Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene

Abstract

:1. Introduction

2. Results

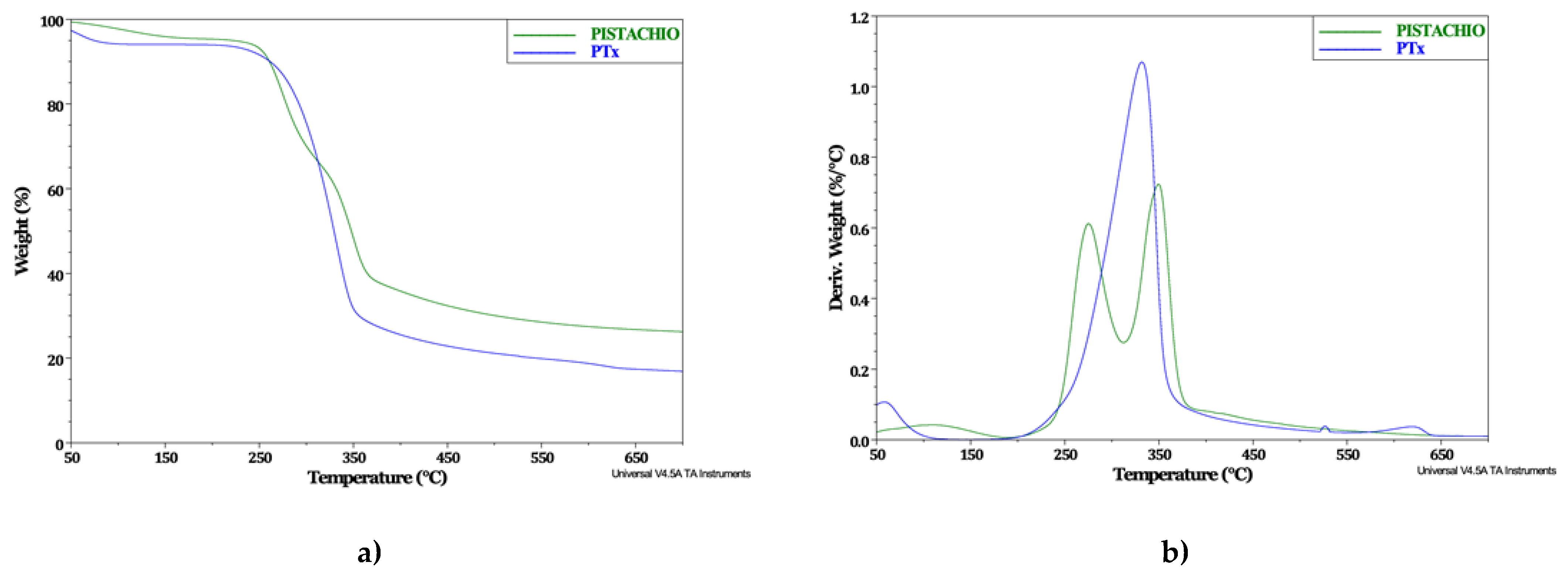

2.1. Thermogravimetric Analysis (TGA) for Pistachio Shell Particles

2.2. Thermogravimetric Analysis (TGA) for PP-PTx Composites

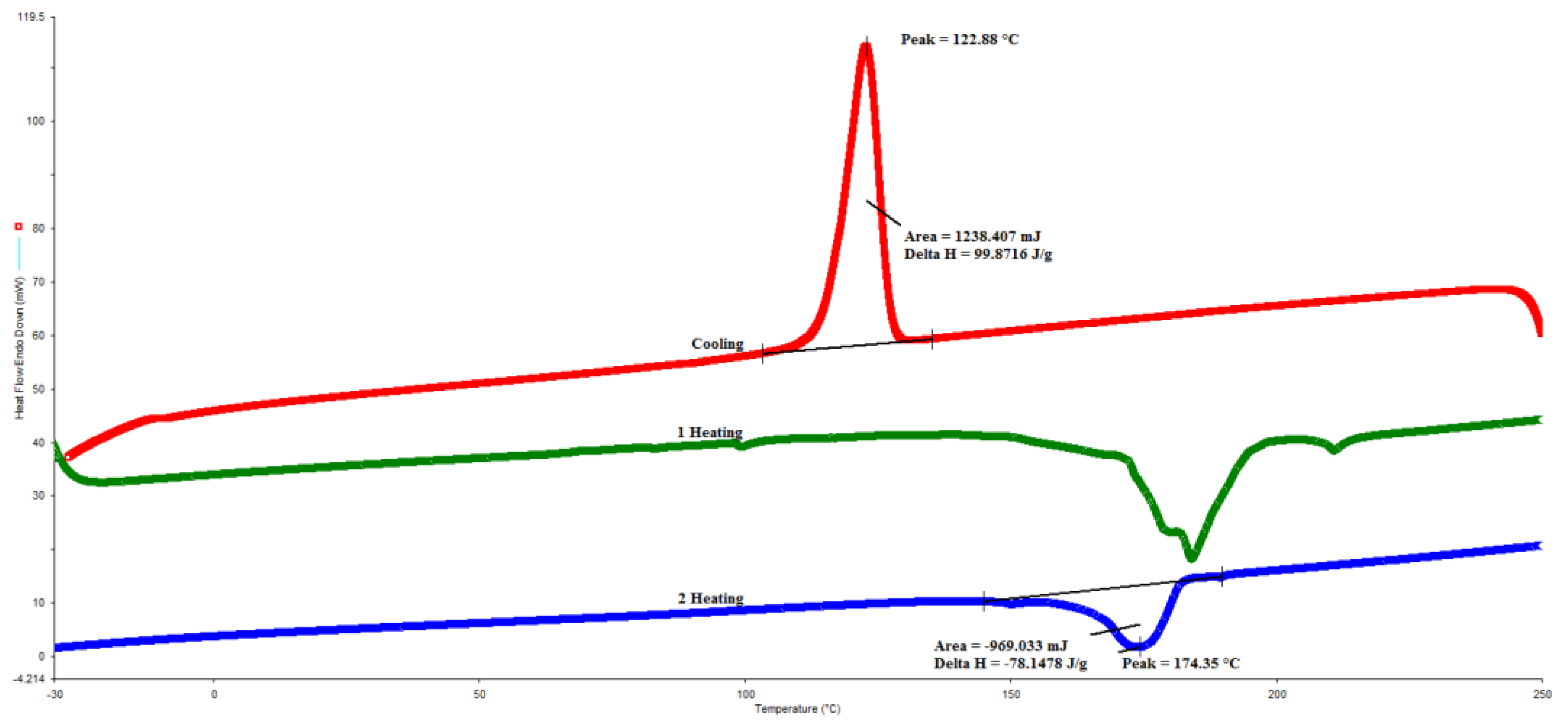

2.3. Differential Scanning Calorimetry (DSC) of Composites

2.4. Dynamic Mechanical Analysis (DMA) of Composites

3. Materials and Methods

3.1. Materials

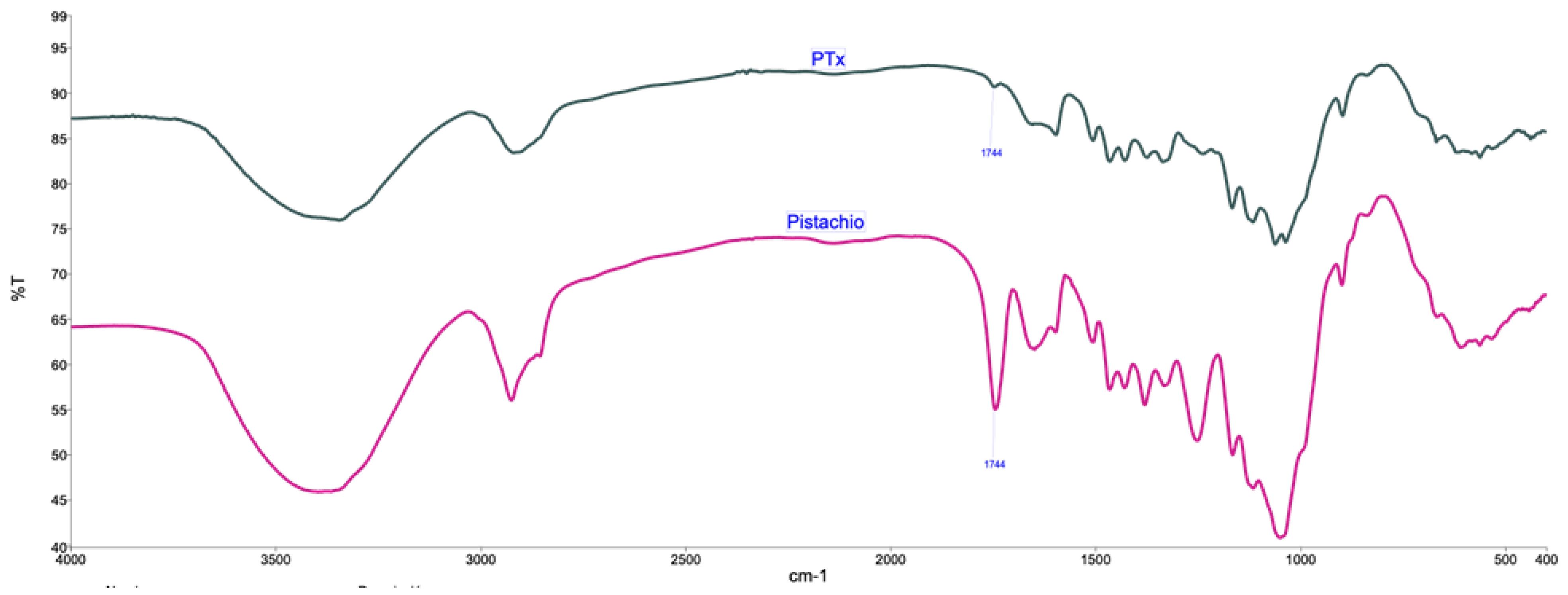

3.2. Particles Characterization

3.3. Composites Preparation

3.4. Composites Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Ortega, F.; Versino, F.; López, O.V.; García, M.A. Biobased composites from agroindustrial wastes and by-products. Emergent Mater. 2021. [Google Scholar] [CrossRef]

- Wahab, R.A.; Gowon, J.A.; Elias, N. On the Renewable Polymers from Agro-industrial Biomass: A Mini Review. J. Indones. Chem. Soc. 2019, 2, 24. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Komnitsas, K.; Zaharaki, D.; Pyliotis, I.; Vamvuka, D.; Bartzas, G. Assessment of pistachio shell biochar quality and its potential for adsorption of heavy metals. Waste Biomass Valorization 2015, 6, 805–816. [Google Scholar] [CrossRef]

- Altun, T.; Pehlivan, E. Removal of Cr (VI) from aqueous solutions by modified walnut shells. Food Chem. 2012, 132, 693–700. [Google Scholar] [CrossRef]

- Zheng, D.; Zhang, Y.; Guo, Y.; Yue, J. Isolation and characterization of nanocellulose with a novel shape from walnut (Juglans regia L.) shell agricultural waste. Polymers 2019, 11, 1130. [Google Scholar] [CrossRef] [Green Version]

- Najafabadi, M.A.; Khorasani, S.N.; Esfahani, J.M. High density polyethylene/pistachio shell flour/nanoclay composites-effect of accelerated weathering conditions on mechanical properties, relative brightness and total colour change. Polym. Polym. Compos. 2017, 25, 299–308. [Google Scholar] [CrossRef]

- Salasinska, K.; Ryszkowska, J. The effect of filler chemical constitution and morphological properties on the mechanical properties of natural fiber composites. Compos. Interfaces 2015, 22, 39–50. [Google Scholar] [CrossRef]

- Kadhim, N.N.; Hamad, Q.A.; Oleiwi, J.K. Tensile and morphological properties of PMMA composite reinforced by Pistachio Shell powder used in denture applications. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020; Volume 2213, p. 020078. [Google Scholar]

- Karaağaç, B. Use of ground pistachio shell as alternative filler in natural rubber/styrene–butadiene rubber-based rubber compounds. Polym. Compos. 2014, 35, 245–252. [Google Scholar] [CrossRef]

- Alsaadi, M.; Erkliğ, A.; Albu-khaleefah, K. Effect of Pistachio Shell Particle Content on the Mechanical Properties of Polymer Composite. Arab. J. Sci. Eng. 2018, 43, 4689–4696. [Google Scholar] [CrossRef]

- Chandraker, S.; Dutt, J.K.; Agrawal, A.; Roy, H.; Chandrakar, K.; Mishra, V. Development and Characterization of Epoxy-Based Polymeric Composite with Bio-particulates as Filler Material. Arabian J. Sci. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Arevalo, J.; Gomez-Caturla, J.; Garcia-Garcia, D.; Torres-Giner, S. Peroxide-Induced Synthesis of Maleic Anhydride-Grafted Poly (butylene succinate) and Its Compatibilizing Effect on Poly(butylene succinate)/Pistachio Shell Flour Composites. Molecules 2021, 26, 5927. [Google Scholar] [CrossRef]

- Kuram, E. UV and thermal weathering of green composites: Comparing the effect of different agricultural waste as fillers. J. Compos. Mater. 2020, 54, 3683–3697. [Google Scholar] [CrossRef]

- El Mechtali, F.Z.; Essabir, H.; Nekhlaoui, S.; Bensalah, M.O.; Jawaid, M.; Bouhfid, R.; Qaiss, A. Mechanical and thermal properties of polypropylene reinforced with almond shells particles: Impact of chemical treatments. J. Bionic Eng. 2015, 12, 483–494. [Google Scholar] [CrossRef]

- Ruggiero, A.; Valášek, P.; Müller, M.; D’Amato, R. Tribological investigation of epoxy/seed particle composite obtained from residues of processing Jatropha Curcas L. fruits. Compos. Part B Eng. 2019, 167, 654–667. [Google Scholar] [CrossRef]

- Demiral, İ.; Şamdan, C.A. Preparation and characterisation of activated carbon from pumpkin seed shell using H3PO4. Anadolu Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2016, 17, 125–138. [Google Scholar] [CrossRef] [Green Version]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1–polyester resin matrix. Compos. Sci Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 2—Cashew nut shell liquid matrix. Compos. Sci. Technol. 2004, 64, 1231–1238. [Google Scholar] [CrossRef]

- Huko, D.; Kamau, D.N.; Ogola, W.O. Effects of varying particle size on mechanical and combustion characteristics of mango seed shell cashew nut shell composite briquettes. Int. J. Eng. Sci. Invent. 2015, 4, 32–39. [Google Scholar]

- Mittal, V.; Sinha, S. Effect of chemical treatment on thermal properties of bagasse fiber-reinforced epoxy composite. Sci. Eng. Compos. Mater. 2017, 24, 237–243. [Google Scholar] [CrossRef]

- Chang, W.P.; Kim, K.J.; Gupta, R.K. Moisture absorption behavior of wood/plastic composites made with ultrasound-assisted alkali-treated wood particulates. Compos. Interfaces 2009, 16, 937–951. [Google Scholar] [CrossRef]

- Fioresi, F.; Vieillard, J.; Bargougui, R.; Bouazizi, N.; Fotsing, P.N.; Woumfo, E.D.; Brun, N.; Mofaddel, N.; Le Derf, F. Chemical modification of the cocoa shell surface using diazonium salts. J. Colloid. Interface Sci. 2017, 494, 92–97. [Google Scholar] [CrossRef] [PubMed]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Aprilia, N.S.; Khalil, H.A.; Bhat, A.H.; Dungani, R.; Hossain, M.S. Exploring material properties of vinyl ester biocomposites filled carbonized jatropha seed shell. BioResources 2014, 9, 4888–4898. [Google Scholar] [CrossRef] [Green Version]

- Garcia, A.; Lopez, Y.; Karimi, K.; Benitez, A.; Lundin, M.; Taherzadeh, M.J.; Martin, C. Chemical and physical characterization and acid hydrolysis of a mixture of Jatropha curcas shells and husks. Cellul. Chem. Technol. 2015, 49, 737–744. [Google Scholar]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Bazan, P.; Salasińska, K.; Kuciel, S. Flame retardant polypropylene reinforced with natural additives. Ind. Crops Prod. 2021, 164, 113356. [Google Scholar] [CrossRef]

- Açıkalın, K. Pyrolytic characteristics and kinetics of pistachio shell by thermogravimetric analysis. J. Therm. Anal. Calorim. 2012, 109, 227–235. [Google Scholar] [CrossRef]

- Gupta, S.; Gupta, G.K.; Mondal, M.K. Thermal degradation characteristics, kinetics, thermodynamic, and reaction mechanism analysis of pistachio shell pyrolysis for its bioenergy potential. Biomass Convers. Biorefinery 2020, 1–15. [Google Scholar] [CrossRef]

- Açıkalın, K. Thermogravimetric analysis of walnut shell as pyrolysis feedstock. J. Therm. Anal. Calorim. 2011, 105, 145–150. [Google Scholar] [CrossRef]

- Mukherjee, A.; Ganguly, P.K.; Sur, D. Structural mechanics of jute: The effects of hemicellulose or lignin removal. J. Text. Inst. 1993, 84, 348–353. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S.; Samal, S.K. Influence of short bamboo/glass fiber on the thermal, dynamic mechanical and rheological properties of polypropylene hybrid composites. Mater. Sci. Eng. A 2009, 523, 32–38. [Google Scholar] [CrossRef]

- Nuñez, A.J.; Kenny, J.M.; Reboredo, M.M.; Aranguren, M.I.; Marcovich, N.E. Thermal and dynamic mechanical characterization of polypropylene-woodflour composites. Polym. Eng. Sci. 2002, 42, 733–742. [Google Scholar] [CrossRef]

- Ardanuy, M.; Antunes, M.; Velasco, J.I. Vegetable fibres from agricultural residues as thermo-mechanical reinforcement in recycled polypropylene-based green foams. Waste Manag. 2012, 32, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Melo, P.M.A.; Macêdo, O.B.; Barbosa, G.P.; Santos, A.S.F.; Silva, L.B. Reuse of Natural Waste to Improve the Thermal Stability, Stiffness, and Toughness of Postconsumer Polypropylene Composites. J. Polym. Environ. 2021, 29, 538–551. [Google Scholar] [CrossRef]

- Quillin, D.T.; Caulfield, D.F.; Koutsky, J.A. Crystallinity in the polypropylene/cellulose system. I. Nucleation and crystalline morphology. J. Appl. Polym. Sci. 1993, 50, 1187–1194. [Google Scholar] [CrossRef]

- Fatou, J.G. Melting temperature and enthalpy of isotactic polypropylene. Eur. Polym. J. 1971, 7, 1057–1064. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Sautereau, H.; Raihane, M.; Erchiqui, F.; Dufresne, A. Short palm tree fibers polyolefin composites: Effect of filler content and coupling agent on physical properties. Macromol. Mater. Eng. 2008, 293, 140–148. [Google Scholar] [CrossRef]

- Levytskyi, V.E.; Masyuk, A.S.; Bilyi, L.M.; Bialopiotrowicz, T.; Humenetskyi, T.V.; Shybanova, A.M. Influence of Silicate Nucleation Agent Modified with Polyvinylpyrrolidone on the Morphology and Properties of Polypropylene. Mater. Sci. 2020, 55, 555–562. [Google Scholar] [CrossRef]

- Sreenivasan, S.; Iyer, P.B.; Iyer, K.K. Influence of delignification and alkali treatment on the fine structure of coir fibres (Cocos nucifera). J. Mater. Sci. 1996, 31, 721–726. [Google Scholar] [CrossRef]

- Lin, N.; Fan, D.; Chang, P.R.; Yu, J.; Cheng, X.; Huang, J. Structure and properties of poly (butylene succinate) filled with lignin: A case of lignosulfonate. J. Appl. Polym. Sci. 2011, 121, 1717–1724. [Google Scholar] [CrossRef]

| Sample | Tc, °C | ∆Hc, J/g | Tm, °C | ∆Hm, J/g | %C |

|---|---|---|---|---|---|

| PP | 123 | 99.87 | 174 | 78.14 | 37.74 |

| PP-2PTx | 124 | 98.45 | 177 | 83.49 | 40.33 |

| PP-4-PTx | 123 | 100.03 | 180 | 81.66 | 39.45 |

| PP-6PTx | 123 | 94.26 | 181 | 85.6 | 41.35 |

| PP-8PTx | 123 | 94.89 | 180 | 77.82 | 37.58 |

| PP-10PTx | 124 | 78.45 | 179 | 64.76 | 31.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar-Cruz, B.A.; Chávez-Cinco, M.Y.; Morales-Cepeda, A.B.; Ramos-Galván, C.E.; Rivera-Armenta, J.L. Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene. Molecules 2022, 27, 426. https://doi.org/10.3390/molecules27020426

Salazar-Cruz BA, Chávez-Cinco MY, Morales-Cepeda AB, Ramos-Galván CE, Rivera-Armenta JL. Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene. Molecules. 2022; 27(2):426. https://doi.org/10.3390/molecules27020426

Chicago/Turabian StyleSalazar-Cruz, Beatriz Adriana, María Yolanda Chávez-Cinco, Ana Beatriz Morales-Cepeda, Claudia Esmeralda Ramos-Galván, and José Luis Rivera-Armenta. 2022. "Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene" Molecules 27, no. 2: 426. https://doi.org/10.3390/molecules27020426