The Impact of Type of Brandy on the Volatile Aroma Compounds and Sensory Properties of Grape Brandy in Montenegro

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Grape Marc Samples

2.3. Distillation of Fermented Grape Marc Samples

2.4. Analysis of the Chemical Quality Parameters of Grape Brandy

2.4.1. Extraction and Concentration of Minor Volatile Constituents

2.4.2. GC/MS Analysis of Minor Volatile Compounds

2.5. Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Volatile Compounds of Brandy Samples

3.1.1. Alcohols

3.1.2. Esters

3.1.3. Terpenes

3.1.4. Volatile Acids

3.1.5. Carbonyl Compound (Aldehydes and Acetals)

3.2. Sensory Analysis

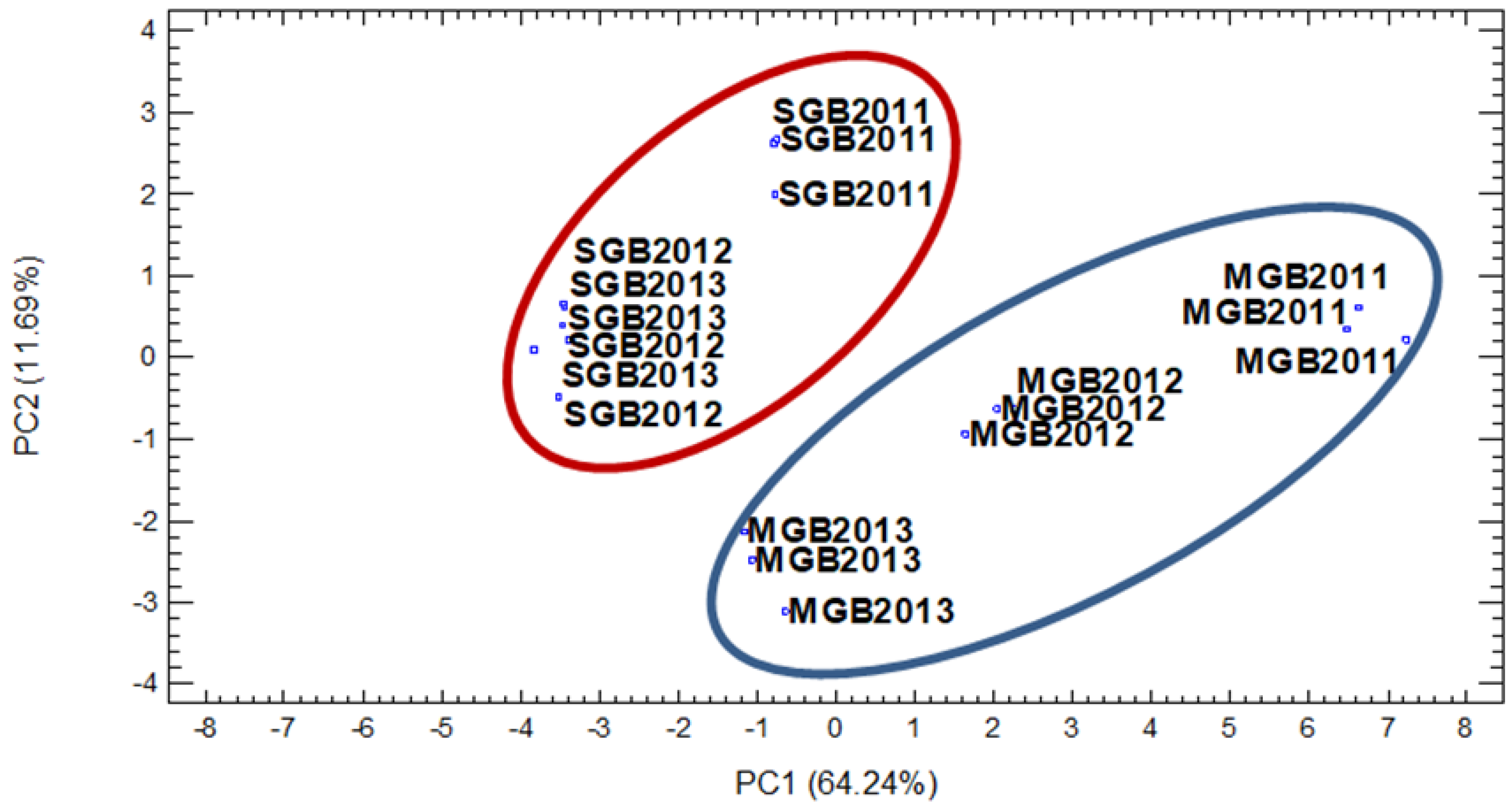

3.3. Classification of the Type of Grape Brandy Based on Aroma Composition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Lučić, R. Production of Strong Alcoholic Beverages; Nolit: Belgrade, Serbia, 1986. [Google Scholar]

- Paunović, R.; Đurišić, B. A contribution to the study of the method of production and properties of grape brandy. Vitic. Winemaking 1981, 35–36, 89–100. [Google Scholar]

- Matijašević, S.; Bešlić, Z.; Przić, Z.; Žunić, D.; Todić, S.; Marković, N.; Ranković-Vasić, Z.; Ćirković, B.; Vukosavljević, V.; Ćirković, D.; et al. Influence of cultivar characteristics of muscat table grapevine cultivars (Vitis vinifera L.) on grape brandy composition and quality. Ann. Univ. Craiova-Agric. Montanology Cadastre Ser. 2016, XLVI, 213–217. [Google Scholar]

- Paunović, R.; Nikićević, N. Impact of grape variety on the composition and properties of grape brandy. Contemp. Agric. 1988, 36, 67–75. [Google Scholar]

- Nikićević, N.; Jović, S.; Sivčev, B. Examination of the suitability of grape-based alcoholic beverages from some newly created grape varieties. In Proceedings of the V Conference of the Industry of Alcoholic and Non-Alcoholic Beverages and Vinegar, Vrnjačka Banja, Serbia, 4–7 June 2000; pp. 123–130. [Google Scholar]

- Zhao, Y.P.; Li, J.M.; Xu, Y.; Fan, W.L.; Jiang, W.G. Characterization of flavour compounds of four brandies by flavour extract dilution analysis. Am. J. Enol. Vitic. 2009, 60, 269–276. [Google Scholar]

- Vukoslavljević, V.; Ranković, V.; Žunić, D.; Matijašević, S. Alcoholic fermentation influence on quality of grape brandies. Acta Agric. Serbica 2015, XX, 117–125. [Google Scholar] [CrossRef] [Green Version]

- The Official Gazette of Montenegro. Law on Spirit Drinks of Montenegro br. 53/2016; The Official Gazette of Montenegro: Podgorica, Montenegro, 2016. [Google Scholar]

- Wei, X.-F.; Ma, X.-L.; Cao, J.-H.; Sun, X.-Y.; Fang, Y.-L. Aroma characteristics and volatile compounds of distilled Crystal grape spirits of different alcohol concentrations: Wine sprits in the Shangri-La region of China. Food Sci. Technol. 2018, 38 (Suppl. S1), 50–58. [Google Scholar] [CrossRef] [Green Version]

- Crespo, J.; Rigou, P.; Romero, V.; García, M.; Arroyo, T.; Mariano Cabellos, J. Effect of seasonal climate fluctuations on the evolution of glycoconjugates along the ripening period of grapevine cv. Muscat a petits grains blancs berries. J. Sci. Food Agric. 2017, 98, 1803–1812. [Google Scholar] [CrossRef]

- Christoph, N.; Bauer-Christoph, C. Flavour of Spirit Drinks: Raw Materials, Fermentation, Distillation and Ageing. Flavours and Fragrances; Springer: Berlin, Germany, 2007; pp. 219–239. [Google Scholar] [CrossRef]

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Grape brandy production, composition and sensory evaluation. J. Sci. Food Agric. 2014, 94, 404–414. [Google Scholar] [CrossRef]

- Soufleros, E.H.; Mygdalia Ageliki, S.; Natskoulis, P. Characterization and safety evaluation of the traditional Greek fruit distillate ‘‘Mouro’’ by flavor compounds and mineralanalysis. Food Chem. 2004, 86, 625–636. [Google Scholar] [CrossRef]

- Apostolopoulou, A.A.; Flouros, A.I.; Demertzis, P.G.; Akrida-Demertzi, K. Differences in concentration of principal volatile constituents in traditional Greek distillates. Food Control. 2005, 16, 157–164. [Google Scholar] [CrossRef]

- Cortés, S.; Rodríguez, R.; Salgado, J.M.; Domínguez, J.M. Comparative study between Italian and Spanish grape marc spirits in terms of major volatile compounds. Food Control. 2011, 22, 673–680. [Google Scholar] [CrossRef]

- Spaho, N. Distillation Techniques in the Fruit Spirits Production. In Distillation—Innovative Applications and Modeling; IntechOpen: London, UK, 2017; Chapter 6. [Google Scholar] [CrossRef] [Green Version]

- Matijašević, S.; Popović-Djordjević, J.; Ristić, R.; Ćirković, D.; Ćirković, B.; Popović, T. Volatile Aroma Compounds of Brandy ‘Lozovača’ Produced from Muscat Table Grapevine Cultivars (Vitis vinifera L.). Molecules 2019, 24, 2485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hernández-Gómez, F.L.; Úbeda-Iranzo, J.; García-Romero, E.; Briones-Pérez, A. Comparative production of diferent melon distillates. Chemical and sensory analyses. Food Chem. 2005, 90, 115–125. [Google Scholar] [CrossRef]

- Lukić, I.; Milićević, B.; Banović, M.; Tomas, S.; Radeka, S.; Peršurić, C. Secondary Aroma Compounds in Fresh Grape Marc Distillates as a Result of Variety and Corresponding Production Technology. Food Technol. Biotechnol. 2011, 49, 214–227. [Google Scholar]

- Plutowska, B.; Biernacka, P.; Wardencki, W. Identification of Volatile Compounds in Raw Spirits of Different Organoleptic Quality. J. Inst. Brew. 2010, 116, 433–439. [Google Scholar] [CrossRef]

- Silva, M.L.; Macedo, A.C.; Malcata, F.X. Review: Steam distilled spirits from fermented grape pomace. Food. Sci Technol. Int. 2000, 6, 285–300. [Google Scholar] [CrossRef]

- Cortés, S.; Gil, M.L.; Fernández, E. Volatile composition of traditional and industrial Orujo spirits. Food Control. 2005, 16, 383–388. [Google Scholar] [CrossRef]

- Raičević, D.; Pajović-Šćepanović, R.; Mijović, S.; Popović, T. Phenolic compounds of red wines in Podgorica sub region (Montenegro). Agric. For. 2015, 61, 359–368. [Google Scholar] [CrossRef]

- Pajović, R.; Raičević, D.; Popović, T.; Sivilotti, P.; Lisjak, K.; Vanzo, A. Polyphenolic characterisation of Vranac, Kratošija and Cabernet Sauvignon (Vitis vinifera L. cv.) grapes and wines from dif-ferent vineyard locations in Montenegro. S. Afr. J. Enol. Vitic. 2014, 35, 139–148. [Google Scholar]

- Pajović-Šćepanović, R.; Raičević, D.; Wendelin, S.; Eder, R. Characterization of the phenolic profile of commercial Montenegrin red and white wines. Eur. Food Res. Technol. 2019, 245, 2233–2245. [Google Scholar] [CrossRef]

- Pajović-Šćepanović, R.; Krstić, M.; Savković, S.; Raičević, D.; Popović, T. Wine quality in Montenegro. Agric. For. 2016, 62, 223–244. [Google Scholar] [CrossRef] [Green Version]

- Raičević, D.; Božinović, Z.; Petkov, M.; Ivanova-Petropulos, V.; Kodžulović, V.; Mugoša, M.; Šućur, S.; Maraš, V. Polyphenolic content and sensory profile of Montenegrin Vranac wines produced with different oenological products and maceration. Maced. J. Chem. Chem. Eng. 2017, 36, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Raičević, D.; Mijović, S.; Popović, T.; Pajović-Šćepanović, R. The influence of variety and vintage on the chemical composition and sensory properties of red wines in Podgorica subregion (Montenegro). In Proceedings of the 3rd International Symposium for Agriculture and Food—ISAF, Ohrid, Macedonia, 18–20 October 2017. [Google Scholar]

- Da Porto, C.; Sensidoni, A.; Battistutta, F. Composition and flavour of muscat of canelli grape distillates obtained using different oenological techniques and unconventional distillation processes. Ital. J. Food Sci. 1995, 1, 41–55. [Google Scholar]

- Milanov, G.; Beleski, K.; Cvetković, J.; Nedelkovski, D. Impact of grape variety and technological procedures on the quality of grape brandies. Agroznanje 2014, 15, 425–438. [Google Scholar]

- The Official Gazette of Montenegro. Rulebook on conditions regarding technical equipment and professional staff, sampling methods and physico-chemical analysis of. Off. Gaz. Monten. 2017, 70, 97–151. [Google Scholar]

- Publications Office of the European Union. Commission Regulation (EC) No 2870/2000 of 19 December 2000 laying down Community reference methods for the analysis of spirits drinks. Off. J. Eur. Union 2000, L333, 20–46. [Google Scholar]

- Ranković, V.; Palić, R.; Živković, J.; Mosić, I.; Stanković, S.; Stojanović, G. Investigation of the impact of grape cultivars on the grape brandies quality. Phys. Chem. Technol. 2004, 3, 61–66. [Google Scholar] [CrossRef] [Green Version]

- Tešević, V.; Nikićević, N.; Jovanović, A.; Djoković, D.; Vujisić, L.; Vučković, I.; Bonić, M. Volatile Components of Plum Brandies. Food Technol. Biotechnol. 2005, 43, 367–372. [Google Scholar]

- Matijašević, S.; Todić, S.; Beslić, Z.; Ranković- Vasić, Z. Volatile components of grape brandies produced from Muscat table grapevine (Vitis vinifera L.) cultivars. Bulg. J. Agric. Sci. 2013, 19, 783–791. [Google Scholar]

- Vulić, T.; Nikićević, N.; Stanković, L.; Veličković, M.; Todosijević, M.; Popović, B.; Urošević, I.; Stanković, M.; Beraha, I.; Tešević, V. Chemical and Sensorial Characteristics of Fruit Spirits Produced from Different Black Currant (Ribes Nigrum L.) and Red Currant (Ribes Rubrum L.) Cultivars. Maced. J. Chem. Chem. Eng. 2012, 31, 217–227. [Google Scholar] [CrossRef] [Green Version]

- Ledauphin, J.; Milbeau, C.L.; Barillier, D.; Hennequin, D. Differences in the volatile compositions of French labeled brandies (Armagnac, Calvados, Cognac, and Mirabelle) using GC-MS and PLS-DA. J. Agric. Food Chem. 2010, 58, 7782–7793. [Google Scholar] [CrossRef] [PubMed]

- Lukić, I.; Miličević, B.; Tomas, S.; Radeka, S.; Peršurić, Đ. Relationship between volatile aroma compounds and sensory quality of fresh grape marc distillates. J. Inst. Brew. 2012, 118, 285–294. [Google Scholar] [CrossRef]

- Arrieta-Garay, Y.; Blanco, P.; López-Vázquez, C.; Rodríguez-Bencomo, J.J.; Pérez-Correa, J.R.; López, F.; Orriols, I. Effects of Distillation System and Yeast Strain on the Aroma Profile of Albarinño (Vitis vinifera L.) Grape Pomace Spirits. J. Agric. Food Chem. 2014, 62, 10552–10560. [Google Scholar] [CrossRef] [PubMed]

- Geroyiannaki, M.; Komaitis, M.E.; Stavrakas, D.E.; Polysiou, M.; Athanasopoulos, P.E.; Spanos, M. Evaluation of acetaldehyde and methanol in greek traditional alcoholic beverages from varietal fermented grape pomaces (Vitis vinifera L.). Food Control. 2007, 18, 988–995. [Google Scholar] [CrossRef]

- Cacho, J.; Moncayo, L.; Palma, J.C.; Ferreiraa, V.; Culleréa, L. Comparison of the aromatic profile of three aromatic varieties of Peruvian pisco (Albilla, Muscat and Torontel) by chemical analysis and gas chromatography-olfactometry. Flavour Fragr. J. 2013, 28, 340–352. [Google Scholar] [CrossRef]

- Matias-Guiua, P.; Rodríguez-Bencomoa, J.J.; Pérez-Correab, J.R.; Lópeza, F. Aroma profile design of wine spirits: Multi-objective optimization using response surface methodology. Food Chem. 2018, 245, 1087–1097. [Google Scholar] [CrossRef]

- Schreier, P.; Drawert, F.; Winkler, F. Composition of Neutral Volatile Constituents in Grape Brandies. J. Agric. Food Chem. 1979, 27, 365–372. [Google Scholar] [CrossRef]

- Doneva-Šapčeska, D.; Dimitrovski, A.; Bojadžiev, T.; Milanov, G.; Vojnovski, B. Free and potentially volatile monoterpenes in grape varieties from the Republic of Macedonia. Bull. Chem. Technol. Maced. 2006, 25, 51–56. [Google Scholar]

- Diéguez, S.C.; De La Peña, M.L.G.; Gómez, E.F. Approaches to spirit aroma: Contribution of some aromatic compounds to the primary aroma in samples of orujo spirits. J. Agric. Food Chem. 2003, 51, 7385–7390. [Google Scholar] [CrossRef]

- Herraiz, M.; Reglero, J.G.; Herraiz, T.; Loyolae, E. Analysis of Wine Distillates Made from Muscat Grapes (Pisco) by Multidimensional Gas Chromatography and Mass Spectrometry. J. Agric. Food Chem. 1990, 38, 1540–1543. [Google Scholar] [CrossRef]

- Vujović, D.; Maletić, R.; Popović-Đorđević, J.; Pejin, B.; Ristić, R. Viticultural and chemical characteristics of Muscat Hamburg preselected clones grown. J. Sci. Food Agric. 2016, 97, 587–594. [Google Scholar] [CrossRef] [PubMed]

- Bortoletto, A.M.; Carolina, C.A.; André, R.A. Fatty acid profile and glycerol concentration in cachaças aged in different wood barrels. J. Inst. Brew. 2016, 122, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Publications Office of the European Union. Regulation (EU) 2019/787 of the European Parliament and of the Council of 17 April 2019 on the definition, description, presentation and labelling of spirit drinks, the use of the names of spirit drinks in the presentation and labelling of other foodstuffs, the protection of geographical indications for spirit drinks, the use of ethyl alcohol and distillates of agricultural origin in alcoholic beverages, and repealing Regulation (EC) No 110/2008. Off. J. Eur. Union 2019, L130, 1–54. [Google Scholar]

| Compound | Standard Grape Brandy (SGB) | Muscat Grape Brandy (MGB) | ||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | M1 | M2 | M3 | |

| Ethanol (%vol.) | 49.9 ± 1.4 | 50.1 ± 1.0 | 50.2 ± 1.0 | 49.8 ± 0.6 | 49.7 ± 0.8 | 49.9 ± 0.9 |

| Methanol (g/hL of 100% vol. alcohol) | 149 ± 10 | 125 ± 5 | 170 ± 6 | 161 ± 8 | 129 ± 8 | 175 ± 10 |

| Aroma compound (mg/L) | ||||||

| 1-hexanol ** | 1.18 ± 0.06 c | 1.06 ± 0.08 c | 1.10 ± 0.15 c | 3.30 ± 0.17 a | 1.82 ± 0.05 b | 0.71 ± 0.05 d |

| 4-heptenol-1ol | 0.03 ± 0.01 | 0.010 ± 0.002 | 0.020 ± 0.004 | 0.05 ± 0.01 | 0.020 ± 0.003 | 0.020 ± 0.002 |

| 1-heptanol ** | 0.21 ± 0.02 b | 0.11 ± 0.02 c | 0.10 ± 0.02 c | 0.75 ± 0.05 a | 0.25 ± 0.03 b | 0.11 ± 0.02 c |

| 1-octen-3-ol | 0.11 ± 0.02 | 0.06 ± 0.01 | 0.050 ± 0.005 | 0.33 ± 0.01 | 0.16 ± 0.02 | 0.08 ± 0.01 |

| n-octanol | 0.17 ± 0.01 | 0.070 ± 0.003 | 0.060 ± 0.001 | 0.33 ± 0.01 | 0.19 ± 0.02 | 0.08 ± 0.01 |

| n-decanol | 0.12 ± 0.04 | 0.08 ± 0.01 | 0.09 ± 0.01 | 0.14 ± 0.02 | 0.06 ± 0.01 | 0.040 ± 0.003 |

| 1-tetradecanol | 0.05 ± 0.02 | 0.050 ± 0.052 | 0.06 ± 0.08 | 0.07 ± 0.32 | 0.09 ± 0.07 | 0.030 ± 0.005 |

| 1-hexadecanol | 0.040 ± 0.002 | 0.030 ± 0.005 | 0.030 ± 0.003 | 0.010 ± 0.001 | 0.04 ± 0.01 | 0.020 ± 0.002 |

| 3,7,11,15-tetramethyl-2-hexadecen-1-ol | 0.040 ± 0.004 | 0.05 ± 0.01 | 0.06 ± 0.01 | 0.010 ± 0.002 | 0.010 ± 0.001 | 0.030 ± 0.003 |

| 1-methyl-cyclohexanol | 0.15 ± 0.03 | 0.22 ± 0.03 | 0.14 ± 0.01 | 0.12 ± 0.01 | 0.07 ± 0.01 | 0.140 ± 0.001 |

| 3-ethyl-4-methylpentanol | n.d. | n.d. | n.d. | 0.020 ± 0.002 | n.d. | n.d. |

| benzyl alcohol | n.d. | 0.160 ± 0.012 | 0.010 ± 0.002 | n.d. | n.d. | n.d. |

| 3,5,5-trimethyl-2-cyclohexen-1-ol | n.d. | n.d. | 0.010 ± 0.001 | 0.010 ± 0.001 | n.d. | n.d. |

| 2-phenylethyl alcohol ** | 6.25 ± 0.08 c | 5.91 ± 0.04 d | 5.78 ± 0.07 e | 7.14 ± 0.09 a | 6.85 ± 0.05 b | 6.29 ± 0.08 c |

| Total high alcohol | 8.35 ± 0.17c | 7.81 ± 0.14 d | 7.51 ± 0.13 d | 12.38 ± 0.31 a | 9.56 ± 0.10 b | 7.55 ± 0.11 d |

| Average | 7.89 ± 0.39 B | 9.80 ± 2.04 A | ||||

| Aroma Compound (mg/L) | Standard Grape Brandy (SGB) | Muscat Grape Brandy (MGB) | ||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | M1 | M2 | M3 | |

| Ethyl butyrate | 0.190 ± 0.001 d | 0.140 ± 0.001 e | 0.14 ± 0.02 e | 0.23 ± 0.02 b | 0.16 ± 0.01 c | 0.18 ± 0.01 a |

| Ethyl lactate ** | 0.40 ± 0.002 | 0.33 ± 0.03 | 0.34 ± 0.02 | 0.63 ± 0.02 | 0.52 ± 0.03 | 0.76 ± 0.01 |

| Ethyl 3-methylbutyrate | 0.020 ± 0.002 | 0.020 ± 0.002 | 0.020 ± 0.001 | 0.020 ± 0.003 | 0.020 ± 0.003 | 0.03 ± 0.01 |

| Isoamyl acetate | 0.160 ± 0.001 | 0.18 ± 0.02 | 0.12 ± 0.02 | 0.36 ± 0.03 | 0.30 ± 0.02 | 0.33 ± 0.02 |

| Ethyl hexanoate ** | 2.960 ± 0.004 b | 1.86 ± 0.03 d | 1.60 ± 0.06 e | 3.69 ± 0.31 a | 2.95 ± 0.07 b | 2.19 ± 0.13 c |

| Ethyl 2-hydroxy-4-methylpentanoate | 0.030 ± 0.004 | 0.010 ± 0.002 | 0.020 ± 0.003 | 0.080 ± 0.004 | 0.040 ± 0.004 | 0.02 ± 0.01 |

| Ethyl succinate ** | 2.57 ± 0.04 b | 2.49 ± 0.04 b | 2.25 ± 0.07 c | 2.80 ± 0.07 a | 2.04 ± 0.11 d | 2.00 ± 0.07 d |

| Ethyl octanoate ** | 2.00 ± 0.09 d | 1.81 ± 0.04 e | 1.09 ± 0.05 f | 5.65 ± 0.08 a | 5.21 ± 0.04 b | 4.63 ± 0.06 c |

| Ethyl nonanoate | 0.06 ± 0.01 | 0.06 ± 0.01 | 0.05 ± 0.01 | 0.13 ± 0.02 | 0.03 ± 0.01 | 0.05 ± 0.01 |

| Ethyl-(4E)-decenoate | 0.14 ± 0.03 | 0.02 ±0.01 | 0.040 ± 0.003 | 0.040 ± 0.003 | 0.04 ± 0.01 | 0.020 ± 0.002 |

| Ethyl decanoate ** | 6.48 ± 0.01 b | 4.87 ± 0.09 d | 4.95 ± 0.09 d | 7.14 ± 0.07 a | 5.75 ± 0.09 c | 5.64 ± 0.07 c |

| Ethyl 3-methylbutyl succinate | 0.03 ± 0.01 | 0.02 ± 0.01 | 0.020 ± 0.003 | n.d. | 0.030 ± 0.003 | 0.030 ± 0.003 |

| Isoamyl octanoate | 0.07 ± 0.01 | 0.030 ± 0.003 | 0.04 ± 0.01 | 0.050 ± 0.003 | 0.05 ± 0.01 | 0.020 ± 0.002 |

| 2-methylbutyl octanoate | 0.020 ± 0.003 | 0.010 ± 0.002 | 0.010 ± 0.002 | n.d. | 0.020 ± 0.003 | n.d. |

| Ethyl 9-oxononanoate | 0.010 ± 0.002 | n.d. | n.d. | 0.070 ± 0.003 | 0.020 ± 0.002 | 0.140 ± 0.001 |

| Isobutyl decanoate | 0.010 ± 0.001 | n.d. | 0.010 ± 0.002 | 0.010 ± 0.001 | 0.010 ± 0.001 | n.d. |

| Ethyl dodecanoate ** | 2.82 ± 0.04 c | 2.80 ± 0.03c | 2.71 ± 0.04 d | 3.09 ± 0.08 a | 2.95 ± 0.05 b | 2.78 ± 0.04 cd |

| Isoamyl decanoate | 0.10 ± 0.01 | 0.06 ± 0.01 | 0.08 ± 0.03 | 0.050 ±0.001 | 0.050 ± 0.003 | 0.030 ± 0.003 |

| 2-methylbutyl decanoate | 0.030 ± 0.003 | 0.020 ± 0.002 | 0.030 ± 0.003 | 0.020 ±0.003 | 0.020 ± 0.002 | 0.01 ± 0.01 |

| Ethyl tridecanoate | 0.030 ± 0.002 | 0.030 ±0.002 | 0.030 ± 0.003 | 0.03 0 ± 0.002 | 0.010 ± 0.001 | 0.040 ± 0.003 |

| Ethyl x-tetradecenoate | 0.040 ± 0.02 | 0.10 ± 0.02 | 0.05 ± 0.01 | 0.22 ± 0.02 | 0.06 ± 0.01 | 0.12 ± 0.03 |

| Ethyl y-tetradecenoate | 0.030 ± 0.002 | 0.050 ± 0.003 | 0.030 ± 0.003 | 0.040 ± 0.002 | 0.01 ± 0.01 | 0.020 ± 0.003 |

| Ethyl tetradecanoate | 0.49 ± 0.03 | 0.75 ± 0.02 | 0.46 ± 0.03 | 0.65 ± 0.04 | 0.42 ± 0.03 | 0.60 ± 0.03 |

| Ethyl pentadecenoate | 0.050 ± 0.003 | 0.090 ± 0.003 | 0.06 ± 0.03 | 0.070 ± 0.003 | 0.030 ± 0.002 | 0.050 ± 0.002 |

| Ethyl pentadecanoate | 0.030 ± 0.003 | 0.070 ± 0.002 | 0.030 ± 0.002 | 0.030 ± 0.001 | 0.010 ± 0.002 | 0.040 ± 0.002 |

| Ethyl 9-hexadecenoate | 0.350 ± 0.002 | 0.42 ± 0.03 | 0.33 ± 0.03 | 0.52 ± 0.27 | 0.31 ± 0.02 | 0.44 ± 0.02 |

| Ethyl x-hexadecenoate | n.d. | 0.040 ± 0.002 | 0.010 ± 0.001 | n.d. | n.d. | 0.010 ± 0.002 |

| Ethyl hexadecanoate | 1.39 ± 0.01 | 1.86 ± 0.04 | 1.03 ± 0.05 | 1.19 ± 0.02 | 0.73 ± 0.03 | 0.87 ± 0.02 |

| Ethyl 9,12-octadecadienoate | 1.41 ± 0.03 | 0.32 ± 0.03 | 0.95 ± 0.05 | 1.23 ± 0.03 | 0.53 ± 0.03 | 1.76 ± 0.03 |

| Ethyl linolenate | 1.11 ± 0.04 | 2.09 ± 0.08 | 0.88 ± 0.02 | 1.02 ± 0.04 | 0.61 ± 0.03 | 0.58 ± 0.03 |

| Ethyl (Z)-9-octadecenoate | 0.03 ± 0.002 | 0.050 ± 0.003 | 0.020 ± 0.001 | 0.030 ± 0.003 | 0.020 ± 0.003 | 0.030 ± 0.002 |

| Ethyl octadecanoate | 0.050 ± 0.002 | 0.320 ± 0.02 | 0.020 ± 0.002 | 0.020 ± 0.002 | 0.010 ± 0.001 | 0.030 ± 0.003 |

| 2-ethylhexyl diphenyl phosphate | 0.010 ± 0.001 | n.d. | 0.020 ± 0.001 | n.d. | n.d. | 0.020 ± 0.002 |

| Total esters | 23.12 ± 1.78 bc | 20.92 ± 1.18 d | 17.44 ± 0.69 e | 29.10 ± 1.28 a | 22.90 ± 1.08 c | 23.40 ± 1.54 b |

| Average | 20.49 ± 0.78 B | 25.18 ± 1.15 A | ||||

| Aroma Compound (mg/L) | Standard Grape Brandy (SGB) | Muscat Grape Brandy (MGB) | ||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | M1 | M2 | M3 | |

| c-linalool oxide | 0.040 ± 0.003 | 0.010 ± 0.001 | 0.010 ± 0.001 | 0.30 ± 0.03 | 0.070 ± 0.003 | 0.020 ± 0.001 |

| t-linalool oxide | 0.010 ± 0.001 | n.d. | n.d. | 0.090 ± 0.002 | 0.030 ± 0.001 | 0.01 ± 0.02 |

| Linalool ** | 0.06 ± 0.01 d | 0.050 ± 0.003 d | 0.050 ± 0.004 d | 0.81 ± 0.04 a | 0.41 ± 0.04 b | 0.28 ± 0.02 c |

| alpha-terpineol ** | 0.05 ± 0.04 | 0.02 ± 0.02 | 0.010 ± 0.002 | 0.26 ± 0.37 | 0.12 ± 0.17 | 0.03 ± 0.02 |

| 2-propyl-1-heptanol | 0.01 ± 0.01 | 0.10 ± 0.01 | 0.020 ± 0.002 | 0.010 ± 0.003 | 0.010 ± 0.001 | 0.030 ± 0.002 |

| Citronellol ** | 0.08 ± 0.01 c | 0.030 ± 0.002 d | 0.040 ± 0.003 d | 0.24 ± 0.021 a | 0.11 ± 0.01 b | 0.080 ± 0.003 c |

| Carvacrol, methyl ether | 0.09 ± 0.01 | 0.030 ± 0.002 | 0.020 ± 0.002 | 0.20 ± 0.03 | 0.030 ± 0.003 | 0.02 ± 0.01 |

| Geraniol ** | 0.010 ± 0.001 d | 0.010 ± 0.001 d | 0.010 ± 0.001 d | 0.31 ± 0.03 a | 0.13 ± 0.01 b | 0.08 ± 0.003 c |

| Vitispirane | 0.030 ± 0.003 | 0.020 ± 0.002 | 0.020 ± 0.002 | 0.13 ± 0.02 | 0.030 ± 0.003 | 0.020 ± 0.001 |

| Carvacrol | 0.010 ± 0.001 | 0.010 ± 0.002 | 0.010 ± 0.003 | 0.040 ± 0.003 | 0.010 ± 0.001 | 0.010 ± 0.001 |

| (E)-beta-damascenone | 0.020 ± 0.003 | 0.020 ± 0.002 | 0.020 ± 0.002 | 0.06 ± 0.01 | 0.020 ± 0.002 | 0.03 ± 0.01 |

| E-nerolidol ** | 0.10 ± 0.02 d | 0.10 ± 0.02 d | 0.23 ± 0.02 c | 0.38 ± 0.03 a | 0.34 ± 0.03 ab | 0.31 ± 0.03 b |

| (2Z,6E)-farnesol ** | 0.22 ± 0.03 a | 0.15 ±0.02 b | 0.12 ± 0.02 | 0.24 ± 0.02 | 0.25 ± 0.03 | 0.22 ± 0.03 |

| 13-epi-manool oxide | 0.040 ± 0.002 | 0.040 ± 0.002 | 0.040 ± 0.002 b | 0.080 ± 0.003 a | 0.040 ± 0.002 a | 0.040 ± 0.003 a |

| Total terpens | 0.77 ± 0.09 c | 0.59 ± 0.01 c | 0.60 ± 0.02 c | 3.15 ± 0.52 a | 1.60 ± 0.14 b | 1.18 ± 0.05 bc |

| Average | 0.65 ± 0.08 B | 1.98 ± 0.16 A | ||||

| Aroma Compound (mg/L) | Standard Grape Brandy (SGB) | Muscat Grape Brandy (MGB) | ||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | M1 | M2 | M3 | |

| Hexanoic acid ** | 0.59 ± 0.02 c | 0.53 ± 0.89 cd | 0.51 ± 0.87 d | 0.78 ± 0.85 a | 0.68 ± 1.06 b | 0.56 ± 0.94 e |

| Octanoic acid ** | 0.86 ± 0.02 c | 0.80 ± 0.05 cd | 0.77 ± 0.03 d | 1.03 ± 0.04 a | 0.94 ± 0.03 b | 0.66 ± 0.05 e |

| Decanoic acid ** | 2.82 ± 0.05 a | 1.58 ± 0.05 d | 1.93 ± 0.03 c | 1.98 ± 0.02 c | 2.42 ± 0.02 b | 1.33 ± 0.02 e |

| Dodecanoic acid ** | 0.67 ± 0.03 bc | 0.49 ± 0.02 d | 0.47 ± 0.03 d | 0.97 ± 0.05 a | 0.72 ± 0.04 b | 0.62 ± 0.03 c |

| Tetradecanoic acid | 0.15 ± 0.02 | 0.20 ± 0.02 | 0.18 ± 0.02 | 0.31 ± 0.02 | 0.17 ± 0.02 | 0.14 ± 0.02 |

| Hexadecenoic acid | 0.09 ± 0.02 | 0.050 ± 0.002 | 0.060 ± 0.003 | 0.05 ± 0.03 | 0.060 ± 0.003 | 0.210 ± 0.002 |

| Hexadecanoic acid ** | 0.50 ± 0.03 a | 0.30 ± 0.04 c | 0.50 ± 0.04 a | 0.45 ± 0.05 ab | 0.400 ± 0.002 b | 0.460 ± 0.002 ab |

| 9,12-octadecadienoic acid (Z,Z) | 0.170 ± 0.002 | 0.21 ± 0.04 | 0.18 ± 0.02 | 0.12 ± 0.02 | 0.090 ± 0.003 | 0.20 ± 0.002 |

| Octadecenoic acid, (E)- | 0.21 ± 0.03 | 0.18 ± 0.02 | 0.16 ± 0.02 | 0.13 ± 0.02 | 0.13 ± 0.02 | 0.240 ± 0.002 |

| Total vol. acid | 6.06 ± 0.93 b | 4.34 ± 0.91 ab | 4.76 ± 1.13 ab | 5.82 ± 0.81 ab | 5.61 ± 1.12 ab | 4.42 ± 0.97 b |

| Average | 5.05 ± 1.00 | 5.28 ± 1.07 | ||||

| Aroma Compound (mg/L) | Standard Grape Brandy (SGB) | Muscat Grape Brandy (MGB) | ||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | M1 | M2 | M3 | |

| Aldehydes | ||||||

| Acetaldehyd | 210 ± 9 | 197 ± 8 | 221 ± 8 | 218 ± 9 | 199 ± 9 | 229 ± 9 |

| Benzaldehyde ** | 0.19 ± 0.02 b | 0.25 ± 0.04 a | 0.20 ± 0.03 b | 0.18 ± 0.03 b | 0.17 ± 0.03 b | 0.17 ± 0.02 b |

| Nonanal ** | 0.030 ± 0.004 c | 0.020 ± 0.002 d | 0.020 ± 0.003 d | 0.09 ±0.01 a | 0.050 ± 0.003 b | 0.05 ± 0.01 b |

| Furfural | 0.140 ± 0.003 | 0.34 ± 0.03 | 0.50 ± 0.03 | 0.29 ± 0.05 | 0.49 ± 0.02 | 0.13 ± 0.02 |

| Total aldehydes | 210.36 ± 77.95 bc | 197.61 ± 7.99 c | 221.72 ± 3.99 ab | 218.56 ± 8.16 ab | 199.71 ± 8.69 c | 229.35 ± 10.39 a |

| Averages | 209.90 ± 12.04 | 215.87 ± 15.20 | ||||

| Acetals | ||||||

| 1,1-diethoxy-2-methylpropane | 0.12 ± 0.03 | 0.150 ± 0.01 | 0.11 ± 0.02 | 0.10 ± 0.02 | 0.08 ± 0.02 | 0.10 ± 0.02 |

| 3,3-diethoxy-2-butanone | 0.11 ± 0.02 | 0.070 ± 0.002 | 0.060 ± 0.004 | 0.18 ± 0.01 | 0.04 ± 0.01 | 0.010 ± 0.001 |

| 1-(1-ethoxyethoxy)pentane | 0.21 ± 0.02 | 0.130 ± 0.002 | 0.13 ± 0.02 | 0.15 ± 0.03 | 0.16 ± 0.02 | 0.21 ± 0.02 |

| Total acetals | 0.44 ± 0.05 a | 0.35 ± 0.01 b | 0.30 ± 0.05 bc | 0.42 ± 0.02 a | 0.28 ± 0.02 c | 0.32 ± 0.04 bc |

| Averages | 0.36 ± 0.07 | 0.34 ± 0.07 | ||||

| Other compounds | ||||||

| Cyclohexane, ethoxy- | 0.040 ± 0.003 | 0.040 ± 0.002 | 0.040 ± 0.002 | 0.11 ± 0.02 | 0.04 ± 0.02 | 0.06 ± 0.01 |

| 2-pentadecanone, 6,10,14-trimethyl- | 0.10 ± 0.09 | 0.090 ± 0.002 | 0.090 ± 0.003 | 0.080 ± 0.002 | 0.05 ± 0.01 | 0.050 ± 0.003 |

| Hexacosane | 0.010 ± 0.001 | 0.010 ± 0.002 | 0.010 ± 0.003 | 0.050 ± 0.003 | 0.010 ± 0.001 | 0.020 ± 0.001 |

| Heptacosane | 0.010 ± 0.001 | 0.010 ± 0.002 | 0.010 ± 0.002 | 0.020 ± 0.002 | 0.010 ± 0.001 | 0.010 ± 0.003 |

| Total | 0.16 ± 0.02 b | 0.15 ± 0.001 bc | 0.15 ± 0.001 bc | 0.26 ± 0.02 a | 0.11 ± 0.01 d | 0.14 ± 0.01 c |

| Average | 0.15 ± 0.01 B | 0.17 ± 0.01 A | ||||

| Sample | Colour (max 1) | Clarity (max 1) | Distinction (max 2) | Odour (max 6) | Taste (max 10) | Total (max 20) |

|---|---|---|---|---|---|---|

| Standard Grape Brandy (SGB) | ||||||

| 2011 | 1.0 | 1.0 | 1.82 ± 0.02 | 5.68 ± 0.17 | 9.48 ± 0.20 | 19.0 ± 0.16 |

| 2012 | 1.0 | 1.0 | 1.87 ± 0.03 | 5.70 ± 0.16 | 9.51 ± 0.18 | 19.1 ± 0.10 |

| 2013 | 1.0 | 1.0 | 1.80 ± 0.02 | 5.59 ± 0.20 | 9.46 ± 0.15 | 18.9 ± 0.15 |

| Averages | 1.0 | 1.0 | 1.83 ± 0.04 | 5.66 ± 0.06 b | 9.48 ± 0.02 a | 19.0 ± 0.10 |

| Muscat Grape Brandy (MGB) | ||||||

| 2011 | 1.0 | 1.0 | 1.81 ± 0.02 | 5.75 ± 0.18 | 9.28 ± 0.20 | 18.8 ± 0.18 |

| 2012 | 1.0 | 1.0 | 1.83 ± 0.02 | 5.79 ± 0.16 | 9.37 ± 0.25 | 19.0 ± 0.00 |

| 2013 | 1.0 | 1.0 | 1.79 ± 0.01 | 5.69 ± 0.20 | 9.23 ± 0.20 | 18.7 ± 0.25 |

| Averages | 1.0 | 1.0 | 1.81 ± 0.02 | 5.74 ± 0.05 a | 9.29 ± 0.07 b | 18.8 ± 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raičević, D.; Popović, T.; Jančić, D.; Šuković, D.; Pajović-Šćepanović, R. The Impact of Type of Brandy on the Volatile Aroma Compounds and Sensory Properties of Grape Brandy in Montenegro. Molecules 2022, 27, 2974. https://doi.org/10.3390/molecules27092974

Raičević D, Popović T, Jančić D, Šuković D, Pajović-Šćepanović R. The Impact of Type of Brandy on the Volatile Aroma Compounds and Sensory Properties of Grape Brandy in Montenegro. Molecules. 2022; 27(9):2974. https://doi.org/10.3390/molecules27092974

Chicago/Turabian StyleRaičević, Danijela, Tatjana Popović, Dejan Jančić, Danijela Šuković, and Radmila Pajović-Šćepanović. 2022. "The Impact of Type of Brandy on the Volatile Aroma Compounds and Sensory Properties of Grape Brandy in Montenegro" Molecules 27, no. 9: 2974. https://doi.org/10.3390/molecules27092974