Electroactive Microorganisms in Advanced Energy Technologies

Abstract

1. Introduction

2. Electrocatalytic Systems

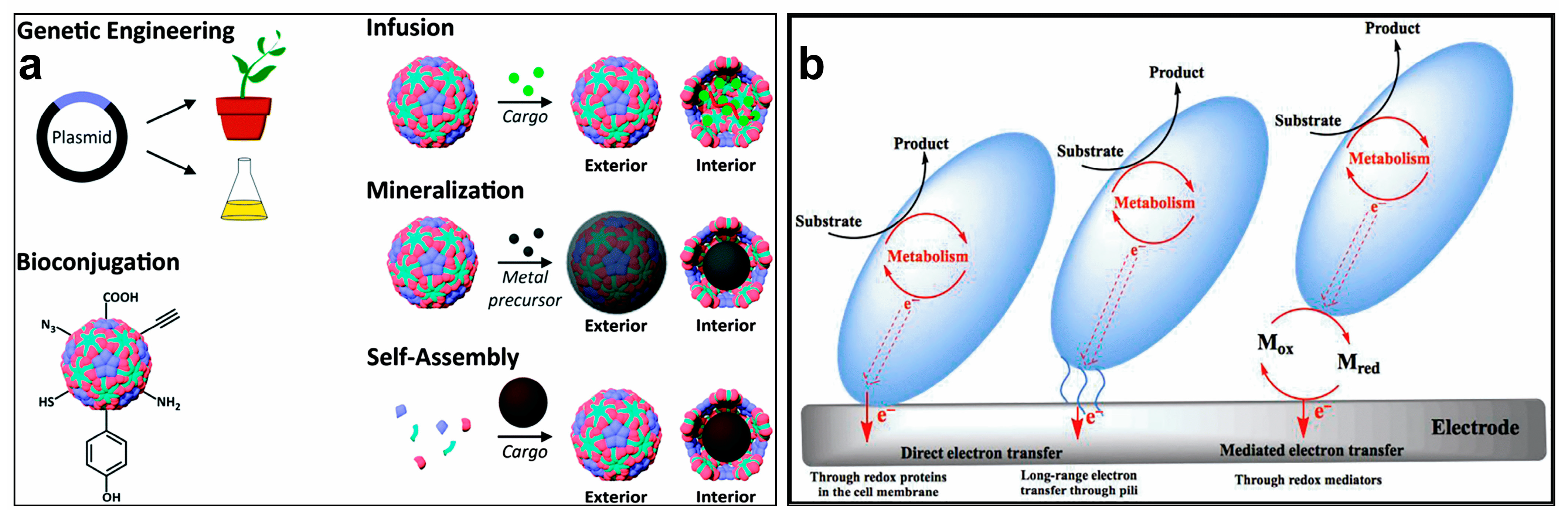

2.1. Microbial Properties in Electrocatalytic Systems

2.2. Electroactive Microorganisms in Electrocatalysis

3. Microbial Sensors

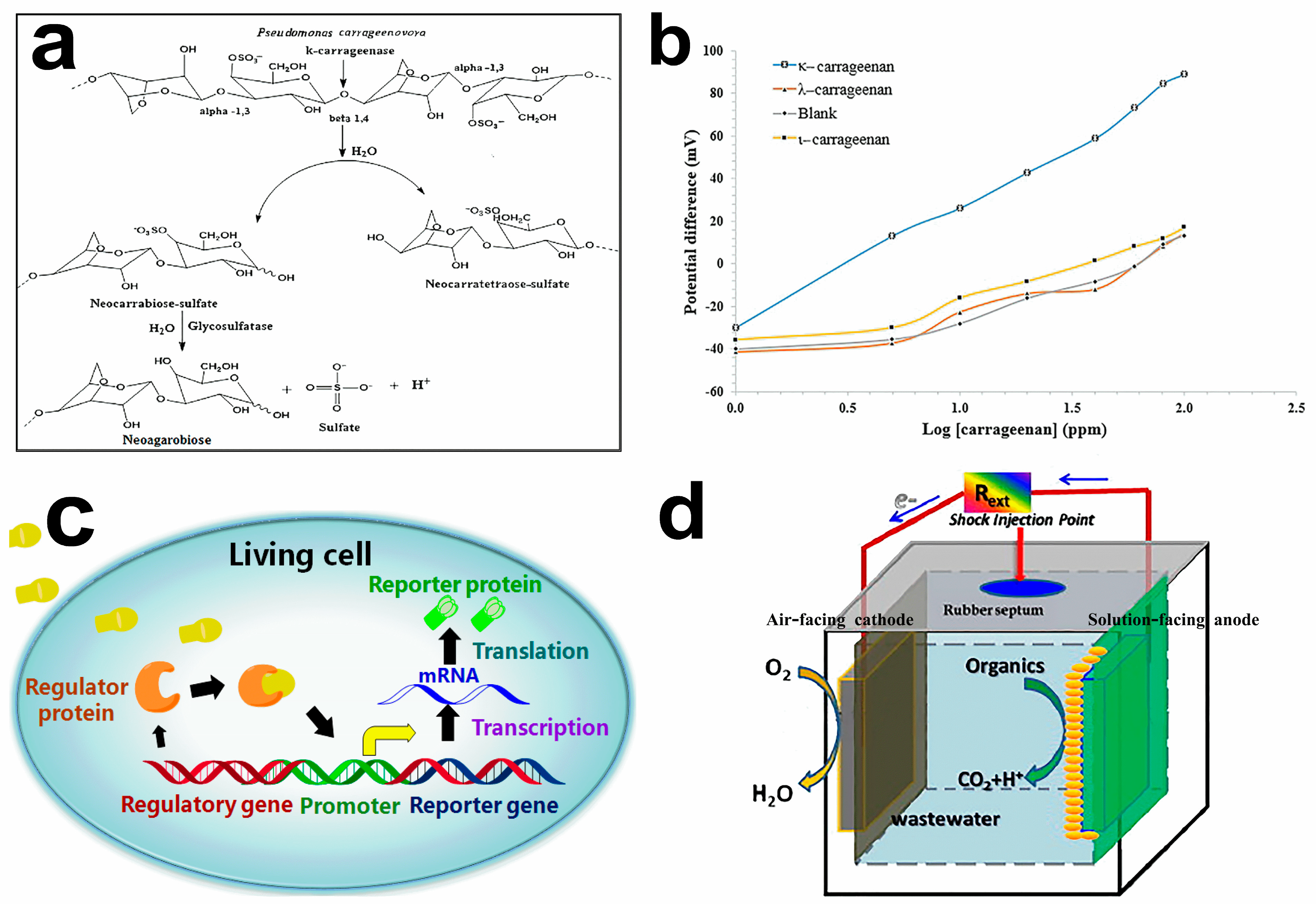

3.1. Microbial Properties in Microbial Sensors

3.2. Electroactive Microorganisms in Microbial Sensors

4. Power Generation Devices

4.1. Microbial Properties in Power Generation Devices

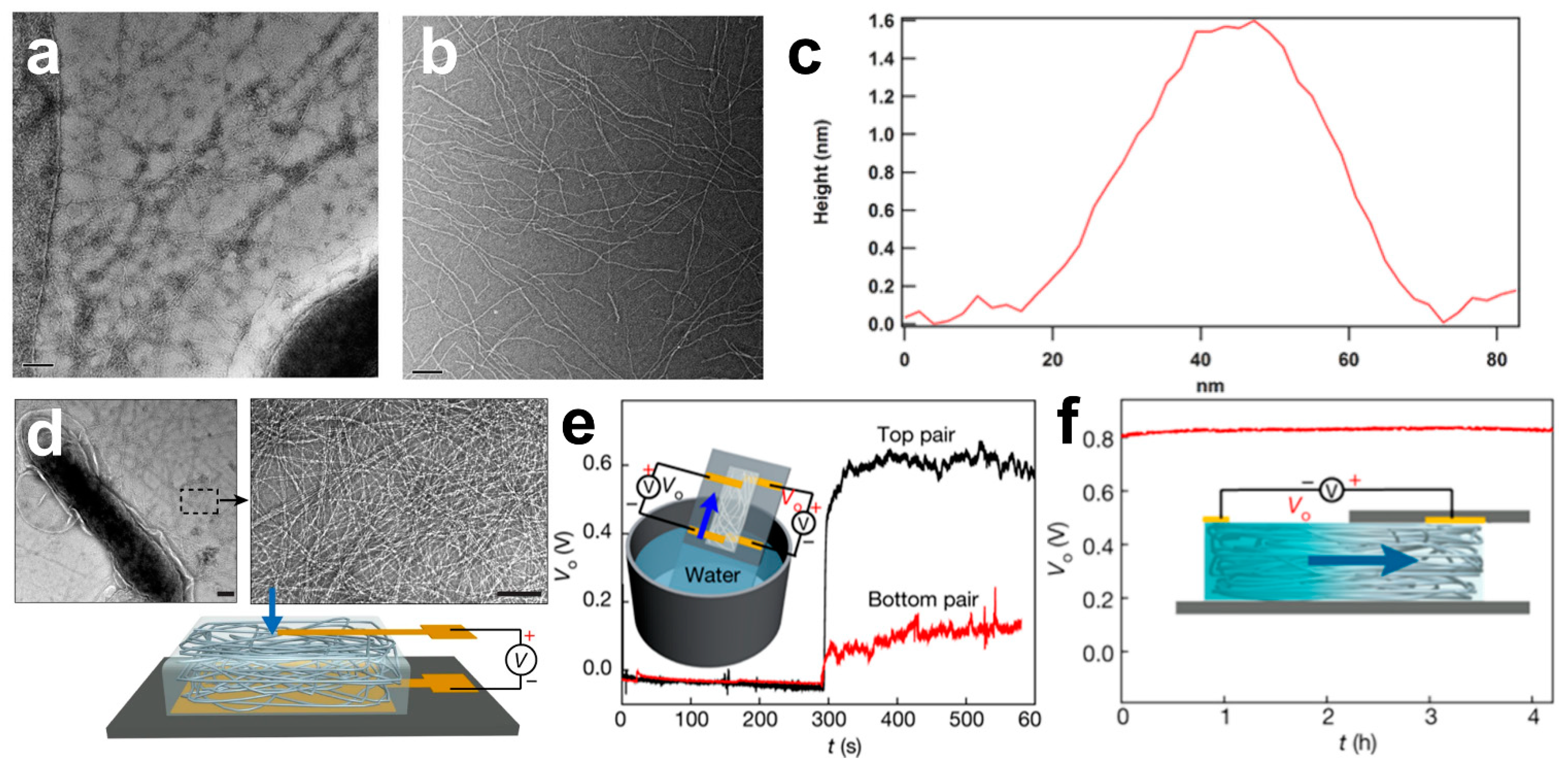

4.2. Electroactive Microorganisms in Protein Nanowires

4.3. Electroactive Microorganisms in Lithium Batteries

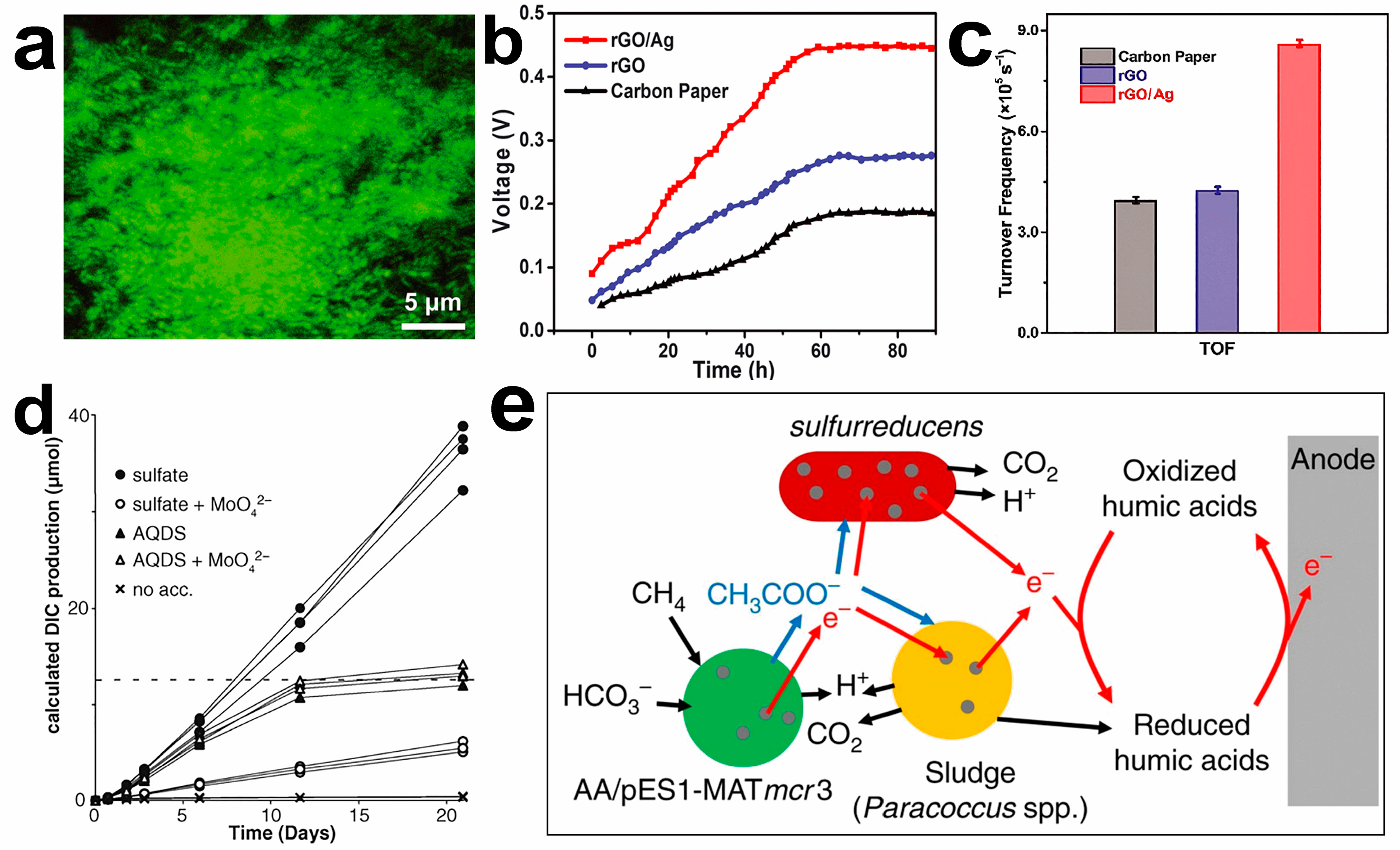

4.4. Electroactive Microorganisms in MFCs

5. Outlook and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, F.Y.; Zhai, L.L.; Liu, Q.Q.; Yu, J.Y.; Lau, S.P.; Xia, B.Y.; Xu, Z.L. Emerging catalytic materials for practical lithium-sulfur batteries. J. Energy Chem. 2023, 76, 127–145. [Google Scholar] [CrossRef]

- Shen, T.; Wang, S.; Zhao, T.; Hu, Y.; Wang, D. Recent advances of single-atom-alloy for energy electrocatalysis. Adv. Energy Mater. 2022, 12, 2201823. [Google Scholar] [CrossRef]

- Yang, H.; Dong, C.L.; Wang, H.M.; Qi, R.J.; Gong, L.Q.; Lu, Y.R.; He, C.H.; Chen, S.H.; You, B.; Liu, H.F.; et al. Constructing nickel-iron oxyhydroxides integrated with iron oxides by microorganism corrosion for oxygen evolution. Proc. Natl. Acad. Sci. USA 2022, 119, e2202812119. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.Y.; Wu, Y.L.; Xu, K.Q.; Jiang, L.P.; Sun, J.K.; Cai, G.Y.; Li, G.F.; Xia, B.Y.; Liu, H.F. Hierarchical oriented metal-organic frameworks assemblies for water-evaporation induced electricity generation. Adv. Funct. Mater. 2021, 31, 2104732. [Google Scholar] [CrossRef]

- Chen, C.; Tian, H.; Fu, Z.Q.; Cui, X.Z.; Kong, F.T.; Meng, G.; Chen, Y.F.; Qi, F.G.; Chang, Z.W.; Zhu, L.B.; et al. Pt NPs-loaded siloxene nanosheets for hydrogen co-evolutions from Zn-H2O fuel cells-powered water-splitting. Appl. Catal. B—Environ. 2022, 304, 121008. [Google Scholar] [CrossRef]

- Luo, H.; Barrio, J.; Sunny, N.; Li, A.; Steier, L.; Shah, N.; Stephens, I.E.L.; Titirici, M.M. Progress and perspectives in photo-and electrochemical-oxidation of biomass for sustainable chemicals and hydrogen production. Adv. Energy Mater. 2021, 11, 2101180. [Google Scholar] [CrossRef]

- Yang, H.; Hu, H.L.; Xia, B.Y. Progress on nanostructured gel catalysts for oxygen electrocatalysis. Nano Res. 2022, 15, 10343–10356. [Google Scholar] [CrossRef]

- Hu, H.L.; Chen, Y.N.; You, F.; Yao, J.L.; Yang, H.; Jiang, X.L.; Xia, B.Y. Recycling and upgrading utilization of polymer plastics. Chin. J. Chem. 2023, 41, 469–480. [Google Scholar] [CrossRef]

- Fu, G.T.; Xia, B.Y.; Ma, R.G.; Chen, Y.; Tang, Y.W.; Lee, J.M. Trimetallic PtAgCu@PtCu core@shell concave nanooctahedrons with enhanced activity for formic acid oxidation reaction. Nano Energy 2015, 12, 824–832. [Google Scholar] [CrossRef]

- Zhang, J.Y.; He, T.; Wang, M.D.; Qi, R.J.; Yan, Y.; Dong, Z.H.; Liu, H.F.; Wang, H.M.; Xia, B.Y. Energy-saving hydrogen production coupling urea oxidation over a bifunctional nickel-molybdenum nanotube array. Nano Energy 2019, 60, 894–902. [Google Scholar] [CrossRef]

- Xie, S.; Sun, B.W.; Sun, H.; Zhan, K.; Zhao, B.; Yan, Y.; Xia, B.Y. Engineering of molybdenum sulfide nanostructures towards efficient electrocatalytic hydrogen evolution. Int. J. Hydrogen Energ. 2019, 44, 15009–15016. [Google Scholar] [CrossRef]

- Li, Z.; Yan, Y.; Xu, S.M.; Zhou, H.; Xu, M.; Ma, L.; Shao, M.; Kong, X.; Wang, B.; Zheng, L.; et al. Alcohols electrooxidation coupled with H2 production at high current densities promoted by a cooperative catalyst. Nat. Commun. 2022, 13, 147. [Google Scholar] [CrossRef] [PubMed]

- Abi, A.; Mohammadpour, Z.; Zuo, X.; Safavi, A. Nucleic acid-based electrochemical nanobiosensors. Biosens. Bioelectron. 2018, 102, 479–489. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.L.; Chen, Y.N.; Zhang, X.; You, F.; Yao, J.L.; Yang, H.; Xia, B.Y. Magnetic field-assisted construction and enhancement of electrocatalysts. Chem. Sus. Chem. 2022, 15, e202201551. [Google Scholar] [CrossRef]

- Yang, X.X.; Deng, P.L.; Liu, D.Y.; Zhao, S.; Li, D.; Wu, H.; Ma, Y.M.; Xia, B.Y.; Li, M.T.; Xiao, C.H.; et al. Partial sulfuration-induced defect and interface tailoring on bismuth oxide for promoting electrocatalytic CO2 reduction. J. Mater. Chem. A 2020, 8, 2472–2480. [Google Scholar] [CrossRef]

- Santovito, E.; Elisseeva, S.; Smyth, C.; Cruz-Romero, M.; Kerry, J.P.; Duffy, G.; Papkovsky, D.B. A sensor-based system for rapid on-site testing of microbial contamination in meat samples and carcasses. J. Appl. Microbiol. 2022, 132, 1210–1220. [Google Scholar] [CrossRef]

- Shi, Z.; Wu, X.; Zou, Z.; Yu, L.; Hu, F.; Li, Y.; Guo, C.; Li, C.M. Screen-printed analytical strip constructed with bacteria-templated porous N-doped carbon nanorods/Au nanoparticles for sensitive electrochemical detection of dopamine molecules. Biosens. Bioelectron. 2021, 186, 113303. [Google Scholar] [CrossRef]

- Ozden, S.; Macwan, I.G.; Owuor, P.S.; Kosolwattana, S.; Autreto, P.A.S.; Silwal, S.; Vajtai, R.; Tiwary, C.S.; Patra, P.K.; Ajayan, P.M. Bacteria as bio-template for 3D carbon nanotube architectures. Sci. Rep. 2017, 7, 9855. [Google Scholar] [CrossRef]

- Wei, X.; Li, Y.; Chen, L.; Shi, J. Formic acid electro-synthesis by concurrent cathodic CO2 reduction and anodic CH3OH oxidation. Angew. Chem. Int. Ed. 2021, 60, 3148–3155. [Google Scholar] [CrossRef]

- Yu, J.; Yu, W.; Chang, B.; Li, X.; Jia, J.; Wang, D.; Xu, Z.; Zhang, X.; Liu, H.; Zhou, W. Waste-yeast biomass as nitrogen/phosphorus sources and carbon template: Environment-friendly synthesis of N, P-Mo2C nanoparticles on porous carbon matrix for efficient hydrogen evolution. Chin. Chem. Lett. 2022, 33, 3231–3235. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, Y.; Hong, Z.; Cai, K.; Zhao, F.; Han, H. Microbial synthesis of highly dispersed PdAu alloy for enhanced electrocatalysis. Sci. Adv. 2016, 2, e1600858. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zhou, H.; Liao, H.; Tan, P.; Tian, W.; Pan, J. Microbial synthesis of efficient palladium electrocatalyst with high loadings for oxygen reduction reaction in acidic medium. J. Colloid Interf. Sci. 2022, 611, 161–171. [Google Scholar] [CrossRef]

- Yu, J.; Chang, B.; Yu, W.; Li, X.; Wang, D.; Xu, Z.; Zhang, X.; Liu, H.; Zhou, W. Chromium phosphide nanoparticles embedded in porous nitrogen-/phosphorus-doped carbon as efficient electrocatalysts for a nitrogen reduction reaction. Carbon Energy 2022, 4, 237–245. [Google Scholar] [CrossRef]

- Cao, J.; Sun, Z.; Li, J.; Zhu, Y.; Yuan, Z.; Zhang, Y.; Li, D.; Wang, L.; Han, W. Microbe-assisted assembly of Ti3C2Tx MXene on fungi-derived nanoribbon heterostructures for ultrastable sodium and potassium ion storage. ACS Nano 2021, 15, 3423–3433. [Google Scholar] [CrossRef]

- Dong, J.; Fernández-Fueyo, E.; Hollmann, F.; Paul, C.E.; Pesic, M.; Schmidt, S.; Wang, Y.; Younes, S.; Zhang, W. Biocatalytic oxidation reactions: A chemist’s perspective. Angew. Chem. Int. Ed. 2018, 57, 9238–9261. [Google Scholar] [CrossRef]

- Evans, R.M.; Siritanaratkul, B.; Megarity, C.F.; Pandey, K.; Esterle, T.F.; Badiani, S.; Armstrong, F.A. The value of enzymes in solar fuels research–efficient electrocatalysts through evolution. Chem. Soc. Rev. 2019, 48, 2039–2052. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Müller, B.; Kirkeby, T.Ø.; Kara, S.; Loderer, C. Development of a thioredoxin-based cofactor regeneration system for NADPH-dependent oxidoreductases. Chem. Cat. Chem. 2022, 14, e202101625. [Google Scholar] [CrossRef]

- Feng, X.; Qin, S.; Zhang, D.; Chen, P.; Hu, J.; Wang, G.; Liu, Y.; Wei, B.; Li, Q.; Yang, Y.; et al. Nitrogen input enhances microbial carbon use efficiency by altering plant-microbe-mineral interactions. Glob. Chang. Biol. 2022, 28, 4845–4860. [Google Scholar] [CrossRef]

- He, K.; Li, W.; Tang, L.; Li, W.; Lv, S.; Xing, D. Suppressing methane production to boost high-purity hydrogen production in microbial electrolysis cells. Environ. Sci. Technol. 2022, 56, 11931–11951. [Google Scholar] [CrossRef]

- Yao, H.; Wang, X.; Li, K.; Li, C.; Zhang, C.; Zhou, J.; Cao, Z.; Wang, H.; Gu, M.; Huang, M.; et al. Strong electronic coupling between ruthenium single atoms and ultrafine nanoclusters enables economical and effective hydrogen production. Appl. Catal. B 2022, 312, 121378. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, H.U.; Chae, T.U.; Cho, J.S.; Kim, J.W.; Shin, J.H.; Kim, D.I.; Ko, Y.S.; Jang, W.D.; Jang, Y.S. A comprehensive metabolic map for production of bio-based chemicals. Nat. Catal. 2019, 2, 18–33. [Google Scholar] [CrossRef]

- Montaño López, J.; Duran, L.; Avalos, J.L. Physiological limitations and opportunities in microbial metabolic engineering. Nat. Rev. Microbiol. 2022, 20, 35–48. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Bonné, R.; Zhang, Y.; Wang, A.; Liu, W. Renewable energy driving microbial electrochemistry toward carbon neutral. Sustain. Horiz. 2022, 4, 100031. [Google Scholar] [CrossRef]

- Ter Heijne, A. Bioelectrochemistry for flexible control of biological processes. Environ. Sci. Ecotechnol. 2020, 1, 100011. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Fan, B.; Ying, L.; Li, N.; Brabec, C.J.; Huang, F.; Cao, Y. Recent progress in thick-film organic photovoltaic devices: Materials, devices, and processing. Sus. Mat. 2021, 23, 4–23. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, K.; Sun, Y. Upgrading CO2 into acetate on Bi2O3@carbon felt integrated electrode via coupling electrocatalysis with microbial synthesis. Sus. Mat. 2023, 3, 235–247. [Google Scholar] [CrossRef]

- Roy, S.; Pandit, S. 1.2-Microbial electrochemical system: Principles and application. In Microbial Electrochemical Technology; Mohan, S.V., Varjani, S., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 19–48. [Google Scholar]

- Zhang, L.; Yuan, S.M.; Yang, L.M.; Fang, Z.; Zhao, G.C. An enzymatic glucose biosensor based on a glassy carbon electrode modified with manganese dioxide nanowires. Microchim. Acta 2013, 180, 627–633. [Google Scholar] [CrossRef]

- Mitrova, B.; Waffo, A.F.T.; Kaufmann, P.; Iobbi-Nivol, C.; Leimkühler, S.; Wollenberger, U. Trimethylamine N-oxide electrochemical biosensor with a Chimeric Enzyme. Chem. Electro. Chem. 2018, 6, 1732–1737. [Google Scholar] [CrossRef]

- Chen, H.; Simoska, O.; Lim, K.; Grattieri, M.; Yuan, M.; Dong, F.; Lee, Y.S.; Beaver, K.; Weliwatte, S.; Gaffney, E.M.; et al. Fundamentals, applications, and future directions of bioelectrocatalysis. Chem. Rev. 2020, 120, 12903–12993. [Google Scholar] [CrossRef]

- Zou, L.; Qiao, Y.; Li, C.M. Boosting microbial electrocatalytic kinetics for high power fensity: Insights into synthetic biology and advanced nanoscience. Electrochem. Energy R. 2018, 1, 567–598. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, S.; Wu, P.; Cai, C.J.A.C. Detection of glucose based on direct electron transfer reaction of glucose oxidase immobilized on highly ordered polyaniline nanotubes. Anal. Chem. 2009, 81, 1638–1645. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.H.; Cheon, D.S.; Liu, F.; Lee, K.B.; Seo, T.S. A graphene oxide based immuno-biosensor for pathogen detection. Angew. Chem. Int. Ed. 2010, 49, 5708–5711. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Du, M.; Wang, C.; Xie, X.; Wang, H.; Zhang, Q. Advances in airborne microorganisms detection using biosensors: A critical review. Front. Environ. Sci. Eng. 2021, 15, 47. [Google Scholar] [CrossRef] [PubMed]

- Klein, R.D.; Hultgren, S.J. Urinary tract infections: Microbial pathogenesis, host-pathogen interactions and new treatment strategies. Nat. Rev. Microbiol. 2020, 18, 211–226. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Xie, G.; Zhang, X.; Yuan, J.; Hou, Y.; Chen, H. Fast detection of E. coli with a novel fluorescent biosensor based on a FRET system between UCNPs and GO@Fe3O4 in urine specimens. Anal. Methods 2021, 13, 2209–2214. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Rossi, R.; Ragab, A.; Saikaly, P.E. Electroactive microorganisms in bioelectrochemical systems. Nat. Rev. Microbiol. 2019, 17, 307–319. [Google Scholar] [CrossRef]

- Wen, A.M.; Steinmetz, N.F. Design of virus-based nanomaterials for medicine, biotechnology, and energy. Chem. Soc. Rev. 2016, 45, 4074–4126. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.N.; Cui, X.S.; Tae, J.C.; Jin, Y.X.; Kim, N.H. DNA synthesis and epigenetic modification during mouse oocyte fertilization by human or hamster sperm injection. J. Assist. Reprod. Genet. 2011, 28, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Yuan, X.; Wang, C.; Shao, X.; Yang, B.; Abdul Razzaq, A.; Zhao, X.; Lian, Y.; Deng, Z.; Chen, M.; et al. Self-phosphorization of MOF-armored microbes for advanced energy storage. Small 2020, 16, 6060–6093. [Google Scholar] [CrossRef]

- Wang, X.; Pu, J.; Liu, Y.; Ba, F.; Cui, M.; Li, K.; Xie, Y.; Nie, Y.; Mi, Q.; Li, T.; et al. Immobilization of functional nano-objects in living engineered bacterial biofilms for catalytic applications. Nat. Sci. Rev. 2019, 6, 929–943. [Google Scholar] [CrossRef]

- Kalathil, S.; Katuri, K.P.; Alazmi, A.S.; Pedireddy, S.; Kornienko, N.; Costa, P.M.F.J.; Saikaly, P.E. Bioinspired synthesis of reduced graphene oxide-wrapped Geobacter sulfurreducens as a hybrid electrocatalyst for efficient oxygen evolution reaction. Chem. Mater. 2019, 31, 3686–3693. [Google Scholar] [CrossRef]

- Hou, G.; Jia, X.; Kang, H.; Qiao, X.; Liu, Y.; Li, Y.; Wu, X.; Qin, W. CoNi nano-alloys modified yolk-shell structure carbon cage via Saccharomycetes as carbon template for efficient oxygen evolution reaction. Appl. Catal. B 2022, 315, 121551. [Google Scholar] [CrossRef]

- Pankratova, G.; Hederstedt, L.; Gorton, L. Extracellular electron transfer features of Gram-positive bacteria. Analytica Chimica Acta. 2019, 1076, 32–47. [Google Scholar] [CrossRef] [PubMed]

- Thapa, B.S.; Kim, T.; Pandit, S.; Song, Y.E.; Afsharian, Y.P.; Rahimnejad, M.; Kim, J.R.; Oh, S.E. Overview of electroactive microorganisms and electron transfer mechanisms in microbial electrochemistry. Bioresour. Technol. 2022, 347, 126579. [Google Scholar] [CrossRef]

- Liu, X.; Gao, H.; Ward, J.E.; Liu, X.; Yin, B.; Fu, T.; Chen, J.; Lovley, D.R.; Yao, J. Power generation from ambient humidity using protein nanowires. Nature 2020, 578, 550–554. [Google Scholar] [CrossRef]

- Myers, C.R.; Nealson, K.H. Microbial reduction of manganese oxides: Interactions with iron and sulfur. Geochim. Cosmochim. Ac. 1988, 52, 2727–2732. [Google Scholar] [CrossRef]

- Lovley, D.R.; Phillips, E.J. Novel mode of microbial energy metabolism: Organic carbon oxidation coupled to dissimilatory reduction of iron or manganese. Appl. Environ. Microbiol. 1988, 54, 1472–1480. [Google Scholar] [CrossRef]

- Vaidyanathan, H.; Kandasamy, V.; Gopal Ramakrishnan, G.; Ramachandran, K.B.; Jayaraman, G.; Ramalingam, S. Glycerol conversion to 1, 3-Propanediol is enhanced by the expression of a heterologous alcohol dehydrogenase gene in Lactobacillus reuteri. AMB Express 2011, 1, 37. [Google Scholar] [CrossRef]

- Zhao, J.; Li, F.; Cao, Y.; Zhang, X.; Chen, T.; Song, H.; Wang, Z. Microbial extracellular electron transfer and strategies for engineering electroactive microorganisms. Biotechnol. Adv. 2021, 53, 107682. [Google Scholar] [CrossRef]

- Çelekli, A.; Bozkurt, H. Bio-sorption of cadmium and nickel ions using Spirulina platensis: Kinetic and equilibrium studies. Desalination 2011, 275, 141–147. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, Y.; Liu, J.; Qin, Y.; Hu, W.J.N.E. Defect engineering for electrochemical nitrogen reduction reaction to ammonia. Nano Energy 2020, 77, 105126. [Google Scholar] [CrossRef]

- Wang, N.; Li, X.; Hu, M.K.; Wei, W.; Zhou, S.H.; Wu, X.T.; Zhu, Q.L. Ordered macroporous superstructure of bifunctional cobalt phosphide with heteroatomic modification for paired hydrogen production and polyethylene terephthalate plastic recycling. Appl. Catal. B 2022, 316, 121667. [Google Scholar] [CrossRef]

- Li, G.; Wang, J.; Yu, J.; Liu, H.; Cao, Q.; Du, J.; Zhao, L.; Jia, J.; Liu, H.; Zhou, W. Ni-Ni3P nanoparticles embedded into N, P-doped carbon on 3D graphene frameworks via in situ phosphatization of saccharomycetes with multifunctional electrodes for electrocatalytic hydrogen production and anodic degradation. Appl. Catal. B 2020, 261, 118147. [Google Scholar] [CrossRef]

- Guo, X.; Qian, C.; Wan, X.; Zhang, W.; Zhu, H.; Zhang, J.; Yang, H.; Lin, S.; Kong, Q.; Fan, T. Facile in situ fabrication of biomorphic Co2P-Co3O4/rGO/C as an efficient electrocatalyst for the oxygen reduction reaction. Nanoscale 2020, 12, 4374–4382. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Xiong, T.; Shi, C.; Zhou, J.; Zhou, K.; Zhu, N.; Li, L.; Tang, Z.; Chen, S. Bioreduction of precious metals by microorganism: Efficient gold@N-doped carbon electrocatalysts for the hydrogen evolution reaction. Angew. Chem. Int. Ed. Engl. 2016, 55, 8416–8420. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Li, G.; Liu, H.; Zhao, L.; Wang, A.; Liu, Z.; Li, H.; Liu, H.; Hu, Y.; Zhou, W. Ru–Ru2PΦNPC and NPC@RuO2 synthesized via environment-friendly and solid-phase phosphating process by saccharomycetes as N/P Sources and carbon template for overall water splitting in acid electrolyte. Adv. Funct. Mater. 2019, 29, 1901154. [Google Scholar] [CrossRef]

- Lovley, D.R.; Holmes, D.E. Electromicrobiology: The ecophysiology of phylogenetically diverse electroactive microorganisms. Nat. Rev. Microbiol. 2022, 20, 5–19. [Google Scholar] [CrossRef]

- Shi, C.; Gu, W.; Zhu, N. Intensification of sorption–reduction coupled gold biorecovery process through microbial surface modification: Effect on gold sorption and reduction. World J. Microb. Biot. 2020, 36, 38. [Google Scholar] [CrossRef]

- Song, Y.; Lee, J.; Shin, J.; Cho, B. Functional cooperation of the glycine synthase-reductase and Wood–Ljungdahl pathways for autotrophic growth of Clostridium drakei. Proc. Natl. Acad. Sci. USA 2020, 117, 7516–7523. [Google Scholar] [CrossRef]

- Kim, J.; Cestellos-Blanco, S.; Shen, Y.X.; Cai, R.; Yang, P. Enhancing biohybrid CO2 to multicarbon reduction via adapted whole-cell catalysts. Nano Lett. 2022, 22, 5503–5509. [Google Scholar] [CrossRef]

- Lovley, D.R. The microbe electric: Conversion of organic matter to electricity. Curr. Opin. Biotechnol. 2008, 19, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Liang, D.; Zhao, Z.; Qi, J.; Huang, L. Enhanced performance of microbial fuel cell with electron mediators from tetracycline hydrochloride degradation. Environ. Res. 2022, 206, 112605. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, B.; Wu, D.; Li, F.; Song, H. Research progress in screening method of exoelectrogens. J. Biotechnol. 2020, 36, 2719–2731. [Google Scholar]

- Ni, G.; Simone, D.; Palma, D.; Broman, E.; Wu, X.; Turner, S.; Dopson, M. A novel inorganic sulfur compound metabolizing ferroplasma-like population is suggested to mediate extracellular electron transfer. Front. Microbiol. 2018, 9, 2945. [Google Scholar] [CrossRef]

- Saunders, S.H.; Tse, E.C.M.; Yates, M.D.; Otero, F.J.; Trammell, S.A.; Stemp, E.D.A.; Barton, J.K.; Tender, L.M.; Newman, D.K. Extracellular DNA promotes efficient extracellular electron transfer by pyocyanin in pseudomonas aeruginosa biofilms. Cell 2020, 182, 919–932. [Google Scholar] [CrossRef]

- Li, S.; Zhu, L.; Lin, S.; Xu, W. Toehold-mediated biosensors: Types, mechanisms and biosensing strategies. Biosens. Bioelectron. 2023, 220, 114922. [Google Scholar] [CrossRef]

- Kumar, R. NiCo2O4 nano-/microstructures as high-performance biosensors: A review. Nano-Micro Lett. 2020, 12, 122. [Google Scholar] [CrossRef]

- Yang, H.; Jia, X.; Han, Y. Microbial redox coenzyme engineering and applications in biosynthesis. Trends Microbiol. 2022, 30, 318–321. [Google Scholar] [CrossRef]

- Zachos, I.; Döring, M.; Tafertshofer, G.; Simon, R.C.; Sieber, V. Carba nicotinamide adenine dinucleotide phosphate: Robust cofactor for redox biocatalysis. Angew. Chem. Int. Edit. 2021, 60, 14701–14706. [Google Scholar] [CrossRef]

- Dai, Y.; Liu, C.C. Recent advances on electrochemical biosensing strategies toward universal point-of-care systems. Angew. Chem. Int. Edit. 2019, 58, 12355–12368. [Google Scholar] [CrossRef]

- Monser, L.; Adhoum, N.J.S.; Technology, P. Modified activated carbon for the removal of copper, zinc, chromium and cyanide from wastewater. Sep. Purif. Technol. 2002, 26, 137–146. [Google Scholar] [CrossRef]

- Kim, M.; Lim, J.W.; Kim, H.J.; Lee, S.K.; Lee, S.J.; Kim, T. Chemostat-like microfluidic platform for highly sensitive detection of heavy metal ions using microbial biosensors. Biosens. Bioelectron. 2015, 65, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Turner, P.F. Biosensors: Sense and sensibility. Chem. Soc. Rev. 2013, 42, 3175–3648. [Google Scholar] [CrossRef]

- Xu, X.; Ying, Y. Microbial biosensors for environmental monitoring and food analysis. Food Rev. Int. 2011, 27, 300–329. [Google Scholar] [CrossRef]

- Sharma, P.; Asad, S.; Ali, A. Bioluminescent bioreporter for assessment of arsenic contamination in water samples of India. J. Biosci. 2013, 38, 251–258. [Google Scholar] [CrossRef] [PubMed]

- de Mora, K.; Joshi, N.; Balint, B.L. A pH-based biosensor for detection of arsenic in drinking water. Anal. Bioanal. Chem. 2011, 400, 1031–1039. [Google Scholar] [CrossRef]

- Willardson, B.; Wilkins, J.; Rand, T.; Schupp, J.; Hill, K.; Keim, P.; Jackson, P. Development and testing of a bacterial biosensor for toluene-based environmental contaminants. Appl. Environ. Microb. 1998, 64, 1006–1012. [Google Scholar] [CrossRef]

- Branco, R.; Cristóvão, A.; Morais, P.V. Highly sensitive, highly specific whole-cell bioreporters for the detection of chromate in environmental samples. PLoS ONE 2013, 8, e54005. [Google Scholar] [CrossRef]

- Joe, M.; Lee, K.; Lim, S.; Im, S.; Song, H.; Lee, I.; Kim, D. Pigment-based whole-cell biosensor system for cadmium detection using genetically engineered Deinococcus radiodurans. Bioproc. Biosyst. Eng. 2012, 35, 265–272. [Google Scholar] [CrossRef]

- Nakamura, S.; Oda, Y.; Shimada, T.; Oki, I.; Sugimoto, K. SOS-inducing activity of chemical carcinogens and mutagens in Salmonella typhimurium TA1535/pSK1002: Examination with 151 chemicals. Mutat. Res. Lett. 1987, 192, 239–246. [Google Scholar] [CrossRef]

- Shingler, V.; Moore, T. Sensing of aromatic compounds by the DmpR transcriptional activator of phenol-catabolizing Pseudomonas sp. strain CF600. J. Bacteriol. 1994, 176, 1555–1560. [Google Scholar] [CrossRef] [PubMed]

- Tecon, R.; Beggah, S.; Czechowska, K.; Sentchilo, V.; Chronopoulou, P.; McGenity, T. Development of a multistrain bacterial bioreporter platform for the monitoring of hydrocarbon contaminants in marine environments. Environ. Sci. Technol. 2010, 44, 1049–1055. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.C.; Wang, Y.X.; Ding, H.T.; Li, J.; Cheng, C.; Zheng, F. Oral metal–organic gel protected whole-cell biosensor for in situ monitoring nitrosamines in the gastrointestinal Tract. Nano Lett. 2022, 22, 8688–8694. [Google Scholar] [CrossRef] [PubMed]

- Ritcharoon, B.; Sallabhan, R.; Toewiwat, N.; Mongkolsuk, S.; Loprasert, S. Detection of 2,4-dichlorophenoxyacetic acid herbicide using a FGE-sulfatase based whole-cell agrobacterium biosensor. J. Microbiol. Meth. 2020, 175, 105997. [Google Scholar] [CrossRef]

- Hassan, R.A.; Heng, L.Y.; Ahmad, A.; Tan, L.L. Rapid determination of kappa-carrageenan using a biosensor from immobilized Pseudomonas carrageenovora cells. PLoS ONE 2019, 14, e0214580. [Google Scholar] [CrossRef]

- Gui, Q.; Lawson, T.; Shan, S.; Yan, L.; Liu, Y. The application of whole cell-based biosensors for use in environmental analysis and in medical diagnostics. Sensors 2017, 17, 1623. [Google Scholar] [CrossRef]

- Liu, B.; Lei, Y.; Li, B. A batch-mode cube microbial fuel cell based "shock" biosensor for wastewater quality monitoring. Biosens. Bioelectron. 2014, 62, 308–314. [Google Scholar] [CrossRef]

- Yin, J.; Zhu, Y.; Liang, Y.; Luo, Y.; Lou, J.; Hu, X.; Meng, Q.; Zhu, T.; Yu, Z. Development of whole-cell biosensors for screening of peptidoglycan-targeting antibiotics in a Gram-negative bacterium. Appl. Environ. Microbiol. 2022, 88, e0084622. [Google Scholar] [CrossRef]

- Wang, H.; Song, D.; Chen, Y.; Xu, W.; Han, X.; Zhu, A.; Long, F. Development of portable whole-cell biosensing platform with lyophilized bacteria and its application for rapid on-site detection of heavy metal toxicity without pre-resuscitation. Anal. Chim. Acta 2022, 1228, 340354. [Google Scholar] [CrossRef]

- Liu, C.; Yu, H.; Zhang, B.; Liu, S.; Liu, C.-g.; Li, F.; Song, H. Engineering whole-cell microbial biosensors: Design principles and applications in monitoring and treatment of heavy metals and organic pollutants. Biotechnol. Adv. 2022, 60, 108019. [Google Scholar] [CrossRef]

- Guo, M.; Du, R.; Xie, Z.; He, X.; Huang, K.; Luo, Y.; Xu, W. Using the promoters of MerR family proteins as “rheostats” to engineer whole-cell heavy metal biosensors with adjustable sensitivity. J. Biol. Eng. 2019, 13, 70. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, J.; Huang, Q.; Tao, Y.; Gu, R.; Li, H.-Y.; Liu, H. Electrochemical biosensor employing PbS colloidal quantum dots/Au nanospheres-modified electrode for ultrasensitive glucose detection. Nano Res. 2022, 16, 4085–4092. [Google Scholar] [CrossRef]

- Wan, X.; Volpetti, F.; Petrova, E.; French, C.; Maerkl, S.J.; Wang, B. Cascaded amplifying circuits enable ultrasensitive cellular sensors for toxic metals. Nat. Chem. Biol. 2019, 15, 540–548. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Liu, B.; Dong, Q.; Lei, Y.; Li, Y.; Ren, J.; McCutcheon, J.; Li, B. Flat microliter membrane-based microbial fuel cell as “on-line sticker sensor” for self-supported in situ monitoring of wastewater shocks. Bioresour. Technol. 2015, 197, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhou, M.; Tian, X.; Tan, C.; McDaniel, C.T.; Hassett, D.J.; Gu, T. Microbial fuel cell (MFC) power performance improvement through enhanced microbial electrogenicity. Biotechnol. Adv. 2018, 36, 1316–1327. [Google Scholar] [CrossRef] [PubMed]

- Castellano-Hinojosa, A.; González-Martínez, A.; Pozo, C.; González-López, J. Diversity of electroactive and non-electroactive microorganisms and their potential relationships in microbial electrochemical systems: A review. J. Water Process Eng. 2022, 50, 103199. [Google Scholar] [CrossRef]

- Ruff, A.; Conzuelo, F.; Schuhmann, W. Bioelectrocatalysis as the basis for the design of enzyme-based biofuel cells and semi-artificial biophotoelectrodes. Nat. Catal. 2020, 3, 214–224. [Google Scholar] [CrossRef]

- Lovley, D.R. e-Biologics: Fabrication of sustainable electronics with “Green” biological materials. mBio 2017, 8, e0069517. [Google Scholar] [CrossRef]

- Paquete, C.M.; Rosenbaum, M.A.; Bañeras, L.; Rotaru, A.E.; Puig, S. Let’s chat: Communication between electroactive microorganisms. Bioresour. Technol. 2022, 347, 126705. [Google Scholar] [CrossRef]

- Gahlawat, G.; Choudhury, A.R. A review on the biosynthesis of metal and metal salt nanoparticles by microbes. RSC Adv. 2019, 9, 12944–12967. [Google Scholar] [CrossRef]

- Shapiro, D.M.; Mandava, G.; Yalcin, S.E.; Arranz-Gibert, P.; Dahl, P.J.; Shipps, C.; Gu, Y.; Srikanth, V.; Salazar-Morales, A.I.; O’Brien, J.P.; et al. Protein nanowires with tunable functionality and programmable self-assembly using sequence-controlled synthesis. Nat. Commun. 2022, 13, 829. [Google Scholar] [CrossRef] [PubMed]

- Reguera, G.; McCarthy, K.D.; Mehta, T.; Nicoll, J.S.; Tuominen, M.T.; Lovley, D.R. Extracellular electron transfer via microbial nanowires. Nature 2005, 435, 1098–1101. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Adhikari, R.Y.; Malvankar, N.S.; Pi, S.; Ward, J.E.; Woodard, T.L.; Nevin, K.P.; Xia, Q.; Tuominen, M.T.; Lovley, D.R. Synthetic biological protein nanowires with high conductivity. Small 2016, 12, 4481–4485. [Google Scholar] [CrossRef] [PubMed]

- Xue, G.; Xu, Y.; Ding, T.; Li, J.; Yin, J.; Fei, W.; Cao, Y.; Yu, J.; Yuan, L.; Gong, L.; et al. Water-evaporation-induced electricity with nanostructured carbon materials. Nat. Nanotechnol. 2017, 12, 317–321. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.K.; Piwek, P.; Ayakar, S.R.; Bonakdarpour, A.; Wilkinson, D.P.; Yadav, V.G. A biogenic photovoltaic material. Small 2018, 14, e1800729. [Google Scholar] [CrossRef]

- Wang, X.T.; Gu, Z.Y.; Ang, E.H.; Zhao, X.X.; Wu, X.L.; Liu, Y. Prospects for managing end-of-life lithium-ion batteries: Present and future. Interdiscip. Mater. 2022, 1, 417–433. [Google Scholar] [CrossRef]

- Huang, Y.J.I.M. The discovery of cathode materials for lithium-ion batteries from the view of interdisciplinarity. Interdiscip. Mater. 2022, 1, 323–329. [Google Scholar] [CrossRef]

- Ai, G.; Dai, Y.; Mao, W.; Zhao, H.; Fu, Y.; Song, X.; En, Y.; Battaglia, V.S.; Srinivasan, V.; Liu, G. Biomimetic ant-nest electrode structures for high sulfur ratio lithium–sulfur batteries. Nano Lett. 2016, 16, 5365–5372. [Google Scholar] [CrossRef]

- Wei, J.; Zhou, M.; Long, A.; Xue, Y.; Liao, H.; Wei, C.; Xu, Z.J. Heterostructured electrocatalysts for hydrogen evolution reaction under alkaline conditions. Nano-Micro Lett. 2018, 10, 75. [Google Scholar] [CrossRef]

- Cao, D.; Zhang, Q.; Hafez, A.M.; Jiao, Y.; Ma, Y.; Li, H.; Cheng, Z.; Niu, C.; Zhu, H. Lignin-derived holey, layered, and thermally conductive 3D scaffold for lithium dendrite suppression. Small Methods 2019, 3, 1800539. [Google Scholar] [CrossRef]

- Mikhaylik, Y.V.; Akridge, J.R. Polysulfide shuttle study in the Li/S battery system. J. Electrochem. Soc. 2004, 151, A1969. [Google Scholar] [CrossRef]

- Liu, N.; Li, W.; Pasta, M.; Cui, Y. Nanomaterials for electrochemical energy storage. Front. Phys. 2014, 9, 323–350. [Google Scholar]

- Wen, Y.; Wang, B.; Huang, C.; Wang, L.; Hulicova-Jurcakova, D. Synthesis of phosphorus-doped graphene and its wide potential window in aqueous supercapacitors. Chemstry 2015, 21, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Shen, S.; Zhong, Y.; Zhang, Y.; Zhang, L.; Wang, X.; Xia, X.; Tong, X.; Zhou, J.; Tu, J. Multifunctional hyphae carbon powering lithium–sulfur batteries. Adv. Mater. 2022, 34, 2107415. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ai, W.; Li, N.; Yu, T.; Chen, P. Graphene–bacteria composite for oxygen reduction and lithium ion batteries. J. Mater. Chem. A 2015, 3, 12873–12879. [Google Scholar] [CrossRef]

- Cheah, L.C.; Stark, T.; Adamson, L.S.R.; Abidin, R.S.; Lau, Y.H.; Sainsbury, F.; Vickers, C.E. Artificial self-assembling nanocompartment for organizing metabolic pathways in yeast. ACS Synth. Biol. 2021, 10, 3251–3263. [Google Scholar] [CrossRef]

- Yu, W.; Bai, H.; Zeng, Y.; Zhao, H.; Xia, S.; Huang, Y.; Lv, F.; Wang, S. Solar-driven producing of value-added chemicals with organic semiconductor-bacteria biohybrid system. Research 2022, 23, 9834093. [Google Scholar] [CrossRef]

- Logan, B.E. Exoelectrogenic bacteria that power microbial fuel cells. Nat. Rev. Microbiol. 2009, 7, 375–381. [Google Scholar] [CrossRef]

- Dutta, R.R.; Puzari, P. Amperometric biosensing of organophosphate and organocarbamate pesticides utilizing polypyrrole entrapped acetylcholinesterase electrode. Biosens. Bioelectron. 2014, 52, 166–172. [Google Scholar] [CrossRef]

- Ke, Z.; Yuan, X.S.; Feng, X.L.; Guo, S.P. Bimetallic catalysts as electrocatalytic cathode materials for the oxygen reduction reaction in microbial fuel cell: A review. Green Energy Environ. 2022. [Google Scholar] [CrossRef]

- Song, H.L.; Zhang, C.; Lu, Y.X.; Li, H.; Shao, Y.; Yang, Y.L. Enhanced removal of antibiotics and antibiotic resistance genes in a soil microbial fuel cell via in situ remediation of agricultural soils with multiple antibiotics. Sci. Total Environ. 2022, 829, 154406. [Google Scholar] [CrossRef]

- Shrivastava, A.; Sharma, R.K. Lignocellulosic biomass based microbial fuel cells: Performance and applications. J. Clean. Prod. 2022, 361, 132269. [Google Scholar] [CrossRef]

- Chae, K.J.; Choi, M.J.; Lee, J.W.; Kim, K.Y.; Kim, I.S. Effect of different substrates on the performance, bacterial diversity, and bacterial viability in microbial fuel cells. Bioresour. Technol. 2009, 100, 3518–3525. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Li, L.; Wang, C.; Wang, Z.; Wang, Y.; Yan, Y.; Qu, J.; Guan, J. Simultaneous enhancement of power generation and chlorophenol degradation in nonmodified microbial fuel cells using an electroactive biofilm carbon felt anode. Sci. Total Environ. 2021, 783, 147045. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Peng, H.; Li, W.; Zhao, D. Monomicellar assembly to synthesize structured and functional mesoporous carbonaceous nanomaterials. Nat. Protoc. 2022, 18, 1155–1178. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.; Zhao, Z.; Peng, L.; Shiu, H.Y.; Ding, M.; Song, F.; Guan, X.; Lee, C.K.; Huang, J.; Zhu, D.; et al. Silver nanoparticles boost charge-extraction efficiency in Shewanella microbial fuel cells. Science 2021, 373, 1336–1340. [Google Scholar] [CrossRef]

- Scheller, S.; Yu, H.; Chadwick, G.L.; McGlynn, S.E.; Orphan, V.J. Artificial electron acceptors decouple archaeal methane oxidation from sulfate reduction. Science 2016, 351, 703–707. [Google Scholar] [CrossRef] [PubMed]

- McAnulty, M.J.; Poosarla, V.G.; Kim, K.Y.; Jasso-Chavez, R.; Logan, B.E.; Wood, T.K. Electricity from methane by reversing methanogenesis. Nat. Commun. 2017, 8, 15419. [Google Scholar] [CrossRef] [PubMed]

- Mohammadifar, M.; Tahernia, M.; Choi, S. A miniaturized, self-sustaining, and integrable bio-solar power system. Nano Energy 2020, 72, 104668. [Google Scholar] [CrossRef]

- Liu, L.; Choi, S. Self-sustaining, solar-driven bioelectricity generation in micro-sized microbial fuel cell using co-culture of heterotrophic and photosynthetic bacteria. J. Power Sources 2017, 348, 138–144. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, L.; Luan, G. A miniaturized bionic ocean-battery mimicking the structure of marine microbial ecosystems. Nat. Commun. 2022, 13, 5608. [Google Scholar] [CrossRef]

- Liu, H.; Ramnarayanan, R.; Logan, B.E. Production of electricity during wastewater treatment using a single chamber microbial fuel cell. Environ. Sci. Technol. 2004, 38, 2281–2285. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Gai, P.; Liu, C. Polyaniline networks grown on graphene nanoribbons-coated carbon paper with a synergistic effect for high-performance microbial fuel cells. J. Mater. Chem. A 2013, 1, 12587–12594. [Google Scholar] [CrossRef]

- Ren, H.; Pyo, S.; Lee, J.I.; Park, T.J.; Gittleson, F.S.; Leung, F.C.; Kim, J.; Taylor, A.D.; Lee, H.S.; Chae, J. A high power density miniaturized microbial fuel cell having carbon nanotube anodes. J. Power Sources 2015, 273, 823–830. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhou, S.; Liu, Y.; Tang, J. Nanostructured macroporous bioanode based on polyaniline-modified natural loofah sponge for high-performance microbial fuel cells. Environ. Sci. Technol. 2013, 47, 14525–14532. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Y.; Yin, H. Three-dimensional graphene/Pt nanoparticle composites as freestanding anode for enhancing performance of microbial fuel cells. Sci. Adv. 2015, 1, e1500372. [Google Scholar] [CrossRef]

- He, Z.; Liu, J.; Qiao, Y.; Li, C.M.; Tan, T.T.Y. Architecture engineering of hierarchically porous chitosan/vacuum-stripped graphene scaffold as bioanode for high performance microbial fuel cell. Nano Lett. 2012, 12, 4738–4741. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Hu, Y.; Li, S.; Xu, Q. Carbon nanotube-coated stainless steel mesh for enhanced oxygen reduction in biocathode microbial fuel cells. J. Power Sources 2013, 239, 169–174. [Google Scholar] [CrossRef]

| Bacteria | Target Analyte | Sensitivity | Ref. |

|---|---|---|---|

| E. coli | Arsenic | 0.74–69 µg L−1 | [86] |

| E. coli | Arsentate | <10 µg L−1 | [87] |

| E. coli | Benzene, toluene, and xylene | 40 µM | [88] |

| E. coli | Chromate | 100 nM | [89] |

| Deinococcus radiodurans | Cadmium | 1–10 mM | [90] |

| Salmonella typhimurium | Single-stranded DNA | 10 nM mitomycinC | [91] |

| Pseudomonas putida | Phenol | 3 µM | [92] |

| Burkholderia sartisoli | Naphthalene and phenanthrene | 0.17 µM | [93] |

| Saccharomyces cerevisiae | Nitrosamine | >1 × 10−10 g L−1 | [94] |

| Agrobacterium | 2,4-Dichlorophenoxyacetic | 12.5 µM | [95] |

| Electrode | Bacteria | Culture | Current Density (mA cm−2) | Power Density (mW cm−2) | QE | Ref. |

|---|---|---|---|---|---|---|

| Graphite fiber brush | Mix | / | 0.8 | 0.143 | / | [143] |

| Carbon paper | Mix | / | 0.28 | 0.05 | / | [143] |

| Graphene/PANI | Shewanella MR-1 | Luria–Bertani broth medium | 0.58 | 0.031 | / | [144] |

| VA-CNT | Geobacter | Sodium acetate medium | 0.26 | 0.083 | 61% | [145] |

| CNT textile fiber | Mix | Sodium acetate medium (conductivity: 7.0 mS cm−1) | 0.5 | 0.11 | / | [146] |

| rGO/Pt | Shewanella MR-1 | M9 buffer solution containing 18 mM sodium (fed-batch mode) | 0.69 | 0.148 | 69% | [147] |

| 3D chitosan hydrogel | Pseudomonas aeruginosa | Luria–Bertani broth medium | 0.55 | 0.153 | / | [148] |

| rGO/Ag | Shewanella MR-1 | The medium with lactate as the nutrient (fed-batch mode) | 3.85 | 0.66 | 81% | [137] |

| Steel/CNT | Geobacter | Sodium acetate medium | / | / | 16% | [149] |

| Carbon fiber/Ti | Mix | Nitrate-containing MBG11-S medium (genetic engineering) | 0.73 | 0.52 | / | [142] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Zhang, X.; Peng, Y.; Douka, A.I.; You, F.; Yao, J.; Jiang, X.; Hu, R.; Yang, H. Electroactive Microorganisms in Advanced Energy Technologies. Molecules 2023, 28, 4372. https://doi.org/10.3390/molecules28114372

Zhou X, Zhang X, Peng Y, Douka AI, You F, Yao J, Jiang X, Hu R, Yang H. Electroactive Microorganisms in Advanced Energy Technologies. Molecules. 2023; 28(11):4372. https://doi.org/10.3390/molecules28114372

Chicago/Turabian StyleZhou, Xingchen, Xianzheng Zhang, Yujie Peng, Abdoulkader Ibro Douka, Feng You, Junlong Yao, Xueliang Jiang, Ruofei Hu, and Huan Yang. 2023. "Electroactive Microorganisms in Advanced Energy Technologies" Molecules 28, no. 11: 4372. https://doi.org/10.3390/molecules28114372

APA StyleZhou, X., Zhang, X., Peng, Y., Douka, A. I., You, F., Yao, J., Jiang, X., Hu, R., & Yang, H. (2023). Electroactive Microorganisms in Advanced Energy Technologies. Molecules, 28(11), 4372. https://doi.org/10.3390/molecules28114372