Improving the Mechanical Properties of Damaged Hair Using Low-Molecular Weight Hyaluronate

Abstract

:1. Introduction

2. Results

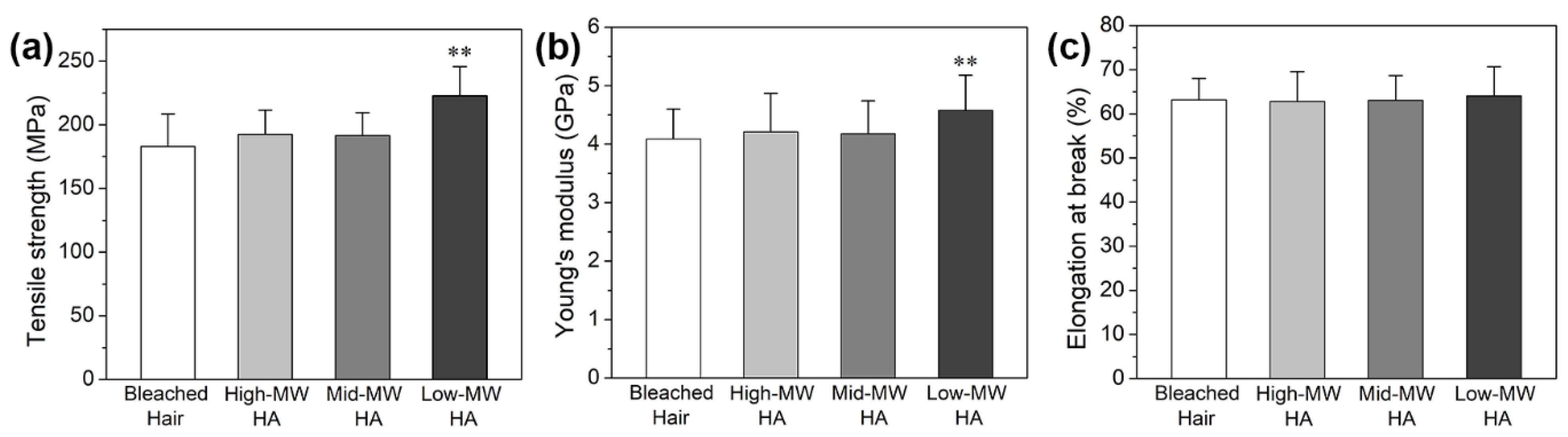

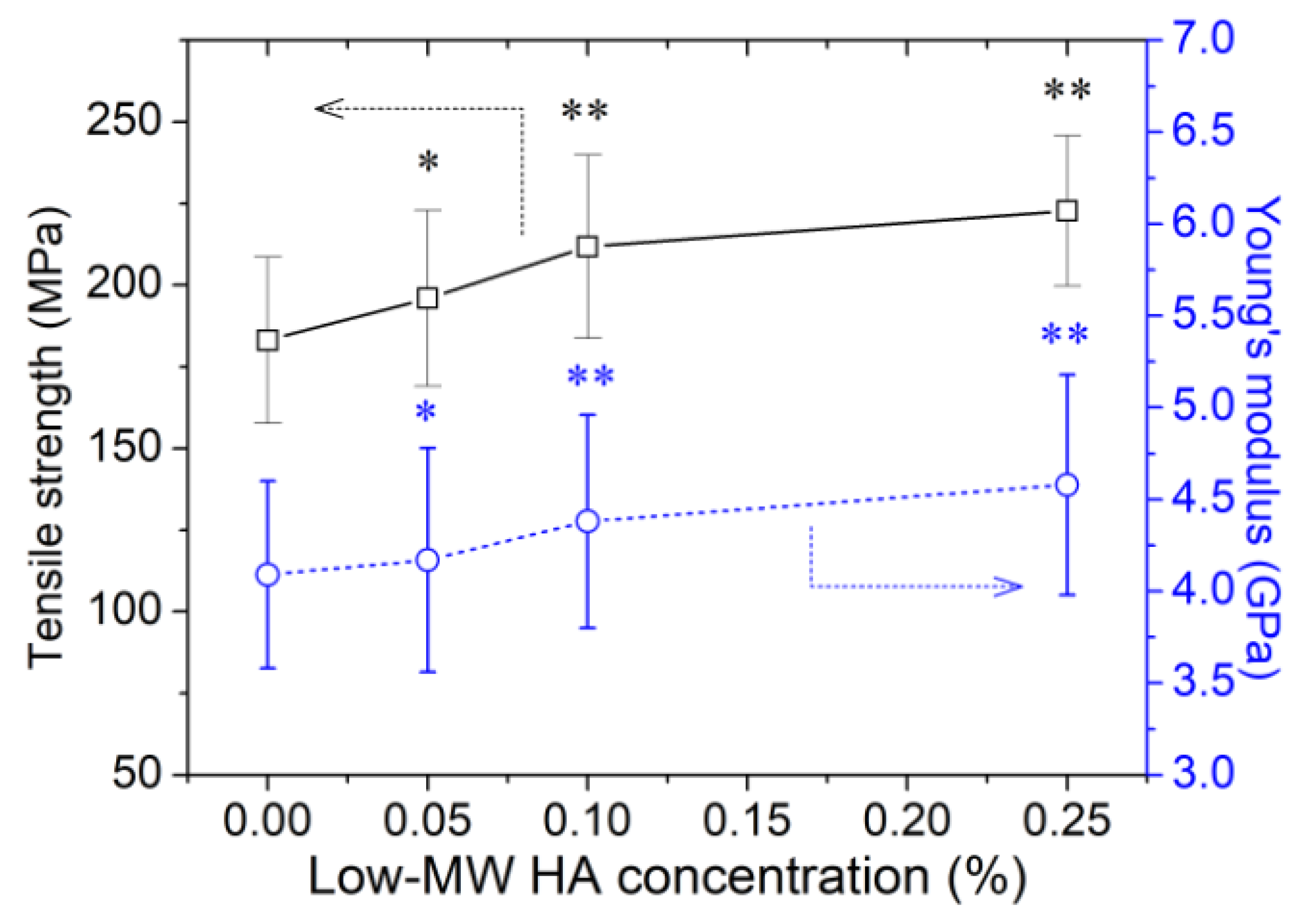

2.1. Effect of HA Treatments on Mechanical Properties of Hair

2.2. Penetration of Labelled HA into Hair Fibers

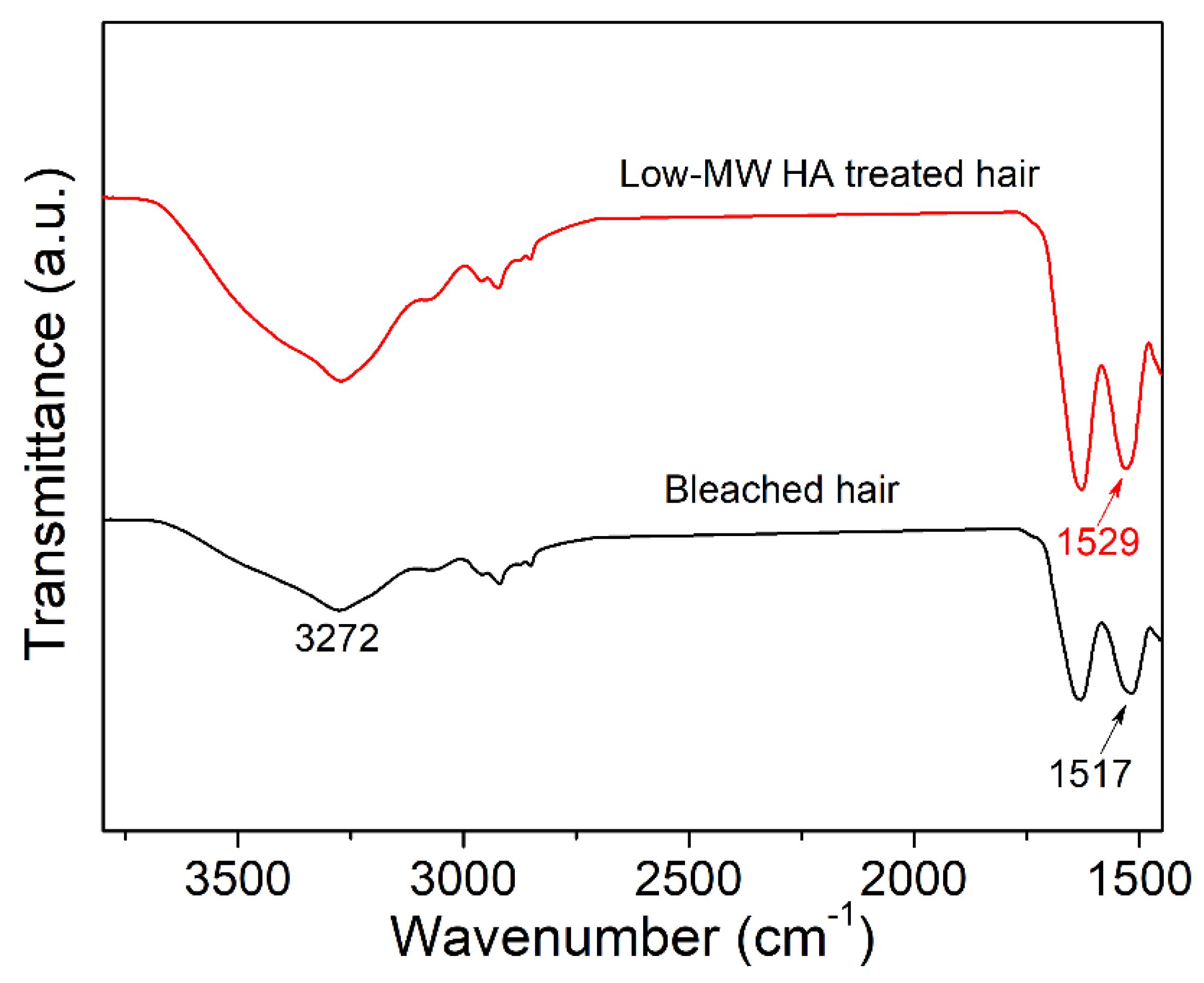

2.3. FT-IR Characterization of the Low-MW HA-Treated Hair

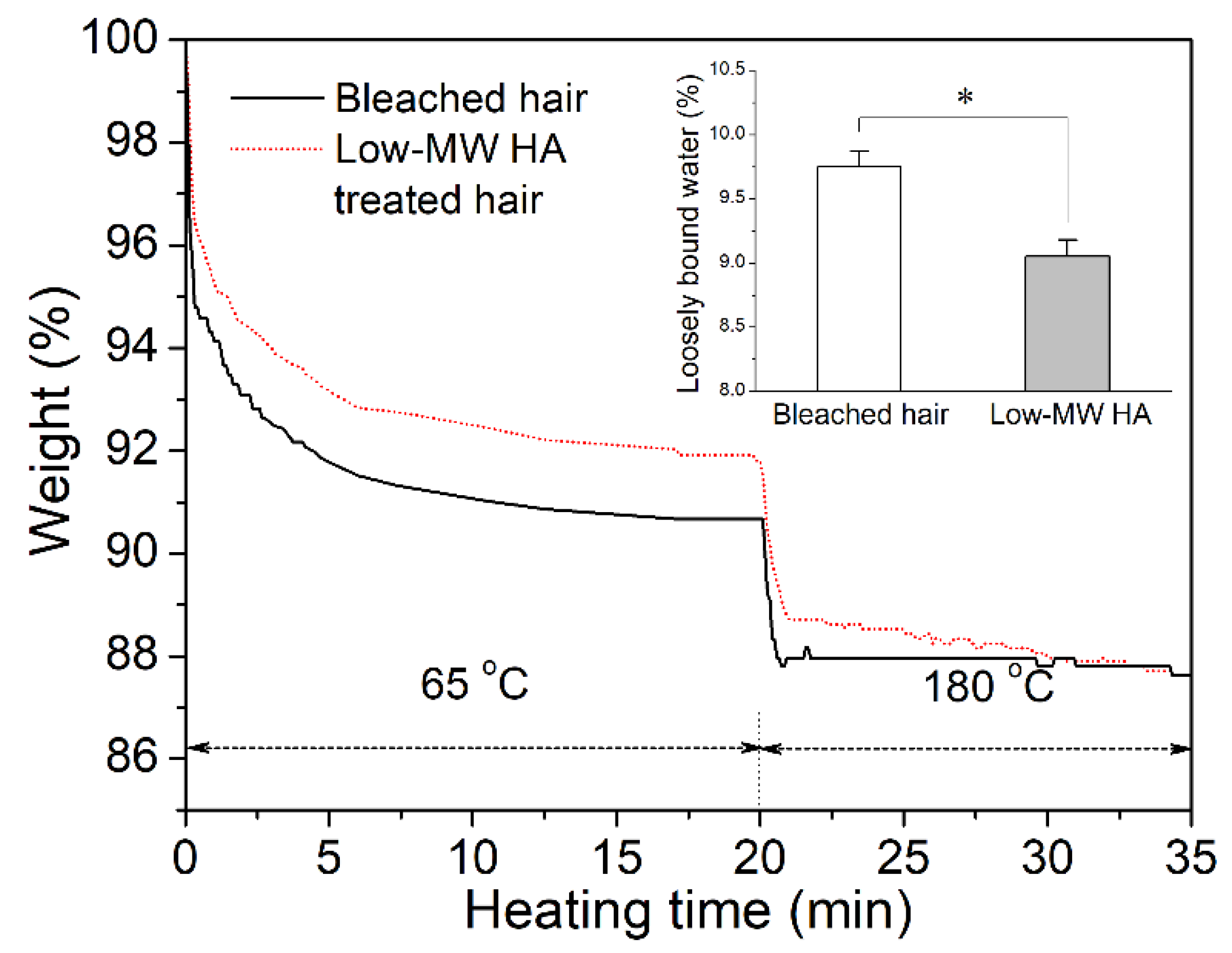

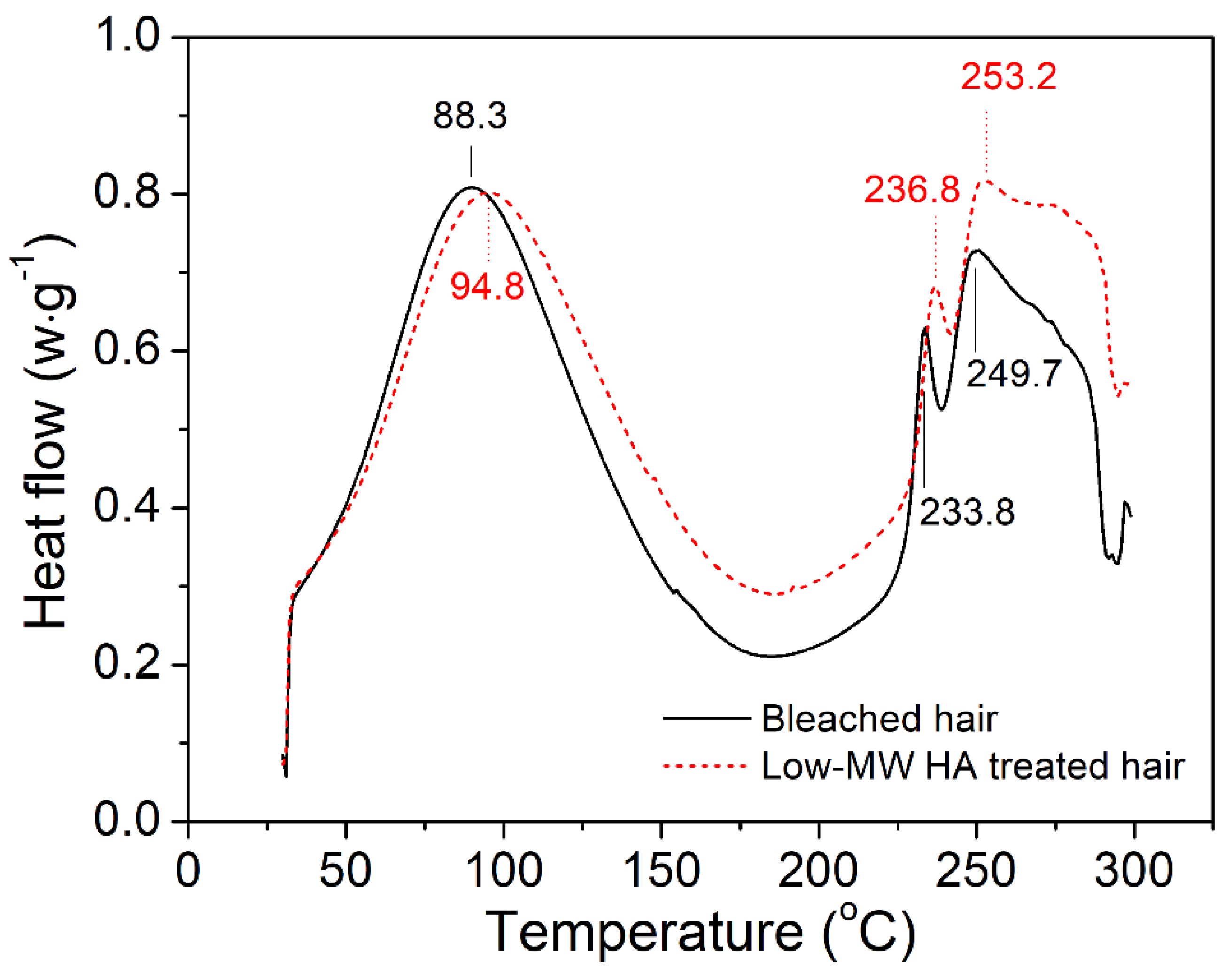

2.4. Effects of HA Treatments on Thermal Properties of Hair

3. Materials and Methods

3.1. Materials

3.2. Hair Treatment

3.3. Hair Tensile Property Tests

3.4. Fluorescent Labeling of HA and Fluorescence Microscopy

3.5. Characterization of Hair

4. Discussion

5. Conclusions

- (1)

- Treating damaged hair with HA could significantly improve the mechanical strength, or more specifically, the elastic modulus of hair.

- (2)

- Only low MW-HA showed mechanical property-restoring effects on hair, while the effect of HA with high molecular weight was negligible due to its poor penetrating capability.

- (3)

- HA treatment led to stronger water bonding inside the hair owing to its high water-binding capacity, therefore promoting the formation of hydrogen bond networks within keratins, and thereby leading to the increased elastic modulus of hair.

- (4)

- The possible formation of intermolecular H-bonds between HA and keratin might also contribute to the improved tensile properties of HA-treated hair.

Author Contributions

Funding

Conflicts of Interest

References

- Jelen, K.; Skřontová, M.; Šimkova, L.; Zeman, J.; Tlapáková, E.; Fanta, O. Changes in the mechanical parameters of hair in a group of women in reproductive age. Neuroendocrinol. Lett. 2014, 35, 481–489. [Google Scholar] [PubMed]

- Jeong, M.S.; Lee, C.M.; Jeong, W.J.; Kim, S.J.; Lee, K.Y. Significant damage of the skin and hair following hair bleaching. J. Dermatol. 2010, 37, 882–887. [Google Scholar] [CrossRef] [PubMed]

- Fernández, E.; Martínez-Teipel, B.; Armengol, R.; Barba, C.; Coderch, L. Efficacy of antioxidants in human hair. J. Photochem. Photobiol. B Biol. 2012, 117, 146–156. [Google Scholar] [CrossRef] [PubMed]

- Sayahi, E.; Harizi, T.; Msahli, S.; Sakli, F. Physical and mechanical properties of Tunisian women hair. Int. J. Cosmet. Sci. 2016, 38, 470–475. [Google Scholar] [CrossRef] [PubMed]

- Tinoco, A.; Gonçalves, J.; Silva, C.; Loureiro, A.; Gomes, A.C.; Cavaco-Paulo, A.; Ribeiro, A. Keratin-based particles for protection and restoration of hair properties. Int. J. Cosmet. Sci. 2018, 40, 408–419. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, M.M.; Lima, C.F.; Loureiro, A.; Gomes, A.C.; Cavaco-Paulo, A. Keratin-based peptide: Biological evaluation and strengthening properties on relaxed hair. Int. J. Cosmet. Sci. 2012, 34, 338–346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, K.; Xu, H.; Xie, K.; Yang, Y. Effects of chemical structures of polycarboxylic acids on molecular and performance manipulation of hair keratin. Rsc Adv. 2016, 6, 58594–58603. [Google Scholar] [CrossRef]

- Kuzuhara, A.; Fujiwara, N.; Hori, T. Analysis of internal structure changes in black human hair keratin fibers with aging using Raman spectroscopy. Biopolym. Orig. Res. Biomol. 2007, 87, 134–140. [Google Scholar] [CrossRef]

- Antunes, E.; Cruz, C.F.; Azoia, N.G.; Cavaco-Paulo, A. Insights on the mechanical behavior of keratin fibrils. Int. J. Biol. Macromol. 2016, 89, 477–483. [Google Scholar] [CrossRef] [Green Version]

- Wortmann, F.J.; Quadflieg, J.M.; Wortmann, G. Comparing hair tensile testing in the wet and the dry state: Possibilities and limitations for detecting changes of hair properties due to chemical and physical treatments. Int. J. Cosmet. Sci. 2022, 44, 421–430. [Google Scholar] [CrossRef]

- Malinauskyte, E.; Shrestha, R.; Cornwell, P.A.; Gourion-Arsiquaud, S.; Hindley, M. Penetration of different molecular weight hydrolysed keratins into hair fibres and their effects on the physical properties of textured hair. Int. J. Cosmet. Sci. 2021, 43, 26–37. [Google Scholar] [CrossRef] [PubMed]

- Mousa, A.M.; El-Mahalaway, A.M.; El-Desoky, R.E. The protective effects of sodium hyaluronate on corneal injuries induced by chlorinated water in adult male rabbits: A histological and immunohistochemical study. Egypt. J. Histol. 2018, 41, 140–149. [Google Scholar] [CrossRef]

- Lee, J.H.; Ahn, H.S.; Kim, E.K. Efficacy of sodium hyaluronate and carboxymethylcellulose in treating mild to moderate dry eye disease. Cornea 2011, 30, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Breakspear, S.; Noecker, B.; Popescu, C. Relevance and evaluation of hydrogen and disulfide bond contribution to the mechanics of hard alpha-keratin fibres. J. Phys. Chem. B 2019, 123, 4505–4511. [Google Scholar] [CrossRef] [PubMed]

- van den Elzen, H.; Schelke, L.; Velthuis, P. Temporary hair loss after injection of hyaluronic acid filler. J. Cosmet. Dermatol. 2022, 21, 625–626. [Google Scholar] [CrossRef]

- Kim, M.J.; Seong, K.Y.; Jeong, J.S.; Kim, S.Y.; Lee, S.; Yang, S.Y.; An, B.S. Minoxidil-loaded hyaluronic acid dissolving microneedles to alleviate hair loss in an alopecia animal model. Acta Biomater. 2022, 143, 189–202. [Google Scholar] [CrossRef]

- Zerbinati, N.; Sommatis, S.; Maccario, C.; Capillo, M.C.; Di Francesco, S.; Rauso, R.; Protasoni, M.; D’Este, E.; Gasperina, D.D.; Mocchi, R. In vitro hair growth promoting effect of a noncrosslinked hyaluronic acid in human dermal papilla cells. BioMed Res. Int. 2021, 2021, 5598110. [Google Scholar] [CrossRef]

- Wei, G.; Bhushan, B. Nanotribological and nanomechanical characterization of human hair using a nanoscratch technique. Ultramicroscopy 2006, 106, 742–754. [Google Scholar] [CrossRef]

- Nikiforidis, G.; Balas, C.; Tsambaos, D. Mechanical parameters of human hair: Possible application in the diagnosis and follow-up of hair disorders. Clin. Phys. Physiol. Meas. 1992, 13, 281–290. [Google Scholar] [CrossRef]

- Rebenfeld, L.; Weigmann, H.D.; Dansizer, C. Temperature dependence of the mechanical properties of human hair in relation to structure. J. Soc. Cosmet. Chem. 1966, 538, 525–538. [Google Scholar]

- Barba, C.; Scott, S.; Roddick-Lanzilotta, A.; Kelly, R.; Manich, A.M.; Parra, J.L.; Coderch, L. Restoring important hair properties with wool keratin proteins and peptides. Fibers Polym. 2010, 11, 1055–1061. [Google Scholar] [CrossRef]

- Barba, C.; Méndez, S.; Martí, M.; Parra, J.L.; Coderch, L. Water content of hair and nails. Thermochim. Acta 2009, 494, 136–140. [Google Scholar] [CrossRef]

- Wortmann, F.J.; Stapels, M.; Elliott, R.; Chandra, L. The effect of water on the glass transition of human hair. Biopolym. Orig. Res. Biomol. 2006, 81, 371–375. [Google Scholar] [CrossRef] [PubMed]

- Popescu, C.; Gummer, C. DSC of human hair: A tool for claim support or incorrect data analysis? Int. J. Cosmet. Sci. 2016, 38, 433–439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kure, J.M.; Pierlot, A.P.; Russell, I.M.; Shanks, R.A. The glass transition of wool: An improved determination using DSC. Text. Res. J. 1997, 67, 18–22. [Google Scholar] [CrossRef]

- Jinan, C.; Frédéric, L. Depression of the melting temperature by moisture for α-form crystallites in human hair keratin. Biopolymers 2005, 77, 38–43. [Google Scholar]

- Fernandes, M.; Cavaco-Paulo, A. Protein disulphide isomerase-mediated grafting of cysteine-containing peptides onto over-bleached hair. Biocatal. Biotransform. 2012, 30, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Mohan, N.H.; Choudhury, M.; Ammayappan, L.; Pathak, P.; Chakraborty, S.; Thomas, R.; Debnath, S.; Paul, M.; Sarma, D.K. Characterization of secondary structure of pig hair fiber using fourier-transform infrared spectroscopy. J. Nat. Fibers 2021, 19, 4223–4235. [Google Scholar] [CrossRef]

- Gourion-Arsiquaud, S.; Coret, J.; Moore, D.J. Quantitative analysis of hair surface properties using ATR-FTIR spectroscopy and high-throughput microfluorometry. J. Investig. Dermatol. 2013, 133, 1425. [Google Scholar]

- Mendes, T.R.O.; Piaceski, A.D. Evaluation of hair fiber hydration by differential scanning calorimetry, gas chromatography, and sensory analysis. J. Cosmet. Sci. 2003, 54, 527–535. [Google Scholar]

- Richena, M.; Rezende, C.A. Effect of photodamage on the outermost cuticle layer of human hair. J. Photochem. Photobiol. B-Biol. 2015, 153, 296–304. [Google Scholar] [CrossRef] [PubMed]

- Da Gama, R.M.; Balogh, T.S.; França, S.; Dias TC, S.; Bedin, V.; Baby, A.R.; do Rosário Matos, J.; Velasco, M.V.R. Thermal analysis of hair treated with oxidative hair dye under influence of conditioners agents. J. Therm. Anal. Calorim. 2011, 106, 399–405. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, W.; Wang, B.; Meyers, M.A. Structure and mechanical behavior of human hair. Mater. Sci. Eng. C 2017, 73, 152–163. [Google Scholar] [CrossRef] [PubMed]

- McKittrick, J.; Chen, P.Y.; Bodde, S.G.; Yang, W.; Novitskaya, E.E.; Meyers, M.A. The structure, functions, and mechanical properties of keratin. Jom 2012, 64, 449–468. [Google Scholar] [CrossRef]

- Morita, T.; Kitagawa, M.; Yamamoto, S.; Sogabe, A.; Imura, T.; Fukuoka, T.; Kitamoto, D. Glycolipid biosurfactants, mannosylerythritol lipids, repair the damaged hair. J. Oleo Sci. 2010, 59, 267–272. [Google Scholar] [CrossRef] [Green Version]

- Bhushan, B. Nanoscale characterization of human hair and hair conditioners. Progress in Materials Science 2008, 53, 585–710. [Google Scholar] [CrossRef]

- Aksakal, B.; Alekberov, V. The effect of temperature and water on the mechanical properties of wool fibres investigated with different experimental methods. Fibers Polym. 2009, 10, 673–680. [Google Scholar] [CrossRef]

- Essendoubi, M.; Meunier, M.; Scandolera, A.; Gobinet, C.; Manfait, M.; Lambert, C.; Auriol, D.; Reynaud, R.; Piot, O. Conformation changes in human hair keratin observed using confocal Raman spectroscopy after active ingredient application. Int. J. Cosmet. Sci. 2019, 41, 203–212. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, W.; Guo, X.; Xu, G.; Zou, S.; Wu, Y.; Hu, C.; Chang, K.; Wang, J. Improving the Mechanical Properties of Damaged Hair Using Low-Molecular Weight Hyaluronate. Molecules 2022, 27, 7701. https://doi.org/10.3390/molecules27227701

Qu W, Guo X, Xu G, Zou S, Wu Y, Hu C, Chang K, Wang J. Improving the Mechanical Properties of Damaged Hair Using Low-Molecular Weight Hyaluronate. Molecules. 2022; 27(22):7701. https://doi.org/10.3390/molecules27227701

Chicago/Turabian StyleQu, Wenjie, Xueping Guo, Guixin Xu, Songyan Zou, Yuwen Wu, Chenyu Hu, Kuan Chang, and Jing Wang. 2022. "Improving the Mechanical Properties of Damaged Hair Using Low-Molecular Weight Hyaluronate" Molecules 27, no. 22: 7701. https://doi.org/10.3390/molecules27227701

APA StyleQu, W., Guo, X., Xu, G., Zou, S., Wu, Y., Hu, C., Chang, K., & Wang, J. (2022). Improving the Mechanical Properties of Damaged Hair Using Low-Molecular Weight Hyaluronate. Molecules, 27(22), 7701. https://doi.org/10.3390/molecules27227701