Nutritional Value and Structure Characterization of Protein Components of Corylus mandshurica Maxim

Abstract

:1. Introduction

2. Results

2.1. Chemical Composition of Corylus mandshurica Maxim Kernel and Defatted Corylus mandshurica Maxim Kernel Flours

2.2. Extraction Rate and Protein Content of Protein Isolates of Corylus mandshurica Maxim Kernel and Graded Proteins from DCF

2.3. Amino Acid Composition of the Five Proteins in Corylus mandshurica Maxim Kernel

2.4. Assessment of the Nutritional Value of Five Proteins in Corylus mandshurica Maxim Kernel Proteins

2.5. Structural Properties

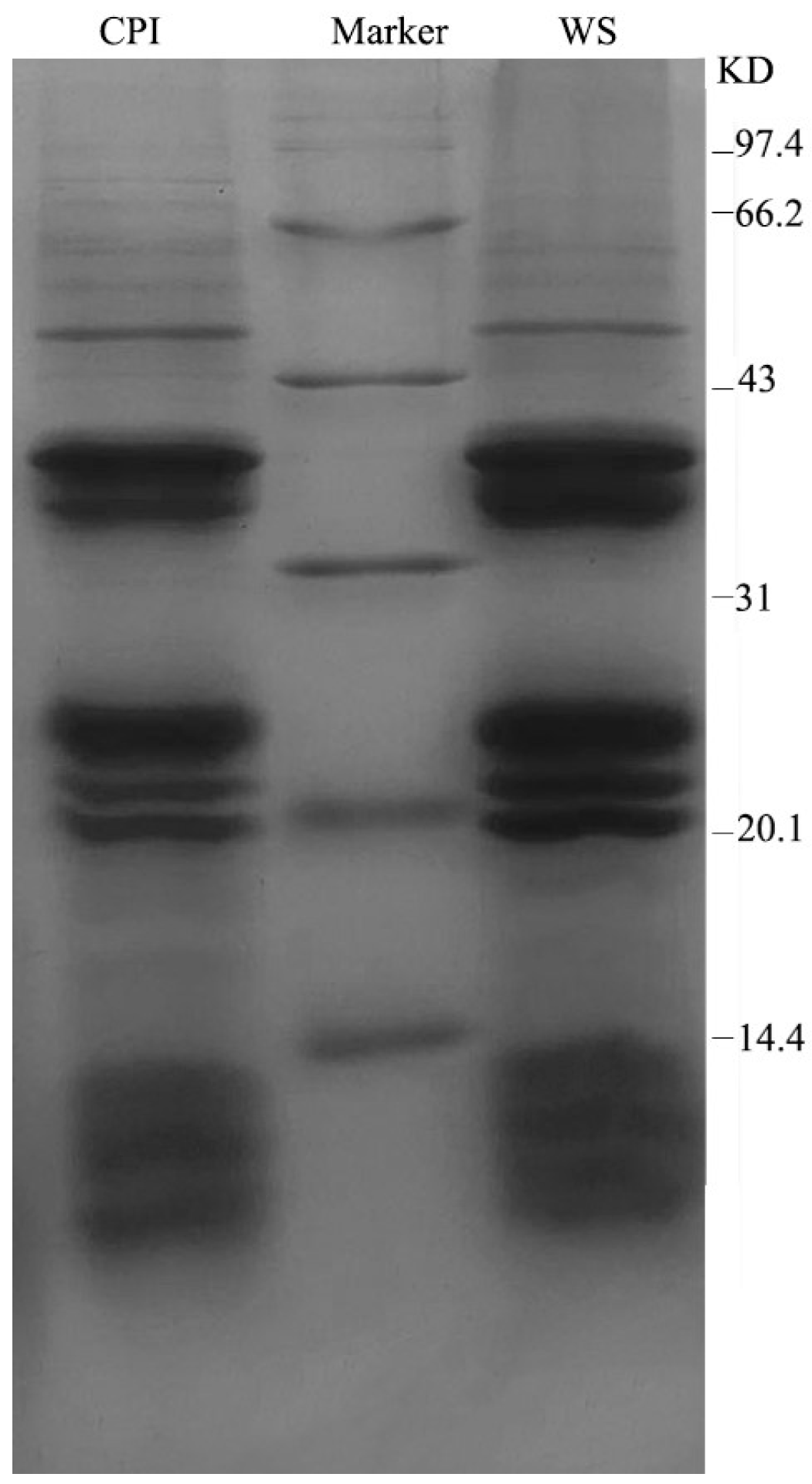

2.5.1. SDS–PAGE Analysis

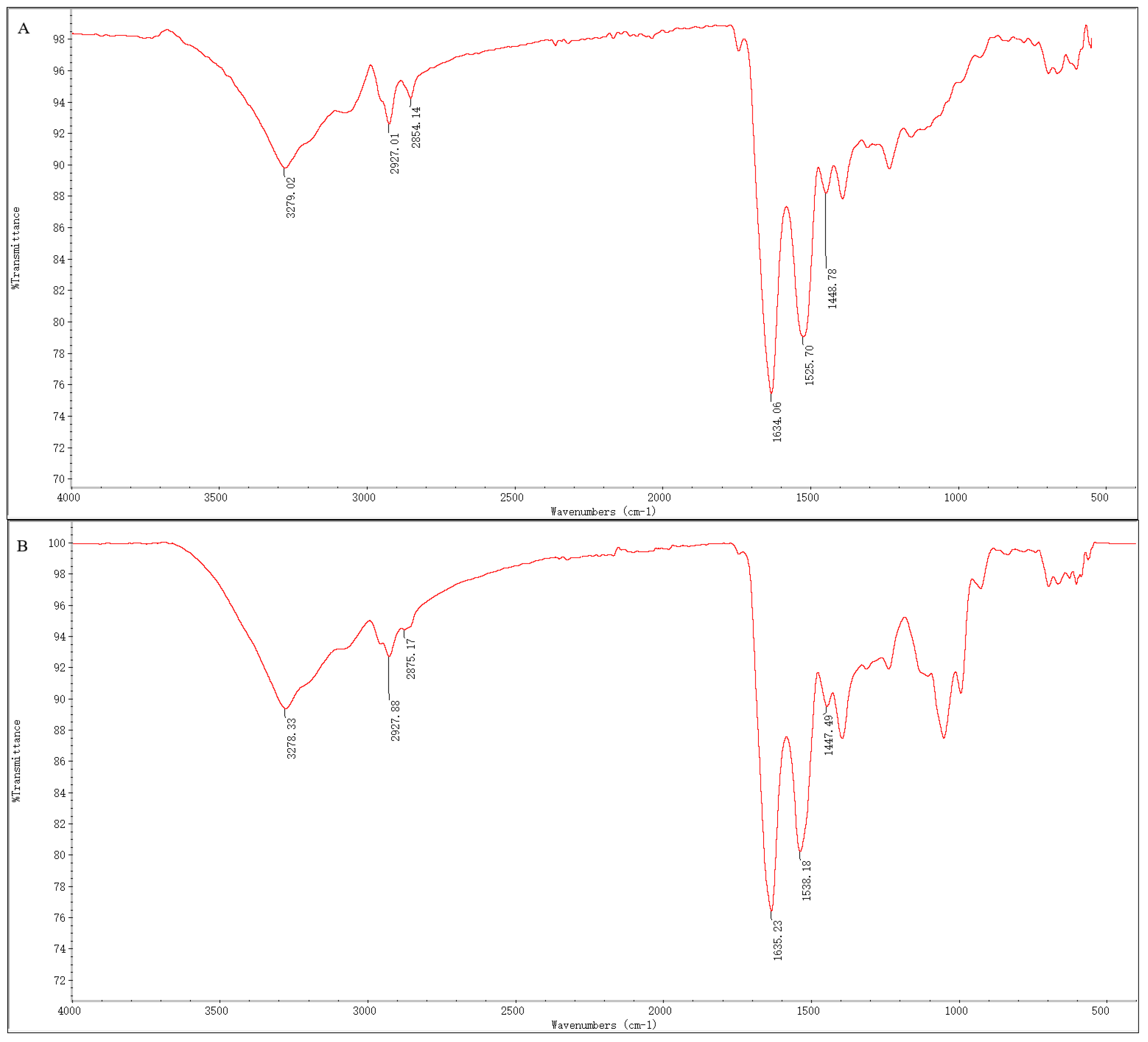

2.5.2. Fourier Transform Infrared Spectroscopic Analysis

2.5.3. Intrinsic Fluorescence Analysis

2.5.4. Microstructural Imaging Analysis

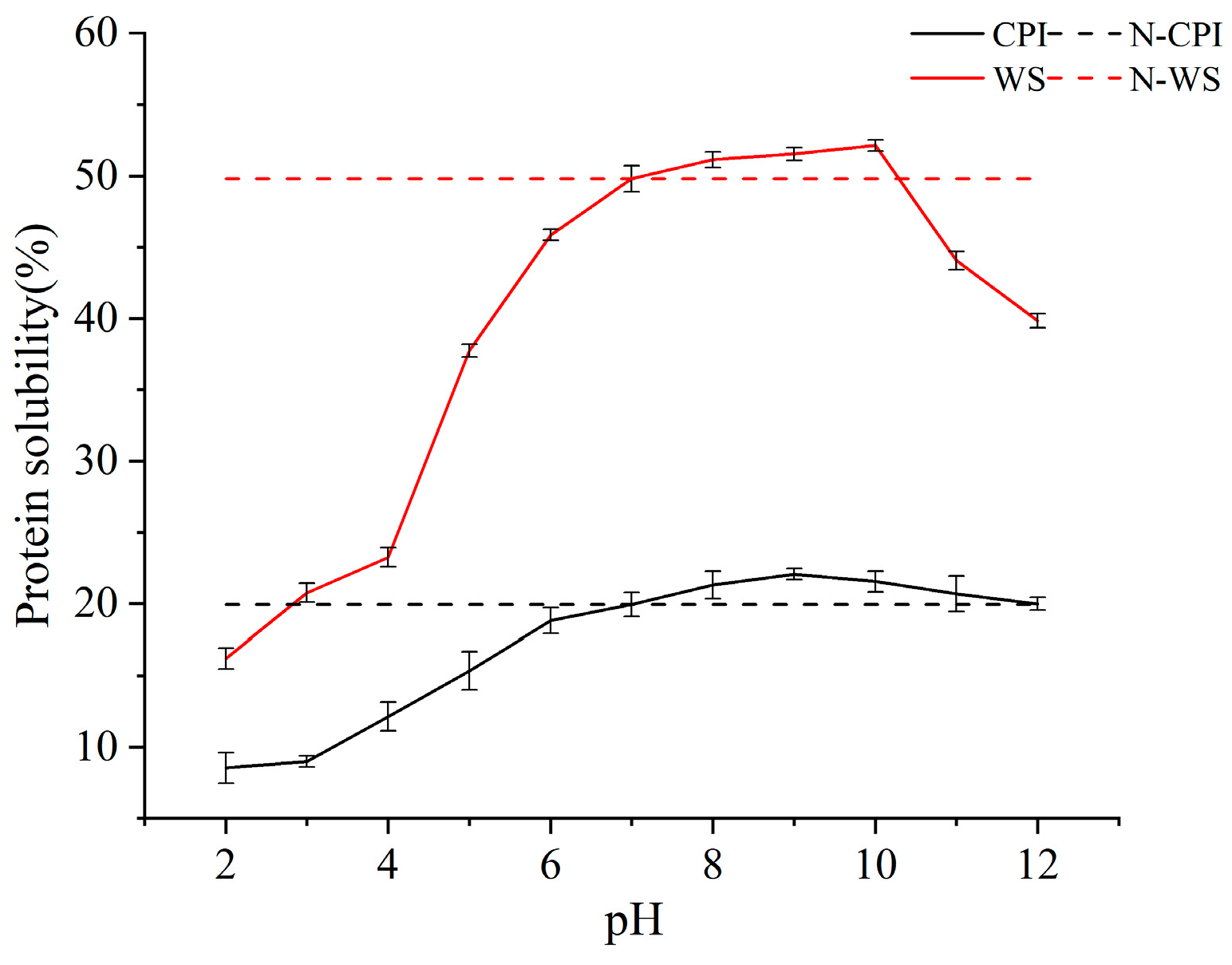

2.5.5. Solubility Analysis

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Chemicals and Reagents

4.3. Preparation of DCF

4.4. Proximate Chemical Analysis of Corylus mandshurica Maxim Kernel and DCF

4.5. Preparation of CPI from DCF

4.6. Preparation of Different Fractions of Proteins from DCF

4.7. Determination of Corylus mandshurica Maxim Kernel Protein Contents and Amino Acid Compositions

4.8. Evaluation of the Nutritional Value of Five Proteins in Corylus mandshurica Maxim Kernel

4.9. Structural Properties

4.9.1. Determination of SDS–PAGE

4.9.2. Determination of FTIR

4.9.3. Intrinsic Fluorescence

4.9.4. Determination of Microstructural Imaging

4.9.5. Determination of Solubility

4.9.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Abbreviations

References

- Delgado, C.L. Rising Consumption of Meat and Milk in Developing Countries Has Created a New Food Revolution. J. Nutr. 2003, 133, 3907–3910. [Google Scholar] [CrossRef] [PubMed]

- Popkin, B.M.; Adair, L.S.; Ng, S.W. Global Nutrition Transition and the Pandemic of Obesity in Developing Countries. Nutr. Rev. 2012, 70, 3–21. [Google Scholar] [CrossRef]

- Nikbakht, N.; Amir, H.; Sedaghat, D.; Roman, B. Plant Based Pickering Stabilization of Emulsions Using Soluble Flaxseed Protein and Mucilage Nano-Assemblies. Colloids Surf. A Physicochem. Eng. Asp. 2018, 563, 170–182. [Google Scholar] [CrossRef]

- Nasrabadi, M.N.; Goli, S.A.H.; Doost, A.S.; Dewettinck, K.; Van der Meeren, P. Bioparticles of Flaxseed Protein and Mucilage Enhance the Physical and Oxidative Stability of Flaxseed Oil Emulsions as a Potential Natural Alternative for Synthetic Surfactants. Colloids Surf. B Biointerfaces 2019, 184, 110489. [Google Scholar] [CrossRef] [PubMed]

- Mahdi, J.; Sedaghat, D.; Nikbakht, N.; Boostani, S. Phytoparticles for the Stabilization of Pickering Emulsions in the Formulation of Novel Food Colloidal Dispersions. Trends Food Sci. Technol. 2020, 98, 117–128. [Google Scholar] [CrossRef]

- Warnakulasuriya, S.N.; Nickerson, M.T. Review on Plant Protein–Polysaccharide Complex Coacervation, and the Functionality and Applicability of Formed Complexes. J. Sci. Food Agric. 2018, 89, 5559–5571. [Google Scholar] [CrossRef]

- Gomes, A.; Maria, F.; Augusto, M. Plant Proteins as High-Quality Nutritional Source for Human Diet. Trends Food Sci. Technol. 2020, 97, 170–184. [Google Scholar] [CrossRef]

- Wang, X.; Gao, W.; Zhang, J.; Zhang, H. Subunit, Amino Acid Composition and in Vitro Digestibility of Protein Isolates from Chinese Kabuli and Desi Chickpea (Cicer arietinum L.) Cultivars. Food Res. Int. 2010, 43, 567–572. [Google Scholar] [CrossRef]

- Frias, J.; Giacomino, S.; Pellegrino, N.; Ferreyra, V.; Apro, N. Assessment of the Nutritional Quality of Raw and Extruded Pisum sativum L. Var. Laguna Seeds. LWT-Food Sci. Technol. 2010, 44, 1303–1308. [Google Scholar] [CrossRef]

- Goldstein, N.; Reifen, R. The Potential of Legume-Derived Proteins in the Food Industry. Grain Oil Sci. Technol. 2022, 5, 167–178. [Google Scholar] [CrossRef]

- López, D.; Galante, M.; Robson, M.; Boeris, V. Amaranth, Quinoa and Chia Protein Isolates: Physicochemical and Structural Properties. Int. J. Biol. Macromol. 2018, 109, 152–159. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, L.; Arendt, E.; Gallagher, E. Nutritive Value of Pseudocereals and their Increasing Use as Functional Gluten-Free Ingredients. Trends Food Sci. Technol. 2009, 21, 106–113. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Zhang, H.; Qiu, W. Alkali Treatment Affects In Vitro Digestibility and Bile Acid Binding Activity of Rice Protein Due to Varying its Ratio of Arginine to Lysine. Food Chem. 2012, 132, 925–930. [Google Scholar] [CrossRef]

- Lilian, R.; Kemilla, S.; Antonio, B.; Janne, S.; Marciane, M. The Use of Alternative Food Sources to Improve Health and Guarantee Access and Food Intake. Food Res. Int. 2021, 149, 110709. [Google Scholar] [CrossRef]

- Ana, M.; Vito, V. Influence of pearling process on phenolic and saponin content in quinoa (Chenopodium quinoa Willd). Food Chem. 2014, 157, 174–178. [Google Scholar] [CrossRef]

- Pereira, E.; Encina, C.; Barros, L.; Gonzales, U. Chemical and Nutritional Characterization of Chenopodium quinoa Willd (Quinoa) Grains: A Good Alternative to Nutritious Food. Food Chem. 2018, 280, 110–114. [Google Scholar] [CrossRef]

- Day, L. Proteins from Land Plants—Potential Resources for Human Nutrition and Food Security. Trends Food Sci. Technol. 2013, 1, 25–42. [Google Scholar] [CrossRef]

- Priyanka, K.; Alka, S. Flaxseed—A Potential Functional Food Source. J. Food Sci. Technol. 2015, 52, 1857–1871. [Google Scholar] [CrossRef]

- Liao, Y. How much do you know about the nutritional value of nuts. Knowl. Is Power 2019, 4, 88–89. [Google Scholar]

- Tang, M.; Wang, Y.; Zhao, C. Development of Macadamia Nut Yogurt. Mod. Food Sci. Technol. 2022, 38, 214–222. [Google Scholar]

- Harish, C.; Ranbeer, S.; Indra, D. Comparative Studies On the Nutritive and Anti-Nutritive Properties of Fruits in Selected Berberis Species of West Himalaya, India. Food Res. Int. 2011, 44, 2352–2356. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Jiang, H. Phenotypic Trait Diversity of Wild Corylus mandshurica Fruitin Heilongjiang Province. J. West China For. Sci. 2022, 51, 20–26. [Google Scholar] [CrossRef]

- Du, J.; Lu, B.; Fu, Y.; Yu, T. Progress of germplasm resources of hazelnut and its application in chemical industry. Guangzhou Chem. 2021, 48, 105–114. [Google Scholar]

- Gong, M.; Zhao, W. Comprehensive utilization of hazelnuts. Guangzhou Chem. 2013, 41, 28–30. [Google Scholar]

- Wei, Y. Analysis of Amino Acid Composition and Nutritional Evaluation of Flat-European Hybrid hazelnut Protein and Its Components. Food Ind. 2022, 43, 334–338. [Google Scholar]

- Zhang, M.; Pang, J.; Wang, X.; Cai, D. Analysis of main nutrient and active components of nuts collected from Hebei mountain area. Food Ind. 2020, 41, 333–336. [Google Scholar]

- Yin, H. Comparative Study Diverse Varieties Hazelnut Powder and Hazelnut Protein of Physicochemical Properties; Henan Agricultural University: Zhengzhou, China, 2013. [Google Scholar]

- Yang, Y.; Pan, S.; Qi, X.; Gao, F.; Tian, Y.; Ding, X. Amino Acid Composition and Nutritional Evaluation of Different Varieties of Walnut. Food Sci. 2017, 38, 207–212. [Google Scholar] [CrossRef]

- Xu, H.; Chen, Y. Electric field treatment improving physicochemical properties of zein film produced by casting. Trans. Chin. Soc. Agric. Eng. 2015, 31, 272–276. [Google Scholar]

- Listed, N. Energy and protein requirements: Report of a joint FAO-WHO ad hoc expert committee. Rome, 22 march–2 April 1971. Fao Nutr. Meet Rep. Ser. 1973, 522, 1–118. [Google Scholar]

- Wang, R.; Tang, F.; Zhong, D.; Shen, Y.; Mo, H. Composition analysis and nutrition evaluation of amino acids and fatty acids in four nuts of Juglandaceae. China Oils Fats 2020, 45, 86–91. [Google Scholar]

- Jiang, Z.; Wu, Y.; Wang, S.; Zhu, X. Amino acid composition and nutritional quality evaluation of wild Amygdalus pedunculatus pall. kernels from different growing regions. Food Sci. 2016, 37, 77–82. [Google Scholar] [CrossRef]

- Liu, G.; Wang, H.; Zhou, B. Determination of amino acids in Tricholoma matsutake and Its nutritional evaluation. Ediblefung China 2007, 26, 51–52. [Google Scholar] [CrossRef]

- Zhang, Z. Food Nutrition; China Agricultural University Press: Beijing, China, 2004; p. 91. [Google Scholar]

- Bao, S.; Zhou, L.; Qi, D.; Tian, H.; Wang, D.; Zhu, B.; Meng, Y.; Ma, R. Comparative study on the fillet nutritional quality of diploid and triploid rainbow trout (Oncorhynchus mykiss). Aquac. Rep. 2023, 28, 101431. [Google Scholar] [CrossRef]

- Wang, G. Food Composition Table (National and Provincial Values); People’s Health Publishing House: Beijing, China, 1992. [Google Scholar]

- Deng, W.; Xu, J.; Guo, S.; Li, Z. Comparative Study on Nutritional Evaluation of Hemp Seed Protein and Soybean Protein. Sci. Technol. Food Ind. 2021, 42, 273–279. [Google Scholar] [CrossRef]

- Xu, X.; Mao, H.; Han, D.; Zhao, H.; Yu, M. Nutritional value evaluation of amino acids of different corn cultivars in Xinjiang. Food Ferment. Ind. 2020, 46, 244–249. [Google Scholar] [CrossRef]

- Witold, K.; Henry, H. New insight into protein secondary structure from resolution-enhanced infrared spectra. Biochim. Biophys. Acta (BBA)-Protein Struct. Mol. Enzymol. 1988, 952, 115–130. [Google Scholar] [CrossRef]

- Zhong, Y. Hazelnut Protein Physical Modification Methods and the Physical and Chemical Properties Change Research; Shenyang Agricultural University: Shenyang, China, 2017. [Google Scholar]

- Sobhan, S.; Anna, B.; Nitin, M.; Kasapis, S. Structural properties of condensed ovalbumin systems following application of high pressure. Food Hydrocoll. 2016, 53, 104–114. [Google Scholar] [CrossRef]

- Tang, S. Effect of Ultrasound Combined with Protease Enzymatic Hydrolysis on Solubility and Emulsifying Stability of Egg Yolk Powder; Huazhong Agricultural University: Wuhan, China, 2019. [Google Scholar]

- Xiao, Y. Study on the Preparation of Tea Seed Cake Protein and Its Functional and Digestion and Absorption Properties; Yangzhou University: Yangzhou, China, 2021. [Google Scholar]

- Ge, S.; Liu, M.; Zhu, J.; Wnag, F.; Ren, F.; Zhang, L.; Guo, D. Application of FTIR method to study the conformational relationship of emulsification properties of phospholipase A2 modified egg yolk powder. Spectrosc. Spectr. Anal. 2011, 31, 2090–2093. [Google Scholar] [CrossRef]

- He, S.; Shi, J.; Walid, E.; Zhang, H.; Ma, Y.; Xue, S. Reverse micellar extraction of lectin from black turtle bean (Phaseolus vulgaris): Optimisation of extraction conditions by response surface methodology. Food Chem. 2015, 166, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Dai, X.; Yang, X.; Liu, Y.; Zhang, X.; Wei, X. Effect of spray freeze drying on the structure and properties of egg white protein. Food Mach. 2020, 36, 30–35. [Google Scholar] [CrossRef]

- Guan, B.; Lin, H.; Wang, G. Food Protein Chemistry; Guan, B., Ed.; Chemical Industry Publishing: Beijing, China, 2005; pp. 47–51. [Google Scholar]

- Liao, L. Study on the Deamidation of Wheat Gluten by Organic Acids upon Hydrothermal Treatment and Reaction Mechanism; South China University of Technology: Guangzhou, China, 2012. [Google Scholar]

- Chio, S.; Ma, C. Structural characterization of globulin from common buckwheat (Fagopyrum esculentum Moench) using circular dichroism and Raman spectroscopy. Food Chem. 2007, 102, 150–160. [Google Scholar] [CrossRef]

- Yi, Y.; Xiang, B.; Tong, L. The application of studying fluorescence spectroscopy on protein. Exp. Technol. Manag. 2010, 27, 33–36. [Google Scholar] [CrossRef]

- Ma, M.; Ren, Y.; Xie, W.; Zhou, D.; Tang, S.; Kuang, M.; Wang, Y.; Du, K. Physicochemical and functional properties of protein isolate obtained from cottonseed meal. Food Chem. 2018, 240, 856–862. [Google Scholar] [CrossRef] [PubMed]

- Adiamo, O.; Netzel, M.; Hoffman, L.; Michael, J.; Simone, O.; Yasmina, S. Structure-Function relationship of Australian Acacia seed protein concentrate: Amino acid composition, in vitro protein digestibility and molecular properties. Food Biosci. 2023, 51, 856–862. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, L.; Wang, S.; Li, D.; Wang, M.; Liu, Q.; Qi, B. Process optimization for aqueous enzymatic extraction of filbert protein. Food Sci. 2012, 33, 143–148. [Google Scholar]

- Lv, M.; Wei, Y.; Meng, X.; Dong, W. Protein isolation and functional characterization of flat European hazelnut (Corylus heterophyllus). Food Ferment. Ind. 2013, 39, 85–89. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Geng, J. Characterization and nutrient analysis of different wild hazelnut fruits. Chin. J. Cereals Oils 2021, 3, 117–122. [Google Scholar]

- Wang, W.; Jung, J.; McGorrin, R. Investigation of Drying Conditions On Bioactive Compounds, Lipid Oxidation, and Enzyme Activity of Oregon Hazelnuts (Corylus avellana L.). LWT 2018, 90, 526–534. [Google Scholar] [CrossRef]

- Lhami, K.; Nevzat, A.; Atilla, I.; Nurdan, G. Nutrient Composition of Hazelnut (Corylus avellana L.) varieties cultivated in Turkey. Food Chem. 2006, 99, 509–515. [Google Scholar] [CrossRef]

- Kumar, M.; Tomar, M.; Potkule, J.; Reetu; Punia, S.; Dhakane-Lad, J.; Singh, S.; Dhumal, S.; Pradhan, P.C.; Bhushan, B.; et al. Functional characterization of plant-based protein to determine its quality for food applications. Food Hydrocoll. 2021, 123, 106986. [Google Scholar] [CrossRef]

- Jiang, J.; Liang, L.; Zhao, T. Kernel Nutrient Composition and Antioxidant Ability of Corylus spp. in China. Front. Plant Sci. 2021, 12, 690966. [Google Scholar] [CrossRef]

- Mo, C. Protein Chemistry and Technology; Chemical Industry Press: Beijing, China, 2007; pp. 118–119. [Google Scholar]

- Zhou, M. Introduction to Nutrition; Chemical Industry Press: Beijing, China, 2019; p. 41. [Google Scholar]

- Sun, M.; Liu, C. Food Nutrition; China Agricultural University Press: Beijing, China, 2010; p. 51. [Google Scholar]

- Mao, X.; Hua, Y. Composition, Structure and Functional Properties of Protein Concentrates and Isolates Produced from Walnut (Juglans regia L.). Int. J. Mol. Sci. 2012, 13, 1561–1581. [Google Scholar] [CrossRef]

- Zhu, M.; Yin, H.; Liang, L.; Wang, G.; Ma, Q. Optimization of the process of removing hazelnut seed coat by lye method. J. Chin. Inst. Food Sci. Technol. 2014, 5, 106–116. [Google Scholar]

- Su, J. The Study on Extraction, Stability and Reduce Blood-Lipid of Juglans mandshurica Maxim. Oil; Northeast Forestry University: Harbin, China, 2008. [Google Scholar]

- GB 5009.5-2016; National Standard for Food Safety, Determination of Protein in Foods. National Health and Family Planning Commission of the People’s Republic of China & National medical products Administration: Beijing, China, 2016.

- GB 5009.6-2016; National Standard for Food Safety, Determination of Fat in Food. National Health and Family Planning Commission of the People’s Republic of China & National medical products Administration: Beijing, China, 2016.

- GB 5009.3-2016; National Standard for Food Safety, Determination of Moisture in Food. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- GB 5009.4-2016; National Standard for Food Safety, Determination of Ash in Foods. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- Jiang, Y.; Du, Y.; Zhu, X.; Xiong, H.; Meng, W.; Hu, J. Physicochemical and comparative properties of pectins extracted from Akebia trifoliata var. australis peel. Carbohydr. Polym. 2012, 87, 1663–1669. [Google Scholar] [CrossRef]

- Ma, Y.; Zheng, L.; Qi, F.; Zheng, Y. Study on extraction of hazelnut protein and its functional properties. Food Sci. 2008, 8, 318–322. [Google Scholar] [CrossRef]

- Siong, H.; Rodney, J.; Christopher, L.; Samson, O. Extraction and characterization of protein fractions from Australian canola meals. Food Res. Int. 2011, 44, 1075–1082. [Google Scholar] [CrossRef]

- Zeng, H.; Cai, L.; Cai, X.; Wang, Y.; Li, Y. Structure characterization of protein fractions from lotus (Nelumbo nucifera) seed. J. Mol. Struct. 2011, 1001, 139–144. [Google Scholar] [CrossRef]

- Jiao, J. Determination of soluble protein content in alfalfa by coomassie brilliant blue G-250 staining. Agric. Eng. Technol. 2016, 36, 33–34. [Google Scholar]

- GB 5009.124-2016; National Standard for Food Safety, Determination of Amino Acids in Foods. National Health and Family Planning Commission of the People’s Republic of China & National Medical Products Administration: Beijing, China, 2016.

- Deng, Y.; Zheng, Z.; Zhang, M.; Zhang, R.; Zhang, Y.; Tang, X.; Ma, Y. Nutrition assessment and anti-fatigue effect of black soybean nutrient. Mod. Food Sci. Technol. 2013, 29, 2015–2019. [Google Scholar]

- Yin, M.; Chen, M.; Yanagisawa, T.; Ryosuke, M.; Long, Z.; Wei, Q.; Ning, T.; Xi, Y.; Wang, X. A comparative study on the nutritional evaluation of the head, meat, roe, and viscera of rainbow smelt (Osmerus mordax). J. Food Compos. Anal. 2022, 109, 104469. [Google Scholar] [CrossRef]

- Liu, S. Nutrition Value Evaluation of Potato Protein and Its Functional Properties; Tianjin University of Science and Technology: Tianjin, China, 2008; pp. 26–27. [Google Scholar]

- Zhang, H. Identification of Major Allergens in Almonds and Their Desensitization Methods; Tianjin Agricultural University: Tianjin, China, 2019; pp. 15–16. [Google Scholar]

- Li, Y.; Li, M.; Zhang, Y.; Jiang, L.; Wang, Z.; Teng, F. Effect of low pressure homogenization on solubility and structure of soybean protein isolate. J. Agric. Mach. 2019, 50, 345–351. [Google Scholar] [CrossRef]

- Li, K.; Tian, J.; Zheng, S.; He, Y.; Xiang, Q.; Bai, Y. Effects of plasma on solubility and emulsifying properties of chickpea protein isolates. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 31–39. [Google Scholar]

- Wang, R.; Wang, L.; Wen, Q.; He, F.; Xu, F.; Chen, B.; Zheng, X. Combination of pulsed electric field and pH shifting improves the solubility, emulsifying, foaming of commercial soy protein isolate. Food Hydrocoll. 2023, 134, 108049. [Google Scholar] [CrossRef]

| Name of Sample | Moisture (%) | Fat (%) | Protein (%) | Ash (%) |

|---|---|---|---|---|

| Corylus mandshurica Maxim kernel | 5.51 ± 0.05 | 61.00 ± 0.69 | 21.89 ± 0.92 | 2.67 ± 0.11 |

| DCF | 3.49 ± 0.06 | 8.68 ± 0.28 | 49.81 ± 0.98 | 6.64 ± 0.13 |

| Name of Amino Acid (mg/g pro) | Protein Fractions | FAO/WHO | ||||

|---|---|---|---|---|---|---|

| WS | SS | AS | LS | CPI | ||

| Threonine (Thr) | 25.67 ± 0.57 | 19.96 ± 0.97 | 1.61 ± 0.34 | 17.82 ± 0.77 | 24.27 ± 3.77 | 40 |

| Valine (Val) | 47.10 ± 0.35 | 38.23 ± 1.19 | 27.96 ± 0.94 | 39.24 ± 1.09 | 47.69 ± 1.21 | 50 |

| Methionine + Methionine (Met + Cys) | 56.78 ± 7.34 | 68.08 ± 7.46 | 144.83 ± 1.01 | 74.44 ± 4.55 | 39.89 ± 6.00 | 35 |

| Isoleucine (Ile) | 36.13 ± 0.47 | 26.44 ± 0.86 | 13.19 ± 1.20 | 24.88 ± 0.97 | 39.33 ± 0.96 | 40 |

| Leucine (Leu) | 64.68 ± 0.84 | 52.34 ± 0.99 | 17.32 ± 1.19 | 47.57 ± 0.85 | 71.35 ± 2.14 | 70 |

| Phenylalanine + Tyrosine (Phe + Tyr) | 71.12 ± 0.29 | 59.12 ± 1.91 | 32.40 ± 8.69 | 47.12 ± 2.70 | 76.09 ± 1.84 | 60 |

| Lysine (Lys) | 23.05 ± 0.06 | 30.57 ± 0.18 | 12.28 ± 0.72 | 21.00 ± 0.29 | 20.94 ± 0.74 | 55 |

| Aspartic (Asp) | 87.94 ± 1.94 | 54.44 ± 0.82 | 0.45 ± 0.73 | 33.25 ± 0.08 | 96.78 ± 3.46 | |

| Serine (Ser) | 38.72 ± 2.38 | 28.61 ± 0.24 | 1.64 ± 0.74 | 21.76 ± 0.68 | 45.24 ± 3.61 | |

| Glutamic (Glu) | 225.08 ± 2.52 | 170.75 ± 2.15 | 6.04 ± 2.65 | 62.20 ± 0.18 | 200.93 ± 7.30 | |

| Glycine (Gly) | 38.48 ± 0.41 | 32.43 ± 0.09 | 1.30 ± 1.08 | 19.74 ± 0.07 | 38.91 ± 1.58 | |

| Alanine (Ala) | 43.42 ± 0.94 | 32.66 ± 0.76 | 30.50 ± 3.67 | 30.36 ± 0.14 | 44.55 ± 1.71 | |

| Histidine (His) | 23.44 ± 0.07 | 23.52 ± 0.58 | 13.96 ± 2.93 | 17.94 ± 0.49 | 25.12 ± 0.93 | |

| Arginine (Arg) | 128.18 ± 0.73 | 106.26 ± 0.88 | 0.00 | 33.19 ± 0.14 | 132.21 ± 5.13 | |

| Proline (Pro) | 33.46 ± 0.72 | 41.16 ± 1.28 | 4.51 ± 4.04 | 32.82 ± 1.41 | 45.21 ± 3.34 | |

| TAA | 943.24 | 784.56 | 307.97 | 523.33 | 948.51 | |

| EAA | 324.52 | 294.73 | 249.58 | 272.08 | 319.56 | |

| NEAA | 618.72 | 489.83 | 58.39 | 251.26 | 628.95 | |

| (EAA/TAA)/% | 34.41 | 37.57 | 81.05 | 51.98 | 33.70 | |

| (EAA/NEAA)/% | 52.46 | 60.17 | 433.62 | 108.29 | 50.85 | |

| Protein Samples | Nutritional Parameters | Thr | Val | Met + Cys | Ile | Leu | Phe + Tyr | Lys |

|---|---|---|---|---|---|---|---|---|

| WS | AAS | 64.16 | 94.20 | 162.22 | 90.31 | 92.40 | 118.53 | 41.91 |

| CS | 54.61 | 71.36 | 99.61 | 66.90 | 75.21 | 76.47 | 32.93 | |

| SS | AAS | 49.89 | 76.47 | 194.50 | 66.10 | 74.77 | 98.53 | 55.58 |

| CS | 42.46 | 57.93 | 119.43 | 48.96 | 60.86 | 63.57 | 43.67 | |

| AS | AAS | 4.02 | 55.92 | 413.79 | 32.96 | 24.74 | 54.01 | 22.33 |

| CS | 3.42 | 42.36 | 254.08 | 24.42 | 20.14 | 34.84 | 17.54 | |

| LS | AAS | 44.56 | 78.49 | 212.70 | 62.20 | 67.95 | 78.54 | 38.17 |

| CS | 37.92 | 59.46 | 130.60 | 46.07 | 55.31 | 50.67 | 29.99 | |

| CPI | AAS | 60.66 | 95.39 | 113.96 | 98.33 | 101.93 | 126.81 | 38.08 |

| CS | 51.63 | 72.26 | 69.98 | 72.84 | 82.97 | 81.82 | 29.92 |

| Indicators | WS | SS | AS | LS | CPI |

|---|---|---|---|---|---|

| EAAI | 72.19 | 65.27 | 30.21 | 58.59 | 69.74 |

| BV | 66.99 | 59.45 | 21.23 | 52.16 | 64.32 |

| NI | 55.78 | 7.92 | 0.49 | 2.50 | 41.68 |

| Secondary Structure | α-Helix | Parallel β-Sheet | Anti-Parallel β-Sheet | β-Turn | Random Coil |

|---|---|---|---|---|---|

| CPI | 22.73 ± 0.92 | 41.52 ± 0.76 | 7.59 ± 0.83 | 15.41 ± 0.64 | 12.75 ± 0.73 |

| WS | 24.58 ± 0.71 | 38.91 ± 0.64 | 7.60 ± 0.67 | 16.06 ± 0.92 | 12.84 ± 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Ding, J.; Guo, Q.; Zhang, N. Nutritional Value and Structure Characterization of Protein Components of Corylus mandshurica Maxim. Molecules 2023, 28, 6355. https://doi.org/10.3390/molecules28176355

Hou Y, Ding J, Guo Q, Zhang N. Nutritional Value and Structure Characterization of Protein Components of Corylus mandshurica Maxim. Molecules. 2023; 28(17):6355. https://doi.org/10.3390/molecules28176355

Chicago/Turabian StyleHou, Yanli, Jie Ding, Qingqi Guo, and Na Zhang. 2023. "Nutritional Value and Structure Characterization of Protein Components of Corylus mandshurica Maxim" Molecules 28, no. 17: 6355. https://doi.org/10.3390/molecules28176355