Thermal Conductive Polymer Composites: Recent Progress and Applications

Abstract

:1. Introduction

2. Thermal Conductive Mechanism

2.1. Intrinsic Thermal Conductive Polymers

2.2. Filled Thermal Conductive Polymer Composites

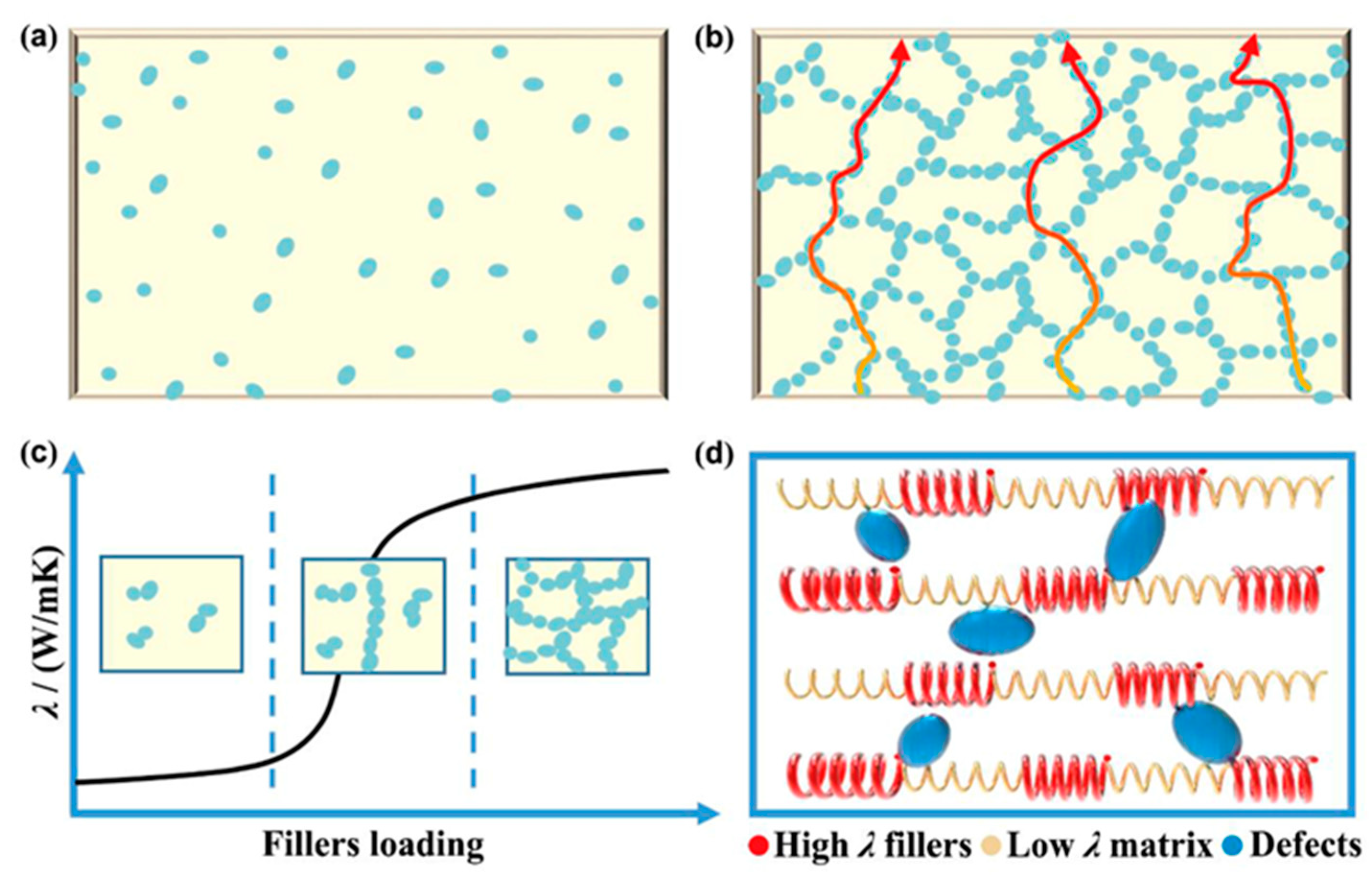

2.2.1. Thermal Conductive Path Theory

2.2.2. Thermal Conductive Percolation Theory

2.2.3. Thermoelastic Coefficient Theory

3. Key Factors Influencing the TC of Polymer Composite Materials

3.1. Key Factors Affecting the TC of Polymer Composites

3.1.1. Intrinsic TC of the Polymer

3.1.2. Filler Properties

3.1.3. Interfacial Thermal Resistance

3.2. Strategies to Enhance the TC of Polymer Composite Materials

3.2.1. Interfacial Functionalization Reduces Interfacial Thermal Resistance

3.2.2. Microstructural Design Governs the Formation of Thermal Conductive Pathways

4. Applications of Thermal Conductive Polymer Composites

4.1. Electronic Devices (Wearable Electronics)

4.2. Energy Storage Devices

4.3. Transmission Systems

4.4. Solar Energy

4.5. Personal Thermal Management

4.6. Aerospace

4.7. Others

5. Conclusions and Outlook

5.1. Conclusions

5.2. Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Mathew, J.; Krishnan, S. A review on transient thermal management of electronic devices. J. Electron. Packag. 2022, 144, 010801. [Google Scholar] [CrossRef]

- Afaynou, I.; Faraji, H.; Choukairy, K.; Arshad, A.; Arıcı, M. Heat transfer enhancement of phase-change materials (PCMs) based thermal management systems for electronic components: A review of recent advances. Int. Commun. Heat Mass Transf. 2023, 143, 106690. [Google Scholar] [CrossRef]

- Deng, C.; Zhang, X.; Peng, J.; Yang, X.; Shang, B.; Luo, X. In51Bi32.5Sn16.5@SiO2 microcapsules-based composite phase change materials with high thermal conductivity and heat storage density for electronics thermal management. J. Energy Storage 2024, 86, 111432. [Google Scholar] [CrossRef]

- Naghibi, S.; Kargar, F.; Wright, D.; Huang, C.Y.T.; Mohammadzadeh, A.; Barani, Z.; Salgado, R.; Balandin, A.A. Noncuring graphene thermal interface materials for advanced electronics. Adv. Electron. Mater. 2020, 6, 1901303. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Zhang, Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy 2021, 216, 119223. [Google Scholar] [CrossRef]

- Lohrasbi, S.; Hammer, R.; Essl, W.; Reiss, G.; Defregger, S.; Sanz, W. A comprehensive review on the core thermal management improvement concepts in power electronics. IEEE Access 2020, 8, 166880–166906. [Google Scholar] [CrossRef]

- Chen, W.; Shi, X.; Zou, J.; Chen, Z. Thermoelectric coolers for on-chip thermal management: Materials, design, and optimization. Mater. Sci. Eng. R Rep. 2022, 151, 100700. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Feng, C.P.; Yang, L.Y.; Yang, J.; Bai, L.; Bao, R.Y.; Liu, Z.Y.; Yang, M.; Yang, W. Recent advances in polymer-based thermal interface materials for thermal management: A mini-review. Compos. Commun. 2020, 22, 100528. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, L.; Zhang, X.; Pan, D.; Wang, M.; Luo, S.; Su, F.; Ji, Y.; Liu, C. Highly thermally conductive, electrically insulating, thermal resistance polyimide-base composites with fibrillated carbon networks for thermal management applications. Compos. Commun. 2023, 37, 101450. [Google Scholar] [CrossRef]

- Jiang, K.; Liao, G.; Jiaqiang, E.; Zhang, F.; Chen, J.; Leng, E. Thermal management technology of power lithium-ion batteries based on the phase transition of materials: A review. J. Energy Storage 2020, 32, 101816. [Google Scholar] [CrossRef]

- Cui, Y.; Li, M.; Hu, Y. Emerging interface materials for electronics thermal management: Experiments, modeling, and new opportunities. J. Mater. Chem. C 2020, 8, 10568–10586. [Google Scholar] [CrossRef]

- Cao, J.; Meng, T.L.; Zhang, X.; Gong, N.; Karyappa, R.; Tan, C.K.I.; Suwardi, A.; Zhu, Q.; Liu, H. Recent advances in thermal interface materials. ES Mater. Manuf. 2020, 7, 4–24. [Google Scholar] [CrossRef]

- Guo, X.; Cheng, S.; Cai, W.; Zhang, Y.; Zhang, X.A. A review of carbon-based thermal interface materials: Mechanism, thermal measurements and thermal properties. Mater. Des. 2021, 209, 109936. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S.; Nayak, S.K. A new way synthesis of expanded graphite as a thermal filler to enhance the thermal conductivity of DGEBA resin as thermal interface material. High Perform. Polym. 2020, 32, 506–523. [Google Scholar] [CrossRef]

- Shin, S.; Wang, Q.; Luo, J.; Chen, R. Advanced materials for high-temperature thermal transport. Adv. Funct. Mater. 2020, 30, 1904815. [Google Scholar] [CrossRef]

- Gupta, P.; Toksha, B.; Patel, B.; Rushiya, Y.; Das, P.; Rahaman, M. Recent developments and research avenues for polymers in electric vehicles. Chem. Rec. 2022, 22, e202200186. [Google Scholar] [CrossRef] [PubMed]

- Previati, G.; Mastinu, G.; Gobbi, M. Thermal management of electrified vehicles—A review. Energies 2022, 15, 1326. [Google Scholar] [CrossRef]

- Widyantara, R.D.; Zulaikah, S.; Juangsa, F.B.; Budiman, B.A.; Aziz, M. Review on battery packing design strategies for superior thermal management in electric vehicles. Batteries 2022, 8, 287. [Google Scholar] [CrossRef]

- Allen, J. Review of polymers in the prevention of thermal runaway in lithium-ion batteries. Energy Rep. 2020, 6, 217–224. [Google Scholar] [CrossRef]

- Wang, Z.; Changqing, D. A comprehensive review on thermal management systems for power lithium-ion batteries. Renew. Sustain. Energy Rev. 2021, 139, 110685. [Google Scholar]

- Ju, Y.S. Thermal management and control of wearable devices. iScience 2022, 25, 104587. [Google Scholar] [CrossRef]

- Yun, J.; Yoo, Y.J.; Kim, H.R.; Song, Y.M. Recent progress in thermal management for flexible/wearable devices. Soft Sci. 2023, 3, 12. [Google Scholar] [CrossRef]

- Nie, S.; Hao, N.; Zhang, K.; Xing, C.; Wang, S. Cellulose nanofibrils-based thermally conductive composites for flexible electronics: A mini review. Cellulose 2020, 27, 4173–4187. [Google Scholar] [CrossRef]

- Niu, Z.; Yuan, W. Smart nanocomposite nonwoven wearable fabrics embedding phase change materials for highly efficient energy conversion–storage and use as a stretchable conductor. ACS Appl. Mater. Interfaces 2021, 13, 4508–4518. [Google Scholar] [CrossRef]

- Ghaffari-Mosanenzadeh, S.; Aghababaei Tafreshi, O.; Dammen-Brower, E.; Rad, E.; Meysami, M.; Naguib, H.E. A review on high thermally conductive polymeric composites. Polym. Compos. 2022, 43, 692–711. [Google Scholar] [CrossRef]

- Yu, H.; Guo, P.; Qin, M.; Han, G.; Chen, L.; Feng, Y.; Feng, W. Highly thermally conductive polymer composite enhanced by two-level adjustable boron nitride network with leaf venation structure. Compos. Sci. Technol. 2022, 222, 109406. [Google Scholar] [CrossRef]

- Meng, X.; Yu, H.; Wang, L.; Wu, X.; Amin, B.U. Recent progress on fabrication and performance of polymer composites with highly thermal conductivity. Macromol. Mater. Eng. 2021, 306, 2100434. [Google Scholar] [CrossRef]

- Tan, X.; Yuan, Q.; Qiu, M.; Yu, J.; Jiang, N.; Lin, C.; Dai, W. Rational design of graphene/polymer composites with excellent electromagnetic interference shielding effectiveness and high thermal conductivity: A mini review. J. Mater. Sci. Technol. 2022, 117, 238–250. [Google Scholar] [CrossRef]

- Du, Y.K.; Shi, Z.X.; Dong, S.; Jin, H.; Ke, X.; Zhao, P.; Jiang, B.; You, F. Recent progress in fabrication and structural design of thermal conductive polymer composites. Chin. J. Polym. Sci. 2024, 42, 277–291. [Google Scholar] [CrossRef]

- Amraei, J.; Katunin, A. Recent advances in limiting fatigue damage accumulation induced by self-heating in polymer–matrix composites. Polymers 2022, 14, 5384. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhi, C.; Lin, Y.; Bao, H.; Wu, G.; Jiang, P.; Mai, Y.W. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R Rep. 2020, 142, 100577. [Google Scholar] [CrossRef]

- Pathumudy, R.D.; Prabhu, K.N. Thermal interface materials for cooling microelectronic systems: Present status and future challenges. J. Mater. Sci. Mater. Electron. 2021, 32, 11339–11366. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Ning, Z.; Huang, H.; Cheng, Z.; Duan, L.; Wang, Y.; Tao, X.; Liu, P.; Ma, Y.; et al. Multi-Interfacial Heterostructure Design of Carbon Fiber/Silicone Rubber-Oriented Composites for Microwave Absorption and Thermal Management. Adv. Funct. Mater. 2024, 2411573. [Google Scholar] [CrossRef]

- Guo, Y.; Lyu, Z.; Yang, X.; Lu, Y.; Ruan, K.; Wu, Y.; Kong, J.; Gu, J. Enhanced thermal conductivities and decreased thermal resistances of functionalized boron nitride/polyimide composites. Compos. Part B Eng. 2019, 164, 732–739. [Google Scholar] [CrossRef]

- Gu, J.; Ruan, K. Breaking through bottlenecks for thermally conductive polymer composites: A perspective for intrinsic thermal conductivity, interfacial thermal resistance and theoretics. Nano-Micro Lett. 2021, 13, 110. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Gao, B.; Wang, M.; Yuan, Z.; Shen, J.; Zhao, J.; Feng, Y. Strategies for enhancing thermal conductivity of polymer-based thermal interface materials: A review. J. Mater. Sci. 2021, 56, 1064–1086. [Google Scholar] [CrossRef]

- Ghosh, S.; Nath, K.; Chowdhury, S.; Paul, S.; Ghosh, T.; Katheria, A.; Das, P.; Das, N. Combination effect of functionalized high aspect ratio carbonaceous nanofillers and carbon black on electrical, thermal conductivity, dielectric and EMI shielding behavior of co-continuous thermoplastic elastomeric blend composite films. Chem. Eng. J Adv. 2023, 15, 100505. [Google Scholar] [CrossRef]

- Lee, D.K.; Yoo, J.; Kim, H.; Kang, B.H.; Park, S.H. Electrical and thermal properties of carbon nanotube polymer composites with various aspect ratios. Materials 2022, 15, 1356. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, J.; Yang, D.; Zhang, J.; Guo, Y.; Zhong, X.; Kong, J.; Gu, J. High-efficiency improvement of thermal conductivities for epoxy composites from synthesized liquid crystal epoxy followed by doping BN fillers. Compos. Part B Eng. 2020, 185, 107784. [Google Scholar] [CrossRef]

- Tarannum, F.; Muthaiah, R.; Annam, R.S.; Gu, T.; Garg, J. Effect of alignment on enhancement of thermal conductivity of polyethylene–graphene nanocomposites and comparison with effective medium theory. Nanomaterials 2020, 10, 1291. [Google Scholar] [CrossRef] [PubMed]

- Ruan, K.; Shi, X.; Guo, Y.; Gu, J. Interfacial thermal resistance in thermally conductive polymer composites: A review. Compos. Commun. 2020, 22, 100518. [Google Scholar] [CrossRef]

- Idumah, C.I.; Obele, C.M. Understanding interfacial influence on properties of polymer nanocomposites. Surf. Interfaces 2021, 22, 100879. [Google Scholar] [CrossRef]

- Saminathan, R.; Hadidi, H.; Fageehi, Y.A.; Manoj Kumar, P.; Venkatasudhahar, M.; Ankit; Ram, S.; Gebreyohannes, D.T. Experimental analysis of mechanical and thermal characteristics of luffa/epoxy polymer composite under the influence of nanosilica. Adv. Mater. Sci. Eng. 2022, 2022, 6040629. [Google Scholar] [CrossRef]

- Zhang, B.; Dou, Z.L.; Zhang, Y.Z.; Fu, Q.; Wu, K. Exploring trade-offs in thermal interface materials: The impact of polymer-filler interfaces on thermal conductivity and thixotropy. Chin. J. Polym. Sci. 2024, 42, 916–925. [Google Scholar] [CrossRef]

- Wu, W.; Ren, T.; Liu, X.; Davis, R.; Huai, K.; Cui, X.; Wei, H.; Hu, J.; Xia, Y.; Huang, S.; et al. Creating thermal conductive pathways in polymer matrix by directional assembly of synergistic fillers assisted by electric fields. Compos. Commun. 2022, 35, 101309. [Google Scholar] [CrossRef]

- Hao, X.; Wan, S.; Zhao, Z.; Zhu, L.; Peng, D.; Yue, M.; Kuang, J.; Cao, W.; Liu, G.; Wang, Q. Enhanced thermal conductivity of epoxy composites by introducing 1D AlN whiskers and constructing directionally aligned 3D AlN filler skeletons. ACS Appl. Mater. Interfaces 2022, 15, 2124–2133. [Google Scholar] [CrossRef] [PubMed]

- Griffin, A.; Guo, Y.; Hu, Z.; Zhang, J.; Chen, Y.; Qiang, Z. Scalable methods for directional assembly of fillers in polymer composites: Creating pathways for improving material properties. Polym. Compos. 2022, 43, 5747–5766. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, D.; Liu, J.; Zhao, H.; Zhao, T.; Li, B.; Yang, W.; Yu, Z.Z. Nature-Inspired Solar-Thermal Gradient Reduced Graphene Oxide Aerogel-based Bilayer Phase Change Composites for Self-Adaptive Personal Thermal Management. Adv. Funct. Mater. 2023, 33, 2212032. [Google Scholar] [CrossRef]

- Zhou, M.; Tan, S.; Wang, J.; Wu, Y.; Liang, L.; Ji, G. “Three-in-One” multi-scale structural design of carbon fiber-based composites for personal electromagnetic protection and thermal management. Nano-Micro Lett. 2023, 15, 176. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Z.; Weng, L.; Ge, S.; Jiang, D.; Huang, M.; Mulvihill, D.M.; Chen, Q.; Guo, Z.; Jazzar, A.; et al. A roadmap review of thermally conductive polymer composites: Critical factors, progress, and prospects. Adv. Funct. Mater. 2023, 33, 2301549. [Google Scholar] [CrossRef]

- Kang, J.H.; Gordon, K.L.; Ward, D.; Belancik, G.; Jagtap, P.; Sauti, G. Highly Thermally Conductive Hybrid Carbon Fiber Polymer Composite for Radiator Application. In Proceedings of the 52nd International Conference on Environmental Systems (ICES 2023), Calgary, AB, Canada, 16–20 July 2023. ICES-2023-123. [Google Scholar]

- Storm, M.L. Heat conduction in simple metals. J. Appl. Phys. 1951, 22, 940–951. [Google Scholar] [CrossRef]

- Tong, Z.; Li, S.; Ruan, X.; Bao, H. Comprehensive first-principles analysis of phonon thermal conductivity and electron-phonon coupling in different metals. Phys. Rev. B 2019, 100, 144306. [Google Scholar] [CrossRef]

- Inogamov, N.A.; Petrov, Y.V. Thermal conductivity of metals with hot electrons. J. Exp. Theor. Phys. 2010, 110, 446–468. [Google Scholar] [CrossRef]

- Das, S.; Muthukumar, M. Thermal conduction and phonon transport in folded polyethylene chains. Macromolecules 2023, 56, 393–403. [Google Scholar] [CrossRef]

- Choy, C.L. Thermal conductivity of polymers. Polymer 1977, 18, 984–1004. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Z.; Tian, Z.; Luo, T. Thermal transport in polymers: A review. J. Heat Transf. 2021, 143, 072101. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Wang, G.; Gu, J. Advances and mechanisms in polymer composites toward thermal conduction and electromagnetic wave absorption. Sci. Bull. 2023, 68, 1195–1212. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Zhou, J.; Chen, G. Phonon-engineered extreme thermal conductivity materials. Nat. Mater. 2021, 20, 1188–1202. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Y.; Guo, Y.; Nakayama, T.; Nomura, M.; Volz, S.; Chen, J. Hydrodynamic phonon transport in bulk crystalline polymers. Phys. Rev. B 2020, 102, 195302. [Google Scholar] [CrossRef]

- Cheng, P.; Chen, X.; Gao, H. Different dimensional nanoadditives for thermal conductivity enhancement of phase change materials: Fundamentals and applications. Nano Energy 2021, 85, 105948. [Google Scholar] [CrossRef]

- Kim, T.; Drakopoulos, S.X.; Ronca, S.; Minnich, A.J. Origin of high thermal conductivity in disentangled ultra-high molecular weight polyethylene films: Ballistic phonons within enlarged crystals. Nat. Commun. 2022, 13, 2452. [Google Scholar] [CrossRef] [PubMed]

- Dinpajooh, M.; Nitzan, A. Heat conduction in polymer chains: Effect of substrate on the thermal conductance. J. Chem. Phys. 2022, 156, 144506. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Wu, Y.; Zhou, S.; Xu, W.; Jiang, W.; Lv, Y.; Guo, W.; Chi, K.; Sun, Q.; Fu, T.; et al. High thermal conductivity polymer chains with reactive groups: A step towards true application. Mater. Adv. 2020, 1, 1996–2002. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Hands, D. The thermal transport properties of polymers. Rubber Chem. Technol. 1977, 50, 480–522. [Google Scholar] [CrossRef]

- Mehra, N.; Mu, L.; Ji, T.; Yang, X.; Kong, J.; Gu, J.; Zhu, J. Thermal transport in polymeric materials and across composite interfaces. Appl. Mater. Today 2018, 12, 92–130. [Google Scholar] [CrossRef]

- Stastna, J. Transport Properties in Polymers; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Li, A.; Zhang, C.; Zhang, Y.F. Thermal conductivity of graphene-polymer composites: Mechanisms, properties, and applications. Polymers 2017, 9, 437. [Google Scholar] [CrossRef] [PubMed]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Kochetov, R.; Korobko, A.V.; Andritsch, T.; Morshuis, P.H.F.; Picken, S.J.; Smit, J.J. Modelling of the thermal conductivity in polymer nanocomposites and the impact of the interface between filler and matrix. J. Phys. D Appl. Phys. 2011, 44, 395401. [Google Scholar] [CrossRef]

- Jasmee, S.; Omar, G.; Othaman, S.S.C.; Masripan, N.A.; Hamid, H.A. Interface thermal resistance and thermal conductivity of polymer composites at different types, shapes, and sizes of fillers: A review. Polym. Compos. 2021, 42, 2629–2652. [Google Scholar] [CrossRef]

- You, H.; Zhao, Q.; Mei, T.; Li, X.; You, R.; Wang, D. Self-Reinforced Polymer Nanofiber Aerogels for Multifunctional Applications. Macromol. Mater. Eng. 2022, 307, 2100971. [Google Scholar] [CrossRef]

- Xiao, H.; Huang, Z.X.; Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Highly thermally conductive flexible copper clad laminates based on sea-island structured boron nitride/polyimide composites. Compos. Sci. Technol. 2022, 230, 109087. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Salgado, R.; Debnath, B.; Lewis, J.S.; Aytan, E.; Balandin, A.A. Thermal percolation threshold and thermal properties of composites with high loading of graphene and boron nitride fillers. ACS Appl. Mater. Interfaces 2018, 10, 37555–37565. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Hansson, J.; Liu, Y.; Chen, S.; Zehri, A.; Samani, M.K.; Wang, N.; Ni, Y.; Zhang, Y.; Zhang, Z.; et al. Graphene related materials for thermal management. 2D Mater. 2020, 7, 012001. [Google Scholar] [CrossRef]

- Jang, J.U.; Nam, H.E.; So, S.O.; Lee, H.; Kim, G.S.; Kim, S.Y.; Kim, S.H. Thermal percolation behavior in thermal conductivity of polymer nanocomposite with lateral size of graphene nanoplatelet. Polymers 2022, 14, 323. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Yang, X.; Li, J.; Shen, Y.; Zhang, L.; Lu, R.; Wang, C.; Zheng, X.; Chen, H.; Zhang, T. Review on polymer composites with high thermal conductivity and low dielectric properties for electronic packaging. Mater. Today Phys. 2022, 22, 100594. [Google Scholar] [CrossRef]

- Ma, T.; Ruan, K.; Gu, J. Theories and mechanisms of thermal conduction. Therm. Conduct. Polym. Compos. 2023, 57, 1–19. [Google Scholar]

- Abbas, I.; Hobiny, A.; Alshehri, H.; Vlase, S.; Marin, M. Analysis of thermoelastic interaction in a polymeric orthotropic medium using the finite element method. Polymers 2022, 14, 2112. [Google Scholar] [CrossRef]

- Kiessling, A.; Simavilla, D.N.; Vogiatzis, G.G.; Venerus, D.C. Thermal conductivity of amorphous polymers and its dependence on molecular weight. Polymer 2021, 228, 123881. [Google Scholar] [CrossRef]

- Xi, Q.; Zhong, J.; He, J.; Xu, X.; Nakayama, T.; Wang, Y.; Liu, J.; Zhou, J.; Li, B. A ubiquitous thermal conductivity formula for liquids, polymer glass, and amorphous solids. Chin. Phys. Lett. 2020, 37, 104401. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; Zhou, J.; Li, B. Thermal conductivity of polymers and their nanocomposites. Adv. Mater. 2018, 30, 1705544. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Zhao, X.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Effect of temperature, crystallinity and molecular chain orientation on the thermal conductivity of polymers: A case study of PLLA. J. Mater. Sci. 2018, 53, 10543–10553. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, K.; Zhan, Y.; Wang, K.; Shi, J. High intrinsic thermal conductive polymer films by engineered interchain hydrogen bond interactions. J. Polym. Sci. 2023, 61, 1622–1633. [Google Scholar] [CrossRef]

- Tu, H.; Xie, K.; Lin, X.; Zhang, R.; Chen, F.; Fu, Q.; Duan, B.; Zhang, L. Superior strength and highly thermoconductive cellulose/boron nitride film by stretch-induced alignment. J. Mater. Chem. A 2021, 9, 10304–10315. [Google Scholar] [CrossRef]

- Zhao, L.; Yan, L.; Wei, C.; Li, Q.; Huang, X.; Wang, Z.; Fu, M.; Ren, J. Synergistic enhanced thermal conductivity of epoxy composites with boron nitride nanosheets and microspheres. J Phys. Chem. C 2020, 124, 12723–12733. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, L.; Li, R.; Xu, Y.; Fu, Q. Preparation of polymer composites with high thermal conductivity by constructing a “double thermal conductive network” via electrostatic spinning. Compos. Commun. 2022, 36, 101371. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, X.; Yan, X.; Zhang, C.; Zhang, Y.; Li, P.; Li, N.; Liu, H.; Wang, Z. A review: From the whole process of making thermal conductive polymer, the effective method of improving thermal conductivity. J. Polym. Sci. 2024, 62, 2410–2442. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Liu, D.; Chen, C.; Chen, Z.; Hao, J.; Li, Y.; Zhang, J.; Naebe, M.; Lei, W. High temperature thermally conductive nanocomposite textile by “green” electrospinning. Nanoscale 2018, 10, 16868–16872. [Google Scholar] [CrossRef]

- Ouyang, Y.; Bai, L.; Tian, H.; Li, X.; Yuan, F. Recent progress of thermal conductive polymer composites: Al2O3 fillers, properties and applications. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106685. [Google Scholar]

- Huang, Y.; Ellingford, C.; Bowen, C.; McNally, T.; Wu, D.; Wan, C. Tailoring the electrical and thermal conductivity of multi-component and multi-phase polymer composites. Int. Mater. Rev. 2020, 65, 129–163. [Google Scholar] [CrossRef]

- Nilagiri Balasubramanian, K.B.; Ramesh, T. Role, effect, and influences of micro and nano-fillers on various properties of polymer matrix composites for microelectronics: A review. Polym. Adv. Technol. 2018, 29, 1568–1585. [Google Scholar] [CrossRef]

- Li, M.; Ali, Z.; Wei, X.; Li, L.; Song, G.; Hou, X.; Do, H.; Greer, J.C.; Pan, Z.; Lin, C.; et al. Stress induced carbon fiber orientation for enhanced thermal conductivity of epoxy composites. Compos. Part B Eng. 2021, 208, 108599. [Google Scholar] [CrossRef]

- Shang, Y.; Ji, Y.; Dong, J.; Yang, G.; Zhang, X.; Su, F.; Feng, Y.; Liu, C. Sandwiched cellulose nanofiber/boron nitride nanosheet/Ti3C2Tx MXene composite film with high electromagnetic shielding and thermal conductivity yet insulation performance. Compos. Sci. Technol. 2021, 214, 108974. [Google Scholar] [CrossRef]

- Chandrashekar, A.; Hegde, M.; Krishna, S.; Gopi, J.A.; Kotresh, T.M.; Prabhu, T.N. Non-covalent surface functionalization of nanofillers towards the enhancement of thermal conductivity of polymer nanocomposites: A mini review. Eur. Polym. J. 2023, 198, 112379. [Google Scholar] [CrossRef]

- Liang, J.; Cui, R.; Zhang, X.; Koumoto, K.; Wan, C. Polymer/Carbon Composites with Versatile Interfacial Interactions for High Performance Carbon-Based Thermoelectrics: Principles and Applications. Adv. Funct. Mater. 2023, 33, 2208813. [Google Scholar] [CrossRef]

- Ruan, K.; Guo, Y.; Lu, C.; Shi, X.; Ma, T.; Zhang, Y.; Kong, J.; Gu, J. Significant reduction of interfacial thermal resistance and phonon scattering in graphene/polyimide thermally conductive composite films for thermal management. Research 2021, 2021, 8438614. [Google Scholar] [CrossRef]

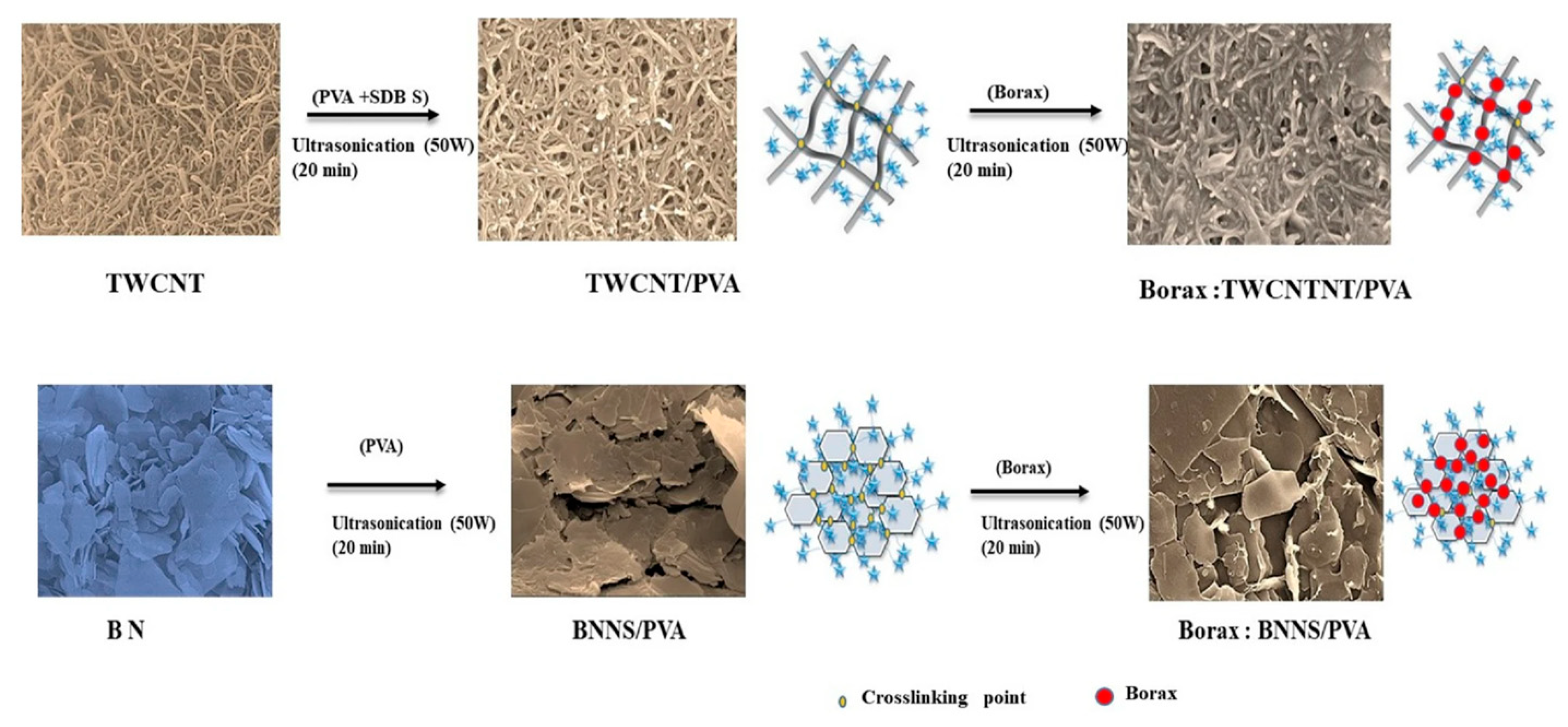

- Chen, G.; Yadav, A.A.; Jung, I.W.; Lee, J.; Choi, K.; Kang, S.W. Crosslinking effect of borax additive on the thermal properties of polymer-based 1D and 2D nanocomposites used as thermal interface materials. Sci. Rep. 2022, 12, 16029. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Tu, Q.; Shen, X.; Fang, Z.; Bi, S.; Yin, Q.; Zhang, X. Enhancing the thermal and mechanical properties of carbon fiber/natural rubber composites by co-modification of dopamine and silane coupling agents. Polym. Test. 2023, 108, 108164. [Google Scholar] [CrossRef]

- Bashir, A.; Maqbool, M.; Lv, R.; Usman, A.; Aftab, W.; Niu, H.; Kang, L.; Bai, S.L. Engineering of interfacial interactions among BN and CNT hybrid towards higher heat conduction within TPU composites. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107428. [Google Scholar] [CrossRef]

- Xie, X.; Yang, D. Construction of thermal conduction networks and decrease of interfacial thermal resistance for improving thermal conductivity of epoxy natural rubber composites. Ceram. Int. 2023, 49, 17650–17659. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Yu, M.Y.; Liu, J.; Li, X.; Min, P.; Yu, Z.Z. Efficient preconstruction of three-dimensional graphene networks for thermally conductive polymer composites. Nano-Micro Lett. 2022, 14, 129. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Li, J.; Wang, W.; Gao, W.; Bai, H. Isotropically ultrahigh thermal conductive polymer composites by assembling anisotropic boron nitride nanosheets into a biaxially oriented network. ACS Nano 2022, 16, 18959–18967. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Feng, W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater. Sci. Eng. R Rep. 2020, 142, 100580. [Google Scholar] [CrossRef]

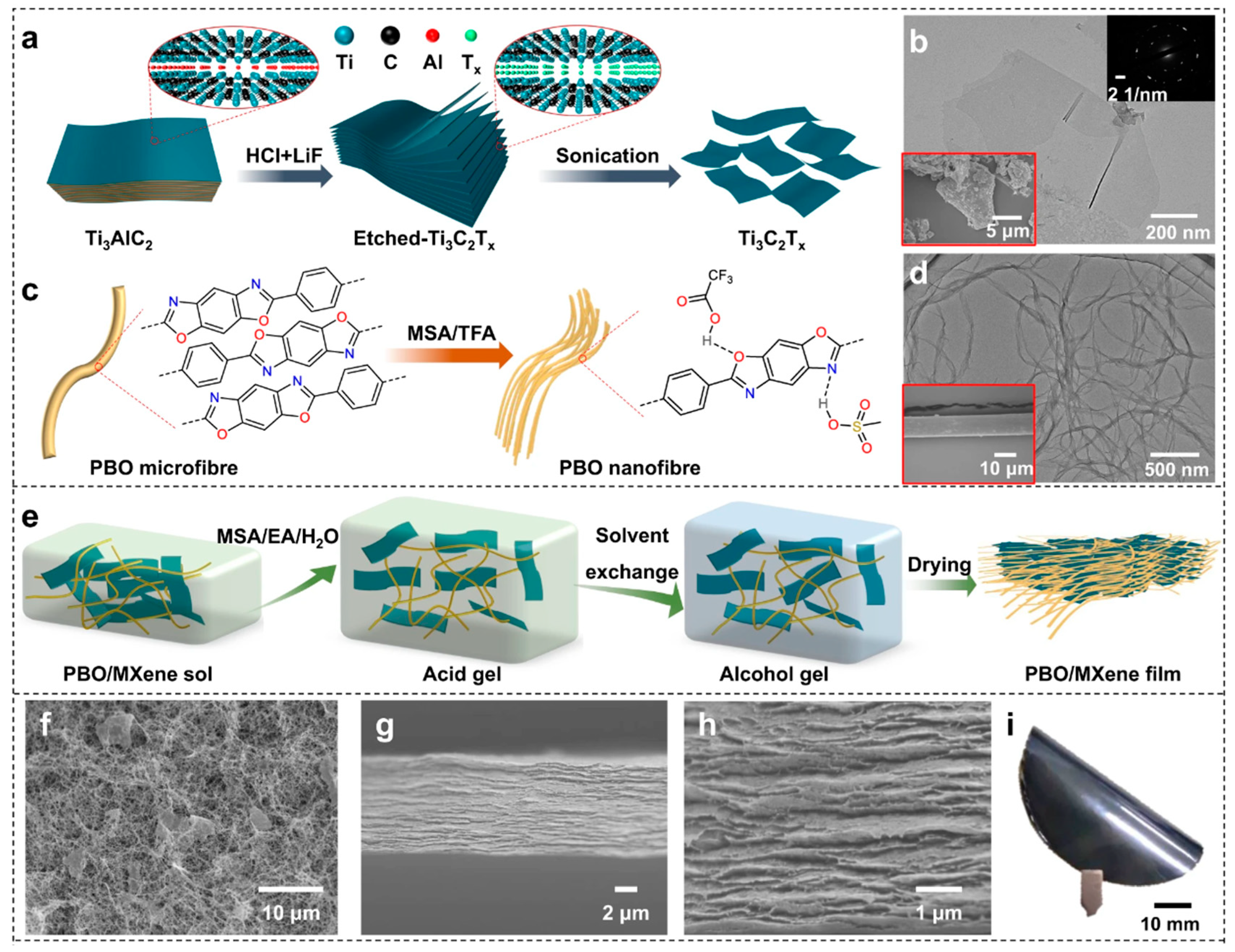

- Liu, Y.; Zou, W.; Zhao, N.; Xu, J. Electrically insulating PBO/MXene film with superior thermal conductivity, mechanical properties, thermal stability, and flame retardancy. Nat. Commun. 2023, 14, 5342. [Google Scholar] [CrossRef]

- Wu, S.; Kondo, Y.; Kakimoto, M.A.; Yang, B.; Yamada, H.; Kuwajima, I.; Lambard, G.; Hongo, K.; Xu, Y.; Shiomi, J.; et al. Machine-learning-assisted discovery of polymers with high thermal conductivity using a molecular design algorithm. NPJ Comput. Mater. 2019, 5, 66. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Y. Vertically aligned silicon carbide nanowires/reduced graphene oxide networks for enhancing the thermal conductivity of silicone rubber composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105873. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Y.; Liu, Y.; Xie, H.; Yu, W. A critical review of the preparation strategies of thermally conductive and electrically insulating polymeric materials and their applications in heat dissipation of electronic devices. Adv. Compos. Hybrid Mater. 2023, 6, 27. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, X.; Zhang, H.; Wang, M.; Feng, Y. Efficient preparation of bn/uhmwpe composites with oriented thermal conductivity by powder solid-state extrusion. Compos. Part A Appl. Sci. Manuf. 2023, 172, 107598. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, C.; Ye, Y.; Xue, Z.; Liu, H.; Zhou, X.; Zhang, Y.; Li, D.; Xie, X.; Mai, Y. Advances on thermally conductive epoxy-based composites as electronic packaging underfill materials-a review. Adv. Mater. 2022, 34, 2201023. [Google Scholar] [CrossRef]

- Qian, Y.; Luo, Y.; Haruna, A.Y.; Xiao, B.; Li, W.; Li, Y.; Xiong, T.; Jiang, Q.; Yang, J. Multifunctional epoxy-based electronic packaging material MDCF@LDH/EP for electromagnetic wave absorption, thermal management, and flame retardancy. Small 2022, 18, 2204303. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Chen, C.; Wen, Y.; Xue, Z.; Zhou, X.; Shi, D.; Hu, G.; Xie, X. Novel micro-nano epoxy composites for electronic packaging application: Balance of thermal conductivity and processability. Compos. Sci. Technol. 2021, 209, 108760. [Google Scholar] [CrossRef]

- Wang, D.; Ren, S.; Chen, J.; Li, Y.; Wang, Z.; Xu, J.; Jia, X.; Fu, J. Healable, highly thermal conductive, flexible polymer composite with excellent mechanical properties and multiple functionalities. Chem. Eng. J. 2022, 430, 133163. [Google Scholar] [CrossRef]

- Jia, L.; Jin, Y.; Ren, J.; Zhao, L.; Yan, D.; Li, Z. Highly thermally conductive liquid metal-based composites with superior thermostability for thermal management. J. Mater. Chem. C 2021, 9, 2904. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Liu, X. Novel functionalized BN nanosheets/epoxy composites with advanced thermal conductivity and mechanical properties. ACS Appl. Mater. Interfaces 2020, 12, 6503. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Dai, X.; Ruan, K.; Zhang, S.; Shi, X.; Guo, Y.; Cai, H.; Gu, J. Flexible thermally conductive and electrically insulating silicone rubber composite films with BNNS@Al2O3 fillers. Adv. Compos. Hybrid Mater. 2021, 4, 36. [Google Scholar] [CrossRef]

- Xiao, C.; Tang, Y.; Chen, L.; Zhang, X.; Zheng, K.; Tian, X. Preparation of highly thermally conductive epoxy resin composites via hollow boron nitride microbeads with segregated structure. Compos. Part A Appl. Sci. Manuf. 2019, 121, 330–340. [Google Scholar] [CrossRef]

- Yan, R.; Su, F.; Zhang, L.; Li, C. Highly enhanced thermal conductivity of epoxy composites by constructing dense thermal conductive network with combination of alumina and carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105496. [Google Scholar] [CrossRef]

- Liu, J.; Feng, H.; Dai, J.; Yang, K.; Chen, G.; Wang, S.; Jin, D.; Liu, X. A Full-component recyclable Epoxy/BN thermal interface material with anisotropy high thermal conductivity and interface adaptability. Chem. Eng. J. 2023, 469, 143963. [Google Scholar] [CrossRef]

- Yan, Q.; Dai, W.; Gao, J.; Tan, X.; Lv, L.; Ying, J.; Lu, X.; Lu, J.; Yao, Y.; Wei, Q.; et al. Ultrahigh-aspect-ratio boron nitride nanosheets leading to superhigh in-plane thermal conductivity of foldable heat spreader. ACS Nano 2021, 15, 6489–6498. [Google Scholar] [CrossRef]

- Li, M.; Shen, X.; Chen, X.; Gan, J.; Wang, F.; Li, J.; Wang, X.; Shen, Q. Thermal management of chips by a device prototype using synergistic effects of 3-D heat-conductive network and electrocaloric refrigeration. Nat. Commun. 2022, 13, 5849. [Google Scholar] [CrossRef] [PubMed]

- Prunet, G.; Pawula, F.; Fleury, G.; Cloutet, E.; Robinson, A.J.; Hadziioannou, G.; Pakdel, A. A review on conductive polymers and their hybrids for flexible and wearable thermoelectric applications. Mater. Today Phys. 2021, 18, 100402. [Google Scholar] [CrossRef]

- Faruk, M.O.; Ahmed, A.; Jalil, M.A.; Islam, M.T.; Adak, B.; Hossain, M.M.; Mukhopadhyay, S. Functional textiles and composite based wearable thermal devices for Joule heating: Progress and perspectives. Appl. Mater. Today 2021, 23, 101025. [Google Scholar] [CrossRef]

- Sun, N.; Li, X. A flexible composite phase change material with ultrahigh stretchability for thermal management in wearable electronics. J. Mater. Sci. 2021, 56, 15937–15949. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, X.; Chen, Y.; Chen, L.; Zhang, L.; Zhao, X.; Bing, N.; Yu, W.; Xie, H. Poly (vinyl alcohol)-based nanofibers with improved thermal conductivity and efficient photothermal response for wearable thermal management. ACS Appl. Nano Mater. 2023, 6, 14733–14744. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Y.; Zhu, G.; Liu, Y.; Fang, Q.; Bai, X.; Zhao, Y.; Li, X.; Huang, X.; Zhang, T.; et al. A new route to fabricate flexible, breathable composites with advanced thermal management capability for wearable electronics. NPJ Flex. Electron. 2023, 7, 24. [Google Scholar] [CrossRef]

- Tan, C.; Dong, Z.; Li, Y.; Zhao, H.; Huang, X.; Zhou, Z.; Jiang, J.; Long, Y.; Jiang, P.; Zhang, T.; et al. A high performance wearable strain sensor with advanced thermal management for motion monitoring. Nat. Commun. 2020, 11, 3530. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, Y.; Gong, F.; Liu, D.; Lei, C.; Fu, Q. Highly thermo-conductive but electrically insulating filament via a volume-confinement self-assembled strategy for thermoelectric wearables. Chem. Eng. J. 2021, 421, 127764. [Google Scholar] [CrossRef]

- Guo, G.; Liu, Y.; Ding, Y.; Liu, W.; Zhu, G.; Hao, X.; Huang, X.; Xia, J.; Li, B.; Zhang, T.; et al. Flexible yet impermeable composites with wrinkle structured BNNSs assembling for high-performance thermal management. NPJ Flex. Electron. 2024, 8, 34. [Google Scholar] [CrossRef]

- Fang, Y.; Dong, J.; Zhao, X.; Chen, T.; Xiang, L.; Xie, Y.; Zhang, Q. Covalently linked polydopamine-modified boron nitride nanosheets/polyimide composite fibers with enhanced heat diffusion and mechanical behaviors. Compos. Part B Eng. 2020, 199, 108281. [Google Scholar] [CrossRef]

- Yoon, D.; Lee, H.; Kim, T.; Song, Y.; Lee, T.; Lee, J.; Seol, J.H. Enhancing the thermal conductivity of amorphous polyimide by molecular-scale manipulation. Eur. Polym. J. 2023, 184, 111775. [Google Scholar] [CrossRef]

- Ruan, K.; Guo, Y.; Gu, J. Liquid crystalline polyimide films with high intrinsic thermal conductivities and robust toughness. Macromolecules 2021, 54, 4934–4944. [Google Scholar] [CrossRef]

- Yu, H.; Chen, C.; Sun, J.; Zhang, H.; Feng, Y.; Qin, M.; Feng, W. Highly thermally conductive polymer/graphene composites with rapid room-temperature self-healing capacity. Nano-Micro Lett. 2022, 14, 135. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.; Yu, Y.; Wu, S.; Wang, C.H. Conductive polymer nanocomposites for stretchable electronics: Material selection, design, and applications. ACS Appl. Mater. Interfaces 2021, 13, 43831–43854. [Google Scholar] [CrossRef] [PubMed]

- Agobi, A.U.; Louis, H.; Magu, T.O.; Dass, P.M. A review on conducting polymers-based composites for energy storage application. J. Chem. Rev. 2019, 1, 19–34. [Google Scholar]

- Lin, X.; Zhang, X.; Liu, L.; Liang, J.; Liu, W. Polymer/expanded graphite-based flexible phase change material with high thermal conductivity for battery thermal management. J. Clean. Prod. 2022, 331, 130014. [Google Scholar] [CrossRef]

- Huang, Q.; Li, X.; Zhang, G.; Deng, J.; Wang, C. Thermal management of lithium-ion battery pack through the application of flexible form-stable composite phase change materials. Appl. Therm. Eng. 2021, 183, 116151. [Google Scholar] [CrossRef]

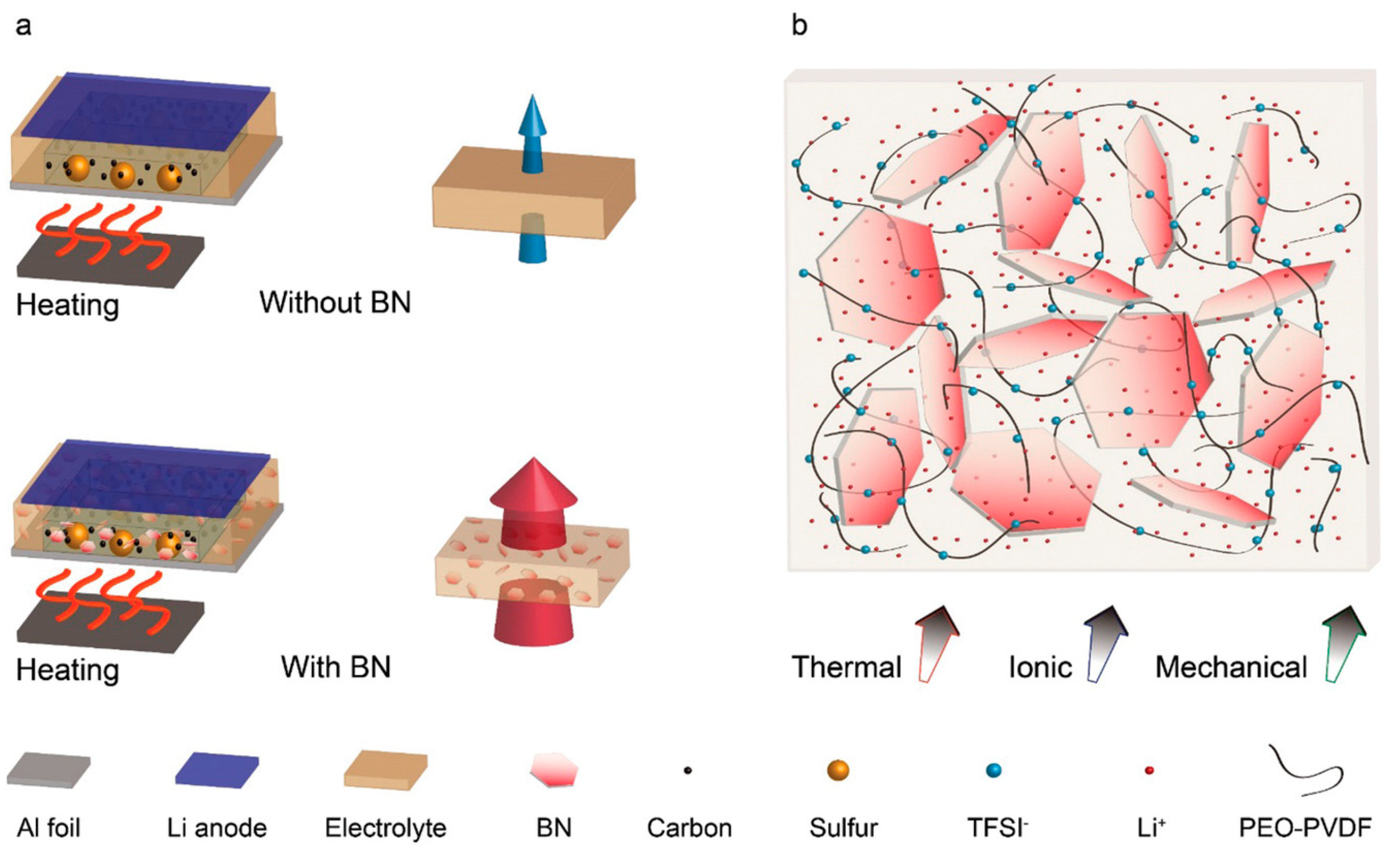

- Yin, X.; Wang, L.; Kim, Y.; Ding, N.; Kong, J.; Safanama, D.; Zheng, Y.; Xu, J.; Repaka, D.V.M.; Hippaigaonkar, K.; et al. Thermal Conductive 2D boron nitride for high-performance all-solid-state lithium–sulfur batteries. Adv. Sci. 2020, 7, 2001303. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Zhao, H.; Niu, H.; Ren, Y.; Fang, H.; Fang, X.; Lv, R.; Maqbool, M.; Bai, S. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano 2021, 15, 6917–6928. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, Z.; Wang, X.; He, Y. All-climate thermal management structure for batteries based on expanded graphite/polymer composite phase change material with a high thermal and electrical conductivity. Appl. Energy 2022, 322, 119509. [Google Scholar] [CrossRef]

- Pei, H.; Yang, C.; Wang, P.; Lin, J.; Yin, L.; Zhou, X.; Xie, X.; Ye, Y. Efficient thermal management of lithium-sulfur batteries by highly thermally conductive LBL-assembled composite separators. Electrochim. Acta 2022, 407, 139807. [Google Scholar]

- Li, H.; Ren, L.; Zhou, Y.; Yao, B.; Wang, Q. Recent progress in polymer dielectrics containing boron nitride nanosheets for high energy density capacitors. High Volt. 2020, 5, 365–376. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, S. Polymer nanocomposites for high-energy-density capacitor dielectrics: Fundamentals and recent progress. IEEE Electr. Insul. Mag. 2020, 36, 7–28. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Lagodkine, E.; Haque, A.; Chen, L.; Jackson, T.N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhou, Y.; Huang, X.; Yu, C.; Han, D.; Wang, A.; Zhu, Y.; Shi, K.; Li, P.; Jiang, P.; et al. Ladderphane copolymers for high-temperature capacitive energy storage. Nature 2023, 615, 62–66. [Google Scholar] [CrossRef]

- Liu, X.J.; Zheng, M.S.; Chen, G.; Dang, Z.M.; Zha, J.W. High-temperature polyimide dielectric materials for energy storage: Theory, design, preparation and properties. Energy Environ. Sci. 2022, 15, 56–81. [Google Scholar] [CrossRef]

- Murali, G.; Sravya, G.S.N.; Jaya, J.; Naga Vamsi, V. A review on hybrid thermal management of battery packs and it’s cooling performance by enhanced PCM. Renew. Sustain. Energy Rev. 2021, 150, 111513. [Google Scholar] [CrossRef]

- Althobiti, R.A.; Morsi, M.A.; Alzahrani, E.; Al-Muntaser, A.A. Enhancing the performance of PVC/PMMA polymer blend through hybrid nanofiller of TiO2 NPs/GNPs for capacitive energy storage applications. Ceram. Int. 2024, 50, 19039–19047. [Google Scholar] [CrossRef]

- Sumdani, M.G.; Islam, M.R.; Yahaya, A.N.A.; Safie, S.I. Recent advancements in synthesis, properties, and applications of conductive polymers for electrochemical energy storage devices: A review. Polym. Eng. Sci. 2022, 62, 269–303. [Google Scholar] [CrossRef]

- Sanker, S.B.; Baby, R. Phase change material based thermal management of lithium ion batteries: A review on thermal performance of various thermal conductivity enhancers. J. Energy Storage 2022, 50, 104606. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sust. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Nilsson, F.; Karlsson, M.; Gedde, U.W.; Kadar, R.; Gaska, K.; Mueller, C.; Hagstrand, P.O.; Olsson, B.T.; Hedenqvist, M.S.; Gkourmpis, T. Nanocomposites and polyethylene blends: Two potentially synergistic strategies for HVDC insulation materials with ultra-low electrical conductivity. Compos. Part B Eng. 2021, 204, 108498. [Google Scholar] [CrossRef]

- Paramane, A.; Chen, X.; Dai, C.; Guan, H.; Yu, L.; Tan, Y. Electrical insulation performance of cross-linked polyethylene/MgO nanocomposite material for ±320 kV high-voltage direct-current cables. Polym. Compos. 2020, 41, 1936–1949. [Google Scholar] [CrossRef]

- Ren, H.; Zhong, L.; Yang, X.; Li, W.; Gao, J.; Yu, Q.; Chen, X.; Li, Z. Electric field distribution based on radial nonuniform conductivity in HVDC XLPE cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 121–127. [Google Scholar] [CrossRef]

- Chi, Q.G.; Yang, M.; Zhang, C.H.; Zhang, T.D.; Feng, Y.; Chen, Q.G. Nonlinear electrical conductivity and thermal properties of AgNPs/BN/EPDM composites for cable accessory. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1081–1088. [Google Scholar] [CrossRef]

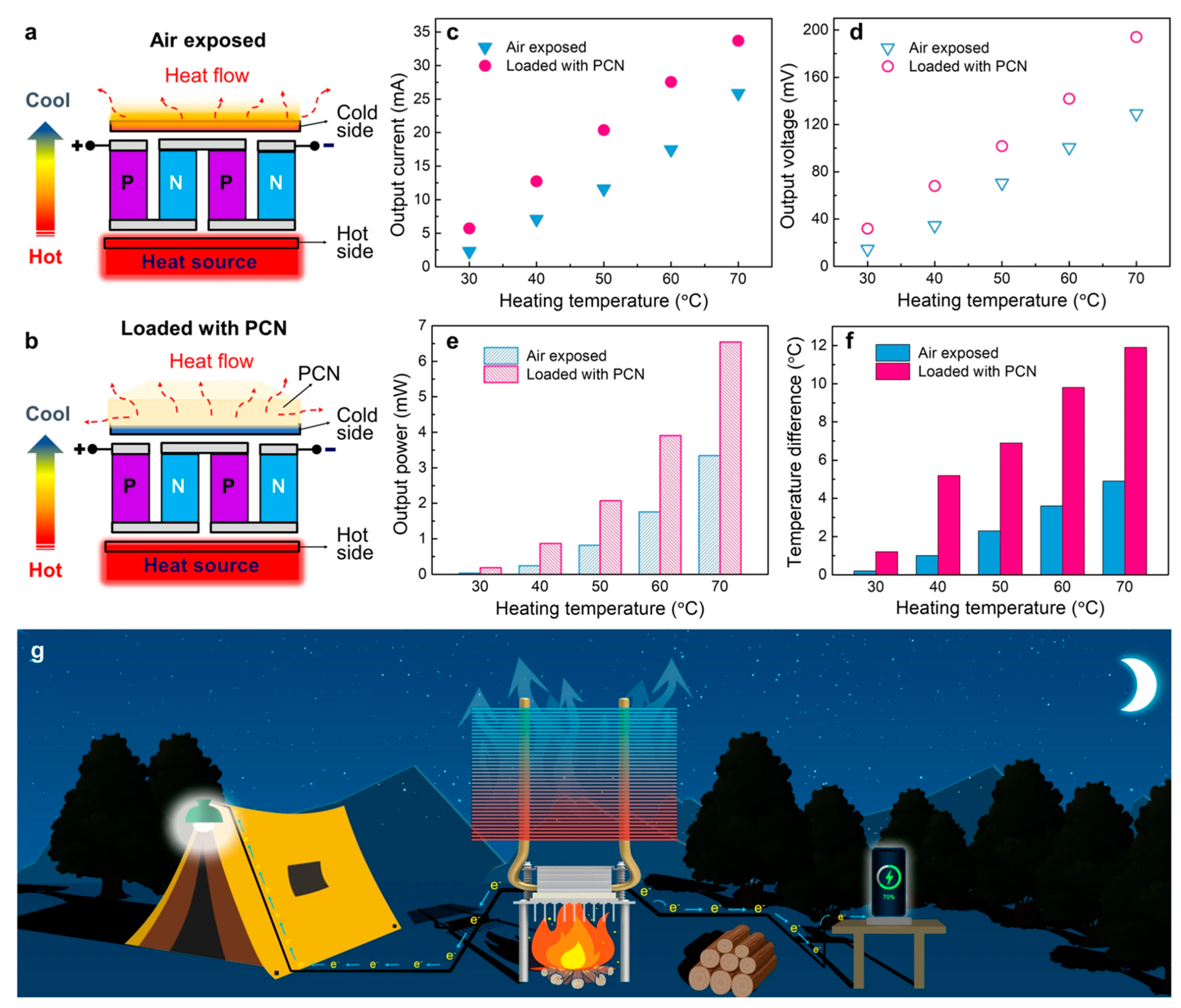

- Lin, Y.; Kang, Q.; Liu, Y.; Zhu, Y.; Jiang, P.; Mai, Y.W.; Huang, X. Flexible, highly thermally conductive and electrically insulating phase change materials for advanced thermal management of 5G base stations and thermoelectric generators. Nano-Micro Lett. 2023, 15, 31. [Google Scholar] [CrossRef] [PubMed]

- Imai, T. Polymer Composites for Switchgears. In Polymer Composites for Electrical Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 339–375. [Google Scholar]

- Li, P.; Huang, X. Thermally conductive polymer composites for high voltage insulation. In Polymer Composites for Electrical Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Wei, Y.; Chen, W.; Yuan, Z.; Zhang, C.; Zhuo, Z.; Chen, X.; Zhao, Y.B. Heat dissipation characteristics of anode saturable reactors with high thermal conductivity epoxy resin used for ultra-high-voltage direct current converter valves. High Volt. 2020, 5, 598–604. [Google Scholar] [CrossRef]

- Nazari, M.A.; Maleki, A.; Assad, M.E.H.; Rosen, M.A.; Haghighi, A.; Sharabaty, H.; Chen, L. A review of nanomaterial incorporated phase change materials for solar thermal energy storage. Sol. Energy 2021, 228, 725–743. [Google Scholar] [CrossRef]

- Shanmugam, M.; Augustin, A.; Mohan, S.; Honnappa, B.; Chuaicham, C.; Rajendran, S.; Hoang, T.K.A.; Sasaki, K.; Sekar, K. Conducting polymeric nanocomposites: A review in solar fuel applications. Fuel 2022, 325, 124899. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, L.; Song, J. Preparation, thermal conductivity, and applications of nano-enhanced phase change materials (NEPCMs) in solar heat collection: A review. J. Energy Storage 2023, 63, 107047. [Google Scholar] [CrossRef]

- Min, P.; Liu, J.; Li, X.; An, F.; Liu, P.; Shen, Y.; Koratkar, N.; Yu, Z.Z. Thermally conductive phase change composites featuring anisotropic graphene aerogels for real-time and fast-charging solar-thermal energy conversion. Adv. Funct. Mater. 2018, 28, 1805365. [Google Scholar] [CrossRef]

- Mo, Z.; Mo, P.; Yi, M.; Hu, Z.; Tan, G.; Selim, M.S.; Chen, Y.; Chen, X.; Hao, Z.; Wei, X. Ti3C2Tx@polyvinyl alcohol foam-supported phase change materials with simultaneous enhanced thermal conductivity and solar-thermal conversion performance. Sol. Energy Mater. Sol. Cells 2021, 219, 110813. [Google Scholar] [CrossRef]

- Aftab, W.; Khurram, M.; Jinming, S.; Tabassum, H.; Liang, Z.; Usman, A.; Guo, W.; Huang, X.; Wu, W.; Yao, R.; et al. Highly efficient solar-thermal storage coating based on phosphorene encapsulated phase change materials. Energy Storage Mater. 2020, 32, 199–207. [Google Scholar] [CrossRef]

- Gao, J.; Han, G.; Song, J.; He, C.; Hu, J.; Wang, W.; Feng, Y.; Liu, C. Customizing 3D thermally conductive skeleton by 1D aramid nanofiber/2D graphene for high-performance phase change composites with excellent solar-to-thermal conversion ability. Mater. Today Phys. 2022, 27, 100811. [Google Scholar] [CrossRef]

- Gaddam, S.K.; Pothu, R.; Boddula, R. Advanced polymer encapsulates for photovoltaic devices-a review. J. Mater. 2021, 7, 920–928. [Google Scholar] [CrossRef]

- Huang, X.; Lin, Y.; Fang, G. Thermal properties of polyvinyl butyral/graphene composites as encapsulation materials for solar cells. Sol. Energy 2018, 161, 187–193. [Google Scholar] [CrossRef]

- Zhang, X.; Chao, X.; Lou, L.; Fan, J.; Chen, Q.; Li, B.; Ye, L.; Shou, D. Personal thermal management by thermally conductive composites: A review. Compos. Commun. 2021, 23, 100595. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.D.; Liu, Q.; Chen, Z.G. Multifunctional wearable thermoelectrics for personal thermal management. Adv. Funct. Mater. 2022, 32, 2200548. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Park, J.B.; Jeon, Y.P.; Hong, J.Y.; Park, H.S.; Lee, J.U. A review of polymer composites based on carbon fillers for thermal management applications: Design, preparation, and properties. Polymers 2021, 13, 1312. [Google Scholar] [CrossRef]

- Soong, Y.C.; Chiu, C.W. Multilayered graphene/boron nitride/thermoplastic polyurethane composite films with high thermal conductivity, stretchability, and washability for adjustable-cooling smart clothes. J. Colloid Interface Sci. 2021, 599, 611–619. [Google Scholar] [CrossRef]

- Huang, X.; Li, Z.; Li, Y.; Wu, X.; Liu, C.; Xie, H.; Yu, W. Thermally conductive boron nitride nanosheets on electrospun thermoplastic polyurethane for wearable janus-type fabrics with simultaneous thermal and moisture management. ACS Appl. Nano Mater. 2024, 7, 8229–8237. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermoconductive, moisture-permeable, and superhydrophobic nanofibrous membranes with interpenetrated boron nitride network for personal cooling fabrics. ACS Appl. Mater. Interfaces 2020, 12, 32078–32089. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Zhao, Z.; Cao, X.; Sun, Q.; Yuan, Y.; Li, T. Ultraflexible, cost-effective and scalable polymer-based phase change composites via chemical cross-linking for wearable thermal management. Nat. Commun. 2023, 14, 8060. [Google Scholar] [CrossRef]

- Zahid, M.; Rathore, H.A.; Tayyab, H.; Rehan, Z.A.; Rashid, I.A.; Lodhi, M.; Zubair, U.; Shahid, I. Recent developments in textile based polymeric smart sensor for human health monitoring: A review. Arab. J. Chem. 2022, 15, 103480. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, K.; Liu, H.; Chen, J.; Yan, X.; Kou, Y.; Shi, Q. Flexible insulating phase change composite film with improved thermal conductivity for wearable thermal management. Nano Energy 2024, 121, 109256. [Google Scholar] [CrossRef]

- Lv, Y.G.; Lv, Y.Y.G.; Wang, Y.T.; Meng, T.; Wang, Q.W.; Chu, W.X. Review on thermal management technologies for electronics in spacecraft environment. Energy Storage Sav. 2024, 3, 153–189. [Google Scholar] [CrossRef]

- Khan, J.; Singh, P. Review on phase change materials for spacecraft avionics thermal management. J. Energy Storage 2024, 87, 111369. [Google Scholar] [CrossRef]

- Ryan, E.A.; Seibers, Z.D.; Reynolds, J.R.; Shofner, M.L. Electrically conducting polymers and composites for applications in space exploration. J. Appl. Polym. Sci. 2024, 141, e55225. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, L.; Wang, J.; Shangguan, Y.; Zheng, Q. Flexible, high thermal conductivity, and EMI shielding performance thermoplastic polyurethane composites through reinforced-orientation carbon fiber. ACS Appl. Polym. Mater. 2024, 6, 6057–6067. [Google Scholar] [CrossRef]

- Ryu, K.H.; Kang, M.; Kim, J.; You, N.H.; Jang, S.G.; Jeong, K.U.; Ahn, S.; Kim, D.Y. Spacesuit textiles from extreme fabric materials: Aromatic amide polymer and boron nitride nanotube composite fiber for neutron shielding and thermal management. Adv. Fiber Mater. 2024, 1–12. [Google Scholar] [CrossRef]

- Almeida, C.M.; Ghica, M.E.; Ramalho, A.L.; Durães, L. Silica-based aerogel composites reinforced with different aramid fibres for thermal insulation in space environments. J. Mater. Sci. 2021, 56, 13604–13619. [Google Scholar] [CrossRef]

- Ince, J.C.; Peerzada, M.; Mathews, L.D.; Pai, A.R.; Al-Qatatsheh, A.; Abbasi, S.; Yin, Y.; Hameed, N.; Lau, A.K.; Salim, N.V. Overview of emerging hybrid and composite materials for space applications. Adv. Compos. Hybrid Mater. 2023, 6, 130. [Google Scholar] [CrossRef]

- Öztürkmen, M.B.; Demirel, M.Ö.; Ağaç, Ö.; Ece, R.E.; Öz, Y. Tailored multifunctional nanocomposites obtained by integration of carbonaceous fillers in an aerospace grade epoxy resin curing at high temperatures. Diam. Relat. Mater. 2023, 135, 109840. [Google Scholar] [CrossRef]

- Barra, G.; Guadagno, L.; Raimondo, M.; Santonicola, M.G.; Toto, E.; Vecchio Ciprioti, S. A comprehensive review on the thermal stability assessment of polymers and composites for aeronautics and space applications. Polymers 2023, 15, 3786. [Google Scholar] [CrossRef] [PubMed]

- Ghotekar, Y.; Vartak, D.; Deshpande, N.; Makwana, B.A.; Bhatt, P.; Upadhyay, M.; Lal, A.K. Optimization of nano fillers content to fabricate electrically conductive carbon fiber reinforced polymer for space use. Compos. Mech. Comput. Appl. Int. J. 2023, 14, 79–88. [Google Scholar] [CrossRef]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent progress in polymer-based building materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Rupal, A.; Meda, S.R.; Gupta, A.; Tank, I.; Kapoor, A.; Sharma, S.K.; Sathish, T.; Murugan, P. Utilization of polymer composite for development of sustainable construction material. Adv. Mater. Sci. Eng. 2022, 2022, 1240738. [Google Scholar] [CrossRef]

- Yuan, S.; Zhou, L.; Chen, T.; Wang, D.; Wang, L. Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers. e-Polymers 2022, 22, 821–833. [Google Scholar] [CrossRef]

- Verma, A. A perspective on the potential material candidate for railway sector applications: PVA based functionalized graphene reinforced composite. Appl. Sci. Eng. Prog. 2022, 15, 5727–5737. [Google Scholar] [CrossRef]

- Kapahi, A.; McKinnon, M.; Lattimer, B. Evaluation of standard and real fire exposures on thermal response of rail car floor assembly. Fire Mater. 2020, 44, 396–408. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Kang, W.; Liu, X.; Wang, Q. Current advances and future perspectives of additive manufacturing for functional polymeric materials and devices. SusMat 2021, 1, 127–147. [Google Scholar] [CrossRef]

- Bahru, R.; Hamzah, A.A.; Mohamed, M.A. Thermal management of wearable and implantable electronic healthcare devices: Perspective and measurement approach. Int. J. Energy Res. 2021, 45, 1517–1534. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, J.; Liu, L.; Hou, G.; Yu, Y.; Yuan, C.; Wang, X. New gutta percha composite with high thermal conductivity and low shear viscosity contributed by the bridging fillers containing ZnO and CNTs. Compos. Part B Eng. 2019, 173, 106903. [Google Scholar] [CrossRef]

| Strategies | Polymer Matrix | Fillers | Enhancement in k (%) | k (W m−1 K−1) | Ref. |

|---|---|---|---|---|---|

| Interfacial Functionalization | PI | Graphene oxide | 820 | 7.13 | [99] |

| PVA | BNNS | 30.6 | 1.909 | [100] | |

| Natural rubber | CF | 71.3 | 0.218 | [101] | |

| TPU | BN and CNT | 210 | 4.52 | [102] | |

| Epoxy natural rubber | Al2O3 and BN | 370 | 0.5147 | [103] | |

| Microstructural Design | Cyclic butylene terephthalate | Graphene nanoplatelets | 1518.8 | 8.094 | [78] |

| Cellulose | BNNS | 3000 | 20.41 | [87] | |

| PDMS | C@BNNS | 1600 | 4.09 | [89] | |

| PI | BNNS | 4773 | 13.1 | [91] | |

| Epoxy resin | CF | 17100 | 32.6 | [95] | |

| Cellulose | BNNS/Ti3C2Tx MXene | / | 19.97 | [96] | |

| Polyurethane | BN | 85.0 | 39.0 | [105] | |

| Poly(p-phenylene-2,6-benzobisoxazole) | MXene | 164 | 42.2 | [107] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, J.; Zhang, Y. Thermal Conductive Polymer Composites: Recent Progress and Applications. Molecules 2024, 29, 3572. https://doi.org/10.3390/molecules29153572

Tan J, Zhang Y. Thermal Conductive Polymer Composites: Recent Progress and Applications. Molecules. 2024; 29(15):3572. https://doi.org/10.3390/molecules29153572

Chicago/Turabian StyleTan, Jianfeng, and Yuan Zhang. 2024. "Thermal Conductive Polymer Composites: Recent Progress and Applications" Molecules 29, no. 15: 3572. https://doi.org/10.3390/molecules29153572