Survey on Antioxidants Used as Additives to Improve Biodiesel’s Stability to Degradation through Oxidation

Abstract

:1. Introduction

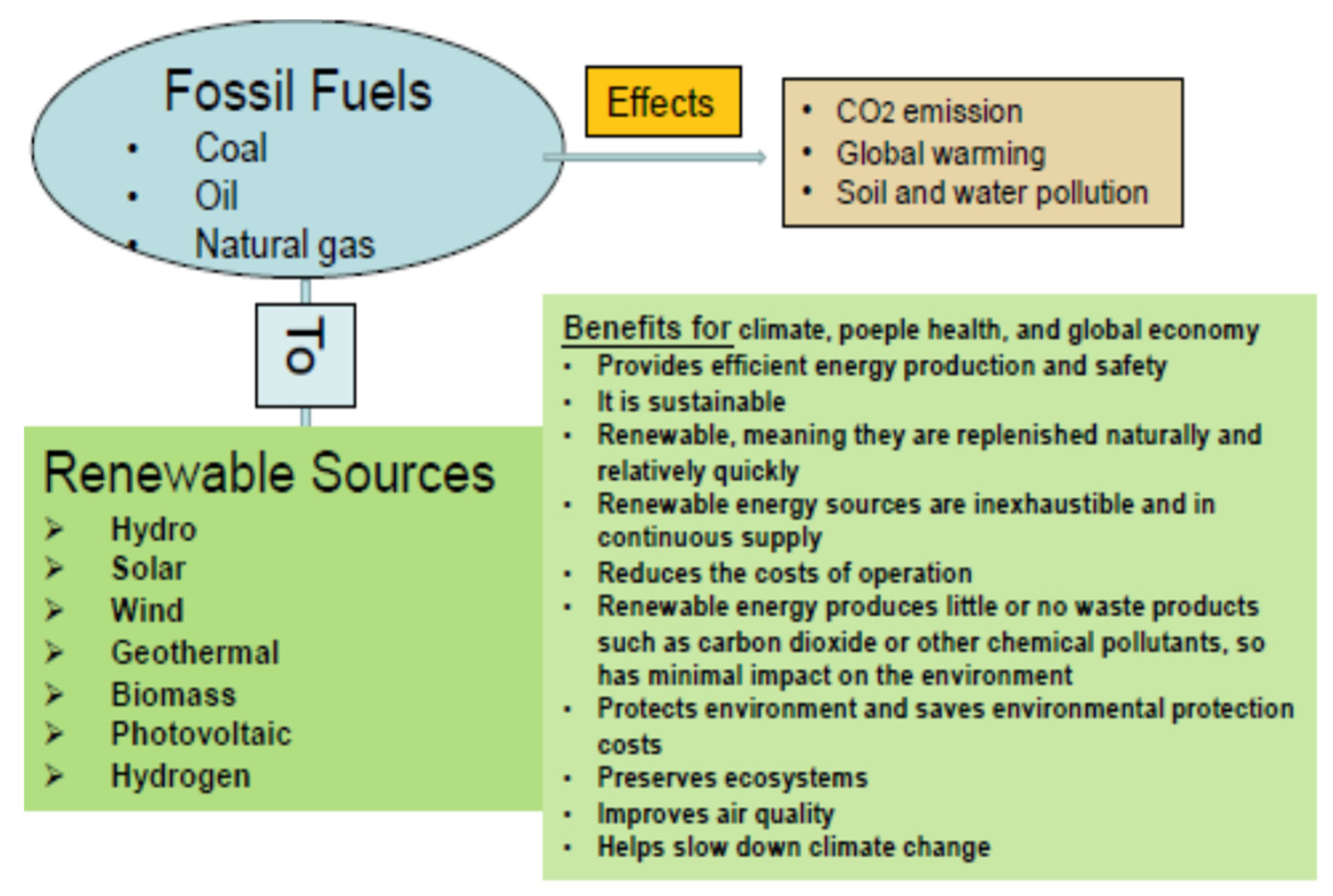

Substitution of Fossil Fuels by Renewable Sources

2. Factors Affecting the Stability to Oxidation of Biodiesel

2.1. Influence of Feedstock Composition on Biodiesel Properties

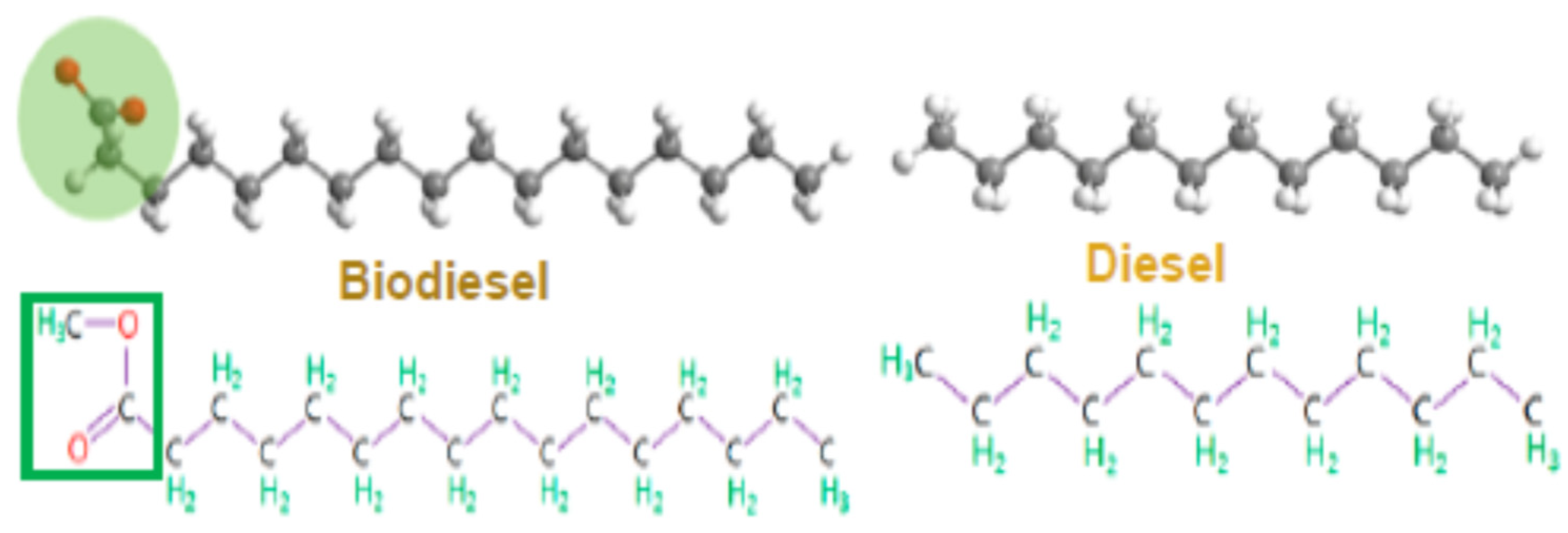

2.2. Biodiesel Chemical Composition

2.3. Presence of Natural Antioxidants in Biodiesel

2.4. Influence of Storage Conditions on Biodiesel’s Stability

2.5. Presence of Metal Contaminants

2.6. The Influence of Other Factors

3. Remediation Methods

4. Antioxidants

4.1. Natural Antioxidants

4.2. Antioxidant Mechanism

Auto-Oxidation

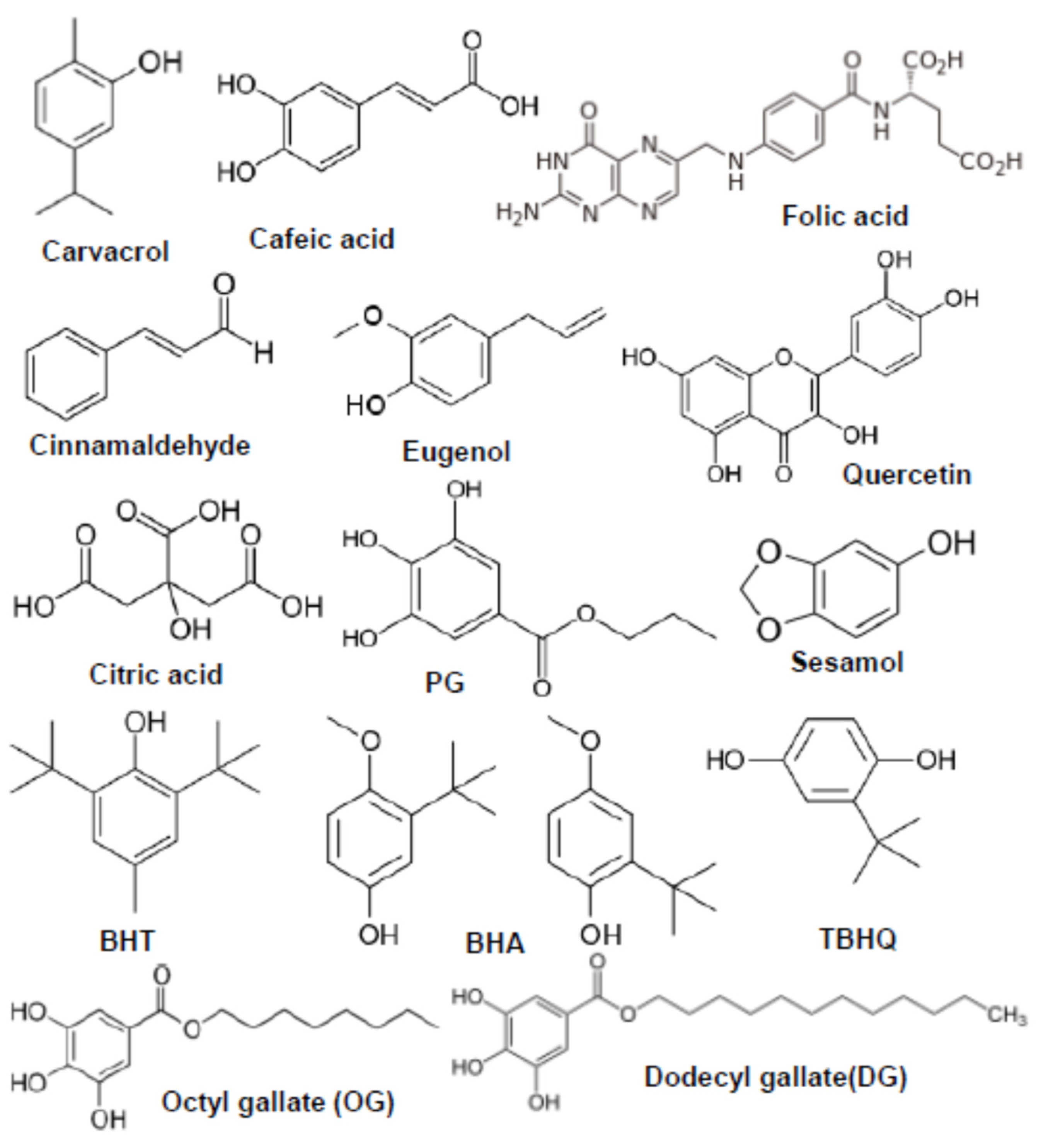

4.3. Structure and Molecular Mass of the Antioxidants

4.4. Concentration Requirements for Antioxidants’ Use

4.5. Effects of Antioxidants on Biodiesel Cold-Flow Properties

4.6. Sustainability of Using Antioxidants to Enhance Biodiesel Stability and Research Trends

5. Conclusions

- Antioxidants are chemical compounds that slow down or stop the auto-oxidation process by delaying the production of oxidants or by interrupting the multiplication of free radicals through various reactions in the auto-oxidation chain.

- The performance of antioxidants is influenced by the source from which the biodiesel fuel was obtained. Pyrogallol, for example, stood out as the most effective antioxidant for biodiesel produced from raw material with a high content of fatty acids (FFA). Biodiesel fuels that contain a small amount of natural antioxidants, such as carotenoids and tocopherols, have a reduced oxidation stability.

- The selection of antioxidants is based on their antioxidant performance, which must be high, and which is due to their good solubility, good efficiency at low concentrations, non-toxicity, and long shelf life.

- Antioxidants with a higher molecular weight ensure better stability of biodiesel over longer storage times because they contain more hydrogen atoms for donation.

- Antioxidants containing polyhydroxyl groups in their structure show higher performance compared to monohydroxyl antioxidants, such as BHT and BHA; however, no improvement in activity was observed for antioxidants with more than three hydroxyl groups in the molecular structure.

- Polar and partially fat-soluble antioxidants are more effective in maintaining the stability of biodiesel than fat-soluble antioxidants.

- The temperature, viscosity, and pH of biodiesel significantly influence the effectiveness of antioxidants. Those containing a greater number of aromatic rings and longer aliphatic chains show a higher resistance to heat. Antioxidants with high pH have a lower concentration of metal ions and improve the stability of biodiesel, and the viscosity of biodiesel greatly influences the uniform distribution of antioxidants in the mass of biodiesel.

- The use of higher concentrations of antioxidants in biofuels should be avoided, because it could lead to an increase in the delay period in combustion and reflects an increase in costs.

- The plant antioxidants have a higher efficiency in increasing the oxidation stability of biodiesel, and less so in maintaining suitable biodiesel cold-flow properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biotechnol. Bioeng. 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Issariyakul, T.; Dalai, A.K. Biodiesel from vegetable oils. Renew. Sust. Energ. Rev. 2014, 31, 446–471. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers. Manag. 2008, 49, 2106–2116. [Google Scholar] [CrossRef]

- Singh, P.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar]

- Fatt, L. A review of cleaner intensification technologies in biodiesel production. J. Clean. Prod. 2017, 146, 181–193. [Google Scholar]

- Tiwari, A.; Rajesh, V.M.; Yadav, S. Energy for sustainable development biodiesel production in micro-reactors: A review. Energy Sustain. Dev. 2018, 43, 143–161. [Google Scholar] [CrossRef]

- Firoz, S. A review: Advantages and disadvantages of biodiesel. Int. Res. J. Eng.Technol. 2017, 4, 530–533. [Google Scholar]

- Atabani, A.E.; Silitonga, A.S.; Badruddina, L.A.; Mahliaa, T.M.I.; Masjukia, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sust. Energ. Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- De Almeida, V.F.; García-Moreno, P.J.; Guadix, A.; Guadix, E.M. Biodiesel production from mixtures of waste fish oil, palm oil and waste frying oil: Optimization of fuel properties. Fuel Process. Technol. 2015, 133, 152–160. [Google Scholar] [CrossRef]

- Anwar, A.; Garforth, A. Challenges and opportunities of enhancing cold flow properties of biodiesel via heterogeneous catalysis. Fuel 2016, 173, 189–208. [Google Scholar] [CrossRef]

- De Carvalho, A.L.; Cardoso, E.A.; Gisele, O.; Teixeira, L.S.G.; Pepe, I.M.; Grosjean, D.M. Carboxylic acid emissions from soybean biodiesel oxidation in the EN14112 (Rancimat) stability test. Fuel 2016, 173, 29–36. [Google Scholar] [CrossRef]

- Vieira, F.S.; Pasquini, C. Determination of the oxidative stability of biodiesel using near infrared emission spectroscopy. Fuel 2014, 117, 1004–1009. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M. Stability of biodiesel and its blends: A review. Renew. Sustain. Energy Rev. 2010, 14, 667–678. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. Experimental study of the factors affecting the oxidation stability of biodiesel FAME fuels. Fuel Process Technol. 2014, 125, 223–235. [Google Scholar] [CrossRef]

- Kreivaitis, R.; Padgurskas, J.; Gumbytė, M.; Makarevičienė, V.; Spruogis, B. The influence of oxidation on tribological properties of rapeseed oil. Transport 2011, 26, 121–127. [Google Scholar] [CrossRef]

- Serrano, M.; Bouaid, A.; Martinez, M.; Aracil, J. Oxidation stability of biodiesel from different feedstocks: Influence of commercial additives and purification step. Fuel 2013, 113, 50–58. [Google Scholar] [CrossRef]

- Bhale, P.V.; Deshpande, N.V.; Thombre, S.B. Improving the low temperature properties of biodiesel fuel. Renew. Energy 2009, 34, 794–800. [Google Scholar] [CrossRef]

- Sierra-Cantor, J.F.; Guerrero-Fajardo, C.A. A review on the oxidation stability of biodiesel. Renew. Sustain. Energy Rev. 2017, 72, 774–790. [Google Scholar] [CrossRef]

- Dwivedi, G.; Sharma, M.P. Impact of cold flow properties of biodiesel on engine performance. Renew. Sustain. Energy Rev. 2014, 31, 650–656. [Google Scholar] [CrossRef]

- Salvado, J.; Pasqualino, J.C.; Montane, D. Synergic effects of biodiesel in the biodegradability of fossil-derived fuels. Biomass Bioenergy 2006, 30, 874–879. [Google Scholar]

- Schleicher, T.; Werkmeister, R.; Russ, W.; Meyer-Pittroff, R. Bioresource technology microbiological stability of biodiesel–diesel-mixtures. Bioresour. Technol. 2009, 100, 724–730. [Google Scholar] [CrossRef]

- Prince, R.C.; Haitmanek, C.; Coyle, C. The primary aerobic biodegradation of biodiesel B20. Chemosphere 2008, 1, 1446–1451. [Google Scholar] [CrossRef] [PubMed]

- Owsianiak, M.; Owsianiak, M.; Chrzanowski, Ł.; Szulc, A.; Staniewski, J.; Olszanowski, A.; Olejnik-Schmidt, A.K.; Heipieper, H.J. Bioresource technology Biodegradation of diesel/biodiesel blends by a consortium of hydrocarbon degraders: Effect of the type of blend and the addition of biosurfactants. Bioresour. Technol. 2009, 100, 1497–1500. [Google Scholar] [CrossRef]

- Makareviciene, V.; Janulis, P. Environmental effect of rapeseed oil ethyl ester. Renew. Energy 2003, 28, 2395–2403. [Google Scholar] [CrossRef]

- Beker, S.A.; Beker, S.A.; da Silva, Y.P.; Bücker, F.; Cazarolli, J.C.; de Quadros, P.D.; Peralba, M.D.C.R.; Piatnicki, C.M.S.; Bento, F.M. Effect of different concentrations of tert-butylhydroquinone (TBHQ) on microbial growth and chemical stability of soybean biodiesel during simulated storage. Fuel 2016, 184, 701–707. [Google Scholar] [CrossRef]

- Çamur, H. Energies prediction of oxidation stability of biodiesel derived from waste and refined vegetable oils by statistical approaches. Energies 2022, 15, 407. [Google Scholar] [CrossRef]

- Fazal, M.; Jakeria, M.; Haseeb, A.; Rubaiee, S. Effect of antioxidants on the stability and corrosiveness of palm biodiesel upon exposure of different metals. Energy 2017, 135, 220–226. [Google Scholar] [CrossRef]

- Nuhanovic, M.; Topalovic, A.; Culum, D.; Ibragic, S. The effectiveness of natural and synthetic antioxidant additives on the oxidation stability of biodiesel synthesized from fresh and waste sunflower oilesized from fresh and waste sunflower oil. Orbital Electron. J. Chem. 2018, 10, 535–542. [Google Scholar] [CrossRef]

- Silitonga, A.S. A comparative study of biodiesel production methods for Reutealis trisperma biodiesel. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 39, 2006–2014. [Google Scholar] [CrossRef]

- Hazrat, M.A. Techniques to improve the stability of biodiesel: A review. Environ. Chem. Lett. 2021, 19, 2209–2236. [Google Scholar] [CrossRef]

- Monirul, I.M. Influence of poly(methyl acrylate) additive on cold flow properties of coconut biodiesel blends and exhaust gas emissions. Renew. Energy 2017, 101, 702–712. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. A critical review on available models to predict engine fuel properties of biodiesel. Renew. Sustain. Energy Rev. 2021, 155, 111925. [Google Scholar] [CrossRef]

- Sorate, K.A.; Bhale, P.V. Biodiesel properties and automotive system compatibility issues. Renew. Sustain. Energy Rev. 2015, 41, 777–798. [Google Scholar] [CrossRef]

- Kochhar, S.P. Deterioration of edible oils, fats and foodstuffs. In Atmospheric Oxidation and Antioxidants; Scott, G., Ed.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1993; pp. 71–140. [Google Scholar]

- Shahidi, F.; Zhong, Y. Lipid oxidation and improving the oxidative stability. Chem. Soc. Rev. 2010, 39, 4067–4079. [Google Scholar] [CrossRef] [PubMed]

- Yaakob, Z.; Narayanan, B.N.; Padikkaparambil, S.; Suryaunni, K.; Akbar, P. A review on the oxidation stability of biodiesel. Renew. Sustain. Energy Rev. 2014, 35, 136–153. [Google Scholar] [CrossRef]

- Lanjekar, R.D.; Deshmukh, D. A review of the effect of the composition of biodiesel on NOx emission, oxidative stability and cold flow properties. Renew. Sustain. Energy Rev. 2016, 54, 1401–1411. [Google Scholar] [CrossRef]

- Kivevele, T.T.; Huan, Z. Effects of antioxidants on the cetane number, viscosity, oxidation stability, and thermal properties of biodiesel produced from nonedible oils. Energy Technol. 2013, 1, 537–543. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2019, 24, 101514. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Pantoja, S.S.; Da Conceiçao, L.R.V.; Da Costa, C.E.F.; Zamian, J.R.; Da Rocha Filho, G.N. Oxidative stability of biodiesels produced from vegetable oils having different degrees of unsaturation. Energy Convers. Manag. 2013, 74, 293–298. [Google Scholar] [CrossRef]

- Patra, J.K.; Kim, S.H.; Hwang, H.; Choi, J.W.; Baek, K. Volatile compounds and antioxidant capacity of the bio-oil obtained by pyrolysis of Japanese red pine (Pinus densif lora Siebold and Zucc.). Molecules 2015, 20, 3986–4006. [Google Scholar] [CrossRef] [PubMed]

- Rashed, M.M. Stability of biodiesel, its improvement and the effect of antioxidant treated blends on engine performance and emission. RSC Adv. 2015, 5, 36240–36261. [Google Scholar] [CrossRef]

- Meira, M.; Santana, P.M.B.; Araújo, A.S.; Silva, C.L.; Filho, J.R.L.L.; Ferreira, H.T. Oxidative degradation and corrosiveness of biodiesel. Corrosion Rev. 2014, 32, 143–161. [Google Scholar] [CrossRef]

- Donoso, D.; Bolonio, D.; Lapuerta, M.; Canoira, L. Oxidation stability: The bottleneck for the development of a fully renewable Biofuel from wine industry waste. ACS Omega 2020, 5, 16645–16653. [Google Scholar] [CrossRef]

- Ondul, E.; Dizge, N.; Keskinler, B.; Albayrak, N. Biocatalytic production of biodiesel from vegetable oils. Biofuels Status Perspect. 2015, 5, 16–20. [Google Scholar]

- Ardhiah, H.H.; Ong, H.C. A review on latest developments and future prospects of heterogeneous catalyst in biodiesel production from non-edible oils. Renew. Sustain. Energy Rev. 2017, 67, 1225–1236. [Google Scholar] [CrossRef]

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Knothe, G. Structure indices in FA chemistry. How relevant is the iodine value? J. Am. Oil Chem. Soc. 2002, 79, 847–854. [Google Scholar] [CrossRef]

- Kumar, N. Oxidative stability of biodiesel: Causes, effects and prevention. Fuel 2016, 190, 328–350. [Google Scholar] [CrossRef]

- McCormick, R.; Ratcliff, M.; Moens, L.; Lawrence, R. Several factors affecting the stability of biodiesel in standard accelerated tests. Fuel Process Technol. 2007, 88, 651–657. [Google Scholar] [CrossRef]

- Lima, R.P.; da Luz, P.T.S.; Braga, M.; Batista, P.R.d.S.; da Costa, C.E.F.; Zamian, J.R.; Nascimento, L.A.S.D.; Filho, G.N.d.R. Murumuru (Astrocaryum murumuru Mart.) butter and oils of buriti (Mauritia flexuosa Mart.) and pracaxi (Pentaclethra macroloba (Willd.) Kuntze) can be used for biodiesel production: Physico-chemical properties and thermal and kinetic studies. Ind. Crops Prod. 2017, 97, 536–544. [Google Scholar] [CrossRef]

- Gureev, A.A.; Prigulskii, G.B. Thermooxidative stability of diesel fuels. Chem. Technol. Fuels Oil 1985, 21, 296–298. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Sousa, R.M.; de Oliveira, A.; Morais, S.A.; Richter, E.M.; Muñoz, R.A. Moringa oleifera: A potential source for production of biodiesel and antioxidant additives. Fuel 2015, 146, 75–80. [Google Scholar] [CrossRef]

- Ramalingam, S.; Govindasamy, M.; Ezhumalai, M.; Kaliyaperumal, A. Effect of leaf extract from Pongamia pinnata on the oxidation stability, performance and emission characteristics of calophyllum biodiesel. Fuel 2016, 180, 263–269. [Google Scholar] [CrossRef]

- Rocha Morais França, F.; dos Santos Freitas, L.; Ramos, A.L.D.; da Silva, G.F.; Brandão, S.T. Storage and oxidation stability of commercial biodiesel using Moringa oleifera Lam as an antioxidant additive. Fuel 2017, 03, 627–632. [Google Scholar] [CrossRef]

- De Sousa, L.S.; De Moura, C.V.R.; De Oliveira, J.E.; De Moura, E.M. Use of natural antioxidants in soybean biodiesel. Fuel 2014, 134, 420–428. [Google Scholar] [CrossRef]

- Nascimento, J.A.; Araújo, K.L.; Epaminondas, P.S.; Pontes, A.L.; Souza, A.L.; Queiroz, N.; Souza, A.G. Ethanolics extracts of Moringa: Antioxidant effect in soybean oil by PDSC and Rancimat. J. Therm. Anal. Calorim. 2014, 117, 265–268. [Google Scholar] [CrossRef]

- Vats, S.; Gupta, T. Evaluation of bioactive compounds and antioxidant potential of hydroethanolic extract of Moringa oleifera Lam. from Rajasthan, India. Physiol. Mol. Biol. Plants 2017, 23, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Bolarinwa, I.F.; Aruna, T.E.; Raji, A.O. Nutritive value and acceptability of bread fortified with moringa seed powder. J. Saudi Soc. Agric. Sci. 2019, 18, 195–200. [Google Scholar] [CrossRef]

- Omotoso, G.O.; Gbadamosi, I.T.; Olajide, O.J.; Dada-Habeeb, S.O.; Arogundade, T.T.; Yawson, E.O. Moringa oleifera phytochemicals protect the brain against experimental nicotine-induced neurobehavioral disturbances and cerebellar degeneration. Pathophysiology 2018, 25, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Jain, R.; Kachhwaha, S.; Kothari, S.L. Nutritional and medicinal applications of Moringa oleifera Lam.-Review of current status and future possibilities. J. Herb. Med. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Devi, A.; Das, V.K.; Deka, D. Ginger extract as a nature based robust additive and its influence on the oxidation stability of biodiesel synthesized from non-edible oil. Fuel 2017, 187, 306–314. [Google Scholar] [CrossRef]

- Gopalakrishnan, L.; Doriya, K.; Kumar, D.S. Moringa oleifera: A review on nutritive importance and its medicinal application. Food Sci. Hum. Wellness 2016, 5, 49–56. [Google Scholar] [CrossRef]

- Djikeng, F.T.; Womeni, H.M.; Anjaneyulu, E.; Karuna, M.S.L.; Prasad, R.B.N.; Linder, M. Effects of natural antioxidants extracted from Cameroonian ginger roots on the oxidative stability of refined palm olein. Eur. Food Res. Technol. 2018, 244, 1015–1025. [Google Scholar] [CrossRef]

- Ganji, S.; Sayyed-Alangi, S.Z. Encapsulation of ginger ethanolic extract in nanoliposome and evaluation of its antioxidant activity on sunflower oil. Chem. Pap. 2017, 71, 1781–1789. [Google Scholar] [CrossRef]

- Spacino, K.R.; Borsato, D.; Buosi, G.M.; Chendynski, L.T. Determination of kinetic and thermodynamic parameters of the B100 biodiesel oxidation process in mixtures with natural antioxidants. Fuel Process Technol. 2015, 137, 366–370. [Google Scholar] [CrossRef]

- Buosi, G.M.; Da Silva, E.T.; Spacino, K.; Silva, L.R.C.; Ferreira, B.A.D.; Borsato, D. Oxidative stability of biodiesel from soybean oil: Comparison between synthetic and natural antioxidants. Fuel 2016, 181, 759–764. [Google Scholar] [CrossRef]

- García, M.; Botella, L.; Gil-Lalaguna, N.; Arauzo, J.; Gonzalo, A.; Sánchez, J.L. Antioxidants for biodiesel: Additives prepared from extracted fractions of bio-oil. Fuel Process Technol. 2017, 156, 407–414. [Google Scholar] [CrossRef]

- Gil-Lalaguna, N.; Bautista, A.; Gonzalo, A.; Sanchez, J.L.; Arauzo, J. Obtaining biodiesel antioxidant additives by hydrothermal treatment of lignocellulosic bio-oil. Fuel Process Technol. 2017, 166, 1–7. [Google Scholar] [CrossRef]

- Garcia-Perez, M.; Adams, T.T.; Goodrum, J.W.; Das, K.C.; Geller, D.P. DSC studies to evaluate the impact of bio-oil on cold flow properties and oxidation stability of bio-diesel. Bioresour. Technol. 2010, 101, 6219–6224. [Google Scholar] [CrossRef]

- Garcia-Perez, M.; Shen, J.; Wang, X.S.; Li, C.Z. Production and fuel properties of fast pyrolysis oil/bio-diesel blends. Fuel Process Technol. 2010, 91, 296–305. [Google Scholar] [CrossRef]

- Alcala, A.; Bridgwater, A.V. Upgrading fast pyrolysis liquids: Blends of biodiesel and pyrolysis oil. Fuel 2013, 109, 417–426. [Google Scholar] [CrossRef]

- Xin, J.; Imahara, H.; Saka, S. Kinetics on the oxidation of biodiesel stabilized with antioxidant. Fuel 2009, 88, 282–286. [Google Scholar] [CrossRef]

- Ashraful, A.; Masjuki, H.; Kalam, M.; Rahman, S.A.; Habibullah, M.; Syazwan, M. Study of the effect of storage time on the oxidation and thermal stability of various biodiesels and their blends. Energy Fuel 2014, 28, 1081–1089. [Google Scholar] [CrossRef]

- Batista, L.; Da Silva, V.F.; Pissurno, É.C.; da Conceição Soares, T.; de Jesus, M.R.; Kunigami, C.N.; Brasil, M.G.; da Fonseca, M.G. Formation of toxic hexanal, 2-heptenal and 2, 4-decadienal during biodiesel storage and oxidation. Environ. Chem. Lett. 2015, 13, 353–358. [Google Scholar] [CrossRef]

- Christensen, E.; McCormick, R.L. Long-term storage stability of biodiesel and biodiesel blends. Fuel Process Technol. 2014, 128, 339–348. [Google Scholar] [CrossRef]

- Kulczynski, B.; Gramza-Michałowska, A.; Krolczyk, J.B. Optimization of extraction conditions for the antioxidant potential of different pumpkin varieties (Cucurbita maxima). Sustain. Times 2020, 12, 1305. [Google Scholar] [CrossRef]

- Rajendran, S.; Venkatesan, E.P.; Dhairiyasamy, R.; Jaganathan, S.; Muniyappan, G.; Hasan, N. Enhancing performance and emission characteristics of biodiesel-operated compression ignition engines through low heat rejection mode and antioxidant additives: A Review. ACS Omega 2023, 8, 34281–34298. Available online: https://pubs.acs.org/journal/acsodf (accessed on 25 August 2023). [CrossRef]

- Yang, Z.; Hollebone, B.P.; Wang, Z.; Yang, C.; Landriault, M. Factors affecting oxidation stability of commercially available biodiesel products. Fuel Process Technol. 2013, 106, 366–375. [Google Scholar] [CrossRef]

- Moser, B.R. Influence of extended storage on fuel properties of methyl esters prepared from canola, palm, soybean and sunflower oils. Renew. Energy 2011, 36, 1221–1226. [Google Scholar] [CrossRef]

- Lau, C.H.; Gan, S.; Nang, H.L.L.; Lee, L.Y. Insights into the effectiveness of synthetic and natural additives in improving biodiesel oxidation stability. Sustain. Energy Technol. Assess. 2022, 52, 102296. [Google Scholar] [CrossRef]

- Longanesi, L.; Pereira, A.P.; Johnston, N.; Chuck, C.J. Oxidative stability of biodiesel: Recent insights. Biofuels Bioprod. Bioref. 2022, 16, 265–289. [Google Scholar] [CrossRef]

- Sonam, K.S.; Guleria, S. Synergistic antioxidant activity of natural products. Ann. Pharmacol. Pharm. 2017, 2, 1086. [Google Scholar]

- Endo, Y.; Usuki, R.; Kaneda, T. Antioxidant effect of chlorophyll and pheophytin on the autoxidation of oils in the dark. 1. Comparison of the inhibitory effects. J. Am. Oil Chem. Soc. 1985, 62, 1375–1378. [Google Scholar] [CrossRef]

- Bart, J.C.J.; Palmeri, N.; Cavallaro, S. Biodiesel Science and Technology from Soil to Oil, 1st ed.; Woodhead Publishing Ltd.: New Delhi, India, 2010. [Google Scholar]

- Komariah, L.N.; Arita, S.; Rendana, M.; Ramayanti, C.; Suriani, N.L.; Erisna, D. Microbial contamination of diesel-biodiesel blends in storage tank; an analysis of colony morphology. Heliyon 2022, 8, e09264. [Google Scholar] [CrossRef]

- Magalhaes, A.M.S.; Pereira, E.; Meirelles, A.J.A.; Sampaio, K.A.; Maximo, G.J. Proposing blends for improving the cold flow properties of ethylic biodiesel. Fuel 2019, 253, 50–59. [Google Scholar] [CrossRef]

- Altaie, M.A.H.; Janius, R.B.; Rashid, U.; Taufiq Yap, Y.H.; Yunus, R.R.; Zakaria, R. Cold flow and fuel properties of methyl oleate and palm-oil methyl ester blends. Fuel 2015, 160, 238–244. [Google Scholar] [CrossRef]

- Leggieri, P.A.; Senra, M.; Soh, L. Cloud point and crystallization in fatty acid ethyl ester biodiesel mixtures with and without additives. Fuel 2018, 222, 243–249. [Google Scholar] [CrossRef]

- Moser, B.R. Comparative oxidative stability of fatty acid alkyl esters by accelerated methods. J. Am. Oil Chem. Soc. 2009, 86, 699–706. [Google Scholar] [CrossRef]

- Sundus, F.; Fazal, M.A.; Masjuki, H.H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sustain. Energy Rev. 2017, 70, 399–412. [Google Scholar] [CrossRef]

- Santos-Sanchez, N.F.; Salas-Coronado, R. Antioxidant compounds and their antioxidant mechanism. IntechOpen 2019, 5, 1–20. [Google Scholar]

- Ibrahim, U.K.; Kamarrudin, N.; Suzihaque, M.U.H.; Abd Hashib, S. Local fruit wastes as a potential source of natural antioxidant: An overview. IOP Conf. Ser. Mater. Sci. Eng. 2017, 206, 12–16. [Google Scholar] [CrossRef]

- Narayanasamy, B.; Jeyakumar, N.; Manoharan, D.K. Effect of natural antioxidants on the oxidation stability of methyl ester of rubber seed oil. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 680–687. [Google Scholar] [CrossRef]

- Pabon-Baquero, L.C.; Otalvaro-Alvarez, A.M.; Fernandez, M.R.R.; Chaparro-Gonzalez, M.P. Plant extracts as antioxidant additives for food industry. Antioxid. Foods Appl. 2018, 20, 135–145. [Google Scholar]

- Ramos, T.C.P.M.; de Souza, E.F.; Pina, C.C.; Cavalheiro, A.A.; Fiorucci, A.R.; da Silva, M.S. Evaluation of natural antioxidants action in oxidative stability of commercial biodiesel. Orbital Electron. J. Chem. 2018, 10, 26–30. [Google Scholar] [CrossRef]

- Focke, W.W.; Van Der Westhuizen, I.; Grobler, A.B.L.; Nshoane, K.T.; Reddy, J.K.; Luyt, A.S. The effect of synthetic antioxidants on the oxidative stability of biodiesel. Fuel 2012, 94, 227–233. [Google Scholar] [CrossRef]

- Jakeria, M.R.; Fazel, M.A.; Haseeb, A.S.M.A. Influence of different factors on the stability of biodiesel: A review. Renew. Sustain. Energy Rev. 2014, 30, 154–163. [Google Scholar] [CrossRef]

- Tang, H.; Wang, A.; Salley, S.O.; Simon-Ng, K.Y. The effect of natural and synthetic antioxidants on the oxidative stability of biodiesel. J. Am. Oil Chem. Soc. 2008, 85, 373–382. [Google Scholar] [CrossRef]

- Almeida, E.S.; Portela, F.M.; Sousa, R.M.; Daniel, D.; Terrones, M.G.; Richter, E.M.; Muñoz, R.A. Behaviour of the antioxidant tert-butylhydroquinone on the storage stability and corrosive character of biodiesel. Fuel 2011, 90, 3480–3484. [Google Scholar] [CrossRef]

- Nagappan, M.; Devaraj, A.; Babu, J.M.; Saxena, N.V.; Prakash, O.; Kumar, P.; Sharma, A. Impact of additives on combustion, performance and exhaust emission of biodiesel fueled direct injection diesel engine. Mater. Today 2022, 62, 2326–2331. [Google Scholar] [CrossRef]

- Ahmad Masudi, A.; Oki Muraza, O.; Che Jusoh, N.W.; Ubaidilla, U. Improvements in the stability of biodiesel fuels: Recent progress and challenges. Environ. Sci. Pollut. Res. 2023, 30, 14104–14125. [Google Scholar] [CrossRef]

- Embuscado, M.E. Herbs and spices as antioxidants for food preservation. In Handbook of Antioxidants for Food Preservation; Shahidi, F., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 250–283. [Google Scholar]

- Fadda, A. Innovative and sustainable technologies to enhance the oxidative stability of vegetable oils. Sustain. Times 2022, 14, 849. [Google Scholar] [CrossRef]

- Klaudia, J.; Michael, L.; Marian, V. Mechanisms of antioxidant activity. In Food Oxidants and Antioxidants Chemical, Biological, and Functional Properties; Bartosz, G., Ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 325–339. [Google Scholar]

- Bassil, D.; Makrus, D.P.; Kefalas, P. Oxidation of caffeic acid in the presence of cysteine: Isolation of 2, 5-cysteinylcaffeic acid and evaluation of its antioxidants properties. Food Res. Int. 2005, 38, 395–402. [Google Scholar] [CrossRef]

- Damasceno, S.S.; Santos, N.A.; Santos, I.M.G.; Souza, A.L.; Souza, A.G.; Queiroz, N. Caffeic and ferulic acids: An investigation of the effect of antioxidants on the stability of soybean biodiesel during storage. Fuel 2013, 107, 641–646. [Google Scholar] [CrossRef]

- Herbinet, O.; Pitz, W.J.; Westbrook, C.K. Detailed chemical kinetic mechanism for the oxidation of biodiesel fuels blend surrogate. Combust. Flame 2010, 157, 893–908. [Google Scholar] [CrossRef]

- Moser, B.R. Efficacy of myricetin as an antioxidant in methyl esters of soybean oil. Eur. J. Lipid Sci. Technol. 2008, 110, 1167–1174. [Google Scholar] [CrossRef]

- Serqueira, D.S.; Dornellas, R.M.; Silva, L.G.; De Melo, P.G.; Castellan, A.; Ruggiero, R.; Richter, E.M.; Munoz, R.A.A. Tetrahydro-curcuminoids as potential antioxidants for biodiesels. Fuel 2015, 160, 490–494. [Google Scholar] [CrossRef]

- Medeiros, M.L.; Cordeiro, A.M.M.T.; Queiroz, N.; Soledade, L.E.B.; Souza, A.L.; Souza, A.G. Efficient antioxidant formulations for use in biodiesel. Energy Fuel 2014, 28, 1074–1080. [Google Scholar] [CrossRef]

- Spacino, K.R.; Silva, E.T.; Angilelli, K.G.; Moreira, I.; Galão, O.F.; Borsato, D. Relative protection factor optimisation of natural antioxidants in biodiesel B100. Ind. Crops Prod. 2016, 80, 109–114. [Google Scholar] [CrossRef]

- Deyab, M.A. Corrosion inhibition of aluminum in biodiesel by ethanol extracts of Rosemary leaves. J. Taiwan Inst. Chem. Eng. 2016, 58, 536–541. [Google Scholar] [CrossRef]

- Elavarasan, P.; Kondamudi, K.; Upadhyayula, S. Synthesis of antioxidants: Green chemistry route. Int. J. Chem. Sci. 2010, 8, S578–S584. [Google Scholar]

- Pullen, J.; Saeed, K. An overview of biodiesel oxidation stability. Renew. Sustain. Energy Rev. 2012, 16, 5924–5950. [Google Scholar] [CrossRef]

- Nakano, M.; Okawa, K. Study of oxygen-containing hydrocarbons in exhaust emission from a spark ignition combustion engine. Int. J. Engine Res. 2014, 15, 572–580. [Google Scholar] [CrossRef]

- Mwang, J.K.; Lee, W.J.; Chang, Y.C.; Chen, C.Y.; Wang, L.C. An overview: Energy saving and pollution reduction by using green fuel blends in diesel engines. Appl. Energy 2015, 159, 214–236. [Google Scholar] [CrossRef]

- Song, H.; Quinton, K.S.; Peng, Z.; Zhao, H.; Ladommatos, N. Effects of Oxygen Content of Fuels on Combustion and Emissions of Diesel Engines. Energies 2016, 9, 28. [Google Scholar] [CrossRef]

- Saluja, R.K.; Kumar, V.; Sham, R. Stability of biodiesel–A review. Renew. Sustain. Energy Rev. 2016, 62, 866–881. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Masjuki, H.; Kalam, M.; Hazrat, M.; Masum, B.; Imtenan, S.; Ashraful, A. Effect of antioxidants on oxidation stability of biodiesel derived from vegetable and animal based feedstocks. Renew. Sustain. Energy Rev. 2014, 30, 356–370. [Google Scholar] [CrossRef]

- Barclay, L.R.C.; Melinda, R.; Vinqvist, M.R. Phenols as antioxidants. In The Chemistry of Phenols; Rappoport, Z., Ed.; John Wiley & Sons Ltd.: Chichester, UK, 2003; pp. 840–908. [Google Scholar]

- Li, B.; Pratt, D.A. Methods for determining the efficacy of radical-trapping antioxidants. Free Radic. Biol. Med. 2015, 82, 187–202. [Google Scholar] [CrossRef] [PubMed]

- Locomte, J. Relationship between hydrophobicity and antioxidant ability of “phenolipids” in emulsion: A parabolic effect of the chain length of rosmarinate esters. J. Agric. Food Chem. 2010, 58, 2869–2876. [Google Scholar]

- Peltzer, M.A.; Wagner, J.R.; Migallon, A.J. Stabilization of polymers with natural antioxidants. In Polymer and Biopolymer Analysis and Characterization; Zaigov, G.E., Jiménez, A., Eds.; Nova Science Publishers, Inc.: New York, NY, USA, 2007; pp. 13–28. [Google Scholar]

- Denisov, E.T.; Denisova, T.G. Handbook of Antioxidants: Bond Dissociation Energies, Rate Constants, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1999; p. 290. [Google Scholar]

- Hawkins, W.L. Stabilization against thermal oxidation. In Polymer Degradation and Stabilization; Hawkins, W.L., Ed.; Springer-Verlag: Berlin, Germany, 1984; pp. 40–73. [Google Scholar]

- Ingendoh, A. Protection of biodiesel against oxidation. Lipid Technol. 2010, 22, 83–86. [Google Scholar] [CrossRef]

- Chen, Y.H.; Luo, Y.M. Oxidation stability of biodiesel derived from free fatty acids associated with kinetics of antioxidants. Fuel Process Technol. 2011, 92, 1387–1393. [Google Scholar] [CrossRef]

- Gordon, M. The mechanism of antioxidant action in vitro. In Food Antioxidants; Hudson, B.J.F., Ed.; Elsevier Publications: London, UK, 1990; pp. 1–18. [Google Scholar]

- Zhong, Y.; Shahidi, F. Antioxidant behavior in bulk oil: Limitations of polar paradox theory. J. Agric. Food Chem. 2012, 60, 4–6. [Google Scholar] [CrossRef] [PubMed]

- Lapuerta, M.; Rodríguez-Fernández, J.; Ramos, Á.; Álvarez, B. Effect of the test temperature and anti-oxidant addition on the oxidation stability of commercial biodiesel fuels. Fuel 2012, 93, 391–396. [Google Scholar] [CrossRef]

- Zuleta, E.C.; Rios, L.A.; Benjumea, P.N. Oxidative stability and cold flow behavior of palm, sacha-inchi, jatropha and castor oil biodiesel blends. Fuel Process Technol. 2012, 102, 96–101. [Google Scholar] [CrossRef]

- Hazrat, M.A. A mini review on the cold flow properties of biodiesel and its blends. Front. Energy Res. 2020, 8, 598651. [Google Scholar] [CrossRef]

- Islam, M.M.; Hassan, M.H.; Kalam, M.A.; Binti, N.W.; Zulkifli, M.; Habibullah, M.; Hossain, M.M. Improvement of cold flow properties of Cocos nucifera and Calophyllum inophyllum biodiesel blends using polymethyl acrylate additive. J. Clean. Prod. 2016, 137, 322–329. [Google Scholar] [CrossRef]

- Boshui, C.; Yuqiu, S.; Jianhua, F.; Jiu, W.; Jiang, W. Effect of cold flow improvers on flow properties of soybean biodiesel. Biomass Bioenergy 2010, 34, 1309–1313. [Google Scholar] [CrossRef]

- Muniz, A.S. Bifunctional additives to improve the cold flow properties and oxidation stability of soybean oil biodiesel. Energy Fuel 2020, 34, 5907–5916. [Google Scholar] [CrossRef]

- Edith, O. Factors affecting the cold flow behaviour of biodiesel and methods for improvement—A review, Pertanika. J. Sci. Technol. 2012, 20, 1–14. [Google Scholar]

- Anoop, G.S.; Hariprasad, V.; Deepak, G.S.; Akhil, P.S. Enhancement of oxidative stability and cold flow properties of coconut oil using natural antioxidant additives for development of bio-lubricant. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 758–764. [Google Scholar]

- Rodrigues, J.S. Comparative study of synthetic and natural antioxidants on the oxidative stability of biodiesel from Tilapia oil. Renew. Energy 2020, 156, 1100–1106. [Google Scholar] [CrossRef]

- Mittelbach, M.; Schober, S. The influence of antioxidants on the oxidation stability of biodiesel. JAOCS J. Am. Oil Chem. Soc. 2003, 80, 817–823. [Google Scholar] [CrossRef]

- Dunn, R.O. Effect of antioxidants on the oxidative stability of methyl soyate (biodiesel). Fuel Process. Technol. 2005, 86, 1071–1085. [Google Scholar] [CrossRef]

- Abril, D. Comparison of the oxidative stability and antioxidant activity of extravirgin olive oil and oils extracted from seeds of Colliguaya integerrima and Cynara cardunculus under normal conditions and after thermal treatment. Antioxidants 2019, 8, 470. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Singhal, S.; Singh, M.; Arora, S.; Tanwer, M. Role of antioxidants in enhancing oxidation stability of biodiesels. ACS Sustain. Chem. Eng. 2018, 6, 11036–11049. [Google Scholar] [CrossRef]

- Jahromi, S.G. Extraction techniques of phenolic compounds from plants. Plant Physiol. Asp. Phenolic Compd. 2019, 1–11. [Google Scholar]

- Neglo, D. Comparative antioxidant and antimicrobial activities of the peels, rind, pulp and seeds of watermelon (Citrullus lanatus) fruit. Sci. Afr. 2021, 11, 58–62. [Google Scholar] [CrossRef]

- Dai, Y.; Row, K.H. Isolation and determination of beta-carotene in carrots by magnetic chitosan beta-cyclodextrin extraction and high-performance liquid chromatography (HPLC). Anal. Lett. 2019, 52, 1828–1843. [Google Scholar] [CrossRef]

| Parameters | References |

|---|---|

| Substitution of fossil fuel by renewable sources | [26,27,28,29,30,31,32,33] |

| Factors affecting the stability to oxidation of biodiesel | [34,35,36] |

| Composition of feedstock in biodiesel production | [17,32,37,38,39,40,41,42,43,44,45,46] |

| Chemical composition of biodiesel | [47,48,49,50,51] |

| Presence of natural antioxidants in biodiesel | [52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68] |

| The effects of bio-oil on the stability to oxidation of biodiesel | [69,70,71,72,73] |

| Influence of storage conditions on biodiesel stability | [74,75,76,77,78,79,80,81,82,83,84] |

| Presence of metal contaminants | [83,84] |

| The influence of other factors on biodiesel stability | [78,85,86] |

| Remediation methods | [37,87,88,89,90,91,92] |

| Antioxidants | [93,94,95,96,97,98,99,100] |

| Natural antioxidants | [101,102,103,104,105,106,107,108,109,110,111,112,113,114,115] |

| Antioxidant mechanism | [116,117,118,119,120,121] |

| Structure and molecular mass of the antioxidants | [122,123,124,125,126,127,128] |

| Concentration requirement for antioxidants’ use | [34,110,129,130,131,132] |

| Effects of antioxidants on biodiesel cold-flow properties | [133,134,135,136,137,138,139] |

| Sustainability of antioxidants’ use for biodiesel stability increase and research trends | [140,141,142,143,144,145,146,147] |

| Feedstock | SFAs (%) | MUFAs (%) | PUFAs (%) | Total UFAs (%) | ID | Reference |

|---|---|---|---|---|---|---|

| APME | 30.7 | 19.4 | 49.9 | 69.3 | 0.2 | [43] |

| Canola | 8.0 | 64.5 | 27.0 | 91.5 | 6.5 | [38] |

| CIME | 25.0 | 43.1 | 38.6 | 72.7 | 6.1 | [17] |

| Coconut | 93.8 | 5.0 | 0.82 | 5.82 | 14.2 | [39] |

| Karanja | 12.0 | 68.0 | 13.0 | 81.0 | 3.9 | [41] |

| Jotropha | 23.4 | 39.2 | 36.2 | 75.4 | 4.2 | [33] |

| Linseed | 11.4 | 21.8 | 66.2 | 88.0 | 2.2 | [21] |

| MOME | 18.6 | 77.1 | 4.3 | 81.4 | - | [42] |

| Palm oil | 44.6 | 39.0 | 11.0 | 50.0 | 17.0 | [32] |

| P/Kernel | 82.1 | 15.4 | 2.4 | 17.8 | 14.0 | [21] |

| PFO | 14.2 | 17.4 | 68.4 | 85.8 | 13.6 | [35] |

| Peanut | 13.0 | 52.0 | 25.0 | 77.0 | 2.0 | [37] |

| Rapeseed | 0.6 | 60.3 | 29.0 | 89.3 | 2.0 | [40] |

| Soybean | 15.0 | 23.1 | 61.9 | 85.0 | 3.0 | [34] |

| Sunflower | 10.0 | 21.0 | 62.0 | 83.0 | 1.5 | [1] |

| SME | 14.5 | 22.8 | 62.3 | 85.1 | 4.1 | [17] |

| WCO | 69.5 | 4.8 | 1.34 | 6.14 | 3.1 | [36] |

| Name | CID | Formula | MW | OH Groups | S (H2O/Alc.) | MP (°C) |

|---|---|---|---|---|---|---|

| (g/mol) | ||||||

| Cinnamon | 637511 | C9H8O | 132.16 | 1 | SS/miscible | −7.5 |

| Sesamol | 68289 | C7H6O3 | 138.12 | 1 | SS/PS | 62–65 |

| Carvacrol | 10364 | C10H14O | 150.22 | 1 | IS/SS | 1.0 |

| Eugenol | 3314 | C10H12O2 | 164.2 | 0 | SS/SS | −7.5 |

| Cafeic acid | 689043 | C9H8O4 | 180.16 | 4 | SS/SS | 225 |

| Citric acid | 311 | C6H8O7 | 192.12 | 4 | CS/SS | 153 |

| Folic acid | 445858 | C10H10O4 | 194.18 | 2 | SS/SS | 168–172 |

| Curcumin | 969516 | C12H20O6 | 260.00 | 3 | SS/CS | 30–32 |

| Black pepper | 638024 | C17H19O3 | 285.34 | 0 | SS/SS | 130 |

| Quercetin | 5280343 | C15H10O7 | 302.23 | 5 | IS/CS | 316.5 |

| Rosemary | 5281792 | C18H16O8 | 360.31 | 5 | SS/SS | −20 |

| α-tocopherol | 14985 | C29H50O2 | 430.7 | 0 | IS/CS | 3.0 |

| β-carotene | 573 | C40H56 | 536.9 | 0 | IS/SS | 180 |

| Ginger extract | 6850776 | C35H52O6 | 568.88 | 1 | SS/CS | – |

| Grape seed extract | 78577443 | C32H30O11 | 590.6 | 9 | IS/IS | – |

| Name | CID | Formula | MW | OH Groups | S (H2O/Alc.) | MP (°C) |

|---|---|---|---|---|---|---|

| (g/mol) | ||||||

| PY | 1057 | C6H3O3 | 126.11 | 3 | SS/CS | 133 |

| TBHQ | 16043 | C10H14O2 | 166.22 | 2 | IS/CS | 128 |

| PG | 4947 | C10H12O5 | 212.2 | 3 | SS/CS | 130 |

| BHA | 31404 | C15H24O2 | 220.35 | 1 | IS/SS | 71 |

| OG | 61253 | C15H22O5 | 282.33 | 3 | IS/SS | 98–101 |

| DG | 14425 | C19H30O5 | 338.44 | 3 | IS/SS | - |

| BHT | 24667 | C22H32O4 | 360.5 | 1 | IS/SS | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

David, E.; Kopac, J. Survey on Antioxidants Used as Additives to Improve Biodiesel’s Stability to Degradation through Oxidation. Molecules 2023, 28, 7765. https://doi.org/10.3390/molecules28237765

David E, Kopac J. Survey on Antioxidants Used as Additives to Improve Biodiesel’s Stability to Degradation through Oxidation. Molecules. 2023; 28(23):7765. https://doi.org/10.3390/molecules28237765

Chicago/Turabian StyleDavid, Elena, and Janez Kopac. 2023. "Survey on Antioxidants Used as Additives to Improve Biodiesel’s Stability to Degradation through Oxidation" Molecules 28, no. 23: 7765. https://doi.org/10.3390/molecules28237765