Sustainable Strategy for Algae Biomass Waste Management via Development of Novel Bio-Based Thermoplastic Polyurethane Elastomers Composites

Abstract

:1. Introduction

2. Results and Discussion

2.1. Fourier Transform Infrared Spectroscopy (FT-IR)

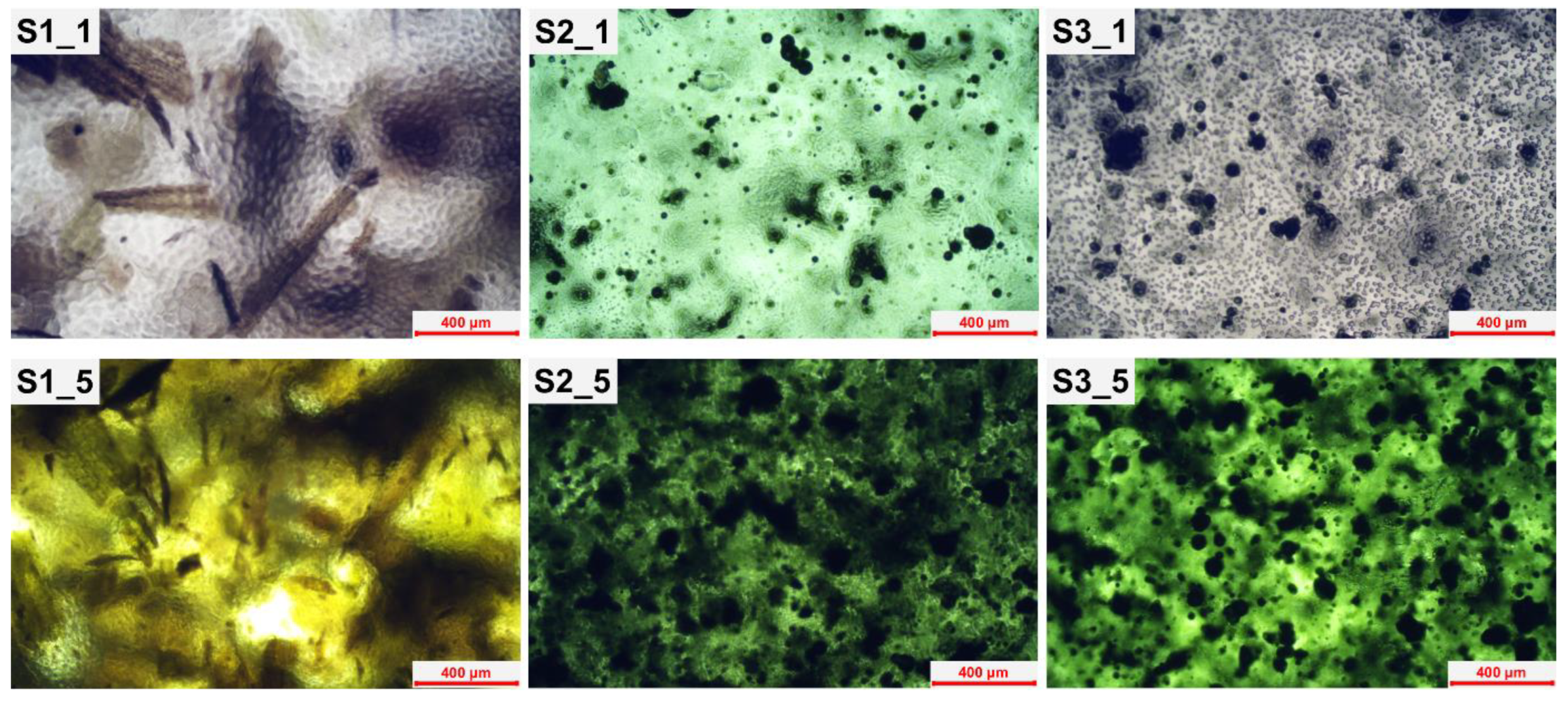

2.2. Optical Microscopy

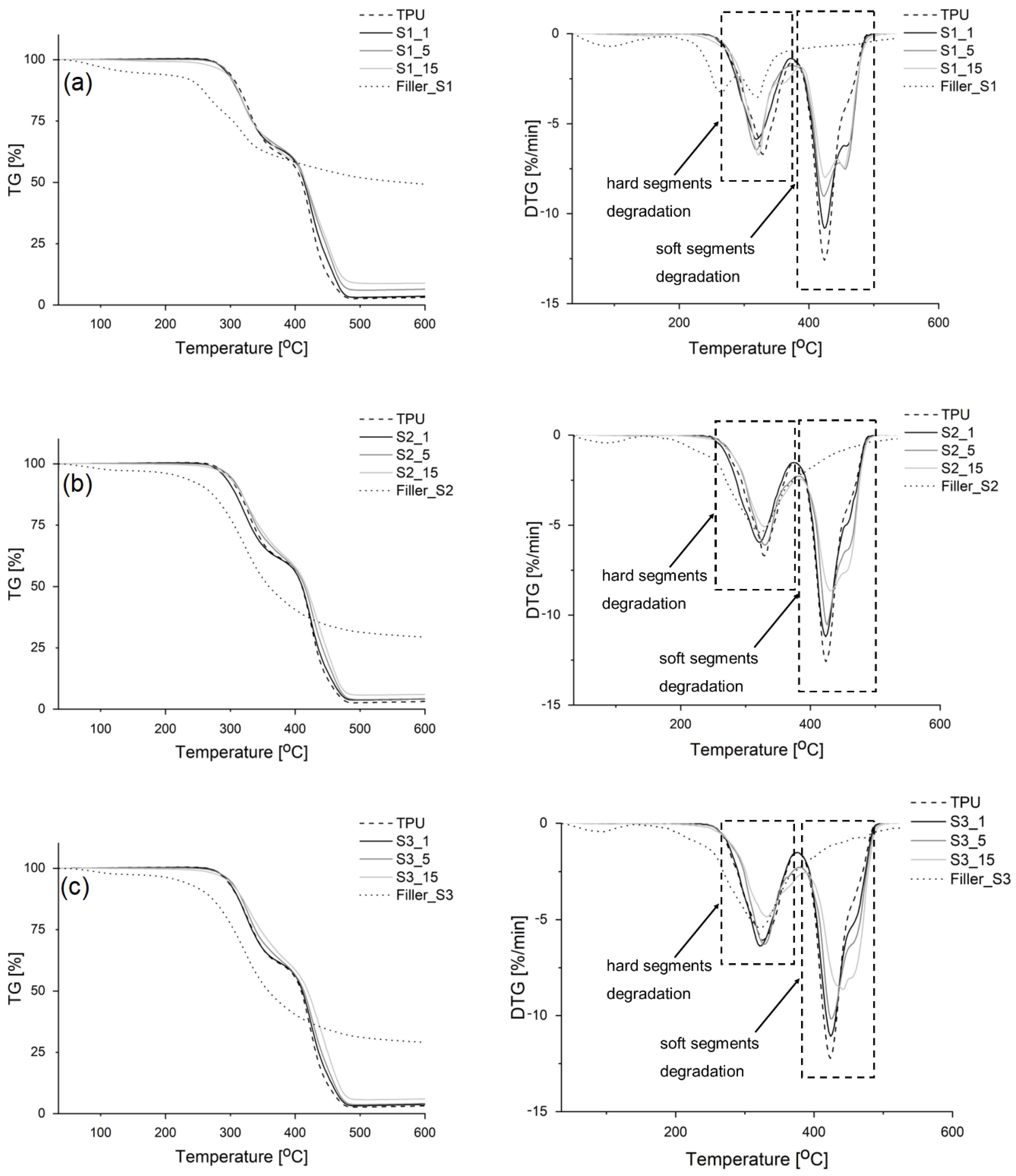

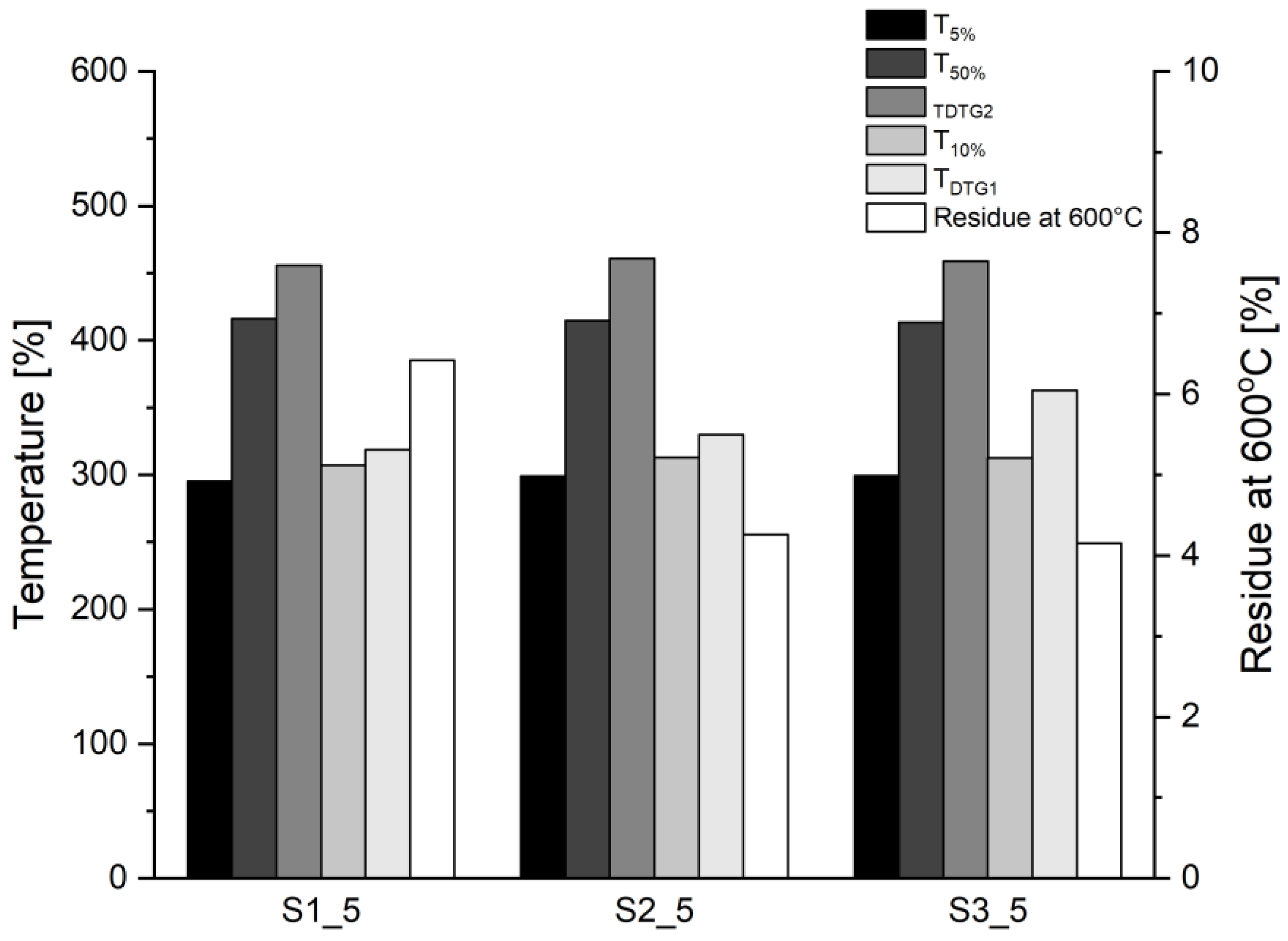

2.3. Thermogravimetry

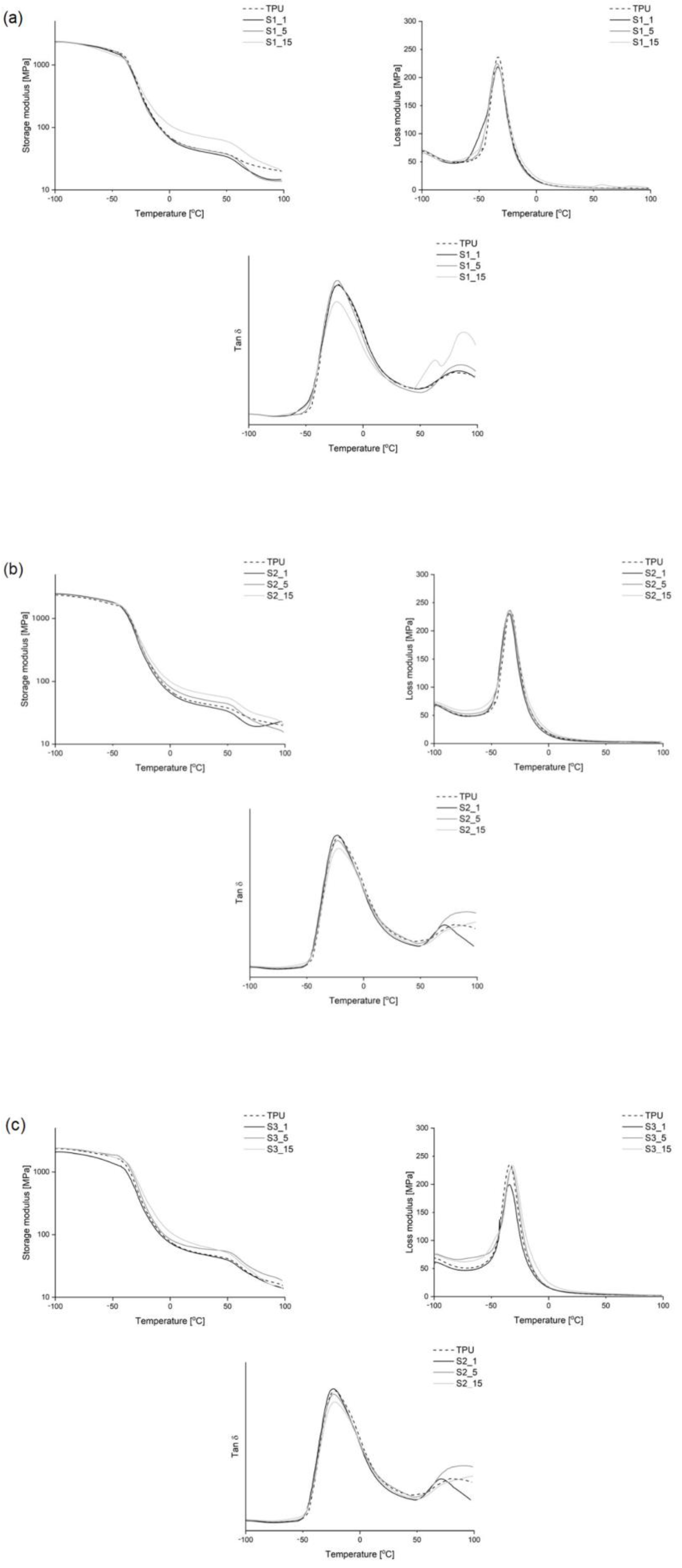

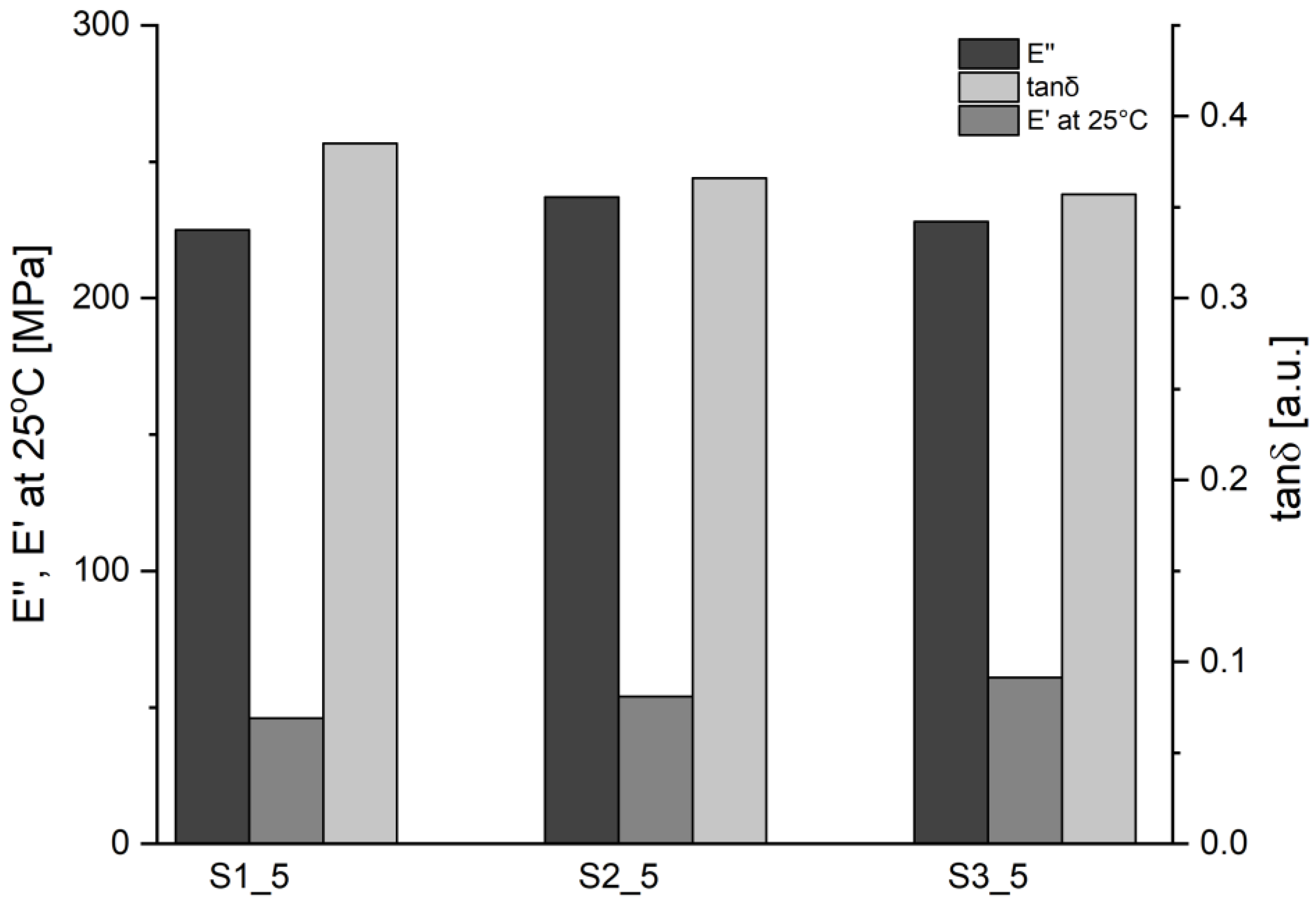

2.4. Dynamic Mechanical Analysis

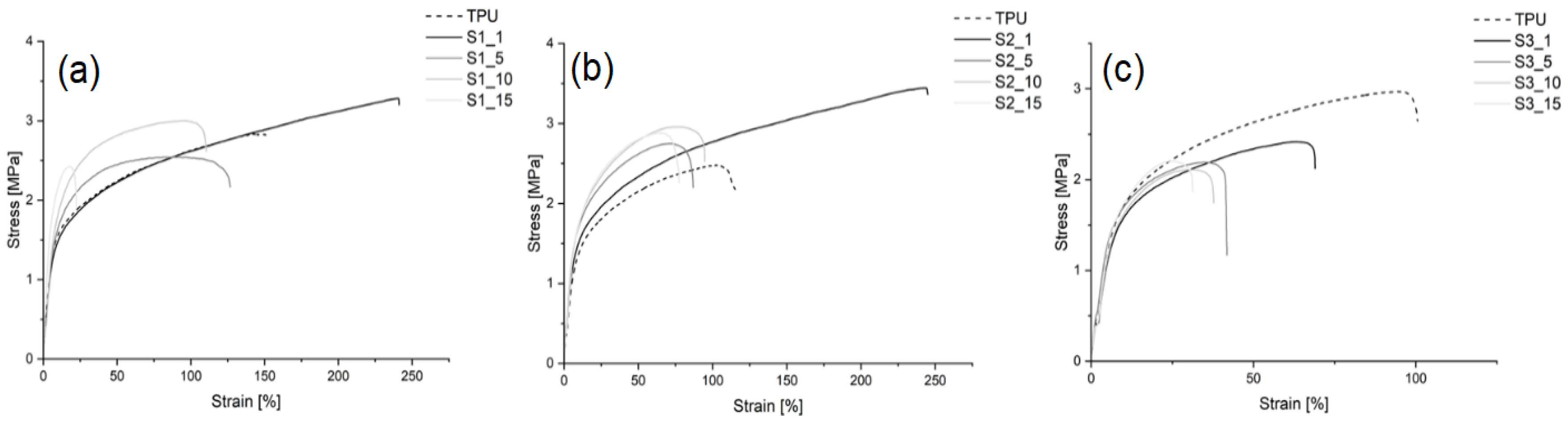

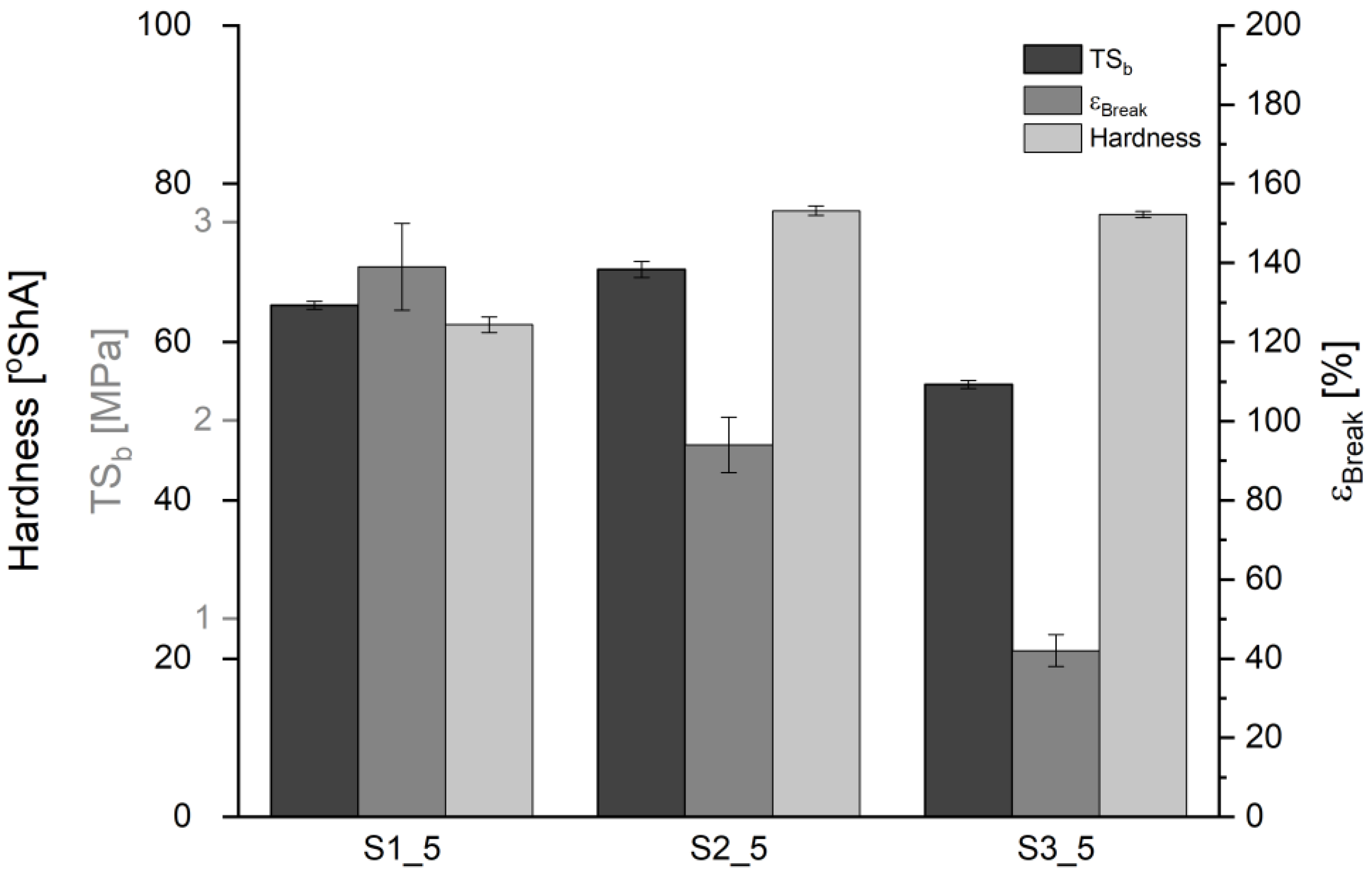

2.5. Tensile Properties and Hardness

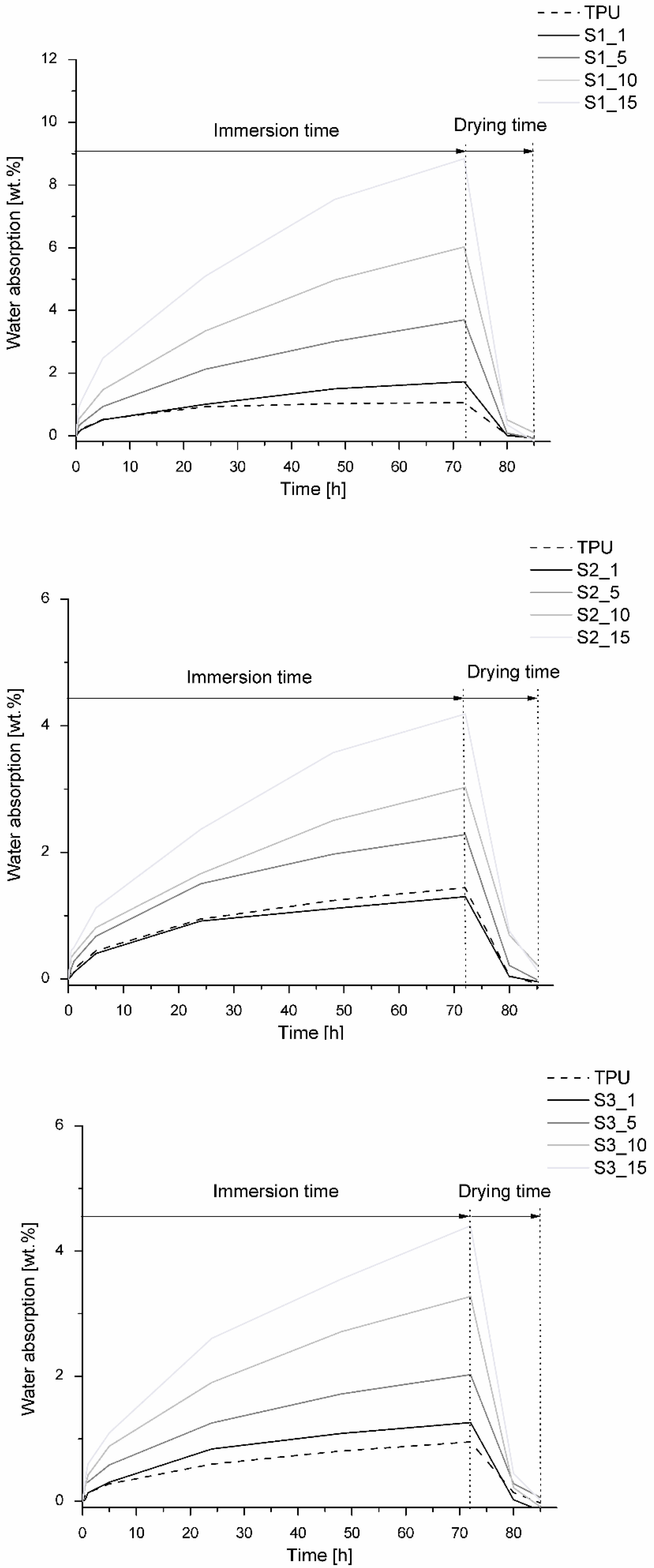

2.6. Water Absorption

3. Materials and Methods

3.1. Materals

3.2. Matrix Preparation

3.3. Composites Preparation

3.4. Characterization of the Bio-Based Composites

3.4.1. Fourier Transform Infrared Spectroscopy (FT-IR)

3.4.2. Optical Microscopy

3.4.3. Thermogravimetry (TGA)

3.4.4. Dynamic Mechanical Analysis (DMA)

3.4.5. Tensile Properties

3.4.6. Hardness

3.4.7. Water Absorption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Plastics—The Facts 2021, An Anal. Eur. Plast. Prod. Demand Waste Data. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 15 November 2022).

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef] [Green Version]

- Abbas, T.; Issa, M.; Ilinca, A. Biomass Cogeneration Technologies: A Review. J. Sustain. Bioenergy Syst. 2020, 10, 101001. [Google Scholar] [CrossRef] [Green Version]

- Azari Marhabi, A.; Arasteh, A.; Paydar, M.M. Sustainable energy development under uncertainty based on the real options theory approach. Int. J. Environ. Sci. Technol. 2022, 19, 5897–5910. [Google Scholar] [CrossRef]

- Zhang, K.; Hamidian, A.; Tubić, A.; Zhang, Y.; Fang, J.; Wu, C.; Lam, P. Understanding plastic degradation and microplastic formation in the environment: A review. Environ. Pollut. 2021, 274, 116554. [Google Scholar] [CrossRef]

- Park, Y.K.; Lee, J. Achievements in the production of bioplastics from microalgae. Phytochem. Rev. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Koçer, A.T.; Özçimen, D. Investigation of the biogas production potential from algal wastes. Waste Manag. Res. 2018, 36, 1100–1105. [Google Scholar] [CrossRef]

- Han, W.; Clarke, W.; Pratt, S. Composting of waste algae: A review. Waste Manag. 2014, 34, 1148–1155. [Google Scholar] [CrossRef]

- Li, R.; Zhang, T.; Zhong, H.; Song, W.; Zhou, Y.; Yin, X. Bioadsorbents from algae residues for heavy metal ions adsorption: Chemical modification, adsorption behaviour and mechanism. Environ. Technol. 2021, 42, 3132–3143. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J.; Filipiak, M.; Mungunkhuyag, K.; Jedynak, P.; Burczyk, J.; Fu, P.; Malec, P. Fast and efficient cadmium biosorption by Chlorella vulgaris K-01 strain: The role of cell walls in metal sequestration. Algal Res. 2021, 60, 102497. [Google Scholar] [CrossRef]

- Chia, W.Y.; Tang, D.Y.Y.; Khoo, K.S.; Lup, A.N.K.; Chew, K.W. Nature’s fight against plastic pollution: Algae for plastic biodegradation and bioplastics production. Environ. Sci. Ecotechnol. 2020, 4, 100065. [Google Scholar] [CrossRef] [PubMed]

- Cinar, S.O.; Chong, Z.K.; Kucuker, M.A.; Wieczorek, N.; Cengiz, U.; Kuchta, K. Bioplastic production from microalgae: A review. Int. J. Environ. Res. Public Health 2020, 17, 3842. [Google Scholar] [CrossRef] [PubMed]

- Rahman, A.; Miller, C.D. Microalgae as a Source of Bioplastics; Elsevier B.V.: Amsterdam, The Netherlands, 2017; ISBN 9780444640413. [Google Scholar]

- Zia, F.; Barikani, M.; Jabeen, F.; Zuber, M.; Zia, K.M.; Khosa, M.K.; Khatri, A. Algae-Based Polyurethane Blends and Composites; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9780128123607. [Google Scholar]

- Drobny, J.G. Handbook of Thermoplastic Elastomers, 2nd ed.; William Andrew: Norwich, NY, USA, 2014; ISBN 9781626239777. [Google Scholar]

- Szycher, M. Szycher’s Handbook of Polyurethanes, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781439839584. [Google Scholar]

- Syed, M.A.; Al Sawafi, M.; Shaik, F.; Nayeemuddin, M. Polyurethane green composites: Synthesize, characterization and treatment of boron present in the oil produced water. Int. J. Eng. Res. Technol. 2020, 13, 1866–1873. [Google Scholar] [CrossRef]

- Syed, M.A.; Al-Shukaili, Z.S.; Shaik, F.; Mohammed, N. Development and Characterization of Algae Based Semi-interpenetrating Polymer Network Composite. Arab. J. Sci. Eng. 2021, 47, 5661–5669. [Google Scholar] [CrossRef]

- Furtwengler, P.; Avérous, L. Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym. Chem. 2018, 9, 4258–4287. [Google Scholar] [CrossRef]

- Phung Hai, T.A.; Neelakantan, N.; Tessman, M.; Sherman, S.D.; Griffin, G.; Pomeroy, R.; Mayfield, S.P.; Burkart, M.D. Flexible polyurethanes, renewable fuels, and flavorings from a microalgae oil waste stream. Green Chem. 2020, 22, 3088–3094. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Wan, X.; Bilić, O.; Zlatanić, A.; Hong, J.; Javni, I.; Ionescu, M.; Milić, J.; Degruson, D. Polyols and polyurethanes from crude algal oil. JAOCS J. Am. Oil Chem. Soc. 2013, 90, 1073–1078. [Google Scholar] [CrossRef]

- Kosmela, P.; Gosz, K.; Kazimierski, P.; Hejna, A.; Haponiuk, J.T.; Piszczyk, Ł. Chemical structures, rheological and physical properties of biopolyols prepared via solvothermal liquefaction of Enteromorpha and Zostera marina biomass. Cellulose 2019, 26, 5893–5912. [Google Scholar] [CrossRef] [Green Version]

- Olejnik, A.; Kosmela, P.; Piszczyk, Ł. Enhancement of PUR/PIR foam thermal stability after addition of Zostera marina biomass component investigated via thermal analysis and isoconversional kinetics. J. Polym. Sci. 2021, 59, 1095–1108. [Google Scholar] [CrossRef]

- Yalcin Duygu, D.; Baykal Özer, T.; Udoh, A.U.; Akbulut, A.; Açikgöz Erkaya, İ.; Yildiz, K.; Guler, D. Fourier transform infrared (FTIR) spectroscopy for identification of Chlorella vulgaris Beijerinck 1890 and Scenedesmus obliquus (Turpin) Kützing 1833. African J. Biotechnol. 2012, 11, 3817–3824. [Google Scholar] [CrossRef]

- Głowińska, E.; Wolak, W.; Datta, J. Eco-friendly Route for Thermoplastic Polyurethane Elastomers with Bio-based Hard Segments Composed of Bio-glycol and Mixtures of Aromatic–Aliphatic and Aliphatic–Aliphatic Diisocyanate. J. Polym. Environ. 2021, 29, 2140–2149. [Google Scholar] [CrossRef]

- Niemczyk, A.; Piegat, A.; Sonseca Olalla, Á.; El Fray, M. New approach to evaluate microphase separation in segmented polyurethanes containing carbonate macrodiol. Eur. Polym. J. 2017, 93, 182–191. [Google Scholar] [CrossRef]

- Barrioni, B.R.; De Carvalho, S.M.; Oréfice, R.L.; De Oliveira, A.A.R.; Pereira, M.D.M. Synthesis and characterization of biodegradable polyurethane films based on HDI with hydrolyzable crosslinked bonds and a homogeneous structure for biomedical applications. Mater. Sci. Eng. C 2015, 52, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Głowińska, E.; Kasprzyk, P.; Datta, J. The green approach to the synthesis of bio-based thermoplastic polyurethane elastomers with partially bio-based hard blocks. Materials 2021, 14, 2334. [Google Scholar] [CrossRef] [PubMed]

- Głowińska, E.; Kasprzyk, P.; Datta, J. Segmented bio-based polyurethane composites containing powdered cellulose obtained from novel bio-based diisocyanate mixtures. Wood Sci. Technol. 2021, 55, 1673–1691. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J.; Zhang, Y. TG-FTIR study on pyrolysis of Enteromorpha prolifera. Biomass Convers. Biorefinery 2018, 8, 151–157. [Google Scholar] [CrossRef]

- Qing, X.; Xiaoqian, M.; Zhaosheng, Y.; Zilin, C.; Changming, L. Decomposition Characteristics and Kinetics of Microalgae in N2 and CO2 Atmospheres by a Thermogravimetry. J. Combust. 2017, 2017, 6160234. [Google Scholar] [CrossRef] [Green Version]

- Figueira, C.E.; Firmino, P.M., Jr.; Giudici, R. Thermogravimetric analysis of the gasification of microalgae Chlorella vulgaris. Bioresour. Technol. 2015, 198, 717–724. [Google Scholar] [CrossRef] [PubMed]

- Gotkiewicz, O. Algi morskie jako źródło komponentów dedykowanych do syntezy i przetwórstwa polimerów. Bechelor’s Thesis, Gdańsk University of Technology, Gdańsk, Poland, 2020. [Google Scholar]

- Kasprzyk, P.; Sadowska, E.; Datta, J. Investigation of Thermoplastic Polyurethanes Synthesized via Two Different Prepolymers. J. Polym. Environ. 2019, 27, 2588–2599. [Google Scholar] [CrossRef] [Green Version]

- Parcheta, P.; Głowińska, E.; Datta, J. Effect of bio-based components on the chemical structure, thermal stability and mechanical properties of green thermoplastic polyurethane elastomers. Eur. Polym. J. 2020, 123, 109422. [Google Scholar] [CrossRef]

- Kimbell, G.; Azad, M.A. 3D printing: Bioinspired materials for drug delivery. In Bioinspired and Biomimetic Materials for Drug Delivery; Nurunnabi, M., Ed.; Woodhead Publishing: New Delhi, India, 2021; pp. 295–318. [Google Scholar]

- Haris, N.I.N.; Hassan, M.Z.; Ilyas, R.A.; Suhot, M.A.; Sapuan, S.M.; Dolah, R.; Mohammad, R.; Asyraf, M.R.M. Dynamic mechanical properties of natural fiber reinforced hybrid polymer composites: A review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Saha, A.; Kumar, S.; Zindani, D. Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym. Compos. 2021, 42, 4497–4516. [Google Scholar] [CrossRef]

- Kumar, S.; Zindani, D.; Bhowmik, S. Investigation of Mechanical and Viscoelastic Properties of Flax- and Ramie-Reinforced Green Composites for Orthopedic Implants. J. Mater. Eng. Perform. 2020, 29, 3161–3171. [Google Scholar] [CrossRef]

- Głowińska, E.; Datta, J.; Włoch, M.; Różańska, M. The influence of chemical structure on mechanical and thermomechanical properties of cast biopolyurethane elastomers. Elastomery 2018, 22, 40–50. [Google Scholar]

- Liu, T.; Butaud, P.; Placet, V.; Ouisse, M. Damping behavior of plant fiber composites: A review. Compos. Struct. 2021, 275, 114392. [Google Scholar] [CrossRef]

- Zaini, M.J.; Fuad, M.Y.A.; Ismail, Z.; Mansor, M.S.; Mustafah, J. The effect of filler content and size on the mechanical properties of polypropylene/oil palm wood flour composites. Polym. Int. 1996, 40, 51–55. [Google Scholar] [CrossRef]

- Głowińska, E.; Datta, J.; Parcheta, P.; Kaźmierczak, N. Novel approaches of using of spirulina platensis in natural rubber based composites. J. Renew. Mater. 2018, 6, 680–687. [Google Scholar] [CrossRef]

- Georgopoulos, S.T.; Tarantili, P.A.; Avgerinos, E.; Andreopoulos, A.G.; Koukios, E.G. Thermoplastic polymers reinforced with fibrous agricultural residues. Polym. Degrad. Stab. 2005, 90, 303–312. [Google Scholar] [CrossRef]

- Kasprzyk, P.; Głowińska, E.; Datta, J. Structure and properties comparison of poly(ether-urethane)s based on nonpetrochemical and petrochemical polyols obtained by solvent free two-step method. Eur. Polym. J. 2021, 157, 110673. [Google Scholar] [CrossRef]

- Meadwell, J.; Paxman-Clarke, L.; Terris, D.; Ford, P. In Search of a Performing Seal: Rethinking the Design of Tight-Fitting Respiratory Protective Equipment Facepieces for Users With Facial Hair. Saf. Health Work 2019, 10, 275–304. [Google Scholar] [CrossRef]

| Series | Code of Sample | T5% (°C) | T10% (°C) | T50% (°C) | TDTG1 (°C) | TDTG2 (°C) | Residue at 600 °C (%) |

|---|---|---|---|---|---|---|---|

| S1 | Filler_S1 | 143.1 | 248.1 | 568.1 | 263.7 | 319.8 | 49.2 |

| TPU | 296.8 | 309.9 | 410.2 | 328.7 | 424.8 | 3.16 | |

| S1_1 | 293.6 | 306.0 | 413.9 | 318.6 | 458.5 | 3.60 | |

| S1_5 | 295.4 | 307.1 | 416.1 | 318.7 | 455.6 | 6.42 | |

| S1_15 | 290.3 | 306.9 | 416.4 | 362.6 | 453.1 | 8.92 | |

| S2 | Filler_S2 | 220.8 | 263.3 | 360.8 | 322.3 | - | 29.5 |

| TPU | 296.8 | 309.9 | 410.2 | 328.9 | 423.9 | 3.16 | |

| S2_1 | 290.4 | 303.4 | 410.7 | 321.3 | 459.2 | 4.15 | |

| S2_5 | 299.1 | 313.0 | 414.7 | 329.8 | 460.9 | 4.26 | |

| S2_15 | 295.4 | 311.7 | 417.1 | 330.2 | 457.2 | 6.04 | |

| S3 | Filler_S3 | 223.5 | 263.6 | 358.6 | 322.2 | - | 29.0 |

| TPU | 294.6 | 307.3 | 409.2 | 326.1 | 422.9 | 3.16 | |

| S3_1 | 295.6 | 307.9 | 410.0 | 322.5 | 459.7 | 3.74 | |

| S3_5 | 299.4 | 312.7 | 413.2 | 362.8 | 458.7 | 4.15 | |

| S3_15 | 295.9 | 312.9 | 419.3 | 363.8 | 456.8 | 6.00 |

| Series | Code of Sample | TgSS (°C) | E’ (MPa) | E’ at 25 °C (MPa) | E” (MPa) | tanδ (-) |

|---|---|---|---|---|---|---|

| S1 | TPU | −25.29 | 2343 | 46 | 236 | 0.375 |

| S1_1 | −25.55 | 2321 | 42 | 219 | 0.372 | |

| S1_5 | −24.84 | 2382 | 46 | 225 | 0.385 | |

| S1_15 | −23.97 | 2326 | 75 | 220 | 0.328 | |

| S2 | TPU | −25.41 | 2351 | 46 | 236 | 0.375 |

| S2_1 | −25.98 | 2488 | 42 | 231 | 0.380 | |

| S2_5 | −25.41 | 2441 | 54 | 237 | 0.366 | |

| S2_15 | −23.31 | 2418 | 67 | 237 | 0.344 | |

| S3 | TPU | −25.29 | 2361 | 51 | 236 | 0.370 |

| S3_1 | −24.76 | 2102 | 50 | 200 | 0.360 | |

| S3_5 | −24.74 | 2406 | 61 | 228 | 0.357 | |

| S3_15 | −24.81 | 2385 | 68 | 234 | 0.330 |

| Series | Code of Sample | TSb (Mpa) | εBreak (%) | Hardness (°ShA) |

|---|---|---|---|---|

| S1 | TPU | 2.85 ± 0.04 | 174 ± 8 | 71.5 ± 0.5 |

| S1_1 | 3.38 ± 0.08 | 243 ± 13 | 71.6 ± 0.5 | |

| S1_5 | 2.58 ± 0.02 | 139 ± 11 | 62.2 ± 1.0 | |

| S1_10 | 2.97 ± 0.06 | 107 ± 11 | 75.8 ± 0.8 | |

| S1_15 | 2.49 ± 0.04 | 27 ± 3 | 72.9 ± 0.6 | |

| S2 | TPU | 2.44 ± 0.04 | 115 ± 7 | 72.8 ± 0.6 |

| S2_1 | 3.54 ± 0.10 | 244 ± 12 | 73.8 ± 0.5 | |

| S2_5 | 2.76 ± 0.04 | 94 ± 7 | 76.6 ± 0.6 | |

| S2_10 | 2.87 ± 0.07 | 109 ± 20 | 78.4 ± 0.3 | |

| S2_15 | 2.89 ± 0.04 | 84 ± 5 | 79.4 ± 0.5 | |

| S3 | TPU | 2.97 ± 0.02 | 111 ± 4 | 73.4 ± 0.9 |

| S3_1 | 2.43 ± 0.02 | 74 ± 4 | 73.5 ± 0.9 | |

| S3_5 | 2.18 ± 0.02 | 42 ± 2 | 76.1 ± 0.4 | |

| S3_10 | 2.14 ± 0.03 | 36 ± 1 | 77.9 ± 0.2 | |

| S3_15 | 2.21 ± 0.05 | 33 ± 1 | 78.4 ± 0.7 |

| Sample Code | Series of Composites | Type of Algae | Algae Content wt.% | Content of the Bio-Components in the Composite |

|---|---|---|---|---|

| TPU | Matrix | - | 0 | 68.7 |

| S1_1 | Series 1 | Blend of seagrass Zostera marina and Enteromorpha | 1 | 69.9 |

| S1_5 | 5 | 71.0 | ||

| S1_10 | 10 | 72.3 | ||

| S1_15 | 15 | 73.5 | ||

| S2_1 | Series 2 | Algae waste based on Chlorella vulgaris after algal oil extraction | 1 | 69.9 |

| S2_5 | 5 | 71.0 | ||

| S2_10 | 10 | 72.3 | ||

| S2_15 | 15 | 73.5 | ||

| S3_1 | Series 3 | Chlorella vulgaris before algal oil extraction (reference filler) | 1 | 69.9 |

| S3_5 | 5 | 71.0 | ||

| S3_10 | 10 | 72.3 | ||

| S3_15 | 15 | 73.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głowińska, E.; Gotkiewicz, O.; Kosmela, P. Sustainable Strategy for Algae Biomass Waste Management via Development of Novel Bio-Based Thermoplastic Polyurethane Elastomers Composites. Molecules 2023, 28, 436. https://doi.org/10.3390/molecules28010436

Głowińska E, Gotkiewicz O, Kosmela P. Sustainable Strategy for Algae Biomass Waste Management via Development of Novel Bio-Based Thermoplastic Polyurethane Elastomers Composites. Molecules. 2023; 28(1):436. https://doi.org/10.3390/molecules28010436

Chicago/Turabian StyleGłowińska, Ewa, Olga Gotkiewicz, and Paulina Kosmela. 2023. "Sustainable Strategy for Algae Biomass Waste Management via Development of Novel Bio-Based Thermoplastic Polyurethane Elastomers Composites" Molecules 28, no. 1: 436. https://doi.org/10.3390/molecules28010436

APA StyleGłowińska, E., Gotkiewicz, O., & Kosmela, P. (2023). Sustainable Strategy for Algae Biomass Waste Management via Development of Novel Bio-Based Thermoplastic Polyurethane Elastomers Composites. Molecules, 28(1), 436. https://doi.org/10.3390/molecules28010436