Abstract

The pomegranate processing industry generates worldwide enormous amounts of by-products, such as pomegranate peels (PPs), which constitute a rich source of phenolic compounds. In this view, PPs could be exploited as a sustainable source of ellagic acid, which is a compound that possesses various biological actions. The present study aimed at the liberation of ellagic acid from its bound forms via ultrasound-assisted alkaline hydrolysis, which was optimized using response surface methodology. The effects of duration of sonication, solvent:solid ratio, and NaOH concentration on total phenol content (TPC), antioxidant activity, and punicalagin and ellagic acid content were investigated. Using the optimum hydrolysis conditions (i.e., 32 min, 1:48 v/w, 1.5 mol/L NaOH), the experimental responses were found to be TCP: 4230 ± 190 mg GAE/100 g dry PPs; AABTS: 32,398 ± 1817 µmol Trolox/100 g dry PPs; ACUPRAC: 29,816 ± 1955 µmol Trolox/100 g dry PPs; 59 ± 3 mg punicalagin/100 g dry PPs; and 1457 ± 71 mg ellagic acid/100 g dry PPs. LC-QTOF-MS and GC-MS analysis of the obtained PP extract revealed the presence of various phenolic compounds (e.g., ellagic acid), organic acids (e.g., citric acid), sugars (e.g., fructose) and amino acids (e.g., glycine). The proposed methodology could be of use for food, pharmaceutical, and cosmetics applications, thus reinforcing local economies.

1. Introduction

Pomegranates (Punica granatum L.) are usually consumed either fresh or in the form of juices, jams, jellies, liqueurs, etc. Considering that the global production of pomegranates was estimated to be ~3.5 million tonnes in 2017 [1], the pomegranate processing industry generates annually enormous amounts of by-products and wastes that are mainly composed of seeds and peels. The latter ones account for about 40% of the whole fruit weight, and their disposal constitutes a major issue for the pomegranate processing industry worldwide. Till today, pomegranate peels (PPs) are either discarded in landfill sites, used as animal feed [2], or used for energy production (e.g., bioethanol) [3,4,5].

Pomegranate peels, apart from carbohydrates, crude fibers, crude protein, and aromatic amino acids, contain high amounts of secondary metabolites, including flavonols, anthocyanins, phenolic acids, gallotannins, and ellagitannins [6]. PPs have been reported to contain higher amounts of phenolic compounds compared to other agroindustrial by-products (e.g., apple peels, black carrot peels, grape pomace, etc.). Even though the majority of phenolic compounds of PPs are found in free soluble form, significant amounts are also found in bound forms [7]. In particular, ellagitannins, often in the form of hexahydroxydiphenic acid (HHDP)-galloyl-hexoside, i.e., punicalagins, are one of the major phenolic compounds present in PPs. Upon alkaline, acidic, or enzymatic hydrolysis, ellagitannins release the HHDP group, which after spontaneous lactonization results in the formation of ellagic acid [8]. The latter one is a dimeric gallic acid derivative of high commercial value considering that it has been reported to possess various biological actions such as antioxidant, anti-inflammatory, antiatherosclerotic, antiviral, and antiobesity, as well as cardio-, gastro-, and neuroprotective properties [9]. It has been reported that ellagic acid can be also released from ellagitannins after their hydrolysis in the small intestine. Even if free ellagic acid is considered to be poorly absorbed, it can be converted by gut microbiota to bioavailable metabolites, namely urolithins, that exhibit chemopreventive, antiatherosclerotic, and anti-inflammatory action [10]. Apart from PPs, which constitute one of their richest source, ellagic acid is also found in strawberries, raspberries, blackberries, and other types of berries, as well as certain nuts (e.g., walnuts, pistachio, cashew) [11].

Until now, the focus has been on extracting free phenolic compounds from PPs using a variety of solvents, such as water, ethanol, and methanol, as well as their mixtures (e.g., [12,13]). However, to the best of our knowledge, extremely limited are the data regarding the recovery of free and bound phenolic compounds, including ellagic acid from PPs [14]. Until now, hydrolysis has been performed using time-consuming conventional techniques that require substantial amounts of solvents and have a low recovery yield. For example, this is illustrated in the work of Liu et al. [15], who treated PPs with 0.5 mol/L sodium hydroxide (NaOH) for 3 h upon stirring. In the same frame, Dadwal et al. [16] performed alkaline hydrolysis for the extraction of bound phenolics from PPs using 4 mol/L NaOH for 4 h with the aid of continuous shaking at room temperature. Sun et al. [17] carried out acidic hydrolysis of PPs with 6 mol/L hydrochloric acid (HCl) for 2 h using a water bath at 45 °C. Towards bioethanol production, Chaudhary et al. [18] carried out alkaline hydrolysis of PPs using 0.5% KOH at 80 °C for 90 min, and Saleem et al. [19] employed acidic hydrolysis of PPs with 5% acid concentration at 100 °C for 30 min, without mentioning the means of extractions. Ultrasound-assisted extraction was employed for the recovery of ellagic acid by Μuniz-Marquez et al. [8]; however, these authors used ethanol as the extraction solvent and concluded that the obtained yield was low, since the release of ellagic acid was attributed only to cell rupture due to the effect of ultrasounds and not in the hydrolysis of ellagitannins. Moreover, hydrolysis of the ellagitannins of pomegranate wastes towards the recovery of ellagic acid has been also carried out using solid state fermentation with Saccharomyces cerevisiae and Aspergillus niger [20].

In this context, the objective of the current work was to systematically investigate the effect of ultrasound-assisted alkaline hydrolysis conditions (i.e., duration, solvent:solid ratio, NaOH concentration) on the total phenol content (TPC), the antioxidant activity (DPPH●, ABTS●+, CUPRAC assays), and on the recovery of the major phenolic compounds, i.e., punicalagin and ellagic acid, of the obtained extracts derived from PPs originating from a Greek pomegranate processing industry. The ultrasound-assisted alkaline hydrolysis conditions were optimized using response surface methodology (RSM). The degree of hydrolysis of punicalagin and the concomitant liberation of ellagic acid was monitored by HPLC-DAD. Moreover, the PP extract prepared under the optimum hydrolysis conditions was further characterized with the aid of liquid chromatography–quadrupole time-of-flight mass spectrometry (LC-QTOF/MS) and gas chromatography–mass spectrometry (GC-MS). The proposed methodology could pave the way for PP exploitation as a sustainable source of ellagic acid, as well as of other valuable phenolic compounds that could be used for novel food, pharmaceutical, and cosmeceutical applications.

2. Results and Discussion

2.1. Extraction of Free Phenolics from Pomegranate Peels

Initially, the free phenolic compounds of PPs were extracted with a mixture of ethanol:water 50:50 (v/v) that was found to be the most effective solvent system in our recent study [12]. The TPC, ADPPH, AABTS, and ACUPRAC, as well as punicalagin (sum of α and β anomeric forms) and ellagic acid content in the free fraction were found to be 10,159 ± 395 mg GAE/100 g dry PPs, 39,205 ± 237 µmol Trolox/100 g dry PPs, 1593 ± 139 µmol Trolox/100 g dry PPs, 84,419 ± 1069 µmol Trolox/100 g dry PPs, 1197 ± 79 mg punicalagin/100 g dry PPs, and 515 ± 19 mg ellagic acid/100 g dry PPs, respectively. The punicalagin content found in the present study is similar to that reported by Gullon et al. [21] (i.e., 1667 mg/100 dry weight), who extracted phenolics from PPs with the aid of ultrasounds using 50% aqueous ethanol as well. Kaderides et al. [13] employed microwave-assisted extraction and reported a punicalagin content of 14,364 mg/100 g dry weight. Even higher values (i.e., 24,547 mg/100 g dry weight) have been reported by Kharchoufi et al. [22], who used water as the extraction solvent upon stirring. Regarding the ellagic acid content found in the present study, it was found to be almost half of that of punicalagin. An ellagic acid content of 39–304 mg/100 g dry weight has been reported by Yan et al. [23], who carried out the extraction using a 80% methanol–water solution with the aid of a Soxhlet apparatus at 80 °C. Sabraoui et al. [24] examined different varieties of pomegranates grown in Morocco and reported an ellagic acid content of 160–3500 mg/100 g dry weight after extracting PPs with methanol using magnetic stirring at room temperature for 24 h. Such quantitative variations could be associated with the different extraction means and solvents, as well as with differences in maturity stage and the geographical origin of the fruits [22].

2.2. Extraction of Bound Phenolics from Pomegranate Peels

2.2.1. Model Fitting for TPC, ADPPH, AABTS, ACUPRAC, Punicalagin and Ellagic Acid Content

The dried solid residue that remained after the extraction of free phenolics was then used for the liberation of bound phenolic compounds from PPs with the aid of ultrasound-assisted alkaline hydrolysis. RSM was applied to investigate the effects of the duration of ultrasound-assisted alkaline hydrolysis (X1), solvent:solid ratio (X2), and NaOH concentration (X3) on the TPC, ADPPH, AABTS, and ACUPRAC, as well as on punicalagin and ellagic acid content. In the present study, ultrasounds were selected as the means of extraction in order to avoid high temperatures that occur during microwave-assisted extraction, as has been reported by Kaderides et al. [25]. The experimental responses (Table 1) for all the examined variables were analysed by ANOVA (Table 2) in order to test the validity of each model. The experimental data in every case were fitted to the second-order polynomial model. The DPPH● scavenging activity model showed a nonsignificant (p < 0.05) lack of fit. On the other hand, the models for TPC, AABTS, and ACUPRAC, as well as punicalagin and ellagic acid content, displayed a statistically significant regression (p < 0.05) and R2 values ranging from 0.858 to 0.996, thus indicating that they could explain >85% of the variability of the responses. The second-order polynomial equations (Equations (1)–(5)) obtained for the five responses (Models A–E) are shown in Table 3.

Table 1.

Experimental design for three-factor five-level CCD and experimental values for the responses of response surface methodology.

Table 2.

Analysis of variance of TPC, ADPPH, AABTS, ACUPRAC, punicalagin, and ellagic acid content values.

Table 3.

Polynomial equations for TPC, AABTS, ACUPRAC, punicalagin and ellagic acid content responses.

2.2.2. Major Effects of Ultrasound-Assisted Alkaline Hydrolysis Conditions

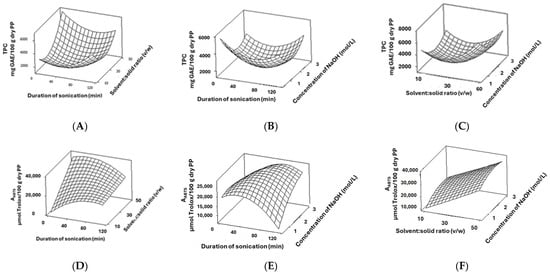

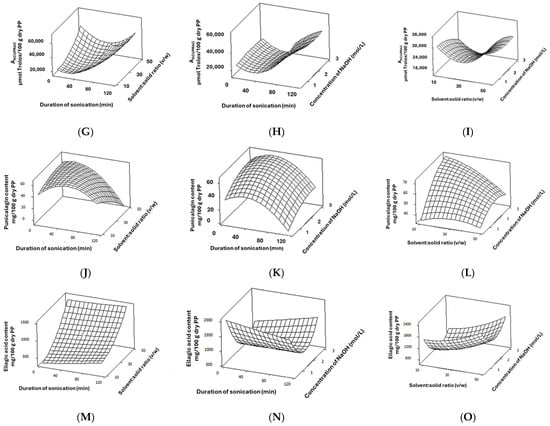

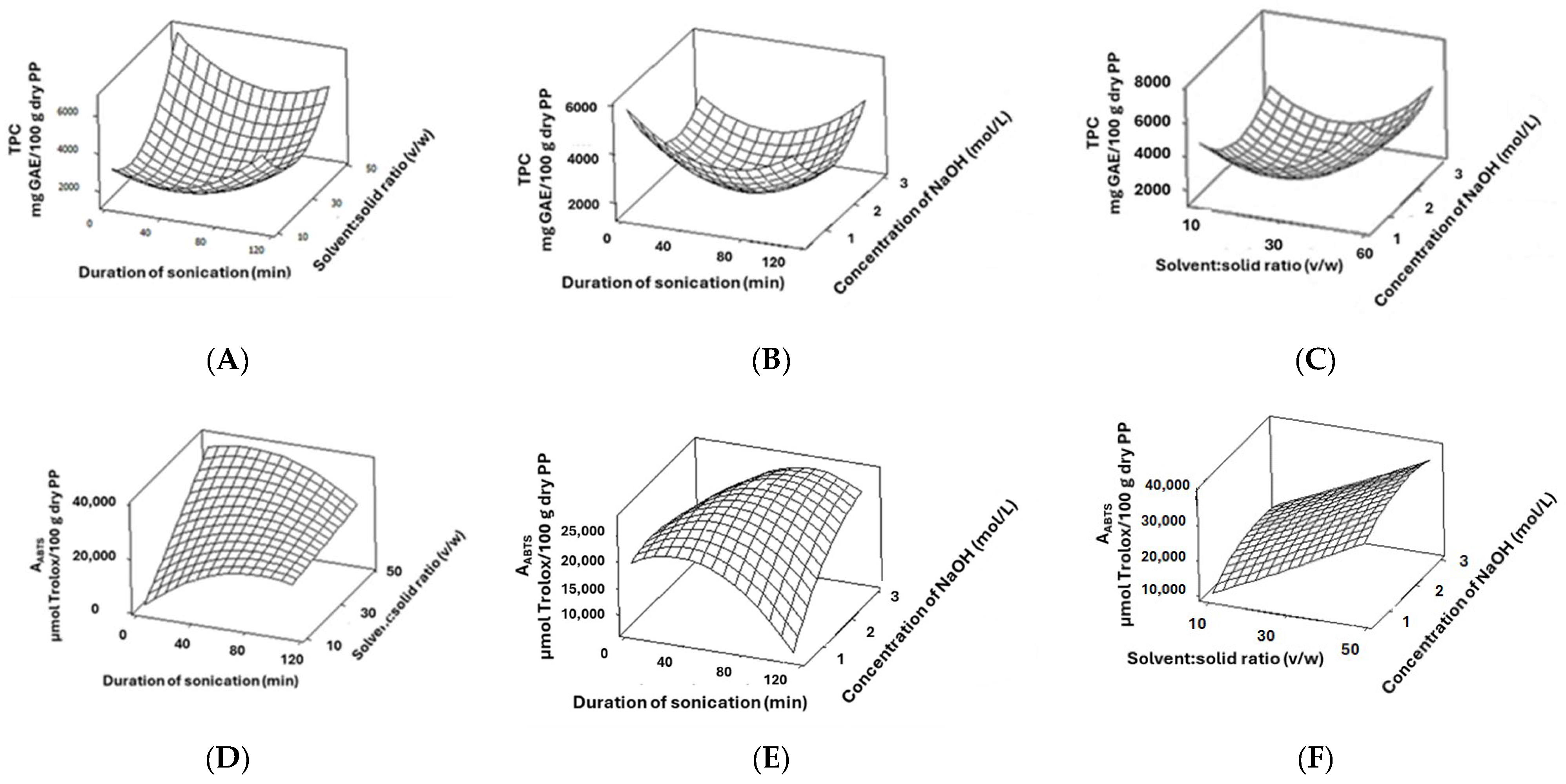

Effects on Total Phenol Content

The TPC of the obtained PP extracts was found to range from 1364 to 5976 ± 173 mg GAE/100 g dry PPs (Table 1). The analysis of variance for the TPC values (Model A) showed that both linear and quadratic X2, as well as the quadratic X1 and X3, exhibited a significant and positive effect, whereas the respective linear terms were statistically nonsignificant. Figure 1A–C show the generated three-dimensional surface plots for each pair of factors, thereby keeping the third one constant at its middle level (Table 1). As it is illustrated, the TPC reached its highest absolute values for short sonication duration at a high solvent:solid ratio and at the middle levels of NaOH concentration.

Effects on In Vitro Antioxidant Activity

The antioxidant activity values of the PP extracts using the DPPH● assay varied from 8810 to 69,832 ± 390 μmol Trolox/100 g dry PPs. A statistically insignificant regression model was found for DPPH● scavenging activity. The lack of a statistically significant model for DPPH● has been reported also by Kyriakoudi et al. [26], who optimized the microwave-assisted alkaline hydrolysis of rice hulls, as well as by Pyrka et al. [27], who optimized olive leaves’ thin layer using intermittent near-infrared drying. These authors attributed this finding to the synergistic and antagonistic phenomena of phenols in extracts (Olszowy-Tomczyk, 2020) [28] that minimize differences in the estimated antioxidant activity, despite variances in their phenolic content. On the contrary, the model for ABTS●+ scavenging activity described 85.77% of the variability of the responses (Table 3). The linear X2 and quadratic X1 were found to have significant effects. As it is shown in the respective surface plots in Figure 1D–F, a maximum ABTS●+ activity could be obtained using a high solvent:solid ratio and low sonication duration when keeping the NaOH concentration at its middle level. A statistically significant model was also found for the CUPRAC assay, which is also based on an electron transfer mechanism, like Folin–Ciocalteau, thus indicating that ultrasound-assisted alkaline hydrolysis affects the redox potential of PP extracts. A similar correlation between the results obtained with Folin–Ciocalteau and CUPRAC assays has been also observed by Pyrka et al. [27]; these authors suggested that drying affects the redox status of olive leaves. The duration of ultrasound-assisted alkaline hydrolysis (X1) showed significant linear and quadratic effects on the CUPRAC response. In Figure 1G–I, a trend toward higher ACUPRAC values can be noted upon increasing the solvent:solid ratio up to high levels.

Effects on Punicalagin and Ellagic Acid Content

A statistically significant regression model was also found for punicalagin. The model for punicalagin could describe 80.50% of the variability of the responses (Table 3). The linear terms of duration of the sonication, solid:solvent ratio and NaOH concentration (X1, X2, and X3), as well as the quadratic terms of the duration of sonication and NaOH concentration, were found to have a significant effect on the punicalagin content. According to the surface plots shown in Figure 1J–L, the punicalagin content values were found to decrease upon increased duration of sonication and low NaOH concentration, which was probably due to its hydrolysis. Moreover, the model for ellagic acid content could describe 99.58% of the variability of the responses (Table 3), with the linear and quadratic effects of X1 having a significant negative and positive effect, respectively. Moreover, the linear and quadratic effects of X2, as well as the quadratic effect of X3, had a significant positive effect, whereas the X1–X2 interaction had a significant negative effect. As shown in the corresponding surface plots in Figure 1M–O, the maximum ellagic acid content values could be obtained when a short duration of sonication and a low NaOH concentration were used.

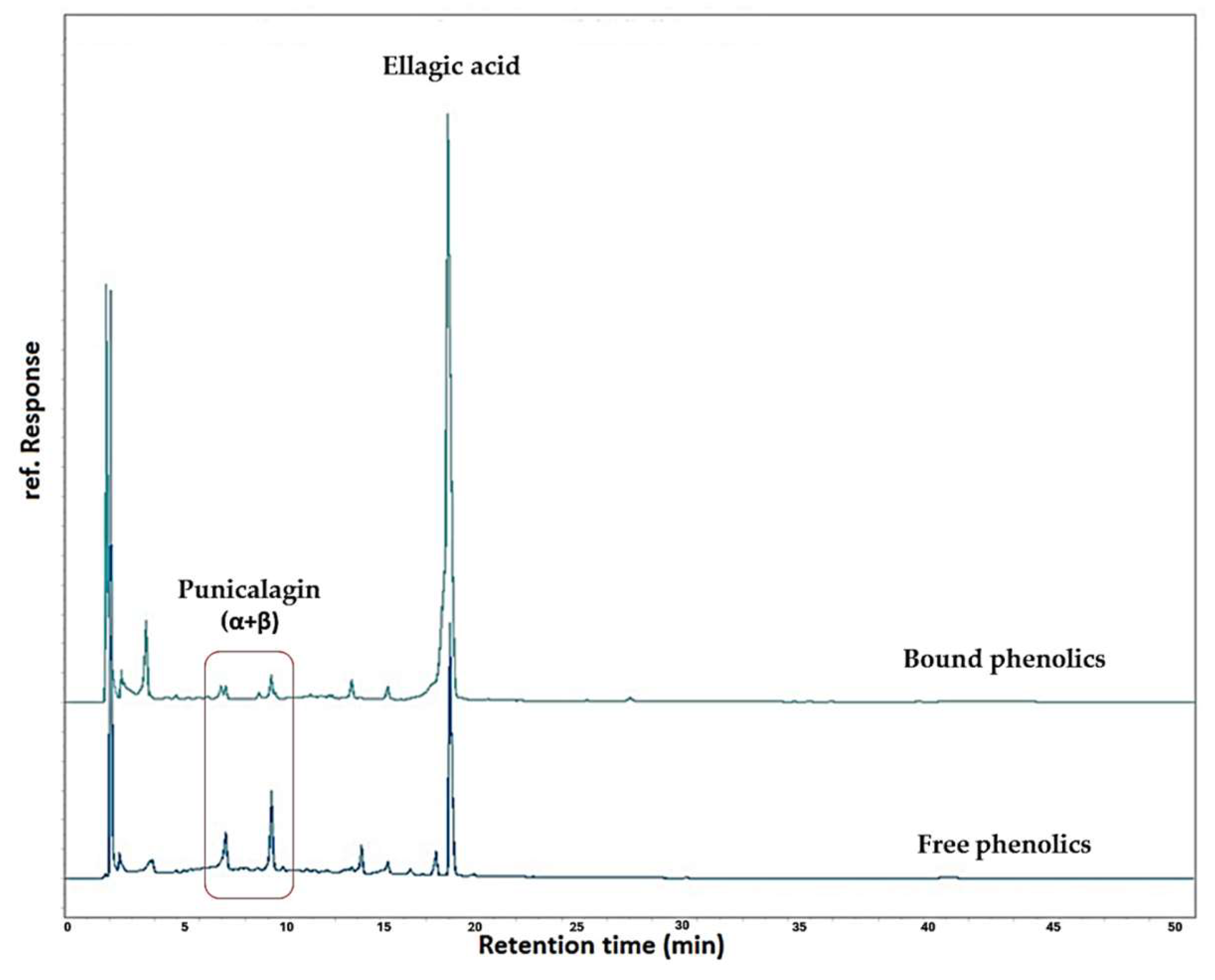

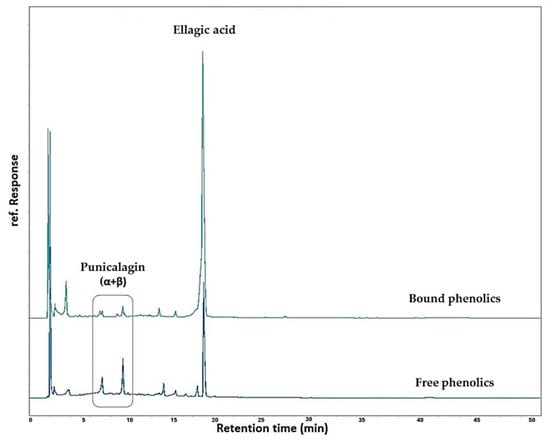

As can be seen in Table 2, the levels of punicalagin (sum of α and β anomeric forms) were found to range from 22 to 109 mg/100 dry PP. As can be observed, these values are much lower than that reported for the punicalagin content in the free fraction prior to alkaline hydrolysis. On the contrary, the ellagic acid content was found to increase after hydrolysis. In particular, the ellagic acid content after hydrolysis was found to range from 727 to 1828 mg/100 g dry PPs compared to the 515 ± 19 mg/100 g dry PPs that was in the free fraction. A RP-HPLC-DAD chromatogram showing the punicalagin and ellagic acid before and after ultrasound-assisted alkaline hydrolysis is given in Figure 2.

Figure 2.

RP-HPLC-DAD chromatograms at 280 nm of PP extracts before (free phenolics) and after (bound phenolics) ultrasound-assisted alkaline hydrolysis.

Figure 1.

Surface plots for total phenol content (A–C), ABTS●+ scavenging activity (D–F), and cupric ion reducing antioxidant capacity (G–I), as well as punicalagin (J–L) and ellagic acid content (M–O) values affected by duration of sonication, solid:solvent ratio, and NaOH concentration. In all cases, the third factor was kept constant at its middle level.

Figure 1.

Surface plots for total phenol content (A–C), ABTS●+ scavenging activity (D–F), and cupric ion reducing antioxidant capacity (G–I), as well as punicalagin (J–L) and ellagic acid content (M–O) values affected by duration of sonication, solid:solvent ratio, and NaOH concentration. In all cases, the third factor was kept constant at its middle level.

2.2.3. Multiple Response Optimisation for Ultrasound-Assisted Alkaline Hydrolysis Conditions

The independent variables, namely the duration of ultrasound-assisted alkaline hydrolysis, the solvent:solid ratio, and the NaOH concentration, that were determined to be optimum for the responses TPC, AABTS, and ACUPRAC, as well as punicalagin and ellagic acid content, using the RSM multiple response optimization approach are shown in Table 4. As can be seen, the predicted values fit well with the experimental ones of the respective responses (the mean % difference between the predicted and the experimental values was 8.6%, which is considered satisfactory).

Table 4.

Optimum values of the duration of ultrasound-assisted alkaline hydrolysis, solvent:solid ratio, and NaOH concentration, as well as predicted and experimental response values.

2.3. Target and Nontarget LC-QTOF-MS Analysis

The targeted LC-QTOF-MS analysis revealed the presence of a variety of bound phenolic compounds present in the examined PP extract prepared under the optimum hydrolysis conditions. More specifically, as it is shown in Table 5, out of the twenty examined target compounds, eight phenolic compounds were determined in the examined PP extract. In particular, from the initial target list, the flavonoids apigenin, catechin, kaempferol, luteolin, quercetin, rutin, and taxifolin, as well as the phenolic acid, namely protocatechuic acid, were identified and quantified based on appropriate standard calibration curves, (i.e., apigenin: y = 2 × 107x + 8 × 106, catechin: y = 9 × 106x + 994,352, kaempferol: y = 2 × 107x + 5 × 106, luteolin: y = 3 × 107x + 7 × 106, protocatechuic acid: y = 2 × 106x−31,489, quercetin: y = 2 × 107x + 2 × 106, rutin: y = 9 × 106x − 703,039, and taxifolin: y = 8 × 106x + 706,635) that were linear over the range 0.01–5 mg/L (R2 > 0.999). The concentrations of these compounds in the examined PP extract were found to range from 0.05 µg/mL for quercetin and taxifolin to 1.04 µg/mL for protocatechuic acid.

Table 5.

Identified phenolic compounds in the PP extract prepared under the optimum hydrolysis conditions with the aid of LC-QTOF-MS.

Apart from the above-mentioned phenolic compounds, the nontarget analysis of the prepared PP extract revealed the present of other phenolic compounds belonging to the classes of hydrolysable tannins and phenolic acids. In particular, ellagic acid, that was liberated during the ultrasound-assisted alkaline hydrolysis from ellagitannins such as punicalagin, was tentatively identified in the samples using the SCIEX Natural Products Library and Formula Finder algorithm, with a score above 50.0. Similarly, caffeic acid, ferulic acid, and p-coumaric acid were also tentatively identified. The chromatograms and MS/MS fragmentation patterns of the target compounds are given in Table S1 of the Supplementary Materials. Many compounds have been identified in PP extracts from various researchers. For example, Ambigaipalan et al. [29] investigated the phenolic compounds of pomegranate by-products of fruits grown in California, and they identified gallic acid as the major phenolic acid in addition to p-coumaric acid, ellagic acid, kaempferol 3-O-glucoside, and procyanidin dimers in insoluble-bound phenolic samples that were subjected to alkaline hydrolysis by UPLC-DAD-ESI-MS. Dadwal et al. [16] identified and quantified punicalagin and catechin-bound phenolics in fresh PPs. Moreover, gallic acid, catechin, ellagic acid, and rutin, along with luteolin-7-O-glucoside, punicalagin, quercetrin-3-O-glucoside, and apigenin-7-glucoside, have been identified in PPs derived from cultivars from China with the aid of UHPLC-QTOF-MS and UPLC-QQQ-MS [30]. The presence of ellagic acid, p-coumaric acid, and catechin has been also confirmed in PP extracts that were prepared using thermal and nonthermal extraction methods by Man et al. [14] using UHPLC-QTOF-MS. Apart from these compounds, the authors also identified gallic acid, epicatechin, gallocatechin, epigallocatechin, and punicalin, as well as α-punicalagin and β-punicalagin.

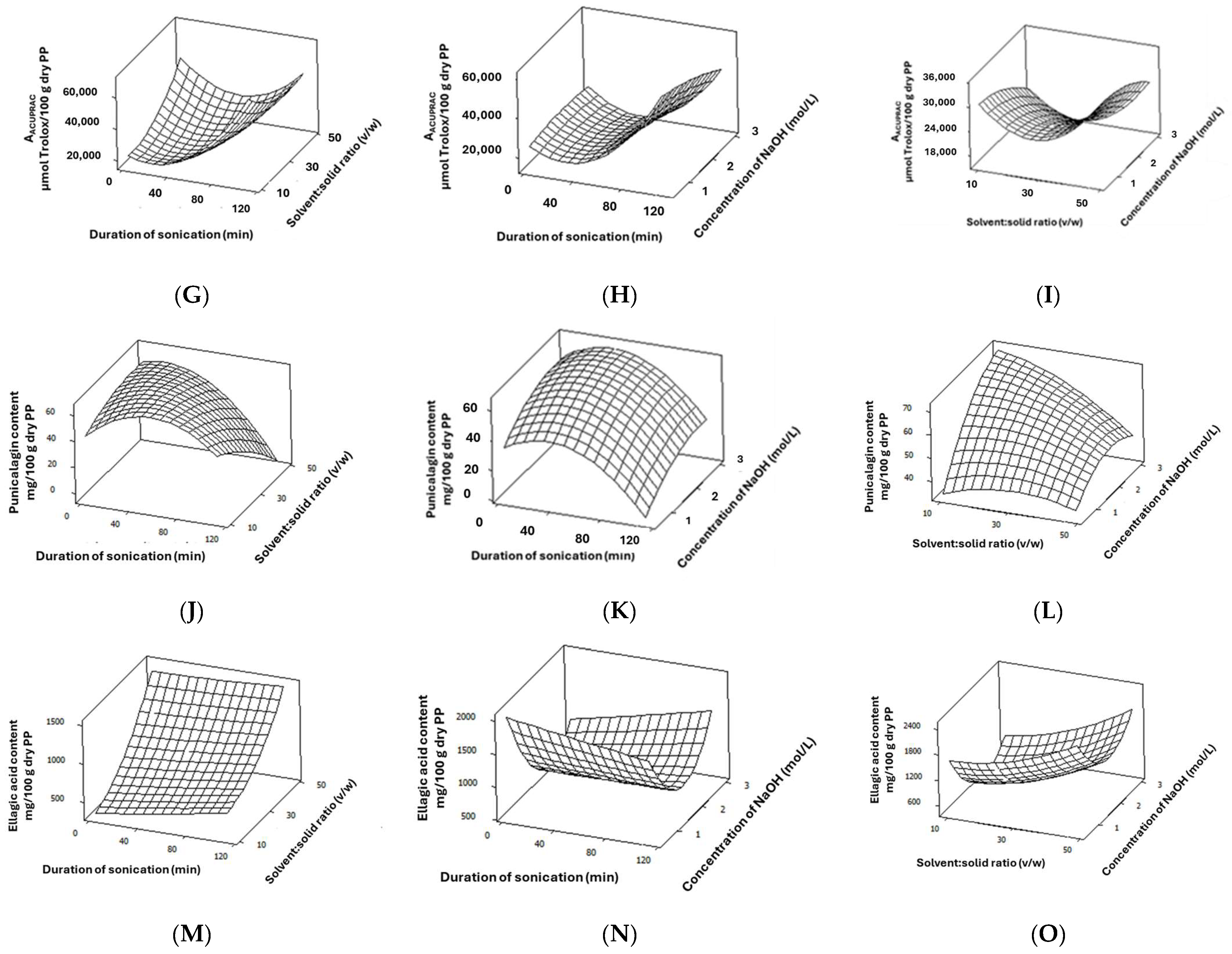

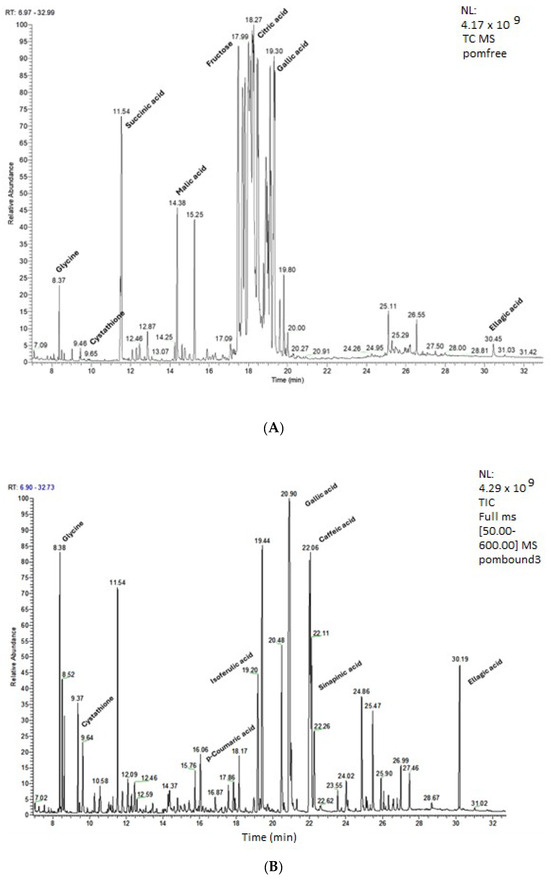

2.4. GC-MS Analysis

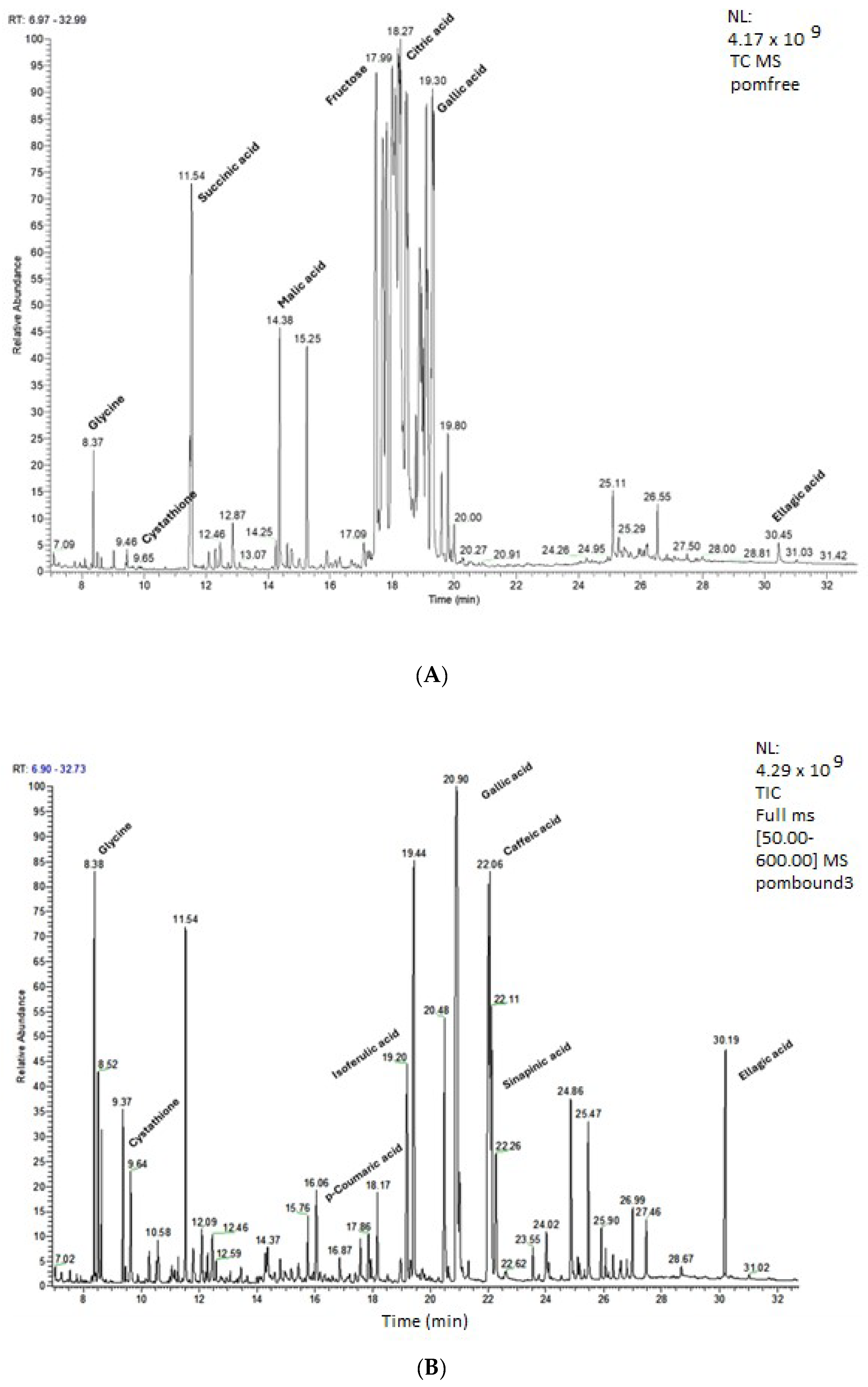

GC coupled to a mass detector was also employed to obtain further evidence for the identity of compounds present in the PP extract prepared under the optimum ultrasound-assisted alkaline hydrolysis. For comparison purposes, the profile of the PP extract prepared without hydrolysis was also examined. The extracts were analysed after silylation. The latter one is a procedure that allows the GC analysis of nonvolatile and thermolabile compounds. In the present study, BSTFA has been used for the preparation of trimethylsilyl (TMS) derivatives, as has been previously reported for other plant materials (e.g., [31,32]). The GC-MS analysis revealed a different profile between the two examined PP extracts (Figure 3A,B). As can be observed, the PP extract prepared without hydrolysis exhibited a more complex profile compared to that of the extract after the alkaline hydrolysis. As can be seen in Table 6 and Figure 3A, various sugars and sugar alcohols, namely D-mannitol, fructose, D-sorbitol, D-glycose, and myoinositol, were identified. Moreover, the GC-MS analysis revealed the presence of certain amino acids, namely glycine and cystathione, as well as organic acids such as succinic acid, malic acid, and citric acid. Additionally, phenolic acids, such as gallic acid, caffeic acid, p-coumaric acid, and ellagic acid, were also identified, thus verifying also the results of the nontarget LC-QTOF-MS analysis. It is worth mentioning that citric acid and gallic acid were the most abundant constituents of the examined PP extract. Punicalagin, also present in high amounts in the examined PP extract as evidenced by the HPLC-DAD analysis, was not identified by GC-MS, because its molecular weight was above the mass range examined in the present study. Even though, to the best of our knowledge, no data exist regarding the analysis of PP extracts using GC-MS, all the above-mentioned compounds are expected to be present in PPs [33].

Figure 3.

GC-MS profile of PP extracts prepared without (A) and with (B) ultrasound-assisted alkaline hydrolysis.

Table 6.

Compounds identified by GC-MS analysis in the PP extracts prepared without or with ultrasound-assisted alkaline hydrolysis.

On the other hand, ultrasound-assisted alkaline hydrolysis was found to cause remarkable changes in the profile of the PP extract. As depicted in Figure 3B, the hydrolyzed PP extract exhibited a diverse profile showcasing the presence of various compounds, such as phenolic acids. Among the identified compounds, gallic acid, along with ellagic acid that was liberated from its bound forms upon hydrolysis as verified by the HPLC-DAD analysis, were some of the major compounds identified in the examined extract. Even though ellagic acid was not the predominant compound in the hydrolyzed PP extract based on the GC-MS analysis, we chose to focus on it, thus considering that PPs constitute one of ellagic acid’s main sources. Moreover, the GC-MS analysis revealed a substantial increase in ellagic acid abundance following its liberation from bound forms during hydrolysis.

3. Materials and Methods

3.1. Reagents and Solvents

Ellagic acid (≥95%) was purchased from Extrasynthese (Genay, Cedex, France). Punicalagin (≥98%) was from Glentham Life Sciences (Corsham, UK). The 6-Hydroxy-2,5,7,8-tetramethyl-chroman-2 acid (Trolox) (97%), 3,4,5-trihydroxybenzoic acid (gallic acid) (99%), apigenin (98%), catechin (98%), chlorogenic acid (98%), epicatechin (98%), isorhamnetin (98%), kaempferol (98%), luteolin (98%), protocatechuic acid (98%), quercetin (98%), quercitrin (98%), rutin (98%), and taxifolin (98%) were all purchased from Sigma-Aldrich (Stenheim, Germany). Ammonium acetate (CH3COONH4) (99%), hydrochloric acid (HCl, 37% w/w), Folin–Ciocalteu reagent, sodium carbonate (Na2CO3, 99.8%), sodium sulphate (Na2SO4) (99%), potassium chloride (KCl) (99.5%), sodium chloride (NaCl) (99.8%), sodium dihydrochloride monoacid phosphate (Na2HPO4·2H2O) (99.5%), potassium dihydrgen phosphate (KH2PO4) (99.5%), sodium hydroxide (NaOH) (99%), and BSFTA [N,O-bis(trimethylsilyl)trifluoroacetamide] were from Chem-Lab (Zedelgen, Belgium). Pyridine (anhydrous 99.5%) was from Thermo Scientific (Kandel, Germany). The radical 2,2-diphenyl-1-picrylhydrazyl (DPPH●) (>97%) was from TCI (Kita-Ku, Tokyo, Japan). Copper dichloride dihydrate (CuCl2·2H2O) (99.99%) was from ThermoFisher (Kandel, Germany), whereas neocuproine (2,9-dimethyl-1, 10-phenanthroline) (≥98%) and the bis-ammonium salt of 2,2′-azino-bis(3-ethylbenzothiazolin-6-sulfonic acid) (ABTS) (≥98%) were from Sigma-Aldrich GmbH (Buchs, Switzerland). Potassium persulfate (K2S2O8) was from Merck (Darmstadt, Germany). Glacial acetic acid, as well as HPLC grade acetonitrile (>99.9%), methanol (>99.8%), and ethyl acetate (>99.8%), were from Chem-Lab (Zedelgen, Belgium). Ultrahigh-purity water was produced in the laboratory using a Micromatic Wasserlab system (Wasserlab, Barañain, Spain). LC-MS grade methanol, water, and formic acid (98–100%) were from Merck (Darmstadt, Germany).

3.2. Plant Material

The pomegranate fruits used in the present study belonged to the “Wonderful” variety, and they were supplied by local producers (Rodi Hellas, Greece). PPs were manually separated. The peels were freeze-dried (HyperCOOL HC8080 freeze dryer, Gyrozen Co., Ltd., Gimpo, Republic of Korea) (−80 °C, 0.1 mbar) and homogenized in a Pulverisette 11 Knife Mill (Fritsch GmbH, Idar-Oberstein, Germany) at 6000 rpm for 20 s, and they were sieved using a sieve shaker (Retax, Labor Siebmaschine, type LS10, No. 4082, Hemmingen, Germany). The average particle size was < 0.22 mm. The pomegranate peel powder was defatted with the aid of a Soxhlet extraction using diethyl ether as solvent in order to ensure the stability of the sample during storage and handling [16].

3.3. Extraction of Free Phenolics Compounds from Pomegranate Peels

Initially, free phenolic compounds were extracted from PPs using a mixture of water:ethanol, 50:50 (v/v) that was found to be the most efficient extraction system based on the results of our previous study [12]. In particular, extraction was carried out with the aid of a sonication bath (Elmasonic S 60 H, Elma, Singen, Germany). The duration of the extraction was 10 min. Sample temperature was kept at ~30 °C using an ice bath. Afterwards, the mixture was centrifuged (6000 rpm, 15 min), and the supernatant was collected and filtered using 0.45 μm PTFE filters and stored in the fridge (4 °C) until analysis for the determination of the free phenolic compounds of PP [12]. The remaining solid residue was then subjected to ultrasound-assisted alkaline hydrolysis in order to liberate bound phenolic compounds from PPs.

3.4. Experimental Design for Optimising the Ultrasound-Assisted Alkaline Hydrolysis of Pomegranate Peels towards the Recovery of Ellagic Acid

Different amounts of dried solid residues of PP after extraction of the free phenolic compounds as described above were weighted directly into Duran bottles with screw caps, and 20 mL of appropriate concentrations of NaOH in the range of 0.5–4 mol/L were added and subjected to ultrasound-assisted alkaline hydrolysis. At the end of each process, the mixture was centrifuged at 6000 rpm for 15 min. The supernatant was collected, and the pH value was adjusted to 1 with 12 mol/L HCl in an ice bath. In order to remove precipitated material, the solution was centrifuged once again (6000 rpm, 15 min). The collected supernatant was then extracted with ethyl acetate (3 × 50 mL). The ethyl acetate fractions were collected, combined, and dried using anhydrous sodium sulfate. Ethyl acetate was then evaporated to dryness, and the dry residue was redissolved in 10 mL methanol for subsequent studies.

Experiments aiming to optimize the ultrasonic-assisted alkaline hydrolysis of PPs were designed with the aid of Minitab 15.1.20.0 (Minitab, Inc., State College, PA, USA) software using an unblocked full factorial central composite design (CCD) of the response surface methodology. Each one of the three independent variables, namely duration of hydrolysis (min) (X1), solvent:solid ratio (X2), and NaOH concentration (X3), had five experimental levels coded as −a, −1, 0, +1, +a (a = 1.41421), where −1, +1 and 0 correspond to the low, high, and middle levels (Table 7). A total of 20 experimental runs with six center points were conducted according to the experimental design (Table 1). The responses that were examined included the total phenol content (TPC) (Y1), DPPH● (ADPPH) (Y2) and ABTS●+ (AABTS) (Y3) radical scavenging activity, cupric ion reducing antioxidant capacity (ACUPRAC) (Y4), and the punicalagin (Y5) and ellagic acid content (Y6). Each experimental response was analysed, and a second-order regression equation (Equation (6)) was obtained:

where Y corresponds to the responses, X1, X2, and X3 represent the factors of duration, temperature, and solvent:solid ratio, and β0, β1, .... β23 are the estimated coefficients, with β0 being a scaling constant.

Y = β0 + β1X1 + β2X2 + β3X3 + β11X12 + β22X22 + β33X32 + β12X1X2 + β13X1X3 + β23X2X3

Table 7.

Levels of independent variables in coded and uncoded values used in the experimental design.

Analysis of variance (ANOVA) was carried out to evaluate the quality of the fit of the model to the responses by investigating the coefficients of determination (R2), the significance of each parameter through the F-test (p-value), and the lack of fit of the model. Coefficients with a p value lower than 0.05 were considered statistically significant. Multiresponse optimisation of the fitted polynomials was also performed using the Minitab software.

3.5. Spectrophotometric Determinations

3.5.1. Determination of the Total Phenol Content (TPC)

Total polar phenol content of the prepared PP extracts was determined spectrophotometrically with the Folin–Ciocalteu assay according to the procedure described by Kyriakoudi et al. [26]. Gallic acid was used as a reference standard, and results were expressed as gallic acid equivalents (mg GAE/100 g dry PP). In a 10 mL volumetric flask, 5 mL of water with the appropriate amount of pomegranate peel extract and 0.5 mL Folin–Ciocalteu reagent were added. After 3 min, 1.0 mL of saturated sodium carbonate solution (37%, w/v) was added, and the mixture was agitated. The volume was adjusted with water, and the flask left in the dark for 1 h at room temperature. The absorbance was measured at 750 nm (UV-1800 spectrophotometer, Shimadzu, Kyoto, Japan) against a blank prepared similarly using methanol instead of the extract. Measurements were performed at least in triplicate, and results were expressed as the mean value ± s.d.

3.5.2. DPPH● Scavenging Activity (ADPPH)

The DPPH● scavenging activity of PP extracts was determined according to the procedure described by Kyriakoudi et al. [26]. Appropriate amounts of pomegranate peel extracts were added to 2.9 mL of a 0.1 mM methanolic solution of DPPH●. The absorbance at 515 nm was recorded at the start and after 30 min using the UV-1800 spectrophotometer. Radical scavenging activity (%) values (%RSA) were determined by using the formula %RSA = [Abs515(t = 0) − Abs515(t)] × 100/Abs515(t = 0) after correction with appropriate blank. These values were applied to a calibration curve constructed using Trolox as a reference compound, and the results were finally expressed as μmol Trolox/100 g dry PPs. Measurements were performed at least in triplicate, and results were expressed as the mean value ± s.d.

3.5.3. ABTS●+ Scavenging Activity (AABTS)

Radical scavenging activity of PP extracts against ABTS●+ was evaluated according to the protocol of Re et al. [34]. In particular, the ABTS●+ solution was prepared by reaction of 5 mL of a 7 mM aqueous ABTS solution and 88 μL of a 140 mM potassium persulfate (K2S2O8) solution. After storage in the dark for 16 h, the radical cation solution was further diluted in PBS (pH 7.4) until the initial absorbance value of 0.70 (±0.05) at 734 nm was reached. An aliquot of each PP extract was mixed with 2 mL of the ABTS●+ solution. The decrease in absorbance was recorded at 0 and after 6 min (UV-1800 spectrophotometer). Inhibition of ABTS radical cation in percent (% Inh) was calculated by using the formula % Inh = [Abs734(t=0) – Abs734(t=6)] × 100/Abs734(t=0) after correction with an appropriate blank. These values were applied to a calibration curve constructed using Trolox as a reference compound, and the results were finally expressed as μmol Trolox/100 g dry PPs. Measurements were performed at least in triplicate, and results were expressed as the mean value ± s.d.

3.5.4. Cupric ion Reducing Antioxidant Capacity (ACUPRAC)

The Cu (II) reducing capacity of PP extracts was measured according to the protocol of Apak et al. [35]. Briefly, 1 mL of a 0.02 M solution of cooper (II) chloride, 1 mL of a 0.0075 Μ neocuproine solution, and 1 mL of a 1 M ammonium acetate buffer (pH = 7.0) were mixed with an appropriate amount of each PP extract. After the addition of deionised water to a final volume of 4.1 mL, the mixture was shaken for 15 s. The absorbance at 450 nm was measured after the solution had been allowed to stand in the dark for 30 min (UV-1800 spectrophotometer). These values were applied to a calibration curve constructed using Trolox as a reference compound, and the results were finally expressed as μmol Trolox/100 g dry PPs. Measurements were performed at least in triplicate, and results were expressed as the mean value ± s.d.

3.6. RP-HPLC-DAD Analysis of Phenolic Compounds

The contents of punicalagin and ellagic acid were determined by RP-HPLC-DAD. The HPLC system consisted of an Agilent 1260 Infinity II Quaternary Pump VL, an Agilent 1260 Infinity II Autosampler, and an Agilent 1260 Infinity II Diode Array Detector High Sensitivity. Separation was carried out on a InfinityLab Poroshell 120 EC-C184 μm (150 × 4.6 mm i.d.) column (Agilent Technologies, Santa Clara, CA, USA). The column temperature was set at 30 ℃. The mobile phase consisted of water–acetic acid (0.5%, v/v) (A) and acetonitrile (B). The elution protocol was based on the method described by Kaderides et al. (2019) [13]: 0–20 min for 5% (B); 20–40 min for 25% (B); 40–45 min for 50% (B); and 45–50 min for 5% (B). The total run time was 50 min with flow rate of 0.8 mL/min, and injection volume was 20 µL. Extracts were analysed after proper dilution (when required) and filtration through 0.45 μm PTFE filters (Frisenette, Knebel, Denmark). Monitoring was in the range of 190–600 nm. Chromatographic data were processed using the OpenLab CDS version 3.5 software (2021, Agilent Technologies, Santa Clara, CA, USA). Peak identification was based on retention times and spectral characteristics (absorption maxima) with those of available standards. Quantification of punicalagin (sum of α and β anomeric forms) and ellagic acid (mg/100 g dry PP) was carried out with the aid of calibration curves of properly diluted solutions of available standards: (i) punicalagin (y = 3.180x − 67.335, R2 = 0.999, λmax = 254 nm) and (ii) ellagic acid (y = 12.485x − 46.950, R2 =0.999, λmax = 280 nm).

3.7. LC-QTOF-MS Analysis

A PP extract prepared under the optimum experimental conditions was further characterised using LC-QTOF-MS. Analysis was performed using an ExionAC LC system (SCIEX, Framingham, MA, USA) that was equipped with two pumps, a solvent degasser, an autosampler, and a controller. The X500R Q-TOF mass spectrometer (SCIEX, Framingham, MA, USA) equipped with an electrospray ionization (ESI) turboVTM source was connected to the LC-system, and it was operated in the negative ionization mode. TOF-MS and TOF-MS/MS data were acquired using a data-dependent acquisition (IDA) electrospray ionisation mode. Separation was carried out using a Fortis C18 column (100 mm length, 2.1 mm i.d., 2.6 µm particle size) provided by Fortis (Cheshire, UK). The temperature of the column was 40 °C. The solvents of the mobile phase were (A) aqueous solution of 0.1% v/v formic acid and (B) methanolic solution of 0.1% v/v formic acid. The elution program was gradient, and the flow rate was set at 0.2 mL/min and 99% (A), thus gradually dropping to 61% (A) for the next 4 min. The aqueous phase dropped even further to 5% until the 12th min, and it remained stable until the 15th min at a flow rate of 0.4 mL/min. The initial conditions were restored within one min, and for the last four minutes, the aqueous phase was again at 99% at a flow rate of 0.2 mL/min to re-equilibrate the column. The QTOF-MS system was equipped with an ESI interface operating in a negative mode with the following settings: spray voltage of –4500 V, 550 °C heater gas temperature, 80 V declustering potential. The MS/MS spectra were obtained at a collision energy of 45 V and a collision energy spread of 15 V. External calibration was performed before analysis with a cluster solution provided by SCIEX, and additionally, the calibration solution was injected at the beginning of each run for internal calibration and once per five samples during batch acquisition. Mass spectra were recorded in the range from 50 to 1000 Da at an accumulation time of 0.25 s. MS/MS experiments were conducted using Information-dependent Acquisition-dependent mode (IDA) at an accumulation time of 0.08 s for the 10 most-abundant precursor ions per full scan. Sample acquisition was monitored by the SCIEX OS software Version 2.0.1., released in 2019 (© 2019 AB Sciex). Extraction ion chromatograms (EICs) were generated using the SCIEX OS software. The established parameters were mass accuracy window of 5 ppm, signal-to-noise threshold of 3, minimum area threshold of 1000, minimum intensity threshold of 500.

3.7.1. Screening Workflows

Target Screening

A list of 20 target phenolic compounds, namely apigenin, catechin, chlorogenic acid, diosmin, epicatechin, epicatechin gallate, epigallocatechin, gallic acid, hesperidin, isorhamnetin, kaempferol, luteolin, myricetin, myricitrin, naringin, protocatechuic acid, quercetin, quercitrin, rutin, and taxifolin was created. To confirm the identity of the target analytes, the mass accuracies of the precursor ion and the qualifiers, the Rt, and the MS/MS spectra of the real samples and standard solutions were compared.

Nontarget Screening

A list of suspect compounds was generated based on the available literature concerning the phytochemical profile of PPs. The mass of the deprotonated ions was calculated based on the molecular formula, and the extracted ion chromatograms were studied using the following parameters: mass accuracy window of 5 ppm; signal-to-noise threshold of 3; minimum area threshold of 1000; minimum intensity threshold of 500. MS/MS fragments were compared to data from SCIEX Natural Products Library for the identification of the unknowns.

3.8. GC-MS Analysis

An appropriate amount of the PP extract prepared under the optimum ultrasound-assisted alkaline hydrolysis conditions (0.5 mL) was dried over N2 stream in a 1 mL volumetric flask. Immediately after, 100 µL of BSTFA and 900 µL of anhydrous pyridine were added, and the mixture was left to stand for 20 min at room temperature. Then, 1 µL amounts of these solutions were subjected to GC-MS analysis that was carried out using a TraceGC Ultra (ThermoFinnigan, Milan, Italy) gas chromatography coupled with a ISQ (Thermo Fisher Scientific, Milan, Italy) single quadrupole mass spectrometer equipped with a Triplus RSH autosampler supplied by Thermo Fisher Scientific (ThermoFinnigan, Offenbach, Germany). Analytes were separated on a nonpolar HP-5ms silica-fused capillary column coated with 0.25 mm film of poly (dimethylsiloxane) as the stationary phase (Agilent) (HP-5 30 m length × 0.25 mm, film thickness, 0.25 μm). Helium was used as the carrier gas at a constant flow rate of 1.8 mL/min. The oven temperature program used was as follows: initial temperature 40 °C for 2 min, followed by an increase of 10 °C/min for 5 min till 300 °C and then holding the final temperature for 5 min. The total runtime of the GC program was 33 min. The transfer line temperature was kept at 280 °C; EI energy: 70 eV, mass range: 50 to 600 m/z. The temperature of the MS source was 300 °C. The GC was equipped with a programmable temperature vaporiser injector (PTV) (ThermoFinnigan, Milan, Italy) that was used in the split ratio mode 6:1 at an injection port base temperature of 250 °C. Data acquisition, processing, and evaluation were carried out using the standard software Xcalibur Data System Version 4.2 (ThermoFinnigan, Austin, TX, USA). Compounds were identified by comparison of their retention time and mass spectra with those of available standards or by spectra matching with literature data and NIST library spectra. (NIST Mass Spectral Database, 2011 from National Institute of Standards and Technology, Gaithersburg, MD, USA)

3.9. Statistical Analysis

Data were analysed by one-way analysis of variance (ANOVA) using Minitab 15.1.20.0 (Minitab, Inc., State College, PA, USA) software.

4. Conclusions

The pomegranate processing industry generates worldwide enormous amounts of by-products, such as pomegranate peels, which constitute a rich source of phenolic compounds. In this view, PP could be exploited as a sustainable source of ellagic acid, which is a compound that possesses various biological actions. Τhe present study aimed at the liberation of ellagic acid from its bound forms via ultrasound-assisted alkaline hydrolysis. The optimum hydrolysis conditions were found to be 32 min, 1:48 v/w, and 1.5 mol/L NaOH. RP-HPLC-DAD, LC-QTOF-MS, and GC-MS analysis of the PP extract obtained under the optimum conditions revealed the presence of various organic acids, sugars, and amino acids, as well as phenolic compounds, e.g., gallic acid, caffeic acid, p-coumaric acid, and ellagic acid. The latter one was liberated from ellagitannins, such as punicalagin, upon hydrolysis. The proposed methodology is expected to add value to the pomegranate processing industry, thereby boosting the local economy, and also could be of use for food, pharmaceutical, and cosmetics applications.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/molecules29112424/s1, Table S1. Chromatograms and MS/MS fragmentation patterns of the target and non-target analytes.

Author Contributions

Conceptualization, A.K. and I.M.; methodology, A.K.; validation, A.K., E.K., E.Z. and N.K.; formal analysis, A.K., E.K., E.Z. and N.K.; investigation, A.K., E.K., E.Z. and N.K.; resources, I.M.; data curation, A.K., E.K., E.Z. and N.K.; writing—original draft preparation, A.K.; writing—review and editing, A.K., E.Z., N.K. and I.M.; visualization, A.K. and E.K.; supervision, I.M.; project administration, I.M.; funding acquisition, I.M. All authors have read and agreed to the published version of the manuscript.

Funding

The research project was supported by the Hellenic Foundation for Research and Innovation (H.F.R.I.) under the “2nd Call for H.F.R.I. Research Projects to support Faculty Members & Researchers” (Project Number: 3308).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the Interdisciplinary Agri-Food Center, Aristotle University of Thessaloniki (KEAGRO-AUTH), for providing access to the LC-QTOF-MS/MS equipment of the unit.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kahramanoglu, I. Trends in pomegranate sector: Production, postharvest handling and marketing. Int. J. Agric. Life Sci. 2019, 3, 239–246. [Google Scholar]

- El Barnossi, A.; Moussaid, F.; Iraqi Housseini, A. Tangerine, banana and pomegranate peels valorisation for sustainable environment: A review. Biotechnol. Rep. 2021, 29, e00574. [Google Scholar] [CrossRef] [PubMed]

- Talekar, S.; Patti, A.F.; Vijayraghavan, R.; Arora, A. An integrated green biorefinery approach towards simultaneous recovery of pectin and polyphenols coupled with bioethanol production from waste pomegranate peels. Bioresour. Technol. 2018, 266, 322–334. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, A.; Hussain, Z.; Aihetasham, A.; El-Sharnouby, M.; Abdul Rehman, R.; Azmat Ullah Khan, M.; Zahra, S.; Saleem, A.; Azhar, S.; Alhazmi, A.; et al. Pomegranate peels waste hydrolyzate optimization by Response Surface Methodology for Bioethanol production. Saudi J. Biol. Sci. 2021, 28, 4867–4875. [Google Scholar] [CrossRef] [PubMed]

- Mazaheri, D.; Orooji, Y.; Mazaheri, M.; Moghaddam, M.S.; Karimi-Maleh, H. Bioethanol production from pomegranate peel by simultaneous saccharification and fermentation process. Biomass Conv. Bioref. 2021. [Google Scholar] [CrossRef]

- Kaderides, K.; Kyriakoudi, A.; Mourtzinos, I.; Goula, A.M. Potential of pomegranate peel extract as a natural additive in foods. Trends Food Sci. Technol. 2021, 115, 380–390. [Google Scholar] [CrossRef]

- Gulsunoglu, Z.; Karbancioglu-Guler, F.; Raes, K.; Kilic-Akyilmaz, M. Soluble and insoluble-bound phenolics and antioxidant activity of various industrial plant wastes. Int. J. Food Prop. 2019, 22, 1501–1510. [Google Scholar] [CrossRef]

- Muñiz-Márquez, D.B.; Wong-Paz, J.E.; Aguilar-Zárate, P.; Sepúlveda, L.; Buenrostro-Figueroa, J.; Ascacio-Valdés, J.A.; Aguilar, C.N. Effect of ultrasound on the extraction of ellagic acid and hydrolysis of ellagitannins from pomegranate husk. Environ. Technol. Innov. 2021, 24, 102063. [Google Scholar] [CrossRef]

- Chen, L.; Xu, J.; Wu, Q.; Chu, J.; Shi, J.; Shi, Q. An economic and eco-friendly method for the recovery of ellagic acid from waste pomegranate peel via thermal hydrolysis assisted extraction and liquid-liquid extraction. Sustain. Chem. Pharm. 2023, 33, 101139. [Google Scholar] [CrossRef]

- Mele, L.; Mena, P.; Piemontese, A.; Marino, V.; López-Gutiérrez, N.; Bernini, F.; Brighenti, F.; Zanotti, I.; Del Rio, D. Antiatherogenic effects of ellagic acid and urolithins in vitro. Arch. Biochem. Biophys. 2016, 599, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Theocharis, G.; Andlauer, W. Innovative microwave-assisted hydrolysis of ellagitannins and quantification as ellagic acid equivalents. Food Chem. 2013, 138, 2430–2434. [Google Scholar] [CrossRef] [PubMed]

- Solomakou, N.; Kalfa, E.; Kyriakoudi, A.; Kaderides, K.; Mourtzinos, I.; Goula, A.M. An approach for the valorization of pomegranate by-products using ultrasound and enzymatic methods. Sustain. Chem. Environ. 2024, 5, 100060. [Google Scholar] [CrossRef]

- Kaderides, K.; Papaoikonomou, L.; Serafim, M.; Goula, A.M. Microwave-assisted extraction of phenolics from pomegranate peels: Optimization, kinetics, and comparison with ultrasounds extraction. Chem. Eng. Process. 2019, 137, 1–11. [Google Scholar] [CrossRef]

- Man, G.; Ma, Y.; Xu, L.; Liao, X.; Zhao, L. Comparison of thermal and non-thermal extraction methods on free and bound phenolics in pomegranate peel. Innov. Food Sci. Emerg. Technol. 2023, 84, 103291. [Google Scholar] [CrossRef]

- Liu, B.; Li, W.; Hu, L.; Zhao, J. Mild alkaline hydrolysis is an efficient and low-cost method for improving the free phenolic content and health benefit of pomegranate peel extract: Enhancing the phenolic content of pomegranate peel. J. Food Process. Preserv. 2013, 37, 694–700. [Google Scholar] [CrossRef]

- Dadwal, V.; Bhatt, S.; Sonkhla, K.; Joshi, R.; Gupta, M. Quantification of free and bound phenolics in bio-waste pomegranate peel and formulation of punicalagin rich rice extruded snacks. Int. J. Food Sci. Nutr. 2017, 4, 98–104. [Google Scholar] [CrossRef]

- Sun, S.; Huang, S.; Shi, Y.; Shao, Y.; Qiu, J.; Sedjoah, R.-C.A.-A.; Yan, Z.; Ding, L.; Zou, D.; Xin, Z. Extraction, isolation, characterization and antimicrobial activities of non-extractable polyphenols from pomegranate peel. Food Chem. 2021, 351, 129232. [Google Scholar] [CrossRef]

- Chaudhary, A.; Hussain, A.; Ahmad, Q.-A.; Manzoor, M.; Tahira, S.A.; Karita, S. Statistical optimization of alkaline treatment of pomegranate peel waste for bioethanol production. Biomass Convers. Bior. 2022. [Google Scholar] [CrossRef]

- Saleem, A.; Hussain, A.; Chaudhary, A.; Ahmad, Q.-A.; Iqtedar, M.; Javid, A.; Akram, A.M. Acid hydrolysis optimization of pomegranate peels waste using response surface methodology for ethanol production. Biomass Convers. Bior. 2022, 12, 1513–1524. [Google Scholar] [CrossRef]

- Moccia, F.; Flores-Gallegos, A.C.; Chávez-González, M.L.; Sepúlveda, L.; Marzorati, S.; Verotta, L.; Panzella, L.; Ascacio-Valdes, J.A.; Aguilar, C.N.; Napolitano, A. Ellagic acid recovery by solid state fermentation of pomegranate wastes by Aspergillus niger and Saccharomyces cerevisiae: A comparison. Molecules 2019, 24, 3689. [Google Scholar] [CrossRef] [PubMed]

- Gullon, B.; Pintado, M.E.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Assessment of polyphenolic profile and antibacterial activity of pomegranate peel (Punica granatum) flour obtained from co-product of juice extraction. Food Control 2016, 59, 94–98. [Google Scholar] [CrossRef]

- Kharchoufi, S.; Licciardello, F.; Siracusa, L.; Muratore, G.; Hamdi, M.; Restuccia, C. Antimicrobial and antioxidant features of ‘Gabsiʼ pomegranate peel extracts. Ind. Crops Prod. 2018, 111, 345–352. [Google Scholar] [CrossRef]

- Yan, L.; Zhou, X.; Shi, L.; Shalimu, D.; Ma, C.; Liu, Y. Phenolic profiles and antioxidant activities of six Chinese pomegranate (Punica granatum L.) cultivars. Int. J. Food Prop. 2017, 20, S94–S107. [Google Scholar] [CrossRef]

- Sabraoui, T.; Khider, T.; Nasser, B.; Eddoha, R.; Moujahid, A.; Benbachir, M.; Essamadi, A. Determination of punicalagins content, metal chelating, and antioxidant properties of edible pomegranate (Punica granatum L.) peels and seeds grown in Μοrocco. Int. J. Food Sci. 2020, 2020, 8885889. [Google Scholar] [CrossRef] [PubMed]

- Kaderides, K.; Goula, A.M.; Adamopoulos, K.G. A process for turning pomegranate peels into a valuable food ingredient using ultrasound-assisted extraction and encapsulation. Innov. Food Sci. Emerg. Technol. 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Kyriakoudi, A.; Misirli, K.; Mourtzinos, I.; Nenadis, N. Recovery of bound phenolic compounds from rice hulls via microwave-assisted alkaline hydrolysis. Sustainability 2023, 15, 8425. [Google Scholar] [CrossRef]

- Pyrka, I.; Mantzouridou, F.T.; Nenadis, N. Optimization of olive leaves’ thin layer, intermittent near-infrared-drying. Innov. Food Sci. Emerg. Technol. 2023, 84, 103264. [Google Scholar] [CrossRef]

- Olszowy-Tomczyk, M. Synergistic, antagonistic and additive antioxidant effects in the binary mixtures. Phytochem. Rev. 2020, 19, 63–103. [Google Scholar] [CrossRef]

- Ambigaipalan, P.; De Camargo, A.C.; Shahidi, F. Phenolic compounds of pomegranate by products (outer skin, mesocarp, divider membrane) and their antioxidant activities. J. Agric. Food Chem. 2016, 64, 6584–6604. [Google Scholar] [CrossRef] [PubMed]

- Man, G.; Xu, L.; Wang, Y.; Liao, X.; Xu, Z. Profiling phenolic composition in pomegranate peel from nine selected cultivars using UHPLC-QTOF-MS and UPLC-QQQ-MS. Front. Nutr. 2022, 8, 807447. [Google Scholar] [CrossRef] [PubMed]

- Nenadis, N.; Kyriakoudi, A.; Tsimidou, M.Z. Impact of alkaline or acid digestion to antioxidant activity, phenolic content and composition of rice hull extracts. LWT—Food Sci. Τechnol. 2013, 54, 207–215. [Google Scholar] [CrossRef]

- Proestos, C.; Sereli, D.; Komaitis, M. Determination of phenolic compounds in aromatic plants by RP-HPLC and GC-MS. Food Chem. 2006, 95, 44–52. [Google Scholar] [CrossRef]

- Poyrazoğlu, E.; Gökmen, V.; Artιk, N. Organic acids and phenolic compounds in pomegranates (Punica granatum L.) grown in Turkey. J. Food Compos. Anal. 2002, 15, 567–575. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Apak, R.; Güçlü, K.; Özyürek, M.; Karademir, S.E. Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine: CUPRAC method. J. Agric. Food Chem. 2004, 52, 7970–7981. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).