Recent Advances of Constructing Metal/Semiconductor Catalysts Designing for Photocatalytic CO2 Hydrogenation

Abstract

:1. Introduction

2. Application of Metal/Semiconductor Catalysts for Photocatalytic CO2 Hydrogenation

2.1. Pd-Based Catalysts

2.2. Ru-Based Catalysts

2.3. Other Metal-Based Catalysts

3. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Bai, X.; Yuan, D.; Yu, C.; San, X.; Guo, Y.; Zhang, L.; Ye, J. Cu-based high-entropy two-dimensional oxide as stable and active photothermal catalyst. Nat. Commun. 2023, 14, 3171. [Google Scholar] [CrossRef]

- Fan, M.; Jimenez, J.D.; Shirodkar, S.N.; Wu, J.; Chen, S.; Song, L.; Royko, M.M.; Zhang, J.; Guo, H.; Cui, J.; et al. Atomic Ru Immobilized on Porous h-BN through Simple Vacuum Filtration for Highly Active and Selective CO2 Methanation. ACS Catal. 2019, 9, 10077–10086. [Google Scholar] [CrossRef]

- Yin, H.; Dong, F.; Wang, D.; Li, J. Coupling Cu Single Atoms and Phase Junction for Photocatalytic CO2 Reduction with 100% CO Selectivity. ACS Catal. 2022, 12, 14096–14105. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Cao, J.; Chen, W.; Wang, G.; Liao, F.; Zhou, X.; Zhou, F.; Li, R.; Yu, Z.Q.; et al. Room-Temperature Synthesis of Single Iron Site by Electrofiltration for Photoreduction of CO2 into Tunable Syngas. ACS Nano 2020, 14, 6164–6172. [Google Scholar] [CrossRef]

- Yang, T.; Mao, X.; Zhang, Y.; Wu, X.; Wang, L.; Chu, M.; Pao, C.-W.; Yang, S.; Xu, Y.; Huang, X. Coordination tailoring of Cu single sites on C3N4 realizes selective CO2 hydrogenation at low temperature. Nat. Commun. 2021, 12, 6022. [Google Scholar] [CrossRef]

- Zhu, X.; Zong, H.; Pérez, C.J.V.; Miao, H.; Sun, W.; Yuan, Z.; Wang, S.; Zeng, G.; Xu, H.; Jiang, Z.; et al. Supercharged CO2 Photothermal Catalytic Methanation: High Conversion, Rate, and Selectivity. Angew. Chem. Int. Ed. 2023, 62, 202218694. [Google Scholar] [CrossRef]

- Zhu, X.; Miao, H.; Chen, J.; Zhu, X.; Yi, J.; Mo, Z.; Li, H.; Zheng, Z.; Huang, B.; Xu, H. Facet-dependent CdS/Bi4TaO8Cl Z-scheme heterojunction for enhanced photocatalytic tetracycline hydrochloride degradation and the carrier separation mechanism study via single-particle spectroscopy. Inorg. Chem. Front. 2022, 9, 2252–2263. [Google Scholar] [CrossRef]

- Ju, L.; Tang, X.; Zhang, Y.; Li, X.; Cui, X.; Yang, G. Single Selenium Atomic Vacancy Enabled Efficient Visible-Light-Response Photocatalytic NO Reduction to NH3 on Janus WSSe Monolayer. Molecules 2023, 28, 2959. [Google Scholar] [CrossRef]

- Saleh, H.M.; Hassan, A.I. 4—Biological conversion of lignocellulosic waste in the renewable energy. In Advanced Technology for the Conversion of Waste into Fuels and Chemicals; Khan, A., Jawaid, M., Pizzi, A., Azum, N., Asiri, A., Isa, I., Eds.; Woodhead Publishing: Cambridge, UK, 2021; pp. 99–115. [Google Scholar]

- Jia, J.; Qian, C.; Dong, Y.; Li, Y.F.; Wang, H.; Ghoussoub, M.; Butler, K.T.; Walsh, A.; Ozin, G.A. Heterogeneous catalytic hydrogenation of CO2 by metal oxides defect engineering—Perfecting imperfection. Chem. Soc. Rev. 2017, 46, 4631–4644. [Google Scholar] [CrossRef]

- Liu, H.; Meng, X.; Dao, T.D.; Zhang, H.; Li, P.; Chang, K.; Wang, T.; Li, M.; Nagao, T.; Ye, J. Conversion of Carbon Dioxide by Methane Reforming under Visible-Light Irradiation: Surface-Plasmon-Mediated Nonpolar Molecule Activation. Angew. Chem. Int. Ed. 2015, 54, 11545–11549. [Google Scholar] [CrossRef]

- Yan, T.; Wang, L.; Liang, Y.; Makaremi, M.; Wood, T.E.; Dai, Y.; Huang, B.; Jelle, A.A.; Dong, Y.; Ozin, G.A. Polymorph selection towards photocatalytic gaseous CO2 hydrogenation. Nat. Commun. 2019, 10, 2521. [Google Scholar] [CrossRef] [Green Version]

- Hoch, L.B.; He, L.; Qiao, Q.; Liao, K.; Reyes, L.M.; Zhu, Y.; Ozin, G.A. Effect of Precursor Selection on the Photocatalytic Performance of Indium Oxide Nanomaterials for Gas-Phase CO2 Reduction. Chem. Mater. 2016, 28, 4160–4168. [Google Scholar] [CrossRef]

- Wang, J.; Heil, T.; Zhu, B.; Tung, C.W.; Yu, J.; Chen, H.M.; Antonietti, M.; Cao, S. A Single Cu-Center Containing Enzyme-Mimic Enabling Full Photosynthesis under CO2 Reduction. ACS Nano 2020, 14, 8584–8593. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Cai, H.; Shen, S. Single Metal Atom Photocatalysis. Small Methods 2019, 3, 1800447. [Google Scholar] [CrossRef]

- Saleh, H.M.; Hassan, A.I. Green Conversion of Carbon Dioxide and Sustainable Fuel Synthesis. Fire 2023, 6, 128. [Google Scholar] [CrossRef]

- Ju, L.; Tang, X.; Li, J.; Dong, H.; Yang, S.; Gao, Y.; Liu, W. Armchair Janus WSSe Nanotube Designed with Selenium Vacancy as a Promising Photocatalyst for CO2 Reduction. Molecules 2023, 28, 4602. [Google Scholar] [CrossRef]

- Francke, R.; Schille, B.; Roemelt, M. Homogeneously Catalyzed Electroreduction of Carbon Dioxide-Methods, Mechanisms, and Catalysts. Chem. Rev. 2018, 118, 4631–4701. [Google Scholar] [CrossRef]

- Wang, H.; Jia, J.; Song, P.; Wang, Q.; Li, D.; Min, S.; Qian, C.; Wang, L.; Li, Y.F.; Ma, C.; et al. Efficient Electrocatalytic Reduction of CO2 by Nitrogen-Doped Nanoporous Carbon Carbon Nanotube Membranes—A Step Towards the Electrochemical CO2 Refinery. Angew. Chem. Int. Ed. 2017, 56, 7847–7852. [Google Scholar] [CrossRef] [Green Version]

- Gao, S.; Lin, Y.; Jiao, X.; Sun, Y.; Luo, Q.; Zhang, W.; Li, D.; Yang, J.; Xie, Y. Partially oxidized atomic cobalt layers for carbon dioxide electroreduction to liquid fuel. Nature 2016, 529, 68–71. [Google Scholar] [CrossRef]

- Gao, S.; Sun, Z.; Liu, W.; Jiao, X.; Zu, X.; Hu, Q.; Sun, Y.; Yao, T.; Zhang, W.; Wei, S.; et al. Atomic layer confined vacancies for atomic-level insights into carbon dioxide electroreduction. Nat. Commun. 2017, 8, 14503. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Lei, B.; Dong, X.; Wang, H.; Sheng, J.; Cui, W.; Li, J.; Sun, Y.; Wang, Z.; Dong, F. Rare-Earth Single-Atom La-N Charge-Transfer Bridge on Carbon Nitride for Highly Efficient and Selective Photocatalytic CO2 Reduction. ACS Nano 2020, 14, 15841–15852. [Google Scholar] [CrossRef]

- Huang, P.; Huang, J.; Pantovich, S.A.; Carl, A.D.; Fenton, T.G.; Caputo, C.A.; Grimm, R.L.; Frenkel, A.I.; Li, G. Selective CO2 Reduction Catalyzed by Single Cobalt Sites on Carbon Nitride under Visible-Light Irradiation. J. Am. Chem. Soc. 2018, 140, 16042–16047. [Google Scholar] [CrossRef]

- Cao, Y.; Guo, L.; Dan, M.; Doronkin, D.E.; Han, C.; Rao, Z.; Liu, Y.; Meng, J.; Huang, Z.; Zheng, K.; et al. Modulating electron density of vacancy site by single Au atom for effective CO2 photoreduction. Nat. Commun. 2021, 12, 1675. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhu, X.; Jiang, Z.; Zhang, W.; Ji, H.; Zhu, X.; Song, Y.; Mo, Z.; Li, H.; Xu, H. Construction of brown mesoporous carbon nitride with a wide spectral response for high performance photocatalytic H2 evolution. Inorg. Chem. Front. 2022, 9, 103–110. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, D.; Chu, Y.; Chang, L.; Xu, J. Space-Confined Growth of Cs2CuBr4 Perovskite Nanodots in Mesoporous CeO2 for Photocatalytic CO2 Reduction: Structure Regulation and Built-in Electric Field Construction. J. Phys. Chem. Lett. 2023, 14, 5249–5259. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zhou, R.; Zhang, Z.; Dong, Z.; Xu, J. Boosted charge transfer and CO2 photoreduction by construction of S-scheme heterojunctions between Cs2AgBiBr6 nanosheets and two-dimensional metal–organic frameworks. J. Mater. Chem. C 2023, 11, 2540–2551. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, D.; Dong, Z.; Jiang, Y.; Li, X.; Chu, Y.; Xu, J. Lead-Free Cs2AgBiBr6 Nanocrystals Confined in MCM-48 Mesoporous Molecular Sieve for Efficient Photocatalytic CO2 Reduction. Sol. RRL 2023, 7, 2300038. [Google Scholar] [CrossRef]

- Shehzad, N.; Tahir, M.; Johari, K.; Murugesan, T.; Hussain, M. A critical review on TiO2 based photocatalytic CO2 reduction system: Strategies to improve efficiency. J. CO2 Util. 2018, 26, 98–122. [Google Scholar] [CrossRef]

- Ye, S.; Wang, R.; Wu, M.-Z.; Yuan, Y.-P. A review on g-C3N4 for photocatalytic water splitting and CO2 reduction. Appl. Surf. Sci. 2015, 358, 15–27. [Google Scholar] [CrossRef]

- Zhao, M.; Huang, Y.; Peng, Y.; Huang, Z.; Ma, Q.; Zhang, H. Two-dimensional metal-organic framework nanosheets: Synthesis and applications. Chem. Soc. Rev. 2018, 47, 6267–6295. [Google Scholar] [CrossRef]

- Wu, J.; Li, X.; Shi, W.; Ling, P.; Sun, Y.; Jiao, X.; Gao, S.; Liang, L.; Xu, J.; Yan, W.; et al. Efficient Visible-Light-Driven CO2 Reduction Mediated by Defect-Engineered BiOBr Atomic Layers. Angew. Chem. Int. Ed. Engl. 2018, 57, 8719–8723. [Google Scholar] [CrossRef] [PubMed]

- Ashley, A.E.; Thompson, A.L.; O’Hare, D. Non-metal-mediated homogeneous hydrogenation of CO2 to CH3OH. Angew. Chem. Int. Ed. Engl. 2009, 48, 9839–9843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kattel, S.; Ramírez, P.J.; Chen, J.G.; Rodriguez, J.A.; Liu, P. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts. Science 2017, 355, 1296–1299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grabowski, R.; Słoczyński, J.; Śliwa, M.; Mucha, D.; Socha, R.P.; Lachowska, M.; Skrzypek, J. Influence of Polymorphic ZrO2 Phases and the Silver Electronic State on the Activity of Ag/ZrO2 Catalysts in the Hydrogenation of CO2 to Methanol. ACS Catal. 2011, 1, 266–278. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Ma, X.; Gong, J. Recent advances in catalytic hydrogenation of carbon dioxide. Chem. Soc. Rev. 2011, 40, 3703–3727. [Google Scholar] [CrossRef] [Green Version]

- Kondratenko, E.V.; Mul, G.; Baltrusaitis, J.; Larrazábal, G.O.; Pérez-Ramírez, J. Status and perspectives of CO2 conversion into fuels and chemicals by catalytic, photocatalytic and electrocatalytic processes. Energy Environ. Sci. 2013, 6, 3112–3135. [Google Scholar] [CrossRef] [Green Version]

- Tountas, A.A.; Peng, X.; Tavasoli, A.V.; Duchesne, P.N.; Dingle, T.L.; Dong, Y.; Hurtado, L.; Mohan, A.; Sun, W.; Ulmer, U.; et al. Towards Solar Methanol Past, Present, and Future. Adv. Sci. 2019, 6, 1801903. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Wang, T.; Liu, L.; Ouyang, S.; Li, P.; Hu, H.; Kako, T.; Iwai, H.; Tanaka, A.; Ye, J. Photothermal conversion of CO2 into CH4 with H2 over Group VIII nanocatalysts: An alternative approach for solar fuel production. Angew. Chem. Int. Ed. Engl. 2014, 53, 11478–11482. [Google Scholar] [CrossRef]

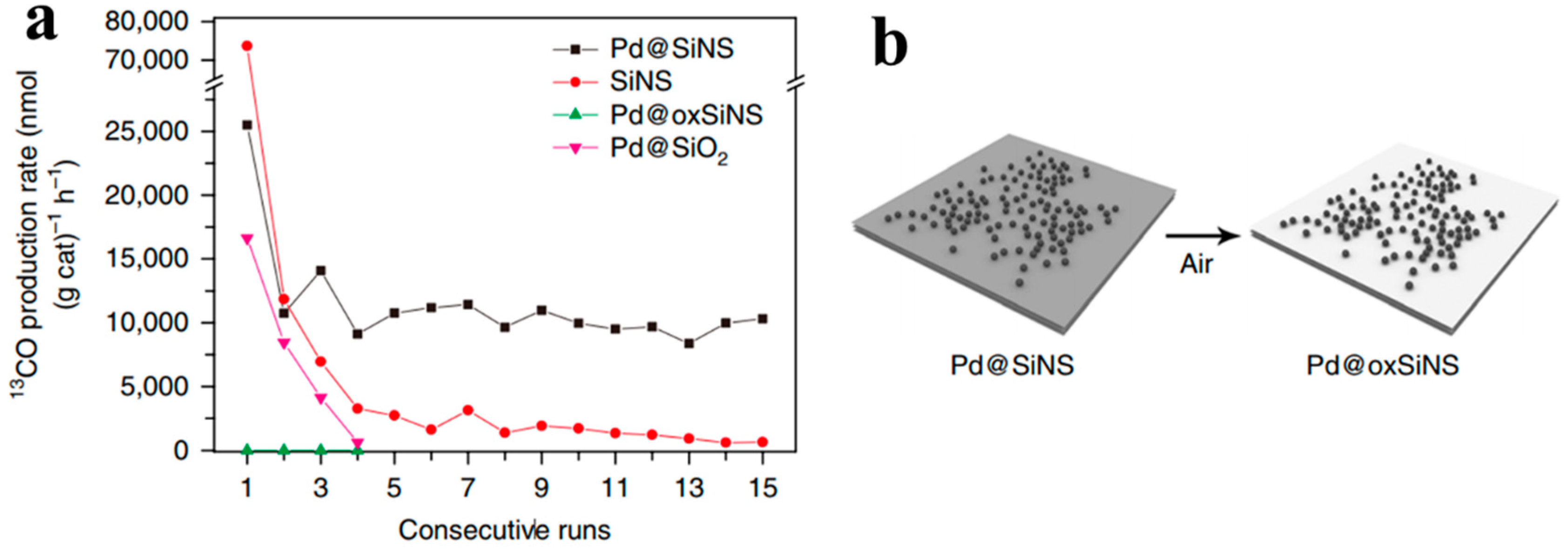

- Qian, C.; Sun, W.; Hung, D.L.H.; Qiu, C.; Makaremi, M.; Kumar, S.G.H.; Wan, L.; Ghoussoub, M.; Wood, T.E.; Xia, M.; et al. Catalytic CO2 reduction by palladium-decorated silicon–hydride nanosheets. Nat. Catal. 2019, 2, 46–54. [Google Scholar] [CrossRef]

- Yang, P.P.; Zhang, X.L.; Gao, F.Y.; Zheng, Y.R.; Niu, Z.Z.; Yu, X.; Liu, R.; Wu, Z.Z.; Qin, S.; Chi, L.P.; et al. Protecting Copper Oxidation State via Intermediate Confinement for Selective CO2 Electroreduction to C2+ Fuels. J. Am. Chem. Soc. 2020, 142, 6400–6408. [Google Scholar] [CrossRef]

- Luc, W.; Fu, X.; Shi, J.; Lv, J.-J.; Jouny, M.; Ko, B.H.; Xu, Y.; Tu, Q.; Hu, X.; Wu, J.; et al. Two-dimensional copper nanosheets for electrochemical reduction of carbon monoxide to acetate. Nat. Catal. 2019, 2, 423–430. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Yu, S.; Louisia, S.; Jin, J.; Li, M.; Ross, M.B.; Yang, P. Cu-Ag Tandem Catalysts for High-Rate CO2 Electrolysis toward Multicarbons. Joule 2020, 4, 1688–1699. [Google Scholar] [CrossRef]

- Voiry, D.; Chhowalla, M.; Gogotsi, Y.; Kotov, N.A.; Li, Y.; Penner, R.M.; Schaak, R.E.; Weiss, P.S. Best Practices for Reporting Electrocatalytic Performance of Nanomaterials. ACS Nano 2018, 12, 9635–9638. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kong, S.; Lv, X.; Wang, X.; Liu, Z.; Li, Z.; Jia, B.; Sun, D.; Yang, C.; Liu, L.; Guan, A.; et al. Delocalization state-induced selective bond breaking for efficient methanol electrosynthesis from CO2. Nat. Catal. 2023, 6, 6–15. [Google Scholar] [CrossRef]

- Tian, F.; Zhang, H.; Liu, S.; Wu, T.; Yu, J.; Wang, D.; Jin, X.; Peng, C. Visible-light-driven CO2 reduction to ethylene on CdS: Enabled by structural relaxation-induced intermediate dimerization and enhanced by ZIF-8 coating. Appl. Catal. B-Environ. 2021, 285, 119834. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, W.; Liu, G.; Chen, H.; Weng, Y.X.; Li, H.; Chu, P.K.; Xia, J. Excited Electron-Rich Bi(3−x)+Sites: A Quantum Well-Like Structure for Highly-Promoted Selective Photocatalytic CO2 Reduction Performance. Adv. Funct. Mater. 2022, 32, 2202885. [Google Scholar] [CrossRef]

- Yang, J.; Hao, J.; Xu, S.; Wang, Q.; Dai, J.; Zhang, A.; Pang, X. InVO4/beta-AgVO3 Nanocomposite as a Direct Z-Scheme Photocatalyst toward Efficient and Selective Visible-Light-Driven CO2 Reduction. ACS Appl. Mater. Interfaces 2019, 11, 32025–32037. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jiang, B.; Henzie, J.; Xu, F.; Liu, C.; Meng, X.; Zou, S.; Song, H.; Pan, Y.; Li, H.; et al. Designing reliable and accurate isotope-tracer experiments for CO2 photoreduction. Nat. Commun. 2023, 14, 2534. [Google Scholar] [CrossRef]

- Wang, S.; Guan, B.Y.; Lu, Y.; Lou, X.W.D. Formation of Hierarchical In2S3–CdIn2S4 Heterostructured Nanotubes for Efficient and Stable Visible Light CO2 Reduction. J. Am. Chem. Soc. 2017, 139, 17305–17308. [Google Scholar] [CrossRef]

- Putta Rangappa, A.; Praveen Kumar, D.; Do, K.H.; Wang, J.; Zhang, Y.; Kim, T.K. Synthesis of Pore-Wall-Modified Stable COF/TiO2 Heterostructures via Site-Specific Nucleation for an Enhanced Photoreduction of Carbon Dioxide. Adv. Sci. 2023, 10, 2300073. [Google Scholar] [CrossRef]

- Singh, P.; Yadav, R.K.; Singh, C.; Chaubey, S.; Singh, S.; Singh, A.P.; Baeg, J.-O.; Kim, T.W.; Gulzhian, D. Photocatalytic activity of ultrathin 2DPNs for enzymatically generating formic acid from CO2 and C–S/C–N bond formation. Sustain. Energy Fuels 2022, 6, 2223–2232. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, R.K.; Choi, S.Y.; Singh, P.; Kim, T.W. An efficient polydopamine modified sulphur doped GCN photocatalyst for generation of HCOOH from CO2 under sun ray irradiation. J. Photo. Photobio. A 2023, 439, 114591. [Google Scholar] [CrossRef]

- Yang, Z.; Qi, Y.; Wang, F.; Han, Z.; Jiang, Y.; Han, H.; Liu, J.; Zhang, X.; Ong, W.J. State-of-the-art advancements in photo-assisted CO2 hydrogenation: Recent progress in catalyst development and reaction mechanisms. J. Mater. Chem. A 2020, 8, 24868–24894. [Google Scholar] [CrossRef]

- Fan, Y.; Ma, X.; Liu, X.; Wang, J.; Ai, H.; Zhao, M. Theoretical Design of an InSe/GaTe vdW Heterobilayer: A Potential Visible-Light Photocatalyst for Water Splitting. J. Phys. Chem. C 2018, 122, 27803–27810. [Google Scholar] [CrossRef]

- Guiglion, P.; Butchosa, C.; Zwijnenburg, M.A. Polymer Photocatalysts for Water Splitting: Insights from Computational Modeling. Macromol. Chem. Phys. 2016, 217, 344–353. [Google Scholar] [CrossRef] [Green Version]

- Shaikh, A.R.; Posada-Pérez, S.; Brotons-Rufes, A.; Pajski, J.J.; Vajiha; Kumar, G.; Mateen, A.; Poater, A.; Solà, M.; Chawla, M.; et al. Selective absorption of H2S and CO2 by azole based protic ionic liquids: A combined density functional theory and molecular dynamics study. J. Mol. Liq. 2022, 367, 120558. [Google Scholar] [CrossRef]

- Posada-Pérez, S.; Vidal-López, A.; Solà, M.; Poater, A. 2D carbon nitride as a support with single Cu, Ag, and Au atoms for carbon dioxide reduction reaction. Phys. Chem. Chem. Phys. 2023, 25, 8574–8582. [Google Scholar] [CrossRef]

- Varvoutis, G.; Lykaki, M.; Marnellos, G.E.; Konsolakis, M. Recent Advances on Fine-Tuning Engineering Strategies of CeO2-Based Nanostructured Catalysts Exemplified by CO2 Hydrogenation Processes. Catalysts 2023, 13, 275. [Google Scholar] [CrossRef]

- Leung, C.-F.; Ho, P.-Y. Molecular Catalysis for Utilizing CO2 in Fuel Electro-Generation and in Chemical Feedstock. Catalysts 2019, 9, 760. [Google Scholar] [CrossRef] [Green Version]

- Posada-Pérez, S.; Solà, M.; Poater, A. Carbon Dioxide Conversion on Supported Metal Nanoparticles: A Brief Review. Catalysts 2023, 13, 305. [Google Scholar] [CrossRef]

- Qiu, L.-Q.; Yao, X.; Zhang, Y.-K.; Li, H.-R.; He, L.-N. Advancements and Challenges in Reductive Conversion of Carbon Dioxide via Thermo-/Photocatalysis. J. Org. Chem. 2023, 88, 4942–4964. [Google Scholar] [CrossRef] [PubMed]

- Meng, C.; Zhao, G.; Shi, X.-R.; Chen, P.; Liu, Y.; Lu, Y. Oxygen-deficient metal oxides supported nano-intermetallic InNi3C0.5 toward efficient CO2 hydrogenation to methanol. Sci. Adv. 2021, 7, eabi6012. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Yu, L.; Deng, J.; Wang, Y.; Cheng, K.; Ma, C.; Zhang, Q.; Wen, W.; Yu, S.; Pan, Y.; et al. Sulfur vacancy-rich MoS2 as a catalyst for the hydrogenation of CO2 to methanol. Nat. Catal. 2021, 4, 242–250. [Google Scholar] [CrossRef]

- Marxer, D.; Furler, P.; Takacs, M.; Steinfeld, A. Solar thermochemical splitting of CO2 into separate streams of CO and O2 with high selectivity, stability, conversion, and efficiency. Energy Environ. Sci. 2017, 10, 1142–1149. [Google Scholar] [CrossRef] [Green Version]

- Heidlage, M.G.; Kezar, E.A.; Snow, K.C.; Pfromm, P.H. Thermochemical Synthesis of Ammonia and Syngas from Natural Gas at Atmospheric Pressure. Ind. Eng. Chem. Res. 2017, 56, 14014–14024. [Google Scholar] [CrossRef]

- Gokon, N.; Yamawaki, Y.; Nakazawa, D.; Kodama, T. Ni/MgO–Al2O3 and Ni–Mg–O catalyzed SiC foam absorbers for high temperature solar reforming of methane. Int. J. Hydrogen Energy 2010, 35, 7441–7453. [Google Scholar] [CrossRef]

- Tou, M.; Michalsky, R.; Steinfeld, A. Solar-Driven Thermochemical Splitting of CO2 and In Situ Separation of CO and O2 across a Ceria Redox Membrane Reactor. Joule 2017, 1, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Chueh, W.C.; Haile, S.M. Ceria as a thermochemical reaction medium for selectively generating syngas or methane from H2O and CO2. ChemSusChem 2009, 2, 735–739. [Google Scholar] [CrossRef] [Green Version]

- Feng, K.; Wang, S.; Zhang, D.; Wang, L.; Yu, Y.; Feng, K.; Li, Z.; Zhu, Z.; Li, C.; Cai, M.; et al. Cobalt Plasmonic Superstructures Enable Almost 100% Broadband Photon Efficient CO2 Photocatalysis. Adv. Mater. 2020, 32, 2000014. [Google Scholar] [CrossRef] [PubMed]

- Linic, S.; Christopher, P.; Ingram, D.B. Plasmonic-metal nanostructures for efficient conversion of solar to chemical energy. Nat. Mater. 2011, 10, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.M.; Kim, D.; Rungtaweevoranit, B.; Trickett, C.A.; Barmanbek, J.T.D.; Alshammari, A.S.; Yang, P.; Yaghi, O.M. Plasmon-Enhanced Photocatalytic CO2 Conversion within Metal–Organic Frameworks under Visible Light. J. Am. Chem. Soc. 2017, 139, 356–362. [Google Scholar] [CrossRef] [PubMed]

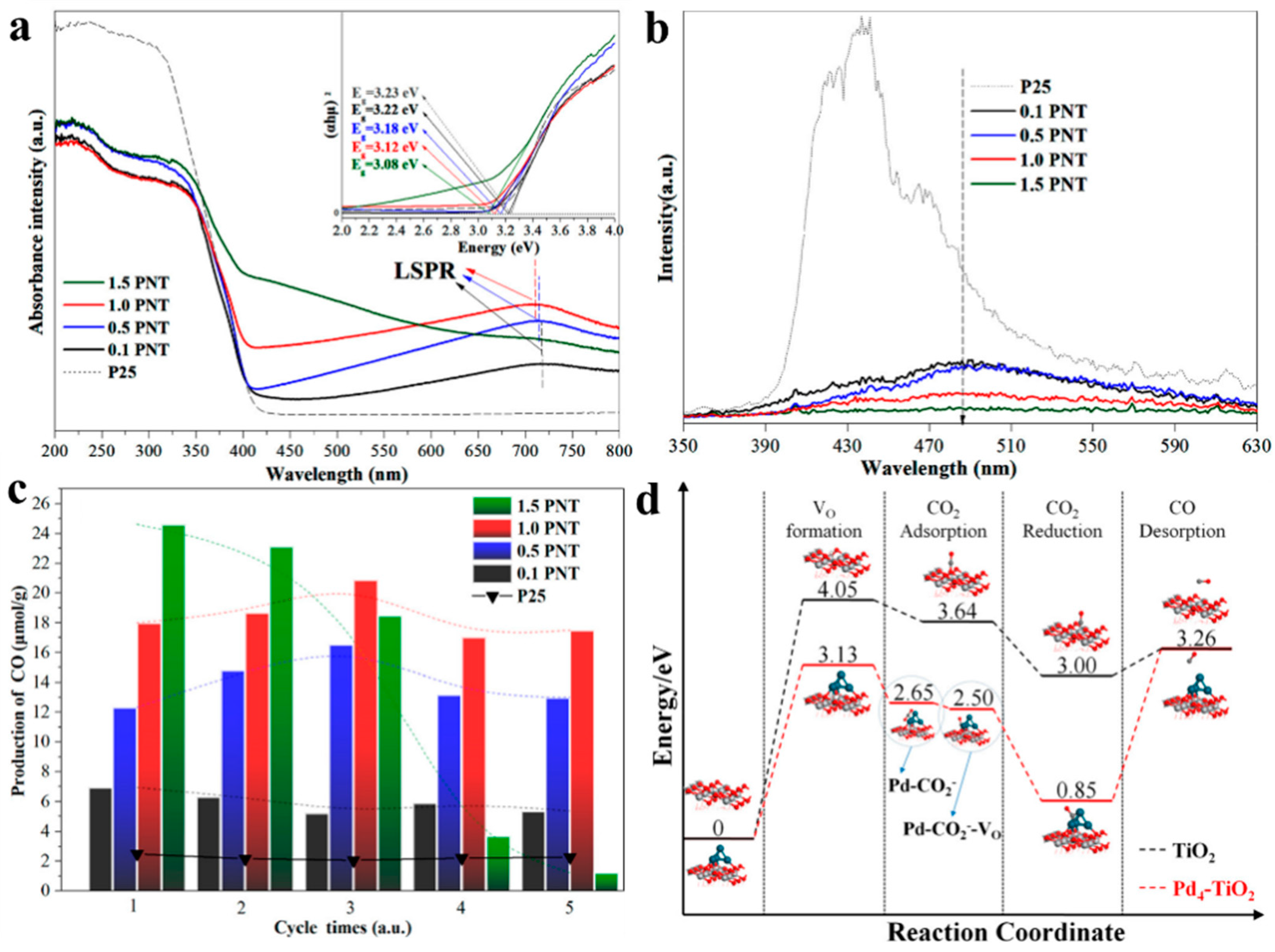

- Xu, C.; Huang, W.; Li, Z.; Deng, B.; Zhang, Y.; Ni, M.; Cen, K. Photothermal Coupling Factor Achieving CO2 Reduction Based on Palladium-Nanoparticle-Loaded TiO2. ACS Catal. 2018, 8, 6582–6593. [Google Scholar] [CrossRef]

- Jia, J.; O’Brien, P.G.; He, L.; Qiao, Q.; Fei, T.; Reyes, L.M.; Burrow, T.E.; Dong, Y.; Liao, K.; Varela, M.; et al. Visible and Near-Infrared Photothermal Catalyzed Hydrogenation of Gaseous CO2 over Nanostructured Pd@Nb2O5. Adv. Sci. 2016, 3, 1600189. [Google Scholar] [CrossRef]

- Li, Y.F.; Soheilnia, N.; Greiner, M.; Ulmer, U.; Wood, T.; Jelle, A.A.; Dong, Y.; Yin Wong, A.P.; Jia, J.; Ozin, G.A. Pd@HyWO3–x Nanowires Efficiently Catalyze the CO2 Heterogeneous Reduction Reaction with a Pronounced Light Effect. ACS Appl. Mater. Interfaces 2019, 11, 5610–5615. [Google Scholar] [CrossRef] [PubMed]

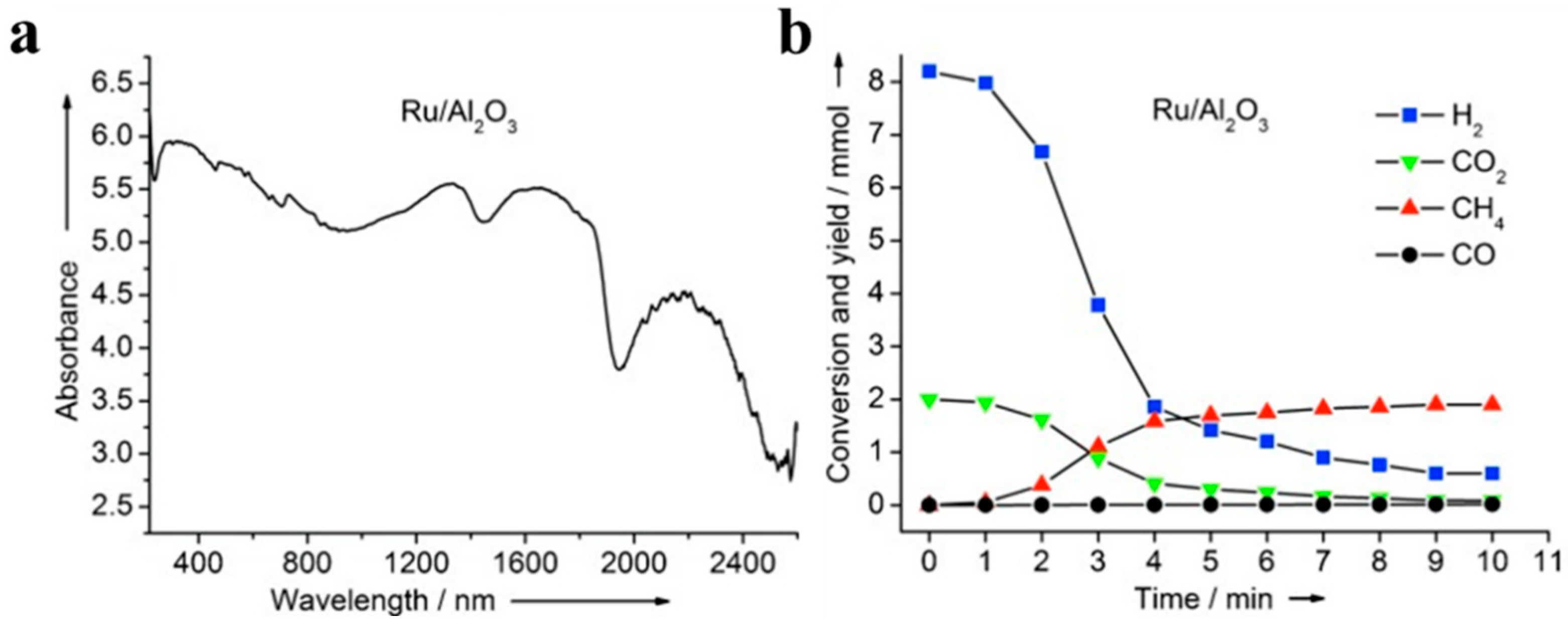

- Ren, J.; Ouyang, S.; Xu, H.; Meng, X.; Wang, T.; Wang, D.; Ye, J. Targeting Activation of CO2 and H2 over Ru-Loaded Ultrathin Layered Double Hydroxides to Achieve Efficient Photothermal CO2 Methanation in Flow-Type System. Adv. Energy Mater. 2017, 7, 1601657. [Google Scholar] [CrossRef]

- Hong, J.; Zhang, W.; Wang, Y.; Zhou, T.; Xu, R. Photocatalytic Reduction of Carbon Dioxide over Self-Assembled Carbon Nitride and Layered Double Hydroxide: The Role of Carbon Dioxide Enrichment. ChemCatChem 2014, 6, 2315–2321. [Google Scholar] [CrossRef]

- Ahmed, N.; Shibata, Y.; Taniguchi, T.; Izumi, Y. Photocatalytic conversion of carbon dioxide into methanol using zinc–copper–M(III) (M=aluminum, gallium) layered double hydroxides. J. Catal. 2011, 279, 123–135. [Google Scholar] [CrossRef]

- Morikawa, M.; Ahmed, N.; Yoshida, Y.; Izumi, Y. Photoconversion of carbon dioxide in zinc–copper–gallium layered double hydroxides: The kinetics to hydrogen carbonate and further to CO/methanol. Appl. Catal. B-Environ. 2014, 144, 561–569. [Google Scholar] [CrossRef]

- Lin, L.; Wang, K.; Yang, K.; Chen, X.; Fu, X.; Dai, W. The visible-light-assisted thermocatalytic methanation of CO2 over Ru/TiO(2−x)Nx. Appl. Catal. B-Environ. 2017, 204, 440–455. [Google Scholar] [CrossRef]

- O’Brien, P.G.; Sandhel, A.; Wood, T.E.; Jelle, A.A.; Hoch, L.B.; Perovic, D.D.; Mims, C.A.; Ozin, G.A. Photomethanation of Gaseous CO2 over Ru/Silicon Nanowire Catalysts with Visible and Near-Infrared Photons. Adv. Sci. 2014, 1, 1400001. [Google Scholar] [CrossRef]

- Jelle, A.A.; Ghuman, K.K.; O’Brien, P.G.; Hmadeh, M.; Sandhel, A.; Perovic, D.D.; Singh, C.V.; Mims, C.A.; Ozin, G.A. Highly Efficient Ambient Temperature CO2 Photomethanation Catalyzed by Nanostructured RuO2 on Silicon Photonic Crystal Support. Adv. Energy Mater. 2018, 8, 1702277. [Google Scholar] [CrossRef] [Green Version]

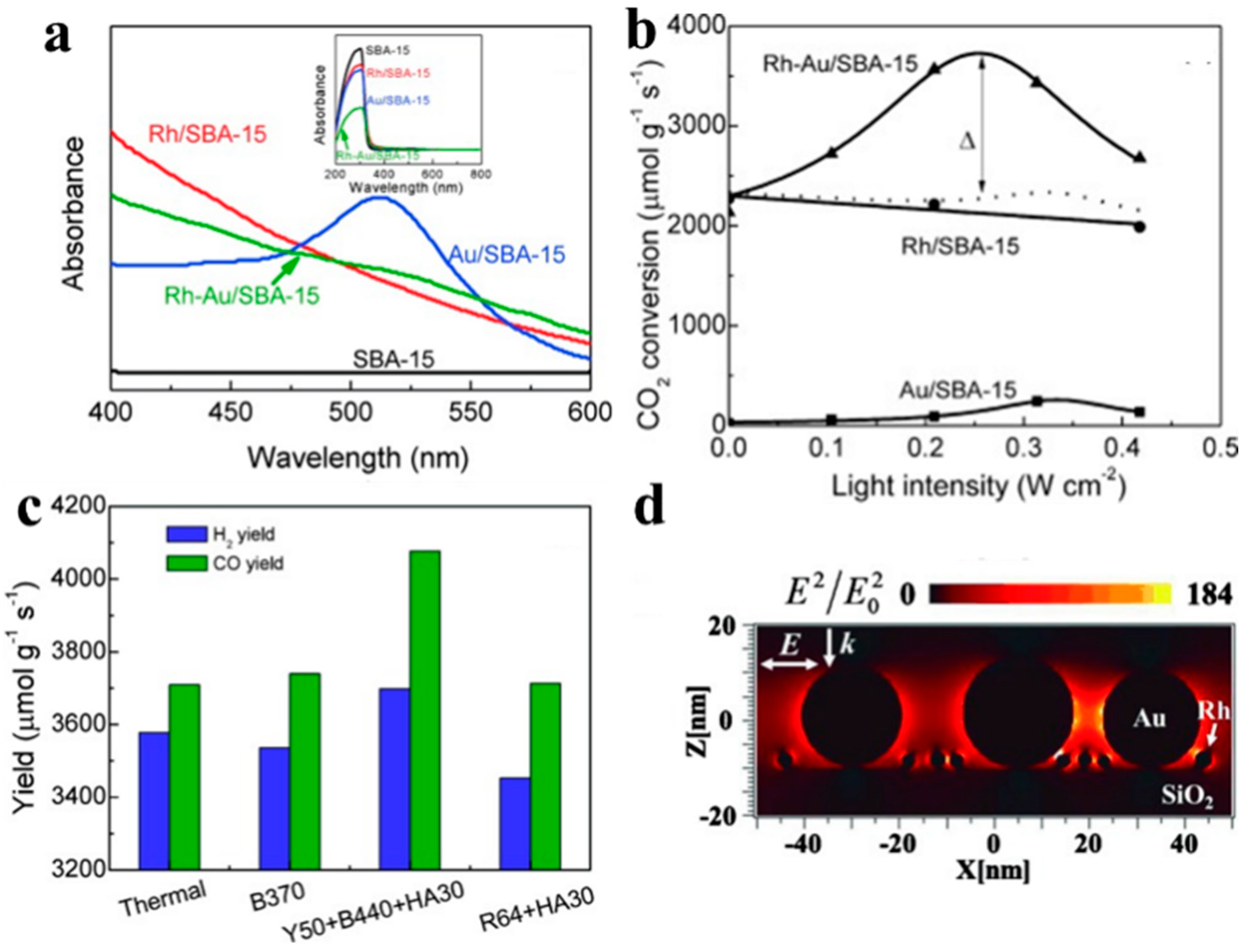

- Zhang, X.; Li, X.; Zhang, D.; Su, N.Q.; Yang, W.; Everitt, H.O.; Liu, J. Product selectivity in plasmonic photocatalysis for carbon dioxide hydrogenation. Nat. Commun. 2017, 8, 14542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

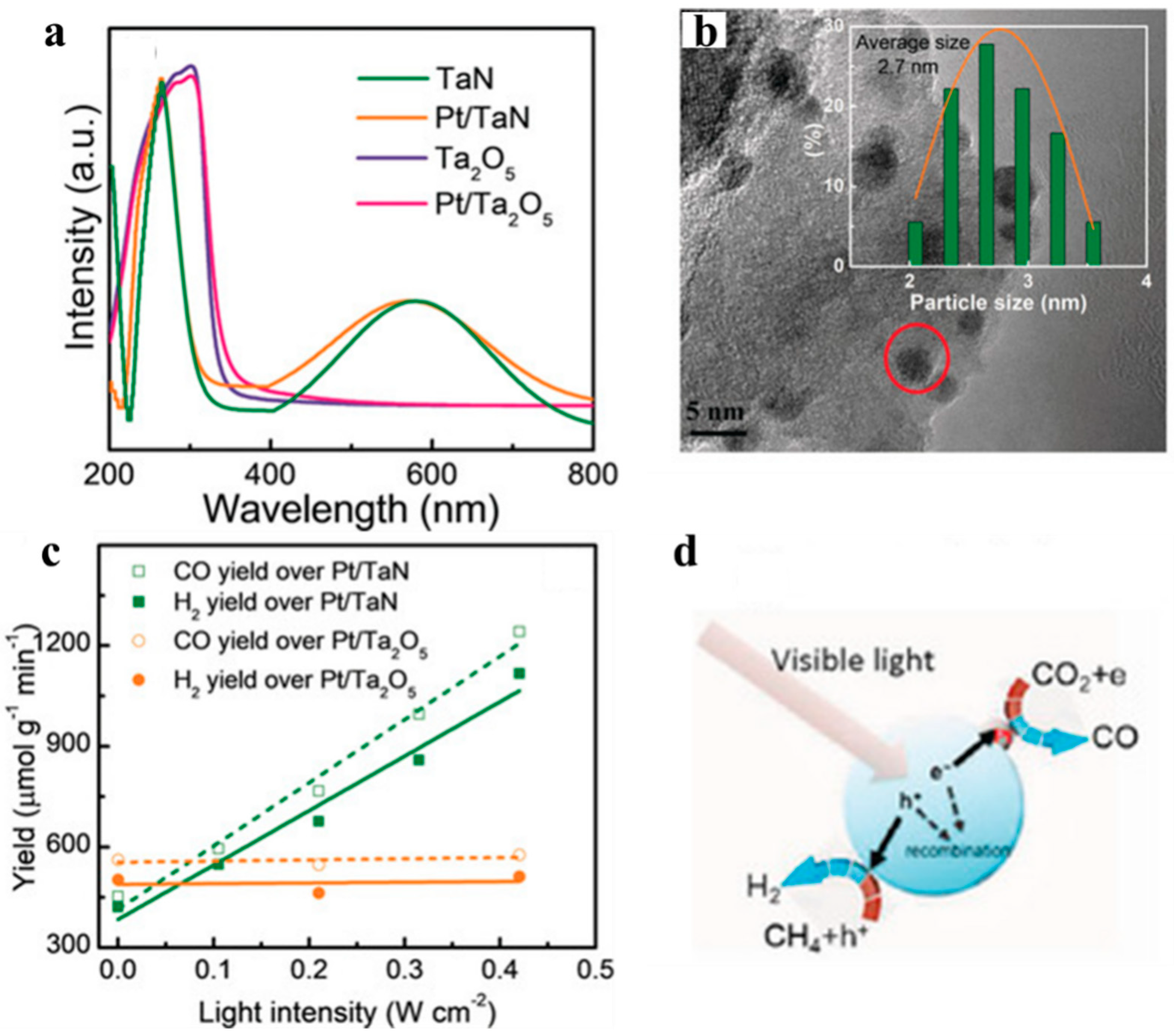

- Liu, H.; Song, H.; Zhou, W.; Meng, X.; Ye, J. A Promising Application of Optical Hexagonal TaN in Photocatalytic Reactions. Angew. Chem. Int. Ed. 2018, 57, 16781–16784. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Z.; Zhu, X.; Jiang, Z. Recent Advances of Constructing Metal/Semiconductor Catalysts Designing for Photocatalytic CO2 Hydrogenation. Molecules 2023, 28, 5693. https://doi.org/10.3390/molecules28155693

Yuan Z, Zhu X, Jiang Z. Recent Advances of Constructing Metal/Semiconductor Catalysts Designing for Photocatalytic CO2 Hydrogenation. Molecules. 2023; 28(15):5693. https://doi.org/10.3390/molecules28155693

Chicago/Turabian StyleYuan, Zhimin, Xianglin Zhu, and Zaiyong Jiang. 2023. "Recent Advances of Constructing Metal/Semiconductor Catalysts Designing for Photocatalytic CO2 Hydrogenation" Molecules 28, no. 15: 5693. https://doi.org/10.3390/molecules28155693

APA StyleYuan, Z., Zhu, X., & Jiang, Z. (2023). Recent Advances of Constructing Metal/Semiconductor Catalysts Designing for Photocatalytic CO2 Hydrogenation. Molecules, 28(15), 5693. https://doi.org/10.3390/molecules28155693