3.1. Diffusion Behavior of Water Molecules

Oil-paper insulation in oil-impregnated transformers gradually deteriorates over time under the influence of various environmental factors, such as temperature, humidity, and electrical fields, resulting in reduced insulation performance and occurrence of insulation faults. Among the factors mentioned above, the water content in insulating oil is generally regarded as the greatest threat to its insulation properties. Therefore, the effect of mixed oil composition on diffusion behavior of water molecules was investigated, and the physical mechanisms behind it were explained in terms of interaction energy, hydrogen bonding, free volume fractions, as well as centroid trajectories of water molecules.

3.1.1. Diffusion Coefficient of Water Molecules

Particle diffusion behavior can be described by the mean square displacement (

MSD) curve, which represents the average distance between the positions of all particles at time

t and their initial positions [

29]. The

MSD is measured over time to determine diffusing ability of the target particle(s) in the specific system, which can be expressed as below:

where

and

are the position vectors of the particle at

t = t and

t = 0, respectively, and < > represents the statistical average of the movement trajectories.

The diffusion coefficient is an important parameter for characterizing the diffusivity of particles. For example, a higher diffusion coefficient of water molecules in oil indicates larger directional or non-directional displacement of water molecules. The greater diffusion ability of water molecules makes it easier for them to overcome the potential barriers imposed by their surroundings, facilitating motion and aggregation of water molecules under external electric fields, which would ultimately deteriorate the electrical and insulating performance of transformer oil. The diffusion coefficient

D of water molecules in oil can be calculated as below [

30]

where

a is the slope of the fitting line for the

MSD curve.

Figure 4 shows the

MSD results for the mixed oil models with 1 wt% to 3 wt% water content at 343 K, respectively. The solid lines represent the

MSD curves of the water molecules in the mixed oil models with different VO ratios, and the dashed lines are the linear fitting lines of the corresponding

MSD curves.

In

Table 2,

Table 3 and

Table 4, the slope of the fitting line for the

MSD curve (

a) and the diffusion coefficient of water molecules (

D) are presented corresponding to the data in

Figure 4. These results show that, for a given water content, the diffusion coefficient of water molecules gradually decreases as the proportion of VO increases. When the water content is 1 wt%, the value of

D in the mixed oil gradually decreases from 0.1196 Å

2/ps in pure MO (0 wt% VO) to 0.0577 Å

2/ps in the 50 wt% VO mixture, while, at 3 wt% water content, the corresponding values are 0.0901 Å

2/ps and 0.0529 Å

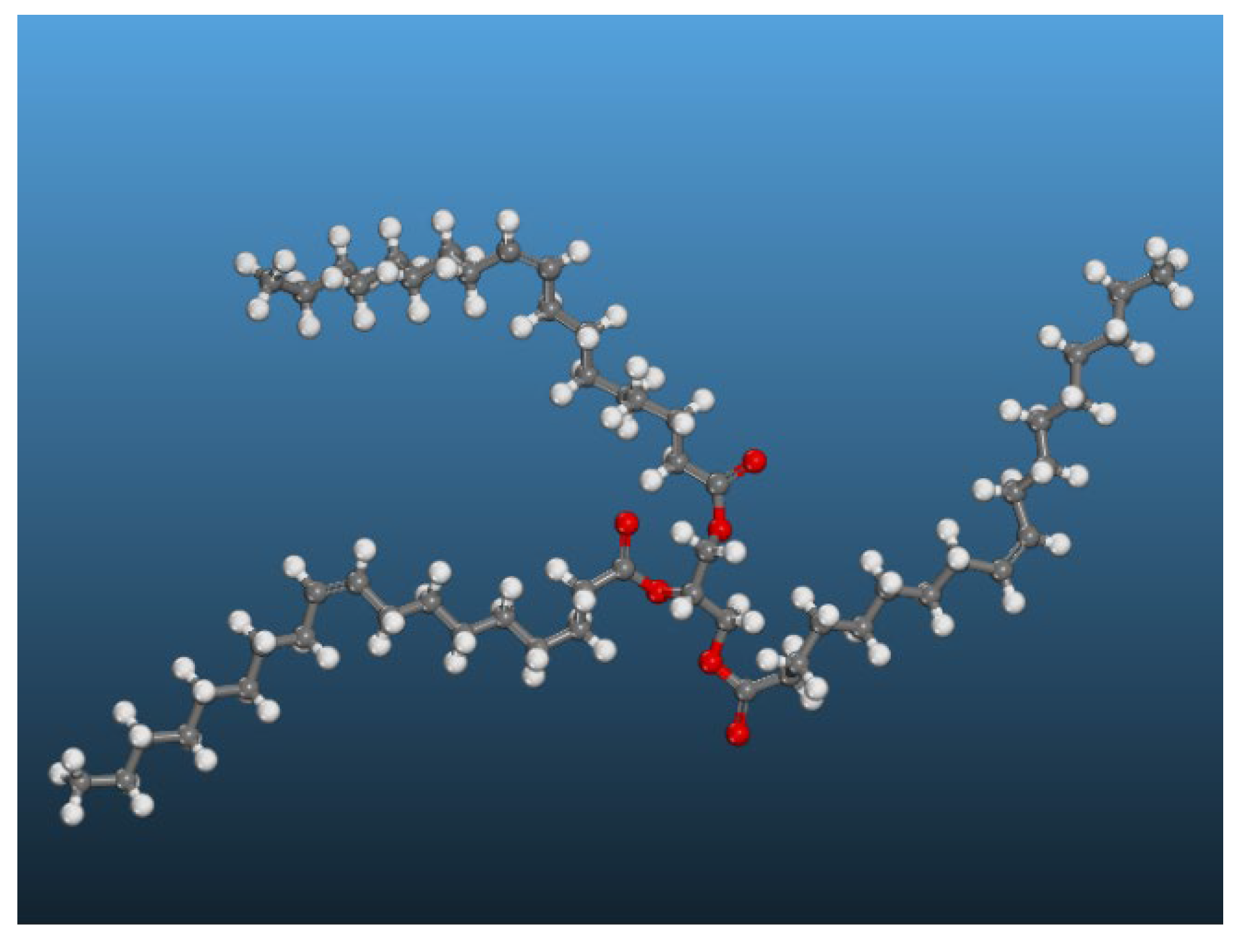

2/ps, respectively. The reason is that the constituent molecules of VO are triglycerides of oleic acid, which contains several stronger atom groups, such as carbonyls (C=O) and ethers (R-O-R), compared to the hydrocarbon atom groups in mineral oil, as illustrated in

Figure 1. The presence of carbonyl and ether groups in VO counterparts could both promote formation of hydrogen bonds and increase the interaction energy in the mixed oil, thereby limiting diffusion of water molecules. For a given water content, a higher proportion of VO in the mixed oil model results in a greater number of the stronger polar groups from VO introduced into the system, which reduces the diffusion coefficient of water molecules.

For mixed oils with a given proportion of VO, the diffusion coefficient of water molecules is negatively correlated with the water concentration in oil. Strong polarity of water molecules promotes formation of hydrogen bonds and increases interaction energy in the system, which inhibits thermal motion and diffusivity of water molecules. Although increasing the water concentration in transformer oil decreases the diffusion coefficient of water molecules, the effect of increasing the water concentration on the insulation performance of transformer oil outweighs the effect of decreasing the diffusion capacity. As an example, for the 30 wt% VO mixed oil, increasing the water content from 1 to 3 wt% (i.e., by a factor 3) will result in a decrease of 30 wt% in the diffusion coefficient of water molecules, from 0.1009 Å

2/ps to 0.0711 Å

2/ps. Therefore, the overall insulation performance still shows a downward trend with increasing water content. The findings above coincide with the diffusion coefficient of water molecules in vegetable oil reported in [

19], which was smaller than that in mineral oil. In addition, introduction of polar groups to which the water molecule would interact would slow the dynamics behavior of water molecules, as reported in [

31], which is also in consistency with our statements above.

Further quantitative analysis of the impact of water and VO content on the diffusion behavior of water molecules in the mixed oil was carried out by calculating the number of hydrogen bonds and the interaction energy between the water and oil molecules.

3.1.2. Hydrogen Bonds

In contrast to chemical bonds, hydrogen bonds refer to non-bonding interactions between hydrogen atoms and strong electronegative atoms or atom groups, whose strength lies between covalent bonds and van der Waals interactions [

32]. The number of hydrogen bonds formed in a system is closely related to the diffusivity of the investigated particles. In general, the more hydrogen bonds formed in a system, the stronger the attractive interactions between molecules, thereby limiting their diffusion.

According to the structural characteristics of the constituent molecules in mixed oil, two types of hydrogen bonds could be formed: In the first type, the hydrogen bonds formed between water molecules, as shown in

Figure 5a. The second type of hydrogen bond occurs between the oxygen atoms from the stronger polar groups in VO molecules and hydrogen atoms in the water molecules, as shown in

Figure 5b.

To qualify as a hydrogen bond, the hydrogen bond donor atom (H atom in our case) and acceptor atom (O atom in this case) should be separated by 2.5 Å or less and the do-nor–acceptor–acceptor antecedent angle should be larger than 100°, which is also a commonly used method in determining the hydrogen bonding in a liquid system, as reported in [

33]. The number of hydrogen bonds in each frame of the 500 ps dynamic trajectory of the different mixed oil models was calculated and averaged using a script written in Perl, with the results shown in

Figure 6.

The results show that, for both levels of water content, the number of hydrogen bonds in mixed oil models increases as the proportion of VO increases. For 1 wt% water content models, the number of hydrogen bonds increased from 41 in 0 wt% VO to 63 in 50 wt% VO, and, when the water content is 2 wt%, the number of hydrogen bonds increased from 125 in 0 wt% VO to 141 in 50 wt% VO, whereas, for 3 wt% water content models, the corresponding numbers were 218 and 235, respectively. Regardless of water content, along with an increase in VO proportion, the number of stronger polar groups increased in the mixed oil, leading to formation of more hydrogen bonds. Due to hydrogen bonding, water molecules are subjected to an increased level of attractive interactions with oil molecules, resulting in a reduction in their diffusion coefficient in the system. This is consistent with the calculation results in

Figure 4. It should be noted, however, that the number of hydrogen bonds is significantly higher in the mixed oil with 3 wt% water content compared to those with 1 wt% and 2 wt% water content. Since the water molecule has a much smaller molecular weight than the oleic triglyceride molecule in VO, increasing water content introduces a significantly higher number of polar molecules compared to increasing VO proportion in mixed oil.

Furthermore, in order to investigate the contributions of the two different types of hydrogen bonds on the total number hydrogen bonds in mixed oil, the average number of hydrogen bonds formed between water molecules and between water and vegetable oil molecules in the system were calculated. The results are shown in the

Table 5,

Table 6 and

Table 7. HB

W-W refers to the hydrogen bonds formed between water molecules, as illustrated in

Figure 5a, and HB

W-V refers to the hydrogen bonds formed between water molecules and vegetable oil molecules, as illustrated in

Figure 5b. For a given VO proportion in mixed oil, both types of hydrogen bonds increased with increasing water content, indicating that movement of water molecules is increasingly constrained in terms of hydrogen bonding with the increase in water content. Additionally, for a given water content in mixed oil, the number of hydrogen bonds between water molecules and vegetable oil molecules showed an increasing trend with increasing VO proportion in mixed oil, which indicates that formation of hydrogen bonds between water molecules and vegetable oil molecules accounts for an increase in total hydrogen bonds in mixed oil with increasing VO proportion, as shown in

Figure 6. The findings above explained our diffusion coefficients results in different mixed oil models in

Table 2,

Table 3 and

Table 4 in terms of hydrogen bonding.

To further analyze the influence of hydrogen bonds on the diffusion coefficient of water molecules, the number of hydrogen bonds formed per unit water molecule was calculated, as shown in

Table 8,

Table 9 and

Table 10. The increased proportion of VO did increase the number of hydrogen bonds in the mixed oil to some extent. In addition, the number of hydrogen bonds per unit water molecule in mixed oil models also increased with the increase in water content. As a result, increasing the water content could limit not only the overall thermal movements of all molecules in the system but could also reduce the thermal movements of the water molecules in transformer oil. This result explains the decrease in diffusion coefficient of water molecules with increasing water content and VO content in the system from the perspective of hydrogen bond formation.

3.1.3. Interaction Energy

In the oil–water system, the interaction energies between water and oil molecules contribute significantly to the diffusivity of water molecules in terms of intermolecular interactions. When quantifying these interactions, a positive or negative sign indicates either repulsive or attractive forces, and the magnitude indicates the interaction strength. In an oil–water system, the total energy includes both kinetic and potential energy of all molecules in the system. The potential energy can be categorized into electrostatic potential energy and van der Waals potential energy based on the different types of interactions. Moreover, it can also be classified as interaction energy between particles of the same type as well as particles of different types. Therefore, the interaction energy between oil and water molecules can be expressed as follows:

where

Eint is the interaction energy between the oil molecules and water molecules,

ET is the total potential energy of the whole oil–water system,

EO is the potential energy of the mixed oil, including the interaction energy among six types of constituent molecules in mixed oil models, as shown in

Figure 1 and

Figure 2, while

EW is the potential energy between the water molecules themselves.

A separate account of the interaction energy between MO or VO molecules and water molecules was made by dividing the oil–water model into “model 1”, composed of VO and water molecules, and “model 2”, composed of MO and water molecules, in order to calculate the interaction energy between the mixed oil and water molecules in terms of the different MO or VO contributions. Then, Equation (3) can be rewritten as follows:

where

Eint-T represents the total interaction energy between the mixed oil and water molecules,

Eint-M represents the interaction energy between MO and water molecules, and

Eint-V represents the interaction energy between VO and water molecules. Through Perl scripting, the potential energies of

ET,

EO, and

EW in each frame of the dynamic trajectory were calculated separately for “model 1” and “model 2” and then averaged. The resulting values of

Eint-V,

Eint-M, and

Eint-T are shown in

Table 11,

Table 12 and

Table 13.

For a given water content, the interaction energy between water molecules and mixed oil molecules is negative, which indicates an attractive interaction. In addition, the interaction energy decreases (i.e., becomes more negative) as the proportion of VO increases, indicating that the attraction between water and oil molecules increases with the increase in VO content in mixed oil. Thus, the movement of water molecules becomes more restricted with increasing VO in mixed oil, resulting in a reduction in their diffusion coefficient, which confirms the results of the diffusion coefficient calculations shown in

Figure 4. Meanwhile, the calculation results for the interaction energy of water molecules with VO and MO in

Table 11,

Table 12 and

Table 13 show that the changing rate of

Eint-V is significantly higher than that of

Eint-M. This is due to the stronger interactions between polar groups (carbonyls and ethers) in VO and water molecules than between MO and water molecules.

In order to quantitively investigate the influence of VO contents in mixed oil on diffusion behavior of an individual water molecule, the average interaction energy between a single water molecule and a single VO molecule was calculated and shown in

Table 14. For a given water content, it can be inferred from the calculated interaction energy between a single water molecule and a single VO molecule that with the increase of VO content in the mixed oil, the attraction ability of VO molecules to water molecules will increase, thus limiting the mobility of water molecules. A similar phenomenon could be found for the results of interaction energy between a single molecule and VO molecule in mixed oil for a given water content. An increase in water content in mixed oil also contributes to enhancement of the attraction between a single water molecule and the VO component molecule, which also restricts the mobility of water molecules in mixed oil in light of the VO constituent in mixed oil. The calculations in

Table 14 directly correspond to the diffusion coefficient of water molecules in mixed oil in

Table 2,

Table 3 and

Table 4, illustrating the significant impact of VO constituent on the diffusion behavior of water molecules in mixed oil.

Due to the strong polarity of water molecules, an increase in their proportion in mixed oil will increase the overall interaction energy of the entire system, including the contributions of hydrogen bonds. The statistical calculations of hydrogen bonds in

Table 8,

Table 9 and

Table 10 indicate that the average number of hydrogen bonds per water molecule increases with increasing water content, which intensifies the attraction between oil molecules and water molecules, resulting in reduced diffusion coefficients of water molecules.

3.1.4. Fractional Free Volume (FFV)

In order to further analyze the decrease in the diffusion coefficient of water molecules in the mixed oil, the FFV of water molecules in the mixed oil under different VO proportions was calculated. According to Fox and Flory’s free volume theory [

34], the total volume (

) of insulating materials can be divided into occupied volume (

) and free volume (

). The FFV formula is shown in Equation (5):

The larger the FFV of the system, the more space available for particle displacement, which is conducive to diffusion and displacement of particles in the system due to thermal motion. At 1 wt%, 2 wt%, and 3 wt% water content, the fractional free volume calculation results of the models with different mixing proportions are shown in

Figures S3–S5 (considering the paper length, the free volume diagram is provided in

Supplementary Materials); the blue area represents the free volume of water molecules, and the gray area represents the occupied volume of the interface structure. Compared to the models with 1 wt% water content, the free volume of water molecules decreased in all models with 3 wt% water content. It is worth noting that, with the increase in VO content under the same water content, the free volume of water molecules also showed a trend of gradual decrease owing to the large number of strong polar groups introduced by water and vegetable oil molecules. These polar groups may combine oil molecules and water molecules more, resulting in a decrease in the free volume of water molecules in oil. The calculated law of free volume fraction is consistent with the law of diffusion coefficient, which explains one of the causes of decreasing water molecular diffusion behavior with increased water content and VO content. To reflect the difference of free volume in different models more intuitively, the free volume fraction of water molecules in each model at moisture contents of 1 wt%, 2 wt%, and 3 wt% were calculated, respectively. The results are shown in

Table 15,

Table 16 and

Table 17.

The results show that the free volume of water molecules gradually decreases and the occupied volume increases with the increase in the mass fraction of VO. At the moisture content of 1 wt%, 2 wt%, and 3 wt%, the FFV decreased from 12.4%,12.2%, and 12.1% (0 wt% VO) to 8.5%, 8.4%, and 8.1% (50 wt% VO), respectively. This verifies the conclusions of this section.

3.1.5. Centroid Trajectories of Water Molecules in Mixed Oil

To describe the effect of the percentage of VO more intuitively on the diffusion behavior of water molecules, the centroid trajectories of water molecules at 500 ps in the NVT process were calculated using a Perl script.

Figures S6–S8 (considering the paper length, the free volume diagram is provided in

Supplementary Materials) illustrate the centroid trajectories of water molecules in the mixed oil at 1 wt%, 2 wt%, and 3 wt% water content. These results show that, at a fixed water content, the movement range of the water molecules gradually decreases as the proportion of VO increases; taking 10 wt% VO content as an example, when the water content increases from 0 wt% to 50 wt%, the motion range of water molecules on the X and Z axes decreases from 4 Å to about 3 Å, and the motion range on the Y axis decreases from 5 Å to 3 Å. This demonstrates a rise in VO content limiting their diffusivity, which is consistent with the earlier results. Furthermore, at a fixed proportion of VO, the movement range of the centroid trajectory of water molecules in the mixed oil is smaller at the relatively higher water content (3 wt%) system; taking 1 wt% water content as an example, when the vegetable oil content increases from 0 wt% to 50 wt%, the motion range of water molecules on the X and Z axes decreases from 4 Å to about 3 Å, and the motion range on the Y axis decreases from 5 Å to 3 Å, which also confirms the previous results.

The diffusion behavior of water molecules in mixed oil shows that, as the proportion of VO increases, the diffusion of water molecules is inhibited, which reduces the moisture in the oil, thereby improving the insulating properties of the mixed oil. This phenomenon is closely related to introduction of stronger polar groups on the oleic triglyceride molecules in VO into the mixture. As the proportion of VO increases, the polar groups promote formation of hydrogen bonds with water molecules and increase the interaction energy, thus limiting the diffusion of water molecules in the oil. Therefore, when considering enhancement of insulation performance through blending VO and MO, the type and proportion of VO added can be selected according to the type and number of polar groups in the VO.

3.2. Static Dielectric Constant of Mixed Oil

The dielectric constant

ε is an important parameter reflecting the polarizing and insulating properties of dielectric materials. It includes the static dielectric constant

εs as well as the optical dielectric constant

ε∞.

εs reflects the relative dielectric constant and the relaxation polarization of a material at a constant electric field, which is closely related to the molecular structure of the material;

ε∞ represents the relative dielectric constant at the frequency of the applied electric field equal to the optical frequency, which is related to the instantaneous displacement polarization of the material. In order to study the effect of the molecular structure and water content of the mixed oil on its dielectric properties, the value of

εs was calculated. The fluctuation method and the applied external field method are two commonly used MD methods for calculating

εs [

35]. The former method relates

εs with the rise and fall of the electric dipole moment within the material, which is solved by applying an infinitesimal electric field excitation to the simulated system. In response to such fluctuations in the electric dipole moment within the system, statistical averaging is used to resolve the issue. As the external field excitation used in the method is infinitesimal, the solution can also be obtained without applying an external electric field. The applied external field method, on the other hand, induces polarization within the system by applying an enhanced external electric field and is suitable for materials with zero permanent dipole moment [

36,

37]. In the present study, since a non-zero permanent dipole moment exists in the mixed oil system,

εs was calculated using the fluctuation method. Accordingly, the fluctuation of the electric dipole moment of the constituent molecules in the system can be expressed as follows:

where

M represents the total electric dipole moment of the system,

Mx,

My, and

Mz are its components in the

x,

y, and

z axes, and < > represent the statistical averaging in the dynamical trajectory.

According to the literature [

38], the relationship between the electric dipole moment fluctuation and the static dielectric constant is provided by [

39,

40,

41]:

where

M represents the total electric dipole moment of the system,

ε0 is vacuum permittivity,

V is the volume of the system,

kB is the Boltzmann constant,

T is the simulated temperature,

ε is the dielectric constant of the system (specifically, the static dielectric constant

εs), and

εRF is the dielectric continuum spectrum within the system. In the fluctuation method,

εRF→∞ hence,

εs can be expressed as follows:

Using Equations (6) and (8), the

εs of the mixed oil with different VO fractions at 0 wt%, 1 wt%, 2 wt%, and 3 wt% water content were calculated by Perl scripting, with the results shown in

Figure 7. In contrast to calculation of parameters such as diffusion coefficients and interaction energies, prediction of the dielectric properties of a material typically requires longer simulations due to the large molecular sizes of the model and the low degree of molecular orientation fluctuations. In such cases, a reasonable simulation duration should be used based on the convergence time. Based on a mixed oil model with 50 wt% VO content at 1 wt% moisture content, a molecular dynamic simulation test was conducted for 500 ps. It was found that the frame-by-frame output of the dielectric constant data fluctuated severely during the initial 300 ps and gradually stabilized afterwards. Consequently, a simulation time of 500 ps is sufficient to ensure convergence and accuracy of the static dielectric constant of our mixed oil models. As shown in

Figure 7, as the proportion of vegetable oil is increased, the calculated dielectric constant of the mixed oil increases from 2.250 (0 wt% VO) to 3.199 (50 wt% VO). In this simulation, it is demonstrated that mixed oil without moisture content has a static dielectric constant between mineral oil and vegetable oil, which is consistent with the expectation (mineral oil’s dielectric constant is 2.2, while vegetable oil’s is 3.2). In addition, the static dielectric constants of the calculated pure mineral oil (0 wt% VO) at a water content of 0 wt%, 1 wt%, 2 wt%, and 3 wt% are 2.250, 3.784, 5.040, and 6.152, respectively. The static dielectric constant of pure mineral oil under different water content was calculated. As expected, the calculated value is higher than the measured value of the power frequency dielectric constant under moist free condition, which is mainly attributed to the influence of water content and low voltage frequency. Especially, a comparison of the effect of voltage frequency and impurities of water on dielectric constant shows that impurities have a greater influence. With increasing water content in mineral oil, the number of particles participating in polarization per unit volume increases. Water is a strongly polar molecule with a relative dielectric constant of 81; thus, a higher concentration increases its dielectric constant. In addition, the static dielectric constant calculated in this paper is in accordance with the numerical trend in the low frequency range (<10

−1 Hz) measured by other scholars; that is, with the increase in water content in mineral oil, the values of both the calculated static dielectric constant and the measured dielectric constant in the low frequency range (<10

−1 Hz) increased significantly, with a similar growth law [

42,

43]. It has been reported that, as the water content of MO increases, the dielectric constant increases more drastically at low frequencies (<10

−1 Hz) than at high frequencies. For a given proportion of VO in mixed oil models, the calculated

εs values were also found to be positively correlated with the water content, which is consistent with the results for pure MO, further indicating that the water content in the oil significantly influences the dielectric constant at low frequency.

When the water content is the same, the calculated value of the static dielectric constant εs of the mixed oil increases significantly with the increase in the content of VO. Compared with MO, the molecules of VO contain more stronger polar groups (carbonyl and ether groups) and thus more particles participating in the polarization process, resulting in an increase in the dielectric constant of the mixed oil with an increase in the proportion of VO. Meanwhile, εs of mixed oils with different water contents increases significantly with an increase in the proportion of VO, indicating that water content has a significant effect on the dielectric constant of VO at low frequency, which is more obvious than that of MO, which could be attributed to the following two factors: with an increase in water content, the number of particles participating in polarization per unit volume increases, leading to an increase in the dielectric constant of the system. In addition, the strong interaction between the stronger polar groups in VO and the water molecules further affects the polarization process of the molecules in the mixed oil, resulting in the dielectric constant of the oil at low frequency increasing significantly with the increase in water content. The effect of water content on the dielectric constant of VO in the low frequency domain has few reports, so the calculation conclusion should be further verified by experiments.

According to the calculation and analysis of the static dielectric constant above, the static dielectric constant of the mixed oil gradually increases with an increase in the proportion of VO, and it is very sensitive to the moisture content, which has a negative impact on the dielectric properties of the mixed oil, which is closely related to introduction of the stronger polar groups (carbonyl and ether groups) in VO. With the increase in the proportion of VO, the increase in the number of stronger polar groups from VO leads to an increase in the static dielectric constant of the mixed oil.