Abstract

Fe-based chemical looping gasification is a clean biomass technology, which has the advantage of reducing CO2 emissions and the potential of self-sustaining operation without supplemental heating. A novel process combining Fe-based chemical looping and biomass pyrolysis was proposed and simulated using Aspen Plus. The biomass was first subjected to pyrolysis to coproduce biochar, bio-oil and pyrolysis gas; the pyrolysis gas was subjected to an Fe looping process to obtain high-purity hydrogen and carbon dioxide. The influences of the pyrolysis reactor operating temperature and fuel reactor operation temperature, and the steam reactor and air reactor on the process performance are researched. The results showed that, under the operating condition of the established process, 23.07 kg/h of bio-oil, 24.18 kg/h of biochar, 3.35 kg/h of hydrogen and a net electricity of 3 kW can be generated from 100 kg/h of rice straw, and the outlet CO2 concentration of the fuel reactor was as high as 80%. Moreover, the whole exergy efficiency and total exergy loss of the proposed process was 58.98% and 221 kW, respectively. Additionally, compared to biomass direct chemical looping hydrogen generation technology, the new process in this paper, using biomass pyrolysis gas as a reactant in the chemical looping hydrogen generation process, can enhance the efficiency of hydrogen generation.

1. Introduction

Hydrogen is regarded as one of the most promising energy sources due to its high energy density and cleanness [1,2]. Nevertheless, the H2 molecule does not exist in nature, and most of the hydrogen exists in water [3,4]. Nowadays, natural gas steam reforming [5] is the most extensive hydrogen production method, which accounts for 48% of the world’s hydrogen production [6,7]. Nevertheless, natural gas steam reforming needs H2 separation and purification as well as the production of a large amount of carbon dioxide (CO2) [8]. Accordingly, it is necessary to develop alternative and renewable sources to produce H2 [9].

Biomass is considered to be a promising renewable source with carbon neutrality to produce H2. From the view of thermodynamics, steam gasification of biomass to generate 53–55 vol% of H2 should be the most popular method for H2 production [6,10], while only 8–10 vol% of H2 can be generated by air gasification of biomass [11]. Nevertheless, steam gasification of biomass requires heat because it is an endothermic reaction, whereas air gasification of biomass is an exothermic process due to the partial combustion of biomass with oxygen. Therefore, the mixing of steam with air in biomass hydrogen production has been extensively developed; however, its H2 content is only 25–30 vol% [12]. Thus, an H2 purification and CO2 separation system are also needed.

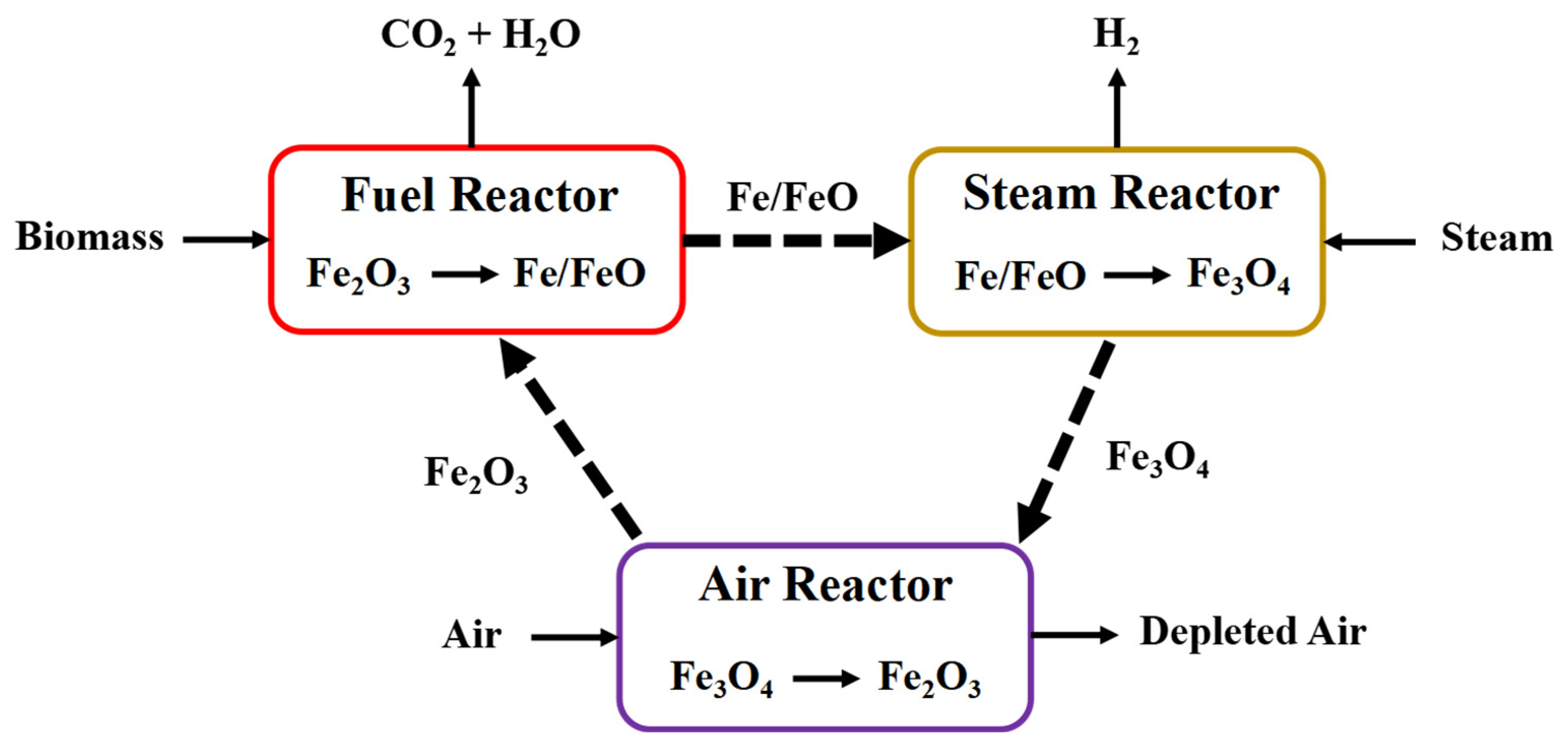

As shown in Figure 1, biomass direct chemical looping is a novel H2 generation method; that is, the solid biomass is directly mixed with the oxygen carrier. High-purity H2 and sequestration-ready CO2 can be generated by biomass direct chemical looping without purification technology, which can theoretically reduce energy consumption [13].

Figure 1.

Schematic diagram of biomass direct chemical looping hydrogen generation.

However, there are some disadvantages in biomass direct chemical looping for hydrogen generation technology. Firstly, the reaction rate of solid biomass with solid oxygen carriers is low due to the low efficiency of solid–solid contact [14]. Secondly, it is hard to separate oxygen carriers from biomass ash and/or biochar [15]. Third, bio-oil has certain value: directing bio-oil to reduce oxygen carrying will reduce the economy of the chemical looping system. More importantly, in the fuel reactor, solid biomass, small molecular gas products (CO, CH4), biochar, bio-oil and oxygen carrier reactions will interact with each other. For example, biochar will hinder the reduction of pyrolysis gas to oxygen carrier, and tar will affect the pore structure of biochar [16,17]. If a chemical looping is coupled to a polygeneration system, biochar, bio-oil, pure hydrogen and sequestration-ready CO2 can be obtained simultaneously. Additionally, the efficiency of the whole biomass conversion process can be increased.

Therefore, it will be interesting to study the combination of chemical looping and polygeneration concepts for biomass to H2 systems. Nguyen et al. [18] proposed novel polygeneration concepts to cogenerate H2, biochar, CH4, bio-oil and methanol from biomass hydropyrolysis and hydrodeoxygenation integrated with water electrolysis. The results demonstrated that the promising processes are those with H2 generation, while the risky systems are those with water electrolysis. Situmorang et al. [19] presented a new process of H2 generation by integrating steam bio-oil reforming as well as a biochar chemical looping hydrogen production system. The results showed that the proposed system can enhance H2 generation efficiency by more than 50% compared with the biomass direct chemical looping hydrogen generation process.

However, to the best of the authors’ knowledge, the polygeneration system for H2, biochar, bio-oil and electricity generation and coproduction by biomass pyrolysis coupled with a chemical looping hydrogen generation process using biomass pyrolysis gas as a reactant has not been reported.

In this paper, a new process integrating biomass pyrolysis and chemical looping H2 generation using pyrolysis gas from the pyrolysis of biomass as the reactant is designed and simulated to produce H2, bio-oil, biochar and electricity. According to the energy and mass balances of the whole process, the exergy efficiency and exergy loss, and the influences of the pyrolysis reactor operating temperature and operation temperatures at the fuel reactor, steam reactor and air reactor on the process performance are studied. It is expected to achieve a novel process to effectively produce H2, bio-oil and biochar from biomass.

2. Results and Discussion

2.1. Material and Energy Calculation of the Proposed System

Based on the simulation results, the whole process can produce 23.07 kg/h of bio-oil (Table 1), 24.18 kg/h of biochar, 52.75 kg/h of pyrolysis gas, 3.35 kg/h of hydrogen and a net electricity of 3 kW per 100 kg/h of rice straw. A total of 100 kg/h of Fe2O3/Al2O3 oxygen carrier, which contains 45% excess as heat carrier, is circulated to completely convert pyrolysis gas in the chemical looping hydrogen generation unit.

Table 1.

Simulation results for the components of the bio-oil.

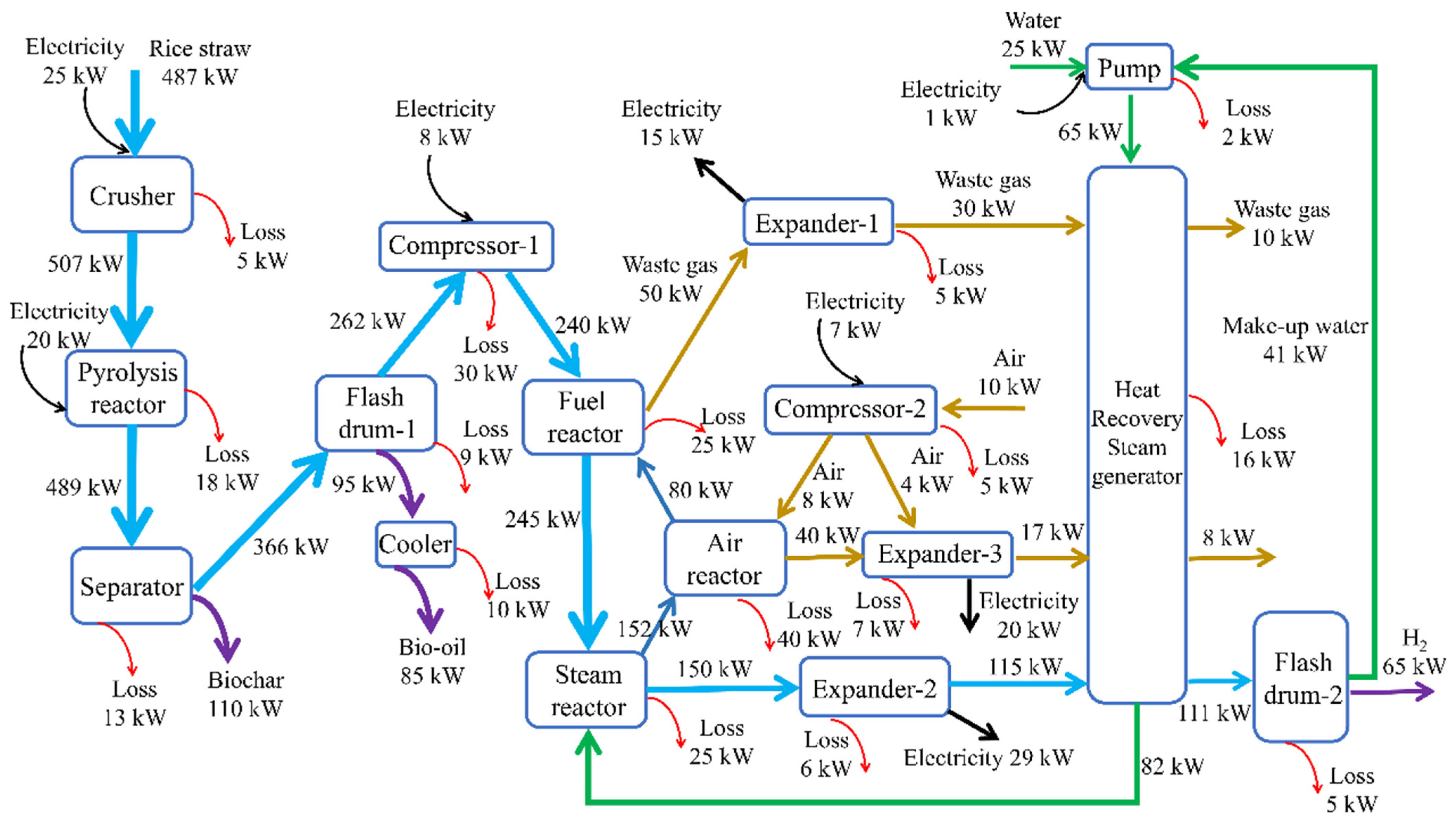

The steam reactor needed 45 kg/h of water, and about 36.65 kg/h of water was recycled back into the steam reactor, which can be gained from the flash drum. Thus, about 8.35 kg/h of make-up water is needed from outside. Table 2 demonstrates the stream results of the proposed system shown in Figure 2 and Table 3 shows the electricity results of the proposed system.

Table 2.

Stream and electricity results of the proposed process.

Figure 2.

Exergy flowchart of the proposed process.

Table 3.

Electricity results of the proposed process.

According to Equations (4)–(6), the efficiency of H2 generation, efficiency of bio-oil generation and efficiency of biochar generation are 6.35%, 23.07% and 24.18%, respectively. The efficiency of hydrogen generation from coal can reach 15% [20]; in contrast, that for biomass can only approach about 5% [14]. Nevertheless, although the efficiency of hydrogen generation for pyrolysis gas is lower than coal, using pyrolysis gas as a reductant in the chemical looping hydrogen generation process can enhance the efficiency of hydrogen generation from biomass.

2.2. Exergy Flowchart

The exergy flowsheet of the proposed system is demonstrated in Figure 2. It can be seen that the overall exergy efficiency of the proposed process is as high as 58.98%. The exergy loss of the whole system is 221 kW. Additionally, the chemical reactions’ irreversibility is the main reason for the losses of exergy for the pyrolysis reactor, fuel reactor, steam reactor and air reactor. The compression and expansion processes’ irreversibility is the primary reason for the exergy losses of compressor-1, compressor-2, the pump, expander-1, expander-2 and expander-3. Heat loss is the main reason for the exergy loss of the heat recovery steam generator, separator, flash drum-1 and flash drum-2.

In order to improve the proposed system’s exergy efficiency, the fuel reactor, air reactor, steam reactor, heat recovery steam generator and compressor-1 are preferred to be improved. Improving the chemical reaction efficiency is necessary to reduce the loss of exergy for the fuel reactor, air reactor and steam reactor such as improving the performance of the oxygen carrier and enhancing the mass and heat transfer efficiency in the above reactor. Enhancing the mechanical efficiency of the compressor can increase exergy efficiency. Additionally, the heat recovery steam generator’s exergy efficiency can be increased by improving the efficiency of heat utilization.

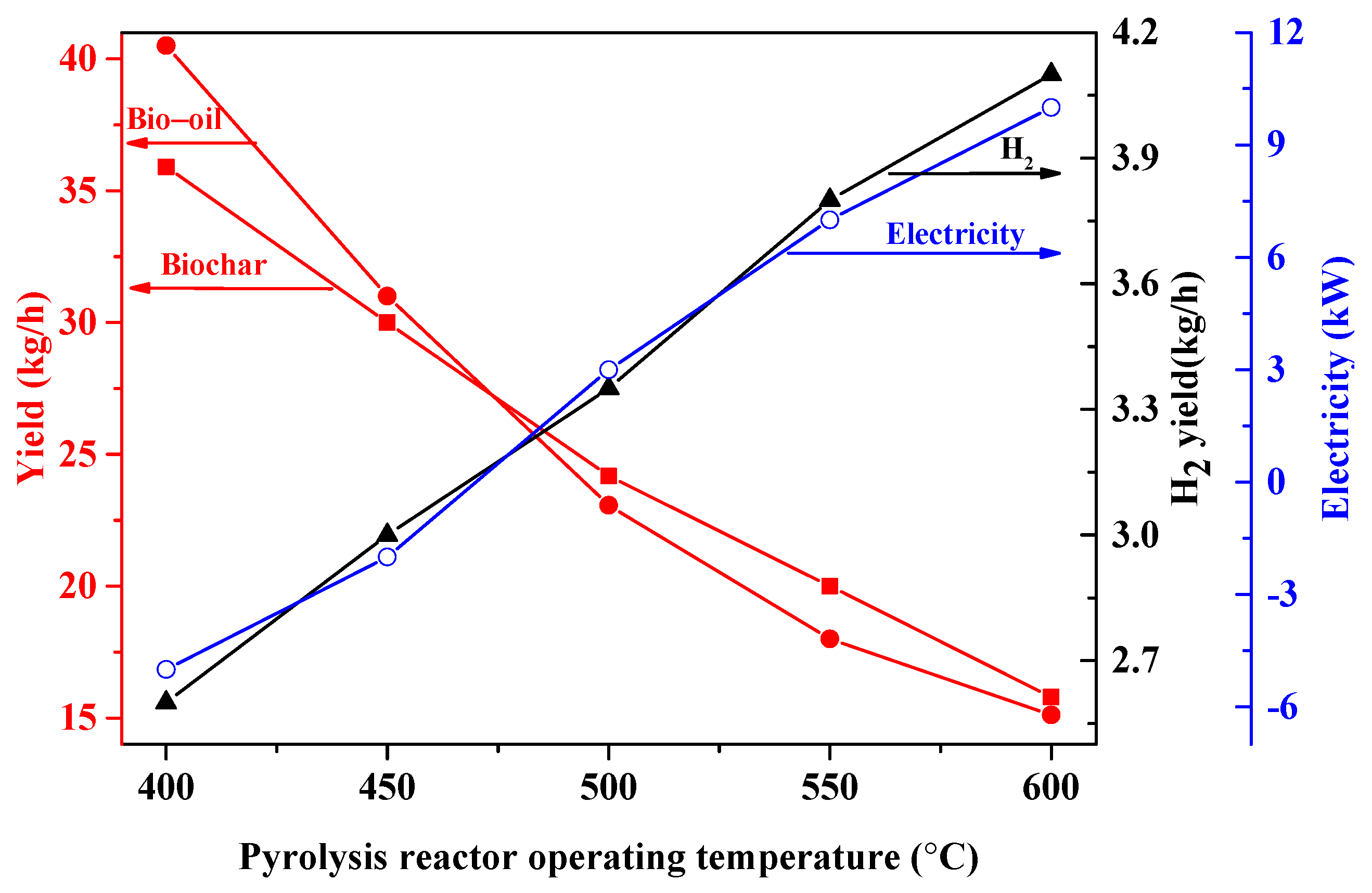

2.3. Effect of Pyrolysis Temperature

The influence of the pyrolysis reactor operating temperature on the hydrogen production yield, bio-oil production yield, biochar production yield and electricity production are shown in Figure 3. The temperatures of the fuel reactor, steam reactor and air reactor are kept at 900 °C, 700 °C and 980 °C, respectively. As the pyrolysis reactor operating temperature increases from 400 °C to 600 °C, the bio-oil production yield and biochar production yield decline from 40.5 kg/h and 35.9 kg/h to 15.12 kg/h and 15.8 kg/h, respectively. The reason is that bio-oil and biochar are converted to pyrolysis gas owing to the primary secondary cracking reactions [10,21].

Figure 3.

Influence of the pyrolysis reactor operating temperature on hydrogen, biochar, bio-oil and electricity production. The temperature of steam reactor and air reactor are kept at 700 and 980 °C.

Nevertheless, the H2 production yield and electricity production are enhanced from 2.6 kg/h and −5 kW to 4.1 kg/h and 10 kW, respectively. The reason is that elevating the amount of pyrolysis gas means more Fe2O3 is converted into FeO and Fe, which react with steam to produce hydrogen. At the same time, more related gas (waste gas from the fuel reactor, H2/steam from the steam reactor) is generated, which affects the work of the expanders.

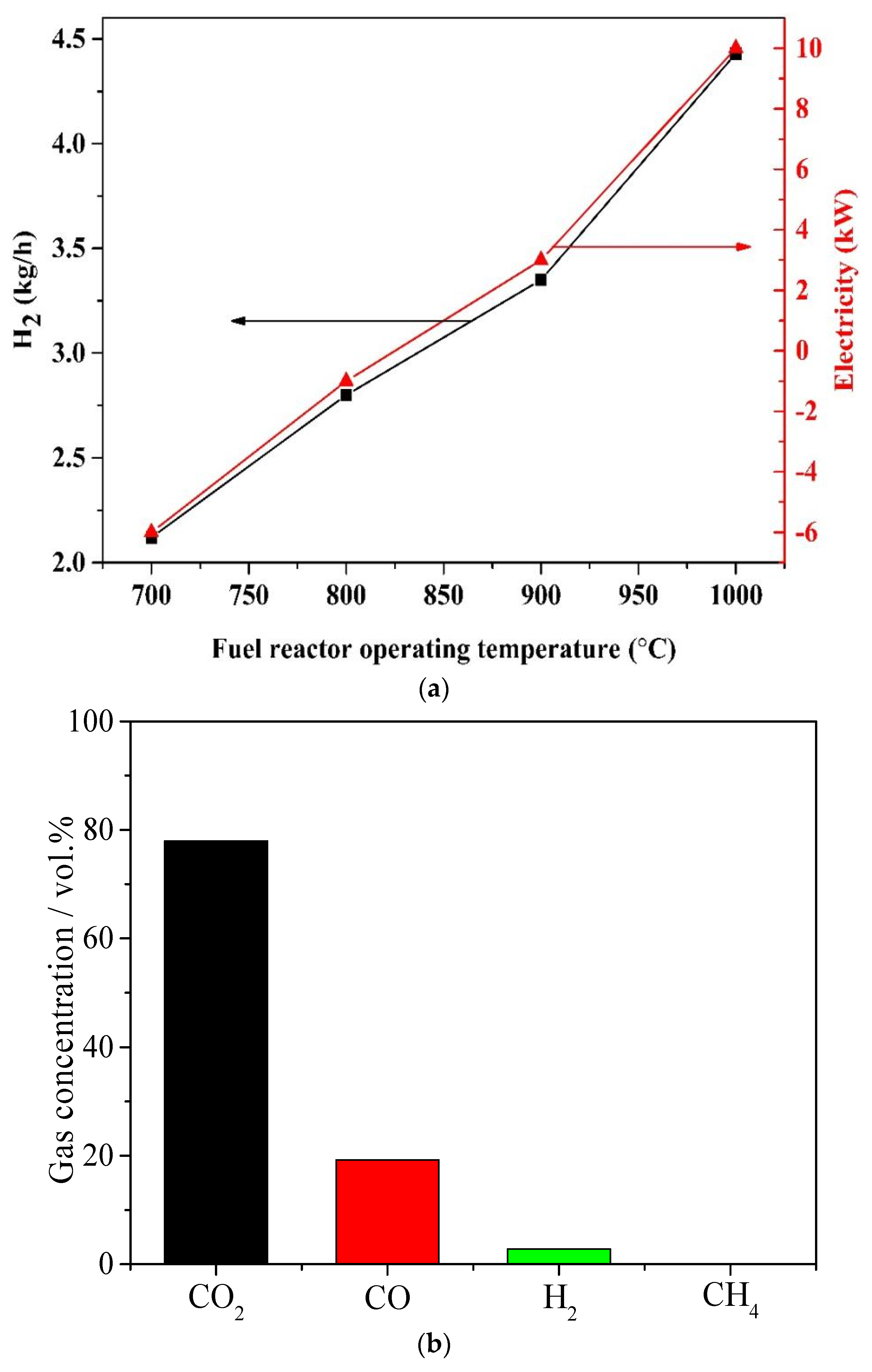

2.4. Effect of Fuel Reactor Operation Temperature

For the chemical looping process, the fuel reactor operation temperature is usually from 750 °C to 950 °C to convert Fe2O3 into FeO/Fe. The influence of the fuel reactor operation temperature on the hydrogen production yield and electricity production is demonstrated in Figure 4. The temperatures of the pyrolysis reactor, steam reactor and air reactor are maintained at 500 °C, 700 °C and 980 °C, respectively.

Figure 4.

Influence of the fuel reactor operating temperature, the temperatures of pyrolysis reactor, steam reactor and air reactor are 500 °C, 700 °C and 980 °C. (a) Hydrogen and electricity production. (b) The gas composition of the outlet of fuel reactor at 900 °C.

As the fuel reactor operating temperature increases from 700 °C to 1000 °C, the H2 production yield and electricity production increase from 2.12 kg/h and 6 kW to 4.43 kg/h and 10 kW, respectively. The pyrolysis gas reaction with Fe2O3 is an endothermic process, which means more FeO is produced with the increase in the fuel reactor temperature; thus, more H2 is produced in the steam reactor. Additionally, more waste gas (CO2 and steam) is produced in the fuel reactor, which results in the increased electricity production of expander-1. However, a higher fuel reactor operation temperature could lead to insufficient air reactor heat [22].

Table 4 shows the outlet gas composition of the fuel reactor at 900 °C. It can be seen that the CO2 concentration of the dry base is about 80%, indicating that the biomass pyrolysis gas in the fuel reactor has been basically oxidized. Therefore, 900 °C is suitable for the fuel reactor.

Table 4.

Gas products and oxygen carrier results of the proposed process.

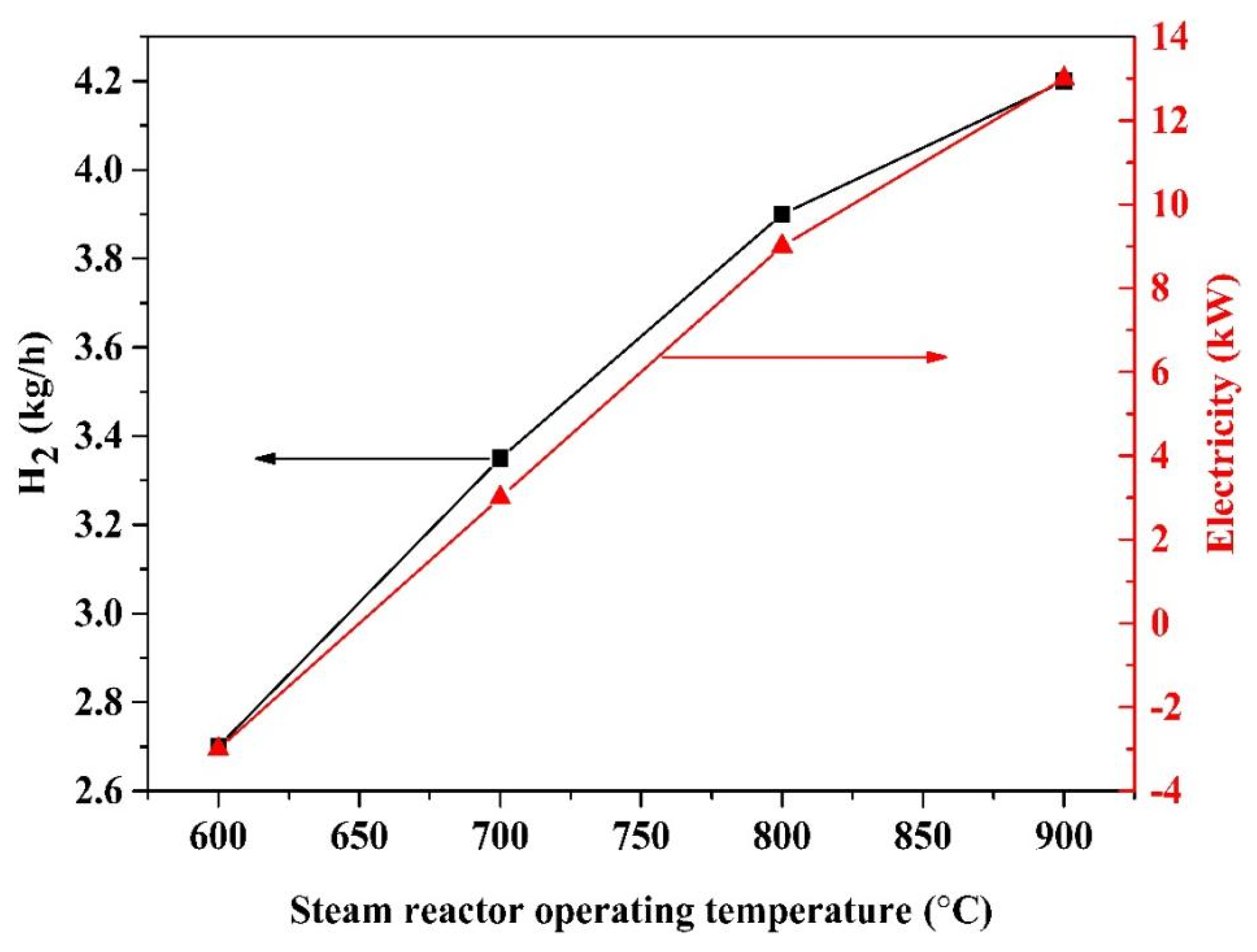

2.5. Effect of Steam Reactor Temperature

In the steam reactor, H2 is generated from steam via the oxidation of FeO/Fe to Fe3O4. The influence of the steam reactor operating temperature on the H2 production yield and electricity production is demonstrated in Figure 5. The temperatures of the pyrolysis reactor, fuel reactor and air reactor are maintained at 500 °C, 900 °C and 980 °C, respectively. As the steam reactor operating temperature increases from 600 °C to 900 °C, the hydrogen production yield decreases from 2.7 kg/h to 4.2 kg/h, whereas the electricity production increases from −3 kW to 13 kW.

Figure 5.

Influence of the steam reactor operating temperature on hydrogen and electricity production, the temperatures of the pyrolysis reactor, fuel reactor and air reactor are 500 °C, 900 °C and 980 °C.

Steam with FeO/Fe are exothermic reactions with the equilibrium obtained at low temperatures. The lower the steam reactor operating temperature is, the higher the hydrogen production yield becomes. Nevertheless, the heat is not to support the chemical looping hydrogen generation process auto-thermally at low temperatures. As the steam reactor operating temperature goes up, the conversion of steam decreases, resulting in an increase in expander-2 electricity generation.

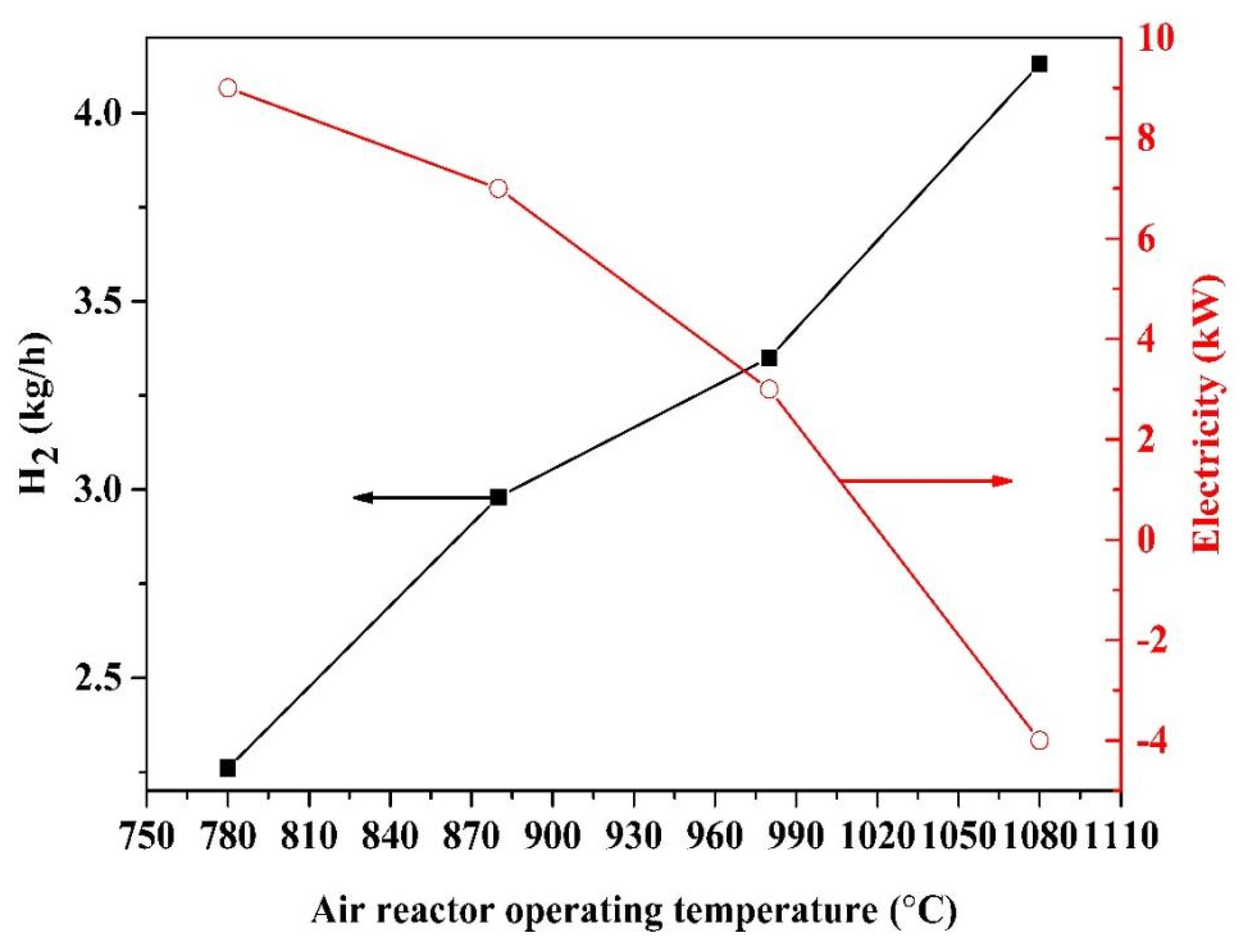

2.6. Effect of Air Reactor Operating Temperature

The operating temperature of the air reactor is a crucial parameter for hydrogen and electricity production. The air reactor operating temperature can affect the fuel reactor temperature due to the energy balance for the chemical looping process. On the other hand, the air reactor operating temperature is limited by the oxygen carrier temperature’s endurance. The influence of the air reactor operating temperature on hydrogen and electricity is shown in Figure 6.

Figure 6.

Influence of the air reactor operating temperature on hydrogen and electricity production, the temperatures of the pyrolysis reactor, fuel reactor and steam reactor are 500 °C, 900 °C and 700 °C.

The temperatures of the pyrolysis reactor, fuel reactor and steam reactor are kept at 500 °C, 900 °C and 700 °C, respectively. As the air reactor operating temperature increases from 780 °C to 1080 °C, the hydrogen production yield enhances from 2.26 kg/h to 4.13 kg/h, whereas the electricity production drops from 9–4 kW. The reason for the decrease in net electricity is that the air flow declines with the rise in the air reactor operating temperature, leading to the temperature declines of the expander-3 inlet stream.

The increase in the air reactor operation temperature leads to the increase in the Fe2O3 temperature, and more FeO is generated in the fuel reactor, which results in the increase in H2 production in the steam reactor. Nevertheless, the high operating temperature of the reactors can cause the sintering of the oxygen carrier [23]. Therefore, the air reactor operation temperature should be less than 1000 °C.

Table 4 shows the gas composition and oxygen carrier results based on Figure 4, Figure 5 and Figure 6. As expected, under optimal conditions, the dry base CO2 concentration at the outlet of the fuel reactor is about 80%. All the Fe is oxidized by steam into FeO in the steam reactor, and the product is pure H2.

3. Methods and Materials

3.1. Materials

China has abundant straw production and the price of straw is low. Therefore, rice straw is selected as the raw material and its properties are listed in Table 5.

Table 5.

Properties of rice straw [24].

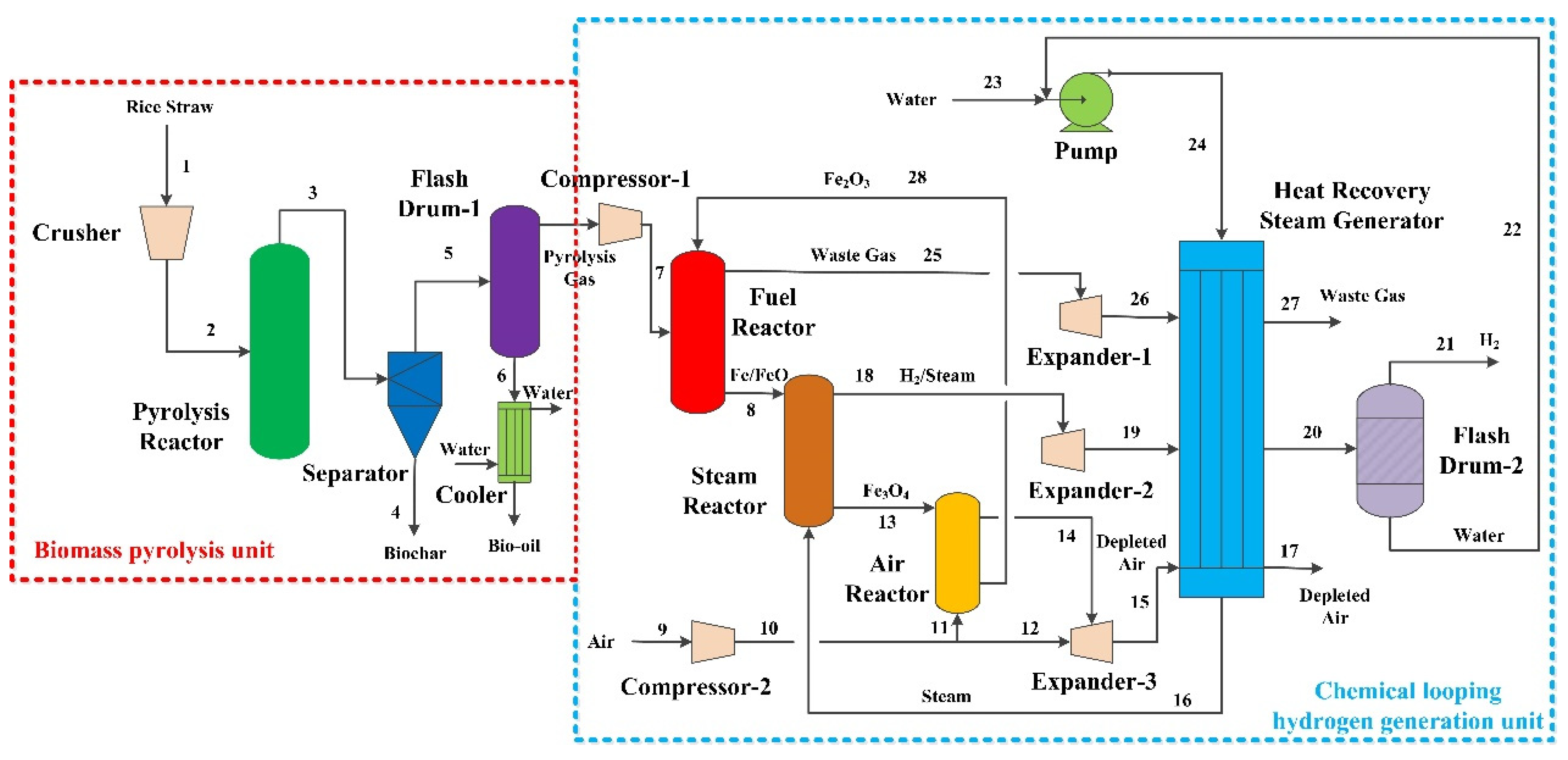

3.2. Model Description

The new process for hydrogen, bio-oil and biochar from biomass was designed in Aspen Plus V9. To simulate the process, all of the reactions are assumed to be in equilibrium and the system is assumed to be in a steady state. As shown in Figure 7, the cogeneration system primarily consists of two units: (i) biomass pyrolysis and (ii) chemical looping hydrogen generation.

Figure 7.

Flowsheet of the process for hydrogen, biochar and bio-oil coproduction by biomass pyrolysis integrated with chemical looping hydrogen generation.

3.2.1. Biomass Pyrolysis Unit

First of all, 100 kg/h of rice straw is transported to the crusher to obtain the required particle size. Particle size of rice straw obtained through the crusher less than 1 mm accounts for 30%. Particle size in the range of 1–2 mm accounts for 40% and that of more than 2 mm accounts for 30%. Then, the crushed rice straw is sent to the pyrolysis reactor. According to the related reference [20], the reaction temperature and pressure of the pyrolysis reactor are set to be 600 °C and 0.1 MPa, respectively. Exiting from the pyrolysis reactor, biochar is separated from the mixture of gas and bio-oil via the separator. The mixture of gas and bio-oil is then transported to the flash drum-1 and the bio-oil is obtained. The pyrolysis gas is sent to the chemical looping hydrogen generation unit.

RK-SOAVE is selected as the property method to achieve the mass and energy balances in the biomass pyrolysis unit. Rice straw, biochar and ash are regarded as nonconventional components and their enthalpy is calculated using HCOALGEN and DCOALIGT.

Bio-oil is a complex mixture of hundreds of organic compounds and the description of pyrolysis modeling for bio-oil is difficult [18]. Therefore, the modeling of bio-oil needs to be simplified. Bio-oil is simulated as a mixture of water, hydroxyacetaldehyde, hydroxypropanone, propionic acid, isoeugenol, acetic acid, phenol, syringol and (5H)-furan-2-one [21] in this paper.

Pyrolysis gas is considered to be a mixture of H2, CO, CH4, CO2 and others (C2H6, C2H4, etc.). Crusher, SSplit and Flash blocks are used to simulate the crusher, separator and flash drum-1, respectively. RYield, REquil and RGibbs blocks are developed to model the pyrolysis reactor. As shown in Table 6, the simulated results of biomass pyrolysis are verified by the work of Zhang [20]. Due to the difference between simulation and actual reaction process, there are relative errors between simulation results and experiment results. The relative errors between the experiment results and simulation results are small, hence the simulation results are rational.

Table 6.

The simulation and experiment results of the rice straw pyrolysis [24].

3.2.2. Chemical Looping Hydrogen Generation Unit

The pyrolysis gas from the biomass pyrolysis unit is compressed to 1 MPa by the compressor-1 and sent to the fuel reactor (900 °C, 1 MPa) and reacts with oxygen carrier Fe2O3/Al2O3 (100 kg, mass ratio 4:6), which is chosen as oxygen carrier due to its advantages of low cost, thermodynamic property and oxygen capacity [6], generating H2O, CO2 and Fe/FeO.

After that, Fe/FeO is sent to the steam reactor (700 °C, 1 MPa) and partially oxidized by steam with the production of H2 and Fe3O4. Then, Fe3O4 is transported to the air reactor (980 °C, 1 MPa) and completely oxidized to Fe2O3 by air. The regenerated oxygen carrier is sent to the fuel reactor and a cycle is completed.

The flue gas is utilized in expanders to generate electricity and introduced to the heat recovery steam generation. The operating parameters of the fuel reactor, steam reactor and air reactor are determined based on previous publications [19,22]. The reactions that take place in the chemical looping hydrogen generation unit can be expressed by Equations (1)–(3).

Fuel reactor CxHyOz (pyrolysis gas) + Fe2O3 → CO2 + H2O + FeO/Fe

Steam reactor FeO/Fe + H2O → Fe3O4 + H2

Air reactor 4Fe3O4 + O2 → 6Fe2O3

RK-SOAVE is developed for nonpolar or mildly polar mixtures such as hydrocarbons and light gases (e.g., carbon dioxide, hydrogen sulfide and hydrogen). Therefore, RK-SOAVE is selected as the property method in the chemical looping hydrogen generation unit to achieve the mass and energy balances. Fe2O3, Al2O3, Fe, FeO and Fe3O4 are assumed to be solid components. The minimum ΔT for heat exchanger is 10 °C. The isentropic efficiency and mechanical efficiency of the pressure changer (compressor, expander and pump) are 0.80 and 0.90, respectively. RGibbs block is used to model the fuel reactor, steam reactor and air reactor [23]. Flash, Pump and MHeatX blocks are developed to simulate the flash drum-2, pump and heat recovery steam generator, respectively. Compr block is used to model the compressor-1, compressor-2, expander-1, expander-2 and expander-3. The Aspen model and input data for the equipment of the proposed system are given in Table 7.

Table 7.

Aspen model and input data for the equipment of the proposed system.

3.3. Evaluation Index of the Proposed System

The performance of the proposed process is assessed by hydrogen production yield, bio-oil production yield, biochar production yield, efficiency of hydrogen generation, the efficiency of bio-oil generation, the efficiency of biochar generation as well as electricity production.

where Eexpander, Epump and Ecompressor are the electricity produced by the expander and the electricity consumed by the pump and compressor, respectively.

3.4. Thermodynamic Analysis

Exergy usually consists of kinetic exergy EKN, potential exergy EPT, physical exergy EPH and chemical exergy ECH [24]. The kinetic exergy and potential exergy can be neglected in a chemical industrial process [25]. Thus, exergy is defined as:

The ECH of gas mixture can be expressed as follows [26]:

The ECH of nongaseous mixture can be defined as follows [27]:

where is the component’s standard ECH, xi stands for the i component’s molar fraction, T0 is 298.15 K, R equals 8.314 kJkmol−1K−1 and the subscript 0 stands for 1 atm and 298.15 K (the reference state). The standard chemical exergy values are demonstrated in those references [26,27,28].

The EPH is expressed as follows [12]:

where H and S stand for the enthalpy and entropy at a given temperature and pressure, H0 and S0 are the enthalpy and entropy at 298.15 K and 1 atm. H, H0, S and S0 are calculated by Aspen Plus. In addition, the ash exergy and rice straw EPH are neglected owing to minor contribution [29].

Additionally, the exergy of biomass can be expressed as:

where C, H and O are carbon, hydrogen and oxygen elements, and are obtained from the ultimate analysis. In addition, the calculation method of exergy for biochar and bio-oil is listed in reference [29].

The exergy destruction ED and exergy efficiency can be calculated as follows:

where Ein stands for the entering exergy and Eout is the outflow exergy.

4. Conclusions

A new process for biochar, bio-oil, H2 and power cogeneration from rice straw was developed. The whole process can produce 23.07 kg/h of bio-oil, 24.18 kg/h of biochar, 52.75 kg/h of pyrolysis gas and 3.35 kg/h of H2 per 100 kg/h of rice straw. The results showed that the process combined biomass pyrolysis with chemical looping hydrogen production, and the hydrogen production efficiency (6.35%) is higher than that of biomass direct chemical looping hydrogen production technology. The proposed process also produces positive net electricity, which is 3 kW per 100 kg/h of rice straw. Additionally, the overall exergy efficiency of the proposed process is 58.98% and the total exergy loss is 221 kW. Furthermore, an economic assessment needs to be carried out to implement this new process.

Author Contributions

Conceptualization, X.Z. and H.J.; methodology, N.L.; validation, X.M. and Z.M.; writing—original draft preparation, P.L.; writing—review and editing, X.Y.; supervision, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financially supported by the National Key R&D Program of China (Grant 2020YFC1909601), the Natural Science Foundation of China under grants: (21878299, 21868021), the Odors Science and Technology Project (2021YY-GONG-119-49), the Science and Technology Project of Hebei Education Department (QN2021090) and the Science Foundation of Hebei Normal University (L2021034, L2021B28).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data were contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Sample Availability

Not applicable.

References

- Pashchenko, D. Liquid organic hydrogen carriers (LOHCs) in the thermochemical waste heat recuperation systems: The energy and mass balances. Int. J. Hydrog. Energy 2022, 47, 28721–28729. [Google Scholar] [CrossRef]

- Pashchenko, D.; Mustafin, R.; Karpilov, I. Thermochemical recuperation by steam methane reforming as an efficient alternative to steam injection in the gas turbines. Energy 2022, 258, 124913. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Ma, J.; Wang, Z.; Liu, J.; Gong, X. ORR and OER of Co-N codoped carbon-based electrocatalysts enhanced by boundary layer oxygen molecules transfer. Carbon 2021, 172, 556–568. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, J.; Guo, S.; Li, J.; Yu, Z.; Song, S.; Li, J.; Fang, Y. High quality syngas production from pressurized K2CO3 catalytic coal gasification with in-situ CO2 capture. Int. J. Hydrog. Energy 2018, 43, 17091–17099. [Google Scholar] [CrossRef]

- Pashchenko, D. Experimental investigation of reforming and flow characteristics of a steam methane reformer filled with nickel catalyst of various shapes. Energy Convers. Manag. 2019, 185, 465–472. [Google Scholar] [CrossRef]

- Samprón, I.; de Diego, L.F.; García-Labiano, F.; Izquierdo, M.T.; Abad, A.; Adánez, J. Biomass Chemical Looping Gasification of pine wood using a synthetic Fe2O3/Al2O3 oxygen carrier in a continuous unit. Bioresour. Technol. 2020, 316, 123908. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Li, G.; Liu, F.; Li, N. Production of ethanol from corn straw based on chemical looping gasification: Economic analysis. Bioresour. Technol. 2022, 360, 127568. [Google Scholar] [CrossRef] [PubMed]

- Pashchenko, D. Experimental investigation of synthesis gas production by methane reforming with flue gas over a NiO-Al2O3 catalyst: Reforming characteristics and pressure drop. Int. J. Hydrog. Energy 2019, 44, 7073–7082. [Google Scholar] [CrossRef]

- Xu, D.; Yang, S.; Su, Y.; Shi, L.; Zhang, S.; Xiong, Y. Simultaneous production of aromatics-rich bio-oil and carbon nanomaterials from catalytic co-pyrolysis of biomass/plastic wastes and in-line catalytic upgrading of pyrolysis gas. Waste Manag. 2021, 121, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar]

- Zou, J.; Oladipo, J.; Fu, S.; Al-Rahbi, A.; Yang, H.; Wu, C.; Cai, N.; Williams, P.; Chen, H. Hydrogen production from cellulose catalytic gasification on CeO2/Fe2O3 catalyst. Energy Convers. Manag. 2018, 171, 241–248. [Google Scholar] [CrossRef]

- He, C.; Feng, X.; Chu, K.H. Process modeling and thermodynamic analysis of Lurgi fixed-bed coal gasifier in an SNG plant. Appl. Energy 2013, 111, 742–757. [Google Scholar] [CrossRef]

- Liu, L.; Cao, Y.; Ma, D.; Liu, Q.; Yang, J. Process simulation of coal-direct chemical looping gasification for syngas production. RSC Adv. 2017, 7, 55450–55458. [Google Scholar] [CrossRef]

- Li, F.; Zeng, L.; Fan, L. Biomass direct chemical looping process: Process simulation. Fuel 2010, 89, 3773–3784. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, X.; Li, J.; Zhao, J.; Song, S.; Hao, Z.; Li, C.; Zhang, J.; Yu, Z.; Fang, Y. High-pressure rapid hydrogasification of pinewood for methane production using calcium looping concept. Energy Convers. Manag. 2020, 203, 112247. [Google Scholar] [CrossRef]

- Ma, S.; Chen, S.; Zhu, M.; Zhao, Z.; Hu, J.; Wu, M.; Toan, S.; Xiang, W. Enhanced sintering resistance of Fe2O3/CeO2 oxygen carrier for chemical looping hydrogen generation using core-shell structure. Int. J. Hydrog. Energy 2019, 44, 6491–6504. [Google Scholar] [CrossRef]

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.H.; Wang, C.X.; He, L.; Nie, H.T.; Wang, J.C.; Zhang, J.C.; Fan, B.G.; et al. Regeneration mechanism of a novel high-performance biochar mercury adsorbent directionally modified by multimetal multilayer loading. J. Environ. Manag. 2023, 326, 116790. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Clausen, L.R. Techno-economic analysis of polygeneration systems based on catalytic hydropyrolysis for the production of bio-oil and fuels. Energy Convers. Manag. 2019, 184, 539–558. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; An, P.; Yu, T.; Rizkiana, J.; Abudula, A.; Guan, G. A novel system of biomass-based hydrogen production by combining steam bio-oil reforming and chemical looping process. Appl. Energy 2020, 268, 115122. [Google Scholar] [CrossRef]

- Zhang, Y.; Lv, P.; Wang, J.; Wei, J.; Cao, P.; Bie, N.; Bai, Y.; Yu, G. Product characteristics of rice straw pyrolysis at different temperature: Role of inherent alkali and alkaline earth metals with different occurrence forms. J. Energy Inst. 2022, 101, 201–208. [Google Scholar] [CrossRef]

- Zhang, L.; Kong, S. Multicomponent vaporization modeling of bio-oil and its mixtures with other fuels. Fuel 2012, 95, 471–480. [Google Scholar] [CrossRef]

- Zeng, D.; Cui, D.; Qiu, Y.; Li, M.; Ma, L.; Zhang, S.; Xiao, R. Mn-Fe-Al-O mixed spinel oxides as oxygen carrier for chemical looping hydrogen production with CO2 capture. Fuel 2020, 274, 117854. [Google Scholar] [CrossRef]

- Bock, S.; Stoppacher, B.; Malli, K.; Lammer, M.; Hacker, V. Techno-economic analysis of fixed-bed chemical looping for decentralized, fuel-cell-grade hydrogen production coupled with a 3 MWth biogas digester. Energy Convers. Manag. 2021, 250, 114801. [Google Scholar] [CrossRef]

- Boughanmi, H.; Lazaar, M.; Farhat, A.; Guizani, A. Evaluation of soil thermal potential under Tunisian climate using a new conic basket geothermal heat exchanger: Energy and exergy analysis. Appl. Therm. Eng. 2017, 113, 912–925. [Google Scholar] [CrossRef]

- Dai, B.; Zhang, L.; Cui, J.; Hoadley, A.; Zhang, L. Integration of pyrolysis and entrained-bed gasification for the production of chemicals from Victorian brown coal-Process simulation and exergy analysis. Fuel Process. Technol. 2017, 155, 21–31. [Google Scholar] [CrossRef]

- Cruz, P.L.; Iribarren, D.; Dufour, J. Exergy analysis of alternative configurations of a system coproducing synthetic fuels and electricity via biomass gasification, Fischer-Tropsch synthesis and a combined-cycle scheme. Fuel 2017, 194, 375–394. [Google Scholar] [CrossRef]

- Xiong, J.; Zhao, H.; Zheng, C. Exergy Analysis of a 600 MWe Oxy-combustion Pulverized-Coal-Fired Power Plant. Energy Fuels 2011, 25, 3854–3864. [Google Scholar] [CrossRef]

- Abuadala, A.; Dincer, I.; Naterer, G.F. Exergy analysis of hydrogen production from biomass gasification. Int. J. Hydrog. Energy 2010, 35, 4981–4990. [Google Scholar] [CrossRef]

- Tumen Ozdil, N.F.; Tantekin, A.; Erbay, Z. Energy and exergy analyses of a fluidized bed coal combustor steam plant in textile industry. Fuel 2016, 183, 441–448. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).