Process and Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo

Abstract

1. Introduction

2. Results and Analysis

2.1. Effect of the Tea Polyphenol-Modified Citral Anti-Mildew Treatment Process on the Drug Loading of Bamboo Strips

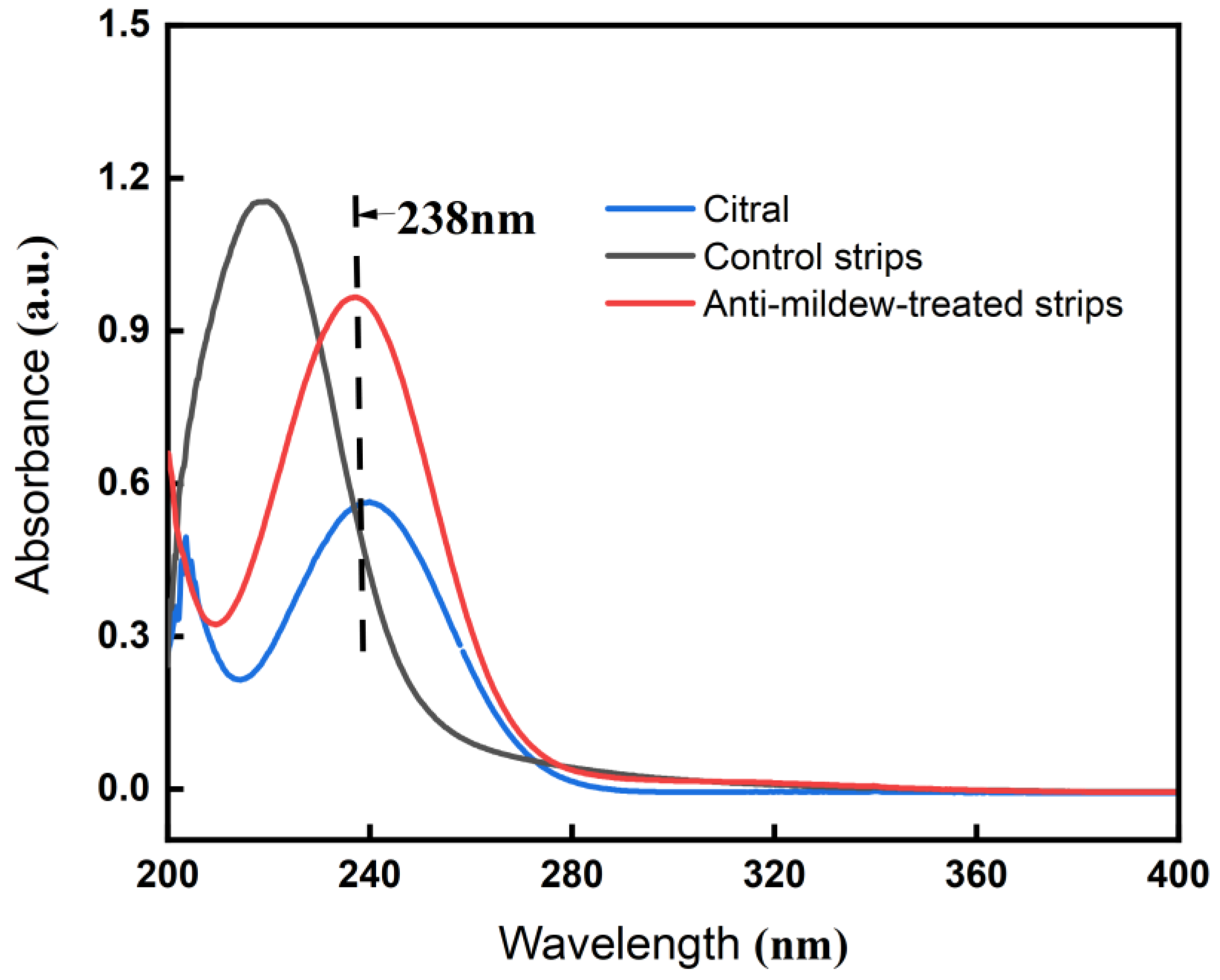

2.2. UV-Vis Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

2.3. XRD Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

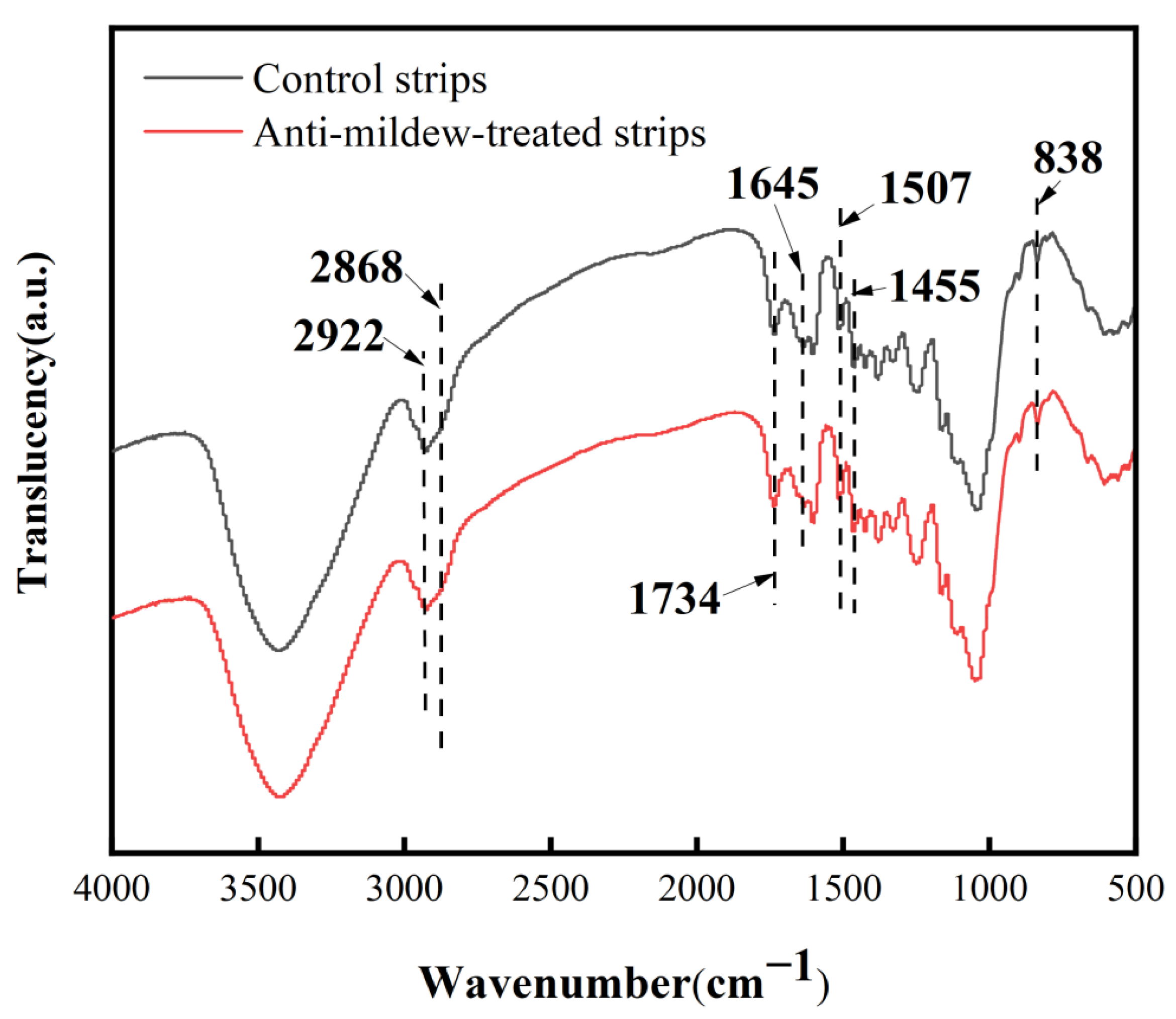

2.4. FT-IR Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

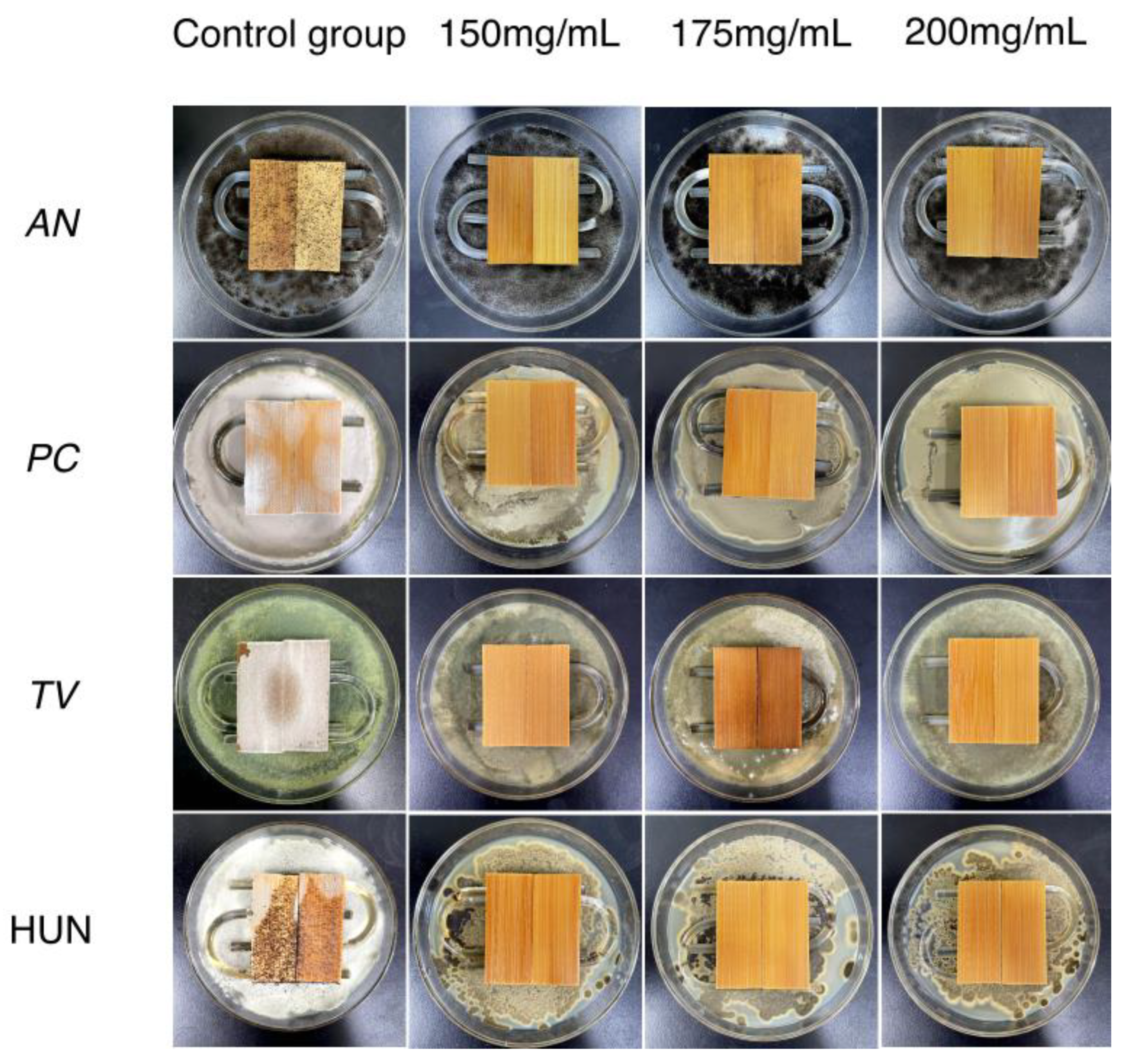

2.5. Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo

3. Materials and Methods

3.1. Materials

3.1.1. Bamboo

3.1.2. Main Reagents

3.1.3. Test Strains

3.2. Methods

3.2.1. Preparation of Tea Polyphenol-Modified Citral

3.2.2. Tea polyphenol-Modified Citral Impregnation Treatment of Bamboo

3.2.3. Experimental Design of the Tea Polyphenol-Modified Citral Anti-Mildew Treatment of Bamboo

3.2.4. Ultraviolet-Visible Spectrophotometer (UV-Vis) Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

3.2.5. X-Ray Diffraction (XRD) Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

3.2.6. Fourier Transform Infrared Spectroscopy (FT-IR) Analysis of Tea Polyphenol-Modified Citral Anti-Mildew-Treated Bamboo

3.2.7. Preparation of Potato Glucose Agar Medium

3.2.8. Preparation of Bacterial Suspension

3.2.9. Experiment on the Tea Polyphenol-Modified Citral Anti-Mildew Treatment of Bamboo

4. Conclusions

- The better treatment parameters of the tea polyphenol-modified citral anti-mildew treatment of bamboo are as follows: impregnation pressure 0.6 MPa, impregnation time 150 min, and tea polyphenol-modified citral concentration 200 mg mL−1, where the impregnation pressure has a significant effect on the dry and wet loading of anti-mildew-treated bamboo.

- Tea polyphenol-modified citral does not react with the chemical composition of bamboo after anti-mildew treatment and does not destroy the original microstructure and chemical form of the bamboo.

- When the concentration of tea polyphenol-modified citral reached 175 mg mL−1 and above, the efficacy of its anti-mildew treatment on common bamboo materials such as PC, TV, AN, and Hun was found to be 100% effective; the tea polyphenol-modified citral anti-mildew treatment on bamboo materials was found to have better anti-mildew properties.

- Following treatment with tea polyphenol-modified citral, bamboo wood had significantly improved its anti-mold performance and added a refreshing lemon fragrance. Thus, tea polyphenol modified-citral has a good application prospect in the anti-mildew treatment of bamboo.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.-Z.; Luan, Y.; Hu, J.-B.; Fang, C.-H.; Liu, L.-T.; Ma, Y.-F.; Liu, Y.; Fei, B.-H. Bamboo heat treatments and their effects on bamboo properties. Constr. Build. Mater. 2022, 331, 127320. [Google Scholar] [CrossRef]

- Hao, X.; Wang, Q.; Wang, Y.; Han, X.; Yuan, C.; Cao, Y.; Lou, Z.; Li, Y. The effect of oil heat treatment on biological, mechanical and physical properties of bamboo. J. Wood Sci. 2021, 67, 26. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Liu, J.; Yan, H.; Han, H.; Bian, H.; Li, Y. Regulating lignin content to obtain excellent bamboo-derived electromagnetic wave absorber with thermal stability. Chem. Eng. J. 2022, 430, 133178. [Google Scholar] [CrossRef]

- Wang, Q.; Han, H.; Lou, Z.; Han, X.; Wang, X.; Li, Y. Surface property enhancement of bamboo by inorganic materials coating with extended functional applications. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106848. [Google Scholar] [CrossRef]

- Syazwani Saadun, N.; Majid, M.A.; Hanif Ismail, M.; Hani Adnan, S. An Overview on Physical and Mechanical Properties of Bamboo as a Natural Reinforcement in Concrete. IOP Conf. Ser. Earth Environ. Sci. 2022, 1022, 012049. [Google Scholar] [CrossRef]

- Sun, Z.; Shao, J. Preliminary study on innovative design of bamboo furniture based on users’ big data. J. Phys. Conf. Ser. 2021, 1774, 012017. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Y.; Wang, Q.; Xu, Z.; Lin, X. Molecular characterization of FLOWERING LOCUS T(FT)genes from bamboo (Phyllostachys violascens). J. Plant Biochem. Biotechnol. 2016, 25, 168–178. [Google Scholar] [CrossRef]

- Yu, H.; Du, C.; Liu, H.; Wei, J.; Zhou, Z. Advance in anti-mildew research of bamboo. J. Bamboo Res. 2016, 35, 46–51. [Google Scholar] [CrossRef]

- Kang, S.; Li, X.; Xing, Z.; Liu, X.; Bai, X.; Yang, Y.; Guo, D.; Xia, X.; Zhang, C.; Shi, C. Antibacterial effect of citral on Yersinia enterocolitica and its mechanism. Food Control. 2022, 135, 108775. [Google Scholar] [CrossRef]

- Quintieri, L.; Fancello, F.; Caputo, L.; Sorrentino, A.; Zara, S.; Lippolis, V.; Cervellieri, S.; Fanelli, F.; Corvino, A.; Pace, B.; et al. Effect of Gaseous Citral on Table Grapes Contaminated by Rhizopus oryzae ITEM 18876. Foods 2022, 11, 2478. [Google Scholar] [CrossRef]

- de Souza Araújo, I.J.; Patel, T.; Bukhari, A.; Sanz, C.K.; Fenno, J.C.; Ribeiro, J.S.; Bottino, M.C. Natural monoterpenes-laden electrospun fibrous scaffolds for endodontic infection eradication. Odontology 2022, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Ju, J.; Xie, Y.; Yu, H.; Guo, Y.; Cheng, Y.; Zhang, R.; Yao, W. Synergistic inhibition effect of citral and eugenol against Aspergillus niger and their application in bread preservation. Food Chem. 2020, 310, 125974. [Google Scholar] [CrossRef]

- Peng, R.; Du, C.; Hu, A.; Li, Q.; Zhang, J.; Zhang, W.; Sun, F. Fabrication of core–shell type poly(NIPAm)-encapsulated citral and its application on bamboo as an anti-molding coating. RSC Adv. 2021, 11, 36884–36894. [Google Scholar] [CrossRef] [PubMed]

- Guan, M.; Zhou, M.; Yong, C. Antimold Effect of Ultrasonic Treatment on Chinese Moso Bamboo. For. Prod. J. 2013, 63, 288–291. [Google Scholar] [CrossRef]

- Zhang, J.; Du, C.; Li, Q.; Hu, A.; Peng, R.; Sun, F.; Zhang, W. Inhibition mechanism and antibacterial activity of natural antibacterial agent citral on bamboo mould and its anti-mildew effect on bamboo. R. Soc. Open Sci. 2021, 8, 202244. [Google Scholar] [CrossRef]

- Zhang, J.; Du, C.; Peng, R.; Hu, A.; Li, Q.; Liu, C.; Shan, Y.; Chen, S.; Yin, W. Antimildew Treatment and Control Effect of Citral on Bamboo. Int. J. Polym. Sci. 2021, 2021, 5949458. [Google Scholar] [CrossRef]

- Sharma, S.; Habib, S.; Sahu, D.; Gupta, J. Chemical Properties and Therapeutic Potential of Citral, a Monoterpene Isolated from Lemongrass. MC 2020, 17, 2–12. [Google Scholar] [CrossRef]

- Yang, X.; Tian, H.; Ho, C.-T.; Huang, Q. Inhibition of Citral Degradation by Oil-in-Water Nanoemulsions Combined with Antioxidants. J. Agric. Food Chem. 2011, 59, 6113–6119. [Google Scholar] [CrossRef]

- Li, Q.; Peng, R.; Du, C.; Zhang, J.; Hu, A. Research progress on the improvement of citral and its application prospect for bamboo mold-proof. China For. Prod. Ind. 2021, 58, 46–51. [Google Scholar] [CrossRef]

- Saddiq, A.A.; Khayyat, S.A. Chemical and antimicrobial studies of monoterpene: Citral. Pestic. Biochem. Physiol. 2010, 98, 89–93. [Google Scholar] [CrossRef]

- Ay, E.; Gérard, V.; Graff, B.; Morlet-Savary, F.; Mutilangi, W.; Galopin, C.; Lalevée, J. Citral Photodegradation in Solution: Highlighting of a Radical Pathway in Parallel to Cyclization Pathway. J. Agric. Food Chem. 2019, 67, 3752–3760. [Google Scholar] [CrossRef] [PubMed]

- Leite, M.C.A.; Bezerra, A.P.D.B.; de Sousa, J.P.; Guerra, F.Q.S.; Lima, E.D.O. Evaluation of Antifungal Activity and Mechanism of Action of Citral against Candida albicans. Evid.-Based Complement. Altern. Med. 2014, 2014, 378280. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Zhong, Y.; Duan, Y.; Chen, Q.; Li, F. Antioxidant mechanism of tea polyphenols and its impact on health benefits. Anim. Nutr. 2020, 6, 115–123. [Google Scholar] [CrossRef]

- Gao, J. Natural antioxidants and synergistic effects. J. Food Saf. Qual. 2020, 11, 1859–1864. [Google Scholar] [CrossRef]

- Du, J.; Zhang, P.; Gao, D. Synergistic Antimicrobial Effect and Antioxidant Activity of the Compound Liquid with Clove Essential Oil and Tea Polyphenols. Mod. Foods 2021, 37, 87–95. [Google Scholar] [CrossRef]

- Ying, L.; Zhang, S.; Wang, Y.; Zhu, L. Progress on the Modification of Tea Polyphenols and Antioxidant Properties of Lipid-soluble Tea Polyphenols. Tea Sci. 2010, 511–515. [Google Scholar] [CrossRef]

- GB/T 18261–2013; Test Method for Anti-Mildew Agents in Controlling Wood Mould and Stain Fungi. Standardization Administration of China: Beijing, China, 2013. Available online: http://www.csres.com/detail/236872.html (accessed on 15 September 2022).

| Experimental Number | Factors | R1 (g/m2 ) | R2 (g/m2 ) | ||

|---|---|---|---|---|---|

| A (Pressure/MPa) | B (Impregnation Time/min) | C (Concentration mg mL−1) | |||

| 1 | 1 | 1 | 1 | 26.80 | 11.92 |

| 2 | 1 | 2 | 2 | 28.89 | 14.46 |

| 3 | 1 | 3 | 3 | 30.42 | 16.27 |

| 4 | 2 | 1 | 2 | 33.69 | 19.86 |

| 5 | 2 | 2 | 3 | 37. 19 | 23.42 |

| 6 | 2 | 3 | 1 | 35.58 | 22.46 |

| 7 | 3 | 1 | 3 | 34.25 | 20.05 |

| 8 | 3 | 2 | 1 | 31.30 | 18.04 |

| 9 | 3 | 3 | 2 | 36.82 | 20.85 |

| X1 (R1) | 28.703 | 31.580 | 31.227 | ||

| X2 (R1) | 35.487 | 32.460 | 33. 133 | ||

| X3 (R1) | 34.123 | 34.273 | 33.953 | ||

| R (R1) | 6.784 | 2.693 | 2.726 | ||

| X1 (R2) | 14.217 | 17.277 | 17.473 | ||

| X2 (R2) | 21.853 | 18.580 | 18.390 | ||

| X3 (R2) | 19.647 | 19.860 | 19.853 | ||

| R (R2) | 7.636 | 2.583 | 2.380 | ||

| Sources of Variance | Sum of Squares of Deviations | Degrees of Freedom | F-Value | F0.1 (2, 2) | Significance |

|---|---|---|---|---|---|

| A | 77.249 | 2 | 15.628 | 9 | * |

| B | 11.317 | 2 | 2.290 | 9 | |

| C | 11.742 | 2 | 2.375 | 9 | |

| Error | 4.94 | 2 | |||

| Sum | 105.248 | 8 |

| Sources of Variance | Sum of Squares of Deviations | Degrees of Freedom | F-Value | F0.1 (2, 2) | Significance |

|---|---|---|---|---|---|

| A | 92.673 | 2 | 68.647 | 9 | * |

| B | 10.011 | 2 | 7.416 | 9 | |

| C | 8.646 | 2 | 6.404 | 9 | |

| Error | 1.35 | 2 | |||

| Sum | 112.68 | 8 |

| Level | Factors | ||

|---|---|---|---|

| A (Pressure/MPa) | B (Impregnation Time/min) | C (Concentration mg mL−1) | |

| 1 | 0.5 | 90 | 150 |

| 2 | 0.6 | 120 | 175 |

| 3 | 0.7 | 150 | 200 |

| Infection Value | Area Infected with Bamboo Strips |

|---|---|

| 0 | No mycelium or mold on the surface of the bamboo strips |

| 1 | Infected area of bamboo strips surface < 1/4 |

| 2 | Infected area of bamboo strips surface 1/4–1/2 |

| 3 | Infected area of bamboo strips surface |

| 4 | Infected area of bamboo strips surface > 3/4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Li, Q.; Liu, C.; Du, C.; Shan, Y.; Yin, W.; Yang, F.; Shao, Y.; Wang, Y. Process and Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo. Molecules 2022, 27, 7549. https://doi.org/10.3390/molecules27217549

Chen S, Li Q, Liu C, Du C, Shan Y, Yin W, Yang F, Shao Y, Wang Y. Process and Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo. Molecules. 2022; 27(21):7549. https://doi.org/10.3390/molecules27217549

Chicago/Turabian StyleChen, Shiqin, Qi Li, Chunlin Liu, Chungui Du, Yingying Shan, Wenxiu Yin, Fei Yang, Yuran Shao, and Yuting Wang. 2022. "Process and Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo" Molecules 27, no. 21: 7549. https://doi.org/10.3390/molecules27217549

APA StyleChen, S., Li, Q., Liu, C., Du, C., Shan, Y., Yin, W., Yang, F., Shao, Y., & Wang, Y. (2022). Process and Anti-Mildew Properties of Tea Polyphenol-Modified Citral-Treated Bamboo. Molecules, 27(21), 7549. https://doi.org/10.3390/molecules27217549