Analysis of Structural Heterogeneity in Low-Rank Coal and Its Pyrolyzed Char Using Multi-Point Scanning Micro-Raman Spectroscopy

Abstract

:1. Introduction

2. Results and Discussion

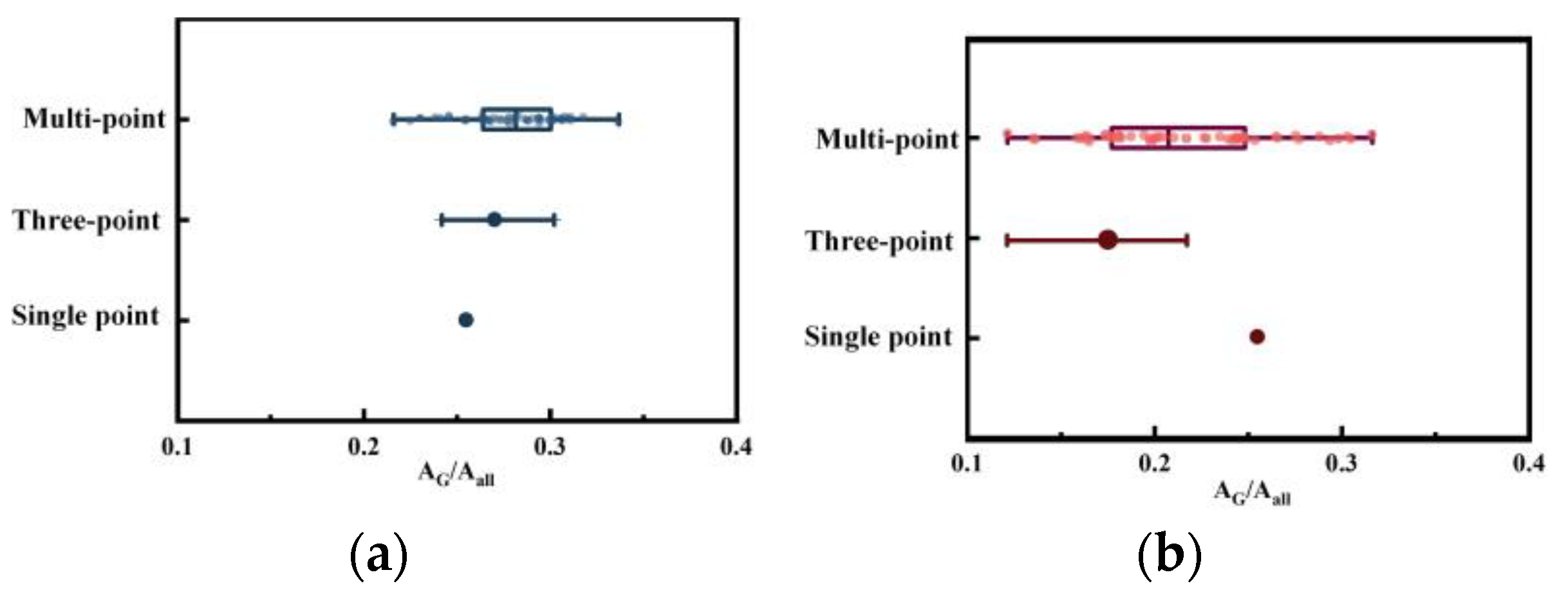

2.1. Area Parameter (A)

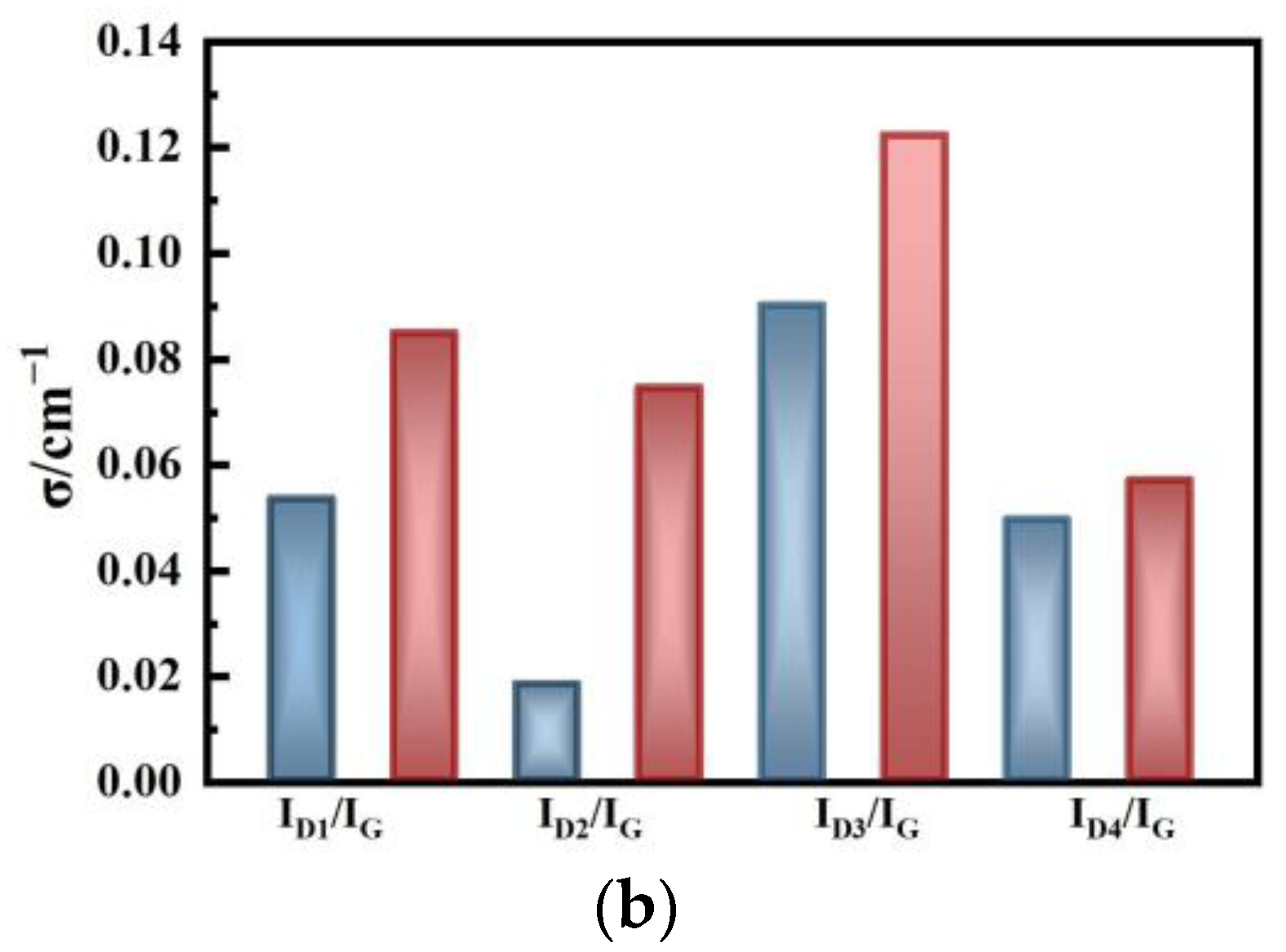

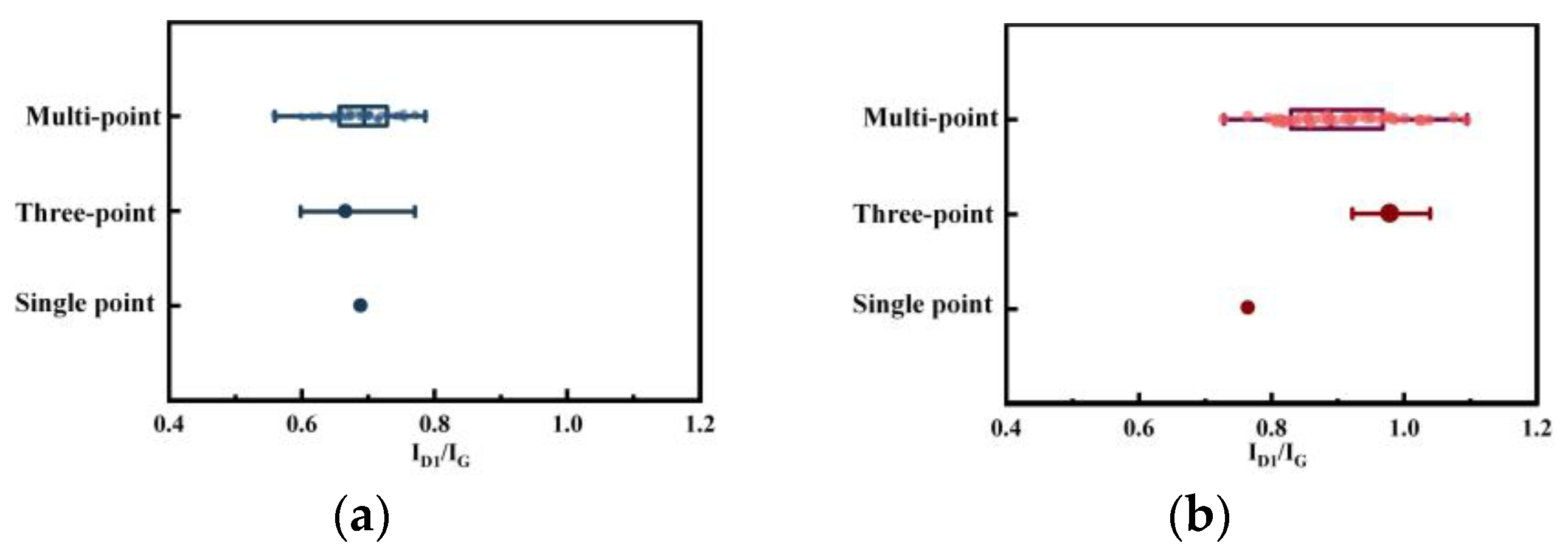

2.2. Intensity Parameter (I)

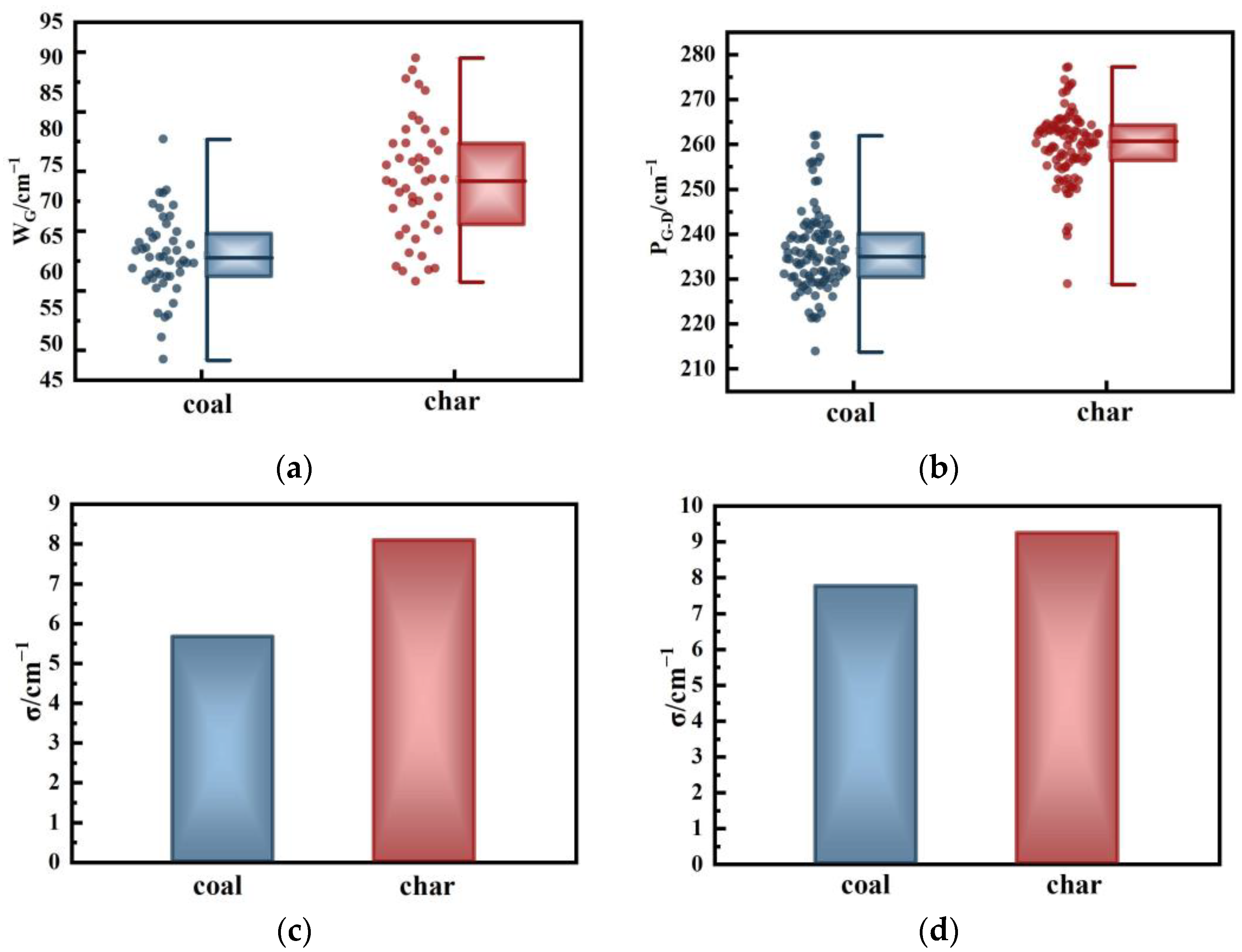

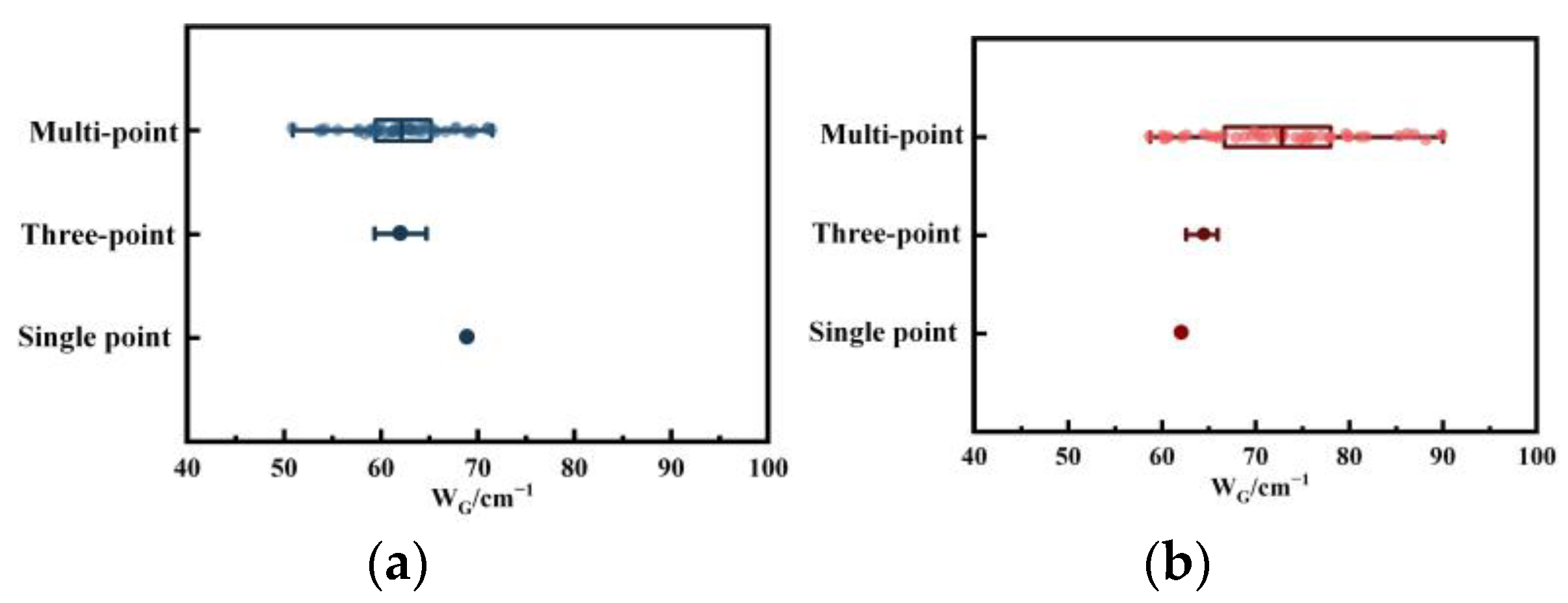

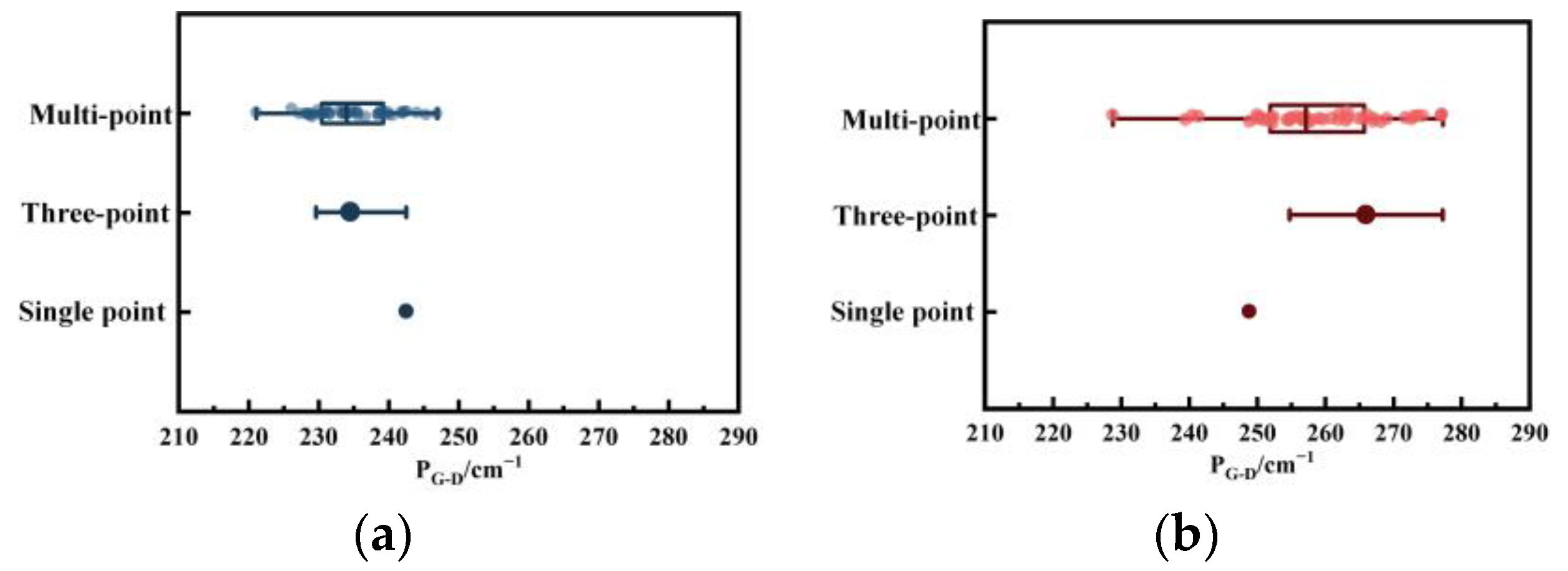

2.3. Full Width at Half Maximum (FWHM/W) and Position (P) Parameter

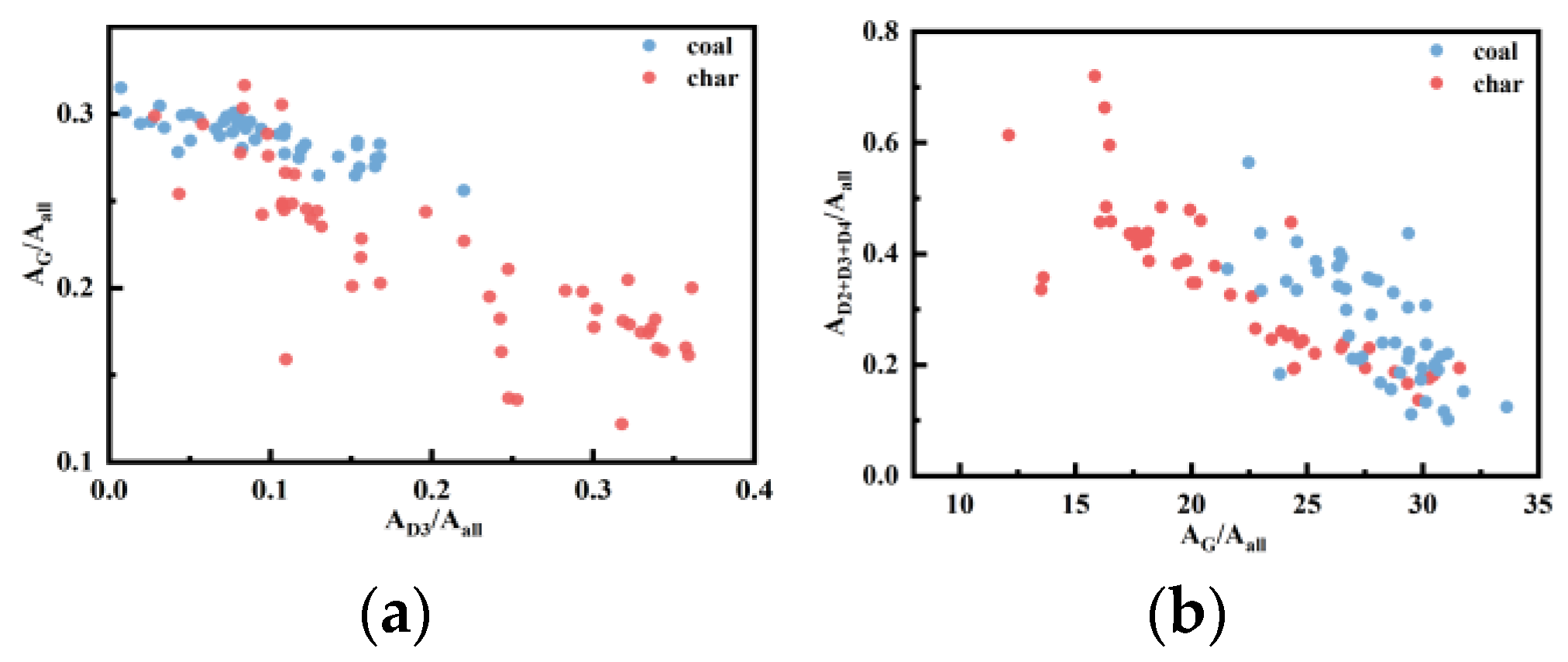

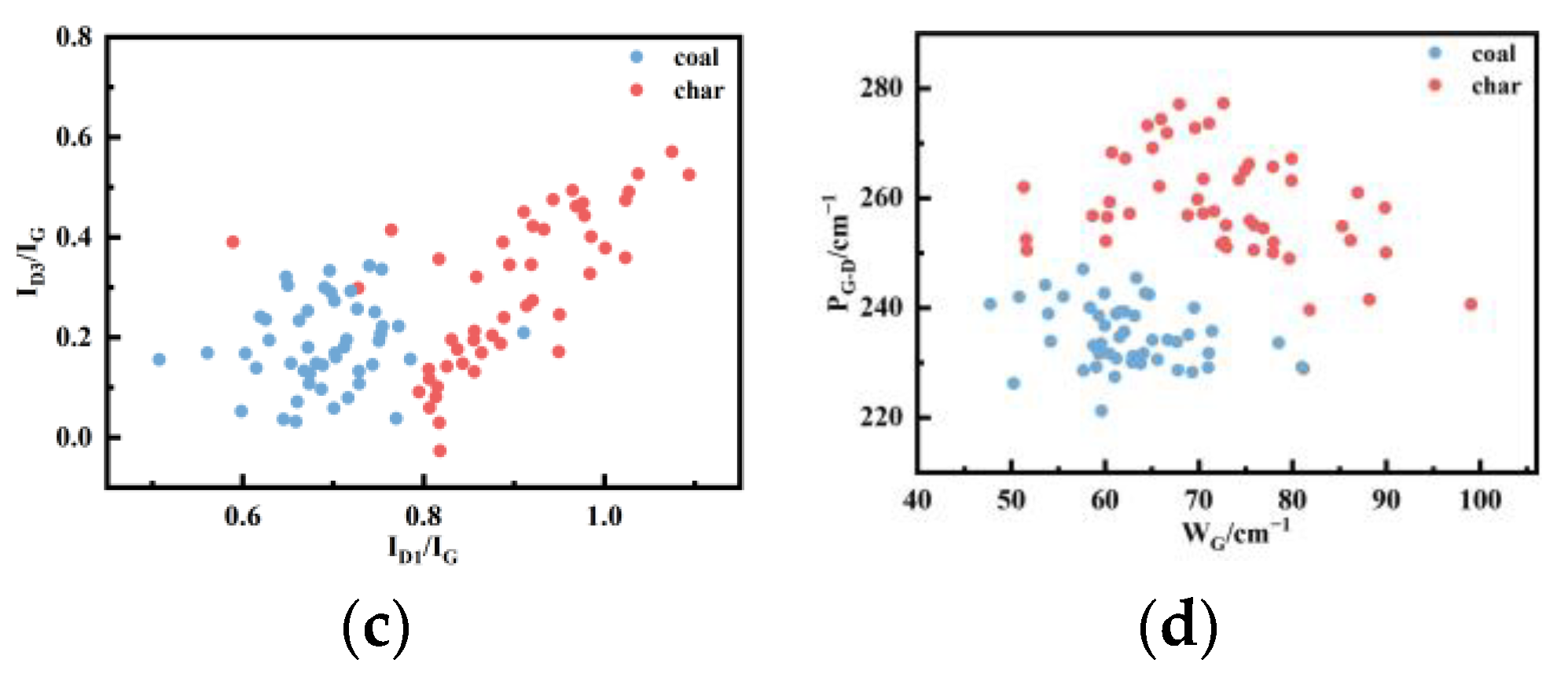

2.4. Correlation between Different Parameters

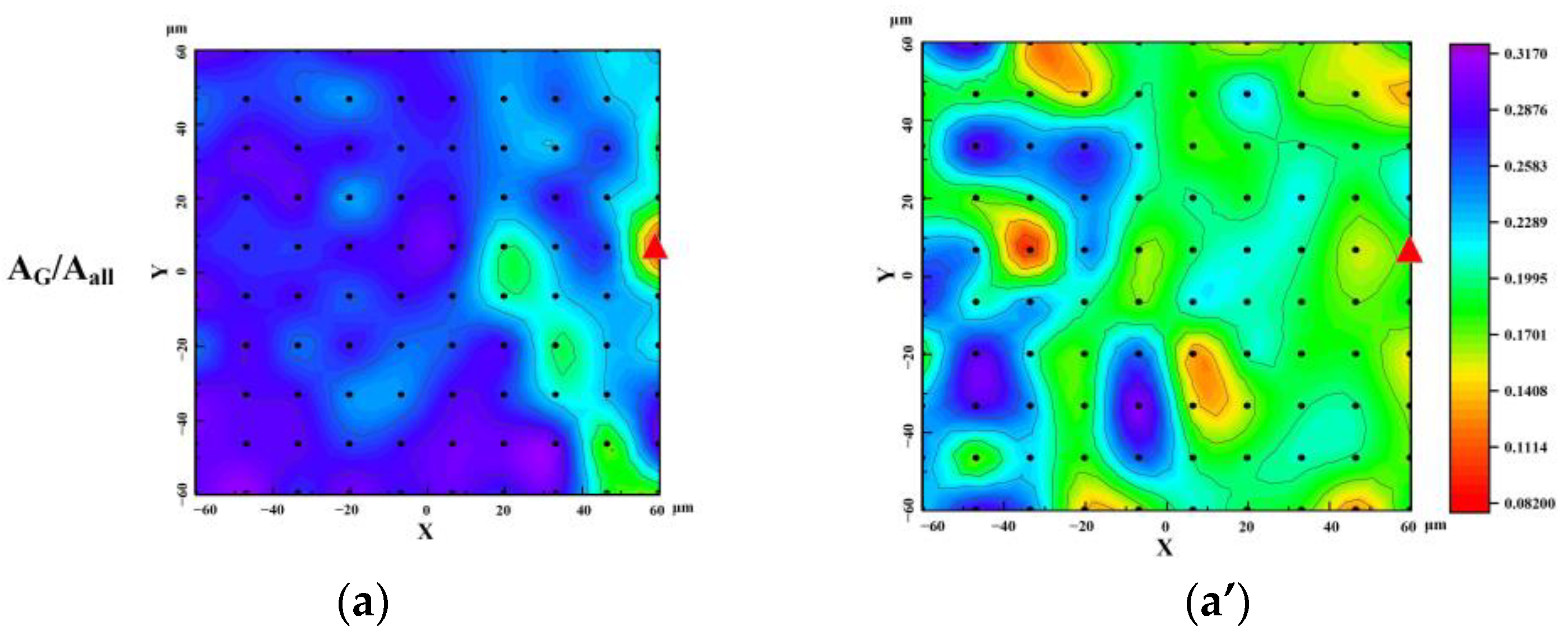

3. Mapping

4. Materials and Methods

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Friedel, R.A.; Carlson, G.L. Difficult carbonaceous materials and their infra-red and Raman spectra: Reassignments for coal spectra. Fuel 1972, 51, 198. [Google Scholar] [CrossRef]

- Wopenka, B.; Pasteris, J. Structural characterization of kerogens to granulite facies graphite: Applicability of Raman microprobe spectroscopy. Am. Miner. 1993, 78, 533–557. [Google Scholar]

- Kawakami, M.; Kanba, H.; Sato, K.; Takenaka, T.; Gupta, S.; Chandratilleke, R.; Sahajwalla, V. Characterization of thermal annealing effects on the evolution of coke carbon structure using Raman spectroscopy and X-ray Diffraction. ISIJ Int. 2006, 46, 1165–1170. [Google Scholar] [CrossRef]

- Lespade, P.; Marchand, A.; Couzi, M.; Cruege, F. Caracterisation de materiaux carbones par microspetrometrie Raman. Carbon 1984, 22, 375–385. [Google Scholar] [CrossRef]

- Beyssac, O.; Goffé, B.; Chopin, C.; Rouzaud, J.N. Raman spectra of carbonaceous material in metasediments: A new geothermometer. J. Metamorph, Geol. 2002, 20, 859–871. [Google Scholar] [CrossRef]

- Beyssac, O.; Goffé, B.; Petitet, J.P.; Froigneux, E.; Moreau, M.; Rouzaud, J.N. On the characterization of disorder and heterogeneous carbonaceous materials by Raman spectroscopy. Spectrochim. Acta Part A 2003, 59, 2267–2276. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.A.; Patrick, J.W.; Thomas, K.M. Characterization of coal chars by Raman spectroscopy X-ray diffraction reflectance measurements. Fuel 1986, 65, 1284–1290. [Google Scholar] [CrossRef]

- Kelemen, S.R.; Fang, H.L. Maturity trends in Raman spectra from kerogen and coal. Energy Fuels 2001, 15, 653–658. [Google Scholar] [CrossRef]

- Pasteris, J.; Wopenka, B. Raman spectra of graphite as indicators of degree of metamorphism. Can. Miner. 1991, 29, 1–9. [Google Scholar]

- Guo, X.; Tay, H.L.; Zhang, S.; Li, C.Z. Changes in char structure during the gasification of a Victorian brown coal in steam and oxygen at 800 °C. Energy Fuels 2008, 22, 4034–4038. [Google Scholar] [CrossRef]

- Dong, S.; Alvarez, P.; Paterson, N.; Dugwell, D.R.; Landiyoti, R. Study on the effect of heat treatment and gasification on the carbon structure of coal chars and metallurgical cokes using fourier transform Raman spectroscopy. Energy Fuels 2009, 23, 1651–1661. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, J.W.; Xu, J.; Su, S.; Tang, H.; Hu, T.; Mostafa, M.E.; Xu, K.; Wang, Y.; Hu, S. The fluorescence interference in Raman spectrum of raw coals and its application for evaluating coal property and combustion characteristics. Proc. Combust. Inst. 2019, 37, 3053–3060. [Google Scholar] [CrossRef]

- Li, W.; Zhu, Y.M.; Wang, G.; Jiang, B. Characterization of coalification jumps during high rank coal chemical structure evolution. Fuel 2016, 185, 298–304. [Google Scholar] [CrossRef]

- Solomon, P.R.; Hamblen, D.G.; Carangelo, R.M.; Serio, M.A.; Deshpande, G.V. General model of coal devolatilization. Energy Fuels 1988, 2, 405–422. [Google Scholar] [CrossRef]

- Saxena, S.C. Devolatilization and combustion characteristics of coal particles. Prog. Energy Combust. Sci. 1990, 16, 55–94. [Google Scholar] [CrossRef]

- Li, C.Z. Some recent advances in the understanding of the pyrolysis and gasification behaviour of Victorian brown coal. Fuel 2007, 86, 1664–1683. [Google Scholar] [CrossRef]

- He, J.Y.; Zou, C.; Zhao, J.X.; Xi, J.L.; She, Y.; Ren, M.M.; Xu, Y.F. Influence of Raman Spectroscopy test conditions on the results of carbon chemical structure of chars. Energies 2022, 15, 5627–5643. [Google Scholar] [CrossRef]

- Guo, X.J.; Xu, X.; Xue, X.Y.; Li, X.Q. Insights into the structures of coals and chars from a bond and radical perspective using Raman spectroscopy. Fuel 2022, 312, 122980. [Google Scholar] [CrossRef]

- Chabalala, V.P.; Wagner, N.; Potgieter-Vermaak, S. Investigation into the evolution of char structure using Raman spectroscopy in conjunction with coal petrography; Part 1. Fuel Process. Technol. 2011, 92, 750–756. [Google Scholar] [CrossRef]

- Manoj, B.; Kunjomana, A.G. Structural characterization of selected Indian coals by X-ray diffraction and spectroscopic techniques. Trends Appl. Sci. Res. 2012, 7, 434–444. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, Z.S. Raman spectroscopic study of chemical structure and thermal maturity of vitrinite from a suite of Australia coals. Fuel 2019, 241, 188–198. [Google Scholar] [CrossRef]

- Liu, M.J.; Bai, J.; Yu, J.L.; Kong, L.X.; Bai, Z.Q.; Li, H.Z.; He, C.; Ge, Z.F.; Cao, X.; Li, W. The correlation between char gasification characteristic at different stages and microstructure of char by combing XRD and Raman. Energy Fuels 2020, 34, 4162. [Google Scholar] [CrossRef]

- Rodrigues, S.; Searez-Ruiz, I.; Marques, M.; Camean, I.; Flores, D. Microstructural evolution of high temperature treated anthracites of different rank. Int. J. Coal Geol. 2011, 87, 204–211. [Google Scholar] [CrossRef]

- Sheng, C.D. Char structure characterised by Raman spectroscopy and its correlations with combustion reactivity. Fuel 2007, 86, 2316–2324. [Google Scholar] [CrossRef]

- Pan, J.N.; Lv, M.M.; Bai, H.L.; Hou, Q.L.; Li, M.; Wang, Z.Z. Effects of metamorphism and deformation on the coal macromolecular structure by laser Raman spectroscopy. Energy Fuels 2017, 31, 1136–1146. [Google Scholar] [CrossRef]

- Nestler, K.; Dietrich, D.; Wieke, K.; Robler, R.; Marx, G. Thermogravimetric and Raman spectroscopic investigations on different coals in comparison to dispersed anthracite found in permineralized tree fern Psaronius sp. J. Mol. Struct. 2003, 661, 357–362. [Google Scholar] [CrossRef]

- Xie, Y.F.; You, J.L.; Lu, L.M.; Wang, M.; Wang, J. Raman spectroscopic study of coal samples during heating. Appl. Sci. 2019, 9, 4699. [Google Scholar] [CrossRef]

- Liu, X.F.; You, J.L.; Wang, Y.Y.; Lu, L.M.; Xie, Y.F.; Yu, L.W.; Fu, Q. Raman spectroscopic study on the pyrolysis of Australia bituminous coal. J. Fuel Chem. Technol. 2014, 42, 270–276. [Google Scholar] [CrossRef]

- Morga, R. Micro-Raman spectroscopy of carbonized semifusinite and fusinite. Int. J. Coal Geol. 2011, 87, 253–267. [Google Scholar] [CrossRef]

- Rantitsch, G.; Bhatatacharyya, A.; Schenk, J.; Lunsdorf, N.K. Assessing the quality of metallurgical coke by Raman spectroscopy. Int. J. Coal Geol. 2014, 130, 1–7. [Google Scholar] [CrossRef]

- Xu, J.; Xiang, X.R.; Xu, K.; He, L.M.; Han, H.D.; Su, S.; Wang, Y.; He, S.; Xiang, J. Developing micro-Raman spectroscopy for char structure characterization in the scale of micro- and bulk: A case study of Zhundong coal pyrolysis. Fuel 2021, 291, 120168. [Google Scholar] [CrossRef]

- Minsky, M. Memoir on inventing the confocal scanning microscope. Scanning 1988, 10, 128–138. [Google Scholar] [CrossRef]

- Dhamelincourt, P.; Barbillat, J.; Dwlhaye, M. Laser confocal Raman microspectrometry. Spectrosc. Eur. 1993, 5, 16. [Google Scholar]

- Barbillat, J.; Dhamelincourt, P.; Dwlhaye, M.; Silva, E.D. Raman Confocal Microprobing, Imaging and Fibre-Optic Remote Sensing: A Further Step in Molecular Analysis. J. Raman Spectrosc. 1994, 25, 3–11. [Google Scholar] [CrossRef]

- Stancovski, V.; Badilescu, S. In situ Raman spectroscopic–electrochemical studies of lithium-ion battery materials: A historical overview. J. Appl. Electrochem. 2014, 44, 23–43. [Google Scholar] [CrossRef]

- Allakhverdiev, K.R.; Lovera, D.; Altstadt, V.; Schreler, P.; Kador, L. Confocal Raman microscopy:non-destructive materials analysis with micrometer resolution. Rev. Adv. Mater. Sci. 2009, 20, 77. [Google Scholar]

- Collins, L.; Tselev, A.; Jesses, S.; Okatan, M.B.; Proksch, R.; Mathews, J.P.; Mitchell, G.D.; Rodriguez, B.J.; Kalinin, S.V.; Ivanov, I.N. Breaking the limits of structural and mechanical imaging of the heterogeneous structure of coal macerals. Nanotechnology 2014, 25, 435402. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.S.; Landry, Z.; Pereira, F.C.; Wagner, M.; Berry, D.; Huang, W.E.; Taylor, G.T.; Kneipp, J.; Popp, J.; Zhang, M.; et al. Raman microspectroscopy for microbiology. Nat. Rev. Methods Primers 2021, 1, 1–25. [Google Scholar] [CrossRef]

- Zhang, R.H.; Zhu, J.; Sun, D.; Li, J.; Yao, L.N.; Meng, S.S.; Li, Y.; Dang, Y.; Wang, K.G. The Mechanism of Dynamic Interaction between Doxorubicin and Calf Thymus DNA at the Single-Molecule Level Based on Confocal Raman Spectroscopy. Micromachines 2022, 13, 940. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Wang, H.F.; Qin, J.; Zeng, H.S.; Wang, K.G.; Wang, S.S. Unveiling osteosarcoma responses to DAPT combined with cisplatin by using confocal Raman microscopy. Biomed. Opt. Express 2021, 12, 5514–5528. [Google Scholar] [CrossRef]

- Li, J.; Qin, J.; Zeng, H.S.; Li, J.; Wang, K.G.; Wang, S.S. Unveiling dose- and time-dependent osteosarcoma cell responses to the γ-secretase inhibitor, DAPT, by confocal Raman microscopy. J. Biophotonics 2020, 13, e202000238. [Google Scholar] [CrossRef]

- Hinrichs, R.; Brown, T.M.; Vasconcellos, M.A.Z.; Abrashev, M.V.; Kalkreuth, W. Simple procedure for an estimation of the coal rank using micro-Raman spectroscopy. Int. J. Coal Geol. 2014, 136, 52–58. [Google Scholar] [CrossRef]

- Xu, J.; Liu, J.W.; Zhang, X.; Ling, P.; Xu, K.; He, L.M.; Su, S.; Wang, Y.; Hu, S.; Xiang, J. Chemical imaging of coal in micro-scale with Raman mapping technology. Fuel 2020, 264, 116826. [Google Scholar] [CrossRef]

- Tuinsta, A.F.; Koeing, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Li, H.J.; Hayashi, J.I.; Li, C.Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal. Fuel 2006, 85, 1700–1707. [Google Scholar] [CrossRef]

- Guedes, A.; Valentim, B.; Prieto, A.C.; Rodrigues, S.; Noronha, F. Raman spectrum of graphite. Int. J. Coal Geol. 2010, 83, 415–422. [Google Scholar] [CrossRef]

- Sadezky, A.; Muckenhuber, H.; Grothe, H.; Niessner, R.; Poschl, U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 2005, 43, 1731–1742. [Google Scholar] [CrossRef]

- Jawhari, T.; Roid, A.; Casado, J. Raman spectroscopic characterization of some commercially available carbon black materials. Carbon 1995, 33, 1561–1565. [Google Scholar] [CrossRef]

- Quirico, E.; Rouzaud, J.N.; Bonal, L. Maturation grade of coals as revealed by Raman spectroscopy: Progress and problems. Spectrochim. Acta Part A 2005, 61, 2368–2377. [Google Scholar] [CrossRef]

- Kudryavtsev, A.B.; Schopf, J.W.; Agresti, D.G. In situ laser-Raman imagery of Precambrian microscopic fossils. Proc. Natl. Acad. Sci. 2001, 98, 823–826. [Google Scholar] [CrossRef]

- Dent, F.J.; Blackburn, W.M.; Mliiett, H.C. Investigation of the use of oxygen and high pressure in gasification. Part 2-Synthesis of gaseous hydrocarbons at high pressure. 41st Rep. Jt. Res. Comm. Inst. Gas Eng. 1937, 167, 231. [Google Scholar]

- Liu, X.H.; Zheng, Y.; Liu, Z.H.; Ding, H.R.; Huang, X.H.; Zheng, C.G. Study on the evolution of the char structure during hydrogasification process using Raman spectroscopy. Fuel 2015, 157, 97–106. [Google Scholar] [CrossRef]

- Cloke, M.; Lester, E. Characterization of coals for combustion using petrographic analysis: A review. Fuel 1994, 73, 315–320. [Google Scholar] [CrossRef]

- Jones, S.P.; Fain, C.; Edie, D.D. Structural development in mesophase pitch based carbon fibers produced from naphithalene. Carbon 1997, 35, 1533–1543. [Google Scholar] [CrossRef]

- Liu, D.D.; Gao, J.H.; Wu, S.H.; Qin, Y.K. XRD and Raman characterization of microstructure changes of char during pyrolysis. J. Harbin Inst. Technol. 2016, 48, 39–45. [Google Scholar]

- Zhang, J.G.; Sun, Z.G.; Guo, Q.; Wang, X.J.; Yu, G.S.; Liu, H.F.; Wang, F.C. Stuctural changes of shenfu coal in pyrolysis and hydrogasification reactivity of the char. J. Fuel Chem. Technol. 2017, 45, 130–137. [Google Scholar]

- Xie, Y.F.; You, J.L.; Lu, L.M.; Wang, J.; Wang, M.; Ma, N. Temperature and atmosphere dependent Raman spectra of coking coals. 26h Int. Conf. Raman Spectrosc. 2018, 8, 1071–1072. [Google Scholar]

- Tromp, P.J.J.; Moulijin, J. New trends in coal science. In Slow and Rapid Pyrolysis of Coal; Kluwer Academic Publisher: Boston, MA, USA, 1987; pp. 305–308. [Google Scholar]

- GB/T 212-2008; Proximate Analysis of Coal. Chinese National Standards: Beijing, China, 2008.

- Van, H.K.H. Progress of coal science in the 20th century. Fuel 2000, 79, 1–26. [Google Scholar]

- Li, W.; Zhu, Y.M. Structural characteristics of coal vitrinite during pyrolysis. Energy Fuels 2014, 28, 3645–3654. [Google Scholar] [CrossRef]

- Sonibare, O.O.; Haeger, T.; Foley, S.F. Structural characterization of nigerian coals by X-ray diffraction, Raman and FTIR spectroscopy. Energy 2010, 35, 5347–5353. [Google Scholar] [CrossRef]

- Niu, Z.Y.; Liu, G.J.; Yin, H.; Wu, D.; Zhou, C.C. Investigation of mechanism and kinetics of non-isothermal low temperature pyrolysis of perhydrous bituminous coal by in-situ FTIR. Fuel 2016, 172, 1–10. [Google Scholar] [CrossRef]

- Chen, C.; Gao, J.S.; Yan, Y.J. Observation of the type of Hydrogen Bonds in Coal by FTIR. Energy Fuels 1998, 12, 446–449. [Google Scholar] [CrossRef]

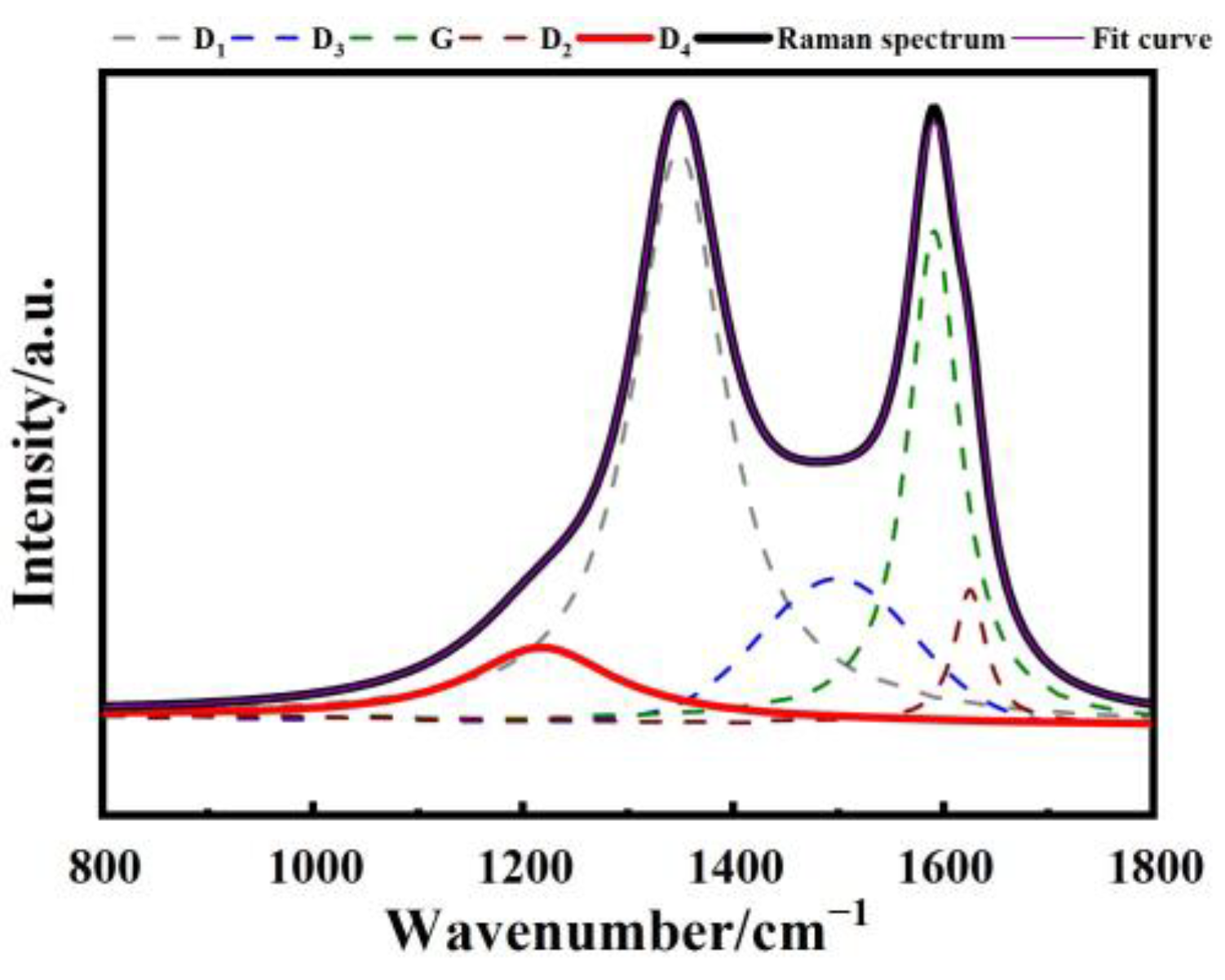

| Band | Wavenumber/cm−1 | Fitting Peak Shape | Vibration Mode |

|---|---|---|---|

| G | 1580 | Lorentzian | Ideal graphitic lattice (E2g-symmetry) |

| D1 | 1350 | Lorentzian | Disordered graphitic lattice (A1g-symmetry) |

| D2 | 1620 | Lorentzian | Disordered graphitic lattice (E2g-symmetry) |

| D3 | 1500 | Gaussian | Amorphous carbon |

| D4 | 1200 | Lorentzian | Disordered graphitic lattice (A1g-symmetry) |

| Sample | Proximate Analysis/% | |||

|---|---|---|---|---|

| Aad | Mad | FCad | Vad | |

| Coal | 8.6 | 3.8 | 52.2 | 37.1 |

| Char | 6.3 | 1.3 | 79.1 | 8.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zou, C.; She, Y.; Huang, Z.; Li, S. Analysis of Structural Heterogeneity in Low-Rank Coal and Its Pyrolyzed Char Using Multi-Point Scanning Micro-Raman Spectroscopy. Molecules 2024, 29, 2361. https://doi.org/10.3390/molecules29102361

Gao Y, Zou C, She Y, Huang Z, Li S. Analysis of Structural Heterogeneity in Low-Rank Coal and Its Pyrolyzed Char Using Multi-Point Scanning Micro-Raman Spectroscopy. Molecules. 2024; 29(10):2361. https://doi.org/10.3390/molecules29102361

Chicago/Turabian StyleGao, Yaqi, Chong Zou, Yuan She, Zhengyan Huang, and Siqi Li. 2024. "Analysis of Structural Heterogeneity in Low-Rank Coal and Its Pyrolyzed Char Using Multi-Point Scanning Micro-Raman Spectroscopy" Molecules 29, no. 10: 2361. https://doi.org/10.3390/molecules29102361

APA StyleGao, Y., Zou, C., She, Y., Huang, Z., & Li, S. (2024). Analysis of Structural Heterogeneity in Low-Rank Coal and Its Pyrolyzed Char Using Multi-Point Scanning Micro-Raman Spectroscopy. Molecules, 29(10), 2361. https://doi.org/10.3390/molecules29102361