Physical and Functional Properties of Powders Obtained during Spray Drying of Cyani flos Extracts

Abstract

1. Introduction

2. Results and Discussion

2.1. Physical Properties of Powders

2.2. Color Profile of Powders

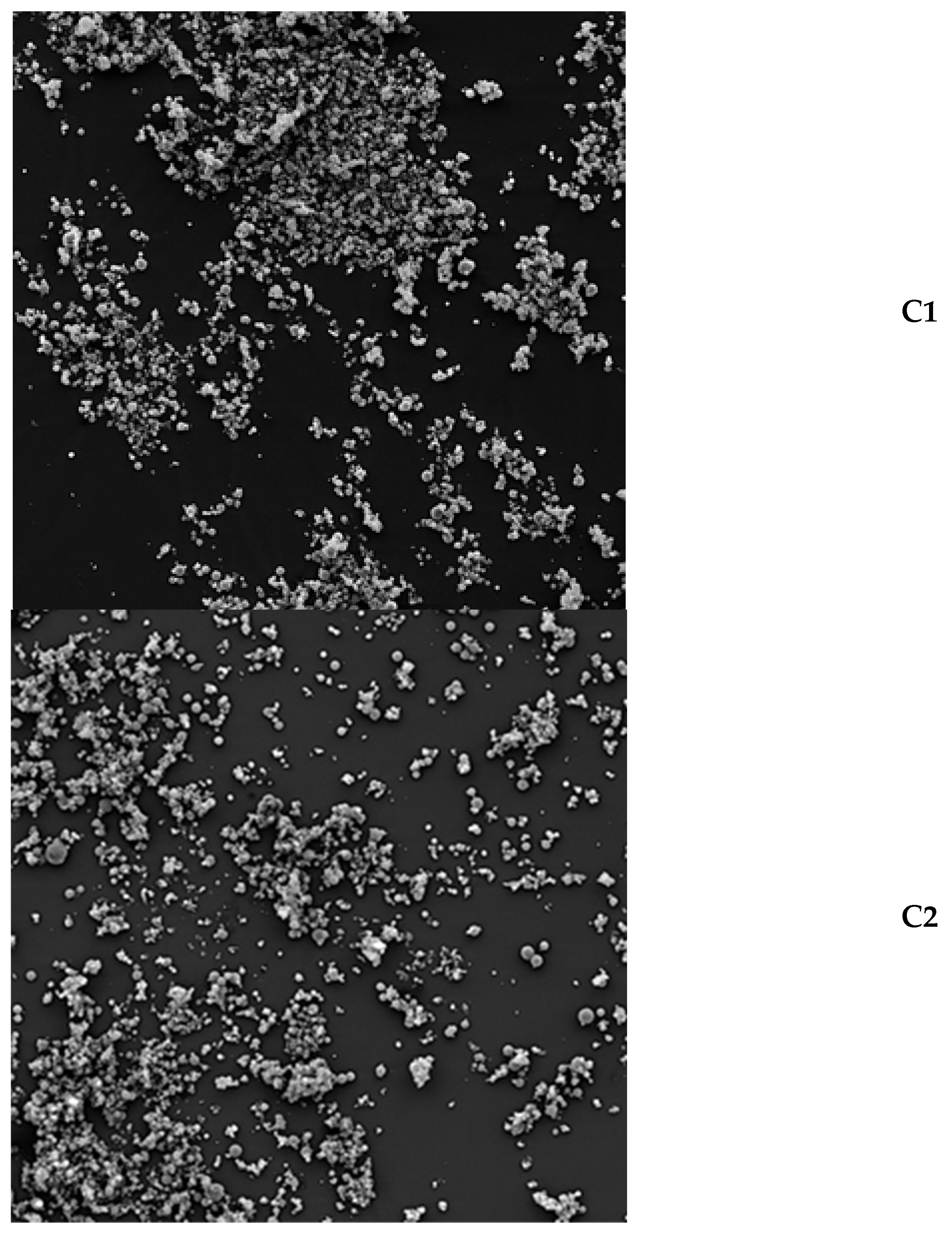

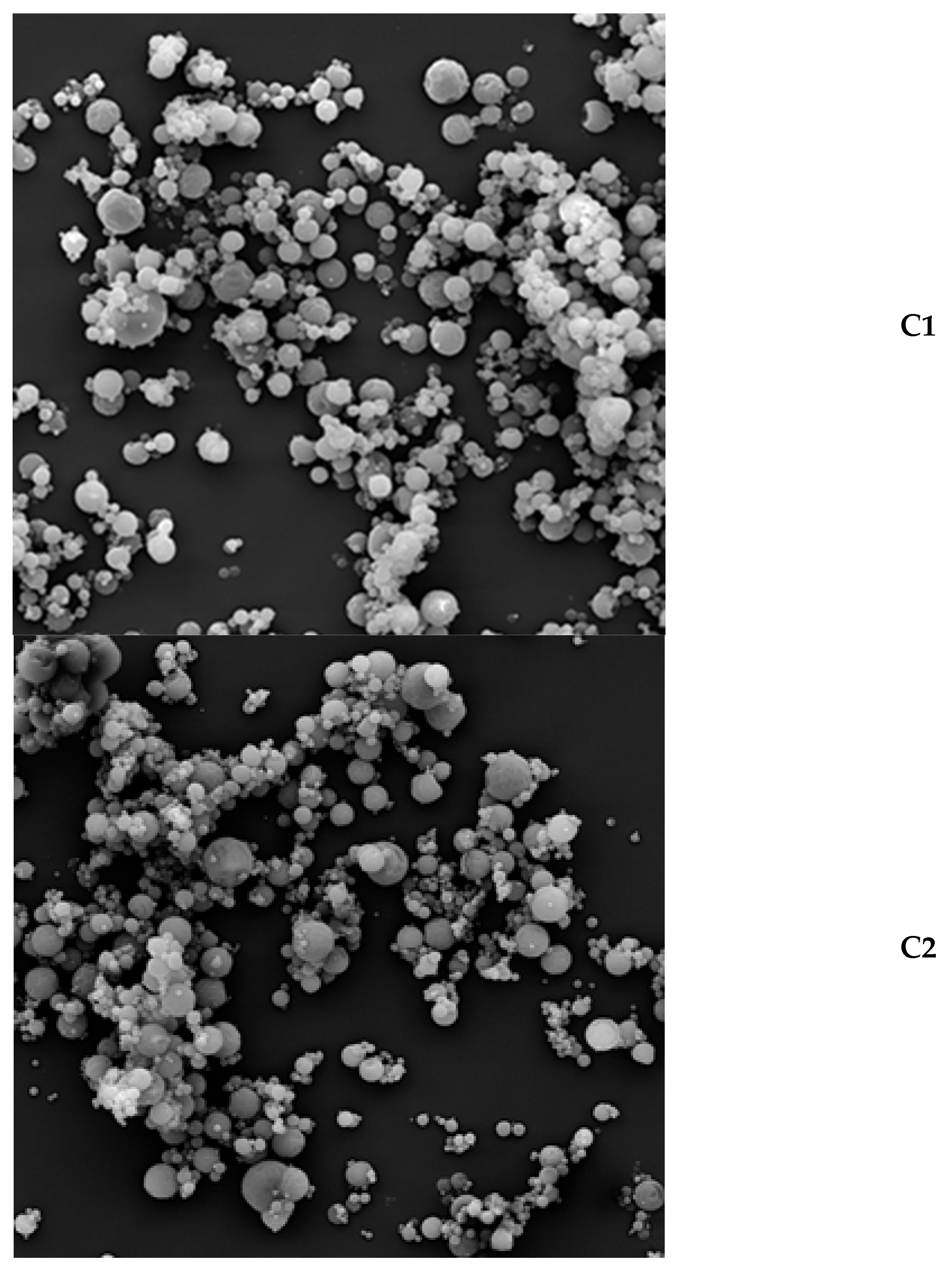

2.3. Particle Structure of Powders with Inulin and Pectin as a Wall Core

2.4. Particle Size Distribution of Powders

2.5. Bioactive Compounds and Antioxidant and Anti-Inflammatory Properties of Powders

3. Materials and Methods

3.1. The Process of Obtaining Powder from Cyani flos

3.2. Physical Properties of Powders

3.2.1. Moisture Content (MC) and Water Activity (WA) of Powders

3.2.2. Hygroscopicity (H) of Powders

3.2.3. Solubility (S) of Powders

3.2.4. The Color Profile of Powders

3.2.5. The Particle Size Distribution of Powders

3.2.6. Microstructure of Powders

3.3. Biochemical Determination of Properties of Powders

3.3.1. Extraction of Powders

3.3.2. In Vitro Digestion of Powders

3.3.3. The Content of Bioactive Substances of Powders

3.3.4. Antioxidant Activity against the ABTS Radical

3.3.5. Ferric-Reducing Antioxidant Power (F) Assay of Powders

3.3.6. Inhibition of Xanthine Oxidase (IXO)

3.3.7. Inhibition of Lipoxygenase (ILOX)

3.3.8. Relative Bioaccessibility

3.4. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haratym, W.; Weryszko-Chmielewska, E.; Konarska, A. Microstructural and histochemical analysis of aboveground organs of Centaurea cyanus used in herbal medicine. Protoplasma 2020, 257, 285–298. [Google Scholar] [CrossRef]

- Lockowandt, L.; Pinela, J.; Roriz, C.L.; Pereira, C.; Abreu, R.M.V.; Calhelha, R.C.; Alves, M.J.; Barros, L.; Bredol, M.; Ferreira, I.C. Chemical features and bioactivities of cornflower (Centaurea cyanus L.) capitula: The blue flowers and the unexplored non-edible part. Ind. Crops Prod. 2019, 128, 496–503. [Google Scholar] [CrossRef]

- Litvinenko, V.I.; Bubenchikova, V.N. Phytochemical study of Centaurea cyanus. Chem. Nat. Compd. 1988, 24, 672–674. [Google Scholar] [CrossRef]

- Lisiecka, K.; Dziki, D.; Gawlik-Dziki, U.; Świeca, M.; Różyło, R. Influence of Soluble Fiber as a Carrier on Antioxidant and Physical Properties of Powders Produced Based on the Spray Drying of Malvae arboreae flos Aqueous Extracts. Foods 2023, 12, 3363. [Google Scholar] [CrossRef]

- Pires, T.C.S.P.; Dias, M.I.; Barros, L.; Calhelha, R.C.; Alves, M.J.; Oliveira, M.B.P.P.; Santos-Buelga, C.; Ferreira, I.C.F.R. Edible flowers as sources of phenolic compounds with bioactive potential. Food Res. Int. 2018, 105, 580–588. [Google Scholar] [CrossRef]

- Akbarbaglu, Z.; Peighambardoust, S.H.; Sarabandi, K.; Jafari, S.M. Spray drying encapsulation of bioactive compounds within protein-based carriers; different options and applications. Food Chem. 2021, 359, 129965. [Google Scholar] [CrossRef] [PubMed]

- Coimbra, P.P.S.; Cardoso, F.d.S.N.; Gonçalves, É.C.B.d.A. Spray-drying wall materials: Relationship with bioactive compounds. Crit. Rev. Food Sci. Nutr. 2020, 61, 2809–2826. [Google Scholar] [CrossRef]

- Lacerda, E.C.Q.; de Araújo Calado, V.M.; Monteiro, M.; Finotelli, P.V.; Torres, A.G.; Perrone, D. Starch, inulin and maltodextrin as encapsulating agents affect the quality and stability of jussara pulp microparticles. Carbohydr. Polym. 2016, 151, 500–510. [Google Scholar] [CrossRef]

- Sheng, W.; Ji, G.; Zhang, L. Immunomodulatory effects of inulin and its intestinal metabolites. Front. Immunol. 2023, 10, 1224092. [Google Scholar] [CrossRef] [PubMed]

- Wikiera, A.; Irla, M.; Mika, M. Health-promoting properties of pectin. Adv. Hyg. Exp. Med. 2014, 68, 590–596. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, B.R.; Datta, N.; Howes, T. Problems associated with spray drying of sugar-rich foods. Dry. Technol. 1997, 15, 671–684. [Google Scholar] [CrossRef]

- Fuzetti, C.G.; de Castilhos, M.B.M.; Nicoletti, V.R. Microencapsulation of natural blue dye from butterfly pea (Clitoria ternatea L.) flowers: The application of different carriers. J. Food Process. Preserv. 2022, 46, e16420. [Google Scholar] [CrossRef]

- George, S.; Thomas, A.; Kumar, M.V.P.; Kamdod, A.S.; Rajput, A.; Abdullah, S. Impact of processing parameters on the quality attributes of spray-dried powders: A review. Eur. Food Res. Technol. 2023, 249, 241–257. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. 2017, 63, 92–102. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Iijima, M.; Nakamuraa, K.; Hatakeyamaa, T.; Hatakeyama, H. Phase transition of pectin with sorbed water. Carbohydr. Polym. 2000, 41, 101–106. [Google Scholar] [CrossRef]

- Abdullah, Z.; Taip, F.S.; Kamal, S.M.M.; Rahman, R.Z.A. Nonlinear Model-Based Inferential Control of Moisture Content of Spray Dried Coconut Milk. Foods 2020, 9, 1177. [Google Scholar] [CrossRef]

- Santana, A.A.; Martin, L.G.P.; de Oliveira, R.A.; Kurozawa, L.E.; Park, K.J. Spray drying of babassu coconut milk using different carrier agents. Dry. Technol. 2016, 35, 76–87. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Barańska, A.; Świeca, M.; Samborska, K. Sour cherry juice concentrate powdered by high and low temperature spray drying with pea protein as a carrier—Physical properties, antioxidant activity and in vitro bioaccessibility. Dry. Technol. 2022, 41, 444–459. [Google Scholar] [CrossRef]

- Sarabandi, K.; Peighambardoust, S.H.; Sadeghi Mahoonak, A.R.; Samae, S.P. Effect of different carriers on microstructure and physical characteristics of spray dried apple juice concentrate. J. Food Sci. Technol. 2018, 55, 3098–3109. [Google Scholar] [CrossRef] [PubMed]

- Lourenço, S.C.; Moldão-Martins, M.; Alves, V.D. Microencapsulation of Pineapple Peel Extract by Spray Drying Using Maltodextrin, Inulin, and Arabic Gum as Wall Matrices. Foods 2020, 2, 718. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, I.; Niazi, M.B.K.; Jahan, Z.; Naqvi, S.R. Effect of drying parameters on the physical, morphological and thermal properties of spray-dried inulin. Polym. Eng. 2018, 38, 775–783. [Google Scholar] [CrossRef]

- Quintriqueo-Cid, A.; Giménez, B.; Romero-Hasler, P.; Soto-Bustamante, E.; Lozano-Sánchez, J.; Robert, P. Influence of the crystallinity on the physicochemical properties of spray-dried quercetin-inulin microparticles and their performance during in vitro digestion. Food Chem. 2024, 434, 137325. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Fernandes, R.V.; de Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532. [Google Scholar] [CrossRef] [PubMed]

- Tarone, A.G.; Silva, E.K.; Betim Cazarin, C.B.; Marostica Junior, M.R. Inulin/fructooligosaccharides/pectin-based structured systems: Promising encapsulating matrices of polyphenols recovered from jabuticaba peel. Food Hydrocoll. 2020, 111, 106387. [Google Scholar] [CrossRef]

- Sansone, F.; Mencherini, T.; Picerno, P.; d’ Amore, M.; Aquino, R.P.; Lauro, M.R. Maltodextrin/pectin microparticles by spray drying as carrier for nutraceutical extracts. J. Food Eng. 2011, 105, 468–476. [Google Scholar] [CrossRef]

- Keppler, K.; Humpf, H.U. Metabolism of anthocyanins and their phenolic degradation products by the intestinal microflora. Bioorg. Med. Chem. 2005, 13, 5195–5205. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Roque, M.J.; Rojas-Grau, M.A.; Elez-Martinez, P.; Martin-Belloso, O. In vitro bioaccessibility of health-related compounds from a blended fruit juice-soymilk beverage: Influence of the food matrix. J. Funct. Foods 2014, 7, 161–169. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, K.; Zhang, M.; Law, C.L.; Lei, H.; Wang, J.; Xu, H. Pectin-interactions and the digestive stability of anthocyanins in thermal and non-thermal processed strawberry pulp. Food Chem. 2023, 424, 136456. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Cervantes, P.; Cancino-Dıaz, J.C.; Fabela-Illescas, H.E.; Cariño-Cortés, R.; Lopez-Villegas, E.O.; Ariza-Ortega, J.A.; Belefant-Miller, H.; Betanzos-Cabrera, G. Spray-Drying Microencapsulation of Pomegranate Juice Increases its Antioxidant Activity After In Vitro Digestion. Int. J. Food Sci. Technol. 2021, 56, 5089–5096. [Google Scholar] [CrossRef]

- Xie, L.; Deng, Z.; Zhang, J.; Dong, H.; Wang, W.; Xing, B.; Liu, X. Comparison of Flavonoid O-Glycoside, C-Glycoside and Their Aglycones on Antioxidant Capacity and Metabolism during In Vitro Digestion and In Vivo. Foods 2022, 11, 882. [Google Scholar] [CrossRef] [PubMed]

- Bermúdez-Soto, M.J.; Tomás-Barberán, F.A.; García-Conesa, M.T. Stability of polyphenols in chokeberry (Aronia melanocarpa) subjected to in vitro gastric and pancreatic digestion. Food Chem. 2007, 102, 865–874. [Google Scholar] [CrossRef]

- Altunkaya, A.; Gokmen, V.; Skibsted, L.H. pH dependent antioxidant activity of lettuce (L. sativa) and synergism with added phenolic antioxidants. Food Chem. 2016, 190, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Sacan, O.; Yildiz Turhan, E. Lipoxygenase Inhibitory Activities of Some Plant Extracts and Chemical Compounds. Eur. J. Biol. 2016, 2, 47–52. [Google Scholar]

- Lestari, P.P.; Kusrini, D.; Anam, K. Anthocyanin Identification of Methanol-HCl Extract Active Fraction in Rosella (Hibiscus sabdariffa. L) and Its Potential as Xanthine Oxidase Inhibitor. JEMAS J. Edukasi Mat. dan Sains 2014, 22, 72–78. [Google Scholar]

- Kaisoon, O.; Siriamornpun, S.; Weerapreeyakul, N.; Meeso, N. Phenolic compounds and antioxidant activities of edible flowers from Thailand. J. Funct. Foods 2011, 3, 88–99. [Google Scholar] [CrossRef]

- Lachowicz, S.; Świeca, M.; Pejcz, E. Biological activity, phytochemical parameters, and potential bioaccessibility of wheat bread enriched with powder and microcapsules made from Saskatoon berry. Food Chem. 2021, 338, 128026. [Google Scholar] [CrossRef]

- da Silva Júnior, M.E.; Araújo, M.V.R.L.; Martins, A.C.S.; Dos Santos Lima, M.; da Silva, F.L.H.; Converti, A.; Maciel, M.I.S. Microencapsulation by spray-drying and freeze-drying of extract of phenolic compounds obtained from ciriguela peel. Sci. Rep. 2023, 13, 15222. [Google Scholar] [CrossRef]

- Tang, Y.; He, W.; Yang, S.; Liu, L. Stabilisation and detoxification of henna (Lawsonia inermis L.) extract for hair dye cosmetics by spray-drying encapsulation. Coloration Technol. 2019, 135, 439–450. [Google Scholar] [CrossRef]

- Haas, K.; Obernberger, J.; Zehetner, E.; Kiesslich, A.; Volkert, M.; Jaeger, H. Impact of powder particle structure on the oxidation stability and color of encapsulated crystalline and emulsified carotenoids in carrot concentrate powders. J. Food Eng. 2019, 263, 398–408. [Google Scholar] [CrossRef]

- Dziki, D.; Tarasiuk, W.; Gawlik-Dziki, U. Micronized Oat Husk: Particle Size Distribution, Phenolic Acid Profile and Antioxidant Properties. Materials 2021, 14, 5443. [Google Scholar] [CrossRef] [PubMed]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A standardised static in vitro digestion method suitable for food—An international consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [PubMed]

- Różyło, R.; Szymańska-Chargot, M.; Zdunek, A.; Gawlik-Dziki, U.; Dziki, D. Microencapsulated Red Powders from Cornflower Extract—Spectral (FT-IR and FT-Raman) and Antioxidant Characteristics. Molecules 2022, 27, 3094. [Google Scholar] [CrossRef] [PubMed]

- Kopjar, M.; Bilić, B.; Piližota, V. Influence of different extracts addition on total phenols, anthocyanin content and antioxidant activity of blackberry juice during storage. Croat. J. Food Sci. Technol. 2011, 3, 9–15. [Google Scholar]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1991, 26, 1231–1237. [Google Scholar] [CrossRef]

- Oyaizu, M. Studies on products of browning reaction. Antioxidative activities of products of browning reaction prepared from glucosamine. Jpn. J. Nutr. 1986, 44, 307–315. [Google Scholar] [CrossRef]

- Habza-Kowalska, E.; Piwowarczyk, K.; Czyż, J.; Gawlik-Dziki, U. Oatmeal and wheat flour as the sources of thyroid peroxidase (TPO), lipoxygenase (LOX) and xanthine oxidase (XO) modulators potentially applicable in the prevention of inflammatory thyroid diseases. BioRxiv 2023, preprint. [Google Scholar] [CrossRef]

- Habza-Kowalska, E.; Gawlik-Dziki, U.; Dziki, D. Mechanism of Action and Interactions between Thyroid Peroxidase and Lipoxygenase Inhibitors Derived from Plant Sources. Biomolecules 2019, 9, 663. [Google Scholar] [CrossRef]

| TS | PY (%) | MC (%) | WA (-) | H (g/100 g) | S (%) |

|---|---|---|---|---|---|

| C1 | 69.93 ± 1.12 b | 4.72 ± 0.06 b | 0.22 ± 0.00 d | 15.48 ± 0.30 b | 91.10 ± 0.90 b |

| C2 | 68.63 ± 1.47 ab | 4.99 ± 0.03 c | 0.21 ± 0.00 c | 14.89 ± 0.20 ab | 87.39 ± 0.85 ab |

| C3 | 68.89 ± 0.98 ab | 4.45 ± 0.03 a | 0.22 ± 0.00 d | 14.59 ± 0.05 ab | 89.83 ± 1.83 b |

| C4 | 63.14 ± 1.15 a | 4.72 ± 0.03 b | 0.16 ± 0.00 a | 14.07 ± 0.30 a | 85.16 ± 0.84 ab |

| C5 | 62.03 ± 1.08 a | 4.97 ± 0.03 c | 0.20 ± 0.00 b | 14.20 ± 0.17 a | 83.18 ± 0.82 a |

| TS | L* (-) | a* (-) | b* (-) | ∆E (-) |

|---|---|---|---|---|

| C1 | 95.24 ± 0.15 c | 1.38 ± 0.05 a | −5.04 ± 0.11 ab | - |

| C2 | 94.63 ± 0.30 b | 2.18 ± 0.14 b | −4.71 ± 0.32 a | 1.01 |

| C3 | 94.66 ± 0.21 b | 2.04 ± 0.07 b | −5.20 ± 0.16 b | 0.88 |

| C4 | 94.09 ± 0.09 a | 2.64 ± 0.03 c | −4.79 ± 0.02 a | 1.71 |

| C5 | 94.29 ± 0.37 ab | 2.62 ± 0.04 c | −4.92 ± 0.15 ab | 1.58 |

| TS | d10 (µm) | d50 (µm) | d90 µm (-) | Span (-) |

|---|---|---|---|---|

| C1 | 0.52 ± 0.02 a | 3.89 ± 0.07 a | 12.97 ± 2.85 a | 3.19 ± 0.68 a |

| C2 | 0.59 + 0.02 b | 3.91 ± 0.08 a | 10.06 ± 0.57 a | 2.42 ± 0.10 a |

| C3 | 0.54 ± 0.02 ab | 3.68 ± 0.06 a | 9.71 ± 0.49 a | 2.49 ± 0.09 a |

| C4 | 0.58 ± 0.01 ab | 3.90 ± 0.06 a | 10.90 ± 0.45 a | 2.65 ± 0.08 a |

| C5 | 0.58 ± 0.0.2 ab | 3.92 ± 0.21 a | 10.50 ± 1.93 a | 2.52 ± 0.36 a |

| TS | C1 | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|---|

| B | TF | 79.25 ±14.78 a | 103.64 ± 4.04 c | 135.34 ± 5.31 c | 142.66 ± 9.37 c | 143.87 ± 7.32 c |

| TA | 4.48 ± 0.34 a | 10.22 ± 1.03 b | 9.99 ± 0.74 b | 10.50 ± 0.68 b | 14.29 ± 1.11 c | |

| AB | 2.12 ± 0.22 a | 2.34 ± 0.24 a | 2.60 ± 0.32 a | 4.47 ± 0.62 b | 5.68 ± 0.86 b | |

| F | 1.00 ± 0.07 a | 1.52 ± 0.10 b | 1.42 ± 0.12 b | 1.48 ± 0.12 b | 1.38 ± 0.02 b | |

| IXO | 0.17 ± 0.00 a | 0.19 ± 0.02 a | 0.18 ± 0.01 a | 0.23 ± 0.01 b | 0.20 ± 0.02 ab | |

| ILOX | 0.07 ± 0.03 a | 0.21 ± 0.03 b | 0.18 ± 0.01 b | 0.21 ± 0.05 b | 0.18 ± 0.03 b | |

| A | TF | 60.96 ± 6.67 a | 87.38 ± 7.71 b | 134.12 ± 5.25 c | 136.15 ± 8.83 c | 132.09 ± 6.74 c |

| TA | 2.62 ± 0.32 a | 7.56 ± 1.10 b | 6.12 ± 0.38 b | 8.61 ± 1.10 b | 12.15 ± 1.52 c | |

| AB | 4.41 ± 0.23 a | 5.44 ± 0.45 ab | 5.36 ± 0.63 ab | 5.47 ± 0.38 bc | 6.52 ± 0.29 c | |

| F | 1.15 ± 0.11 a | 1.51 ± 0.18 b | 1.06 ± 0.07 a | 1.26 ± 0.06 ab | 1.12 ± 0.19 a | |

| IXO | 0.28 ± 0.00 a | 0.29 ± 0.01 a | 0.29 ± 0.01 a | 0.29 ± 0.01 a | 0.29 ± 0.01 a | |

| ILOX | 0.19 ± 0.01 a | 0.19 ± 0.04 a | 0.18 ± 0.06 a | 0.21 ± 0.03 a | 0.18 ± 0.05 a | |

| RBF RAF | TF | 0.77 | 0.84 | 0.99 | 0.95 | 0.92 |

| TA | 0.58 | 0.74 | 0.61 | 0.82 | 0.85 | |

| AB | 2.08 | 2.33 | 2.06 | 1.22 | 1.15 | |

| F | 1.15 | 0.99 | 0.75 | 0.85 | 0.81 | |

| IXO | 1.65 | 1.51 | 1.63 | 1.27 | 1.48 | |

| ILOX | 2.59 | 0.90 | 0.92 | 0.86 | 1.19 | |

| Sample | I [% w/w] | P [% w/w] |

|---|---|---|

| C1 | 100 | 0 |

| C2 | 98 | 2 |

| C3 | 96 | 4 |

| C4 | 94 | 6 |

| C5 | 92 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisiecka, K.; Dziki, D.; Karaś, M. Physical and Functional Properties of Powders Obtained during Spray Drying of Cyani flos Extracts. Molecules 2024, 29, 3400. https://doi.org/10.3390/molecules29143400

Lisiecka K, Dziki D, Karaś M. Physical and Functional Properties of Powders Obtained during Spray Drying of Cyani flos Extracts. Molecules. 2024; 29(14):3400. https://doi.org/10.3390/molecules29143400

Chicago/Turabian StyleLisiecka, Katarzyna, Dariusz Dziki, and Monika Karaś. 2024. "Physical and Functional Properties of Powders Obtained during Spray Drying of Cyani flos Extracts" Molecules 29, no. 14: 3400. https://doi.org/10.3390/molecules29143400

APA StyleLisiecka, K., Dziki, D., & Karaś, M. (2024). Physical and Functional Properties of Powders Obtained during Spray Drying of Cyani flos Extracts. Molecules, 29(14), 3400. https://doi.org/10.3390/molecules29143400