Study on the Effect of Magnesium Chloride-Modified Straw Waste Biochar on Acidic Soil Properties

Abstract

1. Introduction

2. Results

2.1. Modified Biochar Yield, pH, Ash Content

2.2. Effect on Soil pH

2.3. Effect on Soil Available Potassium Content

2.4. Effect on Soil Available Phosphorus Content

2.5. Effect on Soil Alkali-Hydrolyzed Nitrogen Content

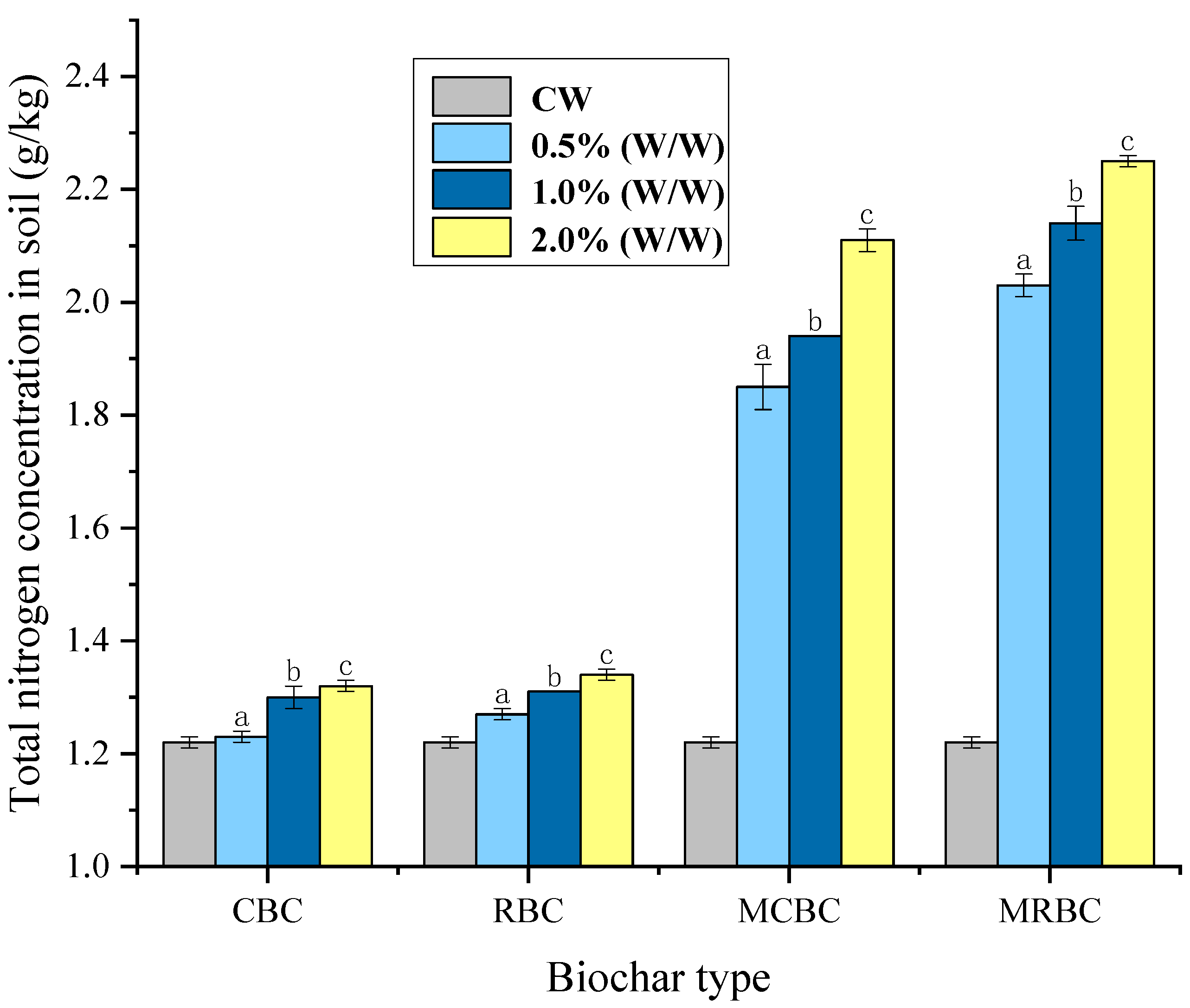

2.6. Effect on Total Nitrogen and Total Phosphorus Contents in Soil

2.6.1. Soil Total Phosphorus

2.6.2. Soil Total Nitrogen

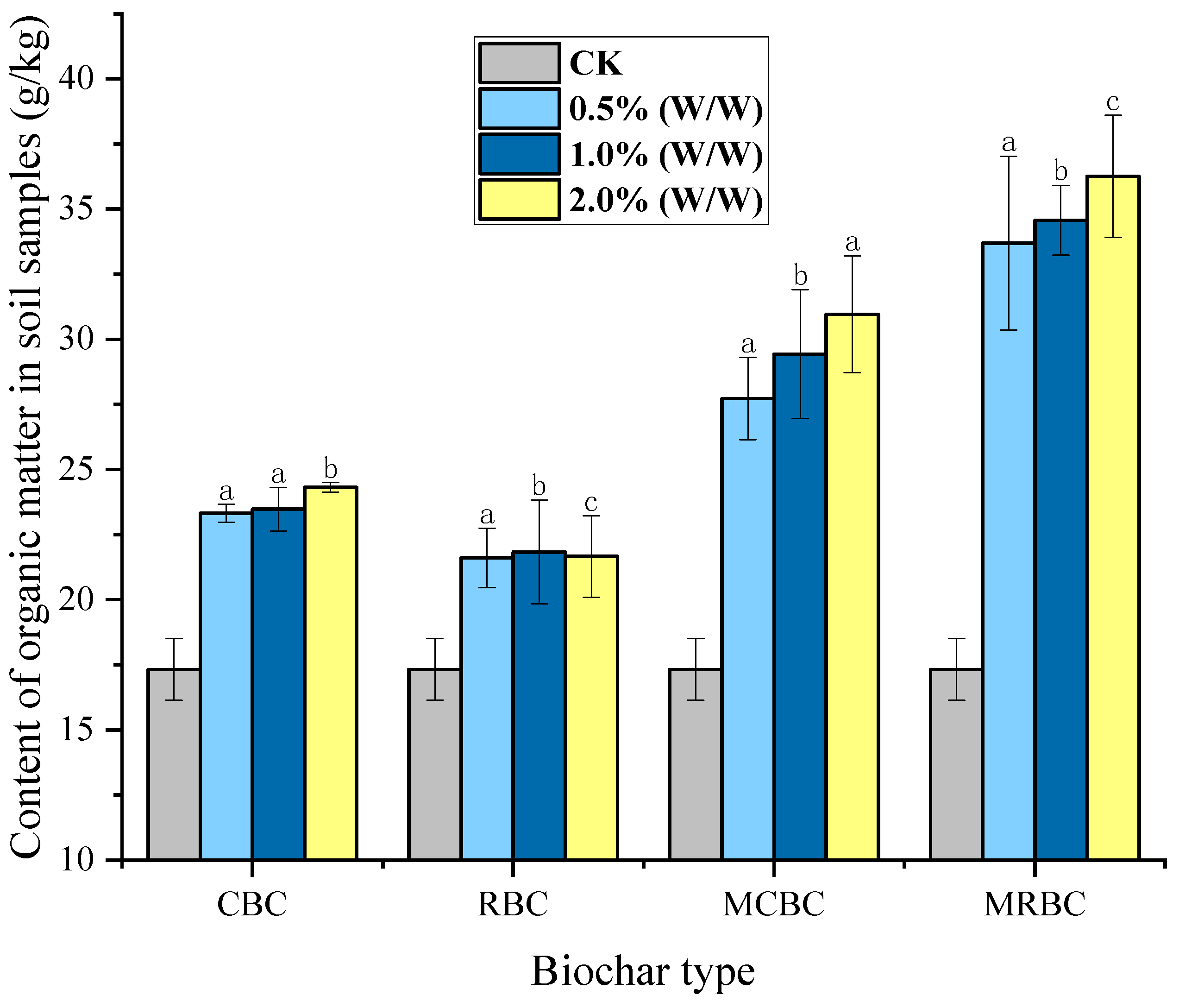

2.7. Effect on Soil Organic Matter Content

3. Discussion

4. Materials and Methods

4.1. Preparation of Modified Biochar

4.2. Determination of Biochar Properties

4.2.1. Yield

4.2.2. Ash Content

4.2.3. pH

4.3. Laboratory-Simulated Soil Culture Experiment

4.3.1. Soil Sampling

4.3.2. Laboratory-Simulated Soil Experiment

4.4. Methods for Determining Soil Properties

4.4.1. Soil pH

4.4.2. Soil Available Potassium

4.4.3. Soil Available Phosphorus

4.4.4. Soil Nitrate Nitrogen

4.4.5. Soil Ammonium Nitrogen

4.4.6. Soil Total Nitrogen

4.4.7. Soil Total Phosphorus

4.4.8. Soil Organic Matter

4.5. Data Processing Method

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bolan, S.; Sharma, S.; Mukherjee, S.; Kumar, M.; Rao, C.S.; Nataraj, K.C.; Bolan, N. Biochar modulating soil biological health: A review. Sci. Total Environ. 2024, 914, 169585. [Google Scholar] [CrossRef]

- Wiesmeier, M.; Urbanski, L.; Hobley, E.; Lang, B.; von Lützow, M.; Marin-Spiotta, E.; Kögel-Knabner, I. Soil organic carbon storage as a key function of soils—A review of drivers and indicators at various scales. Geoderma 2019, 333, 149–162. [Google Scholar] [CrossRef]

- Lai, R. Digging deeper: A holistic perspective of factors affecting soil organic carbon sequestration in agroecosystems. Glob. Chang. Biol. 2018, 24, 3285–3301. [Google Scholar]

- Liu, Z.; Wang, D.; Ning, T.; Zhang, S.; Yang, Y.; He, Z.; Li, Z. Sustainability assessment of straw utilization circulation modes based on the energetic ecological footprint. Ecol. Indic. 2017, 75, 1–7. [Google Scholar] [CrossRef]

- Zuo, H.; Liu, Z. Thermal and structural analysis of the reaction mechanisms during the preparation of activated carbon from sugarcane bagasse by urea phosphate activation. Cellulose 2024, 31, 793–808. [Google Scholar] [CrossRef]

- Wei, S.; Qin, Q.; Liu, Z. Thermal behavior analysis and reaction mechanism in the preparation of activated carbon by ZnCl2 activation of bamboo fibers. J. Anal. Appl. Pyrol. 2024, 179, 106500. [Google Scholar] [CrossRef]

- Izaguirre, N.; Alberro, M.; Erdocia, X.; Labidi, J. Kraft and organosolv lignin-activated carbon composites for supercapaci-tor electrode materials. J. Energy Storage 2024, 80, 110386. [Google Scholar] [CrossRef]

- Xia, Y.; Zuo, H.; Lv, J.; Wei, S.; Yao, Y.; Liu, Z.; Lin, Q.; Yu, Y.; Yu, W.; Huang, Y. Preparation of multi-layered microcap-sule-shaped activated biomass carbon with ultrahigh surface area from bamboo parenchyma cells for energy storage and cation-ic dyes removal. J. Clean. Prod. 2023, 396, 136517. [Google Scholar] [CrossRef]

- Ullah, S.; Shah, S.S.A.; Altaf, M.; Hossain, I.; El Sayed, M.E.; Kallel, M.; El-Bahy, Z.M.; Rehman, A.; Najam, T.; Nazir, M.A. Activated carbon derived from biomass for wastewater treatment: Synthesis, application and future challenges. J. Anal. Appl. Pyrol. 2024, 179, 106480. [Google Scholar] [CrossRef]

- Wu, L.; Wei, C.; Zhang, S.; Wang, Y.; Kuzyakov, Y.; Ding, X. MgO-modified biochar increases phosphate retention and rice yields in saline-alkaline soil. J. Clean. Prod. 2019, 235, 901–909. [Google Scholar] [CrossRef]

- Bolan, N.; Hoang, S.A.; Beiyuan, J.; Gupta, S.; Hou, D.; Karakoti, A.; Van Zwieten, L. Multifunctional applications of biochar beyond carbon storage. Int. Mater. 2022, 67, 150–200. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Nguyen, T.B.; Chen, C.W.; Hung, C.M.; Chang, J.H.; Dong, C.D. Influence of pyrolysis tempera-ture on polycyclic aromatic hydrocarbons production and tetracycline adsorption behavior of biochar derived from spent coffee ground. Bioresour. Technol. 2019, 284, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Joseph, S.; Cowie, A.L.; Van Zwieten, L.; Bolan, N.; Budai, A.; Buss, W.; Lehmann, J. How biochar works, and when it doesn’t: A review of mechanisms con-trolling soil and plant responses to biochar. GCB Bioenergy 2021, 13, 1731–1764. [Google Scholar] [CrossRef]

- Hasan, Ö.Z. A new approach to soil solarization: Addition of biochar to the effect of soil temperature and quality and yield parameters of lettuce. Sci. Hortic. 2018, 228, 153–161. [Google Scholar]

- Li, S.; Tasnady, D. Biochar for Soil Carbon Sequestration: Current Knowledge, Mechanisms, and Future Perspectives. C 2023, 9, 67. [Google Scholar] [CrossRef]

- Nepal, J.; Ahmad, W.; Munsif, F.; Khan, A.; Zou, Z. Advances and prospects of biochar in improving soil fertility, bio-chemical quality, and environmental applications. Front. Environ. Sci. 2023, 11, 111475. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, D.; Qin, X.; He, P.; Fu, Y. Effect of Mg-Modified Waste Straw Biochar on the Chemical and Biological Properties of Acidic Soils. Molecules 2023, 28, 5225. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Meng, J.; Han, X.; Lan, Y.; Zhang, W. Past, present, and future of biochar. Biochar 2019, 1, 75–87. [Google Scholar] [CrossRef]

- Liu, L.; Fan, S. Removal of cadmium in aqueous solution using wheat straw biochar: Effect of minerals and mechanism. Environ. Sci. Pollut. 2018, 25, 8688–8700. [Google Scholar] [CrossRef]

- Jiao, Y.; Wang, T.; He, M.; Liu, X.; Lin, C.; Ouyang, W. Simultaneous stabilization of Sb and as co-contaminated soil by FeMg modified biochar. Sci. Total Environ. 2022, 830, 154831. [Google Scholar] [CrossRef]

- Shan, R.; Li, W.; Chen, Y.; Sun, X. Effects of Mg-modified biochar on the bioavailability of cadmium in soil. BioResources 2020, 15, 8008. [Google Scholar] [CrossRef]

- Angın, D.; Altintig, E.; Köse, T.E. Influence of process parameters on the surface and chemical properties of activated carbon obtained from biochar by chemical activation. Bioresour. Technol. 2013, 148, 542–549. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Lv, Q.; Xu, X.; Li, B.; Sun, M. Effect of Corn Stalk Biochar on the Evolution of Water Evaporation and Cracking of Soil. Geofluids 2022, 2022, 5703377. [Google Scholar] [CrossRef]

- Abhishek, K.; Shrivastava, A.; Vimal, V.; Gupta, A.K.; Bhujbal, S.K.; Biswas, J.K. Biochar application for greenhouse gas mitigation, contaminants immobilization and soil fertility enhancement: A state-of-the-art review. Sci. Total Environ. 2022, 853, 158562. [Google Scholar] [CrossRef] [PubMed]

- Ullah, S.; Liang, H.; Ali, I.; Zhao, Q.; Iqbal, A.; Wei, S.; Shah, T.; Yan, B.; Jiang, L. Biochar coupled with contrasting nitrogen sources mediated changes in carbon and nitrogen pools, microbial and enzymatic activity in paddy soil. J. Saudi Chem. Soc. 2020, 24, 835–849. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, P.; Liu, X.; Huang, X.; Wang, J.; Zhang, S.; Ji, J. Effect of crop straw biochars on the remediation of Cd-contaminated farmland soil by hyperaccumulator Bidens pilosa L. Ecotox. Environ. Saf. 2021, 219, 112332. [Google Scholar] [CrossRef] [PubMed]

- Gul, S.; Whalen, J.K.; Thomas, B.W.; Sachdeva, V.; Deng, H. Physico-chemical properties and microbial responses in bio-char-amended soils: Mechanisms and future directions. Agric. Ecosyst. Environ. 2015, 206, 46–59. [Google Scholar] [CrossRef]

- Li, F.; Liang, X.; Niyungeko, C.; Sun, T.; Liu, F.; Arai, Y. Effects of biochar amendments on soil phosphorus transformation in agricultural soils. Adv. Agron. 2019, 158, 131–172. [Google Scholar]

- Jin, Y.; Liang, X.; He, M.; Liu, Y.; Tian, G.; Shi, J. Manure biochar influence upon soil properties, phosphorus distribution and phosphatase activities: A microcosm incubation study. Chemosphere 2016, 142, 128–135. [Google Scholar] [CrossRef]

- Abagandura, G.O.; Bansal, S.; Karsteter, A.; Kumar, S. Soil greenhouse gas emissions, organic carbon and crop yield following pinewood biochar and biochar-manure applications at eroded and depositional landscape positions: A field trial in South Dakota, USA. Soil Use Manag. 2022, 38, 487–502. [Google Scholar] [CrossRef]

- Amin, A.E.E.A.Z. Comparative effects of different kinds of biochar on ammonia volatilization and chemical properties of saline soil. Arch. Agron. 2023, 69, 1600–1613. [Google Scholar] [CrossRef]

- Wu, M.; Wei, J.; Sun, H.; He, P.; Wu, B.; Gao, L. Improvement of acidic soil by plant materials and their biochar. Chin. J. Trop. Crops 2016, 37, 2276–2282. [Google Scholar]

- Fidel, R.B.; Laird, D.A.; Thompson, M.L.; Lawrinenko, M. Characterization and quantification of biochar alkalinity. Chemosphere 2017, 167, 367–373. [Google Scholar] [CrossRef]

- Shi, R.Y.; Li, J.Y.; Ni, N.; Xu, R.K. Understanding the biochar’s role in ameliorating soil acidity. J. Integr. Agric. 2019, 18, 1508–1517. [Google Scholar] [CrossRef]

- Qin, X.; Luo, J.; Liu, Z.; Fu, Y. Preparation and Characterization of MgO-Modified Rice Straw Biochars. Molecules 2020, 25, 5730. [Google Scholar] [CrossRef]

- Mia, S.; Van Groenigen, J.W.; Van de Voorde, T.F.J.; Oram, N.J.; Bezemer, T.M.; Mommer, L.; Jeffery, S. Biochar application rate affects biological nitrogen fixation in red clover conditional on potassium availability. Agric. Ecosyst. Environ. 2014, 191, 83–91. [Google Scholar] [CrossRef]

- Gao, Y.; Shen, H.; Yang, T.; He, N.; Ma, X. Effects of different biochar additions on soil water movement and simulation study. China Rural Water Hydropower 2021, 9, 134–140. [Google Scholar]

- Zhang, L.Y.; Xu, Y.M.; Gong, C.L.; Zeng, Q.; Qian, C. Zr-loaded NaOH activated pistachio shell biochar and its phosphorus removal and regeneration properties. Guangzhou Chem. Ind. 2021, 49, 65–70. [Google Scholar]

- Gupta, R.K.; Vashisht, M.; Naresh, R.K.; Dhingra, N.; Sidhu, M.; Singh, P.K.; Rani, N.; Al-Ansari, N.; Alataway, A.; Dewidar, A.; et al. Biochar influences nitrogen and phosphorus dynamics in two texturally different soils. Sci. Rep. 2024, 14, 6533. [Google Scholar] [CrossRef]

- Fowles, M. Black carbon sequestration as an alternative to bioenergy. Biomass Bioenerg. 2007, 31, 426–432. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Wu, W.; Zhong, Z.; Chen, Y. Environmental behavior and effects of soil biochar. Chin. J. Appl. Ecol. 2009, 20, 977–982. [Google Scholar]

- Yuan, J.H.; Xu, R.K.; Qian, W.; Wang, R.H. Comparison of the ameliorating effects on an acidic ultisol between four crop straws and their biochars. J. Soil Sediment. 2011, 11, 741–750. [Google Scholar] [CrossRef]

- Zuo, H.; Qin, X.; Liu, Z.; Fu, Y. Preparation and characterization of modified corn stalk biochar. BioResources 2021, 16, 7428. [Google Scholar] [CrossRef]

- Zhao, B.; O’Connor, D.; Zhang, J.; Peng, T.; Shen, Z.; Tsang, D.C.; Hou, D. Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 2018, 174, 977–987. [Google Scholar] [CrossRef]

- Wang, J.; Cao, M.; Jiang, C.; Zheng, Y.; Zhang, C. Adsorption and coadsorption mechanisms of Hg2+ and methyl orange by branched polyethyleneimine modified magnetic straw. Mater. Lett. 2018, 229, 160–163. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Tang, F.; Li, S.; Wang, Y.; Xu, Z. Effects of biochar addition on humification and ammonia emissions from sludge compost. STEJ China 2022, 22, 14057–14064. [Google Scholar]

- Zeng, A.; Liao, Y.; Zhang, J.; Sui, Y.; Wen, X. Effects of biochar on soil water content, organic carbon and available nutrient content in Lou soil. J. Agro Environ. Sci. China 2013, 32, 1009–1015. [Google Scholar]

- Ji-Lu, Z. Bio-oil from fast pyrolysis of rice husk: Yields and related properties and improvement of the pyrolysis system. J. Anal. Appl. Pyrol. 2007, 80, 30–35. [Google Scholar] [CrossRef]

- Liu, T.; Yun, F.; Jiang, W.; Liu, Y.; Wang, C.; Ma, Y.; Fu, Y. Carbon sequestration and emission reduction effects of biochar application in farmland and its influencing factors. J. Agric. Sci. 2021, 49, 7–13. [Google Scholar]

- Liu, Y.; Khan, M.J.; Jin, H.; Bai, X.; Xie, Y.; Zhao, X.; Wang, S.; Wang, C. Effects of straw biochar on crop yield and soil properties in tidal soil. Soil. J. China 2015, 52, 849–858. [Google Scholar]

- Yin, Q.; Wang, R.; Zhao, Z. Application of Mg-Al-modified biochar for simultaneous removal of ammonium, nitrate, and phosphate from eutrophic water. J. Clean. Prod. 2018, 176, 230–240. [Google Scholar] [CrossRef]

- Kavitha, B.; Reddy, P.V.L.; Kim, B.; Lee, S.S.; Pandey, S.K.; Kim, K.H. Benefits and limitations of biochar amendment in agricultural soils: A review. J. Environ. Manag. 2018, 227, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Du, Z.; Guo, W.; Zhang, Q. Effects of biochar application on soil bulk density, cation exchange capacity and par-ticulate matter content in farmland of North China Plain. J. Appl. Ecol. 2011, 22, 2930–2934. [Google Scholar]

- Wang, Y.; Hu, Y.; Zhao, X.; Wang, S.; Xing, G. Comparisons of Biochar Properties from Wood Material and Crop Residues at Different Temperatures and Residence Times. Energy Fuel 2013, 27, 5890–5899. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 2015, 176, 288–291. [Google Scholar] [CrossRef]

| Biochar Type | Yield % | pH | Ash Content |

|---|---|---|---|

| MCBC | 61.65 ± 1.45 | 8.55 ± 0.05 | 11.07 ± 0.04 |

| MRBC | 70.25 ± 0.35 | 10.1 ± 0.15 | 36.47 ± 0.18 |

| Serial Number | The Raw Material | Pyrolysis Temperature (°C) | Continuous Pyrolysis Room (h) | Impregnation Concentration of MgCl2 (mol/L) |

|---|---|---|---|---|

| RBC-300 | Rice straw | 300 | 1 | 0.5 |

| MRBC-500 | Rice straw | 500 | 1 | 0.5 |

| CBC-300 | Corn stover | 300 | 1 | 0.5 |

| MCBC-500 | Corn stover | 500 | 1 | 0.5 |

| pH | Available Potassium Content (mg/kg) | Available Phosphorus Content (mg/kg) | Alkali-Hydrolyzed Nitrogen Content (mg/kg) | Total Nitrogen Content (g/kg) | Total Phosphorus Content (g/kg) | Organic Matter Content (g/kg) |

|---|---|---|---|---|---|---|

| 3.43 ± 0.2 | 49.50 ± 1.5 | 3.35 ± 0.3 | 162.33 ± 3.0 | 1.22 ± 0.2 | 0.15 ± 0.0 | 35.89 ± 0.5 |

| Indicators | Processing Method (Type-Amount Added-Repeat) | Group | Indicators | Processing Method (Type-Amount Added-Repeat) | Group |

|---|---|---|---|---|---|

| 1 | CBC-0.5-1 | A1 | 21 | RBC-0.5-3 | C3 |

| 2 | CBC-0.5-2 | A2 | 22 | RBC-1-1 | C4 |

| 3 | CBC-0.5-3 | A3 | 23 | RBC-1-2 | C5 |

| 4 | CBC-1-1 | A4 | 24 | RBC-1-3 | C6 |

| 5 | CBC-1-2 | A5 | 25 | RBC-2-1 | C7 |

| 6 | CBC-1-3 | A6 | 26 | RBC-2-2 | C8 |

| 7 | CBC-2-1 | A7 | 27 | RBC-2-3 | C9 |

| 8 | CBC-2-2 | A8 | 28 | MRBC-0.5-1 | D1 |

| 9 | CBC-2-3 | A9 | 29 | MRBC-0.5-2 | D2 |

| 10 | MCBC-0.5-1 | B1 | 30 | MRBC-0.5-3 | D3 |

| 11 | MCBC-0.5-2 | B2 | 31 | MRBC-1-1 | D4 |

| 12 | MCBC-0.5-3 | B3 | 32 | MRBC-1-2 | D5 |

| 13 | MCBC-1-1 | B4 | 33 | MRBC-1-3 | D6 |

| 14 | MCBC-1-2 | B5 | 34 | MRBC-2-1 | D7 |

| 15 | MCBC-1-3 | B6 | 35 | MRBC-2-2 | D8 |

| 16 | MCBC-2-1 | B7 | 36 | MRBC-2-3 | D9 |

| 17 | MCBC-2-2 | B8 | 37 | CK-1 | E1 |

| 18 | MCBC-2-3 | B9 | 38 | CK-2 | E2 |

| 19 | RBC-0.5-1 | C1 | 39 | CK-3 | E3 |

| 20 | RBC-0.5-2 | C2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Dai, Y.; Wen, T.; Wei, P.; Fu, Y.; Qiao, M. Study on the Effect of Magnesium Chloride-Modified Straw Waste Biochar on Acidic Soil Properties. Molecules 2024, 29, 3268. https://doi.org/10.3390/molecules29143268

Liu Z, Dai Y, Wen T, Wei P, Fu Y, Qiao M. Study on the Effect of Magnesium Chloride-Modified Straw Waste Biochar on Acidic Soil Properties. Molecules. 2024; 29(14):3268. https://doi.org/10.3390/molecules29143268

Chicago/Turabian StyleLiu, Zhigao, Yuhang Dai, Tianyi Wen, Penglian Wei, Yunlin Fu, and Mengji Qiao. 2024. "Study on the Effect of Magnesium Chloride-Modified Straw Waste Biochar on Acidic Soil Properties" Molecules 29, no. 14: 3268. https://doi.org/10.3390/molecules29143268

APA StyleLiu, Z., Dai, Y., Wen, T., Wei, P., Fu, Y., & Qiao, M. (2024). Study on the Effect of Magnesium Chloride-Modified Straw Waste Biochar on Acidic Soil Properties. Molecules, 29(14), 3268. https://doi.org/10.3390/molecules29143268