1. Introduction

The mechanical properties of 2D materials, such as graphene [

1], hexagonal boron nitride [

2], transition metal dichalcogenide [

3] and phosphorene [

4], are crucial for determining their potential applications and performance. These materials have unique mechanical properties, such as proper strength and stiffness [

5,

6], which make them suitable for a wide range of applications, including electronics [

7], energy storage [

8], catalyst [

9], sensors [

10] and magnetic devices [

11]. The mechanical behavior of 2D materials can be influenced by various factors, including their structure [

12], defects [

13] and interfaces with other materials [

14]. Accurately characterizing the mechanical properties of 2D materials is therefore essential for understanding and optimizing their performance in different applications. In particular, the second-order elastic constants (SOECs) tensor [

15], which describes the material’s response to an applied strain, is a key factor in determining the mechanical properties of 2D materials.

The calculation of SOECs and the relevant mechanical properties of 2D materials via first-principles simulation is a tedious and time-consuming task which requires considering different symmetries of materials and configuring efficient computational resources [

16]. Previous research has proposed algorithms and tools, such as ELASTool [

17], MECHELASTIC [

18], ElATools [

19] and vaspkit [

20], to reduce computational complexity and analyze mechanical properties. However, research gaps still exist in the field of calculating and analyzing the mechanical properties of two-dimensional materials. A clear mathematical principle for SOEC calculation of 2D materials is missing, and the presented tools lack the basic functions for task submission, monitoring, and data collection, which are crucial for high-throughput calculations [

21,

22]. Therefore, it is important to present mathematical principles of 2D SOECs calculation and develop an automated tool that can quickly and efficiently calculate and analyze SOECs tensor and other relevant mechanical properties of 2D materials.

In this work, we design mech2d, a highly automated toolkit for the calculation, analysis and visualization of mechanical properties of 2D materials. To be specific, mech2d allows for the calculation of SOECs using both the strain–energy approach and the stress–strain approach, utilizing first-principles engines such as the Vienna ab initio simulation package (VASP) [

23,

24]. The strain-energy approach (SE) concerns calculating the total energy of the system as a quadratic function of strain, while the stress–strain approach (SS) involves calculating the stress as a linear function of strain. Both approaches can be used to evaluate the mechanical properties of 2D materials. Particularly, mech2d supports automatically submitting and collecting tasks from local or remote machines, making it suitable for high-throughput calculations [

21,

22]. This is particularly useful for evaluating the mechanical properties of a large number of 2D materials, as it allows for efficient and robust calculations without the need for manual intervention [

13]. The effectiveness of mech2d has been demonstrated based on the validation on several common 2D materials, including graphene [

1], black phosphorene [

4] and

[

25] et al.

2. Methods

According to the Lagrangian theory of elasticity, solids can be viewed as a homogeneous and isotropic elastic medium [

15]. The fundamental relationship between the physical stress tensor

(in this work, all of the bold font letters present the matrix or vector) and physical strain tensor

of the solid crystalline body within the linear regime is connected by generalized Hook’s law [

15]:

According to the generalized Hook law, it can be found that the physical stress tensor

is a linear function of the physical strain tensor

, where the proportionality coefficient is the forth-rank elastic tensor

. Generally, it is more convenient to use the Lagrangian stress tensor

and Lagrangian strain tensor

; the corresponding generalized Hook law also has a similar formula:

The relationship between Lagrangian stress tensor

and physical stress

tensor is defined as

where,

is the determinant of matrix,

is the

identity matrix and the physical stress tensor

can be calculated by second-order differentiation of the total energy

E:

where

V is the volume of the crystal. The Lagrangian strain tensor

expression is

As a center physical quantity, the elastic tensor

can be approached in many different ways. From an experimental aspect, an elastic tensor can be obtained based on sound velocity with very high precision. From a theoretical aspect, an elastic constant can be calculated by either the energy–strain or stress–strain approach [

26], since most popular DFT engines can calculate energy and stress precisely. According to the Taylor’s series, the total energy

E of a crystal can be expressed as the summation of a power series of the Lagrangian strain

:

where

and

are the energy and volume of the equilibrium structure. By using the Voigt notation (

,

,

,

,

and

), the Equation (

6) can be simplified as

In a similar way, the Equation (

3) can be read as

Therefore, under the strain–energy approach, the elastic constant

can be expressed as

and for the stress–strain approach, the expression is

As for 2D materials, we assume that the crystal lies in the

plane; therefore, all of the elements with a subscript including

z will be zero. To simplify the formula, we may rewrite total energy

E and generalize Hook’s law in matrix format:

and

As can be seen, the maximum number of independent elastic constants of 2D materials has been reduced to 6, compared with their bulk counterpart of

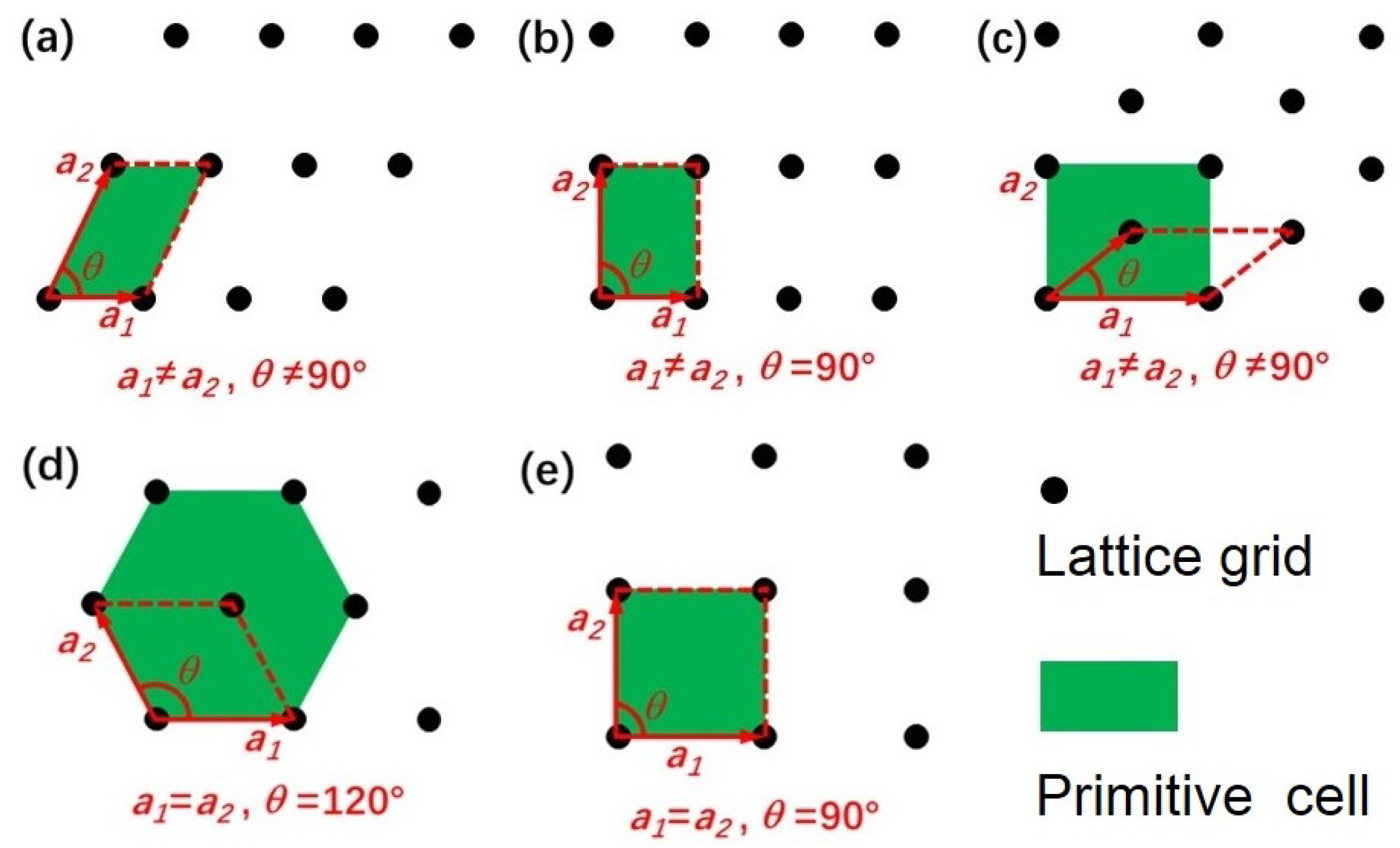

21. Considering that symmetry plays an important role in elastic properties, the number of independent elastic constants of different 2D crystal structure can be further reduced according to their lattice type. Specifically, the independent elastic constants and Born stability conditions for five 2D plan Bravais (see

Figure 1) lattices are listed as follow [

27]:

- (1)

- (2)

- (3)

Rectangular and centered rectangular lattice

- (4)

After the theoretical introduction, we turn our attention to how to calculate elastic constant C via state-of-the-art DFT calculation. Here, we take the square lattice as an example to show how to calculate the independent elastic constant based on the energy–strain approach. It should be noted that the nature of this problem is to solve the linear equation. For the squared lattice, there are 3 independent elastic constants (, and ), which means that we need at least 3 equations to solve this problem.

(1)

Energy–strain approach: By substituting Equation (

14) to Equation (

11), the elastic energy can be written as below:

To simplify the above equation, a set of deformations needs to be applied. The full set of deformation types that are used in mech2d are listed in

Table 1.

As for the square lattice, the required deformation set is

,

and

. When the biaxial strain

is applied, the above Equation can be simplified as

Similarly,

is obtained by using uniaxial strain

:

Moreover,

is calculated by using the shear strain

:

To calculate the elastic constant according to the above equation, a series of deformed structures with different Lagrangian strain (e.g.,

) will be generated and evaluated by DFT engines to calculate the corresponding strain energy

. Then, the quadratic coefficients are determined by polynomial fitting of strain energy and Lagrangian strain. Generally speaking, a 4–6-order polynomial fitting with

= 0.02–0.05 and 9–11 deformed structures is a reasonable setting [

15]. Finally, the second-order elastic constants

can be obtained by solving the system of linear equations which consist Equations (

18)–(

20).

One thing that deserves to be noted is that the Lagrangian strain

for 2D materials is defined as

and the corresponding physical strain

is

Once the Lagrangian strain

is defined, the physical strain

can be solved iteratively. Furthermore, the lattice vector of deformed structure

can be calculated according to the physical strain

and equilibrium lattice vector

by the following equation:

So far, we have presented the energy–strain approach that is used for calculating square lattice 2D materials. For other lattice types, the corresponding deformation type can be found in

Table 2.

(2)

Stress–strain approach: In this part, we take the rectangular lattice as an example to demonstrate how to calculate the independent elastic constant based on the stress–strain approach. For the rectangular lattice, there are 4 independent elastic constants (

,

,

and

), which means that we need at least 4 equations to solve this problem. Similar to the energy–stress approach, by substituting Equation (

14) for Equation (

12), the generalized Hook law can be written as below:

It is obviously that for the given

and

, 3 linear equations can be obtained according to the above matrix equation, which is not enough to calculate the 4 elastic constants. To solve this problem, at least 2 sets of deformations are needed. For the rectangular lattice, the required deformation set is

and

. Therefore, the corresponding equation can be written as

Furthermore, we may rewrite the above equation as

where

The above overdetermined equation can be solved by least square method, namely:

Likewise, a series of deformed structures (by using Equation (

23)) with different Lagrangian strain (e.g.,

) will be generated and evaluated by DFT engines to give the corresponding physical stress

and calculate the Lagrangian stress

by using Equation (

3). Then, the linear coefficients are determined by polynomial fitting of Lagrangian stress and Lagrangian strain. Finally, the second-order elastic constants

can be obtained according to Equation (

28). Similarly, the second-order elastic constants

of other lattice type can be calculated by using the corresponding deformation type, which is listed in

Table 3.

3. Results

3.1. mech2d Design

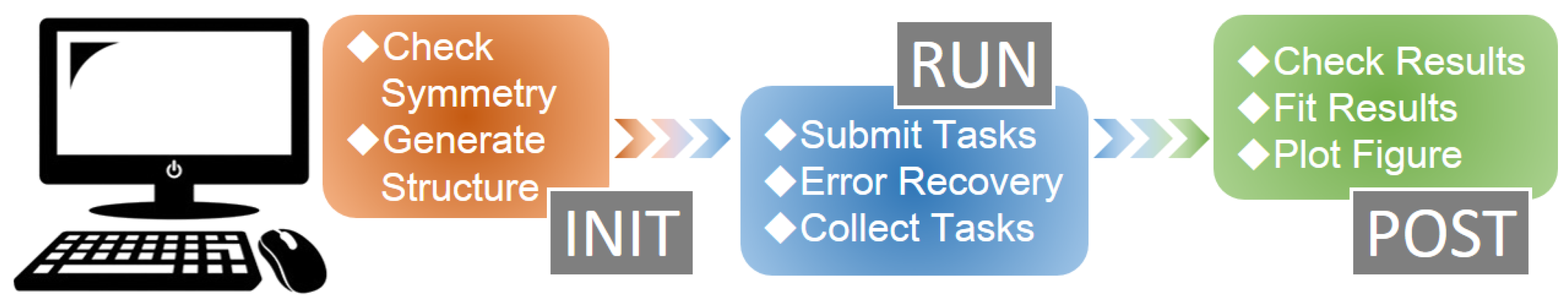

The workflow of the mech2d code is shown in

Figure 2. Implemented with Python, mech2d is designed in a loosely coupled mode, which is considered easy to extend and maintain. Specifically, the workflow of mechanical properties calculation is divided into three stages, including:

init,

run and

post. For the

init stage, the initialization works are carried out. Firstly, the equilibrium crystal structure is read from the configuration file, such as POSCAR, cif, XSF format and so on. Then, the symmetry of the 2D Bravais lattice will be determined. Finally, the deformed structures will be generated according to the required parameters, including number of deformation, maximum strain amplitude, lattice type and calculation approach. In the

run stage, all of the DFT tasks will be submitted to local or remote machine without manually writing the submitting script. As is known, fault tolerance is a key problem for high-throughput calculation. In the mech2d package, the basic errors of VASP during the mechanical properties calculation will be automatically fixed and resubmitted to the server. Once all of the DFT tasks are finished, the calculation results will be collected to working direction from a local or remote machine. In addition, the time-consuming

run stage supports the task to restart. Specifically, tasks that are interrupted for external reasons will be submitted automatically, while the tasks that are already finished or still running will not be submitted. For the

post stage, an internal DFT validator will be used to check the validity of results. Once passed the results checking, the elastic constant or stress–strain curve will be calculated, and the corresponding results will be output to texts and figures. Based on an object-oriented design rule, the mech2d mainly includes four classes, as detailed below.

Elastic class: As the core class of mech2d, the Elastic class is written in mechanics.py file. The Elastic class is used to initialize the mechanical properties calculation, including symmetry detection, Lagrangian strain set selection, Lagrangian strain and physical strain conversion, deformed structure generation and so on. In addition, the postprocessing of mechanical properties calculation is also employed by Elastic class, such as stress–strain fitting and energy–strain fitting.

Calculation class: This class focuses on DFT task initialization, running and result parsing. Three files are included in the calculation subfolder, including

calculator.py,

vasp.py and

runtask.py. The

Calculator class in the

calculator.py file is the base class that defines the basic method that should be implemented in the subclass. The

VASP class in the

vasp.py file is a subclass of

Calculator, which is used to prepare the VASP calculation tasks and to parse the energy and stress from the

vasprun.xml file. As for the

runtask.py file, it contains the

RunTasks class. The

RunTasks class is a wrapper of the open-source code

dpdispatcher, which is part of our previous work [

28] and is used to operate large-scale task management in machine learning potential development. As a key component, the job management framework is employed by

custodian, an open-source code that performs error checking, job management and error recovery.

Analysis class: This class is used to calculate the main mechanical properties of 2D materials, such as , , , , , orientation-dependent Young’s modulus and Poisson’s ratio. In addition, the Born stability condition will be calculated according to the lattice type.

Plot class: This class is responsible for data visualization, including energy–stress fitting curve, stress–strain fitting curve, stress–strain curve under tensile strength and the polar plot of orientation-dependent Young’s modulus and Poisson’s ratio.

This main features of mech2d are listed below:

- (1)

Easy to install (see below).

- (2)

Loosely coupled mode, which is considered easy to extend and maintain.

- (3)

Support for any symmetry of 2D materials.

- (4)

Support for the popular DFT engine VASP. It can be easily extended to other DFT calculators by implementing the corresponding input writer and output parser.

- (5)

Automatical task submission, error correction and collection on both local or remote machines.

3.2. Installation

Developed by python, the simplest way to install the mech2d is using pip. The mech2d code can be installed by downloading and decompressing the code and then running the following command “pip install.” in the source code directory. One thing that deserves to be noted is that three necessary libraries should first be installed, which include the following:

pymatgen.

dpdispatcher.

custodian.

3.3. Running the Code

mech2d provides a user-friendly interface, which can be started via a single line of command. For example, the help information can be obtained by the following command (more details see in the

Appendix A and

Appendix B).

m2d -h

usage: m2d [-h] [-v] {init,run,post} …

Desctiption:

------------

mech2d is a convenient script that use to calculate the mechanical

properties of 2D materials, including Stress-Strain Curve, elastic

constants and relevant properties. The script works based on

several subcommands with their own options. To see the options

for the subcommands, type ‘‘m2d subcommand -h’’.

positional arguments:

{init,run,post}

init Generating initial data for elastic systems.

run Run the DFT calculation for deformed

structures.

post Postprocessing for elastic calculation.

optional arguments:

-h, --help show this help message and exit

-v, --version Display version

The initialization of the calculation of elastic constant calculation by using the stress–strain approach can be specified by the following command:

After running the above command, the corresponding deformed structures will be generated in the elc_stress folder.

To run the DFT calculations, the following command can be used:

Here, the

input.yaml parameter specifies the input file name. In this file, the machine used to conduct the calculation, the queue system of the machine, the resources of hardware information and DFT code input information are supplied. An example of

input.yaml is supplied in the

Appendix A and

Appendix B.

To postprocess the mechanical properties calculation, the following command can be used:

Then the elastic constant will be calculated and orientation-dependent Young’s modulus and Poisson’s ratio will be plotted. As an example, we show the direction-dependent Young’s modulus and Poisson’s ratio of

in

Figure 3, which is consistent with previous work [

25].

3.4. Examples

In this section, we present some results of mechanical properties of some typical 2D materials calculated by our mech2d code. There are six test cases in this work, including graphene,

, penta-graphene,

, black phosphorene and

. The energies and stresses are calculated by the VASP software package [

23,

24]. The generalized gradient approximation (GGA) of Perdew, Burke and Ernzerhof (PBE) exchange correlation functional [

29] and plane wave basis set are used to describe the valence electrons, with the cutoff set to 520 eV [

30]. The energy convergence criteria for static calculation is set to be

eV. The geometry optimization is converged when the force on each atom is smaller than 1 ×

eV

.

Table 4 shows the calculation details for these cases in the present work.

Table 5 presents the in-plane elastic constants of various 2D materials, including graphene,

, penta-graphene,

, alpha-phosphorene and

. The calculation results suggest that the values for the elastic constants reported in this work are consistent with previous studies. For example, in graphene, the values for

and

reported in this work are in good agreement with those reported in refs. [

20,

25,

31,

32,

33,

34,

35]. One thing that deserves to be noted is that there are slight differences in value between our work and references, which may be due to differences in simulation accuracy and methods. Overall, the values for the elastic constants reported in this work are in agreement with previous studies, validating this work.