The Preparation and Contact Drying Performance of Encapsulated Microspherical Composite Sorbents Based on Fly Ash Cenospheres

Abstract

:1. Introduction

2. Results and Discussion

2.1. Preparation and Characterization of Encapsulated Composite Sorbents

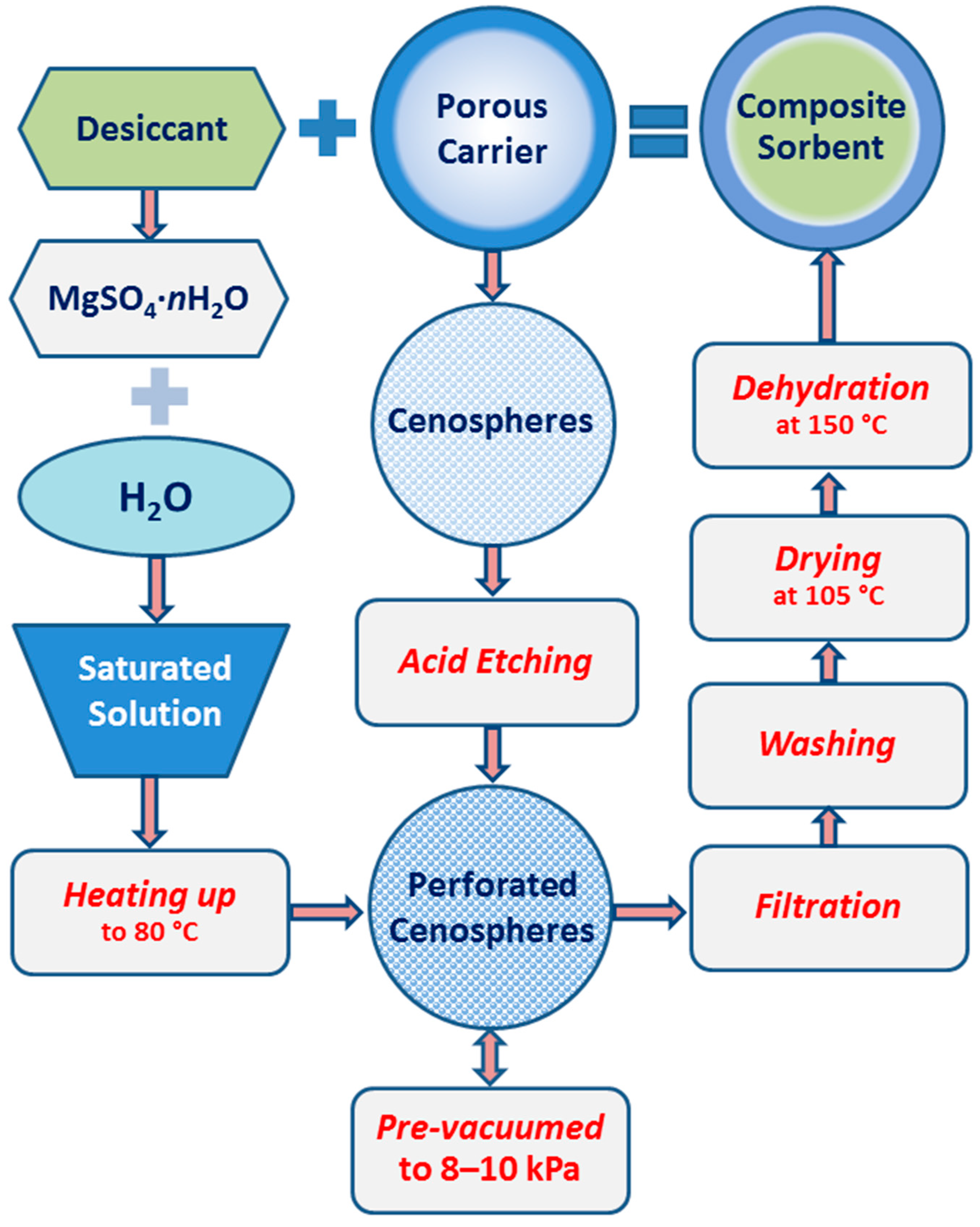

- A saturated solution of magnesium sulfate is prepared by mixing the right amount of salt MgSO4·7H2O and distilled water while heating to 80 °C.

- Microspherical porous carriers are prepared by acid etching of narrow fractions of cenospheres.

- Magnesium sulfate is localized in the internal volume of microspherical carriers by precipitation from a saturated solution.

- Before filling with a saturated solution, the cenosphere cavities are pre-vacuumed through a perforated glass–crystalline shell to a residual pressure of 8–10 kPa.

- After the cenospheres are fully filled, the excess liquid phase is filtered off and the outer surface of the globules is washed with distilled water to remove excess magnesium sulfate.

- The composite sorbent is dried at a temperature of 105 °C for 90 min and dehydrated at 150 °C to a constant weight.

2.1.1. Desiccant Characterization

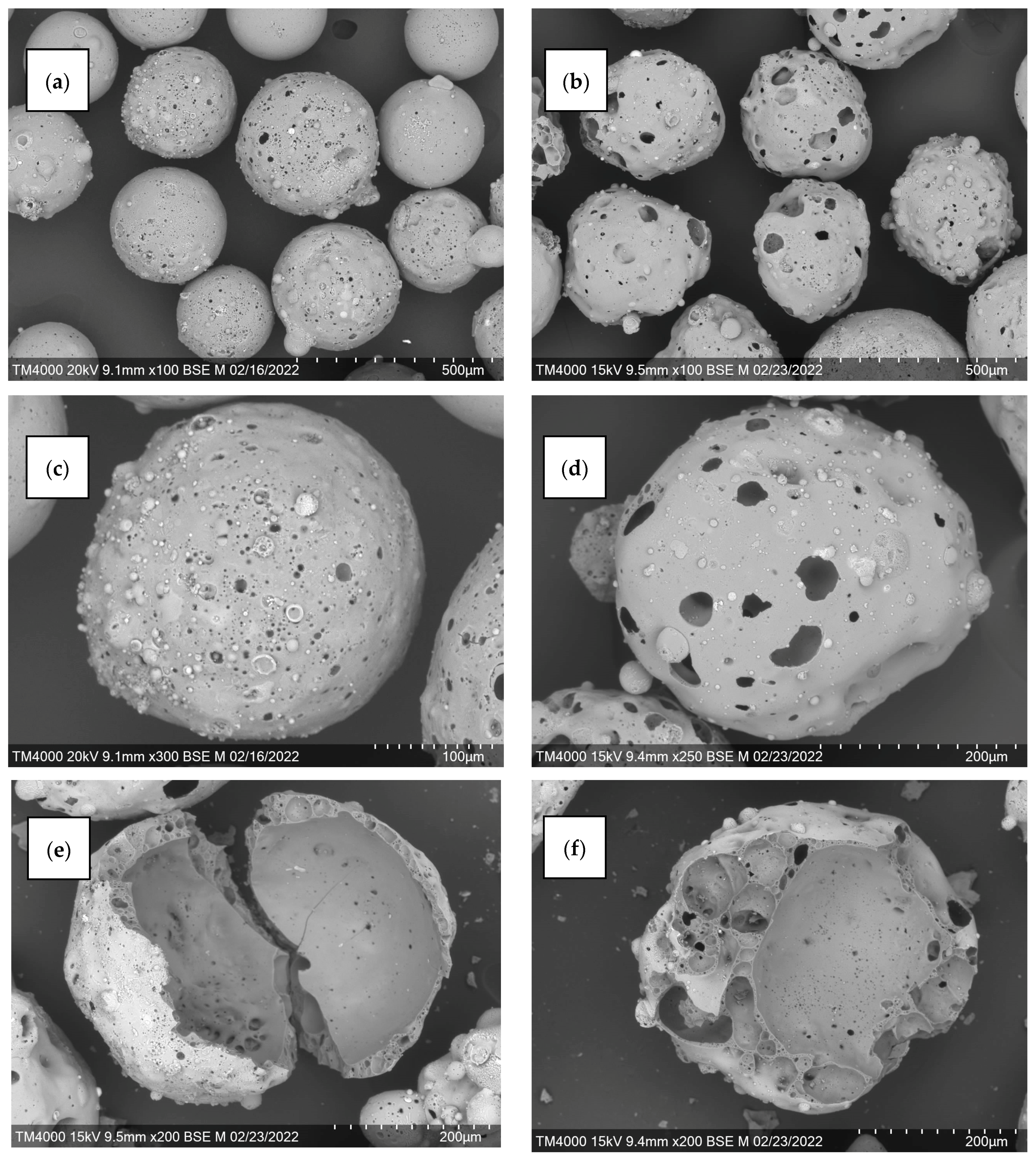

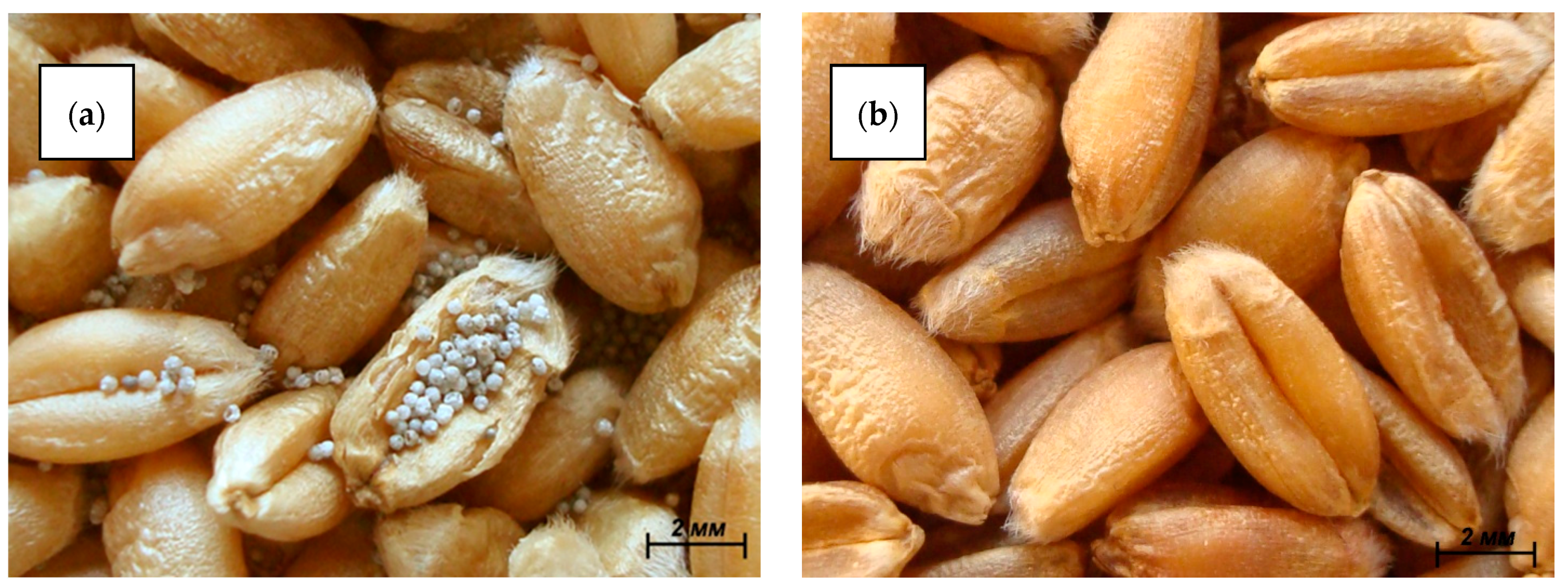

2.1.2. Preparation and Characterization of Microspherical Carriers

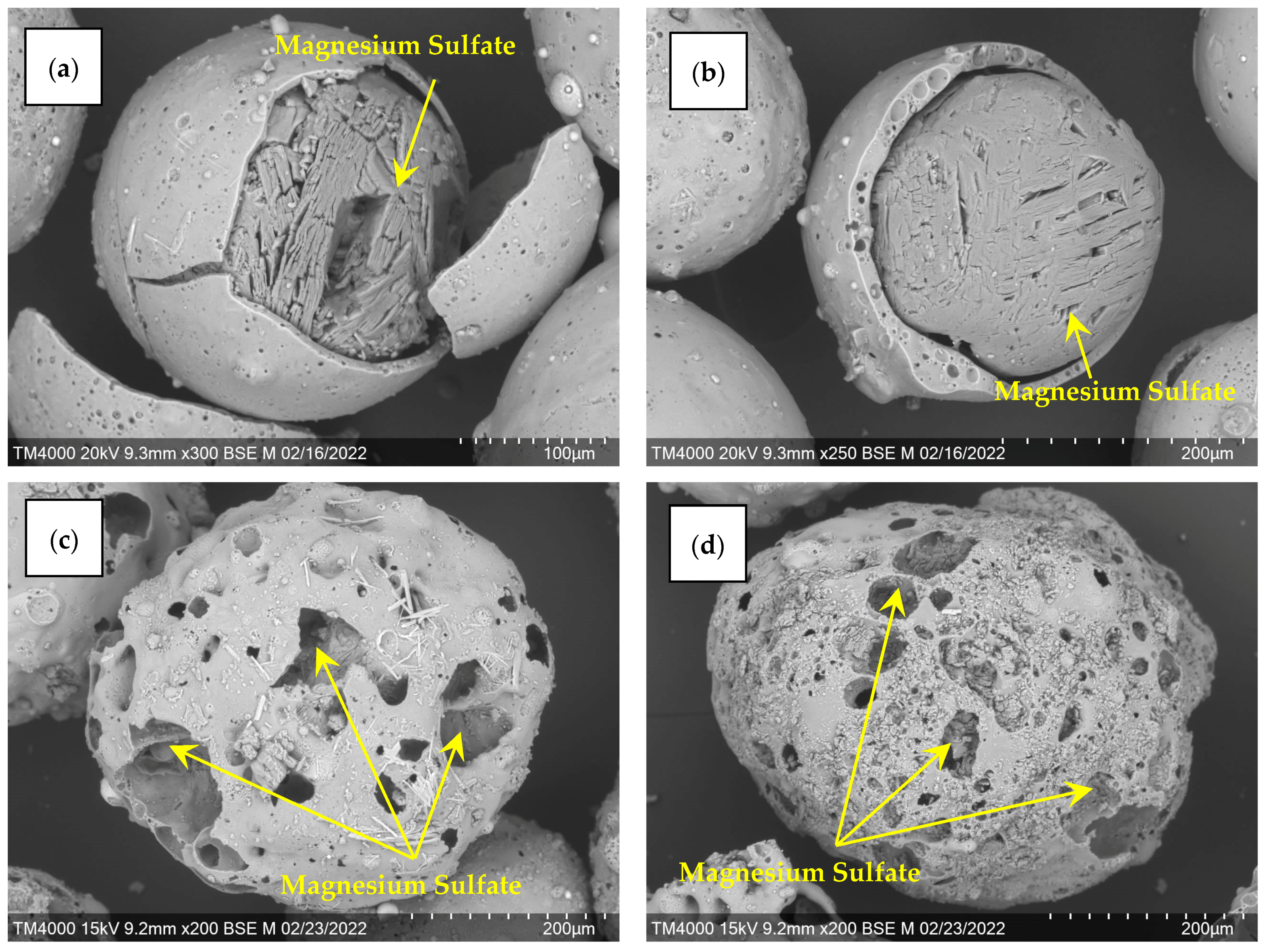

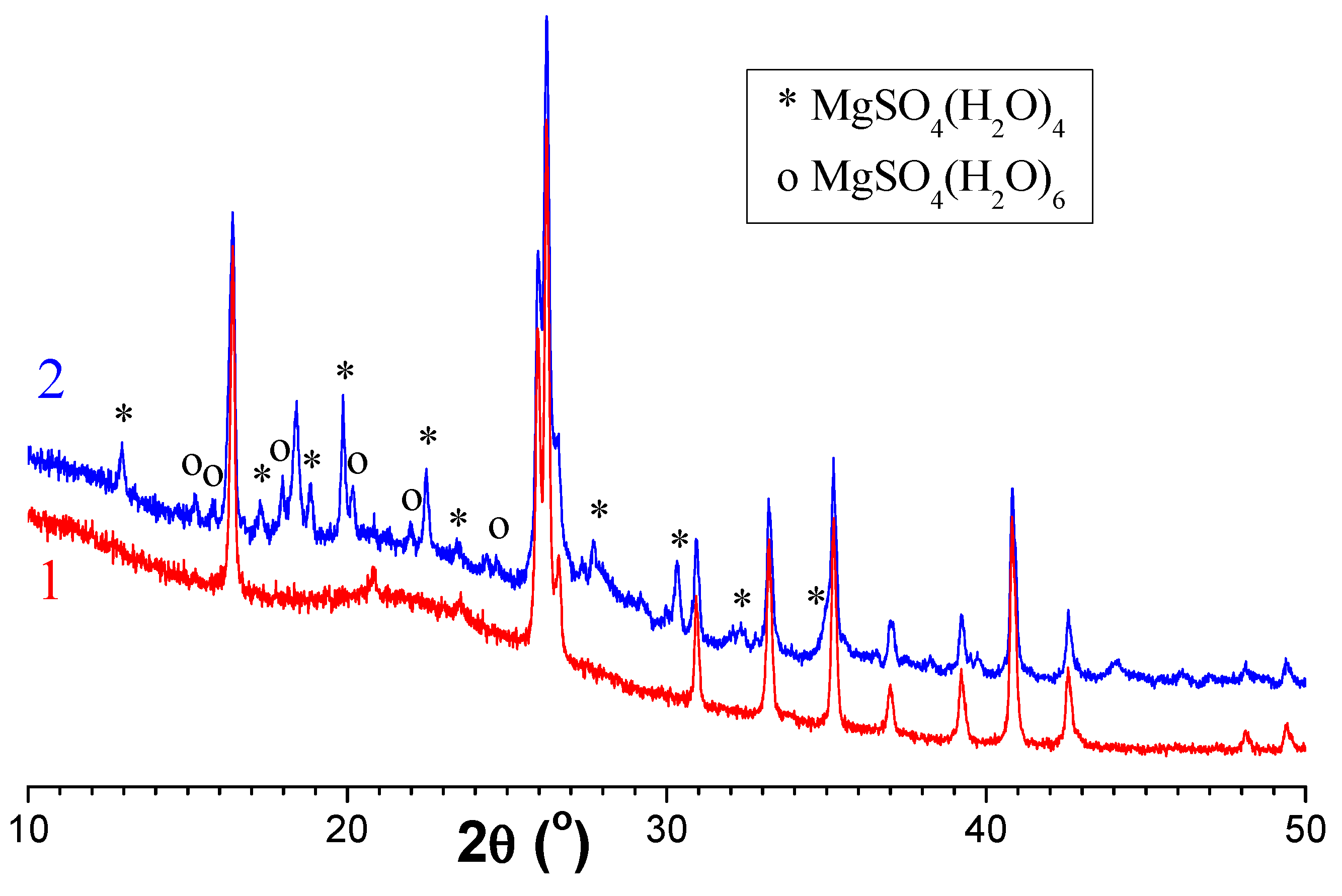

2.1.3. Synthesis Procedure and Characterization of Composite Sorbents

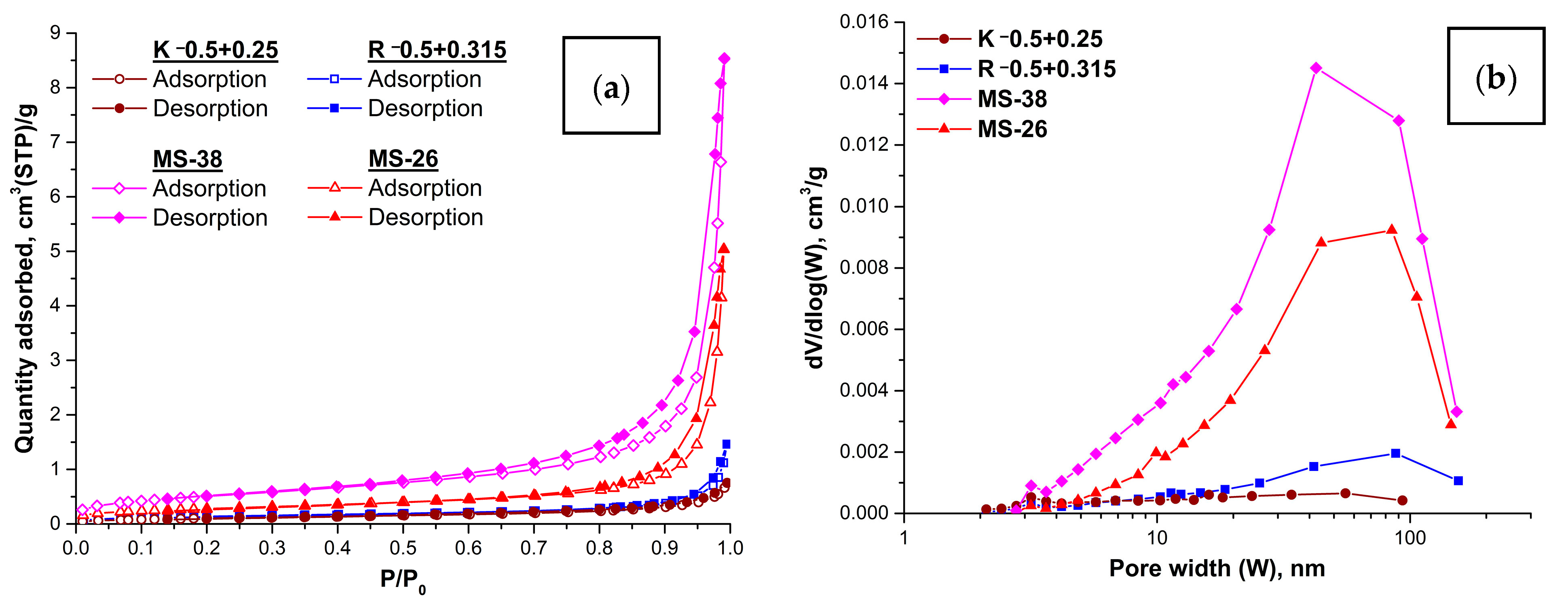

2.1.4. Texture Characteristics of Microspherical Carriers and Composite Sorbents

- The increase in specific surface area was 4.5 times for a sorbent with a ring carrier structure, approximately 2 times for a sorbent with a network carrier structure.

- The total pore volume for a sorbent with a ring carrier structure increased by an order of magnitude, and, in the case of a sorbent with a network carrier structure, a 3-fold increase was observed.

- The average pore size increased approximately 2 times due to an increase in the contribution of meso-/macropores (more than 10–14 nm), which was confirmed by the data of the BJH pore size distribution (Figure 8b), where the main contribution was made by the mesopore size 40–90 nm.

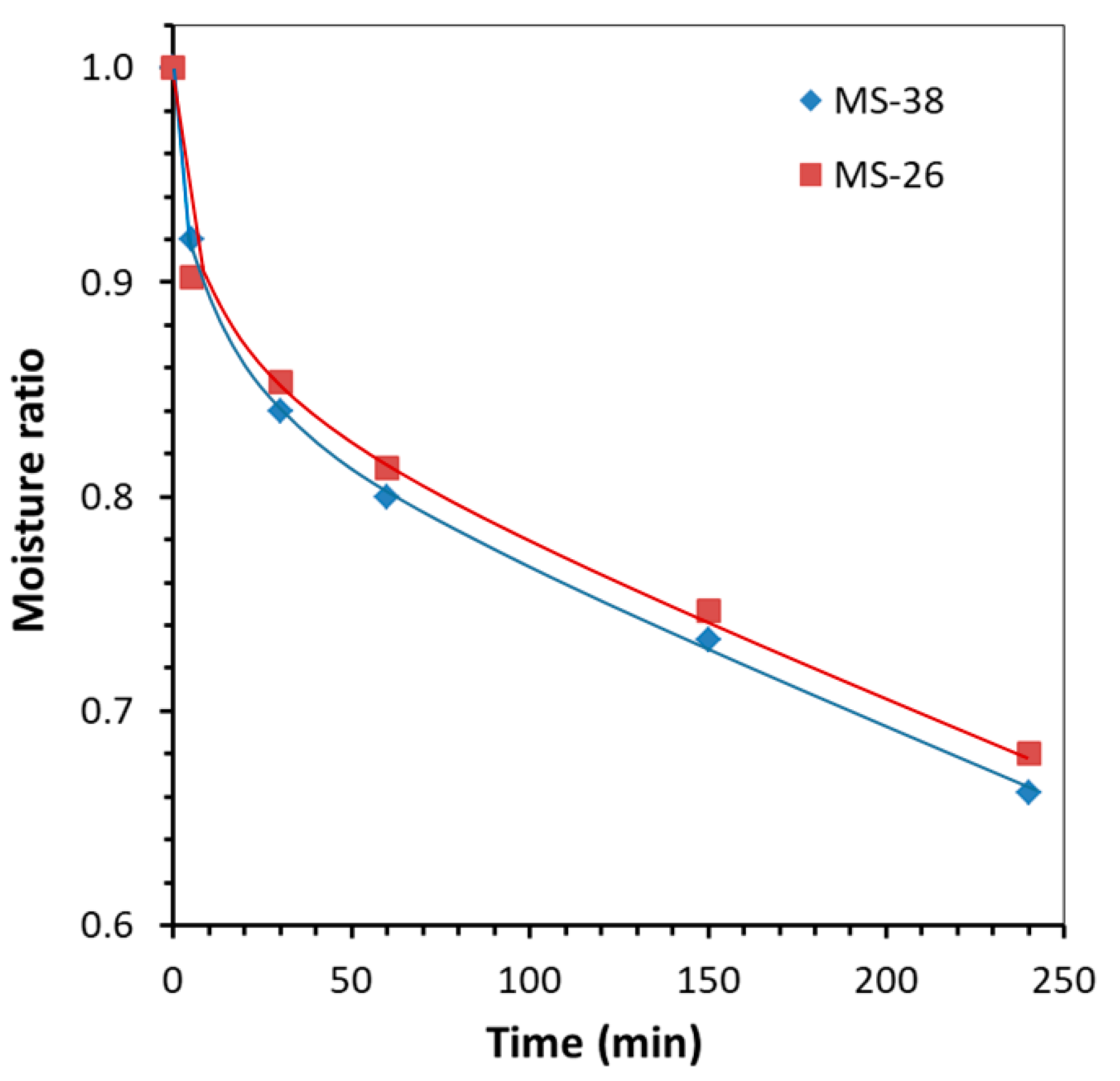

2.2. Sorption Drying of Wheat

2.3. Testing the Cyclicity and Regeneration Ability of Composite Sorbents

3. Materials and Methods

3.1. Materials

3.2. Characterization Techniques

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DallBauman, L.A.; Finn, J.E.; Dabrowski, A. (Eds.) Adsorption and Its Applications in Industry and Environmental Protection; Elsevier: Amsterdam, The Netherlands, 1999; p. 455. [Google Scholar]

- Dabrovski, A. Adsorption—From theory to practice. Adv. Colloid Interface Sci. 2001, 93, 135–224. [Google Scholar] [CrossRef]

- Schueth, F.; Sing, K.S.W.; Weitkamp, J. Handbook of Porous Solids; Willey-VCH: Weinheim, Germany, 2002. [Google Scholar]

- Walton, K.S.; Sholl, D.S. Predicting Multicomponent Adsorption: 50 Years of the Ideal Adsorbed Solution Theory. AIChE J. 2015, 61, 2757–2762. [Google Scholar] [CrossRef]

- Van Assche, T.R.C.; Remy, T.; Desmet, G.; Baron, G.V.; Denayer, J.F.M. Adsorptive separation of liquid water/acetonitrile mixtures. Sep. Purif. Technol. 2011, 82, 76–86. [Google Scholar] [CrossRef]

- Wang, R.; Wang, L.; Wu, J. Adsorption Refrigeration Technology: Theory and Application; John Wiley & Sons: Hoboken, NJ, USA; Singapore Pte. Ltd.: Singapore, 2014. [Google Scholar]

- N’Tsoukpoe, K.E.; Schmidt, T.; Rammelberg, H.U.; Watts, B.A.; Ruck, W.K.L. A systematic multi-step screening of numerous salt hydrates for low temperature thermochemical energy storage. Appl. Energy 2014, 124, 1–16. [Google Scholar] [CrossRef]

- Jarimi, H.; Aydin, D.; Yanan, Z.; Ozankaya, G.; Chen, X.; Riffat, S. Review on the recent progress of thermochemical materials and processes for solar thermal energy storage and industrial waste heat recovery. Int. J. Low-Carbon Technol. 2019, 14, 44–69. [Google Scholar] [CrossRef]

- Tu, Y.D.; Wang, R.Z.; Zhang, Y.N.; Wang, J.Y. Progress and expectation of atmospheric water harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef]

- Alonso, M.J.; Liu, P.; Mathisen, H.M.; Ge, G.; Simonson, C. Review of heat/energy recovery exchangers for use in ZEBs in cold climate countries. Build. Environ. 2015, 84, 228–237. [Google Scholar] [CrossRef]

- Gordeeva, L.; Aristov, Y. Adsorbent Coatings for Adsorption Heat Transformation: From Synthesis to Application. Energies 2022, 15, 7551. [Google Scholar] [CrossRef]

- Grekova, A.; Solovyeva, M.; Cherpakova, A.; Tokarev, M. Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning. Separations 2023, 10, 473. [Google Scholar] [CrossRef]

- Wang, D.C.; Li, Y.H.; Li, D.; Xia, Y.Z.; Zhang, J.P. A review on adsorption refrigeration technology and adsorption deterioration in physical adsorption systems. Renew. Sustain. Energy Rev. 2010, 14, 344–353. [Google Scholar] [CrossRef]

- Tatsidjodoung, P.; Le Pierrès, N.; Heintz, J.; Lagre, D.; Luo, L.; Durier, F. Experimental and numerical investigations of a zeolite 13X/water reactor for solar heat storage in buildings. Energy Convers. Manag. 2016, 108, 488–500. [Google Scholar] [CrossRef]

- Hua, Y.; Ugur, B.; Tezel, F.H. Adsorbent screening for thermal energy storage application. Sol. Energy Mater. Sol. Cells 2019, 196, 119–123. [Google Scholar] [CrossRef]

- Vodianitskaia, P.J.; Soares, J.J.; Melo, H.; Gurgel, J.M. Experimental chiller with silica gel: Adsorption kinetics analysis and performance evaluation. Energy Convers. Manag. 2017, 132, 172–179. [Google Scholar] [CrossRef]

- Vivekh, P.; Kumja, M.; Bui, D.T.; Chua, K.J. Recent developments in solid desiccant coated heat exchangers—A review. Appl. Energy 2018, 229, 778–803. [Google Scholar] [CrossRef]

- Elsayed, A.; Elsayed, E.; AL-Dadah, R.; Mahmoud, S.; Elshaer, A.; Kaialy, W. Thermal energy storage using metal–organic framework materials. Appl. Energy 2017, 186, 509–519. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Tokarev, M.M.; Cacciola, G.; Restuccia, G. Selective water sorbents for multiple application, 1. CaCl2 confined in mesopores of silica gel: Sorption properties. React. Kinet. Catal. Lett. 1996, 59, 325–333. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Restuccia, G.; Cacciola, G.; Aristov, Y.I. Selective water sorbents for multiple applications: 5. LiBr confined in mesopores of silica gel: Sorption properties. React. Kinet. Catal. Lett. 1998, 63, 81–88. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Gordeeva, L.G. “Salt in a porous matrix” adsorbents: Design of the phase composition and sorption properties. Kinet. Catal. 2009, 50, 65–72. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Aristov, Y.I. Composite sorbent of methanol “LiCl in mesoporous silica gel” for adsorption cooling: Dynamic optimization. Energy 2011, 36, 1273–1279. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Grekova, A.D.; Krieger, T.A.; Aristov, Y. Composites “binary salts in porous matrix” for adsorption heat transformation. Appl. Therm. Eng. 2013, 50, 1633–1638. [Google Scholar] [CrossRef]

- Barreneche, C.; Fernández, A.I.; Cabeza, L.F.; Cuypers, R. Thermophysical characterization and thermal cycling stability of two TCM: CaCl2 and zeolite. Appl. Energy 2015, 137, 726–730. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Wang, R.Z.; Zhao, Y.J.; Li, T.X.; Riffat, S.B.; Wajid, N.M. Development and thermochemical characterizations of vermiculite/SrBr2 composite sorbents for low-temperature heat storage. Energy 2016, 115, 120–128. [Google Scholar] [CrossRef]

- Zheng, X.; Ge, T.S.; Jiang, Y.; Wang, R.Z. Experimental study on silica gel-LiCl composite desiccants for desiccant coated heat exchanger. Int. J. Refrig. 2015, 51, 24–32. [Google Scholar] [CrossRef]

- Brancato, V.; Gordeeva, L.G.; Caprì, A.; Grekova, A.D.; Frazzica, A. Experimental comparison of innovative composite sorbents for space heating and domestic hot water storage. Crystals 2021, 11, 476. [Google Scholar] [CrossRef]

- Frazzica, A.; Brancato, V.; Caprì, A.; Cannilla, C.; Gordeeva, L.G.; Aristov, Y.I. Development of “salt in porous matrix” composites based on LiCl for sorption thermal energy storage. Energy 2020, 208, 118338. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Zhang, Y.; Su, Y.; Riffat, S. A study on vermiculite-based salt mixture composite materials for low-grade thermochemical adsorption heat storage. Energy 2023, 278, 127986. [Google Scholar] [CrossRef]

- Li, Y.; Shi, J. Hollow-structured mesoporous materials: Chemical synthesis, functionalization and applications. Adv. Mater. 2014, 26, 3176–3205. [Google Scholar] [CrossRef]

- Lou, X.W.D.; Archer, L.A.; Yang, Z. Hollow micro-/nanostructures: Synthesis and applications. Adv. Mater. 2008, 20, 3987–4019. [Google Scholar] [CrossRef]

- Yang, K.; Shi, Y.; Wu, M.; Wang, W.; Jin, Y.; Li, R.; Shahzad, M.W.; Nga, K.C.; Wang, P. Hollow spherical SiO2 micro-container encapsulation of LiCl for high-performance simultaneous heat reallocation and seawater desalination. J. Mater. Chem. A 2020, 8, 1887–1895. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. A new approach for the classification of coal fly ashes based on their origin, composition, properties, and behavior. Fuel 2007, 86, 1490–1512. [Google Scholar] [CrossRef]

- Zyrkowski, M.; Neto, R.C.; Santos, L.F.; Witkowski, K. Characterization of fly-ash cenospheres from coal-fired power plant unit. Fuel 2016, 174, 49–53. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Anshits, N.N.; Mikhailova, O.A.; Salanov, A.N.; Anshits, A.G. Chemical composition and structure of the shell of fly ash non-perforated cenospheres produced from the combustion of the Kuznetsk coal (Russia). Fuel 2010, 89, 1849–1862. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Solovyov, L.A.; Mikhailova, O.A.; Anshits, A.G. Compositions and morphology of fly ash cenospheres produced from the combustion of Kuznetsk coal. Energy Fuels 2013, 27, 5440–5448. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Vasilieva, N.G.; Mikhaylova, O.A.; Rogovenko, E.S.; Zhizhaev, A.M.; Anshits, A.G. Characterization of fly ash cenospheres produced from the combustion of Ekibastuz coal. Energy Fuels 2015, 29, 5390–5403. [Google Scholar] [CrossRef]

- Pankova, M.V.; Fomenko, E.V.; Anshits, N.N.; Vereshchagina, T.A.; Anshits, A.G. Microspherical carriers and adsorbents for the processes in corrosive media. Chem. Sustain. Dev. 2010, 18, 509–516. Available online: https://www.sibran.ru/en/journals/issue.php?ID=119885&ARTICLE_ID=130950 (accessed on 20 January 2024).

- Anshits, A.G.; Vereshchagina, T.A.; Fomenko, E.V. Method of Preparing Microspherical Sorbent for Treating Liquid Wasters to Remove Radionuclides, Nonferrous and Heavy Metal. Ions. Patent RU No. 2262383, 20 October 2005. [Google Scholar]

- Vereshchagina, T.A.; Anshits, N.N.; Sharonova, O.M.; Vasil’eva, N.G.; Vereshchagin, S.N.; Shishkina, N.N.; Fomenko, E.V.; Anshits, A.G. Polyfunctional microspherical materials for long-term disposal of liquid radioactive wastes. Glass Phys. Chem. 2008, 34, 547–558. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, A.G.; Bobko, A.A.; Khramtsov, V.V.; Salanov, A.N.; Kirilyuk, I.A.; Grigor’ev, I.A. Perforated cenosphere-supported pH-sensitive spin probes. Russ. Chem. Bull. 2008, 57, 493–498. [Google Scholar] [CrossRef]

- Jimoh, K.A.; Hashim, N.; Shamsudin, R.; Che Man, H.; Jahari, M.; Onwude, D.I. Recent Advances in the Drying Process of Grains. Food Eng. Rev. 2023, 15, 548–576. [Google Scholar] [CrossRef]

- Motevali, A.; Chayjan, R.A. Effect of Various Drying Bed on Thermodynamic Characteristics. Case Stud. Therm. Eng. 2017, 10, 399–406. [Google Scholar] [CrossRef]

- Sundareswaran, S.; Ray Choudhury, P.; Vanitha, C.; Yadava, D.K. Seed Quality: Variety Development to Planting—An Overview. In Seed Science and Technology; Dadlani, M., Yadava, D.K., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Li, Z.; Kobayashi, N.; Watanabe, F.; Hasatani, M. Sorption drying of soybean seeds with silica gel. I. Hydrodynamics of a fluidized bed dryer. Dry. Technol. 2002, 20, 223–233. [Google Scholar] [CrossRef]

- Falabella, M.C.; Suarez, K.; Viollaz, P.E. Drying kinetics of corn in contact with a solid adsorbent. J. Food Eng. 1991, 13, 273–283. [Google Scholar] [CrossRef]

- Kirov, G.; Petrova, N.; Staminirova, T.S. Matching of the water states of products and zeolite during contact adsorption drying. Dry. Technol. 2017, 35, 2015–2020. [Google Scholar] [CrossRef]

- Gordon, A.J.; Ford, R.A. The Chemist’s Companion: A Handbook of Practical Data, Techniques, and References; Wiley: New York, NY, USA, 1972; 560p. [Google Scholar]

- Marschner, H. Mineral Nutrition of Higher Plants, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands; Academic Press: London, UK, 1995; 899p. [Google Scholar]

- Grzebisz, W.; Zielewicz, W.; Przygocka-Cyna, K. Deficiencies of secondary nutrients in crop plants—A real challenge to improve nitrogen management. Agronomy 2023, 13, 66. [Google Scholar] [CrossRef]

- GOST 4523-77; Reagents. Magnesium Sulfate 7-Hydrate. Technical Conditions. Standartinform: Moscow, Russia, 2013; 12p. (In Russian)

- Powder Diffraction File Database. Available online: https://www.icdd.com/pdf-2 (accessed on 13 February 2024).

- Solovyov, L.A. Full-profile refinement by derivative difference minimization. J. Appl. Crystallogr. 2004, 37, 743–749. [Google Scholar] [CrossRef]

- Ngu, L.; Wu, H.; Zhang, D. Characterization of ash cenospheres in fly ash from Australian power stations. Energy Fuels 2007, 21, 3437–3445. [Google Scholar] [CrossRef]

- Anshits, N.N.; Vereshchagina, T.A.; Bayukov, O.A.; Salanov, A.N.; Anshits, A.G. The nature of nanoparticles of crystalline phases in cenospheres and morphology of their shells. Glass Phys. Chem. 2005, 31, 306–315. [Google Scholar] [CrossRef]

- GOST 13586.5–2015; Grain. Moisture Determination Method. Standartinform: Moscow, Russia, 2019; 12p. (In Russian)

- ISO 712:2009; Cereals and Cereal Products Determination of Moisture Content Reference Method. ISO: Geneva, Switzerland, 2009.

- GOST 12038-84; Seeds of Agricultural Crops. Germination Methods. Publishing of Standards: Moscow, Russia, 2004; 29p. (In Russian)

- ISTA. International Rules for Seed Testing (Bassersdorf: International Seed Testing Association). 2005. Available online: https://www.seedtest.org/en/publications/international-rules-seed-testing.html (accessed on 13 February 2024).

- DIN 51007:1994-06; Thermal Analysis; Differential Thermal Analysis; Principles. Deutsche Institut für Normung e.V. (DIN): Berlin, Germany, 1994.

- GOST 5382-2019; Cements and Materials for Cement Production. Chemical Analysis Methods. Publishing House of Standards: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200168999 (accessed on 20 January 2024). (In Russian)

| Parameter | Temperature Range (°C) | |||||

|---|---|---|---|---|---|---|

| 40–100 | 40–150 | 40–200 | 40–250 | 40–300 | 40–350 | |

| ∆m (wt %) | 23.04 | 37.61 | 43.19 | 45.21 | 46.54 | 46.67 |

| Water capacity (mg/g) * | 432 | 705 | 810 | 848 | 873 | 875 |

| Fraction | Physical Characteristics | Content of Cenospheres (%) | |||

|---|---|---|---|---|---|

| Bulk Density (g/cm3) | Average Diameter (μm) | Apparent Thickness of Shell (μm) | Single-Ring Structure with Porous Shell | Network Structure | |

| K −0.5 + 0.25 | 0.38 | 280 | 11 | 100 | 0 |

| R −0.5 + 0.315 | 0.40 | 383 | 19 | 21 | 79 |

| Fraction | LOI | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|

| K −0.5 + 0.25 | 0.64 | 66.58 | 20.54 | 3.02 | 2.30 | 2.30 | 1.35 | 3.25 |

| R −0.5 + 0.315 | 0.80 | 54.82 | 39.80 | 1.10 | 1.54 | 1.09 | 0.30 | 0.21 |

| Fraction | Glass Phase | Mullite | Quartz | Calcite |

|---|---|---|---|---|

| K −0.5 + 0.25 | 92.7 | 1.2 | 5.5 | 0.6 |

| R −0.5 + 0.315 | 64.1 | 34.0 | 1.7 | 0.2 |

| Fraction | SBET (m2/g) | Vtot (cm3/g) | Average Pore Size (nm) |

|---|---|---|---|

| K −0.5 + 0.25 | 0.41 | 0.001 | 10.0 |

| R −0.5 + 0.315 | 0.50 | 0.002 | 14.0 |

| MS-38 | 1.87 | 0.010 | 21.9 |

| MS-26 | 1.01 | 0.006 | 25.4 |

| Sample | Desiccant/Grain Mass Ratio | Time (min) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 5 | 30 | 60 | 150 | 240 | ||

| MS-38 | 1:5 | 22.5 | 20.7 | 18.9 | 18.0 | 16.5 | 14.9 |

| MS-26 | 1:4 | 22.5 | 20.3 | 19.2 | 18.3 | 16.8 | 15.3 |

| MgSO4 −2.0 + 1.0 mm | 1:2 | 21.4 | 20.6 | 19.2 | 18.5 | 15.8 | 14.9 |

| MgSO4 −0.2 mm | 1:2 | 22.6 | 21.0 | 19.5 | 18.4 | 16.0 | 14.4 |

| Sample | Desiccant/Grain Mass Ratio | Time (min) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 5 | 30 | 60 | 150 | 240 | ||

| MS-38 (2nd cycle) | 1:5 | 22.5 | 20.6 | 18.8 | 18.2 | 16.6 | 15.1 |

| MS-26 (2nd cycle) | 1:4 | 22.5 | 20.4 | 19.4 | 18.0 | 16.8 | 15.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fomenko, E.V.; Anshits, N.N.; Solovyov, L.A.; Shabanov, V.F.; Anshits, A.G. The Preparation and Contact Drying Performance of Encapsulated Microspherical Composite Sorbents Based on Fly Ash Cenospheres. Molecules 2024, 29, 2391. https://doi.org/10.3390/molecules29102391

Fomenko EV, Anshits NN, Solovyov LA, Shabanov VF, Anshits AG. The Preparation and Contact Drying Performance of Encapsulated Microspherical Composite Sorbents Based on Fly Ash Cenospheres. Molecules. 2024; 29(10):2391. https://doi.org/10.3390/molecules29102391

Chicago/Turabian StyleFomenko, Elena V., Natalia N. Anshits, Leonid A. Solovyov, Vasily F. Shabanov, and Alexander G. Anshits. 2024. "The Preparation and Contact Drying Performance of Encapsulated Microspherical Composite Sorbents Based on Fly Ash Cenospheres" Molecules 29, no. 10: 2391. https://doi.org/10.3390/molecules29102391

APA StyleFomenko, E. V., Anshits, N. N., Solovyov, L. A., Shabanov, V. F., & Anshits, A. G. (2024). The Preparation and Contact Drying Performance of Encapsulated Microspherical Composite Sorbents Based on Fly Ash Cenospheres. Molecules, 29(10), 2391. https://doi.org/10.3390/molecules29102391