Cerium Dioxide–Dextran Nanocomposites in the Development of a Medical Product for Wound Healing: Physical, Chemical and Biomedical Characteristics

Abstract

1. Introduction

2. Results

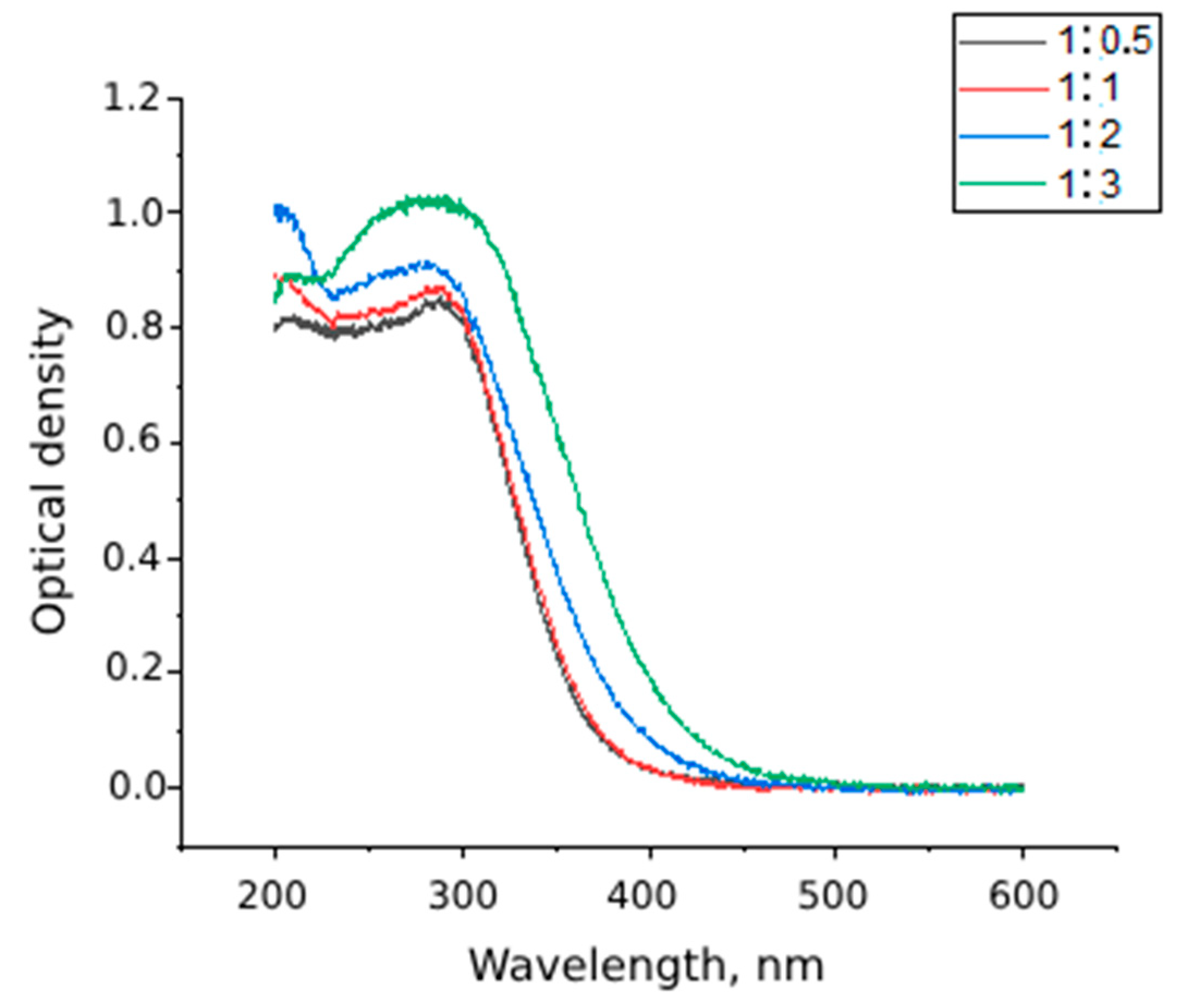

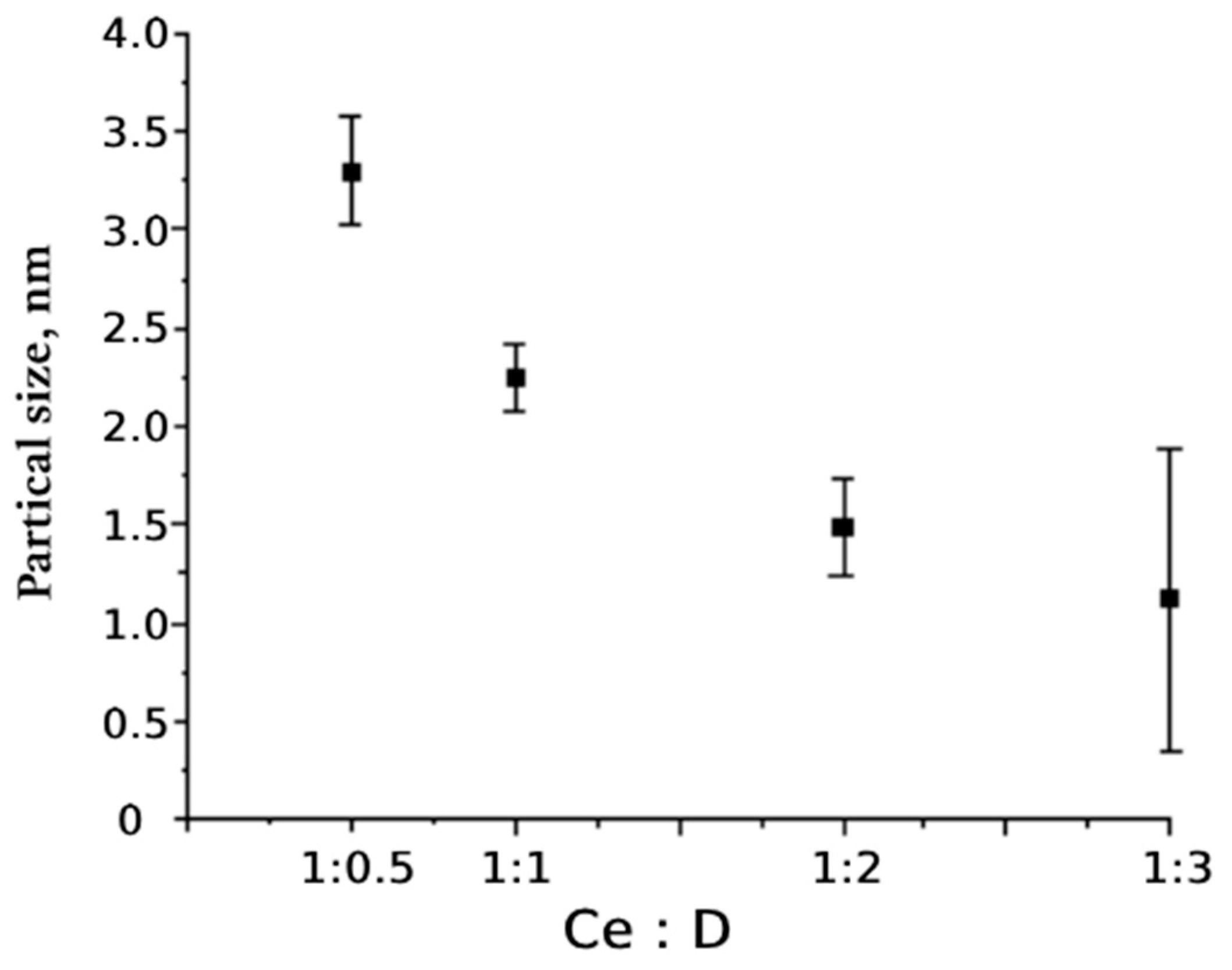

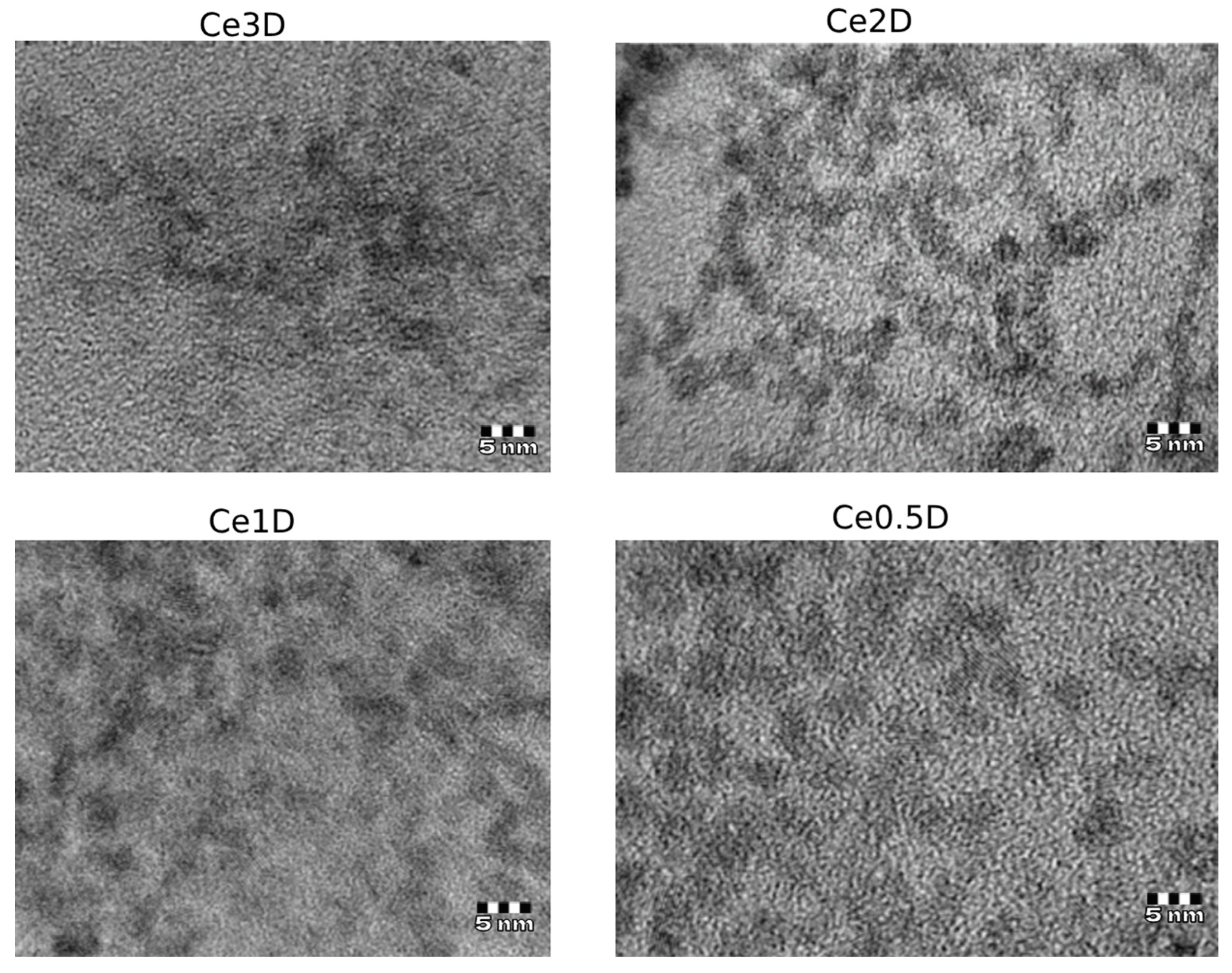

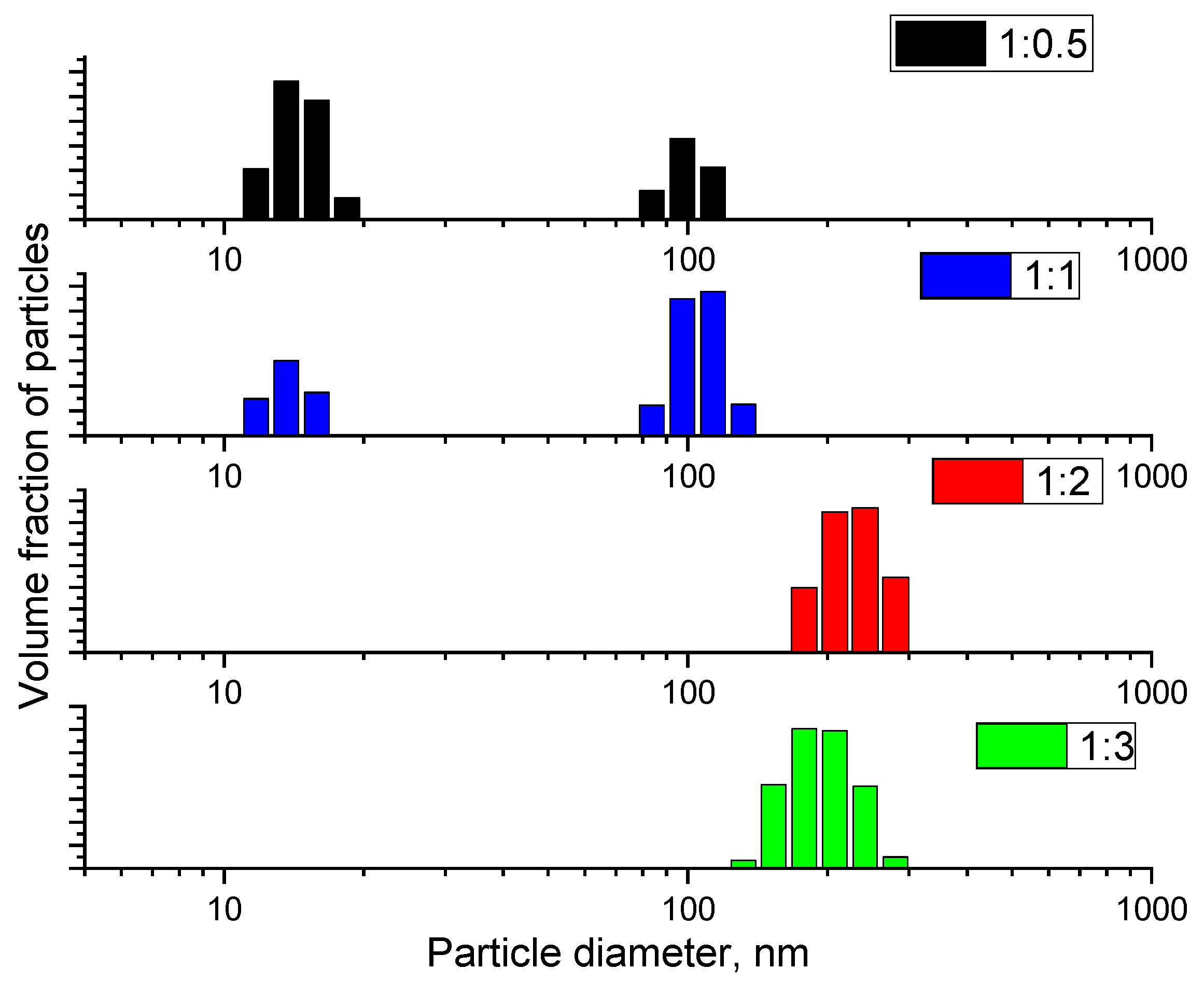

2.1. Results of Evaluation of Physicochemical Properties of the Synthesized Dextran-CeO2 Nanocomposites

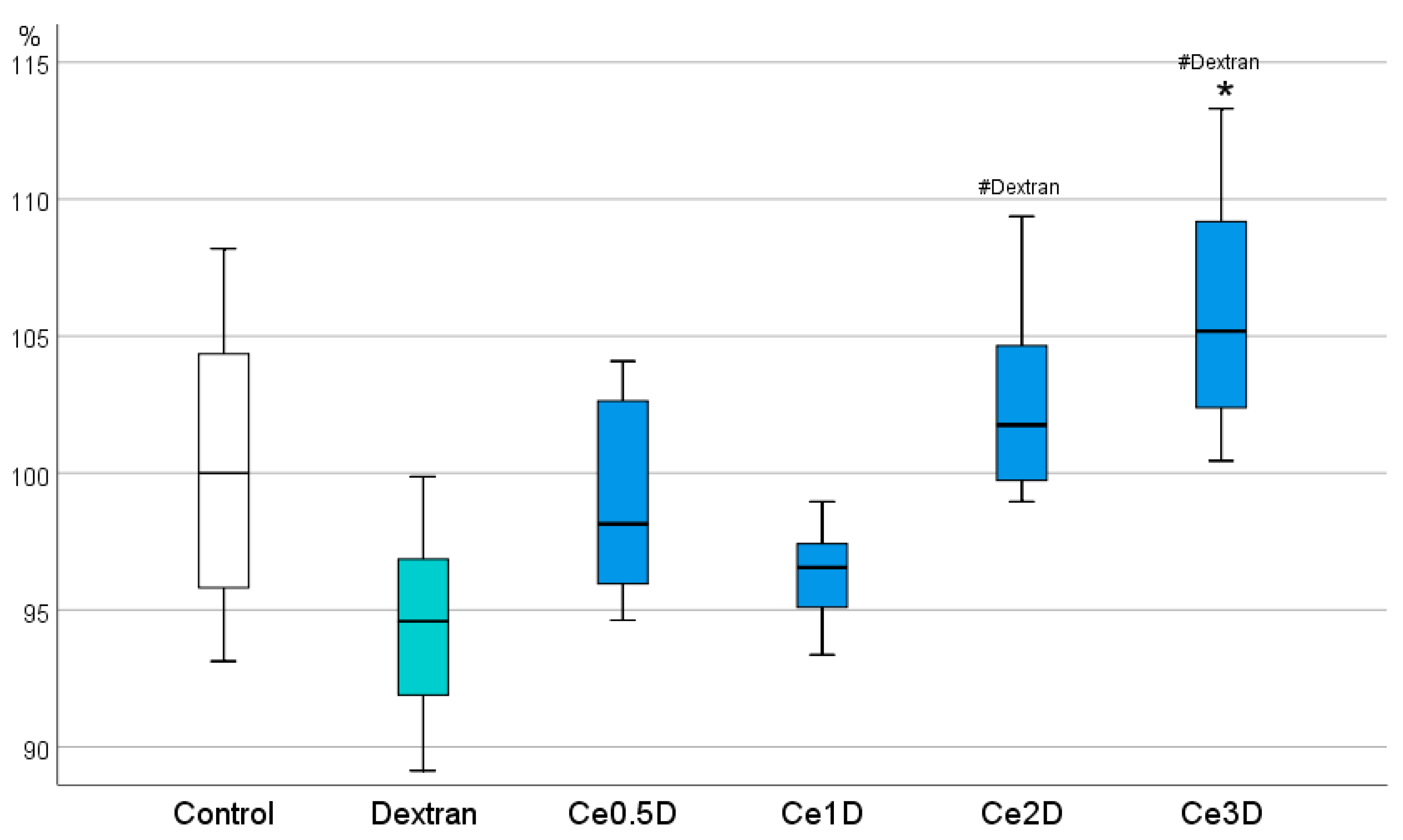

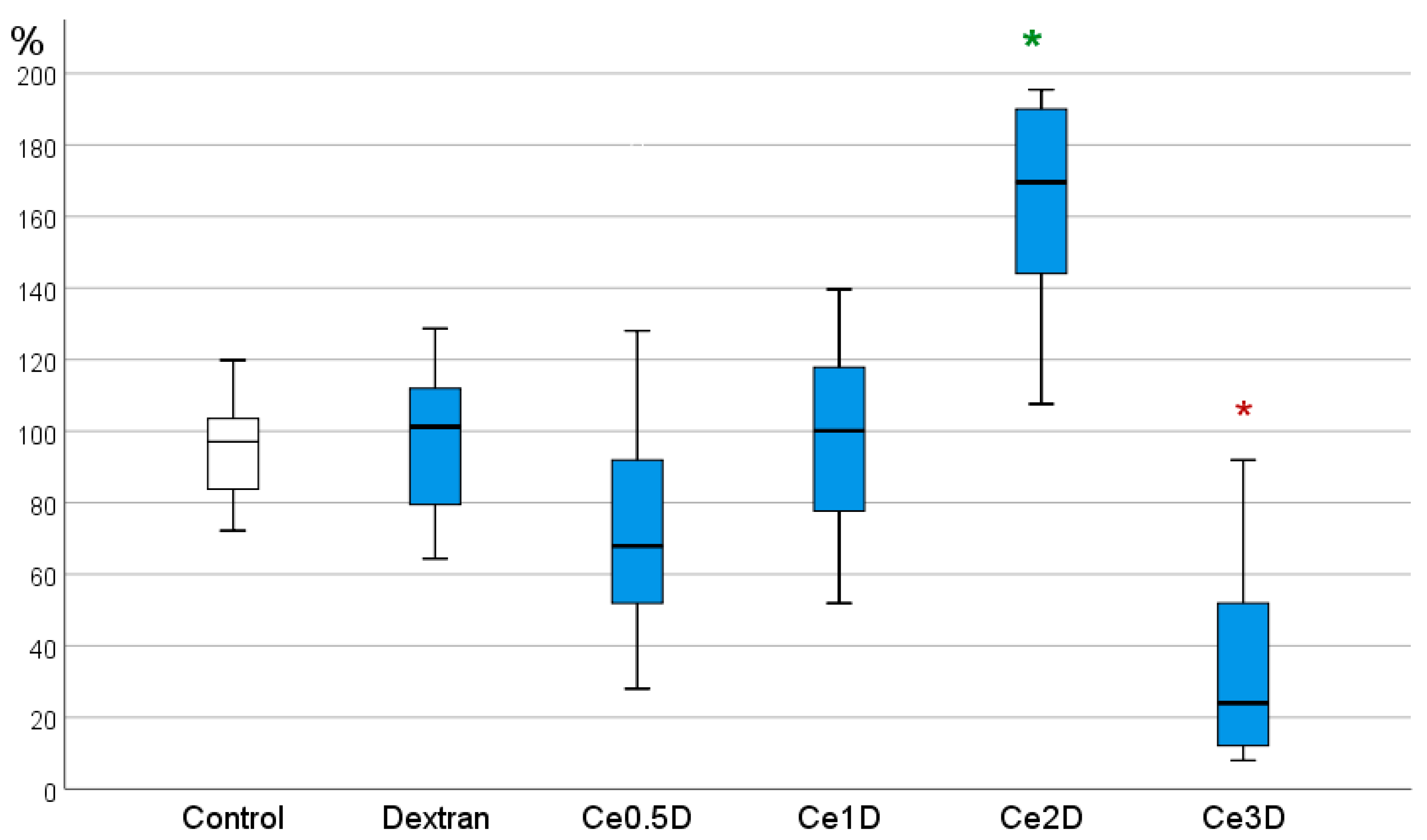

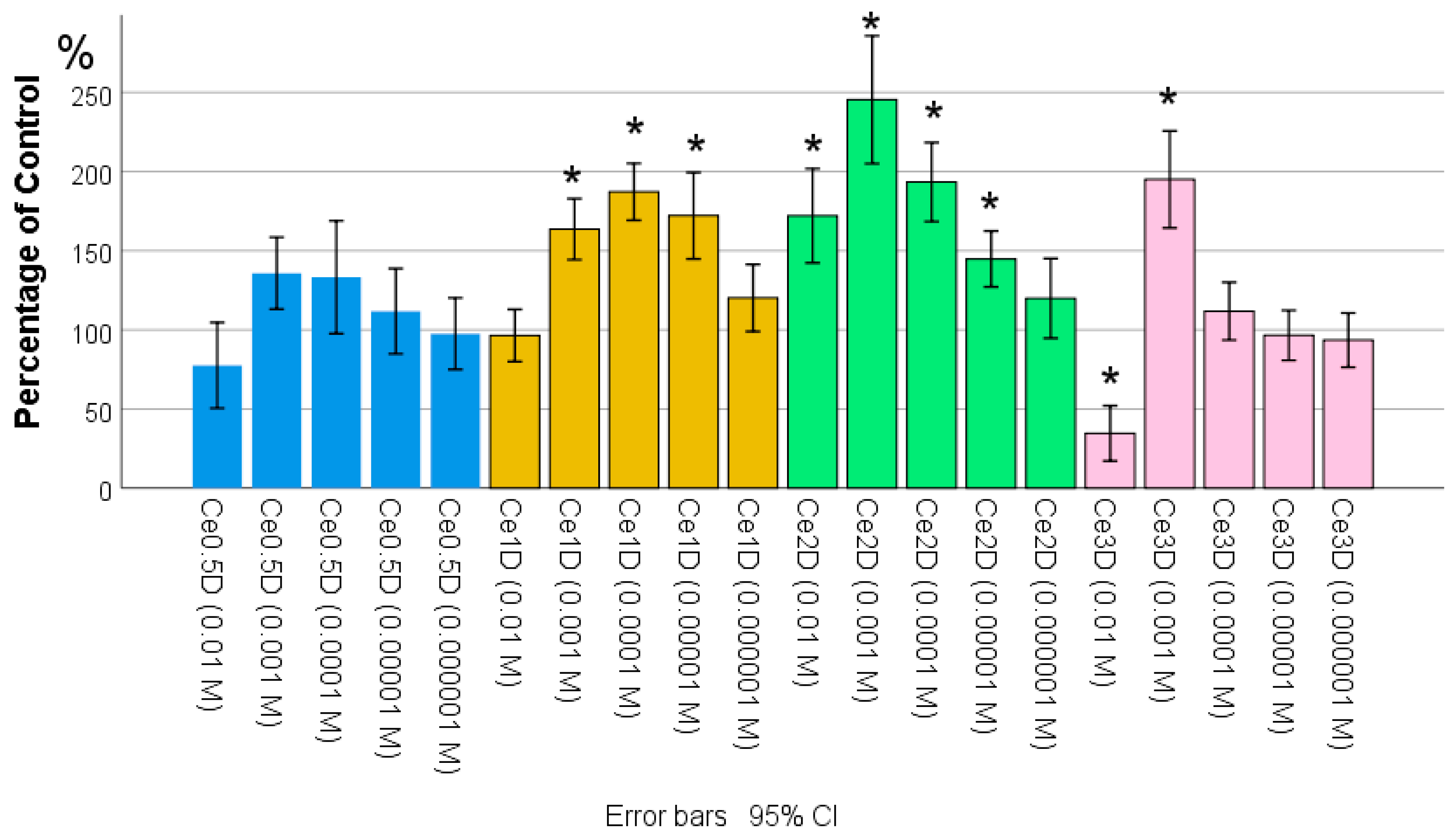

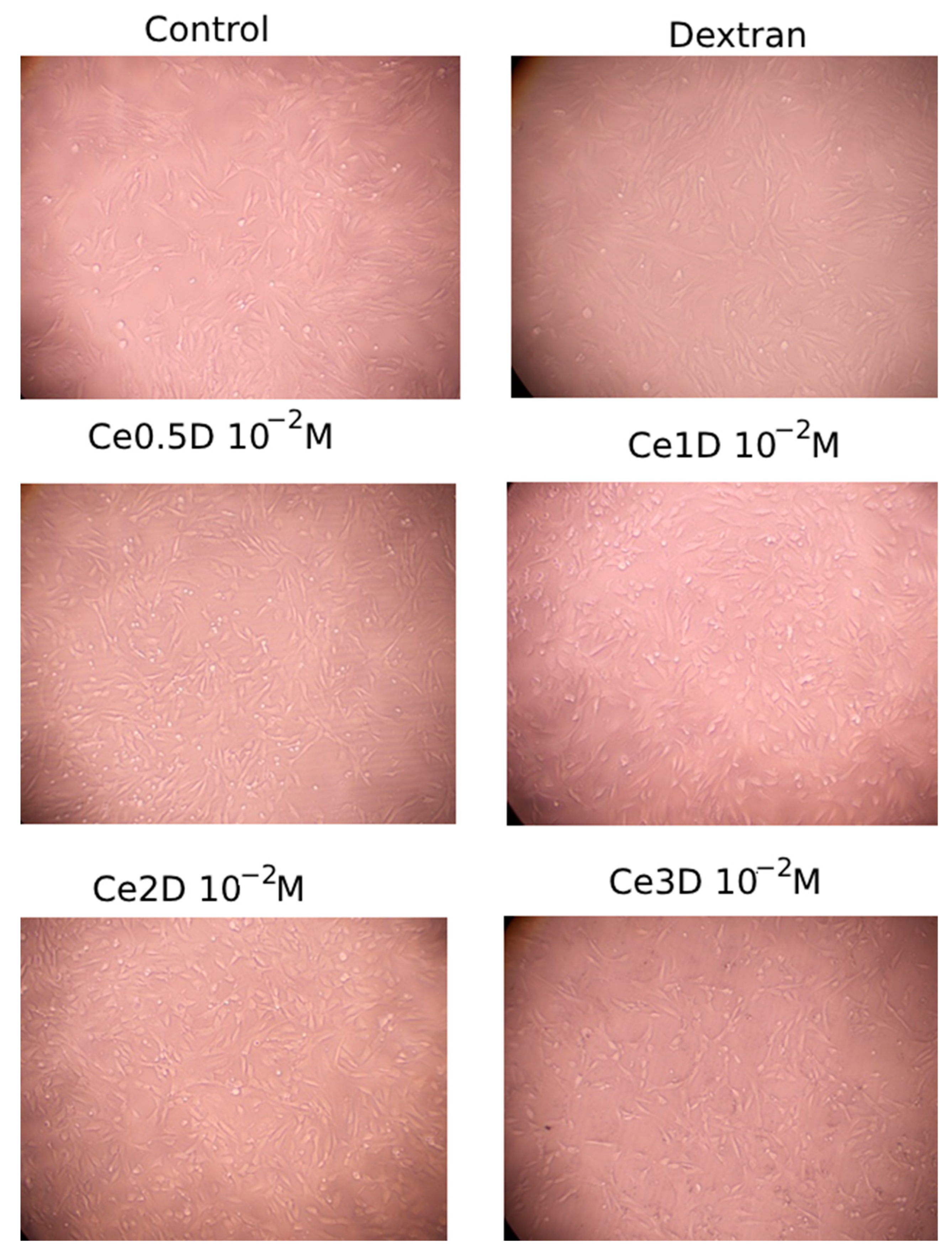

2.2. Results of Evaluation of the Effect of Nanocomposites on Cytotoxicity, Metabolic and Proliferative Activity of Human Fibroblast Cell Culture

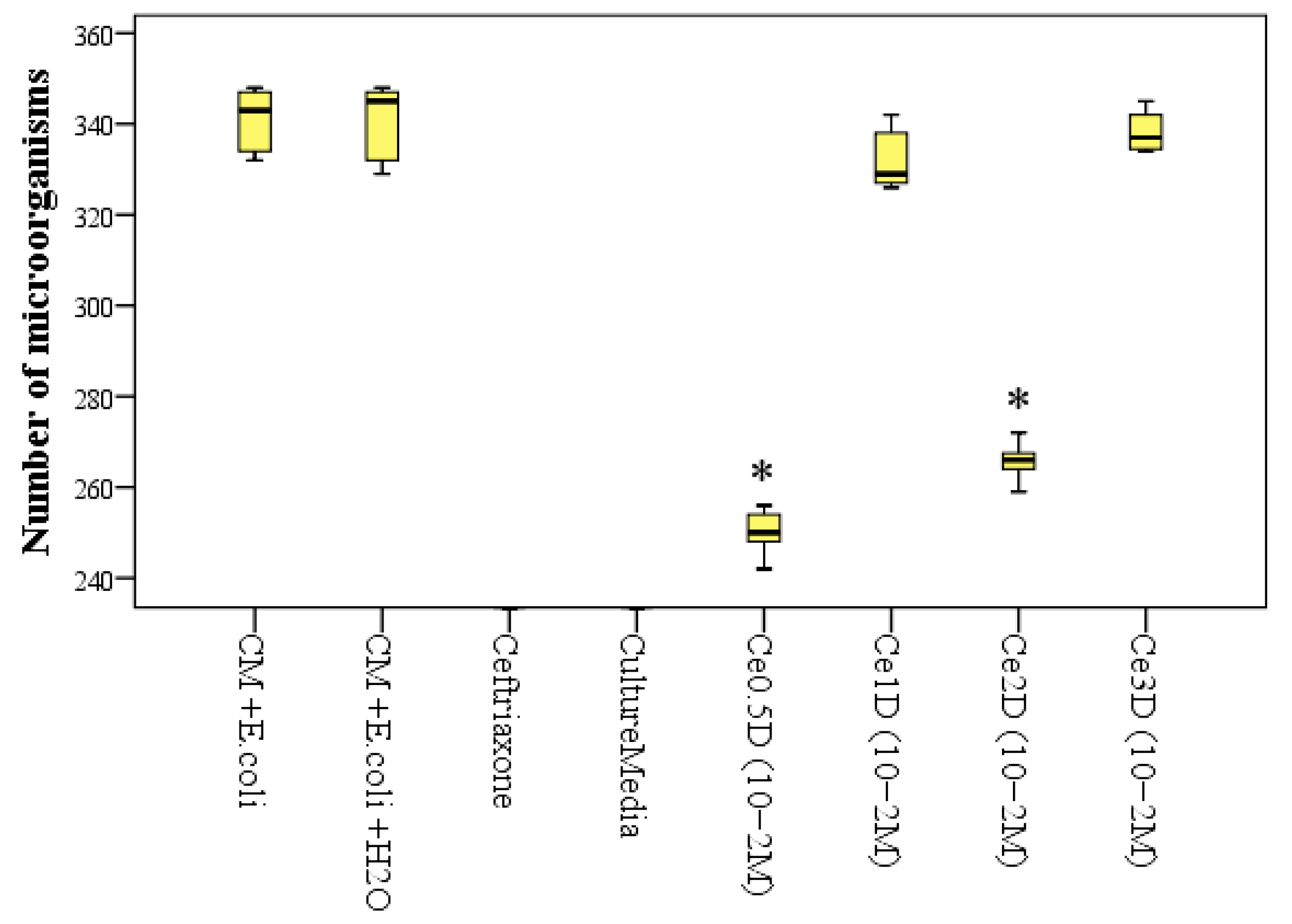

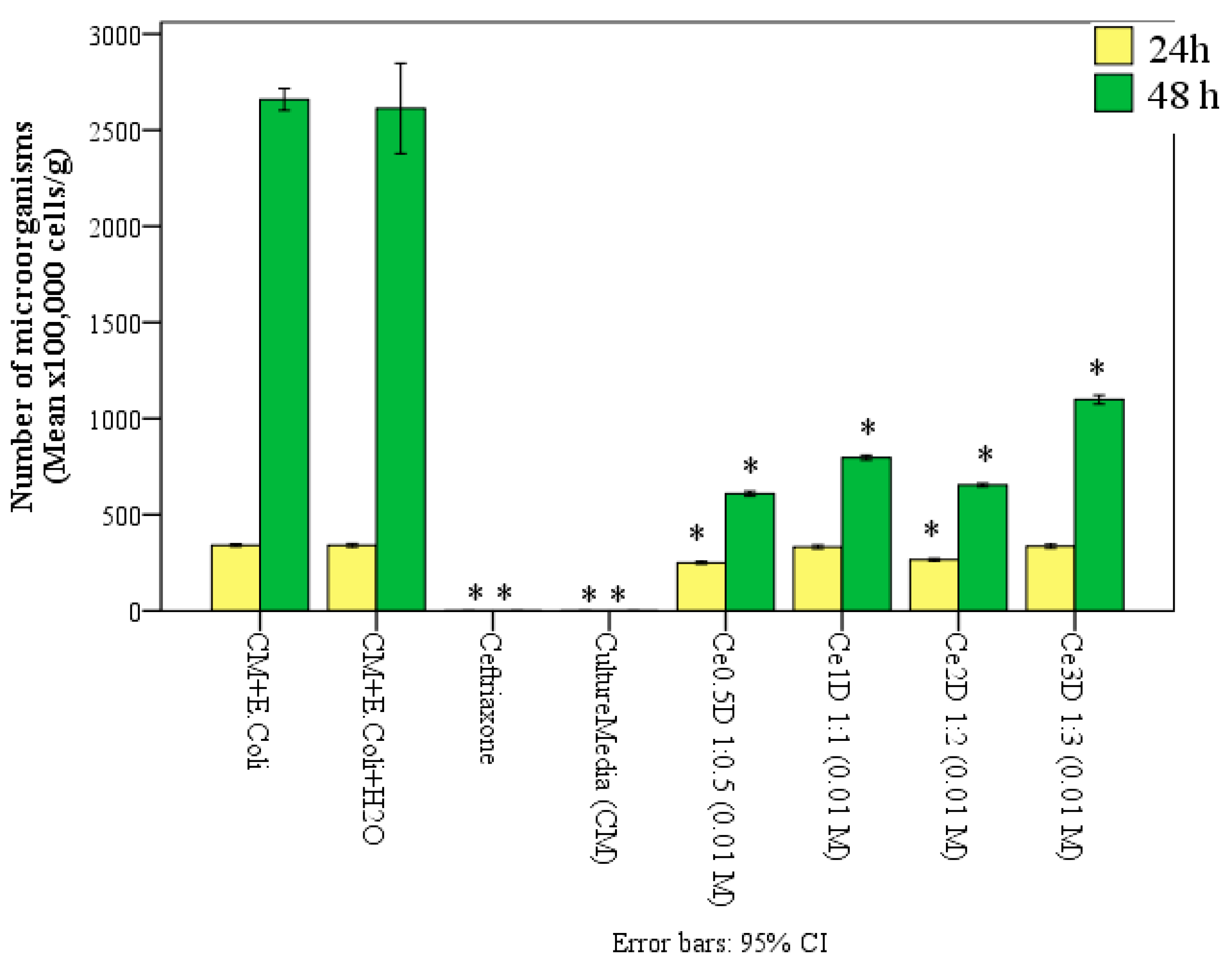

2.3. Antimicrobial Activity of Nanocomposites

3. Materials and Methods

3.1. Synthesis of Nanocomposites Using Dextran and Cerium Nitrate in Different Ratios

3.2. Studied Samples and Comparison Groups

3.3. Methods of Evaluation of Physicochemical Properties of Nanocomposites

3.4. Methods of Evaluation of the Effect of Cerium–Dextran Sols on Cytotoxicity, Metabolic and Proliferative Activity of Human Fibroblast Cell Culture

3.4.1. Cell Culturing

3.4.2. MTT Test

3.4.3. Determination of Fibroblast Proliferative Activity and Assessment of Cytotoxicity by Cell Counting and Assessment of Plasma Membrane Integrity by Trypan Blue Staining

3.5. Determination of Antimicrobial Activity of Cerium–Dextran Nanocomposites by Mass Spectrometry of Microbial Markers Using Gas Chromatograph with Mass-Selective Detector

3.6. Statistical Analysis

4. Discussion

5. Conclusions

- The synthesis of sols of nanocomposites—nanocrystalline cerium dioxide less than 5nm in size, coated with polysaccharide dextran, differing in the initial ratio (by mass) of cerium nitrate to dextran, which is reflected in the physicochemical characteristics and final biological properties—was carried out.

- As the content of dextran in the nanocomposite increases, the particle size of cerium dioxide decreases and the hydrodynamic radius increases.

- A high level of safety of nanocomposites was proved, while the absence of cytotoxicity (100% cell survival at the maximum tested concentration) was established for Ce2D and Ce3D.

- Metabolic and proliferative activity of fibroblasts increases as the dextran content increases (and as the size of cerium oxide crystals, the core of nanocomposites, decreases). The lowest level of fibroblast activity was recorded for Ce0.5D and the highest for Ce2D. In all types of nanocomposites, the most effective stimulation of human fibroblasts proliferation was registered at the concentration of 10−3 M, with a clear advantage of Ce2D composite, with which the number of fibroblasts was 2.5 times higher than in the control (at 10−3 M Ce0.5D—1.4 times, Ce1D—1.5 times, Ce3D—2.0 times relative to the control).

- The best antimicrobial activity of nanocomposites at a concentration of 10−2 M (bacteriostatic action) was found in Ce0.5D and Ce2D, inhibiting the growth and multiplication of E. coli after 24 h by an average of 22–27%, and after 48 h, all variants of nanocomposites significantly inhibit the growth and multiplication of E. coli by 58–77%, which is most (and equally) expressed in Ce0.5D, Ce1D, and Ce2D, at which E. coli multiplication was inhibited equally by an average of three-fold compared to the control groups. After 48 h, all concentrations of Se2D composite showed bacteriostatic activity, inhibiting E. coli multiplication by 47–80%, and a dose-dependent effect was determined: the higher the concentration of nano-ceria, the higher the antimicrobial activity.

- The complex of interdisciplinary studies allowed us to select for further development the Ce2D composite at a concentration of 10−3 M, characterized by the balance of simultaneous stimulation of cells with the most predictable dose-dependent effect, including stimulating cell proliferation and metabolism up to 2.5 times and allowing a reduction in the rate of microorganism multiplication by 4 times.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roussas, A.; Masjedi, A.; Hanna, K.; Zeeshan, M.; Kulvatunyou, N.; Gries, L.; Tang, A.; Joseph, B. Number and Type of Complications Associated with Failure to Rescue in Trauma Patients. J. Surg. Res. 2020, 254, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Boodhoo, K.; Vlok, M.; Tabb, D.L.; Myburgh, K.H.; van de Vyver, M. Dysregulated healing responses in diabetic wounds occur in the early stages postinjury. J. Mol. Endocrinol. 2021, 66, 141–155. [Google Scholar] [CrossRef] [PubMed]

- Roberts, Z.; Collins, J.A.; James, D.; Bouamra, O.; Young, M.; Lyttle, M.D.; Roland, D.; Mullen, S.; on behalf of PERUKI. Epidemiology of adolescent trauma in England: A review of TARN data 2008–2017. Emerg. Med. J. 2020, 37, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Voth, M.; Sommer, K.; Schindler, C.; Frank, J.; Marzi, I. Rise of extremity fractures and sport accidents in children at 8-12 years and increase of admittance via the resuscitation room over a decade. Eur. J. Trauma. Emerg. Surg. 2022, 48, 3439–3448. [Google Scholar] [CrossRef] [PubMed]

- Spitzer, S.A.; Vail, D.G.; Heindel, P.; Dey, T.; Cooper, Z.; Salim, A.; Jarman, M.P. Gentrification as a Factor in the Incidence of Firearm Injuries. JAMA Surg. 2023, 158, 1152–1158. [Google Scholar] [CrossRef] [PubMed]

- Nyberger, K.; Caragounis, E.C.; Djerf, P.; Wahlgren, C.M. Epidemiology of firearm injuries in Sweden. Eur. J. Trauma. Emerg. Surg. 2022, 48, 2349–2357. [Google Scholar] [CrossRef] [PubMed]

- Feinglass, J.; Patel, T.R.; Rydland, K.; Sheehan, K. Trends in Hospital Care for Intentional Assault Gunshot Wounds Among Residents of Cook County, Illinois, 2018–2020. Am. J. Public Health 2022, 112, 795–802. [Google Scholar] [CrossRef] [PubMed]

- Huemer, M.; Mairpady Shambat, S.; Brugger, S.D.; Zinkernagel, A.S. Antibiotic resistance and persistence-Implications for human health and treatment perspectives. EMBO Rep. 2020, 21, e51034. [Google Scholar] [CrossRef]

- Eisenreich, W.; Rudel, T.; Heesemann, J.; Goebel, W. Link Between Antibiotic Persistence and Antibiotic Resistance in Bacterial Pathogens. Front. Cell. Infect. Microbiol. 2022, 12, 900848. [Google Scholar] [CrossRef]

- Rather, M.A.; Gupta, K.; Mandal, M. Microbial biofilm: Formation, architecture, antibiotic resistance, and control strategies. Braz. J. Microbiol. 2021, 52, 1701–1718. [Google Scholar] [CrossRef]

- Wencewicz, T.A. Crossroads of Antibiotic Resistance and Biosynthesis. J. Mol. Biol. 2019, 431, 3370–3399. [Google Scholar] [CrossRef]

- Baquero, F. Threats of antibiotic resistance: An obliged reappraisal. Int. Microbiol. 2021, 24, 499–506. [Google Scholar] [CrossRef] [PubMed]

- Abdelrazik, E.; El-Hadidi, M. Tracking Antibiotic Resistance from the Environment to Human Health. Methods Mol. Biol. 2023, 2649, 289–301. [Google Scholar] [CrossRef] [PubMed]

- Bombaywala, S.; Mandpe, A.; Paliya, S.; Kumar, S. Antibiotic resistance in the environment: A critical insight on its occurrence, fate, and eco-toxicity. Environ. Sci. Pollut. Res. 2021, 28, 24889–24916. [Google Scholar] [CrossRef]

- Arabpour, Z.; Abedi, F.; Salehi, M.; Baharnoori, S.M.; Soleimani, M.; Djalilian, A.R. Hydrogel-Based Skin Regeneration. Int. J. Mol. Sci. 2024, 25, 1982. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, C.; Wang, B.; Yin, J.; Yan, S. Progress in Hydrogels for Skin Wound Repair. Macromol. Biosci. 2022, 22, e2100475. [Google Scholar] [CrossRef]

- Kolimi, P.; Narala, S.; Nyavanandi, D.; Youssef, A.A.A.; Dudhipala, N. Innovative Treatment Strategies to Accelerate Wound Healing: Trajectory and Recent Advancements. Cells 2022, 11, 2439. [Google Scholar] [CrossRef]

- Kim, H.S.; Sun, X.; Lee, J.H.; Kim, H.W.; Fu, X.; Leong, K.W. Advanced drug delivery systems and artificial skin grafts for skin wound healing. Adv. Drug Deliv. Rev. 2019, 146, 209–239. [Google Scholar] [CrossRef] [PubMed]

- Guillamat-Prats, R. The Role of MSC in Wound Healing, Scarring and Regeneration. Cells 2021, 10, 1729. [Google Scholar] [CrossRef]

- Mazini, L.; Rochette, L.; Admou, B.; Amal, S.; Malka, G. Hopes and Limits of Adipose-Derived Stem Cells (ADSCs) and Mesenchymal Stem Cells (MSCs) in Wound Healing. Int. J. Mol. Sci. 2020, 21, 1306. [Google Scholar] [CrossRef]

- Ding, J.Y.; Chen, M.J.; Wu, L.F.; Shu, G.F.; Fang, S.J.; Li, Z.Y.; Chu, X.R.; Li, X.K.; Wang, Z.G.; Ji, J.S. Mesenchymal stem cell-derived extracellular vesicles in skin wound healing: Roles, opportunities and challenges. Mil. Med. Res. 2023, 10, 36. [Google Scholar] [CrossRef] [PubMed]

- Díaz-García, D.; Filipová, A.; Garza-Veloz, I.; Martinez-Fierro, M.L. A Beginner’s Introduction to Skin Stem Cells and Wound Healing. Int. J. Mol. Sci. 2021, 22, 11030. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Lu, K.J.; Yu, C.H.; Huang, Q.L.; Du, Y.Z. Nano-drug delivery systems in wound treatment and skin regeneration. J. Nanobiotechnology 2019, 17, 82. [Google Scholar] [CrossRef] [PubMed]

- Bellu, E.; Medici, S.; Coradduzza, D.; Cruciani, S.; Amler, E.; Maioli, M. Nanomaterials in Skin Regeneration and Rejuvenation. Int. J. Mol. Sci. 2021, 22, 7095. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Yu, Z.; Hu, K.; Wang, D.; Zhou, T.; Rao, W. Rigid metal/liquid metal nanoparticles: Synthesis and application for locally ablative therapy. Nanomedicine 2022, 42, 102535. [Google Scholar] [CrossRef] [PubMed]

- Kuchur, O.A.; Tsymbal, S.A.; Shestovskaya, M.V.; Serov, N.S.; Dukhinova, M.S.; Shtil, A.A. Metal-derived nanoparticles in tumor theranostics: Potential and limitations. J. Inorg. Biochem. 2020, 209, 111117. [Google Scholar] [CrossRef] [PubMed]

- Pavelić, K.; Kraljević Pavelić, S.; Bulog, A.; Agaj, A.; Rojnić, B.; Čolić, M.; Trivanović, D. Nanoparticles in Medicine: Current Status in Cancer Treatment. Int. J. Mol. Sci. 2023, 24, 12827. [Google Scholar] [CrossRef] [PubMed]

- Scafa Udriște, A.; Burdușel, A.C.; Niculescu, A.G.; Rădulescu, M.; Grumezescu, A.M. Metal-Based Nanoparticles for Cardiovascular Diseases. Int. J. Mol. Sci. 2024, 25, 1001. [Google Scholar] [CrossRef] [PubMed]

- Vodyanoy, V. The Role of Endogenous Metal Nanoparticles in Biological Systems. Biomolecules 2021, 11, 1574. [Google Scholar] [CrossRef]

- Fernandes, D.A. Review on Metal-Based Theranostic Nanoparticles for Cancer Therapy and Imaging. Technol. Cancer Res. Treat. 2023, 22, 15330338231191493. [Google Scholar] [CrossRef]

- Mortezaee, K.; Najafi, M.; Samadian, H.; Barabadi, H.; Azarnezhad, A.; Ahmadi, A. Redox interactions and genotoxicity of metal-based nanoparticles: A comprehensive review. Chem. Biol. Interact. 2019, 312, 108814. [Google Scholar] [CrossRef] [PubMed]

- Barker, E.; Shepherd, J.; Asencio, I.O. The Use of Cerium Compounds as Antimicrobials for Biomedical Applications. Molecules 2022, 27, 2678. [Google Scholar] [CrossRef] [PubMed]

- Manturova, N.E.; Stupin, V.A.; Silina, E.V. Cerium oxide nanoparticles for surgery, plastic surgery and aesthetic medicine. Plast. Surg. Aesthetic Med. 2023, 3, 120–129. [Google Scholar] [CrossRef]

- Pugachevskii, M.A.; Rasseko, D.S.; Stupin, V.A.; Manturova, N.E.; Artyushkova, E.B.; Silina, E.V. Effect of CeO2 nanoparticles on hydroxyl radicals in EPR studies of the photodegradation of methylene blue under influence of red light. J. Mol. Liq. 2024, 404, 124946. [Google Scholar] [CrossRef]

- Silina, E.V.; Ivanova, O.S.; Manturova, N.E.; Medvedeva, O.A.; Shevchenko, A.V.; Vorsina, E.S.; Achar, R.R.; Parfenov, V.A.; Stupin, V.A. Antimicrobial Activity of Citrate-Coated Cerium Oxide Nanoparticles. Nanomaterials 2024, 14, 354. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Kang, X.; Ma, Q.; Xu, Z.; Sun, H.; Hao, D.; Chen, X. Novel Approach for Efficient Recovery for Spinal Cord Injury Repair via Biofabricated Nano-Cerium Oxide Loaded PCL with Resveratrol to Improve in Vitro Biocompatibility and Autorecovery Abilities. Dose Response 2020, 18, 1559325820933518. [Google Scholar] [CrossRef] [PubMed]

- Ye, Q.; Jia, D.; Ji, J.; Liu, Y.; Wu, G. Effects of nano-cerium dioxide on intestinal microflora in rats by oral subchronic exposure. PLoS ONE 2024, 19, e0298917. [Google Scholar] [CrossRef]

- Thakur, N.; Manna, P.; Das, J. Synthesis and biomedical applications of nanoceria, a redox active nanoparticle. J. Nanobiotechnol. 2019, 17, 84. [Google Scholar] [CrossRef] [PubMed]

- Silina, E.V.; Stupin, V.A.; Manturova, N.E.; Ivanova, O.S.; Popov, A.L.; Mysina, E.A.; Artyushkova, E.B.; Kryukov, A.A.; Dodonova, S.A.; Kruglova, M.P.; et al. Influence of the Synthesis Scheme of Nanocrystalline Cerium Oxide and Its Concentration on the Biological Activity of Cells Providing Wound Regeneration. Int. J. Mol. Sci. 2023, 24, 14501. [Google Scholar] [CrossRef]

- Römer, I.; Briffa, S.M.; Arroyo Rojas Dasilva, Y.; Hapiuk, D.; Trouillet, V.; Palmer, R.E.; Valsami-Jones, E. Impact of particle size, oxidation state and capping agent of different cerium dioxide nanoparticles on the phosphate-induced transformations at different pH and concentration. PLoS ONE 2019, 14, e0217483. [Google Scholar] [CrossRef]

- Silina, E.V.; Manturova, N.E.; Erokhina, A.G.; Shatokhina, E.A.; Stupin, V.A. Nanomaterials based on cerium oxide nanoparticles for wound regeneration: A literature review. Russ. J. Transplantology Artif. Organs 2024, 26, 113–124. [Google Scholar] [CrossRef]

- Wu, Y.; Ta, H.T. Different approaches to synthesising cerium oxide nanoparticles and their corresponding physical characteristics, and ROS scavenging and anti-inflammatory capabilities. J. Mater. Chem. B 2021, 9, 7291–7301. [Google Scholar] [CrossRef] [PubMed]

- Shlapa, Y.; Solopan, S.; Sarnatskaya, V.; Siposova, K.; Garcarova, I.; Veltruska, K.; Timashkov, I.; Lykhova, O.; Kolesnik, D.; Musatov, A.; et al. Cerium dioxide nanoparticles synthesized via precipitation at constant pH: Synthesis, physical-chemical and antioxidant properties. Colloids Surf. B Biointerfaces 2022, 220, 112960. [Google Scholar] [CrossRef] [PubMed]

- Solano, R.; Patiño-Ruiz, D.; Tejeda-Benitez, L.; Herrera, A. Metal- and metal/oxide-based engineered nanoparticles and nanostructures: A review on the applications, nanotoxicological effects, and risk control strategies. Environ. Sci. Pollut. Res. 2021, 28, 16962–16981. [Google Scholar] [CrossRef] [PubMed]

- Gimenez-Ingalaturre, A.C.; Rubio, E.; Chueca, P.; Laborda, F.; Goñi, P. Contribution to optimization and standardization of antibacterial assays with silver nanoparticles: The culture medium and their aggregation. J. Microbiol. Methods 2022, 203, 106618. [Google Scholar] [CrossRef] [PubMed]

- Lavagna, E.; Bochicchio, D.; De Marco, A.L.; Güven, Z.P.; Stellacci, F.; Rossi, G. Ion-bridges and lipids drive aggregation of same-charge nanoparticles on lipid membranes. Nanoscale 2022, 14, 6912–6921. [Google Scholar] [CrossRef] [PubMed]

- Mao, Q.; Fang, J.; Wang, A.; Zhang, Y.; Cui, C.; Ye, S.; Zhao, Y.; Feng, Y.; Li, J.; Shi, H. Aggregation of Gold Nanoparticles Triggered by Hydrogen Peroxide-Initiated Chemiluminescence for Activated Tumor Theranostics. Angew. Chem. Int. Ed. Engl. 2021, 60, 23805–23811. [Google Scholar] [CrossRef] [PubMed]

- Cervantes-Avilés, P.; Huang, X.; Keller, A.A. Dissolution and Aggregation of Metal Oxide Nanoparticles in Root Exudates and Soil Leachate: Implications for Nanoagrochemical Application. Environ. Sci. Technol. 2021, 55, 13443–13451. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, P.; Wang, C.; Ao, Y. Effects of interactions between humic acid and heavy metal ions on the aggregation of TiO2 nanoparticles in water environment. Environ. Pollut. 2019, 248, 834–844. [Google Scholar] [CrossRef]

- Azadpour, B.; Kashanian, F.; Habibi-Rezaei, M.; Seyyed Ebrahimi, S.A.; Yazdanpanah, R.; Lalegani, Z.; Hamawandi, B. Covalently-Bonded Coating of L-Arginine Modified Magnetic Nanoparticles with Dextran Using Co-Precipitation Method. Materials 2022, 15, 8762. [Google Scholar] [CrossRef]

- Turrina, C.; Milani, D.; Klassen, A.; Rojas-González, D.M.; Cookman, J.; Opel, M.; Sartori, B.; Mela, P.; Berensmeier, S.; Schwaminger, S.P. Carboxymethyl-Dextran-Coated Superparamagnetic Iron Oxide Nanoparticles for Drug Delivery: Influence of the Coating Thickness on the Particle Properties. Int. J. Mol. Sci. 2022, 23, 14743. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Li, H.; Zhu, J.; Liu, C.; Sun, X.; Wang, D.; Xu, Y. Fabrication and characterization of zein nanoparticles by dextran sulfate coating as vehicles for delivery of curcumin. Int. J. Biol. Macromol. 2020, 151, 1074–1083. [Google Scholar] [CrossRef] [PubMed]

- Chircov, C.; Ștefan, R.E.; Dolete, G.; Andrei, A.; Holban, A.M.; Oprea, O.C.; Vasile, B.S.; Neacșu, I.A.; Tihăuan, B. Dextran-Coated Iron Oxide Nanoparticles Loaded with Curcumin for Antimicrobial Therapies. Pharmaceutics 2022, 14, 1057. [Google Scholar] [CrossRef] [PubMed]

- Predoi, G.; Ciobanu, C.S.; Iconaru, S.L.; Predoi, D.; Dreghici, D.B.; Groza, A.; Barbuceanu, F.; Cimpeanu, C.; Badea, M.L.; Barbuceanu, S.F.; et al. Preparation and Characterization of Dextran Coated Iron Oxide Nanoparticles Thin Layers. Polymers 2021, 13, 2351. [Google Scholar] [CrossRef] [PubMed]

- Ramasundaram, S.; Saravanakumar, G.; Sobha, S.; Oh, T.H. Dextran Sulfate Nanocarriers: Design, Strategies and Biomedical Applications. Int. J. Mol. Sci. 2022, 24, 355. [Google Scholar] [CrossRef] [PubMed]

- Alpaslan, E.; Yazici, H.; Golshan, N.H.; Ziemer, K.S.; Webster, T.J. pH-Dependent Activity of Dextran-Coated Cerium Oxide Nanoparticles on Prohibiting Osteosarcoma Cell Proliferation. ACS Biomater. Sci. Eng. 2015, 1, 1096–1103. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Chamoli, S.; Kumar, P.; Maurya, P.K. Structural and functional insights in polysaccharides coated cerium oxide nanoparticles and their potential biomedical applications: A review. Int. J. Biol. Macromol. 2023, 246, 125673. [Google Scholar] [CrossRef] [PubMed]

- Strober, W. Trypan Blue Exclusion Test of Cell Viability. Curr. Protoc. Immunol. 2015, 111, A3.B.1–A3.B.3. [Google Scholar] [CrossRef] [PubMed]

- Nadeem, M.; Khan, R.; Afridi, K.; Nadhman, A.; Ullah, S.; Faisal, S.; Mabood, Z.U.; Hano, C.; Abbasi, B.H. Green Synthesis of Cerium Oxide Nanoparticles and Their Antimicrobial Applications: A Review. Int. J. Nanomed. 2020, 15, 5951–5961. [Google Scholar] [CrossRef]

- Devi, N.S.; Ganapathy, D.M.; Rajeshkumar, S.; Maiti, S. Characterization and antimicrobial activity of cerium oxide nanoparticles synthesized using neem and ginger. J. Adv. Pharm. Technol. Res. 2022, 13 (Suppl. S2), 491–495. [Google Scholar] [CrossRef]

- Salas Orozco, M.F.; Niño-Martínez, N.; Martínez-Castañón, G.A.; Méndez, F.T.; Ruiz, F. Molecular Mechanisms of Bacterial Resistance to Metal and Metal Oxide Nanoparticles. Int. J. Mol. Sci. 2019, 20, 2808. [Google Scholar] [CrossRef] [PubMed]

- Franco, D.; Calabrese, G.; Guglielmino, S.P.P.; Conoci, S. Metal Based Nanoparticles: Antibacterial Mechanisms and Biomedical Application. Microorganisms 2022, 10, 1778. [Google Scholar] [CrossRef]

- Rodríguez-Barajas, N.; de Jesús Martín-Camacho, U.; Pérez-Larios, A. Mechanisms of Metallic Nanomaterials to Induce an Antibacterial Effect. Curr. Top. Med. Chem. 2022, 22, 2506–2526. [Google Scholar] [CrossRef]

- Dewberry, L.C.; Niemiec, S.M.; Hilton, S.A.; Louiselle, A.E.; Singh, S.; Sakthivel, T.S.; Hu, J.; Seal, S.; Liechty, K.W.; Zgheib, C. Cerium oxide nanoparticle conjugation to microRNA146a mechanism of correction for impaired diabetic wound healing. Nanomedicine 2022, 40, 102483. [Google Scholar] [CrossRef]

- Sajjad, H.; Sajjad, A.; Haya, R.T.; Khan, M.M.; Zia, M. Copper oxide nanoparticles: In vitro and in vivo toxicity, mechanisms of action and factors influencing their toxicology. Comp. Biochem. Physiol. C Toxicol. Pharmacol. 2023, 271, 109682. [Google Scholar] [CrossRef] [PubMed]

- Bellio, P.; Luzi, C.; Mancini, A.; Cracchiolo, S.; Passacantando, M.; Di Pietro, L.; Perilli, M.; Amicosante, G.; Santucci, S.; Celenza, G. Cerium oxide nanoparticles as potential antibiotic adjuvant. Effects of CeO2 nanoparticles on bacterial outer membrane permeability. Biochim. Biophys. Acta Biomembr. 2018, 1860, 2428–2435. [Google Scholar] [CrossRef]

- Lin, Y.E.; Chen, M.C. Dextran-40 Reduces Partial Flap Failure: A Systematic Review and Meta-analysis for Antithrombotics after Free Flaps. Plast. Reconstr. Surg. Glob. Open 2024, 12, e5812. [Google Scholar] [CrossRef] [PubMed]

- Safiejko, K.; Smereka, J.; Pruc, M.; Ladny, J.R.; Jaguszewski, M.J.; Filipiak, K.J.; Yakubtsevich, R.; Szarpak, L. Efficacy and safety of hypertonic saline solutions fluid resuscitation on hypovolemic shock: A systematic review and meta-analysis of randomized controlled trials. Cardiol. J. 2022, 29, 966–977. [Google Scholar] [CrossRef]

- Biermann, N.; Chak, J.C.; Wiesmeier, A.; Klein, S.M.; Ruewe, M.; Spoerl, S.; Kruppa, P.; Prantl, L.; Anker, A.M. Evidence-Based Approaches to Anticoagulation in Reconstructive Microsurgery—A Systematic Literature Review. Life 2024, 14, 82. [Google Scholar] [CrossRef]

| Groups | Culture Media | Microorganisms | Test Substance | Total Volume | |

|---|---|---|---|---|---|

| Study groups | Ce0.5De | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL of Ce0.5D (10−2 M) sol | 5.0 mL |

| Ce1D | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL of Ce1D (10−2 M) sol | 5.0 mL | |

| Ce2D | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL of Ce2D (10−2 M) sol | 5.0 mL | |

| Ce3D | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL of Ce3D (10−2 M) sol | 5.0 mL | |

| Control groups | CM + E. coli | 4.5 mL | 0.5 mL of E. coli suspension | – | 5.0 mL |

| CM + E. coli + H2O | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL H2O | 5.0 mL | |

| Comparison groups | CM | 5.0 mL | – | – | 5.0 mL |

| Ceftriaxone | 4.0 mL | 0.5 mL of E. coli suspension | 0.5 mL solution | 5.0 mL |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silina, E.V.; Manturova, N.E.; Ivanova, O.S.; Baranchikov, A.E.; Artyushkova, E.B.; Medvedeva, O.A.; Kryukov, A.A.; Dodonova, S.A.; Gladchenko, M.P.; Vorsina, E.S.; et al. Cerium Dioxide–Dextran Nanocomposites in the Development of a Medical Product for Wound Healing: Physical, Chemical and Biomedical Characteristics. Molecules 2024, 29, 2853. https://doi.org/10.3390/molecules29122853

Silina EV, Manturova NE, Ivanova OS, Baranchikov AE, Artyushkova EB, Medvedeva OA, Kryukov AA, Dodonova SA, Gladchenko MP, Vorsina ES, et al. Cerium Dioxide–Dextran Nanocomposites in the Development of a Medical Product for Wound Healing: Physical, Chemical and Biomedical Characteristics. Molecules. 2024; 29(12):2853. https://doi.org/10.3390/molecules29122853

Chicago/Turabian StyleSilina, Ekaterina V., Natalia E. Manturova, Olga S. Ivanova, Alexander E. Baranchikov, Elena B. Artyushkova, Olga A. Medvedeva, Alexey A. Kryukov, Svetlana A. Dodonova, Mikhail P. Gladchenko, Ekaterina S. Vorsina, and et al. 2024. "Cerium Dioxide–Dextran Nanocomposites in the Development of a Medical Product for Wound Healing: Physical, Chemical and Biomedical Characteristics" Molecules 29, no. 12: 2853. https://doi.org/10.3390/molecules29122853

APA StyleSilina, E. V., Manturova, N. E., Ivanova, O. S., Baranchikov, A. E., Artyushkova, E. B., Medvedeva, O. A., Kryukov, A. A., Dodonova, S. A., Gladchenko, M. P., Vorsina, E. S., Kruglova, M. P., Kalyuzhin, O. V., Suzdaltseva, Y. G., & Stupin, V. A. (2024). Cerium Dioxide–Dextran Nanocomposites in the Development of a Medical Product for Wound Healing: Physical, Chemical and Biomedical Characteristics. Molecules, 29(12), 2853. https://doi.org/10.3390/molecules29122853