Ta3N5 Nanobelt-Loaded Ru Nanoparticle Hybrids’ Electrocatalysis for Hydrogen Evolution in Alkaline Media

Abstract

:1. Introduction

2. Results

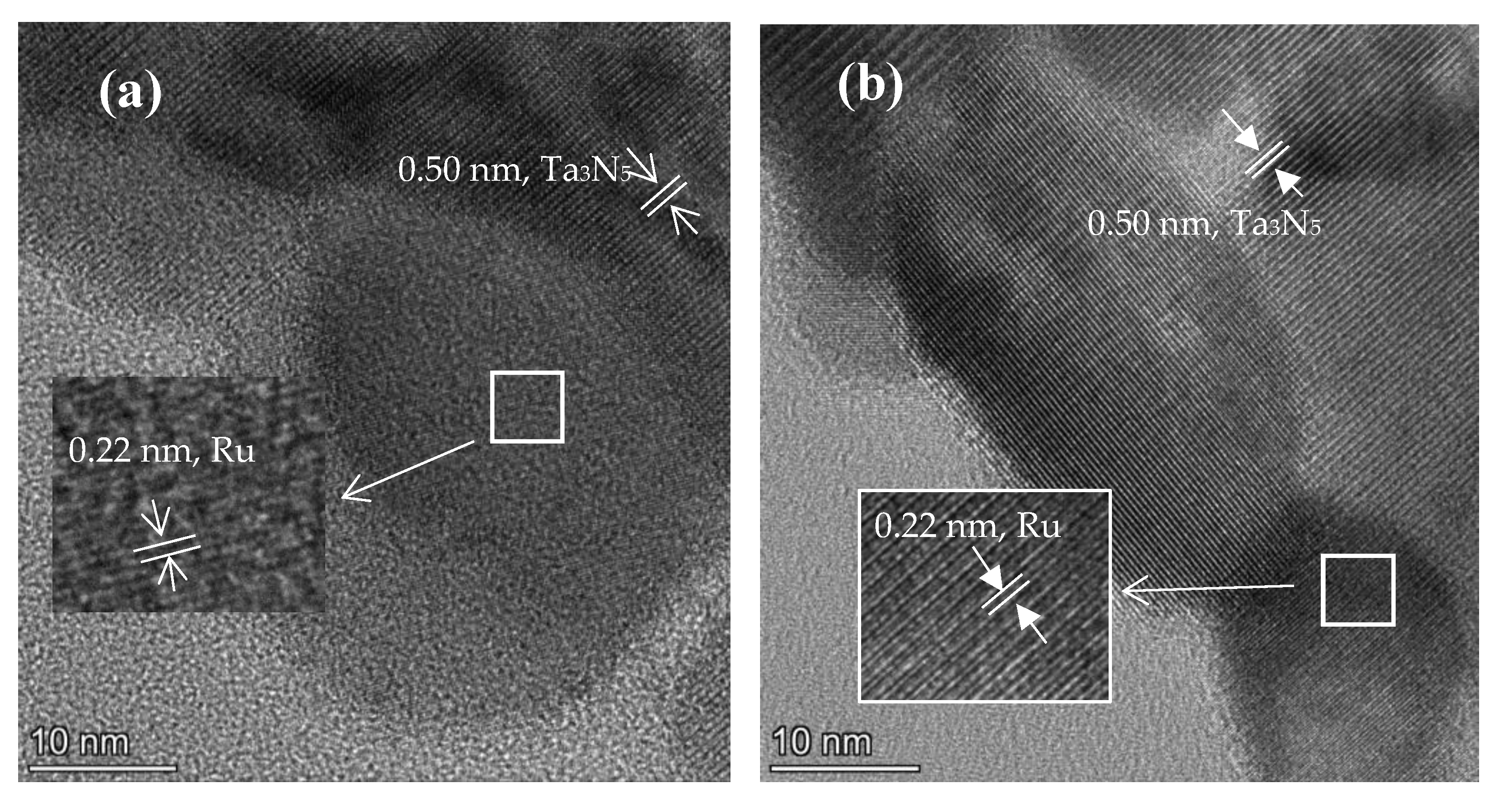

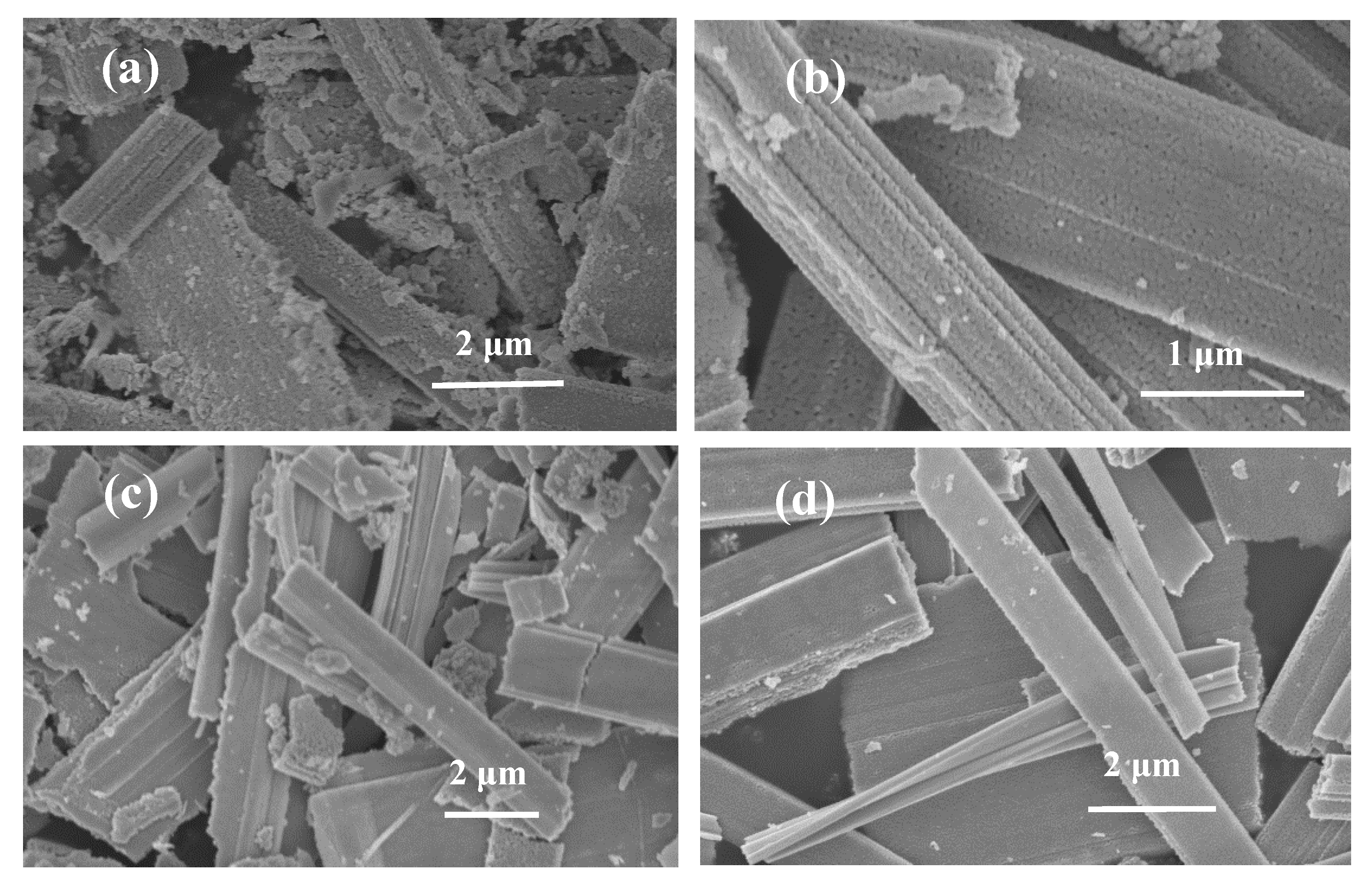

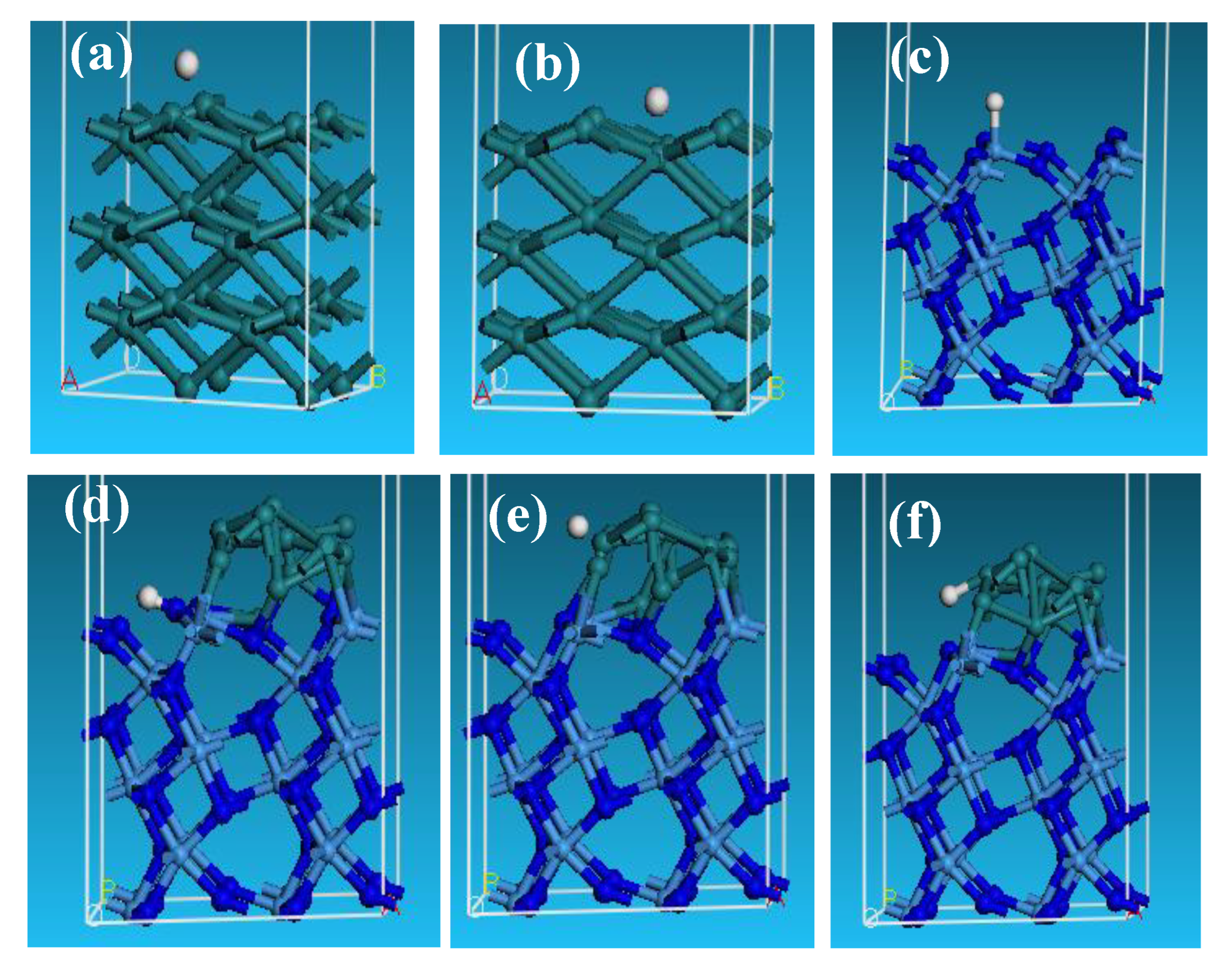

2.1. Structures and Morphologies of Catalysts

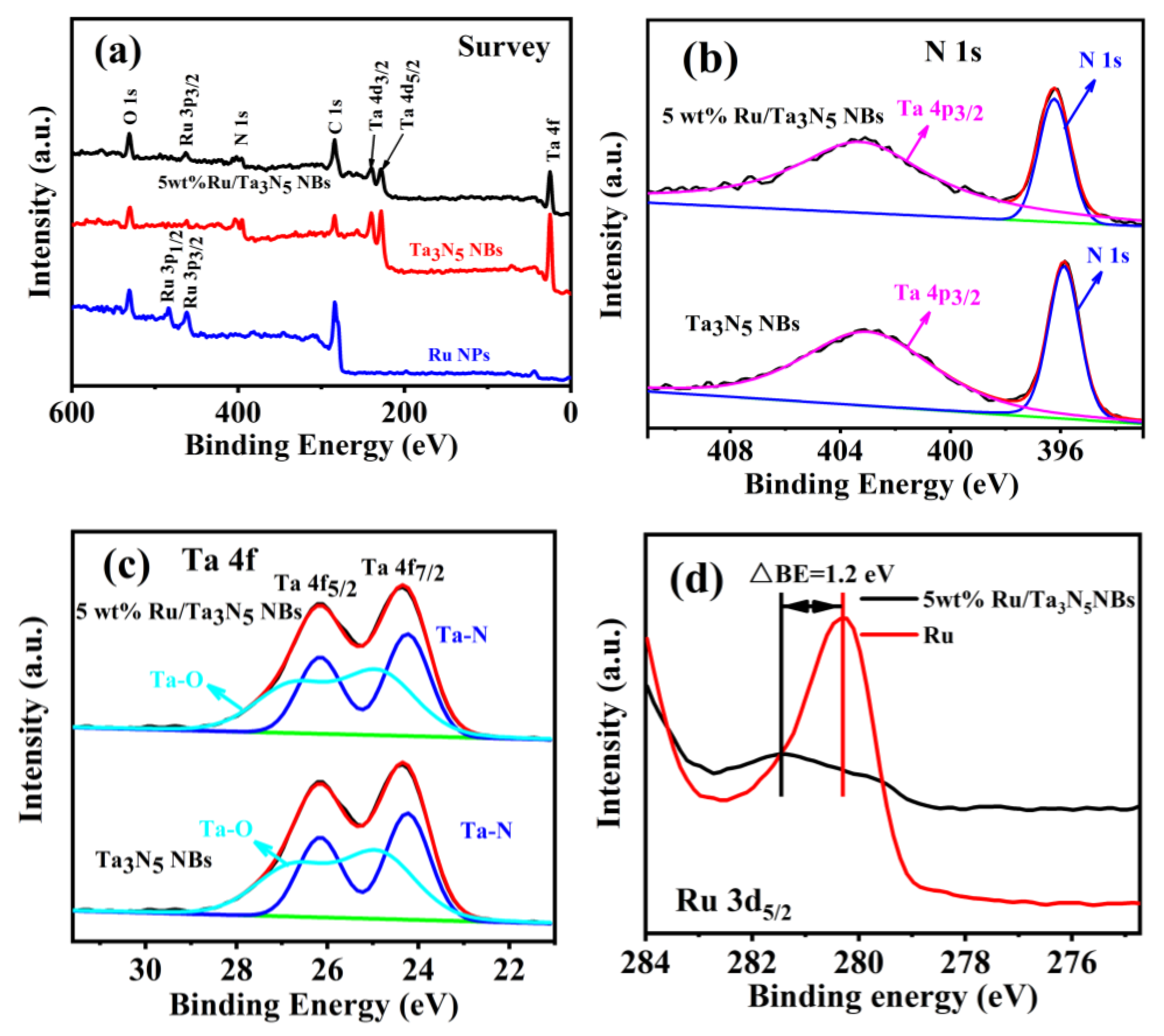

2.2. The Surface Properties

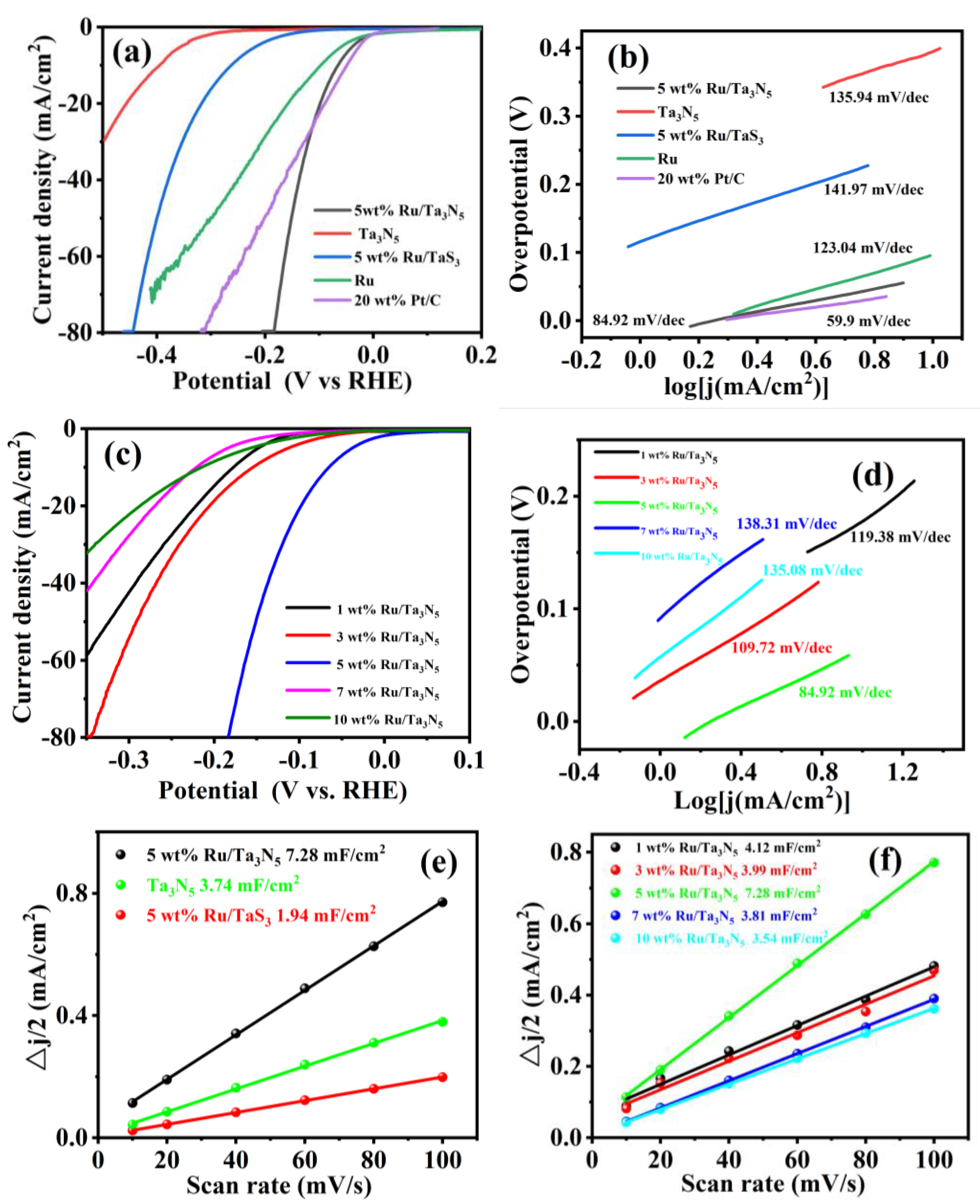

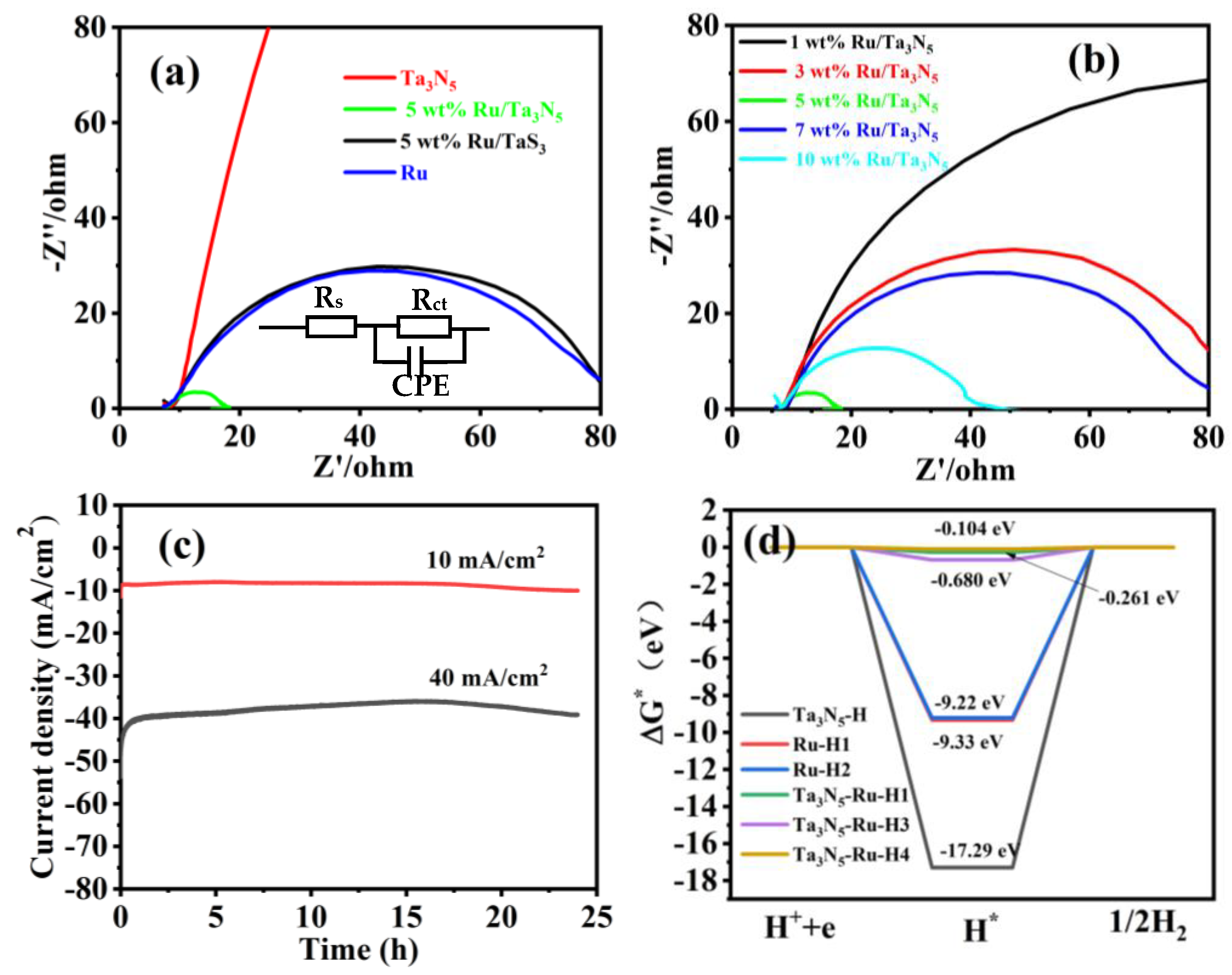

2.3. Hydrogen Evolution Performance

3. Materials and Methods

3.1. Experimental Reagents

3.2. Preparation of the Catalysts

3.3. Characterization

3.4. Electrochemical Performance Test

3.5. Theoretical Computation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Wang, T.; Wang, X.J.; Liu, Y.; Zheng, J.; Li, X.G. A highly efficient and stable biphasic nanocrystalline Ni–Mo–N catalyst for hydrogen evolution in bothacidic and alkaline electrolytes. Nano Energy 2016, 22, 111–119. [Google Scholar] [CrossRef]

- Fan, X.J.; Zhou, H.Q.; Guo, X. WC nanocrystals grown on vertically aligned carbon nanotubes: An efficient and stable electrocatalyst for hydrogen evolution reaction. ACS Nano 2015, 9, 5125–5134. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.M.; Shao, Z.P.; Jiang, S.P. High-entropy materials for water electrolysis. Energy Technol. 2022, 10, 2200573. [Google Scholar] [CrossRef]

- Abdelghafar, F.; Xu, X.M.; Jiang, S.P.; Shao, Z.P. Designing single-atom catalysts toward improved alkaline hydrogen evolution reaction. Mater. Rep. Energy 2022, 2, 100144. [Google Scholar] [CrossRef]

- Xu, X.M.; Pan, Y.L.; Zhong, Y.J.; Ge, L.; Jiang, S.P.; Shao, Z.P. From scheelite BaMoO4 to perovskite BaMoO3: Enhanced electrocatalysis toward the hydrogen evolution in alkaline media. Compos. Part B Eng. 2020, 198, 108214. [Google Scholar] [CrossRef]

- Lv, Y.L.; Batool, A.; Wei, Y.X.; Xin, Q.; Boddula, R.; Jan, S.U.; Akram, M.Z.; Tian, L.Q.; Guo, B.D.; Gong, J.R. Homogeneously distributed NiFe alloy nanoparticles on 3D carbon fiber network as a bifunctional electrocatalyst for overall water splitting. ChemElectroChem 2019, 6, 2497–2502. [Google Scholar] [CrossRef]

- Boddula, R.; Xie, G.C.; Guo, B.D.; Gong, J.R. Role of transition-metal electrocatalysts for oxygen evolution with Si-based photoanodes. Chin. J. Catal. 2021, 42, 1387–1394. [Google Scholar] [CrossRef]

- Boddula, R.; Guo, B.D.; Ali, A.; Xie, G.C.; Dai, Y.W.; Zhao, C.; Wei, Y.X.; Jan, S.U.; Gong, J.R. Synergetic effects of dual electrocatalysts for high-performance solar-driven water oxidation. ACS Appl. Energy Mater. 2019, 2, 7256–7262. [Google Scholar] [CrossRef]

- Ji, Z.; Trickett, C.; Pei, X.K.; Yaghi, O.M. Linking molybdenum–sulfur clusters for electrocatalytic hydrogen evolution. J. Am. Chem. Soc. 2018, 140, 13618–13622. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Zhao, Y.F.; Guo, X.; Chen, C.; Dong, C.L.; Liu, R.S.; Han, C.P.; Li, Y.D.; Gogotsi, Y.; Wang, G.X. Single platinum atoms immobilized on an MXene as an efficient catalyst for the hydrogen evolution reaction. Nat. Catal. 2018, 1, 985–992. [Google Scholar] [CrossRef]

- Zheng, C.; Zhu, Z.Z.; Wang, S.B.; Hou, Y.D. NaF-assisted hydrothermal synthesis of Ti-doped hematite nanocubes with enhanced photoelectrochemical activity for water splitting. Appl. Surf. Sci. 2015, 359, 805–811. [Google Scholar] [CrossRef]

- Lu, X.F.; Yu, L.; Lou, X.W. Highly crystalline Ni-doped FeP/carbon hollow nanorods as all-pH efficient and durable hydrogen evolving electrocatalysts. Sci. Adv. 2019, 5, eaav6009. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, X.F.; Yu, L.; Zhang, J.T.; Lou, X.W. Ultrafine dual-phased carbide nanocrystals confined in porous nitrogen-doped carbon dodecahedrons for efficient hydrogen evolution reaction. Adv. Mater. 2019, 31, 1900699. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.W.; Zhang, L.F.; Tang, J.; Chai, J.W.; Xu, J.C.; Cao, L.J.; Yang, M.Y.; Yang, M.; Kong, W.G.; Wang, S.J.; et al. Efficient coupling of a hierarchical V2O5@Ni3S2 hybrid nanoarray for pseudocapacitors and hydrogen production. J. Mater. Chem. A 2017, 5, 17954–17962. [Google Scholar] [CrossRef]

- Safizadeh, F.; Ghali, E.; Houlachi, G. Electrocatalysis developments for hydrogen evolution reaction in alkaline solutions–a Review. Int. J. Hydrogen Energy 2015, 40, 256–274. [Google Scholar] [CrossRef]

- Li, Y.J.; Zhang, H.C.; Xu, T.H.; Lu, Z.Y.; Wu, X.C.; Wan, P.B.; Sun, X.M.; Jiang, L. Under-water superaerophobic pine-shaped Pt nanoarray electrode for ultrahigh-performance hydrogen evolution. Adv. Funct. Mater. 2015, 25, 1737–1744. [Google Scholar] [CrossRef]

- Yan, Y.; Xia, B.Y.; Xu, Z.C.; Wang, X. Recent development of molybdenum sulfides as advanced electrocatalysts for hydrogen evolution reaction. ACS Catal. 2014, 4, 1693–1705. [Google Scholar] [CrossRef]

- Mahmood, J.; Li, F.; Jung, S.M.; Okyay, M.S.; Ahmad, I.; Kim, S.J.; Park, N.; Jeong, H.Y.; Baek, J.B. An efficient and pH-universal ruthenium-based catalyst for the hydrogen evolution reaction. Nat. Nanotechnol. 2017, 12, 441–446. [Google Scholar] [CrossRef]

- Wu, K.L.; Sun, K.A.; Liu, S.J.; Cheong, W.C.; Chen, Z.; Zhang, C.; Pan, Y.; Cheng, Y.S.; Zhuang, Z.W.; Wei, X.W.; et al. Atomically dispersed Ni–Ru–P interface sites for high-efficiency pH-universal electrocatalysis of hydrogen evolution. Nano Energy 2021, 80, 105467. [Google Scholar] [CrossRef]

- Peng, J.; Chen, Y.H.; Wang, K.; Tang, Z.H.; Chen, S.W. High-performance Ru-based electrocatalyst composed of Ru nanoparticles and Ru single atoms for hydrogen evolution reaction in alkaline solution. Int. J. Hydrogen Energy 2020, 45, 18840–18849. [Google Scholar] [CrossRef]

- Li, H.J.W.; Liu, K.; Fu, J.W.; Chen, K.J.; Yang, K.X.; Lin, Y.Y.; Yang, B.P.; Wang, Q.Y.; Pan, H.; Cai, Z.J.; et al. Paired Ru–O–Mo ensemble for efficient and stable alkaline hydrogen evolution reaction. Nano Energy 2021, 82, 105767. [Google Scholar] [CrossRef]

- Li, Q.Q.; Huang, F.Z.; Li, S.K.; Zhang, H.; Yu, X.Y. Oxygen vacancy engineering synergistic with surface hydrophilicity modification of hollow Ru doped CoNi-LDH nanotube arrays for boosting hydrogen evolution. Small 2022, 18, 2104323. [Google Scholar] [CrossRef] [PubMed]

- Su, J.W.; Yang, Y.; Xia, G.L.; Chen, J.T.; Jiang, P.; Chen, Q.W. Ruthenium-cobalt nanoalloys encapsulated in nitrogen-doped graphene as active electrocatalysts for producing hydrogen in alkaline media. Nat. Commun. 2017, 8, 14969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, X.Z.; Li, W.H.; Chen, J.; Yang, X.L.; Wu, B.F.; Wang, Z.X.; Li, B.; Zhang, H.B. Boron-induced activation of Ru nanoparticles anchored on carbon nanotubes for the enhanced pH-independent hydrogen evolution reaction. J. Colloid Interface Sci. 2022, 616, 338–346. [Google Scholar] [CrossRef]

- Wang, W.; Tao, Y.R.; Wu, X.C.; Yang, L.J. Flower-like CeO2-supported small-sized Ru nanoparticle hybrids for highly efficient alkaline hydrogen evolution: Roles of interfacial effects. Appl. Surf. Sci. 2022, 581, 152256. [Google Scholar] [CrossRef]

- Wu, X.C.; Tao, Y.R.; Li, L.; Bando, Y.; Golberg, D. Centimeter-long Ta3N5 nanobelts: Synthesis, electrical transport, and photoconductive properties. Nanotechnology 2013, 24, 175701. [Google Scholar] [CrossRef]

- Fu, J.; Wang, F.Z.; Xiao, Y.Q.; Yao, Y.S.; Feng, C.; Chang, L.; Jiang, C.M.; Kunzelmann, V.F.; Wang, Z.M.; Govorov, A.O.; et al. Identifying performance-limiting deep traps in Ta3N5 for solar water splitting. ACS Catal. 2020, 10, 10316–10324. [Google Scholar] [CrossRef]

- Guo, Q.H.; Zhao, J.J.; Yang, Y.; Huang, J.L.; Tang, Y.T.; Zhang, X.L.; Li, Z.H.; Yu, X.; Shen, J.; Zhao, J.W. Mesocrystalline Ta3N5 superstructures with long-lived charges for improved visible light photocatalytic hydrogen production. J. Colloid Interface Sci. 2020, 560, 359–368. [Google Scholar] [CrossRef]

- Tao, Y.R.; Chen, J.Q.; Wu, X.C. Phototransistor based on single TaON nanobelt and its photoresponse from ultraviolet to near–infrared. J. Inorg. Mater. 2019, 34, 1004–1010. [Google Scholar]

- Higashi, M.; Domen, K.; Abe, R. Fabrication of efficient TaON and Ta3N5 photoanodes for water splitting under visible light irradiation. Energy Environ. Sci. 2011, 4, 4138–4147. [Google Scholar] [CrossRef]

- Pei, L.; Wang, H.X.; Wang, X.H.; Xu, Z.; Yan, S.C.; Zou, Z.G. Nanostructured TaON/Ta3N5 as a highly efficient type-II heterojunction photoanode for photoelectrochemical water splitting. Dalton Trans. 2018, 47, 8949–8955. [Google Scholar] [CrossRef] [PubMed]

- Pei, L.; Yuan, Y.J.; Zhong, J.S.; Li, T.Z.; Yang, T.; Yan, S.C.; Ji, Z.G.; Zou, Z.G. Ta3N5 nanorods encapsulated into 3D hydrangea-like MoS2 for enhanced photocatalytic hydrogen evolution under visible light irradiation. Dalton Trans. 2019, 48, 13176–13183. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.W.; Cha, S.; Kwak, I.; Kwon, I.S.; Park, K.; Jung, C.S.; Cha, E.H.; Park, J. Surface-modified Ta3N5 nanocrystals with boron for enhanced visible-light-driven photoelectrochemical water splitting. ACS Appl. Mater. Interfaces 2017, 9, 36715–36722. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.N.; Wang, W.; Tao, Y.R.; Zhang, X.Y.; Wu, X.C.; Zhang, D.M. Co3O4/CeO2 Heterojunction: Preparation electrocatalytic oxygen evolution performance in alkaline medium. Chin. J. Inorg. Chem. 2021, 37, 1337–1344. [Google Scholar]

- Mao, J.J.; He, C.T.; Pei, J.J.; Chen, W.X.; He, D.S.; He, Y.Q.; Zhuang, Z.B.; Chen, C.; Peng, Q.; Wang, D.S.; et al. Accelerating water dissociation kinetics by isolating cobalt atoms into ruthenium lattice. Nat. Commun. 2018, 9, 4958. [Google Scholar] [CrossRef]

| Catalysts | Electrolytes | Overpotential at 10 mAcm−2 (mV) | Tafel Slope (mVdec−1) | Stability (10 mAcm−2) | Ref. |

|---|---|---|---|---|---|

| Ru/Ta3N5 NBs (Ru: 5 wt%) | 1.0 M KOH | 64.6 | 84.92 | Stability in 24 h | This work |

| Ru-NMCNs-500 1 (Ru: 3.04 wt%) | 1.0 M KOH | 28 | 35.2 | Increase of 28 mV after 10,000 cycles | [20] |

| Ru/MoO2/C 2 | 1.0 M KOH | 16 | 32 | Stability in 40 h | [21] |

| Ru-Co@N-Graphene (Ru:3.58 wt%) | 1.0 M KOH | 28 | 31 | Stability in 10,000 cycles | [23] |

| B-Ru@CNT (Ru:9.2 wt%; B: 0.06 wt%) | 1.0 M KOH | 17 | 30 | 85% of initial current after 15 h | [24] |

| Ru/CeO2 (Ru:3 wt%) | 1.0 M KOH | 28.9 | 53.2 | Stability in 18 h | [25] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Xu, L.; Wu, X.; Tao, Y.; Xiong, W. Ta3N5 Nanobelt-Loaded Ru Nanoparticle Hybrids’ Electrocatalysis for Hydrogen Evolution in Alkaline Media. Molecules 2023, 28, 1100. https://doi.org/10.3390/molecules28031100

Zhang X, Xu L, Wu X, Tao Y, Xiong W. Ta3N5 Nanobelt-Loaded Ru Nanoparticle Hybrids’ Electrocatalysis for Hydrogen Evolution in Alkaline Media. Molecules. 2023; 28(3):1100. https://doi.org/10.3390/molecules28031100

Chicago/Turabian StyleZhang, Xinyu, Lulu Xu, Xingcai Wu, Yourong Tao, and Weiwei Xiong. 2023. "Ta3N5 Nanobelt-Loaded Ru Nanoparticle Hybrids’ Electrocatalysis for Hydrogen Evolution in Alkaline Media" Molecules 28, no. 3: 1100. https://doi.org/10.3390/molecules28031100