Review of Polymer-Based Composites for Electromagnetic Shielding Application

Abstract

:1. Introduction

2. Electromagnetic Shielding Mechanism

3. Research Progress of Polymer-Based Composites with Different Structures in the Field of Electromagnetic Shielding

3.1. Uniform Structure

3.1.1. Solution-Blending Method

3.1.2. Melt Blending

3.1.3. In Situ Polymerization Method

3.2. Foam Structure

3.2.1. Physical Foaming Method

3.2.2. Chemical Foaming Method

3.2.3. Freeze-Drying Method

3.3. Segregated Structure

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| Starch/CNT | 3 vol% | 33.12 | 1.6 | 8–12 Ghz | [146] |

| PEBA/CNS composites | 0.2 wt% | 33 | 3.4 | 8–12 Ghz | [39] |

| PS/CNT/PEDOT:PSS | 6 wt% | 33.4 | 0.6 | 8–12 Ghz | [147] |

| PVDF/Fe3O4-RGC | 2.02 vol% | 44.5 | - | 8–12 Ghz | [150] |

| Fe3O4@PA6/MWCNT | 9 wt% | 24.8 | 0.5 | 8–12 Ghz | [151] |

| BPEI/MLG | 5 wt% | 62.2 | 2.3 | 8–12 Ghz | [153] |

| PP/RGO/MWCNT | 5 wt% | 16 | - | 8–12 Ghz | [145] |

| PLA/PBS/MWCNT | 2 wt% | 27.56 | 2 | 8–12 Ghz | [148] |

| PA12/CNT | 5.66 wt% | 23.9 | 2 | 8–12 Ghz | [149] |

| POM/CNT | 4 wt% | 21.5 | 2 | 8–12 Ghz | [40] |

| BN/GNP/PPS | 40 wt% | 70 | 3 | 8–12 Ghz | [157] |

| SiO2/CNT/PDMS | 35.4 vol% | 52.2 | 2 | 8–12 Ghz | [159] |

| NR/CNT | 7 wt% | 44.2 | 2 | 8–12 Ghz | [158] |

| PBS/CNT | 2 wt% | 24 | 2 | 8–12 Ghz | [142] |

| CNT/PDMS | 2.2 vol% | 47 | 2 | 8–12 Ghz | [154] |

| TPU/EG/AG | 0.58 vol% | 56.3 | - | 8–12 Ghz | [152] |

3.4. Layered Structure

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| PI/Ti3C2Tx Mxene/AgNW | 20 wt% | 79.54 | 0.15 | 8–12 Ghz | [169] |

| PLA/MWCNT | 5 vol% | 26 | 1.5 | 24–40 Ghz | [41] |

| PPA6@NiM/PDMS | 54.9 wt% | 39.9 | 1 | 8–12 Ghz | [170] |

| PLLA/GNP/Fe3O4 | 10wt% | 41.7 | 0.4 | 8–12 Ghz | [176] |

| CF@(CNT/Fe3O4/EP) | 0.045 wt% | 30.5 | 2 | 8–12 Ghz | [177] |

| h-PANI/CNF/Mxene | 8 wt% | 35.3 | - | 8–12 Ghz | [171] |

| PVDF/SiBi58/Co-C | 30 vol% | 50 | 2 | 8–12 Ghz | [166] |

| EP/LMPA | 20 vol% | 20 | - | 8–12 Ghz | [161] |

| SR/Mxene/Fe3O4 | 21.2 wt% | 55.5 | 2 | 8–12 Ghz | [165] |

| CF/GF/PDMS | 1 wt% | 30 | 1 | 8–18 Ghz | [167] |

| ANF/AgNW/GN | 2 vol% | 68.3 | 0.04 | 8–12 Ghz | [172] |

| NR/MXene/CNT | 50 wt% | 49.9 | 0.2 | 8–12 Ghz | [43] |

| PEEK/MWCNT | 20 wt% | 44.5 | 0.56 | 8–12 Ghz | [42] |

| TPU/MWCNT | 5 wt% | 53.3 | 2.4 | 8–12 Ghz | [173] |

| NiFe2O4/AgNW/EPM | 10 wt% | 66.5 | 2 | 8–12 Ghz | [174] |

| MXene/AgNW/MoS2 | 10 wt% | 86.3 | 0.03 | 8–12 Ghz | [175] |

4. Applications of Polymer-Based Electromagnetic Shielding Composites

4.1. EMI Shielding Composites in Military Fields

4.2. EMI Shielding Composites in Civilian Field

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wan, Y.; Xiong, P.; Liu, J.; Feng, F.; Xun, X.; Gama, F.M.; Zhang, Q.; Yao, F.; Yang, Z.; Luo, H.; et al. Ultrathin, Strong, and Highly Flexible Ti3C2Tx MXene/Bacterial Cellulose Composite Films for High-Performance Electromagnetic Interference Shielding. ACS Nano 2021, 15, 8439–8449. [Google Scholar] [CrossRef]

- Zhan, Y.; Oliviero, M.; Wang, J.; Sorrentino, A.; Buonocore, G.G.; Sorrentino, L.; Lavorgna, M.; Xia, H.; Iannace, S. Enhancing the EMI shielding of natural rubber-based supercritical CO2 foams by exploiting their porous morphology and CNT segregated networks. Nanoscale 2019, 11, 1011–1020. [Google Scholar] [CrossRef]

- Zhao, B.; Deng, J.; Zhang, R.; Liang, L.; Fan, B.; Bai, Z.; Shao, G.; Park, C.B. Recent Advances on the Electromagnetic Wave Absorption Properties of Ni Based Materials. Eng. Sci. 2018, 3, 5–40. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, W.; Shi, T.; Wu, G.; Lu, Y. One pot green synthesis and EM wave absorption performance of MoS2@nitrogen doped carbon hybrid decorated with ultrasmall cobalt ferrite nanoparticles. Carbon 2020, 163, 202–212. [Google Scholar] [CrossRef]

- Limthin, D.; Klamchuen, A.; Phromyothin, D. Surface modification of superparamagnetic iron oxide nanoparticles and methyl methacrylate molecularly imprinted polymer for gluten detection. Ferroelectrics 2019, 552, 97–107. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Z.; Xu, J.; Ouyang, Q.; Zhu, C.; Zhang, X.; Zhang, X.; Chen, Y. N-doped carbon nanotube arrays on reduced graphene oxide as multifunctional materials for energy devices and absorption of electromagnetic wave. Carbon 2021, 177, 216–225. [Google Scholar] [CrossRef]

- Shao, H.; Wen, Z.; Cheng, P.; Sun, N.; Shen, Q.; Zhou, C.; Peng, M.; Yang, Y.; Xie, X.; Sun, X. Multifunctional power unit by hybridizing contact-separate triboelectric nanogenerator, electromagnetic generator and solar cell for harvesting blue energy. Nano Energy 2017, 39, 608–615. [Google Scholar] [CrossRef]

- Xia, L.; Zhang, Y. An overview of world geothermal power generation and a case study on China—The resource and market perspective. Renew. Sustain. Energy Rev. 2019, 112, 411–423. [Google Scholar] [CrossRef]

- Joseph, J.; Koroth, A.K.; John, D.A.; Sidpara, A.M.; Paul, J. Highly filled multilayer thermoplastic/graphene conducting composite structures with high strength and thermal stability for electromagnetic interference shielding applications. J. Appl. Polym. Sci. 2019, 136, 47792. [Google Scholar] [CrossRef]

- Ma, F.; Yuan, N.; Ding, J. The conductive network made up by the reduced graphene nanosheet/polyaniline/polyvinyl chloride. J. Appl. Polym. Sci. 2012, 128, 3870–3875. [Google Scholar] [CrossRef]

- Singh, S.K.; Akhtar, M.J.; Kar, K.K. Hierarchical Carbon Nanotube-Coated Carbon Fiber: Ultra Lightweight, Thin, and Highly Efficient Microwave Absorber. ACS Appl. Mater. Interfaces 2018, 10, 24816–24828. [Google Scholar] [CrossRef] [PubMed]

- Wongkasem, N. Electromagnetic pollution alert: Microwave radiation and absorption in human organs and tissues. Electromagn. Biol. Med. 2021, 40, 236–253. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yang, Y.; Xiong, Y.; Zhang, L.; Xu, W.; Duan, G.; Mei, C.; Jiang, S.; Rui, Z.; Zhang, K. Porous aerogel and sponge composites: Assisted by novel nanomaterials for electromagnetic interference shielding. Nano Today 2021, 38, 101204. [Google Scholar] [CrossRef]

- Rajavel, K.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C. MXene/metal oxides-Ag ternary nanostructures for electromagnetic interference shielding. Chem. Eng. J. 2020, 399, 125791. [Google Scholar] [CrossRef]

- Oh, K.; Hong, S.M.; Seo, Y. Effect of crosslinking reaction on the electromagnetic interference shielding of a Fe-Si-Al alloy (Sendust)/polymer composite at high frequency. Polym. Adv. Technol. 2014, 25, 1366–1370. [Google Scholar] [CrossRef]

- Choi, H.K.; Lee, A.; Park, M.; Lee, D.S.; Bae, S.; Lee, S.-K.; Lee, S.H.; Lee, T.; Kim, T.-W. Hierarchical Porous Film with Layer-by-Layer Assembly of 2D Copper Nanosheets for Ultimate Electromagnetic Interference Shielding. ACS Nano 2021, 15, 829–839. [Google Scholar] [CrossRef]

- Zhang, C.-S.; Ni, Q.-Q.; Fu, S.-Y.; Kurashiki, K. Electromagnetic interference shielding effect of nanocomposites with carbon nanotube and shape memory polymer. Compos. Sci. Technol. 2007, 67, 2973–2980. [Google Scholar] [CrossRef] [Green Version]

- Geetha, S.; Satheesh Kumar, K.K.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Cao, M.-S.; Wang, X.-X.; Cao, W.-Q.; Yuan, J. Ultrathin graphene: Electrical properties and highly efficient electromagnetic interference shielding. J. Mater. Chem. C 2015, 3, 6589–6599. [Google Scholar] [CrossRef]

- Jiang, X.; Li, S.; He, S.; Bai, Y.; Shao, L. Interface manipulation of CO2–philic composite membranes containing designed UiO-66 derivatives towards highly efficient CO2 capture. J. Mater. Chem. A 2018, 6, 15064–15073. [Google Scholar] [CrossRef]

- Ye, W.; Xie, M.; Huang, Z.; Wang, H.; Zhou, Q.; Wang, L.; Chen, B.; Wang, H.; Liu, W. Microstructure and tribological properties of in-situ carbide/CoCrFeNiMn high entropy alloy composites synthesized by flake powder metallurgy. Tribol. Int. 2023, 181, 108295. [Google Scholar] [CrossRef]

- Hua, D.; Liu, X.; Wang, W.; Zhou, Q.; Xia, Q.; Li, S.; Shi, J.; Wang, H. Formation mechanism of hierarchical twins in the CoCrNi medium entropy alloy. J. Mater. Sci. Technol. 2023, 140, 19–32. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Z.; Wang, Y.; Zhou, Q.; Yang, T.; Li, Q.; Jia, Q.; Wang, H. Friction-induced rapid amorphization in a wear-resistant (CoCrNi)88Mo12 dual-phase medium-entropy alloy at cryogenic temperature. Compos. Part B Eng. 2023, 263, 110833. [Google Scholar] [CrossRef]

- Wan, Q.; Hua, K.; Zhou, Z.; Zhang, F.; Wu, H.; Zhou, Q.; Wang, H. Revealing the B addition on tribology performance in TiZrHfTa0.5 refractory high-entropy alloy at ambient and elevated temperature. J. Alloys Compd. 2022, 931, 167521. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of High Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Zhang, K.; Gu, X.; Dai, Q.; Yuan, B.; Yan, Y.; Guo, M. Flexible polyaniline-coated poplar fiber composite membranes with effective electromagnetic shielding performance. Vacuum 2019, 170, 108990. [Google Scholar] [CrossRef]

- Dogan, S.; Kayacan, O.; Goren, A. A lightweight, strength and electromagnetic shielding polymer composite structure for infant carrier strollers. Polym. Compos. 2019, 40, 4559–4572. [Google Scholar] [CrossRef]

- Tan, Y.-J.; Li, J.; Cai, J.-H.; Tang, X.-H.; Liu, J.-H.; Hu, Z.-Q.; Wang, M. Comparative study on solid and hollow glass microspheres for enhanced electromagnetic interference shielding in polydimethylsiloxane/multi-walled carbon nanotube composites. Compos. Part B Eng. 2019, 177, 107378. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, M.; Yu, Y.; Wen, B.; Cheng, L. A Novel Polyaniline-Coated Bagasse Fiber Composite with Core–Shell Heterostructure Provides Effective Electromagnetic Shielding Performance. ACS Appl. Mater. Interfaces 2016, 9, 809–818. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Hou, L.; Bi, S.; Lu, Y. Enhanced X-Band Electromagnetic-Interference Shielding Performance of Layer-Structured Fabric-Supported Polyaniline/Cobalt–Nickel Coatings. ACS Appl. Mater. Interfaces 2017, 9, 33059–33070. [Google Scholar] [CrossRef]

- Wang, Y.; Jing, X. Intrinsically conducting polymers for electromagnetic interference shielding. Polym. Adv. Technol. 2005, 16, 344–351. [Google Scholar] [CrossRef]

- Sun, F.; Xu, J.; Liu, T.; Li, F.; Poo, Y.; Zhang, Y.; Xiong, R.; Huang, C.; Fu, J. An autonomously ultrafast self-healing, highly colourless, tear-resistant and compliant elastomer tailored for transparent electromagnetic interference shielding films integrated in flexible and optical electronics. Mater. Horiz. 2021, 8, 3356–3367. [Google Scholar] [CrossRef]

- Nazir, A.; Yu, H.; Wang, L.; Haroon, M.; Ullah, R.S.; Fahad, S.; Naveed, K.-U.-R.; Elshaarani, T.; Khan, A.; Usman, M. Recent progress in the modification of carbon materials and their application in composites for electromagnetic interference shielding. J. Mater. Sci. 2018, 53, 8699–8719. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, H.; Liang, C.; Song, P.; Han, Y.; Han, Y.; Gu, J.; Kong, J.; Pan, D.; Guo, Z. Electromagnetic Interference Shielding MWCNT-Fe3O4@Ag/Epoxy Nanocomposites with Satisfactory Thermal Conductivity and High Thermal Stability. Carbon 2018, 141, 506–514. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Song, P.; Liang, C.; Lu, Y.; Qiu, H.; Zhang, Y.; Kong, J.; Gu, J. Fabrication on the annealed Ti3C2Tx MXene/Epoxy nanocomposites for electromagnetic interference shielding application. Compos. Part B Eng. 2019, 171, 111–118. [Google Scholar] [CrossRef]

- Zhu, N.; Jiang, T.; Zeng, X.; Li, S.; Shen, C.; Zhang, C.; Gong, W.; He, L. High strength and light weight polyamide 6/carbon fiber composite foams for electromagnetic interference shielding. J. Appl. Polym. Sci. 2023, 140, e53818. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Wang, L.; Liu, X. In Situ Growth of Fe3O4 Nanoparticles in Poly(arylene ether nitrile)/Graphene/Carbon Nanotube Foams for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2023, 6, 7802–7813. [Google Scholar] [CrossRef]

- Huang, B.; Yue, J.; Fan, B.; Tang, X.Z.; Liu, Y.; Huang, X. Constructing hierarchical structure via in situ growth of CNT in SiO2-coated carbon foam for high-performance EMI shielding application. Compos. Sci. Technol. 2022, 222, 109372. [Google Scholar] [CrossRef]

- Li, X.; Wu, M.; Chen, J.; Zhou, X.; Ren, Q.; Wang, L.; Shen, B.; Zheng, W. A facile and large-scale approach to prepare macroscopic segregated polyether block amides/carbon nanostructures composites with a gradient structure for absorption-dominated electromagnetic shielding with ultra-low reflection. Compos. Commun. 2023, 40, 101628. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, X.; Ye, L. Low Percolation Threshold and Enhanced Electromagnetic Interference Shielding in Polyoxymethylene/Carbon Nanotube Nanocomposites with Conductive Segregated Networks. Ind. Eng. Chem. Res. 2022, 61, 3962–3972. [Google Scholar] [CrossRef]

- Bertašius, P.; Plyushch, A.; Macutkevič, J.; Banys, J.; Selskis, A.; Platnieks, O.; Gaidukovs, S. Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application. Polymers 2023, 15, 1053. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.H.; Mei, X.H.; Liang, L.B.; Ma, Y.M.; Wang, G.B.; Zhang, S.L. Achieving structurally and functionally integrated electromagnetic shielding composites based on polyetheretherketone by sandwich structure. J. Sandw. Struct. Mater. 2021, 24, 484–502. [Google Scholar] [CrossRef]

- Wu, H.; Zhu, C.; Li, X.; Hu, X.; Xie, H.; Lu, X.; Qu, J.-P. Layer-by-Layer Assembly of Multifunctional NR/MXene/CNTs Composite Films with Exceptional Electromagnetic Interference Shielding Performances and Excellent Mechanical Properties. Macromol. Rapid Commun. 2022, 43, e2200387. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.H.; Kim, H.; Park, S.-W.; Kwon, S.J.; Kim, S.; Lim, H.-R.; Park, B.; Lee, S.-B.; Choa, Y.-H. Millimeter-Scale Percolated Polyethylene/Graphene Composites for 5G Electromagnetic Shielding. ACS Appl. Nano Mater. 2022, 5, 8429–8439. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, J. A Perspective for Developing Polymer-Based Electromagnetic Interference Shielding Composites. Nano-Micro Lett. 2022, 14, 1–9. [Google Scholar] [CrossRef]

- Zhao, B.; Hamidinejad, M.; Wang, S.; Bai, P.; Che, R.; Zhang, R.; Park, C.B. Advances in electromagnetic shielding properties of composite foams. J. Mater. Chem. A 2021, 9, 8896–8949. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Khadheer Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Wang, L.; Song, P.; Lin, C.-T.; Kong, J.; Gu, J. 3D Shapeable, Superior Electrically Conductive Cellulose Nanofibers/Ti3C2Tx MXene Aerogels/Epoxy Nanocomposites for Promising EMI Shielding. Research 2020, 2020, 4093732. [Google Scholar] [CrossRef]

- Ji, H.; Zhao, R.; Zhang, N.; Jin, C.; Lu, X.; Wang, C. Lightweight and flexible electrospun polymer nanofiber/metal nanoparticle hybrid membrane for high-performance electromagnetic interference shielding. NPG Asia Mater. 2018, 10, 749–760. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Liu, M.; Li, J.; Zhou, X. Review on Shielding Mechanism and Structural Design of Electromagnetic Interference Shielding Composites. Macromol. Mater. Eng. 2021, 306, 2100032. [Google Scholar] [CrossRef]

- Omana, L.; Chandran, A.; John, R.E.; Wilson, R.; George, K.C.; Unnikrishnan, N.V.; Varghese, S.S.; George, G.; Simon, S.M.; Paul, I. Recent Advances in Polymer Nanocomposites for Electromagnetic Interference Shielding: A Review. ACS Omega 2022, 7, 25921–25947. [Google Scholar] [CrossRef]

- Abdi, M.M.; Kassim, A.B.; Ekramul Mahmud, H.N.M.; Yunus, W.M.M.; Talib, Z.A. Electromagnetic Interference Shielding Effectiveness of New Conducting Polymer Composite. J. Macromol. Sci. Part A 2009, 47, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Rathi, V.; Panwar, V. Electromagnetic Interference Shielding Analysis of Conducting Composites in Near- and Far-Field Region. IEEE Trans. Electromagn. Compat. 2018, 60, 1795–1801. [Google Scholar] [CrossRef]

- Xu, W.; Pan, Y.-F.; Wei, W.; Wang, G.-S. Nanocomposites of Oriented Nickel Chains with Tunable Magnetic Properties for High-Performance Broadband Microwave Absorption. ACS Appl. Energy Mater. 2018, 1, 1116–1123. [Google Scholar] [CrossRef]

- Gargama, H.; Thakur, A.K.; Chaturvedi, S.K. Polyvinylidene fluoride/nanocrystalline iron composite materials for EMI shielding and absorption applications. J. Alloys Compd. 2016, 654, 209–215. [Google Scholar] [CrossRef]

- Tian, D.; Xu, Y.; Wang, Y.; Lei, Z.; Lin, Z.; Zhao, T.; Hu, Y.; Sun, R.; Wong, C.-P. In-Situ Metallized Carbon Nanotubes/Poly(Styrene-Butadiene-Styrene) (CNTs/SBS) Foam for Electromagnetic Interference Shielding. Chem. Eng. J. 2021, 420, 130482. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, L.; Duan, S.; Jing, S.; Jiang, H.; Luo, M.; Li, C. Highly conductive and flexible polymer composites with improved mechanical and electromagnetic interference shielding performances. Nanoscale 2014, 6, 3796–3803. [Google Scholar] [CrossRef]

- Kamkar, M.; Ghaffarkhah, A.; Hosseini, E.; Amini, M.; Ghaderi, S.; Arjmand, M. Multilayer polymeric nanocomposites for electromagnetic interference shielding: Fabrication, mechanisms, and prospects. New J. Chem. 2021, 45, 21488–21507. [Google Scholar] [CrossRef]

- Kumar, R.; Choudhary, H.K.; Pawar, S.P.; Bose, S.; Sahoo, B. Carbon encapsulated nanoscale iron/iron-carbide/graphite particles for EMI shielding and microwave absorption. Phys. Chem. Chem. Phys. 2017, 19, 23268–23279. [Google Scholar] [CrossRef]

- Manna, K.; Srivastava, S.K. Tuning of Shells in Trilaminar Core@Shell Nanocomposites in Controlling Electromagnetic Interference through Switching of the Shielding Mechanism. Langmuir 2020, 36, 4519–4531. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; You, K.Y. Electromagnetic Interference Shielding Mechanisms of MMG@PVDF Composites for a Broadband Frequency Range. Mater. Today Commun. 2023, 35, 106273. [Google Scholar] [CrossRef]

- Han, T.; Luo, R. Effect of carbon nanotubes on the electromagnetic shielding properties of SiC f /SiC composites. J. Alloys Compd. 2018, 745, 90–99. [Google Scholar] [CrossRef]

- Hu, X.-S.; Shen, Y.; Lu, L.-S.; Xu, J.; Zhen, J.-J. Enhanced electromagnetic interference shielding effectiveness of ternary PANI/CuS/RGO composites. J. Mater. Sci. Mater. Electron. 2017, 28, 6865–6872. [Google Scholar] [CrossRef]

- Zhao, Z.J.; Zhang, B.Y.; Du, Y.; Hei, Y.W.; Yi, X.S.; Shi, F.H.; Xian, G.J. MWCNT modified structure-conductive composite and its electromagnetic shielding behavior. Compos. Part B Eng. 2017, 130, 21–27. [Google Scholar] [CrossRef]

- Bera, R.; Das, A.K.; Maitra, A.; Paria, S.; Karan, S.K.; Khatua, B.B. Salt leached viable porous Fe3O4 decorated polyaniline—SWCNH/PVDF composite spectacles as an admirable electromagnetic shielding efficiency in extended Ku-band region. Compos. Part B Eng. 2017, 129, 210–220. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Y.; Huang, Y.; Ma, Y.; Liu, Z.; Cai, J.; Zhang, C.; Gao, H.; Chen, Y. Electromagnetic interference shielding of graphene/epoxy composites. Carbon 2009, 47, 922–925. [Google Scholar] [CrossRef]

- Byeon, J.H.; Kim, J.-W. Aerosol based fabrication of a Cu/polymer and its application for electromagnetic interference shielding. Thin Solid Film. 2011, 520, 1048–1052. [Google Scholar] [CrossRef]

- Okazaki, Y.; Ueno, K. Magnetic shielding by soft magnetic materials in alternating magnetic field. J. Magn. Magn. Mater. 1992, 112, 192–194. [Google Scholar] [CrossRef]

- Gahlout, P.; Choudhary, V. EMI shielding response of polypyrrole-MWCNT/polyurethane composites. Synth. Met. 2020, 266, 116414. [Google Scholar] [CrossRef]

- Shakir, M.F.; Abdul Rashid, I.; Tariq, A.; Nawab, Y.; Afzal, A.; Nabeel, M.; Naseem, A.; Hamid, U. EMI Shielding Characteristics of Electrically Conductive Polymer Blends of PS/PANI in Microwave and IR Region. J. Electron. Mater. 2020, 49, 1660–1665. [Google Scholar] [CrossRef]

- Li, X.; Xu, T.; Cao, W.; Wang, M.; Chen, F.; Jin, L.; Song, N.; Sun, S.; Ding, P. Graphene/carbon fiber network constructed by co-carbonization strategy for functional integrated polyimide composites with enhanced electromagnetic shielding and thermal conductive properties. Chem. Eng. J. 2023, 464, 142595. [Google Scholar] [CrossRef]

- Meher, D.; Suman, N.; Karna, N.; Sahoo, B.P. Development of Poly (vinylidene fluoride) and Polyaniline blend with high dielectric permittivity, excellent electromagnetic shielding effectiveness and Ultra low optical energy band gap: Effect of ionic liquid and temperature. Polymer 2019, 181, 121759. [Google Scholar] [CrossRef]

- Acharya, S.; Datar, S. Wideband (8–18 GHz) microwave absorption dominated electromagnetic interference (EMI) shielding composite using copper aluminum ferrite and reduced graphene oxide in polymer matrix. J. Appl. Phys. 2020, 128, 104902. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Yue, T.-N.; Gao, Y.-N.; Shi, Y.-D.; Shen, J.-B.; Wu, H.; Wang, M. Robust electromagnetic interference shielding, joule heating, thermal conductivity, and anti-dripping performances of polyoxymethylene with uniform distribution and high content of carbon-based nanofillers. Compos. Sci. Technol. 2021, 206, 108681. [Google Scholar] [CrossRef]

- Li, T.; Zhao, G.; Wang, G. Effect of preparation methods on electrical and electromagnetic interference shielding properties of PMMA/MWCNT nanocomposites. Polym. Compos. 2018, 40, E1786–E1800. [Google Scholar] [CrossRef]

- Chung, D.D.L. Carbon materials for structural self-sensing, electromagnetic shielding and thermal interfacing. Carbon 2012, 50, 3342–3353. [Google Scholar] [CrossRef]

- Gupta, S.; Tai, N.-H. Carbon Materials and Their Composites for Electromagnetic Interference Shielding Effectiveness in X-band. Carbon 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Khodiri, A.A.; Al-Ashry, M.Y.; El-Shamy, A.G. Novel hybrid nanocomposites based on polyvinyl alcohol/graphene/magnetite nanoparticles for high electromagnetic shielding performance. J. Alloys Compd. 2020, 847, 156430. [Google Scholar] [CrossRef]

- Zhang, H.; Heng, Z.; Zhou, J.; Shi, Y.; Chen, Y.; Zou, H.; Liang, M. In-situ co-continuous conductive network induced by carbon nanotubes in epoxy composites with enhanced electromagnetic interference shielding performance. Chem. Eng. J. 2020, 398, 125559. [Google Scholar] [CrossRef]

- Serrato, V.M.; Padilla, V.; Jones, D.; Herrera, S.; Campos, L.; Serrato, I.; Foltz, H.; Lozano, K. Electromagnetic interference shielding effectiveness of compression molded carbon nanofiber-reinforced polyvinylidene difluoride film. Polym. Compos. 2022, 44, 592–608. [Google Scholar] [CrossRef]

- Mohsina, T.; Manohara, S.R.; Siddlingeshwar, B.; Narasimha, R.; Muhammad, F.; Khadke, U.V. Anticorrosion and electromagnetic interference shielding performance of bifunctional PEDOT-graphene nanocomposites. Diam. Relat. Mater. 2023, 132, 109690. [Google Scholar]

- Vineeta, S.; Sanjeev, K.S. Reduced graphene oxide/PdNi/poly(ethylene-co-vinyl acetate) nanocomposites for electromagnetic interference shielding. Mater. Chem. Phys. 2021, 276, 125418. [Google Scholar]

- Zhao, Y.; Hou, J.; Bai, Z.; Yang, Y.; Guo, X.; Cheng, H.; Zhao, Z.; Zhang, X.; Chen, J.; Shen, C. Facile preparation of lightweight PE/PVDF/Fe3O4/CNTs nanocomposite foams with high conductivity for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106095. [Google Scholar] [CrossRef]

- Kuang, T.; Chang, L.; Chen, F.; Sheng, Y.; Fu, D.; Peng, X. Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 105, 305–313. [Google Scholar] [CrossRef]

- Zeng, Q.; Du, Z.; Qin, C.; Wang, Y.; Liu, C.; Shen, C. Enhanced thermal, mechanical and electromagnetic interference shielding properties of graphene nanoplatelets-reinforced poly(lactic acid)/poly(ethylene oxide) nanocomposites. Mater. Today Commun. 2020, 25, 101632. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Ni, J.; Zhan, R.; Qiu, J.; Fan, J.; Dong, B.; Guo, Z. Multi-interfaced graphene aerogel/polydimethylsiloxane metacomposites with tunable electrical conductivity for enhanced electromagnetic interference shielding. J. Mater. Chem. C 2020, 8, 11748–11759. [Google Scholar] [CrossRef]

- Chakraborty, T.; Debnath, T.; Bhowmick, S.; Bandyopadhyay, A.; Karmakar, A.; Das, S.; Mahapatra, A.S.; Sutradhar, S. Enhancement of EMI shielding effectiveness of flexible Co2U-type hexaferrite (Ba4Co2Fe36O60)-poly(vinylidene fluoride) heterostructure composite materials: An improved radar absorbing material to combat against electromagnetic pollution. J. Appl. Phys. 2020, 128, 095301. [Google Scholar] [CrossRef]

- Cheng, Z.; Cao, Y.; Wang, R.; Xia, L.; Ma, S.; Li, Z.; Cai, Z.; Zhang, Z.; Huang, Y. Hierarchical Surface Engineering of Carbon Fiber for Enhanced Composites Interfacial Properties and Microwave Absorption Performance. Carbon 2021, 185, 669–680. [Google Scholar] [CrossRef]

- Schmitz, D.P.; Silva, T.I.; Ramoa, S.D.A.S.; Barra, G.M.O.; Pegoretti, A.; Soares, B.G. Hybrid composites of ABS with carbonaceous fillers for electromagnetic shielding applications. J. Appl. Polym. Sci. 2018, 135, 46546. [Google Scholar] [CrossRef]

- George, G.; Simon, S.M.; Prakashan, V.P.; Sajna, M.S.; Faisal, M.; Chandran, A.; Wilson, R.; Biju, P.R.; Joseph, C.; Unnikrishnan, N.V. Morphological, dielectric, tunable electromagnetic interference shielding and thermal characteristics of multiwalled carbon nanotube incorporated polymer nanocomposites: A facile, environmentally benign and cost effective approach realized via polymer latex/waterborne polymer as matrix. Polym. Compos. 2017, 39, E1169–E1183. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Z.; Yu, Y.; Wen, B.; Liu, Y.; Qiu, M. Tunable Electromagnetic Interference Shielding Ability in a One-Dimensional Bagasse Fiber/Polyaniline Heterostructure. ACS Appl. Energy Mater. 2019, 1, 737–745. [Google Scholar] [CrossRef]

- Ankur, K.; Palash, D.; Sangit, P.; Krishnendu, N.; Suman Kumar, G.; Narayan, C.D. Preferential localization of conductive filler in ethylene-co-methyl acrylate/thermoplastic polyolefin polymer blends to reduce percolation threshold and enhanced electromagnetic radiation shielding over K band region. Polym. Compos. 2022, 44, 1603–1616. [Google Scholar]

- Wang, Y.; Yang, C.; Xin, Z.; Luo, Y.; Wang, B.; Feng, X.; Mao, Z.; Sui, X. Poly(lactic acid)/carbon nanotube composites with enhanced electrical conductivity via a two-step dispersion strategy. Compos. Commun. 2022, 30, 101087. [Google Scholar] [CrossRef]

- Raju, P.; Rani, G.N.; Kumar, S.U.; Andrews, J.; Raju, K.C.J. Ultrasonically induced in situ polymerization of PANI-SWCNT nanocomposites for electromagnetic shielding applications. J. Mater. Sci. Mater. Electron. 2022, 33, 5138–5148. [Google Scholar] [CrossRef]

- Chen, K.; Feng, Y.; Shi, Y.; Wang, H.; Fu, L.; Liu, M.; Lv, Y.; Yang, F.; Yu, B.; Liu, M.; et al. Flexible and fire safe sandwich structured composites with superior electromagnetic interference shielding properties. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107070. [Google Scholar] [CrossRef]

- Marka, S.K.; Sindam, B.; James Raju, K.C.; Srikanth, V.V.S.S. Flexible few-layered graphene/poly vinyl alcohol composite sheets: Synthesis, characterization and EMI shielding in X-band through the absorption mechanism. RSC Adv. 2015, 5, 36498–36506. [Google Scholar] [CrossRef]

- Park, Y.; Baeg, K.-J.; Kim, C. Solution-Processed Nonvolatile Organic Transistor Memory Based on Semiconductor Blends. ACS Appl. Mater. Interfaces 2019, 11, 8327–8336. [Google Scholar] [CrossRef]

- Leydecker, T.; Squillaci, M.A.; Liscio, F.; Orgiu, E.; Samorì, P. Controlling Ambipolar Transport and Voltage Inversion in Solution-Processed Thin-Film Devices through Polymer Blending. Chem. Mater. 2018, 31, 6491–6498. [Google Scholar] [CrossRef]

- Duan, H.; Yang, J.; Yang, Y.; Zhao, G.; Liu, Y. TiO2 hybrid polypropylene/nickel coated glass fiber conductive composites for highly efficient electromagnetic interference shielding. J. Mater. Sci. Mater. Electron. 2016, 28, 5725–5732. [Google Scholar] [CrossRef]

- Na, R.; Liu, J.; Wang, G.; Zhang, S. Light weight and flexible poly(ether ether ketone) based composite film with excellent thermal stability and mechanical properties for wide-band electromagnetic interference shielding. RSC Adv. 2018, 8, 3296–3303. [Google Scholar] [CrossRef] [PubMed]

- Sharika, T.; Abraham, J.; Arif, P.M.; George, S.C.; Kalarikkal, N.; Thomas, S. Excellent electromagnetic shield derived from MWCNT reinforced NR/PP blend nanocomposites with tailored microstructural properties. Compos. Part B Eng. 2019, 173, 106798. [Google Scholar] [CrossRef]

- Naz, A.; Kausar, A.; Siddiq, M. Influence of Graphite Filler on Physicochemical Characteristics of Polymer/Graphite Composites: A Review. Polym. -Plast. Technol. Mater. 2015, 55, 604–625. [Google Scholar] [CrossRef]

- Chen, W.; Hu, W.; Li, D.; Chen, S.; Dai, Z. A critical review on the development and performance of polymer/graphene nanocomposites. Sci. Eng. Compos. Mater. 2018, 25, 1059–1073. [Google Scholar] [CrossRef] [Green Version]

- Yun, J.; Kim, H.-I. Electromagnetic interference shielding effects of polyaniline-coated multi-wall carbon nanotubes/maghemite nanocomposites. Polym. Bull. 2011, 68, 561–573. [Google Scholar] [CrossRef]

- Loste, J.; Lopez-Cuesta, J.-M.; Billon, L.; Garay, H.; Save, M. Transparent polymer nanocomposites: An overview on their synthesis and advanced properties. Prog. Polym. Sci. 2018, 89, 133–158. [Google Scholar] [CrossRef]

- Harito, C.; Bavykin, D.V.; Yuliarto, B.; Dipojono, H.K.; Walsh, F.C. Polymer nanocomposites having a high filler content: Synthesis, structures, properties, and applications. Nanoscale 2019, 11, 4653–4682. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Yang, X.; Ruan, K.; Kong, J.; Dong, M.; Zhang, J.; Gu, J.; Guo, Z. Reduced Graphene Oxide Heterostructured Silver Nanoparticles Significantly Enhanced Thermal Conductivities in Hot-Pressed Electrospun Polyimide Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 25465–25473. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Zhu, P.-L.; Yu, S.-H.; Sun, R.; Wong, C.-P.; Liao, W.-H. Anticorrosive, Ultralight, and Flexible Carbon-Wrapped Metallic Nanowire Hybrid Sponges for Highly Efficient Electromagnetic Interference Shielding. Small 2018, 14, 1800534. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, Y.; Ma, X.; Shahabadi, S.I.S.; Che, B.; Wang, P.; Lu, X. Biomass-based honeycomb-like architectures for preparation of robust carbon foams with high electromagnetic interference shielding performance. Carbon 2018, 140, 227–236. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, S.; Sun, H.; Zeng, W.; Ling, C.; Chen, D.; Chan, V.; Liao, K. Engineering closed-cell structure in lightweight and flexible carbon foam composite for high-efficient electromagnetic interference shielding. Carbon 2018, 136, 299–308. [Google Scholar] [CrossRef]

- Dhakate, S.R.; Subhedar, K.M.; Singh, B.P. Polymer nanocomposite foam filled with carbon nanomaterials as an efficient electromagnetic interference shielding material. RSC Adv. 2015, 5, 43036–43057. [Google Scholar] [CrossRef]

- Li, M.; Xu, Q.; Jiang, W.; Farooq, A.; Qi, Y.; Liu, L. Preparation and Investigation of Fe3O4@rGO/CNF Foams for Electromagnetic Interference Shielding. Fibers Polym. 2023, 24, 771–778. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Hua, W.; Zhang, A.; Bao, J. Light-Weight Silver Plating Foam and Carbon Nanotube Hybridized Epoxy Composite Foams with Exceptional Conductivity and Electromagnetic Shielding Property. ACS Appl. Mater. Interfaces 2016, 8, 24131–24142. [Google Scholar] [CrossRef]

- Ling, J.; Zhai, W.; Feng, W.; Shen, B.; Zhang, J.; Zheng, W.G. Facile Preparation of Lightweight Microcellular Polyetherimide/Graphene Composite Foams for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2013, 5, 2677–2684. [Google Scholar] [CrossRef]

- Oraby, H.; Naeem, I.; Darwish, M.; Senna, M.H.; Tantawy, H.R. Electromagnetic interference shielding of thermally exfoliated graphene/polyurethane composite foams. J. Appl. Polym. Sci. 2022, 139, 53008. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, W.J.; Zeng, Z.; Sun, D.X.; Qi, X.D.; Yang, J.H.; Wang, Y. Multifunctional shape memory foam composites integrated with tunable electromagnetic interference shielding and sensing. Chem. Eng. J. 2023, 466, 143373. [Google Scholar] [CrossRef]

- Li, Z.; Sun, Y.; Zhou, B.; Feng, Y.; Liu, C.; Shen, C. Flexible thermoplastic polyurethane/MXene foams for compressible electromagnetic interference shielding. Mater. Today Phys. 2023, 32, 101017. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, Z.; Tian, N.; Li, Y.; You, C.; Islam, S.M. Synergistically-enhanced flexible electromagnetic interference shielding nanocomposites. Appl. Surf. Sci. 2023, 628, 157379. [Google Scholar] [CrossRef]

- Lee, C.W.; Lin, C.H.; Wang, L.Y.; Lee, Y.H. Developing sustainable and recyclable high-efficiency electromagnetic interference shielding nanocomposite foams from the upcycling of recycled poly(ethylene terephthalate). Chem. Eng. J. 2023, 468, 143447. [Google Scholar] [CrossRef]

- Oraby, H.; Naeem, I.; Darwish, M.; Senna, M.H.; Tantawy, H.R. Optimization of electromagnetic shielding and mechanical properties of reduced graphene oxide/polyurethane composite foam. Polym. Eng. Sci. 2022, 62, 3075–3087. [Google Scholar] [CrossRef]

- Wang, X.; Wang, G.; He, G.; Liao, X.; Song, P.; Zou, F.; Liu, S.; Luo, Y.; Li, G. Fabrication of lightweight flexible thermoplastic polyurethane/multiwalled carbon nanotubes composite foams for adjustable frequency-selective electromagnetic interference shielding by supercritical carbon dioxide. J. Supercrit. Fluids 2022, 188, 105675. [Google Scholar] [CrossRef]

- Dun, D.; Luo, J.; Wang, M.; Wang, X.; Zhou, H.; Wang, X.; Wen, B.; Zhang, Y. Electromagnetic Interference Shielding Foams Based on Poly(vinylidene fluoride)/Carbon Nanotubes Composite. Macromol. Mater. Eng. 2021, 306, 2100468. [Google Scholar] [CrossRef]

- Zou, F.; Chen, J.; Liao, X.; Song, P.; Li, G. Efficient electrical conductivity and electromagnetic interference shielding performance of double percolated polymer composite foams by phase coarsening in supercritical CO2. Compos. Sci. Technol. 2021, 213, 108895. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Z.; Liu, X.; Zhao, T.; Zhu, P.; Zeng, X.; Hu, Y.; Sun, R.; Wong, C.-P. Robust and flexible silver-embedded elastomeric polymer/carbon black foams with outstanding electromagnetic interference shielding performance. Compos. Sci. Technol. 2021, 213, 108942. [Google Scholar] [CrossRef]

- Luo, J.; Yin, D.; Yu, K.; Zhou, H.; Wen, B.; Wang, X. Facile Fabrication of PBS/CNTs Nanocomposite Foam for Electromagnetic Interference Shielding. ChemPhysChem 2022, 23, 202100778. [Google Scholar] [CrossRef]

- Kim, E.; Zhang, H.; Lee, J.-H.; Chen, H.; Zhang, H.; Javed, M.H.; Shen, X.; Kim, J.-K. MXene/polyurethane auxetic composite foam for electromagnetic interference shielding and impact attenuation. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106430. [Google Scholar] [CrossRef]

- Liang, S.; Qin, Y.; Gao, W.; Wang, M. A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding. e-Polymers 2022, 22, 223–233. [Google Scholar] [CrossRef]

- Wang, P.; Yang, L.; Ling, J.; Song, J.; Song, T.; Chen, X.; Gao, S.; Feng, S.; Ding, Y.; Murugadoss, V.; et al. Frontal ring-opening metathesis polymerized polydicyclopentadiene carbon nanotube/graphene aerogel composites with enhanced electromagnetic interference shielding. Adv. Compos. Hybrid Mater. 2022, 5, 2066–2077. [Google Scholar] [CrossRef]

- Xia, B.; Zhang, X.; Jiang, J.; Wang, Y.; Li, T.; Wang, Z.; Chen, M.; Liu, T.; Dong, W. Facile preparation of high strength, lightweight and thermal insulation Polyetherimide/Ti3C2Tx MXenes/Ag nanoparticles composite foams for electromagnetic interference shielding. Compos. Commun. 2021, 29, 101028. [Google Scholar] [CrossRef]

- Bai, Y.A.; Wei, X.; Dun, D.; Bai, S.; Zhou, H.; Wen, B.; Wang, X.; Hu, J. Lightweight poly(vinylidene fluoride) based quaternary nanocomposite foams with efficient and tailorable electromagnetic interference shielding properties. Polym. Compos. 2023, 44, 1951–1966. [Google Scholar] [CrossRef]

- Bai, Y.A.; Zheng, K.; Cui, W.; Luo, J.; Zhou, H.; Wang, X.; Wen, B.; Xing, Q. Electromagnetic shielding performance of acrylonitrile-butadiene-styrene/CNTs composite foams with different cell structures. J. Supercrit. Fluids 2022, 186, 105608. [Google Scholar] [CrossRef]

- Gedler, G.; Antunes, M.; Velasco, J.I.; Ozisik, R. Enhanced electromagnetic interference shielding effectiveness of polycarbonate/graphene nanocomposites foamed via 1-step supercritical carbon dioxide process. Mater. Des. 2016, 90, 906–914. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Wang, X.; Pan, Z.; Huang, H. Sodium bicarbonate/azodiisobutyronitrile synergistic effect on low-density unsaturated polyester resin fabrication. Iran. Polym. J. 2018, 27, 207–216. [Google Scholar] [CrossRef]

- Li, R.; Lin, H.; Lan, P.; Gao, J.; Huang, Y.; Wen, Y.; Yang, W. Lightweight Cellulose/Carbon Fiber Composite Foam for Electromagnetic Interference (EMI) Shielding. Polymers 2018, 10, 1319. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Qiu, H.; Han, Y.; Gu, H.; Song, P.; Wang, L.; Kong, J.; Cao, D.; Gu, J. Superior electromagnetic interference shielding 3D graphene nanoplatelets/reduced graphene oxide foam/epoxy nanocomposites with high thermal conductivity. J. Mater. Chem. C 2019, 7, 2725–2733. [Google Scholar] [CrossRef]

- Zhao, N.; Li, M.; Gong, H.; Bai, H. Controlling ice formation on gradient wettability surface for high-performance bioinspired materials. Sci. Adv. 2020, 6, eabb4712. [Google Scholar] [CrossRef]

- Li, D.; Bu, X.; Xu, Z.; Luo, Y.; Bai, H. Bioinspired Multifunctional Cellular Plastics with a Negative Poisson’s Ratio for High Energy Dissipation. Adv. Mater. 2020, 32, e2001222. [Google Scholar] [CrossRef]

- Göldel, A.; Kasaliwal, G.; Pötschke, P. Selective Localization and Migration of Multiwalled Carbon Nanotubes in Blends of Polycarbonate and Poly(styrene-acrylonitrile). Macromol. Rapid Commun. 2009, 30, 423–429. [Google Scholar] [CrossRef]

- Grady, B.P. Recent Developments Concerning the Dispersion of Carbon Nanotubes in Polymers. Macromol. Rapid Commun. 2009, 31, 247–257. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; He, H.; He, G.; Zhao, J.; Yang, Y.; Tian, G. Segregated polylactide/poly(butylene adipate-co-terephthalate)/MWCNTs nanocomposites with excellent electrical conductivity and electromagnetic interference shielding. J. Appl. Polym. Sci. 2021, 139, 51668. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Cui, C.-H.; Ji, X.; Li, Z.-M. A Unique Double Percolated Polymer Composite for Highly Efficient Electromagnetic Interference Shielding. Macromol. Mater. Eng. 2016, 301, 1232–1241. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.-H.; Feng, L.-M.; Wang, N.; Guo, J.; Sun, K.; Yu, K.-X.; Zeng, J.-B.; Li, T.; Guo, Z.; et al. Ultralow percolation threshold and enhanced electromagnetic interference shielding in poly(L-lactide)/multi-walled carbon nanotube nanocomposites with electrically conductive segregated networks. J. Mater. Chem. C 2017, 5, 9359–9369. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, C.; Xia, L.; Wang, L.; Qi, C.; Zhang, G.; Tan, Z.; Ren, B.; Yuan, B. Bridge-graphene connecting polymer composite with a distinctive segregated structure for simultaneously improving electromagnetic interference shielding and flame-retardant properties. Colloids Surf. A Physicochem. Eng. Asp. 2022, 661, 130853. [Google Scholar] [CrossRef]

- Mei, X.; Zhao, Y.; Jiang, H.; Gao, T.; Huang, Z.X.; Qu, J.P. Multifunctional starch/carbon nanotube composites with segregated structure: Electrical conductivity, electromagnetic interference shielding effectiveness, thermal conductivity, and electro-thermal conversion. J. Appl. Polym. Sci. 2023, 2023, e53904. [Google Scholar] [CrossRef]

- Navid, K.; Amir Hosein Ahmadian, H.; Parisa, N.; Jian, L.; Abbas, S.M.; Mohammad, A. Highly conductive polystyrene/carbon Nanotube/PEDOT:PSS nanocomposite with segregated structure for electromagnetic interference shielding. Carbon 2023, 212, 118104. [Google Scholar]

- Tian, G.; He, H.; Xu, M.; Liu, Y.; Gao, Q.; Zhu, Z. Ultralow percolation threshold biodegradable PLA/PBS/MWCNTs with segregated conductive networks for high-performance electromagnetic interference shielding applications. J. Appl. Polym. Sci. 2022, 140, e53558. [Google Scholar] [CrossRef]

- Xiong, Y.; Pei, H.; Lv, Q.; Chen, Y. A Facile Fabrication of PA12/CNTs Nanocomposites with Enhanced Three-Dimensional Segregated Conductive Networks and Electromagnetic Interference Shielding Property through Selective Laser Sintering. ACS Omega 2022, 7, 4293–4304. [Google Scholar] [CrossRef]

- Zhang, Q.; Cui, J.; Zhao, S.; Gao, A.; Zhang, G.; Yan, Y. Regulation binary electromagnetic filler networks in segregated poly(vinylidenefluoride) composite for absorption-dominated electromagnetic interference shielding. J. Appl. Polym. Sci. 2023, 140, e53650. [Google Scholar] [CrossRef]

- Wu, B.; Zhu, K.; Wen, X.; Li, M.; Yang, Y.; Yang, J. Fe3O4@PA6/MWCNT composites with multiple gradient segregated structures for electromagnetic shielding with low reflection. J. Appl. Polym. Sci. 2022, 139, 52085. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Liu, C.; Wang, H.; Yan, X.; Chai, X.; Chen, Z.; Xia, Y.; Gao, H.; Zhang, H.; et al. Constructing 3D expanded graphite-silver segregated network structure for ultra-efficient EMI shielding and low reflection. J. Mater. Res. Technol. 2023, 23, 5115–5126. [Google Scholar] [CrossRef]

- Wang, X.; Smith, P.; Qiang, Z.; Guan, Q.; You, Z.; Ye, C.; Zhu, M. Fire-retardant, self-extinguishing multiblock poly(esterimide)s/graphene composites with segregated structure for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107262. [Google Scholar] [CrossRef]

- Ma, R.-Y.; Yi, S.-Q.; Li, J.; Zhang, J.-L.; Sun, W.-J.; Jia, L.-C.; Yan, D.-X.; Li, Z.-M. Highly efficient electromagnetic interference shielding and superior mechanical performance of carbon nanotube/polydimethylsiloxane composite with interface-reinforced segregated structure. Compos. Sci. Technol. 2022, 232, 109874. [Google Scholar] [CrossRef]

- Pang, H.; Xu, L.; Yan, D.X.; Li, Z.M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Yu, W.-C.; Xu, J.-Z.; Wang, Z.-G.; Huang, Y.-F.; Yin, H.-M.; Xu, L.; Chen, Y.-W.; Yan, D.-X.; Li, Z.-M. Constructing highly oriented segregated structure towards high-strength carbon nanotube/ultrahigh-molecular-weight polyethylene composites for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2018, 110, 237–245. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, S.; Peng, L.; Zhong, K.; Chen, Y. Optimized Properties in Multifunctional Polyphenylene Sulfide Composites via Graphene Nanosheets/Boron Nitride Nanosheets Dual Segregated Structure under High Pressure. Nanomaterials 2022, 12, 3543. [Google Scholar] [CrossRef]

- Xie, Z.; Cai, Y.; Zhan, Y.; Meng, Y.; Li, Y.; Xie, Q.; Xia, H. Thermal insulating rubber foams embedded with segregated carbon nanotube networks for electromagnetic shielding applications. Chem. Eng. J. 2022, 435, 135118. [Google Scholar] [CrossRef]

- Yang, D.; Tao, J.-R.; Yang, Y.; He, Q.-M.; Weng, Y.-X.; Fei, B.; Wang, M. Effect interfacial size and multiple interface on electromagnetic shielding of silicon rubber/carbon nanotube composites with mixing segregated particles. Compos. Struct. 2022, 292, 115668. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, X.-D.; Song, W.-L.; Ma, C.-J.; Bian, X.-M.; Chen, M. Hydro-sensitive sandwich structures for self-tunable smart electromagnetic shielding. Chem. Eng. J. 2018, 344, 342–352. [Google Scholar] [CrossRef]

- Zhang, P.; Tian, R.; Zhang, X.; Ding, X.; Wang, Y.; Xiao, C.; Zheng, K.; Liu, X.; Chen, L.; Tian, X. Electromagnetic interference shielding epoxy composites with satisfactory thermal conductivity and electrical insulation performance enabled by low-melting-point alloy layered structure. Compos. Part B Eng. 2022, 232, 109611. [Google Scholar] [CrossRef]

- Sheng, A.; Ren, W.; Yang, Y.; Yan, D.-X.; Duan, H.; Zhao, G.; Liu, Y.; Li, Z.-M. Multilayer WPU conductive composites with controllable electro-magnetic gradient for absorption-dominated electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2019, 129, 105692. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The influence of gradient and sandwich configurations on the electromagnetic interference shielding performance of multilayered thermoplastic polyurethane/graphene composite foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Park, K.; Lee, S.; Kim, C.; Han, J. Fabrication and electromagnetic characteristics of electromagnetic wave absorbing sandwich structures. Compos. Sci. Technol. 2006, 66, 576–584. [Google Scholar] [CrossRef]

- Li, H.; Ru, X.; Song, Y.; Wang, H.; Yang, C.; Zheng, S.; Gong, L.; Zhang, X.; Duan, H.; Liu, Z.; et al. Flexible Sandwich-Structured Silicone Rubber/MXene/Fe3O4 Composites for Tunable Electromagnetic Interference Shielding. Ind. Eng. Chem. Res. 2022, 61, 11766–11776. [Google Scholar] [CrossRef]

- Wang, H.; Bi, H.; Liang, D.; Gui, X.; Ding, X.; Zhang, X.; Gao, J.; Zi, Z. Absorption-dominated electromagnetic shielding and excellent thermal conduction properties of poly(vinylidene fluoride)/SnBi58/Co-C composites with layered structure. J. Alloys Compd. 2022, 921, 165998. [Google Scholar] [CrossRef]

- Xu, L.; Wan, S.; Heng, Y.; Wang, S.; Yang, J.; Dong, Y.; Fu, Y.; Ni, Q. Double layered design for electromagnetic interference shielding with ultra-low reflection features: PDMS including carbon fibre on top and graphene on bottom. Compos. Sci. Technol. 2022, 231, 109797. [Google Scholar] [CrossRef]

- Zhou, Q.; Luo, D.; Hua, D.; Ye, W.; Li, S.; Zou, Q.; Chen, Z.; Wang, H. Design and characterization of metallic glass/graphene multilayer with excellent nanowear properties. Friction 2022, 10, 1913–1926. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Q.; Sheng, X.; Zhang, S.; Chen, J.; Ma, Y.; Qin, J.; Zhao, Y.; Shi, X.; Zhang, G. Flexible, robust, sandwich structure polyimide composite film with alternative MXene and Ag NWs layers for electromagnetic interference shielding. J. Mater. Sci. Technol. 2023, 159, 194–203. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Zhu, K.; Yang, Y.; Wen, X.; Liu, R.; Zhu, H.; Huang, J. Efficient Electromagnetic Interference Shielding of PPA6@NiM/PDMS Composites with Porous and Asymmetric Gradient Structures. ACS Appl. Polym. Mater. 2023, 5, 4789–4798. [Google Scholar] [CrossRef]

- Chu, Q.; Tao, W.; Lin, H.; Ma, M.; Chen, S.; Shi, Y.; He, H.; Wang, X. Well-designed structure of sandwich-like composite films based on hollow polyaniline and MXene with enhanced electromagnetic wave absorption. Ind. Crops Prod. 2023, 194, 116299. [Google Scholar] [CrossRef]

- Guo, D.; Huo, Y.; Mu, C.; Wang, B.; Xiang, J.; Nie, A.; Zhai, K.; Xue, T.; Wen, F.; Liu, Z. Flexible aramid nanofiber/Ag nanowires/graphene nanosheets composite films with sandwich structure for high-performance electromagnetic interference shielding and Joule heating. J. Alloys Compd. 2022, 923, 166401. [Google Scholar] [CrossRef]

- Song, P.; Liao, X.; Zou, F.; Wang, X.; Liu, F.; Liu, S.; Li, G. Frequency-adjustable electromagnetic interference shielding performance of sandwich-structured conductive polymer composites by selective foaming and tunable filler dispersion. Compos. Commun. 2022, 34, 101264. [Google Scholar] [CrossRef]

- Liu, F.; Wei, Z.; Hu, X.; Cai, Y.; Chen, Z.; Yang, C.; Zhan, Y.; Xia, H. Asymmetric segregated network design of ultralight and thermal insulating polymer composite foams for green electromagnetic interference shielding. Compos. Commun. 2022, 38, 101492. [Google Scholar] [CrossRef]

- Xing, Y.; Wan, Y.; Wu, Z.; Wang, J.; Jiao, S.; Liu, L. Multilayer Ultrathin MXene@AgNW@MoS2 Composite Film for High-Efficiency Electromagnetic Shielding. ACS Appl. Mater. Interfaces 2023, 15, 5787–5797. [Google Scholar] [CrossRef] [PubMed]

- Gu, T.; Zeng, Z.; Wu, S.; Sun, D.X.; Zhao, C.S.; Wang, Y. Poly(L-lactic acid)/graphene composite films with asymmetric sandwich structure for thermal management and electromagnetic interference shielding. Chem. Eng. J. 2023, 466, 143190. [Google Scholar] [CrossRef]

- Zhang, C.; Bi, L.; Shi, S.; Wang, H.; Zhang, D.; He, Y.; Li, W. Two-Steps Method to Prepare Multilayer Sandwich Structure Carbon Fiber Composite with Thermal and Electrical Anisotropy and Electromagnetic Interference Shielding. Materials 2023, 16, 680. [Google Scholar] [CrossRef]

- Xia, Q.; Zhang, Z.; Chu, H.; Liu, Y.; Leng, J. Research on high electromagnetic interference shielding effectiveness of a foldable buckypaper/polyacrylonitrile composite film via interface reinforcing. Compos. Part A Appl. Sci. Manuf. 2018, 113, 132–140. [Google Scholar] [CrossRef]

- Thomassin, J.-M.; Jérôme, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Jayalakshmi, C.G.; Inamdar, A.; Anand, A.; Kandasubramanian, B. Polymer matrix composites as broadband radar absorbing structures for stealth aircrafts. J. Appl. Polym. Sci. 2018, 136, 47241. [Google Scholar] [CrossRef] [Green Version]

- Joshi, A.M.; Athawale, A.A. Electrically Conductive Silicone/Organic Polymer Composites. Silicon 2013, 6, 199–206. [Google Scholar] [CrossRef]

- Scott, P. Aerospace and military [Technology 2000 analysis and forecast]. IEEE Spectr. 2000, 37, 97–102. [Google Scholar] [CrossRef]

- Wang, C.; Chen, M.; Lei, H.; Yao, K.; Li, H.; Wen, W.; Fang, D. Radar stealth and mechanical properties of a broadband radar absorbing structure. Compos. Part B Eng. 2017, 123, 19–27. [Google Scholar] [CrossRef]

- Amudhu, L.B.T.; Samsingh, R.V.; Florence, S.E.; Abirami, B.S. Novel radar absorbing material using resistive frequency selective surface based polymer composites for enhanced broadband microwave absorption. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 2023, 14644207231169362. [Google Scholar] [CrossRef]

- Teber, A.; Unver, I.; Kavas, H.; Aktas, B.; Bansal, R. Knitted radar absorbing materials (RAM) based on nickel–cobalt magnetic materials. J. Magn. Magn. Mater. 2016, 406, 228–232. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Pu, N.-W.; Liu, Y.-M.; Huang, S.-Y.; Wu, C.-H.; Ger, M.-D.; Gong, Y.-J.; Chou, Y.-C. Remarkable microwave absorption performance of graphene at a very low loading ratio. Compos. Part B Eng. 2017, 114, 395–403. [Google Scholar] [CrossRef]

- Kasgoz, A.; Korkmaz, M.; Durmus, A. Compositional and structural design of thermoplastic polyurethane/carbon based single and multi-layer composite sheets for high-performance X-band microwave absorbing applications. Polymer 2019, 180, 121672. [Google Scholar] [CrossRef]

- Pratap, V.; Soni, A.K.; Baskey, H.B.; Abbas, S.M.; Siddiqui, A.M.; Prasad, N.E. Electromagnetic and radar absorbing properties of γ Fe2O3/Ba4Co2Fe36O60-epoxy polymeric composites for stealth applications. Solid State Sci. 2021, 113, 106553. [Google Scholar] [CrossRef]

- Gu, W.; Ong, S.J.H.; Shen, Y.; Guo, W.; Fang, Y.; Ji, G.; Xu, Z.J. A Lightweight, Elastic, and Thermally Insulating Stealth Foam with High Infrared-Radar Compatibility. Adv. Sci. 2022, 9, 2204165. [Google Scholar] [CrossRef]

- Lan, D.; Gao, Z.; Zhao, Z.; Kou, K.; Wu, H. Application progress of conductive conjugated polymers in electromagnetic wave absorbing composites. Compos. Commun. 2021, 26, 100767. [Google Scholar] [CrossRef]

- Engels, S.; Schneider, N.-L.; Lefeldt, N.; Hein, C.M.; Zapka, M.; Michalik, A.; Elbers, D.; Kittel, A.; Hore, P.J.; Mouritsen, H. Anthropogenic electromagnetic noise disrupts magnetic compass orientation in a migratory bird. Nature 2014, 509, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Erogul, O.; Oztas, E.; Yildirim, I.; Kir, T.; Aydur, E.; Komesli, G.; Irkilata, H.C.; Irmak, M.K.; Peker, A.F. Effects of electromagnetic radiation from a cellular phone on human sperm motility: An in vitro study. Arch. Med. Res. 2006, 37, 840–843. [Google Scholar] [CrossRef] [PubMed]

- Song, W.-L.; Wang, J.; Fan, L.-Z.; Li, Y.; Wang, C.-Y.; Cao, M.-S. Interfacial Engineering of Carbon Nanofiber–Graphene–Carbon Nanofiber Heterojunctions in Flexible Lightweight Electromagnetic Shielding Networks. ACS Appl. Mater. Interfaces 2014, 6, 10516–10523. [Google Scholar] [CrossRef]

- Savi, P.; Giorcelli, M.; Quaranta, S. Multi-Walled Carbon Nanotubes Composites for Microwave Absorbing Applications. Appl. Sci. 2019, 9, 851. [Google Scholar] [CrossRef] [Green Version]

- Sharma, G.K.; James, N.R. Progress in Electrospun Polymer Composite Fibers for Microwave Absorption and Electromagnetic Interference Shielding. ACS Appl. Electron. Mater. 2021, 3, 4657–4680. [Google Scholar] [CrossRef]

- Guo, H.; Wang, F.; Luo, H.; Li, Y.; Lou, Z.; Ji, Y.; Liu, X.; Shen, B.; Peng, Y.; Liu, K.; et al. Flexible TaC/C electrospun non–woven fabrics with multiple spatial-scale conductive frameworks for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2021, 151, 106662. [Google Scholar] [CrossRef]

- Long, T.; Hu, L.; Dai, H.; Tang, Y. Facile synthesis of Ag-reduced graphene oxide hybrids and their application in electromagnetic interference shielding. Appl. Phys. A 2014, 116, 25–32. [Google Scholar] [CrossRef]

- Xie, S.; Ji, Z.; Zhu, L.; Zhang, J.; Cao, Y.; Chen, J.; Liu, R.; Wang, J. Recent progress in electromagnetic wave absorption building materials. J. Build. Eng. 2019, 27, 100963. [Google Scholar] [CrossRef]

- Terukov, E.I.; Babaev, A.A.; Tkachev, A.G.; Zhilina, D.V. Radio-Wave Absorbing Properties of Polymer Composites on the Basis of Shungite and Carbon Nanomaterial Taunit-M. Tech. Phys. 2018, 63, 1044–1048. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Shuai, X.; Zhao, R.; Guo, T.; Li, K.; Wang, D.; Ma, C.; Li, J.; Du, J. Design and Synthesis Strategies: 2D Materials for Electromagnetic Shielding/Absorbing. Chem. Asian J. 2021, 16, 3817–3832. [Google Scholar] [CrossRef]

- Lan, C.; Li, C.; Hu, J.; Yang, S.; Qiu, Y.; Ma, Y. High-Loading Carbon Nanotube/Polymer Nanocomposite Fabric Coatings Obtained by Capillarity-Assisted “Excess Assembly” for Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2018, 5, 201800116. [Google Scholar] [CrossRef]

- Tao, W.; Ma, M.; Liao, X.; Shao, W.; Chen, S.; Shi, Y.; He, H.; Wang, X. Cellulose nanofiber/MXene/mesoporous carbon hollow spheres composite films with porous structure for deceased reflected electromagnetic interference shielding. Compos. Commun. 2023, 2023, 101647. [Google Scholar] [CrossRef]

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| PVA/GN/Fe3O4 | 0.1 wt% | 40.7 | 0.2 | 8–12 Ghz | [79] |

| EP/PES/MWCNT | 2.9 wt% | 23 | 2.2 | 8–12 Ghz | [80] |

| GN/CFN | 20 wt% | 73 | 2 | 8–12 Ghz | [72] |

| VGCNF/PVDF | 5 wt% | 16.4 | 0.82 | 30 Khz–1.5 Ghz | [81] |

| PEDOT/GNP | 15 wt% | 18 | - | 8–12 Ghz | [82] |

| RGO/PdNi/EVA | 1 wt% | 30 | - | 8–12 Ghz | [83] |

| POM/MWCNT | 40 wt% | 45.7 | 0.15 | 8–12 Ghz | [75] |

| PE/PVDF/Fe3O4/CNT | 10 wt% | 26 | 2.6 | 18–26 Ghz | [84] |

| PLLA/MWCNT | 10 vol% | 23 | 2.5 | 8–12 Ghz | [85] |

| PVDF/RGO | 21 wt% | 60 | 1.5 | 8–12 Ghz | [74] |

| PLA/PEO/GNP | 6 wt% | 10.5 | - | 8–12 Ghz | [86] |

| PMMA/GNP-MWCNT | 8 wt% | 36 | 2 | 8–12 Ghz | [87] |

| PDMS/GA | 12.5 wt% | 52 | 3 | 4–16 Ghz | [88] |

| PVDF/Ba4CO2Fe36O60 | 20 wt% | 83 | 0.12 | 8–18 Ghz | [89] |

| CF/PAA/Fe3O4 | 10 wt% | 40.6 | 3.5 | 2–18 Ghz | [90] |

| PVDF/PANI | 30 wt% | 65 | 1 | 8–12 Ghz | [73] |

| ABS/CB/CNT | 3 wt% | 29 | 2 | 8–12 Ghz | [91] |

| PP/MWCNT | 20 wt% | 47 | 2 | 8–12 Ghz | [92] |

| BF/PANI | 7 wt% | 35.73 | - | 8–12 Ghz | [93] |

| PS/PANI | 40 wt% | 45 | 0.25 | 8–12 Ghz | [71] |

| CB/EMA/TPO | 30 wt% | 29 | 1 | 14–20 Ghz | [94] |

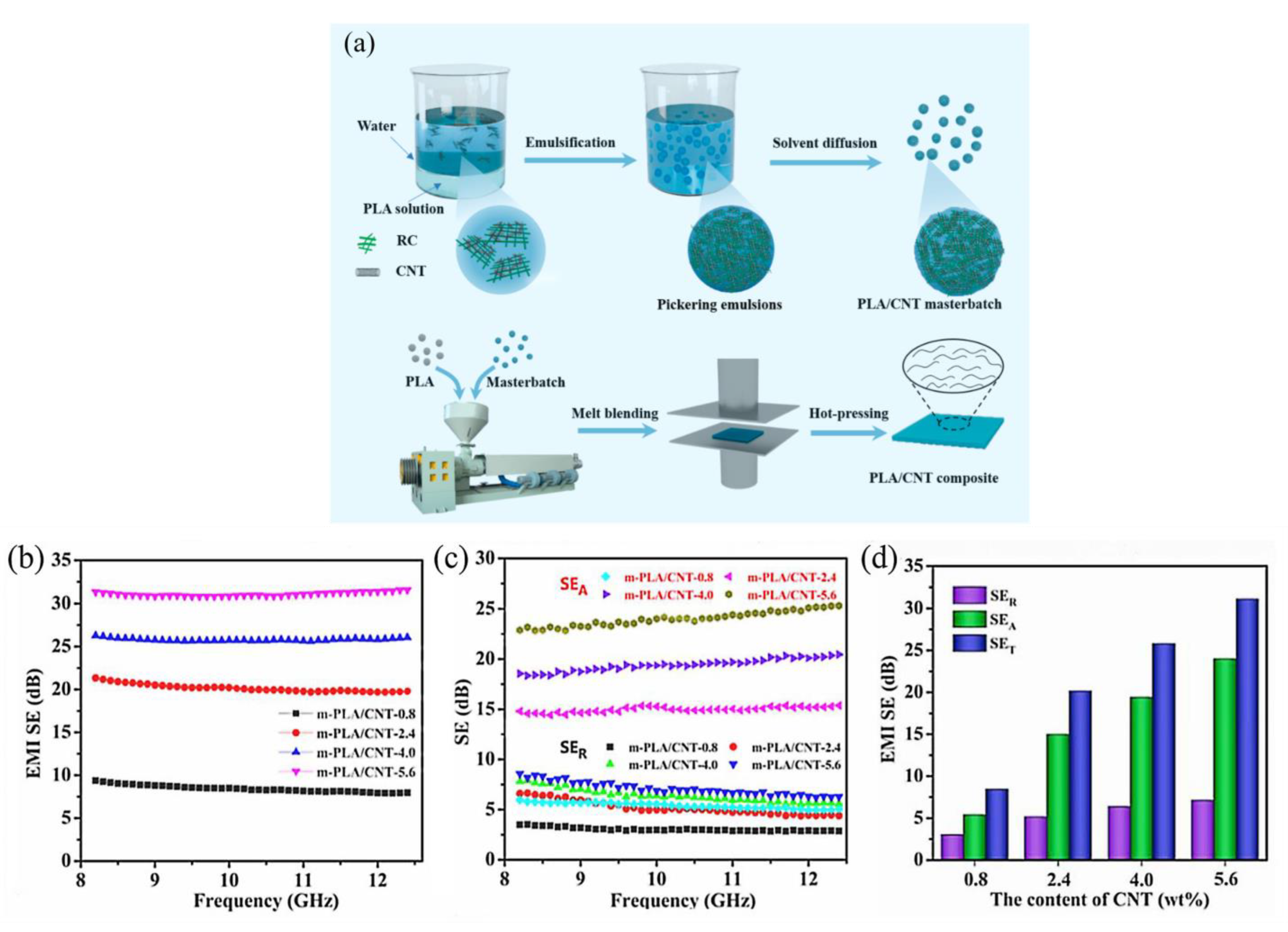

| PLA/CNT | 5.6 wt% | 31.1 | - | 8–12 Ghz | [95] |

| SWCNT/PANI | 3 wt% | 32.8 | 0.5 | 8–12 Ghz | [96] |

| TPU/SiAPP/SCF/Ti3C2Tx MXene | 20 wt% | 50.5 | 1 | 8–12 Ghz | [97] |

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| TEG/PU | 3 wt% | 20.4 | - | 8–12 Ghz | [117] |

| EVA/PPy/AgNPs | 52 wt% | 107.45 | 2.4 | 8–12 Ghz | [118] |

| PEN/GN/CNT/Fe4O3 | 3.5 wt% | 38 | 0.6 | 8–12 Ghz | [37] |

| TPU/Ti3C2Tx MXene | 0.66 vol% | 72.2 | 2 | 8–12 Ghz | [119] |

| CO3O4/CNT/MF | - | 25.6 | 3 | 8–12 Ghz | [120] |

| PET/BAHT/SWCNT | 2 wt% | 45.7 | - | 8–12 Ghz | [121] |

| RGO/PU | 5 wt% | 23 | - | 8–12 Ghz | [122] |

| CMF/SiO2/CNT | 30 wt% | 61.34 | 2 | 8–12 Ghz | [38] |

| TPU/MWCNT | 2.5 wt% | 44.86 | - | 10–14 Ghz | [123] |

| PVDF/CNT | 8 wt% | 41 | 1 | 8–12 Ghz | [124] |

| PS/PMMA/MWCNT | 2 vol% | 25.3 | 2 | 8–12 Ghz | [125] |

| ABS/CB:CNT | 15 wt% | 81.3 | 5 | 8–12 Ghz | [126] |

| PBS/CNT | 4 wt% | 24 | - | 8–12 Ghz | [127] |

| PA6/CF | 22 wt% | 36.6 | 1 | 18–26 Ghz | [36] |

| MXene/APU | 22 wt% | 76.2 | 5 | 8–12 Ghz | [128] |

| MWCNT/WPU/PVA/MCHM | 40 wt% | 23 | 2.5 | 8–12 Ghz | [129] |

| PDCPD-CNT/GN | 3.5 wt% | 43 | 3 | 8–12 Ghz | [130] |

| PEI/Ti3C2Tx MXene/AG | 1 wt% | 28 | - | 8–12 Ghz | [131] |

| PVDF/GNPs/CNT/Ni | 16 wt% | 19.4 | 1 | 8–12 Ghz | [132] |

| ABS/CNT | 7 wt% | 26.6 | 2 | 8–12 Ghz | [133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, W.; Tan, L.; Li, Y.; Qin, L.; Li, S. Review of Polymer-Based Composites for Electromagnetic Shielding Application. Molecules 2023, 28, 5628. https://doi.org/10.3390/molecules28155628

Wang Y, Zhao W, Tan L, Li Y, Qin L, Li S. Review of Polymer-Based Composites for Electromagnetic Shielding Application. Molecules. 2023; 28(15):5628. https://doi.org/10.3390/molecules28155628

Chicago/Turabian StyleWang, Yuqi, Wei Zhao, Linli Tan, Yingru Li, Liu Qin, and Shidong Li. 2023. "Review of Polymer-Based Composites for Electromagnetic Shielding Application" Molecules 28, no. 15: 5628. https://doi.org/10.3390/molecules28155628