Enrichment of Trypsin Inhibitor from Soybean Whey Wastewater Using Different Precipitating Agents and Analysis of Their Properties

Abstract

1. Introduction

2. Results and Discussion

2.1. Analysis of Yield and Protein Recovery Rate

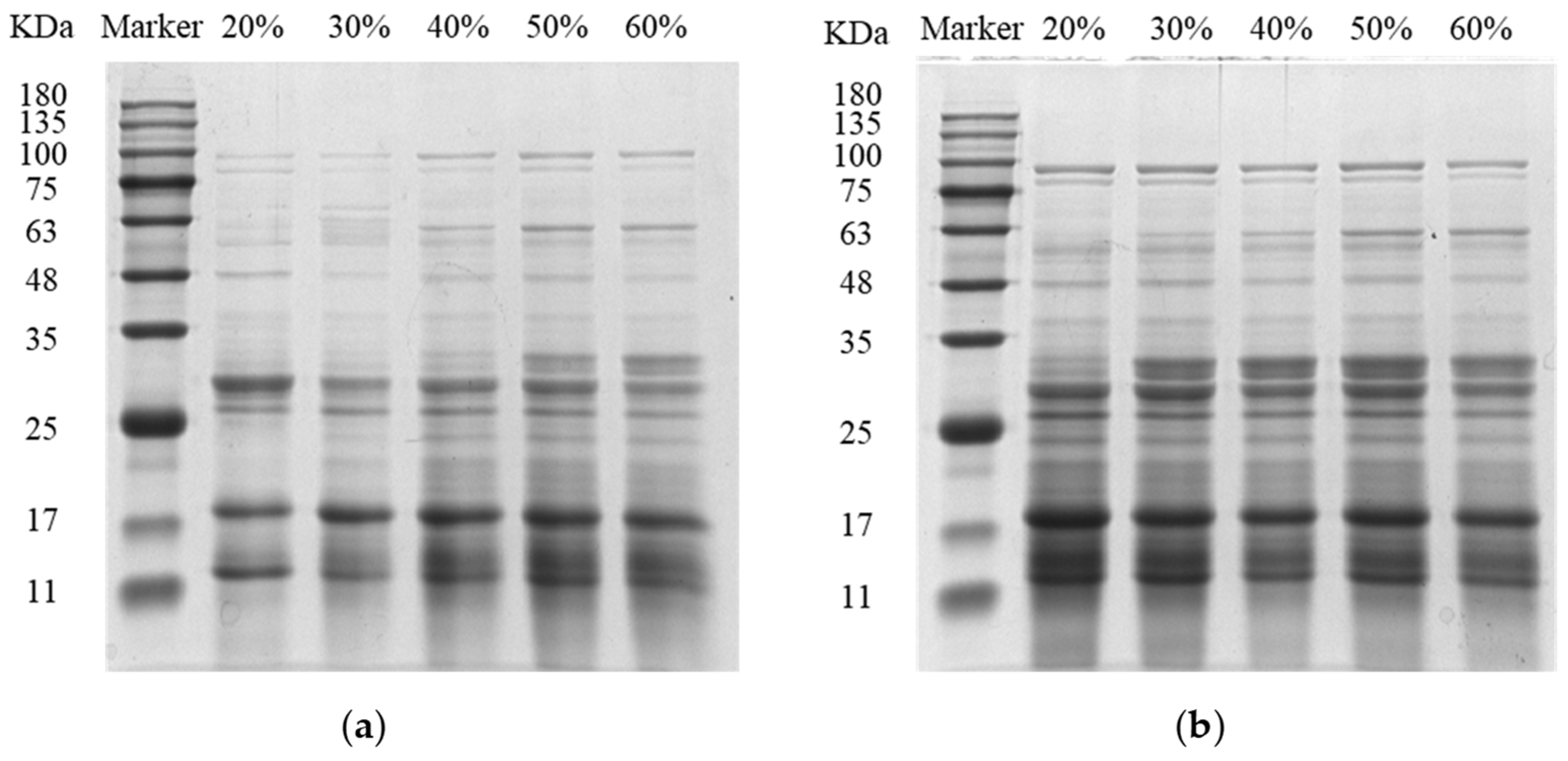

2.2. STI Composition Analysis

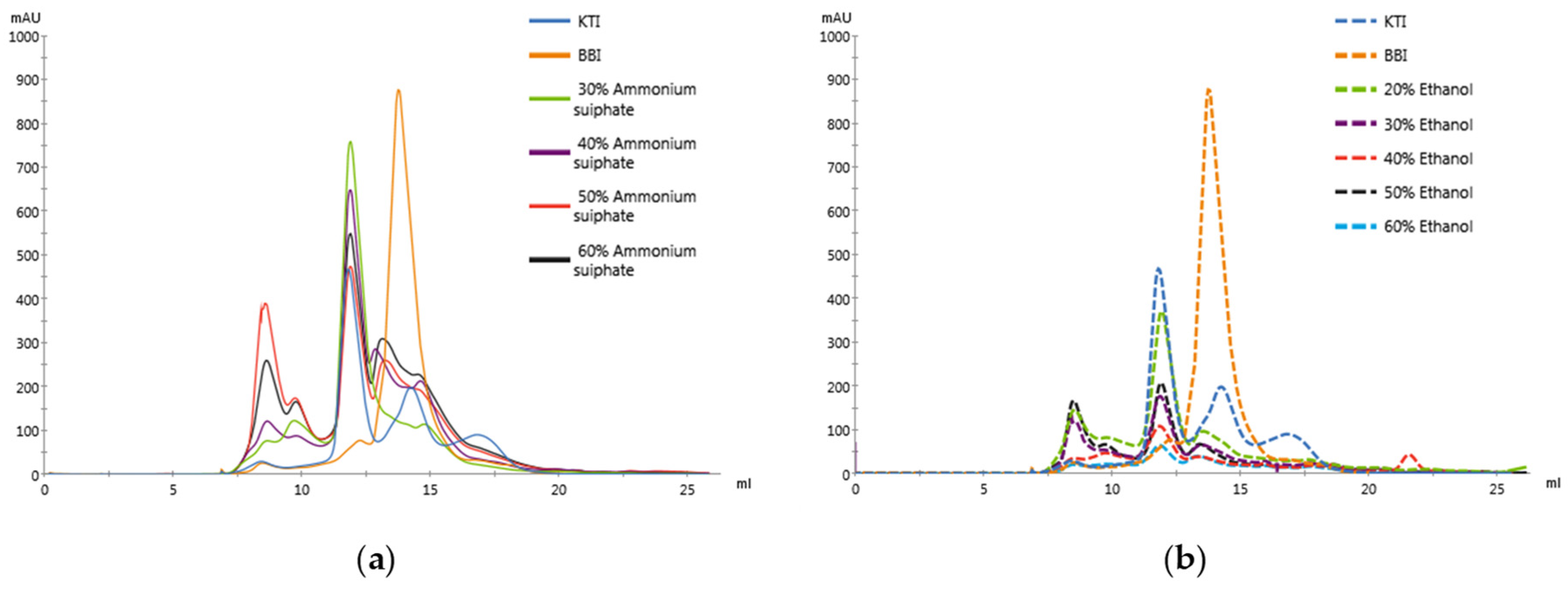

2.3. STI Purity Analysis

2.4. Analysis of STI Activity

2.5. Effect of Temperature and pH on the Solubility of STI

2.6. Effect of Temperature and pH on the Turbidity of STI

2.7. Surface Hydrophobicity Analysis of STI

2.8. Thermal Characterization of STI

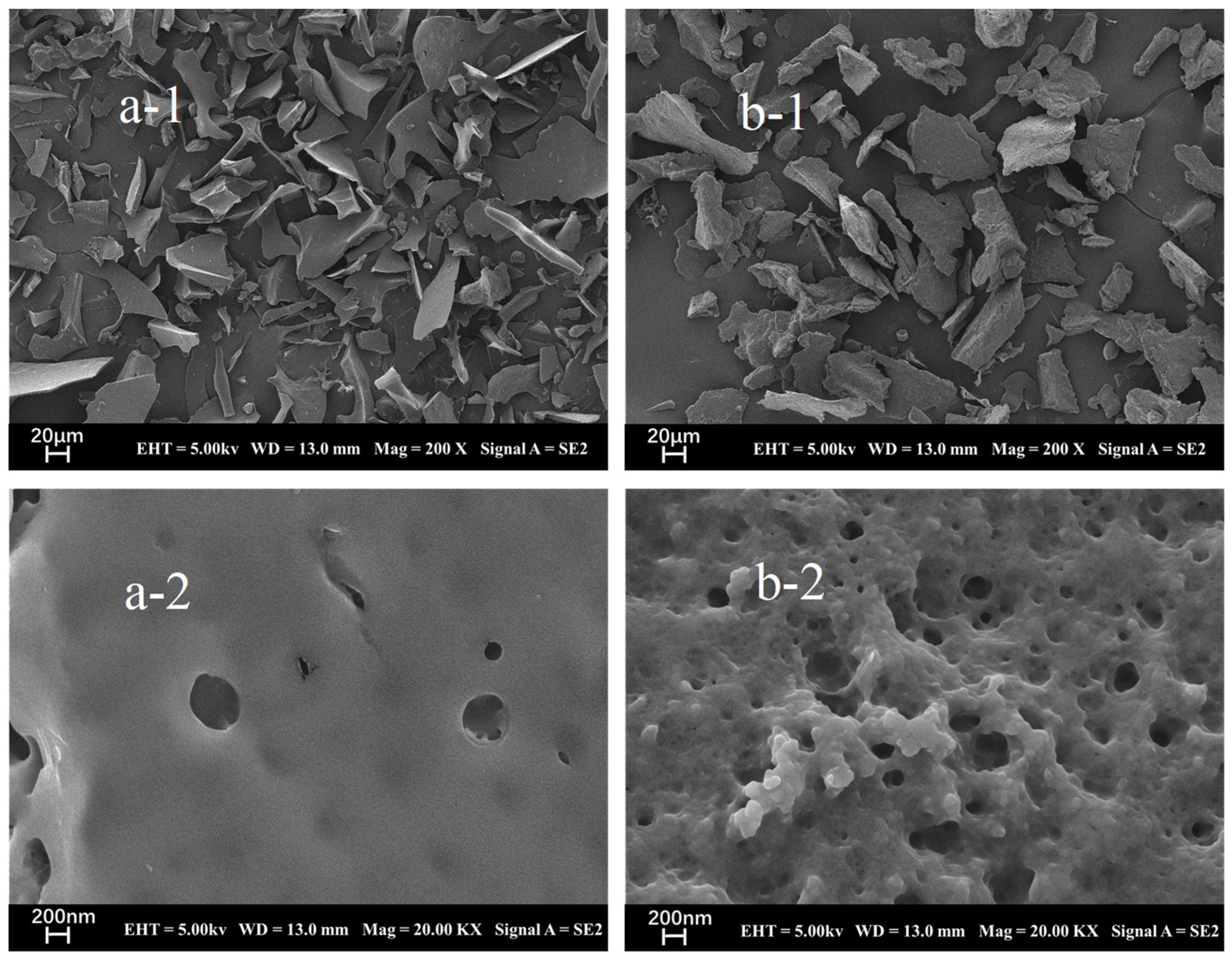

2.9. Surface Structure Analysis of STI

3. Materials and Methods

3.1. Feedstocks and Reagents

3.2. Preparation of the Soybean Whey

3.3. Preparation of Soybean Whey Concentrate

3.4. Enrichment of STI by Ammonium Sulfate Precipitation

3.5. Enrichment of STI by Ethanol Precipitation Method

3.6. Analytical Method

3.6.1. Calculation of STI Yield

3.6.2. Determination of STI Protein Content

3.6.3. Analysis of STI Composition by SDS-PAGE

3.6.4. Analysis of STI Purity by Gel Filtration Chromatography

3.6.5. Determination of the Trypsin Inhibitory Activity

3.6.6. Determination of Solubility

3.6.7. Determination of Turbidity

3.6.8. Determination of Surface Hydrophobicity

3.6.9. Thermal Characteristics of STI by Differential Scanning Calorimetry

3.6.10. Morphology of STI by Scanning Electron Microscopy (SEM)

3.7. Data Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, P.; Sharma, M.; Abubakar, A.A.; Nizam bin Hayat, M.; Ahmed, M.A.; Kaka, U.; Sazili, A.Q. Health implications of plant-based meat analogs. In Handbook of Plant-Based Meat Analogs; Academic Press: Cambridge, MA, USA, 2023; pp. 219–231. [Google Scholar] [CrossRef]

- Singh, P.; Krishnaswamy, K. Sustainable zero-waste processing system for soybeans and soy by-product valorization. Trends Food Sci. Technol. 2022, 128, 331–344. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Ying, Z.; Li, W.; Li, H.; Liu, X. Trypsin Inhibitor from Soybean Whey Wastewater: Isolation, Purification and Stability. Appl. Sci. 2022, 12, 10084. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Z.; Li, R.; Liu, Q. Technology of protein separation from whey wastewater by two-stage foam separation. Biochem. Eng. J. 2011, 55, 43–48. [Google Scholar] [CrossRef]

- Belén, F.; Sánchez, J.; Hernández, E.; Auleda, J.M.; Raventós, M. One option for the management of wastewater from tofu production: Freeze concentration in a falling-film system. J. Food Eng. 2012, 110, 364–373. [Google Scholar] [CrossRef]

- Wang, Y.; Serventi, L. Sustainability of dairy and soy processing: A review on wastewater recycling. J. Clean. Prod. 2019, 237, 117821. [Google Scholar] [CrossRef]

- Chua, J.-Y.; Liu, S.-Q. Soy whey: More than just wastewater from tofu and soy protein isolate industry. Trends Food Sci. Technol. 2019, 91, 24–32. [Google Scholar] [CrossRef]

- Tu, C.; Tang, S.; Azi, F.; Hu, W.; Dong, M. Use of kombucha consortium to transform soy whey into a novel functional beverage. J. Funct. Foods 2019, 52, 81–89. [Google Scholar] [CrossRef]

- Dai, Y.; Zhou, J.; Wang, L.; Dong, M.; Xia, X. Biotransformation of soy whey into a novel functional beverage by Cordyceps militaris SN-18. Food Prod. Process Nutr. 2021, 3, 13. [Google Scholar] [CrossRef]

- Li, X.; Dong, D.; Hua, Y.; Chen, Y.; Kong, X.; Zhang, C. Soybean whey protein/chitosan complex behavior and selective recovery of kunitz trypsin inhibitor. J. Agric. Food Chem. 2014, 62, 7279–7286. [Google Scholar] [CrossRef]

- Cruz-Huerta, E.; Fernandez-Tome, S.; Arques, M.C.; Amigo, L.; Recio, I.; Clemente, A.; Hernandez-Ledesma, B. The protective role of the Bowman-Birk protease inhibitor in soybean lunasin digestion: The effect of released peptides on colon cancer growth. Food Funct. 2015, 6, 2626–2635. [Google Scholar] [CrossRef]

- Fang, E.F.; Wong, J.H.; Ng, T.B. Thermostable Kunitz trypsin inhibitor with cytokine inducing, antitumor and HIV-1 reverse transcriptase inhibitory activities from Korean large black soybeans. J. Biosci. Bioeng. 2010, 109, 211–217. [Google Scholar] [CrossRef] [PubMed]

- de Siqueira Patriota, L.L.; Ramos, D.D.; e Silva, M.G.; dos Santos, A.C.; Silva, Y.A.; de Oliveira Marinho, A.; Coelho, L.C.; Paiva, P.M.; Pontual, E.V.; Mendes, R.L.; et al. The trypsin inhibitor from Moringa oleifera flowers (MoFTI) inhibits acute inflammation in mice by reducing cytokine and nitric oxide levels. S. Afr. J. Bot. 2021, 143, 474–481. [Google Scholar] [CrossRef]

- Arrutia, F.; Binner, E.; Williams, P.; Waldron, K.W. Oilseeds beyond oil: Press cakes and meals supplying global protein requirements. Trends Food Sci. Technol. 2020, 100, 88–102. [Google Scholar] [CrossRef]

- Benelhadj, S.; Gharsallaoui, A.; Degraeve, P.; Attia, H.; Ghorbel, D. Effect of pH on the functional properties of Arthrospira (Spirulina) platensis protein isolate. Food Chem. 2016, 194, 1056–1063. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Yu, B.; Wang, S.; Shen, Y.; Cong, H. Recent advances on protein separation and purification methods. Adv. Colloid. Interface Sci. 2020, 284, 102254. [Google Scholar] [CrossRef]

- Li, C.; Li, W.; Zhang, Y.; Simpson, B.K. Comparison of physicochemical properties of recombinant buckwheat trypsin inhibitor (rBTI) and soybean trypsin inhibitor (SBTI). Protein. Expr. Purif. 2020, 171, 105614. [Google Scholar] [CrossRef]

- O’Fagain, C.; Cummins, P.M.; O’Connor, B.F. Gel-filtration chromatography. Methods Mol. Biol. 2011, 681, 25–33. [Google Scholar] [CrossRef]

- Nikolaidis, A.; Moschakis, T. On the reversibility of ethanol-induced whey protein denaturation. Food Hydrocoll. 2018, 84, 389–395. [Google Scholar] [CrossRef]

- Wouters, A.G.B.; Rombouts, I.; Fierens, E.; Brijs, K.; Delcour, J.A. Relevance of the Functional Properties of Enzymatic Plant Protein Hydrolysates in Food Systems. Compr. Rev. Food Sci. Food Saf. 2016, 15, 786–800. [Google Scholar] [CrossRef]

- Srikar, L.N.; Reddy, G.V.S. Protein solubility and emulsifying capacity in frozen stored fish mince. J. Sci. Food Agric. 1991, 55, 447–453. [Google Scholar] [CrossRef]

- Nguyen, Q.; Hettiarachchy, N.; Rayaprolu, S.; Seo, H.S.; Horax, R.; Chen, P.; Kumar, T.K. Protein-rich beverage developed using non-GM soybean (R08-4004) and evaluated for sensory acceptance and shelf-life. J. Food Sci. Technol. 2016, 53, 3271–3281. [Google Scholar] [CrossRef] [PubMed]

- Bakwo Bassogog, C.B.; Nyobe, C.E.; Ngui, S.P.; Minka, S.R.; Mune Mune, M.A. Effect of heat treatment on the structure, functional properties and composition of Moringa oleifera seed proteins. Food Chem 2022, 384, 132546. [Google Scholar] [CrossRef]

- Holtz, C.; Gastl, M.; Becker, T. Turbidity potentials of single long-chain fatty acids and gelatinised starch in synthetic lautering wort. Int. J. Food Sci. Technol. 2015, 50, 906–912. [Google Scholar] [CrossRef]

- Li, N.; Wang, Y.; Gan, Y.; Wang, S.; Wang, Z.; Zhang, C.; Wang, Z. Physicochemical and functional properties of protein isolate recovered from Rana chensinensis ovum based on different drying techniques. Food Chem. 2022, 396, 133632. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.-T.; Tu, Z.-C.; Xiao, H.; Wang, H.; Huang, X.-Q.; Liu, G.-X.; Liu, C.-M.; Shi, Y.; Fan, L.-L.; Lin, D.-R. Influence of ultrasonic treatment on the structure and emulsifying properties of peanut protein isolate. Food Bioprod. Process 2014, 92, 30–37. [Google Scholar] [CrossRef]

- Bartova, V.; Barta, J. Chemical composition and nutritional value of protein concentrates isolated from potato (Solanum tuberosum L.) fruit juice by precipitation with ethanol or ferric chloride. J. Agric. Food Chem. 2009, 57, 9028–9034. [Google Scholar] [CrossRef] [PubMed]

- Nieto-Veloza, A.; Zhong, Q.; Kim, W.S.; D’Souza, D.; Krishnan, H.B.; Dia, V.P. Utilization of tofu processing wastewater as a source of the bioactive peptide lunasin. Food Chem. 2021, 362, 130220. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Song, J.; Qi, M.; Suo, W.; Deng, Y.; Liu, Y.; Li, L.; Zhang, D.; Wang, C.; Li, H. Modification mechanism of protein in rice adjuncts upon extrusion and its effects on nitrogen conversion during mashing. Food Chem. 2023, 407, 135150. [Google Scholar] [CrossRef]

- Zhu, L.; Li, X.; Song, X.; Li, Q.; Zheng, F.; Li, H.; Sun, J.; Huang, M.; Sun, B. Characterization of prolamin recycled from the byproduct of the Baijiu brewing industry (Jiuzao) by SDS-PAGE, multispectral analysis, and morphological analysis. Food Biosci. 2022, 49, 101854. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, R.; Li, H.; Li, Y.; Liu, X. Interactions between Soybean Trypsin Inhibitor and Chitosan in an Aqueous Solution. Polymers 2023, 15, 1594. [Google Scholar] [CrossRef]

- Cheng, J.H.; Li, J.; Sun, D.W. Effects of dielectric barrier discharge cold plasma on structure, surface hydrophobicity and allergenic properties of shrimp tropomyosin. Food Chem. 2023, 409, 135316. [Google Scholar] [CrossRef] [PubMed]

| Precipitation Agent | Yield (mg/mL) | Protein Content (%) | Recovery Rate (%) |

|---|---|---|---|

| Soybean whey | 24.90 ± 0.15 | 17.19 ± 0.44 | 100.00 |

| Ammonium sulfate (%) | |||

| 20 | 0.317 ± 0.047 g | 95.33 ± 0.48 b | 7.06 ± 0.28 e |

| 30 | 0.950 ± 0.041 f | 98.00 ± 0.55 a | 21.75 ± 0.69 d |

| 40 | 2.900 ± 0.071 c | 94.84 ± 0.84 b | 64.27 ± 0.57 c |

| 50 | 3.567 ± 0.131 b | 93.24 ± 0.37 b | 77.71 ± 0.11 b |

| 60 | 3.833 ± 0.332 a | 93.11 ± 0.75 b | 83.39 ± 0.03 a |

| Ethanol (%) | |||

| 20 | 1.533 ± 0.062 e | 94.00 ± 2.36 b | 33.67 ± 0.85 e |

| 30 | 2.517 ± 0.085 d | 97.89 ± 0.65 a | 57.57 ± 0.44 d |

| 40 | 2.933 ± 0.062 c | 93.12 ± 0.44 b | 63.81 ± 0.30 c |

| 50 | 3.317 ± 0.062 b | 92.69 ± 0.77 b | 71.83 ± 0.64 b |

| 60 | 3.983 ± 0.340 a | 93.70 ± 0.27 b | 87.20 ± 0.25 a |

| Sample | Peak 1 Area (%) | Peak 2 Area (%) | Peak 3 Area (%) |

|---|---|---|---|

| KTI | 0 | 53.95 | 46.05 |

| BBI | 0 | 0 | 100.00 |

| A-30% | 18.23 | 57.00 | 24.77 |

| A-40% | 14.08 | 49.48 | 36.44 |

| A-50% | 31.84 | 33.04 | 35.13 |

| A-60% | 24.07 | 31.82 | 46.57 |

| E-20% | 27.99 | 43.96 | 28.05 |

| E-30% | 31.23 | 36.30 | 32.47 |

| E-40% | 27.20 | 38.30 | 34.50 |

| E-50% | 36.60 | 36.40 | 27.01 |

| E-60% | 21.78 | 29.72 | 49.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhou, S.; Lu, C.; Zhang, Y.; Zhao, H. Enrichment of Trypsin Inhibitor from Soybean Whey Wastewater Using Different Precipitating Agents and Analysis of Their Properties. Molecules 2024, 29, 2613. https://doi.org/10.3390/molecules29112613

Zhou Y, Zhou S, Lu C, Zhang Y, Zhao H. Enrichment of Trypsin Inhibitor from Soybean Whey Wastewater Using Different Precipitating Agents and Analysis of Their Properties. Molecules. 2024; 29(11):2613. https://doi.org/10.3390/molecules29112613

Chicago/Turabian StyleZhou, Yongsheng, Siyun Zhou, Cuiwen Lu, Yihao Zhang, and Haiyan Zhao. 2024. "Enrichment of Trypsin Inhibitor from Soybean Whey Wastewater Using Different Precipitating Agents and Analysis of Their Properties" Molecules 29, no. 11: 2613. https://doi.org/10.3390/molecules29112613

APA StyleZhou, Y., Zhou, S., Lu, C., Zhang, Y., & Zhao, H. (2024). Enrichment of Trypsin Inhibitor from Soybean Whey Wastewater Using Different Precipitating Agents and Analysis of Their Properties. Molecules, 29(11), 2613. https://doi.org/10.3390/molecules29112613