Trend in Research on Characterization, Environmental Impacts and Treatment of Oily Sludge: A Systematic Review

Abstract

:1. Introduction

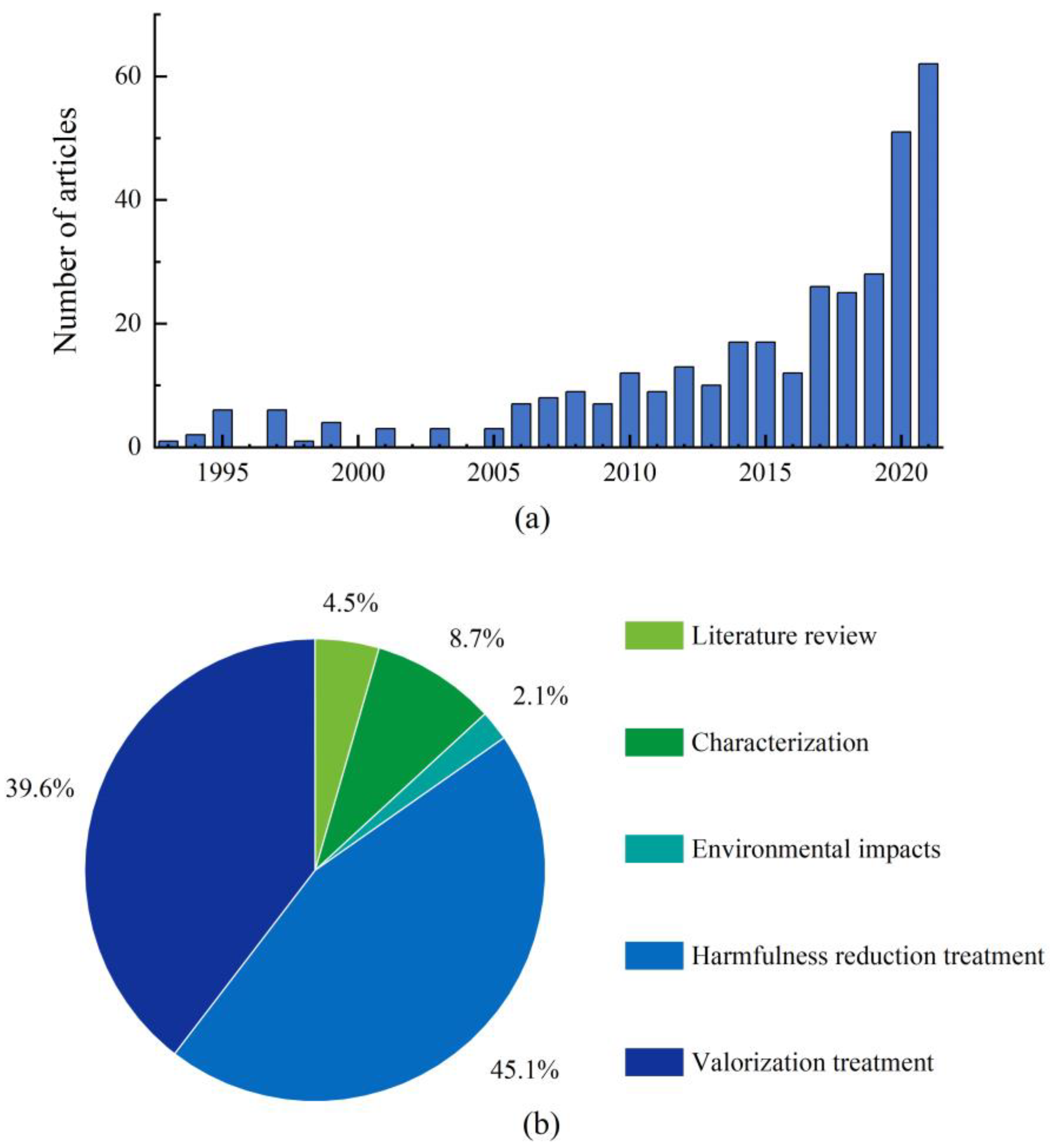

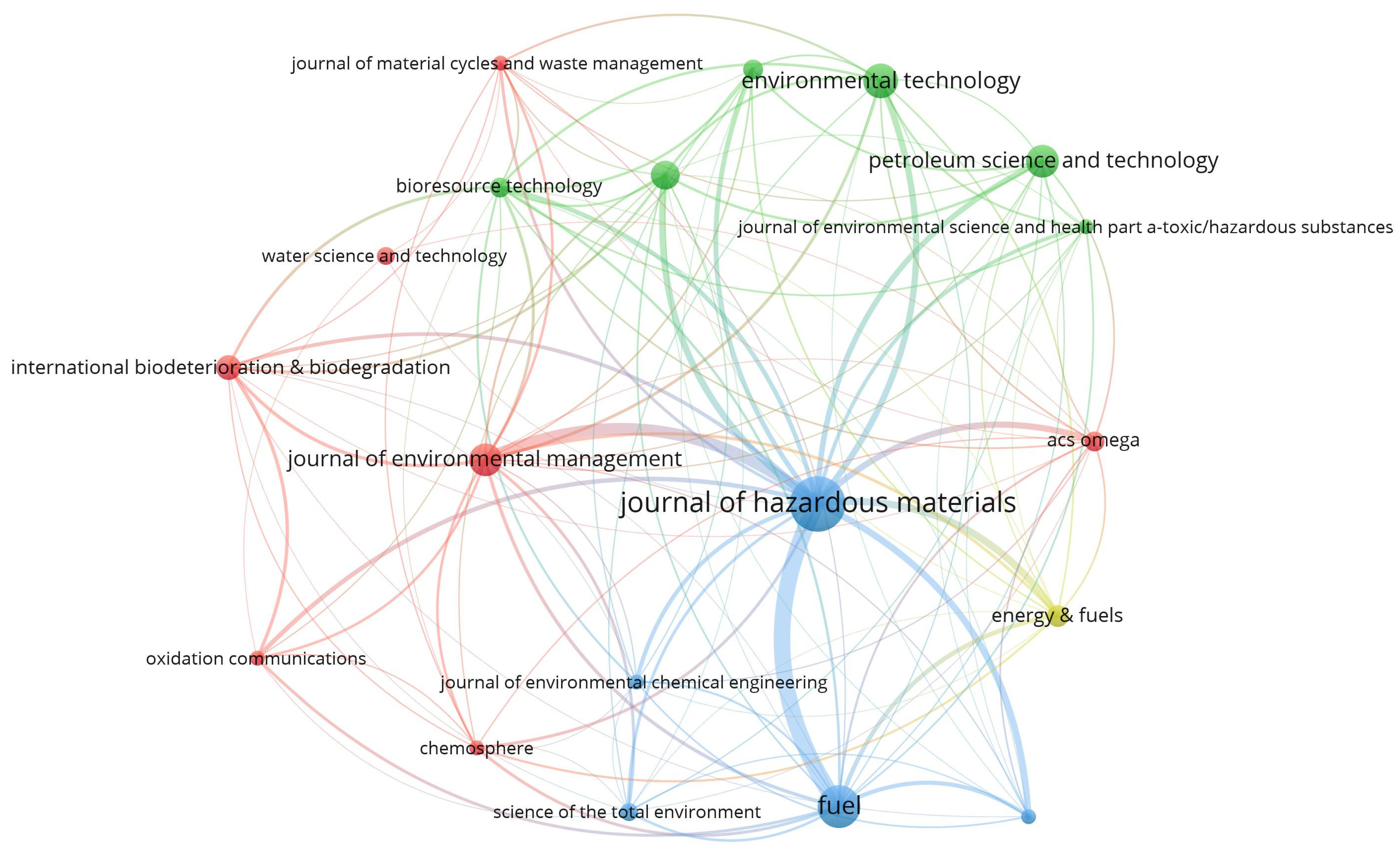

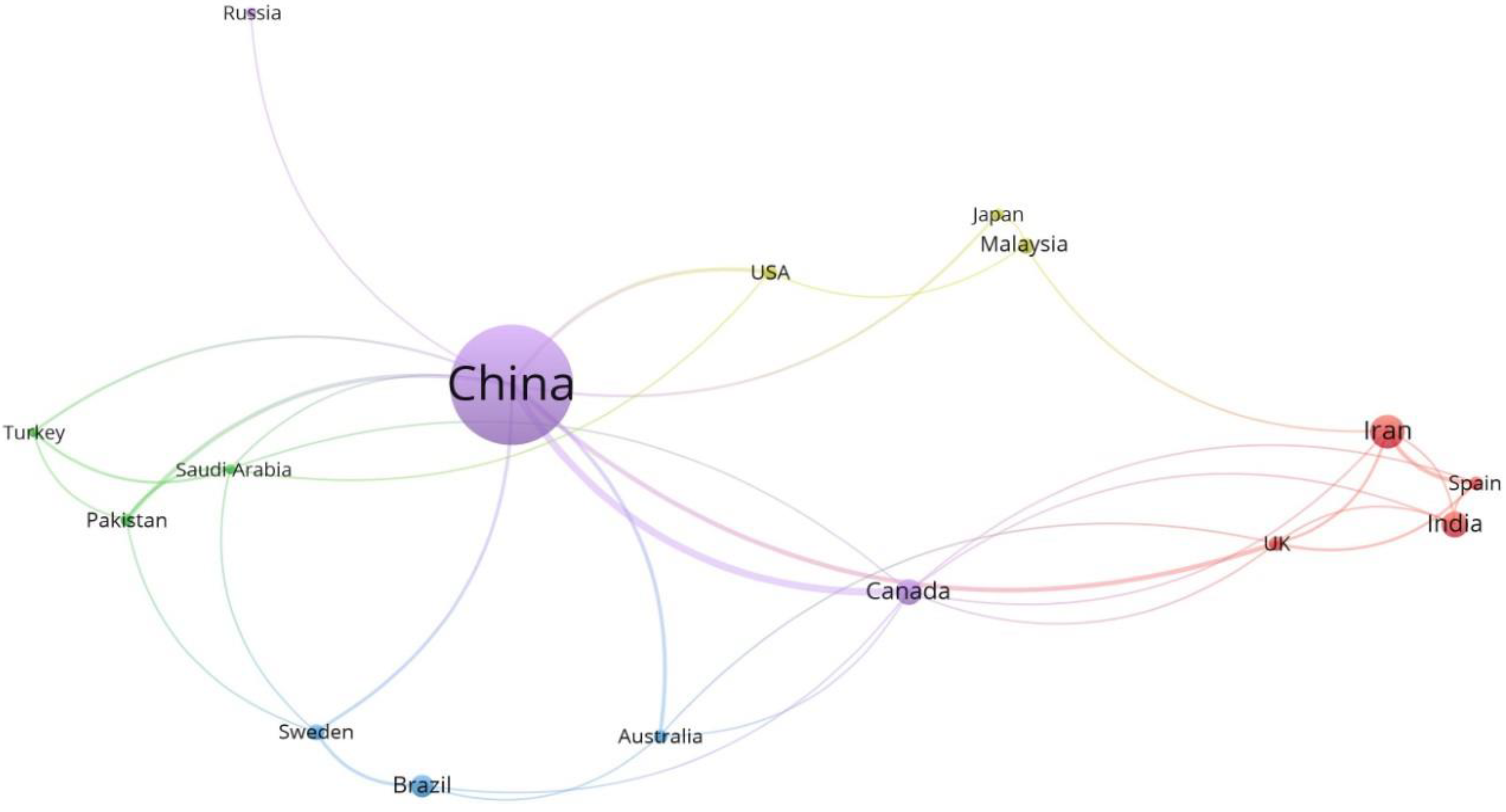

2. Overall Trend

3. Formation and Characterization of Oily Sludge

| Parameter | Range | References |

|---|---|---|

| pH | 5.5–8.0 | [20,21] |

| Zn (mg/kg) | 15.4–12,249 | [21,28,31,32,33] |

| Cu (mg/kg) | 22.6–4420 | [21,28,31,33] |

| Pb (mg/kg) | 40–850 | [21,28,31,32,33] |

| Cr (mg/kg) | 14–200 | [21,31,33] |

| Ni (mg/kg) | 15.2–2700 | [21,28,31,32,33] |

| Cd (mg/kg) | 7.6–100 | [32] |

| Hg (mg/kg) | 2.1–376.6 | [28,31,34] |

| Ra (Bq/kg) | 150–1000 | [35] |

4. Environmental Impacts of Oily Sludge

5. Harmfulness Reduction Treatment of Oily Sludge

5.1. Dewatering of Oily Sludge

5.2. Biological Treatment

5.3. Solidification

5.4. Chemical Oxidation

5.5. Incineration

5.6. Other Harmfulness Reduction Treatment-Related Articles

5.7. Comparison among the Different Treatment Approaches

6. Valorization Treatment of Oily Sludge

6.1. Ultrasonic Extraction

6.2. Solvent Extraction

6.3. Surfactant Treatment

6.4. Hydrothermal Treatment

6.5. Pyrolytic Treatment

6.6. A Comparison of Features of the Valorization Treatment Approaches

7. Conclusions and Outlook

8. Materials and Methods

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Xu, X.; Liu, W.; Tian, S.; Wang, W.; Qi, Q.; Jiang, P.; Gao, X.; Li, F.; Li, H.; Yu, H. Petroleum Hydrocarbon-Degrading Bacteria for the Remediation of Oil Pollution Under Aerobic Conditions: A Perspective Analysis. Front. Microbiol. 2018, 9, 2885. [Google Scholar] [CrossRef]

- IEA. Key World Energy Statistics 2021. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 18 September 2022).

- Reinecke, A.J.; Van Wyk, M.; Reinecke, S.A. Toxicity to Earthworms and Chemical Composition of Oil Refinery Sludge Destined for Landfarming. Soil Sediment Contam. Int. J. 2016, 25, 868–881. [Google Scholar] [CrossRef]

- ElNawawy, A.; ElBagouri, I.; Al-Daher, R.; Khalafawi, S. Plant growth and uptake of mineral elements at an oily sludge landfarming site in Kuwait. Resour. Conserv. Recycl. 1994, 11, 111–121. [Google Scholar] [CrossRef]

- Hejazi, R.F.; Husain, T.; Khan, F.I. Landfarming operation of oily sludge in arid region—Human health risk assessment. J. Hazard. Mater. 2003, 99, 287–302. [Google Scholar] [CrossRef]

- Teng, Q.; Zhang, D.; Yang, C. A review of the application of different treatment processes for oily sludge. Environ. Sci. Pollut. Res. 2021, 28, 121–132. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Li, J.; Zeng, G. Recent development in the treatment of oily sludge from petroleum industry: A review. J. Hazard. Mater. 2013, 261, 470–490. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Li, L.H.; Zhang, J.S.; Ma, C.; Wu, X. Solidification of oily sludge. Pet. Sci. Technol. 2018, 36, 273–279. [Google Scholar] [CrossRef]

- Mishra, S.; Jyot, J.; Kuhad, R.C.; Lal, B. Evaluation of Inoculum Addition To Stimulate In Situ Bioremediation of Oily-Sludge-Contaminated Soil. Appl. Environ. Microbiol. 2001, 67, 1675–1681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tahhan, R.A.; Ammari, T.G.; Goussous, S.J.; Al-Shdaifat, H.I. Enhancing the biodegradation of total petroleum hydrocarbons in oily sludge by a modified bioaugmentation strategy. Int. Biodeterior. Biodegrad. 2011, 65, 130–134. [Google Scholar] [CrossRef]

- Koolivand, A.; Naddafi, K.; Nabizadeh, R.; Saeedi, R. Optimization of combined in-vessel composting process and chemical oxidation for remediation of bottom sludge of crude oil storage tanks. Environ. Technol. 2017, 39, 2597–2603. [Google Scholar] [CrossRef]

- Lin, K.-H.; Lai, N.; Zeng, J.-Y.; Chiang, H.-L. Temperature influence on product distribution and characteristics of derived residue and oil in wet sludge pyrolysis using microwave heating. Sci. Total Environ. 2017, 584–585, 1248–1255. [Google Scholar] [CrossRef]

- Tay, J.-H.; Jeyaseelan, S. Dewatering Characteristics of Oily Sludge. Water Sci. Technol. 1993, 28, 249–256. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, Y.; Nie, C.; Yan, F.; Ouyang, X.; Gong, J. Oil Sludge Deposition in Storage Tanks: A Case Study for Russian Crude Oil in Mo-he Station. Appl. Sci. 2021, 11, 321. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Saadat-Targhi, M.; Nabati, A.; Rasekh, A.R.; Niazmand, H. Effects of the Exterior Surface Paint Color on Sludge Formation in a Crude Oil Storage Tank (Case Study: Khark Island). Energy Fuels 2010, 24, 6489–6500. [Google Scholar] [CrossRef]

- Hassanzadeh, M.; Tayebi, L.; Dezfouli, H. Investigation of factors affecting on viscosity reduction of sludge from Iranian crude oil storage tanks. Pet. Sci. 2018, 15, 634–643. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Zhao, L.; Wang, C.; Chen, S.; Wu, X.; Li, Q.; Zuo, Q. The analysis of formation of polymer-containing oily sludge produced during the wastewater treatment in offshore oilfield. Energy Sci. Eng. 2018, 6, 675–682. [Google Scholar] [CrossRef] [Green Version]

- Haq, I.U.; Ahmad, W.; Ahmad, I.; Yaseen, M. Photocatalytic oxidative degradation of hydrocarbon pollutants in refinery wastewater using TiO2 as catalyst. Water Environ. Res. 2020, 92, 2086–2094. [Google Scholar] [CrossRef]

- Al-Mebayedh, H.; Niu, A.; Lin, C. Petroleum Hydrocarbon Composition of Oily Sludge and Contaminated Soils in a Decommissioned Oilfield Waste Pit under Desert Conditions. Appl. Sci. 2022, 12, 1355. [Google Scholar] [CrossRef]

- Jerez, S.; Ventura, M.; Molina, R.; Pariente, M.I.; Martínez, F.; Melero, J.A. Comprehensive characterization of an oily sludge from a petrol refinery: A step forward for its valorization within the circular economy strategy. J. Environ. Manag. 2021, 285, 112124. [Google Scholar] [CrossRef]

- Aguelmous, A.; El Fels, L.; Souabi, S.; Zamama, M.; Hafidi, M. The fate of total petroleum hydrocarbons during oily sludge composting: A critical review. Rev. Environ. Sci. Bio/Technol. 2019, 18, 473–493. [Google Scholar] [CrossRef]

- Asgari, A.; Nabizadeh, R.; Mahvi, A.H.; Nasseri, S.; Dehghani, M.H.; Nazmara, S.; Yaghmaeian, K. Biodegradation of total petroleum hydrocarbons from acidic sludge produced by re-refinery industries of waste oil using in-vessel composting. J. Environ. Health Sci. Eng. 2017, 15, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fazal, S.A.; Zarapkar, S.; Joshi, G. Studies on Sludge from Storage Tank of Waxy Crude Oil Part-I: Structure and Composition of Distillate Fractions. Fuel Sci. Technol. Int. 1995, 13, 881–893. [Google Scholar] [CrossRef]

- Fazal, S.; Rai, R.; Joshi, G. Characterization of sludge waxes from crude oil storage tanks handling offshore crude. Pet. Sci. Technol. 1997, 15, 755–764. [Google Scholar] [CrossRef]

- Fazal, S.A.; Zarapkar, S.S.; Joshi, G.C. Studies on sludge from waxy crude oil storage tank. II. Solvent fractionation. Fuel Sci. Technol. Int. 2007, 13, 1239–1249. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Pan, Y.; Chen, Y. Analysis of oil content in drying petroleum sludge of tank bottom. Int. J. Hydrogen Energy 2017, 42, 18681–18684. [Google Scholar] [CrossRef]

- Cho, Y.; Abed, H.N.; Kim, S. Molecular Level Investigation of Oil Sludge at the Bottom of Oil Tank in Ratawi Oil Field by Atmospheric Pressure Photo Ionization Ultrahigh-resolution Mass Spectrometry. Bull. Korean Chem. Soc. 2020, 41, 450–453. [Google Scholar] [CrossRef]

- Kriipsalu, M.; Marques, M.; Maastik, A. Characterization of oily sludge from a wastewater treatment plant flocculation-flotation unit in a petroleum refinery and its treatment implications. J. Mater. Cycles Waste Manag. 2008, 10, 79–86. [Google Scholar] [CrossRef]

- Da Silva Scharf, J.; Moro, T.T.; Luvizon, F.; Santos de Oliveira, F.J.; de Andrade Maranhão, T.; Frescura Bascuñan, V.L.A.; Chaves, E.S. Eco-friendly ultrasound-assisted extraction method for determination of metals in oily sludges using inductively coupled plasma-mass spectrometry. Int. J. Environ. Anal. Chem. 2021, 1–15. [Google Scholar] [CrossRef]

- Wang, T.; Jiao, L.; Yan, C.; He, Y.; Li, M.; Zhang, T.; Li, H. Simultaneous quantitative analysis of four metal elements in oily sludge by laser induced breakdown spectroscopy coupled with wavelet transform-random forest (WT-RF). Chemom. Intell. Lab. Syst. 2019, 194, 103854. [Google Scholar] [CrossRef]

- Al-Futaisi, A.; Jamrah, A.; Yaghi, B.; Taha, R. Assessment of alternative management techniques of tank bottom petroleum sludge in Oman. J. Hazard. Mater. 2007, 141, 557–564. [Google Scholar] [CrossRef]

- Heidarzadeh, N.; Gitipour, S.; Abdoli, M.A. Characterization of oily sludge from a Tehran oil refinery. Waste Manag. Res. J. Sustain. Circ. Econ. 2009, 28, 921–927. [Google Scholar] [CrossRef] [PubMed]

- American Petroleum Institute. API Environmental Guidance Document: Onshore Solid Waste Management in Exploration and Production Operations, 1st ed.; API: Washington, DC, USA, 1989; pp. 1–64. [Google Scholar]

- Camera, A.S.; Maranhão, T.A.; Oliveira, F.J.S.; Silva, J.S.A.; Frescura, V.L.A. Total Mercury Determination in Petroleum Green Coke and Oily Sludge Samples by Cold Vapor Atomic Fluorescence Spectrometry. J. Braz. Chem. Soc. 2015, 26, 2116–2124. [Google Scholar] [CrossRef]

- Salih, F.M.; Pillay, A.E.; Jayasekara, K. Levels of radium in oily sludge. Int. J. Environ. Anal. Chem. 2005, 85, 141–147. [Google Scholar] [CrossRef]

- Karamalidis, A.K.; Voudrias, E.A. Anion Leaching from Refinery Oily Sludge and Ash from Incineration of Oily Sludge Stabilized/Solidified with Cement. Part I. Experimental Results. Environ. Sci. Technol. 2008, 42, 6116–6123. [Google Scholar] [CrossRef] [PubMed]

- Quan, C.; Zhang, G.; Gao, N.; Su, S.; Artioli, N.; Feng, D. Behavior Study of Migration and Transformation of Heavy Metals during Oily Sludge Pyrolysis. Energy Fuels 2022, 36, 8311–8322. [Google Scholar] [CrossRef]

- Liu, W.-J.; Shao, Z.-G.; Xu, Y. Emission characteristics of nitrogen and sulfur containing pollutants during the pyrolysis of oily sludge with and without catalysis. J. Hazard. Mater. 2020, 401, 123820. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Sun, Z.; Ma, K.; Du, L.; Yuan, R. Evolution of S/N containing compounds in pyrolysis of highly oily petroleum sludge. Fuel 2022, 318, 123687. [Google Scholar] [CrossRef]

- Wang, S.-J.; Yan, Z.-G.; Guo, G.-L.; Lu, G.-L.; Wang, Q.-H.; Li, F.-S. Ecotoxicity assessment of aged petroleum sludge using a suite of effects-based end points in earthworm Eisenia fetida. Environ. Monit. Assess. 2009, 169, 417–428. [Google Scholar] [CrossRef]

- Li, M.; Fu, H.; Du, Y.; Huang, X.; Zhang, T.; Tang, H.; Li, H. Laser induced breakdown spectroscopy combined with hybrid variable selection for the prediction of the environmental risk Nemerow index of heavy metals in oily sludge. J. Anal. At. Spectrom. 2022, 37, 1099–1108. [Google Scholar] [CrossRef]

- Gao, N.; Li, J.; Quan, C.; Tan, H. Product property and environmental risk assessment of heavy metals during pyrolysis of oily sludge with fly ash additive. Fuel 2020, 266, 117090. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, L.; Gong, Z.; Zhang, H.; Wu, J. Study on the ecological risk of heavy metals during oily sludge incineration with CaO additive. J. Environ. Sci. Health Part A 2021, 56, 797–803. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xu, Y.; Zhao, Z.; Zhang, D.; Lin, X.; Ma, B.; Zhang, H. Analysis of Pyrolysis Characteristics of Oily Sludge in Different Regions and Environmental Risk Assessment of Heavy Metals in Pyrolysis Residue. ACS Omega 2022, 7, 26265–26274. [Google Scholar] [CrossRef] [PubMed]

- da Silva, L.J.; Alves, F.C.; de França, F.P. A review of the technological solutions for the treatment of oily sludges from petroleum refineries. Waste Manag. Res. J. Sustain. Circ. Econ. 2012, 30, 1016–1030. [Google Scholar] [CrossRef]

- Allamin, I.A.; Halmi, M.I.E.; Yasid, N.A.; Ahmad, S.A.; Abdullah, S.R.S.; Shukor, Y. Rhizodegradation of Petroleum Oily Sludge-contaminated Soil Using Cajanus cajan Increases the Diversity of Soil Microbial Community. Sci. Rep. 2020, 10, 4094. [Google Scholar] [CrossRef] [Green Version]

- Shahzad, A.; Siddiqui, S.; Bano, A.; Sattar, S.; Hashmi, M.Z.; Qin, M.; Shakoor, A. Hydrocarbon degradation in oily sludge by bacterial consortium assisted with alfalfa (Medicago sativa L.) and maize (Zea mays L.). Arab. J. Geosci. 2020, 13, 879. [Google Scholar] [CrossRef]

- Jing, G.; Luan, M.; Chen, T. Prospects for development of oily sludge treatment. Chem. Technol. Fuels Oils 2011, 47, 312–326. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, J.; Dong, P.; Zhang, L.; Yue, M.; Xie, J.; Guo, X.; Ren, A. Application of hydrothermal method in dewatering of oily sludge from waste oil-based drilling fluid. Energy Chem. Ind. 2021, 42, 47–50. [Google Scholar]

- Deng, S.; Wang, X.; Tan, H.; Mikulčić, H.; Li, Z.; Cao, R.; Wang, Z.; Vujanović, M. Experimental and modeling study of the long cylindrical oily sludge drying process. Appl. Therm. Eng. 2015, 91, 354–362. [Google Scholar] [CrossRef]

- Gao, N.; Duan, Y.; Li, Z.; Quan, C.; Yoshikawa, K. Hydrothermal treatment combined with in-situ mechanical compression for floated oily sludge dewatering. J. Hazard. Mater. 2020, 402, 124173. [Google Scholar] [CrossRef]

- Long, X.; Zhang, G.; Han, L.; Meng, Q. Dewatering of floated oily sludge by treatment with rhamnolipid. Water Res. 2013, 47, 4303–4311. [Google Scholar] [CrossRef]

- Lv, X.; Song, Z.; Yu, J.; Su, Y.; Zhao, X.; Sun, J.; Mao, Y.; Wang, W. Study on the demulsification of refinery oily sludge enhanced by microwave irradiation. Fuel 2020, 279, 118417. [Google Scholar] [CrossRef]

- Yang, L.; Nakhla, G.; Bassi, A. Electro-kinetic dewatering of oily sludges. J. Hazard. Mater. 2005, 125, 130–140. [Google Scholar] [CrossRef] [PubMed]

- Hwa, T.J.; Jeyaseelan, S. Comparison of lime and alum as oily sludge conditioners. Water Sci. Technol. 1997, 36, 117–124. [Google Scholar] [CrossRef]

- Guo, S.; Li, G.; Qu, J.; Liu, X. Improvement of acidification on dewaterability of oily sludge from flotation. Chem. Eng. J. 2011, 168, 746–751. [Google Scholar] [CrossRef]

- Hwa, T.J.; Jeyaseelan, S. Conditioning of oily sludges with municipal solid wastes incinerator fly ash. Water Sci. Technol. 1997, 35, 231–238. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, W.; Huang, R. Study of oily sludge treatment by centrifugation. Desalin. Water Treat. 2017, 68, 99–106. [Google Scholar] [CrossRef]

- Mao, F.; Han, X.; Huang, Q.; Yan, J.; Chi, Y. Effect of frequency on ultrasound-assisted centrifugal dewatering of petroleum sludge. Dry. Technol. 2016, 34, 1948–1956. [Google Scholar] [CrossRef]

- Jean, D.S.; Chu, C.P.; Lee, D.J. Freeze/Thaw Treatment of Oily Sludge From Petroleum Refinery Plant. Sep. Sci. Technol. 2001, 36, 2733–2746. [Google Scholar] [CrossRef]

- Jasmine, J.; Mukherji, S. Evaluation of bioaugmentation and biostimulation effects on the treatment of refinery oily sludge using 2n full factorial design. Environ. Sci. Process. Impacts 2014, 16, 1889–1896. [Google Scholar] [CrossRef] [Green Version]

- Mishra, S.; Jyot, J.; Kuhad, R.C.; Lal, B. In Situ Bioremediation Potential of an Oily Sludge-Degrading Bacterial Consortium. Curr. Microbiol. 2001, 43, 328–335. [Google Scholar] [CrossRef] [PubMed]

- Mansur, A.A.; Adetutu, E.M.; Kadali, K.K.; Morrison, P.D.; Nurulita, Y.; Ball, A. Assessing the hydrocarbon degrading potential of indigenous bacteria isolated from crude oil tank bottom sludge and hydrocarbon-contaminated soil of Azzawiya oil refinery, Libya. Environ. Sci. Pollut. Res. 2014, 21, 10725–10735. [Google Scholar] [CrossRef]

- Adetutu, E.M.; Bird, C.; Kadali, K.K.; Bueti, A.; Shahsavari, E.; Taha, M.; Patil, S.; Sheppard, P.J.; Makadia, T.; Simons, K.L.; et al. Exploiting the intrinsic hydrocarbon-degrading microbial capacities in oil tank bottom sludge and waste soil for sludge bioremediation. Int. J. Environ. Sci. Technol. 2014, 12, 1427–1436. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, X.; Bu, K.; Wen, F.; Zhang, D.; Zhang, C. Fungal proliferation and hydrocarbon removal during biostimulation of oily sludge with high total petroleum hydrocarbon. Environ. Sci. Pollut. Res. 2019, 26, 33192–33201. [Google Scholar] [CrossRef]

- Kriipsalu, M.; Nammari, D. Monitoring of biopile composting of oily sludge. Waste Manag. Res. J. Sustain. Circ. Econ. 2010, 28, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Koolivand, A.; Naddafi, K.; Nabizadeh, R.; Nasseri, S.; Jafari, A.J.; Yunesian, M.; Yaghmaeian, K.; Nazmara, S. Biodegradation of petroleum hydrocarbons of bottom sludge from crude oil storage tanks by in-vessel composting. Toxicol. Environ. Chem. 2013, 95, 101–109. [Google Scholar] [CrossRef]

- Mansur, A.A.; Taha, M.; Shahsavari, E.; Haleyur, N.; Adetutu, E.M.; Ball, A.S. An effective soil slurry bioremediation protocol for the treatment of Libyan soil contaminated with crude oil tank bottom sludge. Int. Biodeterior. Biodegrad. 2016, 115, 179–185. [Google Scholar] [CrossRef]

- Zarei, F.; Fazaelipoor, M.H. Effect of surfactants on the bioremediation of oily sludge from gasoil storage facilities. Int. J. Environ. Sci. Technol. 2022, 19, 5473–5480. [Google Scholar] [CrossRef]

- Pemmaraju, S.C.; Sharma, D.; Singh, N.; Panwar, R.; Cameotra, S.S.; Pruthi, V. Production of Microbial Surfactants from Oily Sludge-Contaminated Soil by Bacillus subtilis DSVP23. Appl. Biochem. Biotechnol. 2012, 167, 1119–1131. [Google Scholar] [CrossRef]

- Suganthi, S.H.; Murshid, S.; Sriram, S.; Ramani, K. Enhanced biodegradation of hydrocarbons in petroleum tank bottom oil sludge and characterization of biocatalysts and biosurfactants. J. Environ. Manag. 2018, 220, 87–95. [Google Scholar] [CrossRef]

- Koolivand, A.; Naddafi, K.; Nabizadeh, R.; Jafari, A.J.; Nasseri, S.; Yunesian, M.; Yaghmaeian, K.; Alimohammadi, M. Application of Hydrogen Peroxide and Fenton as Pre- and Post-treatment Steps for Composting of Bottom Sludge from Crude Oil Storage Tanks. Pet. Sci. Technol. 2014, 32, 1562–1568. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, Z.; Hu, Y.; Liu, Y.; Xu, J. Mechanical Properties of Cement-Solidified Oily Sludge. Environ. Eng. Sci. 2017, 34, 607–615. [Google Scholar] [CrossRef]

- Leonard, S.A.; Roy, A.D.; Stegemann, J.A. Stabilization/solidification of petroleum drill cuttings: Thermal and microstructural studies of binder hydration products. Environ. Eng. Sci. 2010, 27, 889–903. [Google Scholar] [CrossRef]

- Xiao, W.; Yao, X.; Zhang, F. Recycling of oily sludge as a roadbed material utilizing phosphogypsum-based cementitious materials. Adv. Civ. Eng. 2019, 2019, 1687–8086. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, K.; Wu, X.; Ling, Q.; Hu, J.; Li, X.; Liu, H. Effect of Oily Sludge Treatment with Molten Blast Furnace Slag on the Mineral Phase Reconstruction of Water-Quenched Slag Properties. Materials 2021, 14, 7285. [Google Scholar] [CrossRef] [PubMed]

- Farzadkia, M.; Dehghani, M.; Moafian, M. The effects of Fenton process on the removal of petroleum hydrocarbons from oily sludge in Shiraz oil refinery, Iran. J. Environ. Health Sci. Eng. 2014, 12, 31. [Google Scholar] [CrossRef] [Green Version]

- Qiu, S.; Xia, M.; Li, Z. Ultrasonic irradiation as pretreatment for the reduction of excess sludge by Fenton-acclimation treatment. Water Sci. Technol. 2013, 67, 1701–1707. [Google Scholar] [CrossRef]

- He, D.-Q.; Chen, J.-Y.; Bao, B.; Pan, X.-L.; Li, J.; Qian, C.; Yu, H.-Q. Optimizing sludge dewatering with a combined conditioner of Fenton’s reagent and cationic surfactant. J. Environ. Sci. 2020, 88, 21–30. [Google Scholar] [CrossRef] [PubMed]

- Mehrizi, E.A.; Kermani, M.; Farzadkia, M.; Esarfili, A.; Ghorbanian, M. Study of improvement of bioremediation performance for the degradation of petroleum hydrocarbons in oily sludge by a chemical pretreatment strategy. J. Mater. Cycles Waste Manag. 2019, 21, 1052–1062. [Google Scholar] [CrossRef]

- Sun, Z.; Xia, F.; Lou, Z.; Chen, X.; Zhu, N.; Yuan, H.; Shen, Y. Innovative process for total petroleum hydrocarbons reduction on oil refinery sludge through microbubble ozonation. J. Clean. Prod. 2020, 256, 120337. [Google Scholar] [CrossRef]

- YAN, X.; Qiao, W.; Li, P.; Ye, J.; Zhou, Q. Reduction of oily sludge by hydrothermal method. Environ. Prot. Chem. Ind. 2014, 34, 340–343. [Google Scholar]

- Chen, Z.; Zheng, Z.; He, C.; Liu, J.; Zhang, R.; Chen, Q. Oily sludge treatment in subcritical and supercritical water: A review. J. Hazard. Mater. 2022, 433, 128761. [Google Scholar] [CrossRef] [PubMed]

- Jing, G.L.; Luan, M.M.; Han, C.J.; Chen, T.T. Pretreatment of oily sludge by wet air oxidation. J. Energy Inst. 2012, 85, 240–242. [Google Scholar] [CrossRef]

- Zhao, Y.; Yan, X.; Zhou, J.; Li, R.; Yang, S.; Wang, B.; Deng, R. Treatment of oily sludge by two-stage wet air oxidation. J. Energy Inst. 2019, 92, 1451–1457. [Google Scholar] [CrossRef]

- Shi, P.; Wu, Y.; Li, F.; Bai, C. Research on thermal hydrolysis oxidation process of oily sludge. J. Dalian Univ. 2015, 36, 61–65. [Google Scholar]

- Cui, B.; Cui, F.; Jing, G.; Xu, S.; Huo, W.; Liu, S. Oxidation of oily sludge in supercritical water. J. Hazard. Mater. 2009, 165, 511–517. [Google Scholar] [CrossRef]

- Xu, X.; Lu, J. Treatment of oily sludge by supercritical water oxidation process. Environ. Prot. Chem. Ind. 2016, 36, 681–685. [Google Scholar]

- Chen, Z.; Zheng, Z.; Li, D.; Chen, H.; Xu, Y. Continuous supercritical water oxidation treatment of oil-based drill cuttings using municipal sewage sludge as diluent. J. Hazard. Mater. 2020, 384, 121225. [Google Scholar] [CrossRef]

- Jing, G.; Luan, M.; Chen, T. Wet air oxidation of oily sludge using Ni2+ catalyst. Environ. Prog. Sustain. Energy 2013, 32, 99–102. [Google Scholar] [CrossRef]

- Yuan, X.; Guan, R.; Wu, Z.; Jiang, L.; Li, Y.; Chen, X.; Zeng, G. Effective treatment of oily scum via catalytic wet persulfate oxidation process activated by Fe2+. J. Environ. Manag. 2018, 217, 411–415. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Zhou, L.; Wang, H.; Han, X. Co-firing of oil sludge with coal–water slurry in an industrial internal circulating fluidized bed boiler. J. Hazard. Mater. 2009, 167, 817–823. [Google Scholar] [CrossRef]

- Zhou, L.; Jiang, X.; Liu, J. Characteristics of oily sludge combustion in circulating fluidized beds. J. Hazard. Mater. 2009, 170, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Liu, J.; Gao, F.; Zhou, J.; Cen, K. The slurrying properties of slurry fuels made of petroleum coke and petrochemical sludge. Fuel Process. Technol. 2012, 104, 57–66. [Google Scholar] [CrossRef]

- Deng, S.; Wang, X.; Tan, H.; Mikulčić, H.; Yang, F.; Li, Z.; Duić, N. Thermogravimetric study on the Co-combustion characteristics of oily sludge with plant biomass. Thermochim. Acta 2016, 633, 69–76. [Google Scholar] [CrossRef]

- Liu, C.; Liu, J.; Sun, G.; Xie, W.; Kuo, J.; Li, S.; Liang, J.; Chang, K.; Sun, S.; Buyukada, M.; et al. Thermogravimetric analysis of (co-)combustion of oily sludge and litchi peels: Combustion characterization, interactions and kinetics. Thermochim. Acta 2018, 667, 207–218. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Li, Z.; Zong, P.; Hou, J.; Zhang, Q.; Gou, X. Synergistic effect, kinetics, and pollutant emission characteristics of co-combustion of polymer-containing oily sludge and cornstalk using TGA and fixed-bed reactor. Renew. Energy 2022, 185, 748–758. [Google Scholar] [CrossRef]

- Zou, H.; Liu, C.; Evrendilek, F.; He, Y.; Liu, J. Evaluation of reaction mechanisms and emissions of oily sludge and coal co-combustions in O2/CO2 and O2/N2 atmospheres. Renew. Energy 2021, 171, 1327–1343. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhang, L.; Li, J.X.; Zhong, H. Disposal of Oily Sludge. Pet. Sci. Technol. 2015, 33, 1045–1052. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Shi, H.-W.; Wang, S.-Y.; Wang, Z.-M.; Hao, M.-M.; Wang, J. Theoretical study on the pressurization characteristics of disc-seal single screw pump used in high viscosity oily sludge conveying field. Pet. Sci. 2021, 19, 1361–1370. [Google Scholar] [CrossRef]

- Matsui, T.; Namihira, T.; Mitsuta, T.; Saeki, H. Removal of Oil Tank Bottom Sludge by Novel Biosurfactant, JE1058BS. J. Jpn. Pet. Inst. 2012, 55, 138–141. [Google Scholar] [CrossRef]

- Elektorowicz, M.; Habibi, S.; Chifrina, R. Effect of electrical potential on the electro-demulsification of oily sludge. J. Colloid Interface Sci. 2006, 295, 535–541. [Google Scholar] [CrossRef]

- Hu, G.; Feng, H.; He, P.; Li, J.; Hewage, K.; Sadiq, R. Comparative life-cycle assessment of traditional and emerging oily sludge treatment approaches. J. Clean. Prod. 2019, 251, 119594. [Google Scholar] [CrossRef]

- Rasiah, V.; Biederbeck, V.O. Fractal dimension of soil aggregates: Influence of bulk density, fitting procedure, and oily waste sludge incorporation. Soil Sci. 1995, 160, 250–255. [Google Scholar] [CrossRef]

- Roldan, F.; Maldonado, C.; Guevara, C.; Cubillos, A.M. Natural Attenuation of Oily Sludge Used for the Maintenance of an Unpaved Road in Arauca (Colombia). Bioremediation J. 2010, 14, 81–91. [Google Scholar] [CrossRef]

- Pinheiro, B.; Holanda, J. Obtainment of porcelain floor tiles added with petroleum oily sludge. Ceram. Int. 2013, 39, 57–63. [Google Scholar] [CrossRef]

- Hu, G.; Li, J.; Thring, R.W.; Arocena, J. Ultrasonic oil recovery and salt removal from refinery tank bottom sludge. J. Environ. Sci. Health Part A 2014, 49, 1425–1435. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Ding, R.; Wu, S.; Wu, Y.; Zhang, Y.; Yang, M. Influence of ultrasonic waves on the removal of different oil components from oily sludge. Environ. Technol. 2015, 36, 1771–1775. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Liu, L.; Fan, L.; Ge, D. Effect of ultrasonic reactor and auxiliary stirring on oil removal from oily sludge. Environ. Technol. 2017, 38, 3109–3114. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Thring, R.W.; Hu, X.; Song, X. Oil recovery from refinery oily sludge via ultrasound and freeze/thaw. J. Hazard. Mater. 2012, 203–204, 195–203. [Google Scholar] [CrossRef]

- Gao, Y.-X.; Ding, R.; Chen, X.; Gong, Z.-B.; Zhang, Y.; Yang, M. Ultrasonic washing for oily sludge treatment in pilot scale. Ultrasonics 2018, 90, 1–4. [Google Scholar] [CrossRef]

- Hu, G.; Li, J.; Huang, S.; Li, Y. Oil recovery from petroleum sludge through ultrasonic assisted solvent extraction. J. Environ. Sci. Health Part A 2016, 51, 921–929. [Google Scholar] [CrossRef]

- Hui, K.; Tang, J.; Lu, H.; Xi, B.; Qu, C.; Li, J. Status and prospect of oil recovery from oily sludge:A review. Arab. J. Chem. 2020, 13, 6523–6543. [Google Scholar] [CrossRef]

- Zubaidy, E.A.; Abouelnasr, D.M. Fuel recovery from waste oily sludge using solvent extraction. Process Saf. Environ. Prot. 2010, 88, 318–326. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, L.; Du, N.; Li, H.; Hou, W. Solid effect in solvent extraction treatment of pre-treated oily sludge. Sep. Purif. Technol. 2014, 130, 28–33. [Google Scholar] [CrossRef]

- Dai, S.; Li, X.; Zhao, J.; Lu, H. Hybrid Extraction of Oily Sludge by Tertiary Amines and Protonated Tertiary Amines. Chem. Eng. Technol. 2020, 43, 2160–2166. [Google Scholar] [CrossRef]

- Mohit, M.A.; Ghazban, F.; Omidvar, B. Optimization of influential parameters of hydrocarbon recovery from waste oily sludge by solvent extraction using solvent blend. Environ. Monit. Assess. 2020, 192, 407. [Google Scholar] [CrossRef]

- Ma, Y.; Yao, M.; Liu, L.; Qin, C.; Qin, B.; Deng, N.; Liang, C.; Yao, S. Mechanism and Characteristics of Oil Recovery from Oily Sludge by Sodium Lignosulfonate Treatment. ACS Omega 2021, 6, 25819–25827. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Song, F.; Ji, X.; Lin, S. Ionic Liquids enhanced Oil Recovery from Oily Sludge-Experiment and Mechanism. Arab. J. Chem. 2022, 15, 104210. [Google Scholar] [CrossRef]

- Al Zubaidi, I. Heavy Fuel Oil Recovery from Oil Sludge by Multiple Extraction Processes. Prog. Petrochem. Sci. 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Tian, Y.; McGill, W.B.; Whitcombe, T.W.; Li, J.-B. Ionic Liquid-Enhanced Solvent Extraction for Oil Recovery from Oily Sludge. Energy Fuels 2019, 33, 3429–3438. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, L.; Hou, W. Solid effect in chemical cleaning treatment of oily sludge. Colloids Surf. A Physicochem. Eng. Asp. 2017, 522, 38–42. [Google Scholar] [CrossRef]

- Abdel-Azim, A.-A.; Abdul-Raheim, A.-R.M.; Kamel, R.K.; Abdel-Raouf, M. Demulsifier systems applied to breakdown petroleum sludge. J. Pet. Sci. Eng. 2011, 78, 364–370. [Google Scholar] [CrossRef]

- Jing, G.; Chen, T.; Luan, M. Studying oily sludge treatment by thermo chemistry. Arab. J. Chem. 2016, 9, S457–S460. [Google Scholar] [CrossRef] [Green Version]

- Al-Doury, M.M.I. Treatment of oily sludge produced from Baiji oil refineries using surfactants. Pet. Sci. Technol. 2019, 37, 718–726. [Google Scholar] [CrossRef]

- Liu, X.; Yao, T.; Lai, R.; Xiu, J.; Huang, L.; Sun, S.; Luo, Y.; Song, Z.; Zhang, Z. Recovery of crude oil from oily sludge in an oilfield by sophorolipid. Pet. Sci. Technol. 2019, 37, 1582–1588. [Google Scholar] [CrossRef]

- Zheng, X.; Ying, Z.; Cui, J.; Wang, B.; Chen, J.; Zhang, Q. Simultaneous Dewatering and Recovering Oil from High-Viscosity Oily Sludge through the Combination Process of Demulsification, Viscosity Reduction, and Centrifugation. Energy Fuels 2017, 31, 14401–14407. [Google Scholar] [CrossRef]

- Yao, M.; Ma, Y.; Liu, L.; Qin, C.; Huang, H.; Zhang, Z.; Liang, C.; Yao, S. Efficient Separation and Recovery of Petroleum Hydrocarbon from Oily Sludge by a Combination of Adsorption and Demulsification. Int. J. Mol. Sci. 2022, 23, 7504. [Google Scholar] [CrossRef]

- Chirwa, E.M.N.; Mampholo, T.; Fayemiwo, O. Biosurfactants as demulsifying agents for oil recovery from oily sludge—Performance evaluation. Water Sci. Technol. 2013, 67, 2875–2881. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Wu, L.; Chen, M.; Tu, C.; Luo, Y.; Christie, P. Isolation, identification and characterization of Bacillus amyloliquefaciens BZ-6, a bacterial isolate for enhancing oil recovery from oily sludge. Chemosphere 2012, 87, 1105–1110. [Google Scholar] [CrossRef]

- Yan, P.; Lu, M.; Yang, Q.; Zhang, H.-L.; Zhang, Z.-Z.; Chen, R. Oil recovery from refinery oily sludge using a rhamnolipid biosurfactant-producing Pseudomonas. Bioresour. Technol. 2012, 116, 24–28. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Sun, S.; Huang, L.; Yu, L.; Liu, X.; Lai, R.; Luo, Y.; Zhang, Z.; Zhang, Z. Oil recovery from tank bottom sludge using rhamnolipids. J. Pet. Sci. Eng. 2018, 170, 14–20. [Google Scholar] [CrossRef]

- Pornsunthorntawee, O.; Arttaweeporn, N.; Paisanjit, S.; Somboonthanate, P.; Abe, M.; Rujiravanit, R.; Chavadej, S. Isolation and comparison of biosurfactants produced by Bacillus subtilis PT2 and Pseudomonas aeruginosa SP4 for microbial surfactant-enhanced oil recovery. Biochem. Eng. J. 2008, 42, 172–179. [Google Scholar] [CrossRef]

- Radfarnia, H.R.; Khulbe, C.; Little, E.C. Supercritical water treatment of oil sludge, a viable route to valorize waste oil materials. Fuel 2015, 159, 653–658. [Google Scholar] [CrossRef]

- Islam, M.N.; Jung, S.-K.; Jung, H.-Y.; Park, J.-H. The feasibility of recovering oil from contaminated soil at petroleum oil spill site using a subcritical water extraction technology. Process Saf. Environ. Prot. 2017, 111, 52–59. [Google Scholar] [CrossRef]

- Nazem, M.A.; Tavakoli, O. Bio-oil production from refinery oily sludge using hydrothermal liquefaction technology. J. Supercrit. Fluids 2017, 127, 33–40. [Google Scholar] [CrossRef]

- Khan, M.K.; Cahyadi, H.S.; Kim, S.-M.; Kim, J. Efficient oil recovery from highly stable toxic oily sludge using supercritical water. Fuel 2019, 235, 460–472. [Google Scholar] [CrossRef]

- Pauline, A.L.; Joseph, K. Hydrothermal carbonization of crude oil sludge—Characterization of hydrochar and hydrothermal liquor. Process Saf. Environ. Prot. 2021, 154, 89–96. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Zhao, T. Gasification of petrochemical sludge in supercritical water. In Proceedings of the Institution of Civil Engineers-Water Management; Thomas Telford Ltd.: London, UK, 2016; Volume 169, pp. 285–290. [Google Scholar] [CrossRef]

- Jiang, H.; Duan, Y.; Wang, Y.; Zou, S.; Zhang, L.; Li, J.; Wang, B. Supercritical water gasification of oily sludge to produce hydrogen based on uniform design method. Chem. Ind. Eng. Prog. 2020, 39, 3819–3825. [Google Scholar]

- Peng, P.; Guo, S.; Li, L.; Jin, H.; Ge, Z.; Guo, L. Supercritical water gasification mechanism of polymer-containing oily sludge. Int. J. Hydrogen Energy 2021, 46, 26834–26847. [Google Scholar] [CrossRef]

- Wang, C.; Wu, C.; Zhang, H.; Lai, J.; Luo, X.; Liang, Y.; Tian, J. Hydrothermal treatment of petrochemical sludge in subcritical and supercritical water: Oil phase degradation and syngas production. Chemosphere 2021, 278, 130392. [Google Scholar] [CrossRef]

- Chen, Z.; Tong, K.; He, C.; Xue, M.; Lyu, C.; Chen, H.; Chen, Q.; Xu, Y. High quality oil recovery from oil-based drill cuttings via catalytic upgrading in presence of near-/supercritical water and different industrial wastes. J. Clean. Prod. 2021, 321, 129061. [Google Scholar] [CrossRef]

- Dang, Z.; Zhu, X.; Wang, L.; Ji, G. Titanium dioxide catalytic hydrothermal liquefaction to treat oily sludge: As hydrogen production catalyst. Chem. Eng. J. Adv. 2021, 8, 100139. [Google Scholar] [CrossRef]

- Ávila-Chávez, M.A.; Eustaquio-Rincón, R.; Reza, J.; Trejo, A. Extraction of Hydrocarbons from Crude Oil Tank Bottom Sludges using Supercritical Ethane. Sep. Sci. Technol. 2007, 42, 2327–2345. [Google Scholar] [CrossRef]

- Qin, H.; Wu, X.; Zheng, Y.-X.; Zhang, Y.; Meng, X.; Duan, L.; Sun, C.; Chen, G. Insight into water-enhanced CO2 extraction in the treatment of oily sludge. J. CO2 Util. 2022, 57, 101868. [Google Scholar] [CrossRef]

- Li, J.; Lin, F.; Xiang, L.; Zheng, F.; Che, L.; Tian, W.; Guo, X.; Yan, B.; Song, Y.; Chen, G. Hazardous elements flow during pyrolysis of oily sludge. J. Hazard. Mater. 2020, 409, 124986. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Guo, Q.; Liu, X.; Cao, C. Low Temperature Pyrolysis Characteristics of Oil Sludge under Various Heating Conditions. Energy Fuels 2007, 21, 957–962. [Google Scholar] [CrossRef]

- Gong, Z.; Wang, Z.; Wang, Z.; Fang, P.; Meng, F. Study on pyrolysis characteristics of tank oil sludge and pyrolysis char combustion. Chem. Eng. Res. Des. 2018, 135, 30–36. [Google Scholar] [CrossRef]

- Ali, I.; Tariq, R.; Naqvi, S.R.; Khoja, A.H.; Mehran, M.T.; Naqvi, M.; Gao, N. Kinetic and thermodynamic analyses of dried oily sludge pyrolysis. J. Energy Inst. 2021, 95, 30–40. [Google Scholar] [CrossRef]

- Wan, G.; Bei, L.; Yu, J.; Xu, L.; Sun, L. Products distribution and hazardous elements migration during pyrolysis of oily sludge from the oil refining process. Chemosphere 2021, 288, 132524. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Taqvi, S.A.A.; Khoja, A.H.; Ali, I.; Mehran, M.T.; Farooq, W.; Tippayawong, N.; Juchelková, D.; Atabani, A. Valorization of Wet Oily Petrochemical Sludge via Slow Pyrolysis: Thermo-Kinetics Assessment and Artificial Neural Network Modeling. Front. Energy Res. 2022, 9, 782139. [Google Scholar] [CrossRef]

- Li, J.; Lin, F.; Li, K.; Zheng, F.; Yan, B.; Che, L.; Tian, W.; Chen, G.; Yoshikawa, K. A critical review on energy recovery and non-hazardous disposal of oily sludge from petroleum industry by pyrolysis. J. Hazard. Mater. 2020, 406, 124706. [Google Scholar] [CrossRef]

- Qu, Y.; Li, A.; Wang, D.; Zhang, L.; Ji, G. Kinetic study of the effect of in-situ mineral solids on pyrolysis process of oil sludge. Chem. Eng. J. 2019, 374, 338–346. [Google Scholar] [CrossRef]

- Gong, Z.; Du, A.; Wang, Z.; Fang, P.; Li, X. Experimental Study on Pyrolysis Characteristics of Oil Sludge with a Tube Furnace Reactor. Energy Fuels 2017, 31, 8102–8108. [Google Scholar] [CrossRef]

- Miao, W.; Li, X.; Wang, Y.; Lv, Y. Pyrolysis characteristics of oil-field sludge and the comparison of kinetic analysis with two representative methods. J. Pet. Sci. Eng. 2019, 182, 106309. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, H.; Jiang, Z.; Song, Y.; Zhang, T.; Siyal, A.A.; Dai, J.; Bi, X.; Fu, J.; Ao, W.; et al. Microwave pyrolysis of oily sludge under different control modes. J. Hazard. Mater. 2021, 416, 125887. [Google Scholar] [CrossRef]

- da Silva, E.B.; Santos, D.; de Brito, M.P.; Guimarães, R.C.; Ferreira, B.M.; Freitas, L.; de Campos, M.C.V.; Franceschi, E.; Dariva, C.; Santos, A.; et al. Microwave demulsification of heavy crude oil emulsions: Analysis of acid species recovered in the aqueous phase. Fuel 2014, 128, 141–147. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.-R. Microwave pyrolysis of oily sludge with activated carbon. Environ. Technol. 2016, 37, 3139–3145. [Google Scholar] [CrossRef]

- Wen, Y.; Li, W.; Xie, Y.; Qin, Z.; Gu, M.; Wang, T.; Hou, Y. A study on the reaction mechanism of microwave pyrolysis of oily sludge by products analysis and ReaxFF MD simulation. Environ. Technol. 2022, 43, 2002–2016. [Google Scholar] [CrossRef] [PubMed]

- Motasemi, F.; Afzal, M.T. A review on the microwave-assisted pyrolysis technique. Renew. Sustain. Energy Rev. 2013, 28, 317–330. [Google Scholar] [CrossRef]

- Gupta, K.; Jana, A.K.; Chakraborty, M.; Parikh, P.A. Treating crude oil storage tank sludge by catalytic process and recovering valuable hydrocarbons. Chem. Pap. 2021, 75, 4285–4296. [Google Scholar] [CrossRef]

- Lin, F.; Zheng, F.; Li, J.; Sun, B.; Che, L.; Yan, B.; Chen, G. Catalytic pyrolysis of oily sludge with iron-containing waste for production of high-quality oil and H2-rich gas. Fuel 2022, 326, 124995. [Google Scholar] [CrossRef]

- Shie, J.L.; Lin, J.P.; Chang, C.Y.; Lee, D.J.; Wu, C.H. Use of calcium compounds as additives for oil sludge pyrolysis. Zhongguo Huanjing Gongcheng Xuekan 2002, 12, 363–371. [Google Scholar]

- Milato, J.V.; França, R.J.; Marques, M.R.C. Pyrolysis of oil sludge from the offshore petroleum industry: Influence of different mesoporous zeolites catalysts to obtain paraffinic products. Environ. Technol. 2019, 42, 1013–1022. [Google Scholar] [CrossRef]

- Hu, G.; Li, J.; Zhang, X.; Li, Y. Investigation of waste biomass co-pyrolysis with petroleum sludge using a response surface methodology. J. Environ. Manag. 2017, 192, 234–242. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Zhou, X.; Wang, C.; Jia, H. Dewatering and low-temperature pyrolysis of oily sludge in the presence of various agricultural biomasses. Environ. Technol. 2018, 39, 2715–2723. [Google Scholar] [CrossRef]

- Wang, A.-Y.; Sun, K.; Wu, L.; Wu, P.; Zeng, W.; Tian, Z.; Huang, Q.-X. Co-carbonization of biomass and oily sludge to prepare sulfamethoxazole super-adsorbent materials. Sci. Total Environ. 2022, 698, 134238. [Google Scholar] [CrossRef]

- Wen, Y.; Xie, Y.; Jiang, C.; Li, W.; Hou, Y. Products distribution and interaction mechanism during co-pyrolysis of rice husk and oily sludge by experiments and reaction force field simulation. Bioresour. Technol. 2021, 329, 124822. [Google Scholar] [CrossRef]

- Chen, C.; Ling, H.; Qiu, S.; Huang, X.; Fan, D.; Zhao, J. Microwave catalytic co-pyrolysis of chlorella vulgaris and oily sludge: Characteristics and bio-oil analysis. Bioresour. Technol. 2022, 360, 127550. [Google Scholar] [CrossRef]

- Li, X.Y.; Yang, X.X.; Cheng, G.; Feng, H.Q.; Liu, X.J.; Ma, Y.F. Experimental Study on Co-Pyrolysis of Oil Sludge and Coal. Adv. Mater. Res. 2012, 356–360, 2515–2519. [Google Scholar] [CrossRef]

- Önenç, S.; Brebu, M.; Vasile, C.; Yanik, J. Copyrolysis of scrap tires with oily wastes. J. Anal. Appl. Pyrolysis 2012, 94, 184–189. [Google Scholar] [CrossRef]

- Kasar, P.; Sharma, D.K.; Ahmaruzzaman, M. Thermal and catalytic decomposition of waste plastics and its co-processing with petroleum residue through pyrolysis process. J. Clean. Prod. 2020, 265, 121639. [Google Scholar] [CrossRef]

| Approach | Effectiveness | Duration | Cost | Optimized Application |

|---|---|---|---|---|

| Dewatering | It only reduces the volume of oily sludge. No toxic materials are removed or eliminated from the oily sludge | Depending on the method selected | Generally Low | Pre-treatment of oily sludge for disposal or further treatment using other approaches |

| Biodegradation | Some long-chain hydrocarbons cannot be decomposed. The toxicity of oily sludge-borne heavy metal(loid)s cannot be reduced | Time-consuming | Generally low | Only suitable for the treatment of oily sludge containing less long-chain hydrocarbons and under warm and humid climate conditions |

| Solidification | The mobility of petroleum hydrocarbon and heavy metal(loid)s are effectively reduced, minimizing the environmental risk of the oily sludge-borne hazardous materials | Treatment can be performed within a reasonably short period of time | High | It may only be practical for treating a small amount of oily sludge in order to meet legal requirements for rapidly eliminating the environmental risk |

| Chemical degradation | Effective decomposition of petroleum hydrocarbons but no effect on reducing the toxicity of heavy metal(loid)s | Treatment can be performed within a reasonably short period of time | High | More appropriate to be used as a pre-treatment for the follow-up biological treatment |

| Incineration | Complete decomposition of petroleum hydrocarbons. However, toxic gases can be generated. No effect on reducing the toxicity of heavy metal(loid)s | Treatment can be performed within a reasonably short period of time | Extremely high | Only where capital investment is available to install facilities for heat recovery |

| Approach | Recovered Products | Waste Products | Disadvantages | Optimized Application |

|---|---|---|---|---|

| Ultrasonic treatment | Oil | Wastewater Residue | High equipment costs and low treatment capacity | Small-scale treatment of oily sludge |

| Solvent extraction | Oil | Wastewater Residue | Secondary pollution | Large-scale treatment of oily sludge |

| Hydrothermal treatment | Oil, fuel gases, hydrochar | Wastewater | High energy and water consumption | Capital is available for investment in equipment |

| Surfactant treatment | Oil | Wastewater Residue | Secondary pollution | Large-scale treatment of oily sludge |

| Pyrolytic treatment | Oil, fuel gases, biochar | Waste gases | High energy consumption | Treatment of oily sludge with low water content |

| Category 1 | Category 2 | Category 3 |

|---|---|---|

| Literature review | ||

| Formation and characterization | ||

| Environmental impacts | ||

| Harmfulness reduction treatment | Dewatering | |

| Biological degradation | ||

| Chemical degradation | ||

| Solidification | ||

| Incineration | ||

| Other treatments | ||

| Valorization treatment | Pyrolytic treatment | Fuel recovery |

| Adsorbents | ||

| Others | ||

| Solvent extraction | ||

| Surfactant treatment | ||

| Hydrothermal treatment | ||

| Ultrasonic treatment | ||

| Use of untreated oily sludge | ||

| Use of oily sludge treatment residues | ||

| Other treatments |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, A.; Sun, X.; Lin, C. Trend in Research on Characterization, Environmental Impacts and Treatment of Oily Sludge: A Systematic Review. Molecules 2022, 27, 7795. https://doi.org/10.3390/molecules27227795

Niu A, Sun X, Lin C. Trend in Research on Characterization, Environmental Impacts and Treatment of Oily Sludge: A Systematic Review. Molecules. 2022; 27(22):7795. https://doi.org/10.3390/molecules27227795

Chicago/Turabian StyleNiu, Anyi, Xuechao Sun, and Chuxia Lin. 2022. "Trend in Research on Characterization, Environmental Impacts and Treatment of Oily Sludge: A Systematic Review" Molecules 27, no. 22: 7795. https://doi.org/10.3390/molecules27227795