng, Z.; Jin, J.; Wu, J.; Chen, X.; Liu, J.; Li, Q.; Chen, M.; Zhang, Z.; et al. Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording. Molecules 2022, 27, 6283. https://doi.org/10.3390/molecules27196283

Li J, Hu P, Zeng Z, Jin J, Wu J, Chen X, Liu J, Li Q, Chen M, Zhang Z, et al. Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording. Molecules. 2022; 27(19):6283. https://doi.org/10.3390/molecules27196283

Chicago/Turabian StyleLi, Jinhong, Po Hu, Zeyi Zeng, Junchao Jin, Junhui Wu, Xi Chen, Jie Liu, Qingdong Li, Mingyong Chen, Zuoyu Zhang, and et al. 2022. "Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording" Molecules 27, no. 19: 6283. https://doi.org/10.3390/molecules27196283

APA StyleLi, J., Hu, P., Zeng, Z., Jin, J., Wu, J., Chen, X., Liu, J., Li, Q., Chen, M., Zhang, Z., Zhang, Y., Lin, X., & Tan, X. (2022). Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording. Molecules, 27(19), 6283. https://doi.org/10.3390/molecules27196283